trunk MITSUBISHI 380 2005 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 390 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-390

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

MB991813: SWS Monitor Kit

MB991806: SWS Monitor Cartridge

MB991812: SWS Monitor Harness (For Column-ECU)

MB991822: Test Probe Harness

STEP 1. Check the interior lamps.

If the interior lamp switch is moved to the "door interlock posi-

tion", the interior lamps should illuminate when either door is

opened.

Q: Do the interior lamp illuminate normally?

All the interior lamps illuminate normally. : Go to Step 2.

None of the interior lamps illuminate normally. : Refer to

Inspection Procedure K-1 "The dome lamp do not

illuminate and go out normally P.54B-359."

Some of the interior lamps do not illuminate normally. :

Refer to Inspection Procedure K-2 "The front dome

lamp, rear dome lamp or trunk lamp do not illuminate

or go out normally P.54B-366."

STEP 2. Check the adjustment function.

Q: Has a setting other than "No auto-shutoff" been

selected for the interior lamp automatic shutdown

function by the adjustment function?

YES : Go to Step 3.

NO : Set the interior lamp automatic shutdown function to

another setting other than "No auto-shutoff".

Page 393 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-393

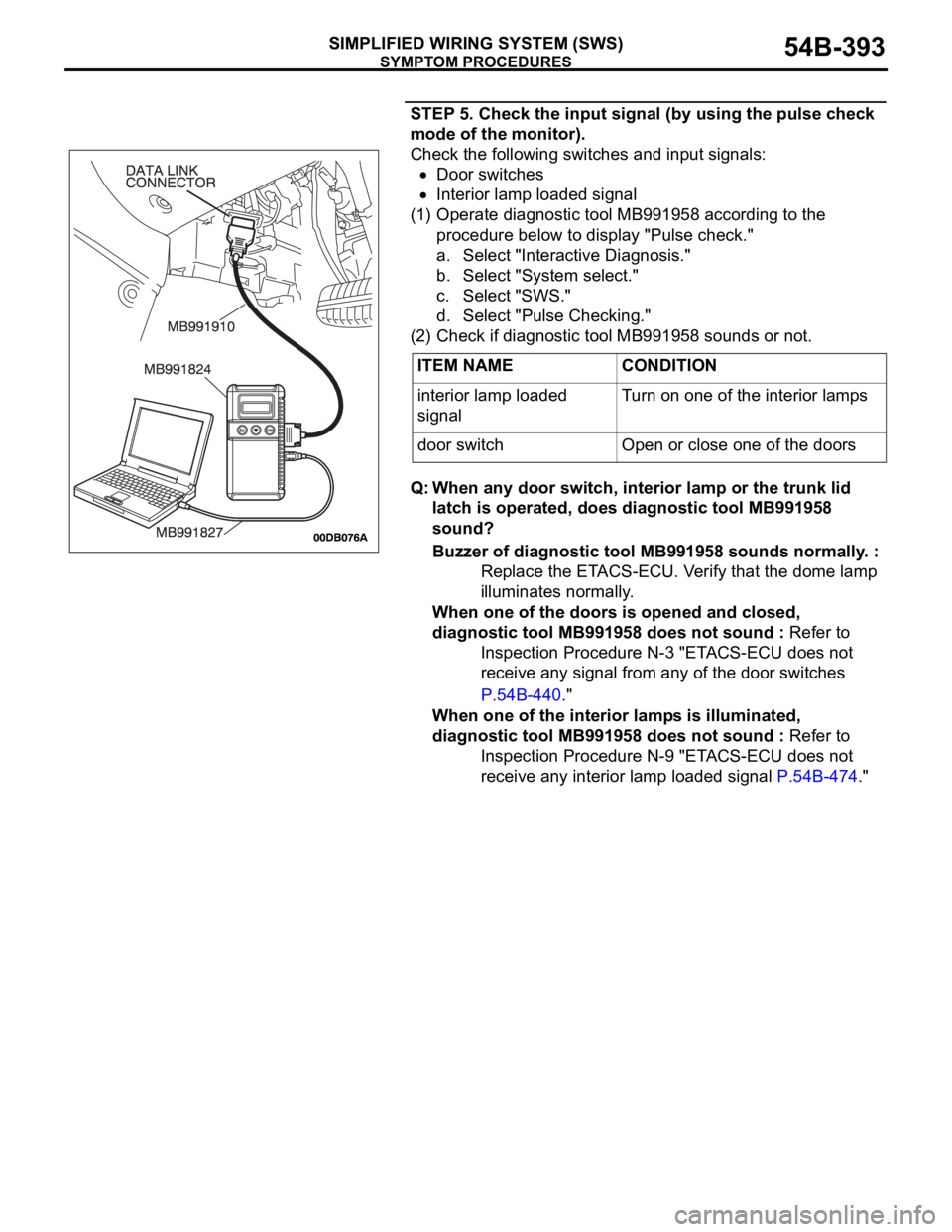

STEP 5. Check the input signal (by using the pulse check

mode of the monitor).

Check the following switches and input signals:

Door switches

Interior lamp loaded signal

(1) Operate diagnostic tool MB991958 according to the

procedure below to display "Pulse check."

a. Select "Interactive Diagnosis."

b. Select "System select."

c. Select "SWS."

d. Select "Pulse Checking."

(2) Check if diagnostic tool MB991958 sounds or not.

Q: When any door switch, interior lamp or the trunk lid

latch is operated, does diagnostic tool MB991958

sound?

Buzzer of diagnostic tool MB991958 sounds normally. :

Replace the ETACS-ECU. Verify that the dome lamp

illuminates normally.

When one of the doors is opened and closed,

diagnostic tool MB991958 does not sound : Refer to

Inspection Procedure N-3 "ETACS-ECU does not

receive any signal from any of the door switches

P.54B-440."

