Cruis control MITSUBISHI 380 2005 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1364 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-33