When one of the interior lamps is illuminated,

diagnostic tool MB991958 does not sound : Refer to

Inspection Procedure N-9 "ETACS-ECU does not

receive any interior lamp loaded signal P.54B-474." ITEM NAME CONDITION

interior lamp loaded

signalTurn on one of the interior lamps

door switch Open or close one of the doors

Page 469 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-469

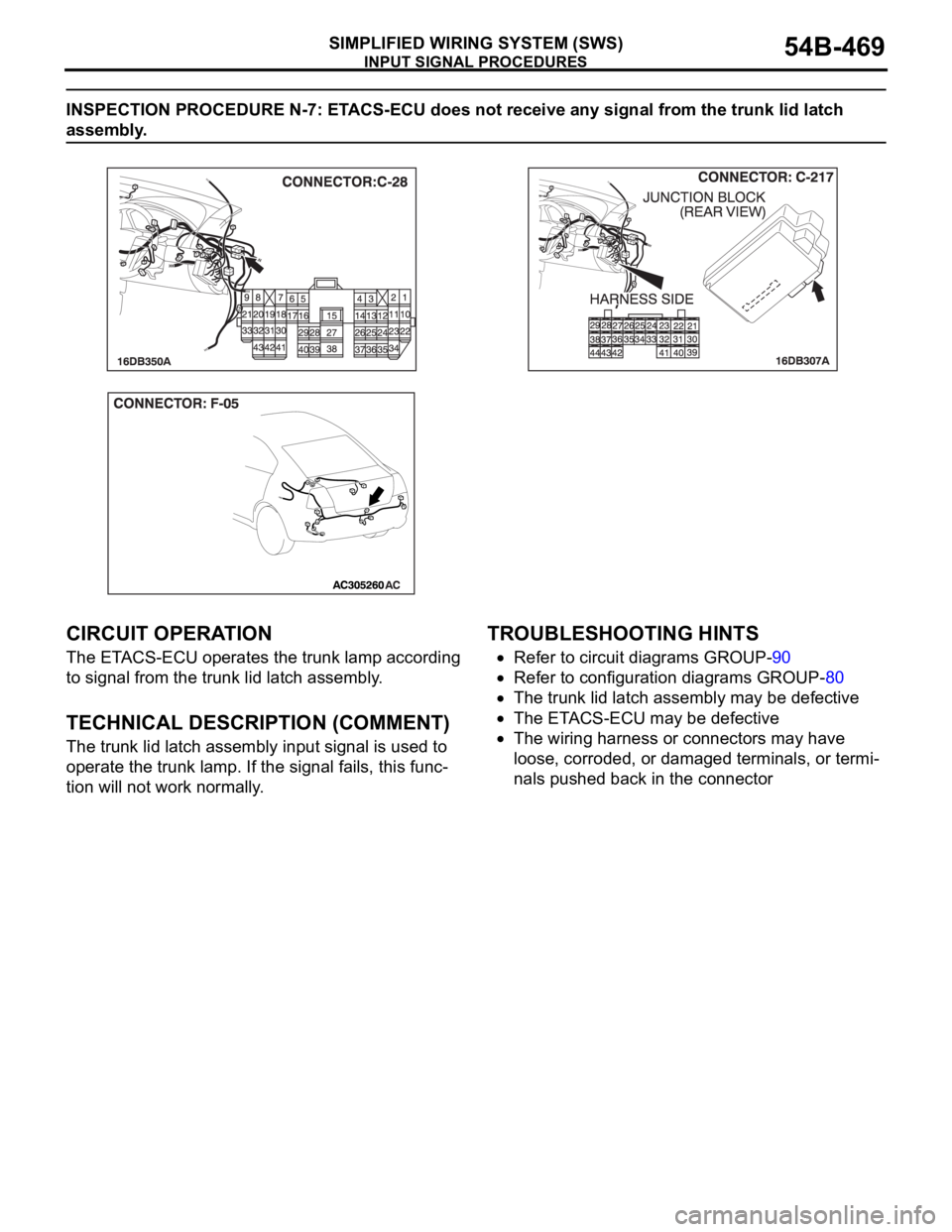

INSPECTION PROCEDURE N-7: ETACS-ECU does not receive any signal from the trunk lid latch

assembly.

.

CIRCUIT OPERATION

The ETACS-ECU operates the trunk lamp according

to signal from the trunk lid latch assembly.

.

TECHNICAL DESCRIPTION (COMMENT)

The trunk lid latch assembly input signal is used to

operate the trunk lamp. If the signal fails, this func-

tion will not work normally.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The trunk lid latch assembly may be defective

The ETACS-ECU may be defective

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

Page 470 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-470

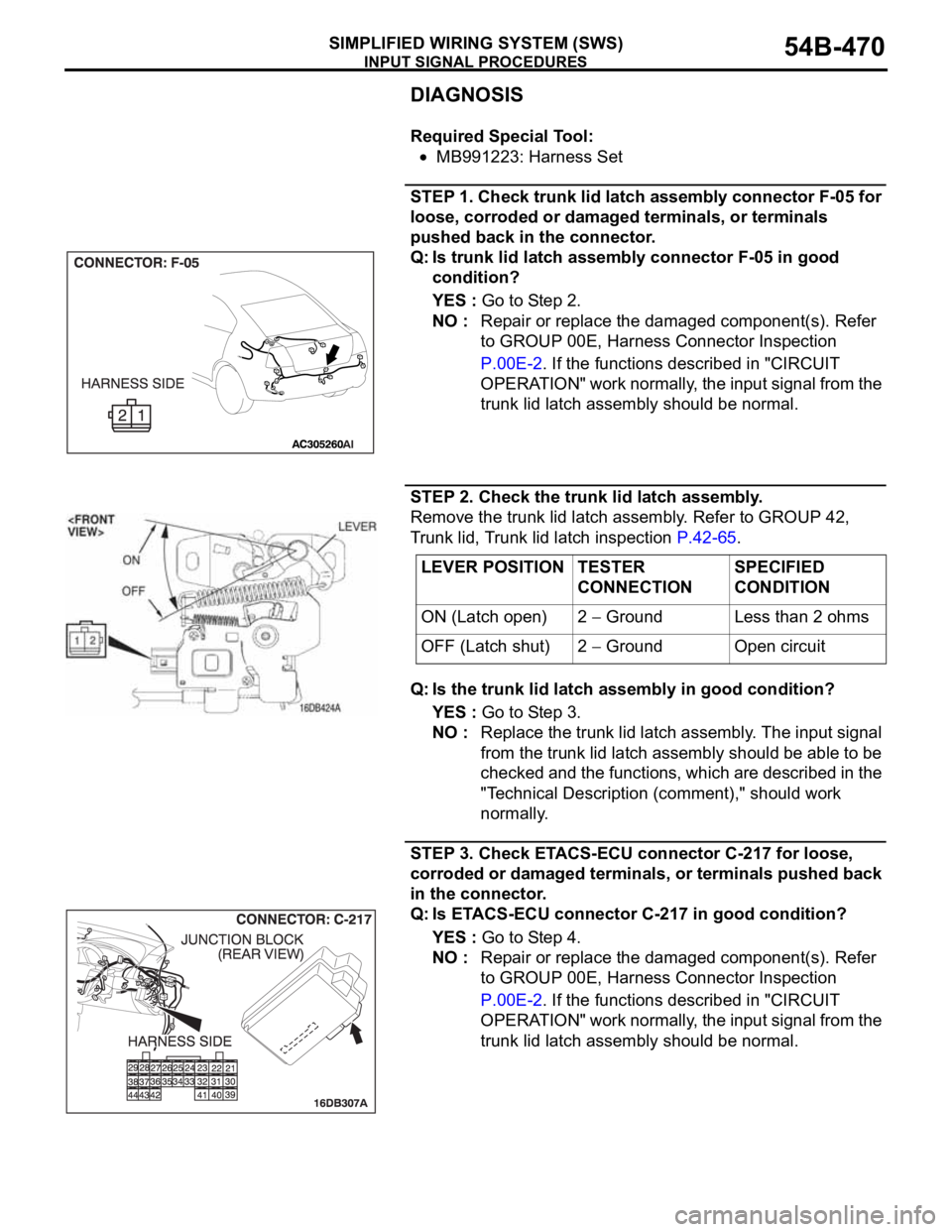

DIAGNOSIS

.

Required Special Tool:

MB991223: Harness Set

STEP 1. Check trunk lid latch assembly connector F-05 for

loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is trunk lid latch assembly connector F-05 in good

condition?

YES : Go to Step 2.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. If the functions described in "CIRCUIT

OPERATION" work normally, the input signal from the

trunk lid latch assembly should be normal.

STEP 2. Check the trunk lid latch assembly.

Remove the trunk lid latch assembly. Refer to GROUP 42,

Trunk lid, Trunk lid latch inspection P.42-65.

Q: Is the trunk lid latch assembly in good condition?

YES : Go to Step 3.

NO : Replace the trunk lid latch assembly. The input signal

from the trunk lid latch assembly should be able to be

checked and the functions, which are described in the

"Technical Description (comment)," should work

normally.

STEP 3. Check ETACS-ECU connector C-217 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is ETACS-ECU connector C-217 in good condition?

YES : Go to Step 4.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. If the functions described in "CIRCUIT

OPERATION" work normally, the input signal from the

trunk lid latch assembly should be normal.

LEVER POSITION TESTER

CONNECTIONSPECIFIED

CONDITION

ON (Latch open) 2

Ground Less than 2 ohms

OFF (Latch shut) 2

Ground Open circuit

Page 471 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-471

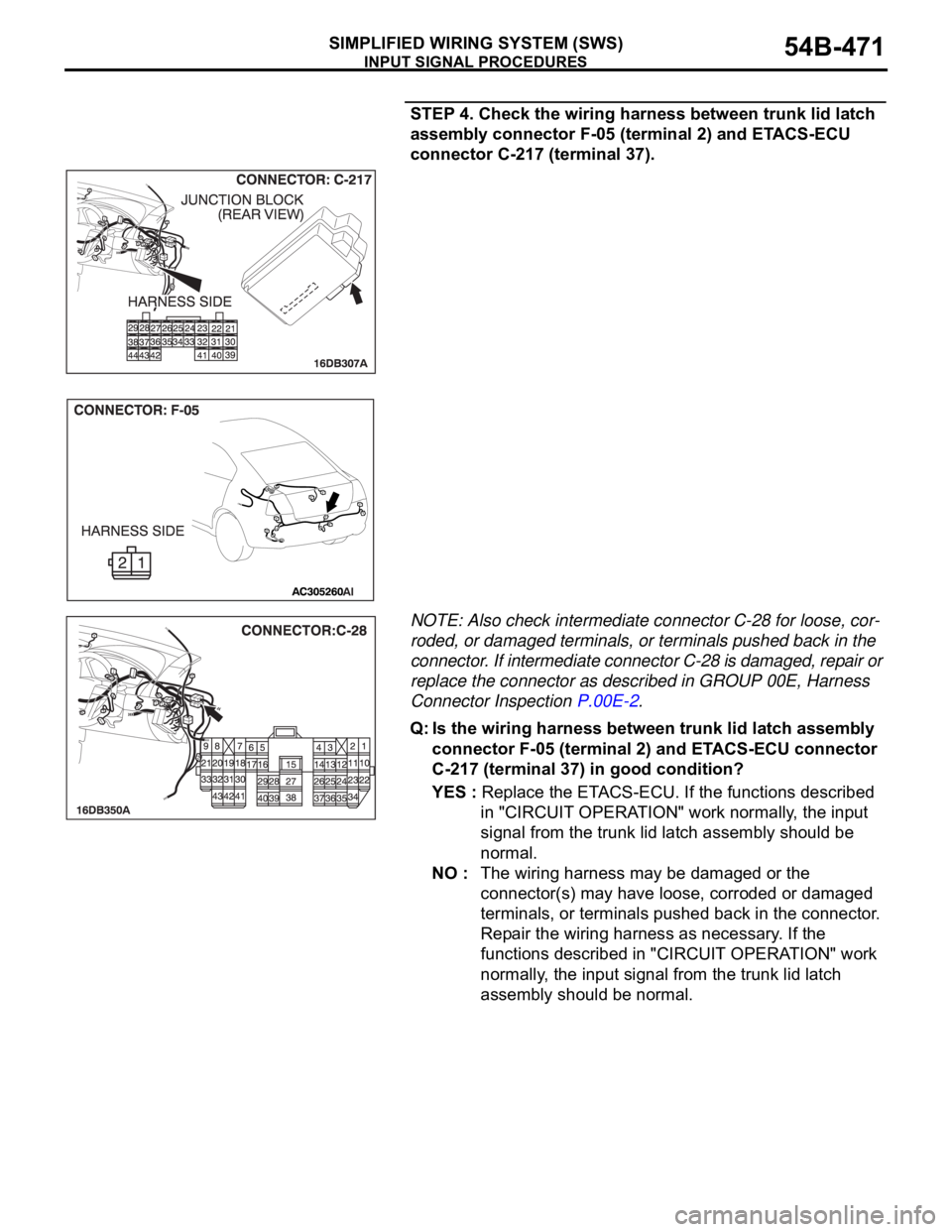

STEP 4. Check the wiring harness between trunk lid latch

assembly connector F-05 (terminal 2) and ETACS-ECU

connector C-217 (terminal 37).

NOTE: Also check intermediate connector C-28 for loose, cor-

roded, or damaged terminals, or terminals pushed back in the

connector. If intermediate connector C-28 is damaged, repair or

replace the connector as described in GROUP 00E, Harness

Connector Inspection P.00E-2.

Q: Is the wiring harness between trunk lid latch assembly

connector F-05 (terminal 2) and ETACS-ECU connector

C-217 (terminal 37) in good condition?

YES : Replace the ETACS-ECU. If the functions described

in "CIRCUIT OPERATION" work normally, the input

signal from the trunk lid latch assembly should be

normal.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. If the

functions described in "CIRCUIT OPERATION" work

normally, the input signal from the trunk lid latch

assembly should be normal.

Page 472 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-472

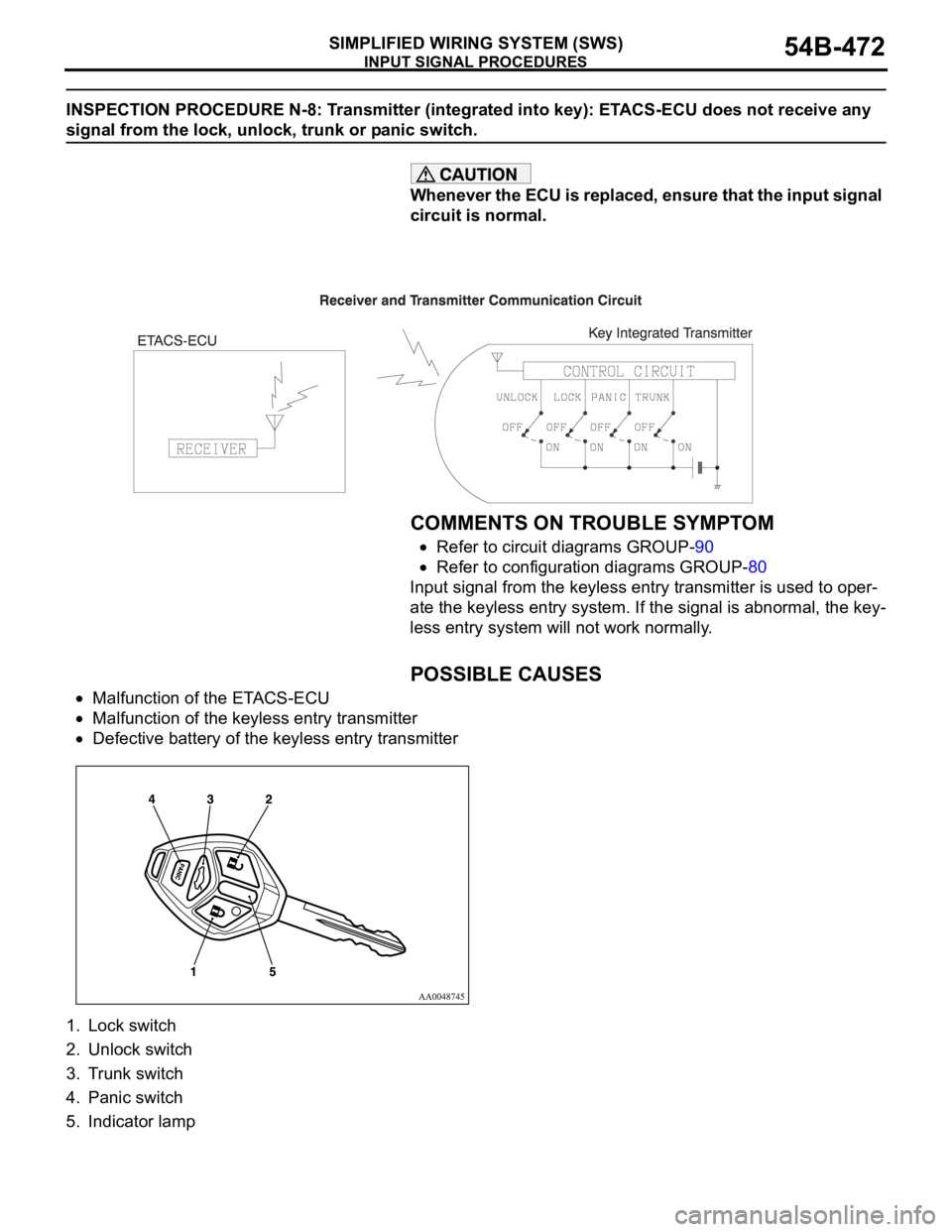

INSPECTION PROCEDURE N-8: Transmitter (integrated into key): ETACS-ECU does not receive any

signal from the lock, unlock, trunk or panic switch.

Whenever the ECU is replaced, ensure that the input signal

circuit is normal.

.

COMMENTS ON TROUBLE SYMPTOM

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Input signal from the keyless entry transmitter is used to oper-

ate the keyless entry system. If the signal is abnormal, the key-

less entry system will not work normally.

.

POSSIBLE CAUSES

Malfunction of the ETACS-ECU

Malfunction of the keyless entry transmitter

Defective battery of the keyless entry transmitter

1. Lock switch

2. Unlock switch

3. Trunk switch

4. Panic switch

5. Indicator lamp

Page 473 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-473

DIAGNOSTIC PROCEDURE

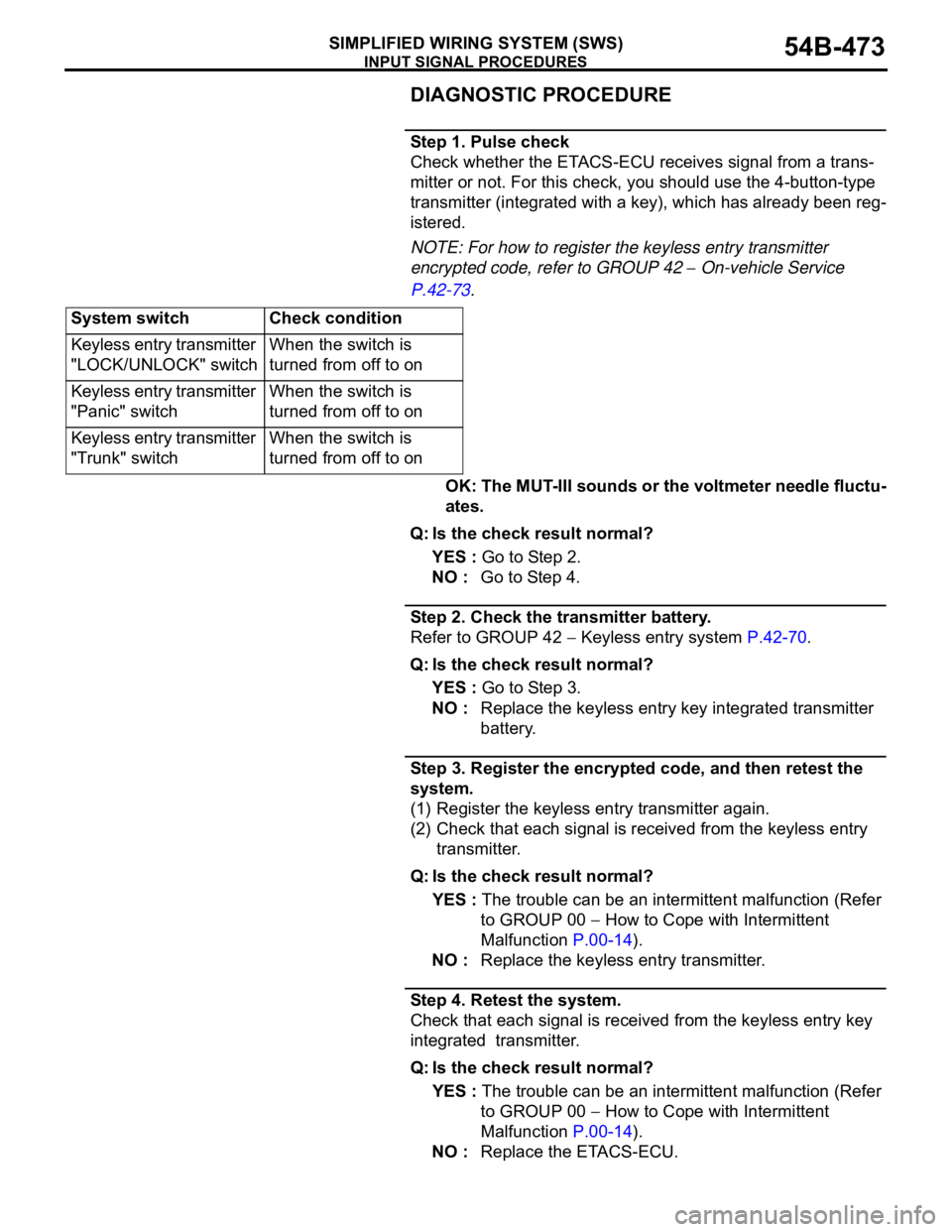

Step 1. Pulse check

Check whether the ETACS-ECU receives signal from a trans-

mitter or not. For this check, you should use the 4-button-type

transmitter (integrated with a key), which has already been reg-

istered.

NOTE: For how to register the keyless entry transmitter

encrypted code, refer to GROUP 42

On-vehicle Service

P.42-73.

OK: The MUT-III sounds or the voltmeter needle fluctu-

ates.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Go to Step 4.

Step 2. Check the transmitter battery.

Refer to GROUP 42

Keyless entry system P.42-70.

Q: Is the check result normal?

YES : Go to Step 3.

NO : Replace the keyless entry key integrated transmitter

battery.

Step 3. Register the encrypted code, and then retest the

system.

(1) Register the keyless entry transmitter again.

(2) Check that each signal is received from the keyless entry

transmitter.

Q: Is the check result normal?

YES : The trouble can be an intermittent malfunction (Refer

to GROUP 00

How to Cope with Intermittent

Malfunction P.00-14).

NO : Replace the keyless entry transmitter.

Step 4. Retest the system.

Check that each signal is received from the keyless entry key

integrated transmitter.

Q: Is the check result normal?

YES : The trouble can be an intermittent malfunction (Refer

to GROUP 00

How to Cope with Intermittent

Malfunction P.00-14).

NO : Replace the ETACS-ECU. System switch Check condition

Keyless entry transmitter

"LOCK/UNLOCK" switchWhen the switch is

turned from off to on

Keyless entry transmitter

"Panic" switchWhen the switch is

turned from off to on

Keyless entry transmitter

"Trunk" switchWhen the switch is

turned from off to on

Page 481 of 1500

CHECK AT ECU TERMINAL

SIMPLIFIED WIRING SYSTEM (SWS)54B-481

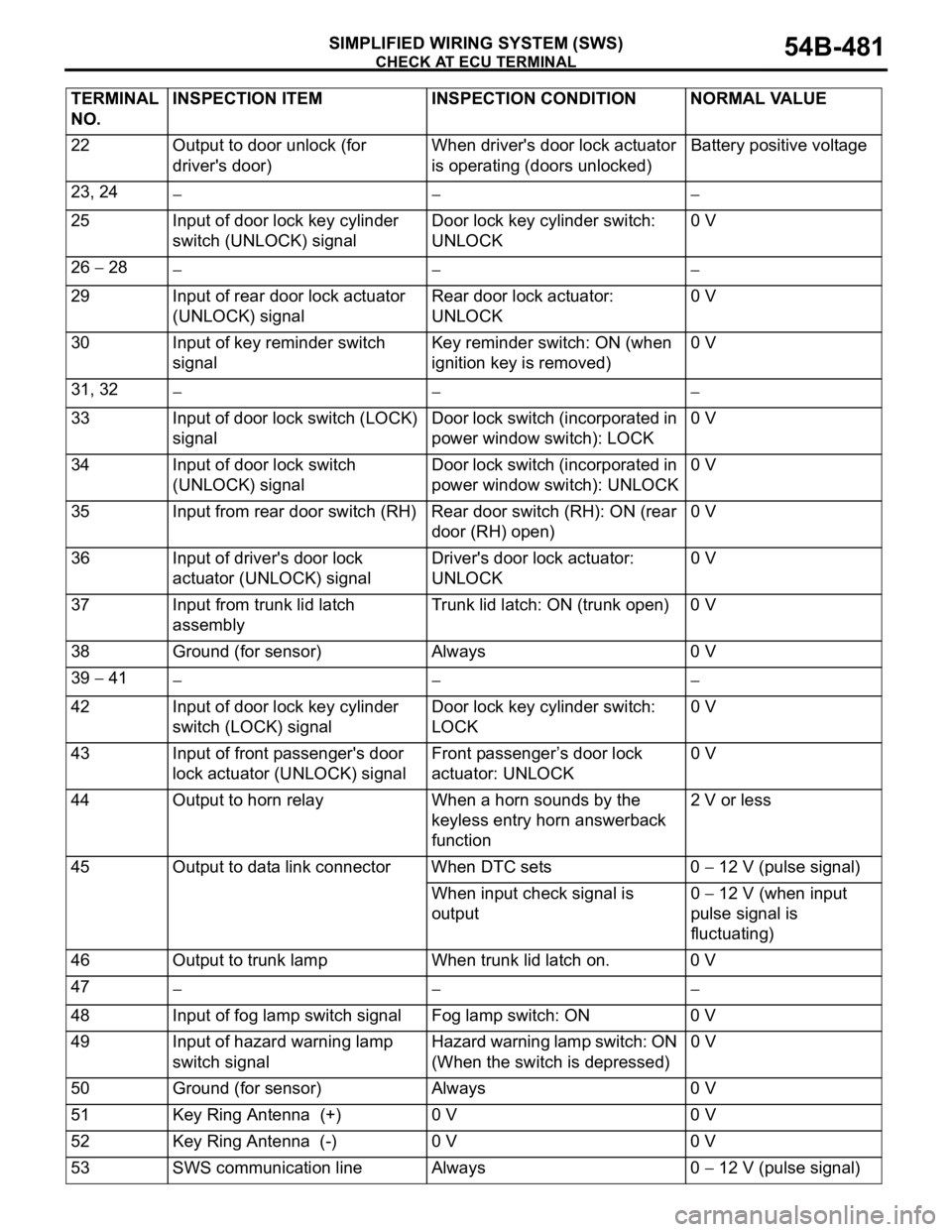

22 Output to door unlock (for

driver's door)When driver's door lock actuator

is operating (doors unlocked)Battery positive voltage

23, 24

25 Input of door lock key cylinder

switch (UNLOCK) signalDoor lock key cylinder switch:

UNLOCK0 V

26

28

29 Input of rear door lock actuator

(UNLOCK) signalRear door lock actuator:

UNLOCK0 V

30 Input of key reminder switch

signalKey reminder switch: ON (when

ignition key is removed)0 V

31, 32

33 Input of door lock switch (LOCK)

signalDoor lock switch (incorporated in

power window switch): LOCK0 V

34 Input of door lock switch

(UNLOCK) signalDoor lock switch (incorporated in

power window switch): UNLOCK0 V

35 Input from rear door switch (RH) Rear door switch (RH): ON (rear

door (RH) open)0 V

36 Input of driver's door lock

actuator (UNLOCK) signalDriver's door lock actuator:

UNLOCK0 V

37 Input from trunk lid latch

assemblyTrunk lid latch: ON (trunk open) 0 V

38 Ground (for sensor) Always 0 V

39

41

42 Input of door lock key cylinder

switch (LOCK) signalDoor lock key cylinder switch:

LOCK0 V

43 Input of front passenger's door

lock actuator (UNLOCK) signalFront passenger’s door lock

actuator: UNLOCK0 V

44 Output to horn relay When a horn sounds by the

keyless entry horn answerback

function2 V or less

45 Output to data link connector When DTC sets 0

12 V (pulse signal)

When input check signal is

output0

12 V (when input

pulse signal is

fluctuating)

46 Output to trunk lamp When trunk lid latch on. 0 V

47

48 Input of fog lamp switch signal Fog lamp switch: ON 0 V

49 Input of hazard warning lamp

switch signalHazard warning lamp switch: ON

(When the switch is depressed)0 V

50 Ground (for sensor) Always 0 V

51 Key Ring Antenna (+) 0 V 0 V

52 Key Ring Antenna (-) 0 V 0 V

53 SWS communication line Always 0

12 V (pulse signal) TERMINAL

NO.INSPECTION ITEM INSPECTION CONDITION NORMAL VALUE

Page 500 of 1500

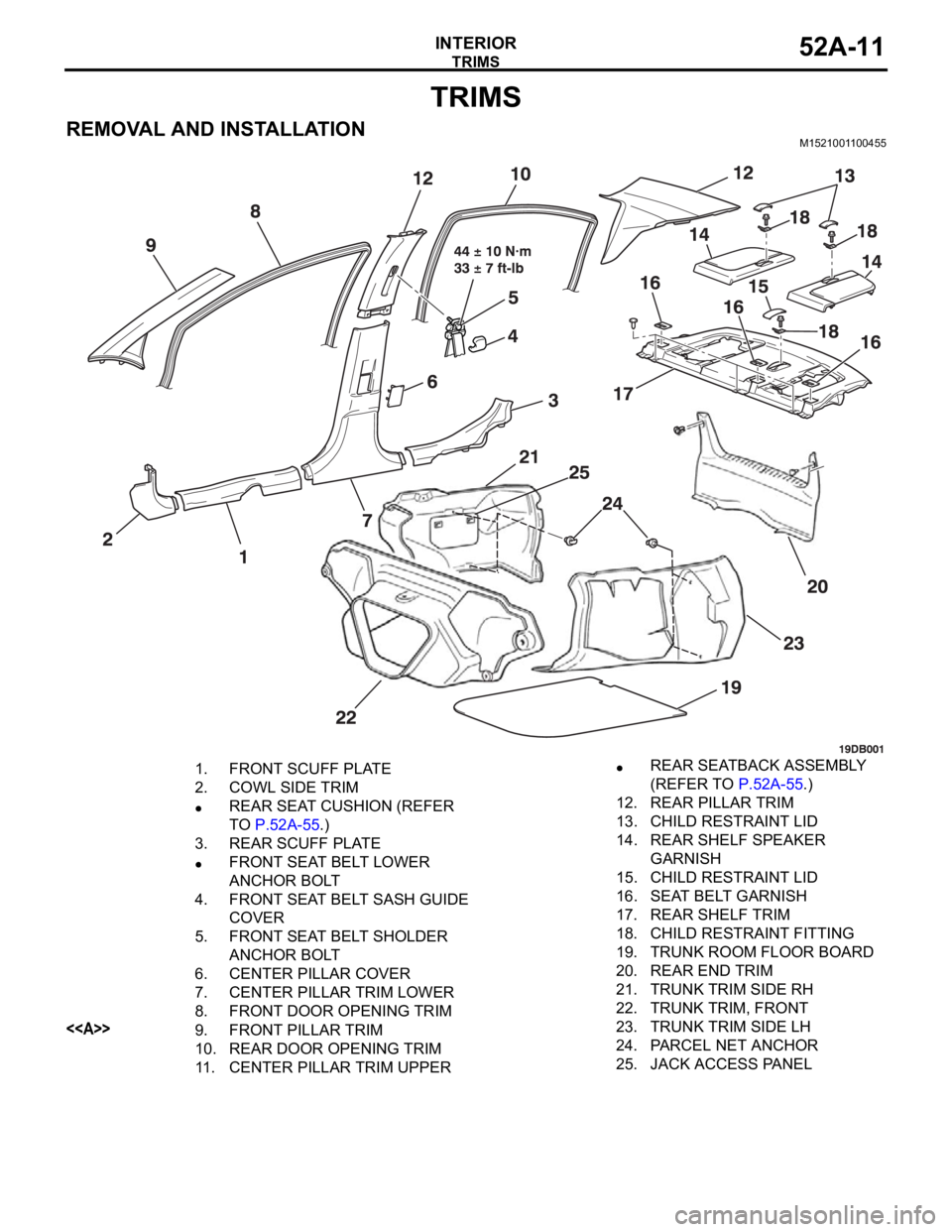

TRIMS

INTERIOR52A-11

TRIMS

REMOVAL AND INSTALLATIONM1521001100455

1. FRONT SCUFF PLATE

2. COWL SIDE TRIM

REAR SEAT CUSHION (REFER

TO P.52A-55.)

3. REAR SCUFF PLATE

FRONT SEAT BELT LOWER

ANCHOR BOLT

4. FRONT SEAT BELT SASH GUIDE

COVER

5. FRONT SEAT BELT SHOLDER

ANCHOR BOLT

6. CENTER PILLAR COVER

7. CENTER PILLAR TRIM LOWER

8. FRONT DOOR OPENING TRIM

<>9. FRONT PILLAR TRIM

10. REAR DOOR OPENING TRIM

11. CENTER PILLAR TRIM UPPER

REAR SEATBACK ASSEMBLY

(REFER TO P.52A-55.)

12. REAR PILLAR TRIM

13. CHILD RESTRAINT LID

14. REAR SHELF SPEAKER

GARNISH

15. CHILD RESTRAINT LID

16. SEAT BELT GARNISH

17. REAR SHELF TRIM

18. CHILD RESTRAINT FITTING

19. TRUNK ROOM FLOOR BOARD

20. REAR END TRIM

21. TRUNK TRIM SIDE RH

22. TRUNK TRIM, FRONT

23. TRUNK TRIM SIDE LH

24. PARCEL NET ANCHOR

25. JACK ACCESS PANEL

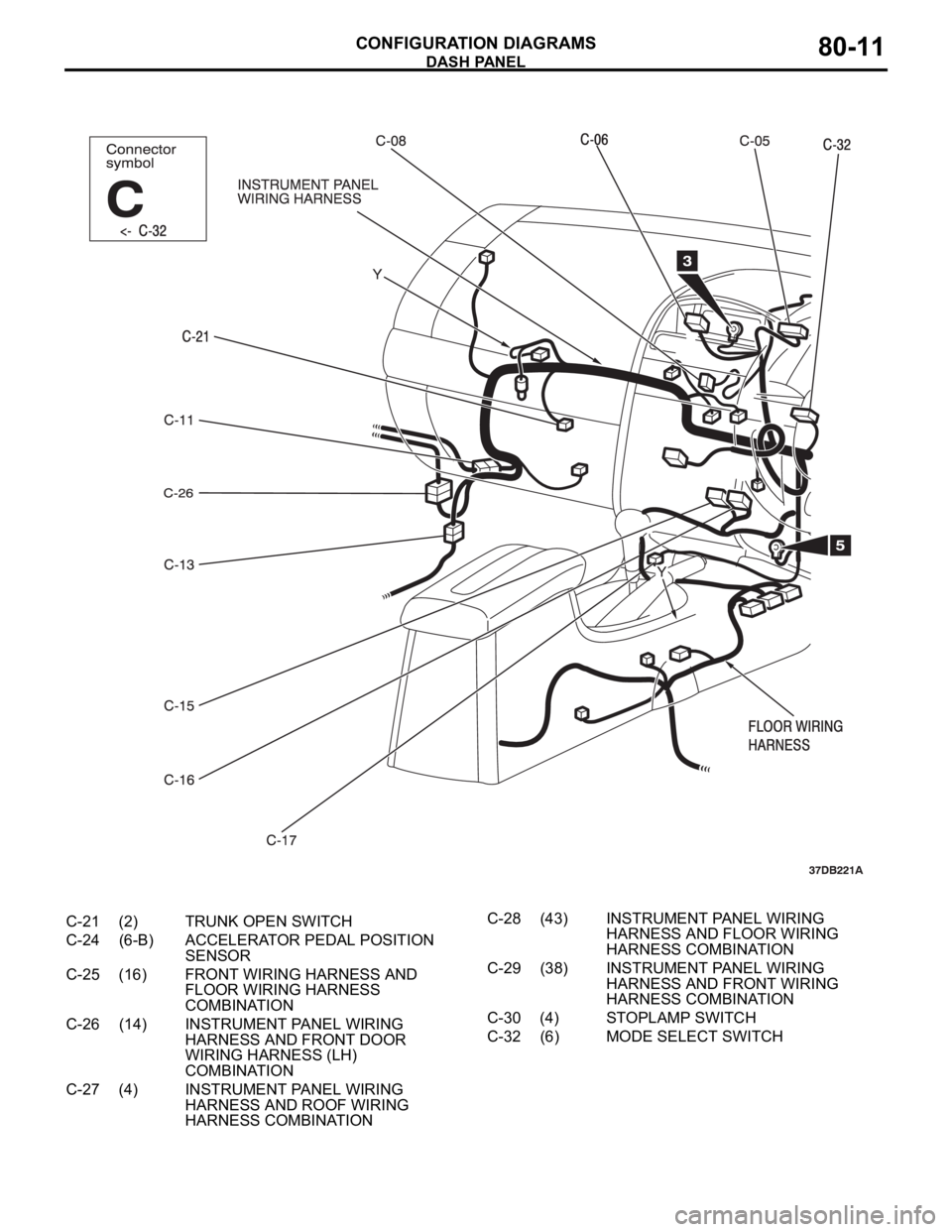

Page 560 of 1500

DASH PANEL

CONFIGURATION DIAGRAMS80-11

C-21 (2) TRUNK OPEN SWITCH

C-24 (6-B) ACCELERATOR PEDAL POSITION

SENSOR

C-25 (16) FRONT WIRING HARNESS AND

FLOOR WIRING HARNESS

COMBINATION

C-26 (14) INSTRUMENT PANEL WIRING

HARNESS AND FRONT DOOR

WIRING HARNESS (LH)

COMBINATION

C-27 (4) INSTRUMENT PANEL WIRING

HARNESS AND ROOF WIRING

HARNESS COMBINATIONC-28 (43) INSTRUMENT PANEL WIRING

HARNESS AND FLOOR WIRING

HARNESS COMBINATION

C-29 (38) INSTRUMENT PANEL WIRING

HARNESS AND FRONT WIRING

HARNESS COMBINATION

C-30 (4) STOPLAMP SWITCH

C-32 (6) MODE SELECT SWITCH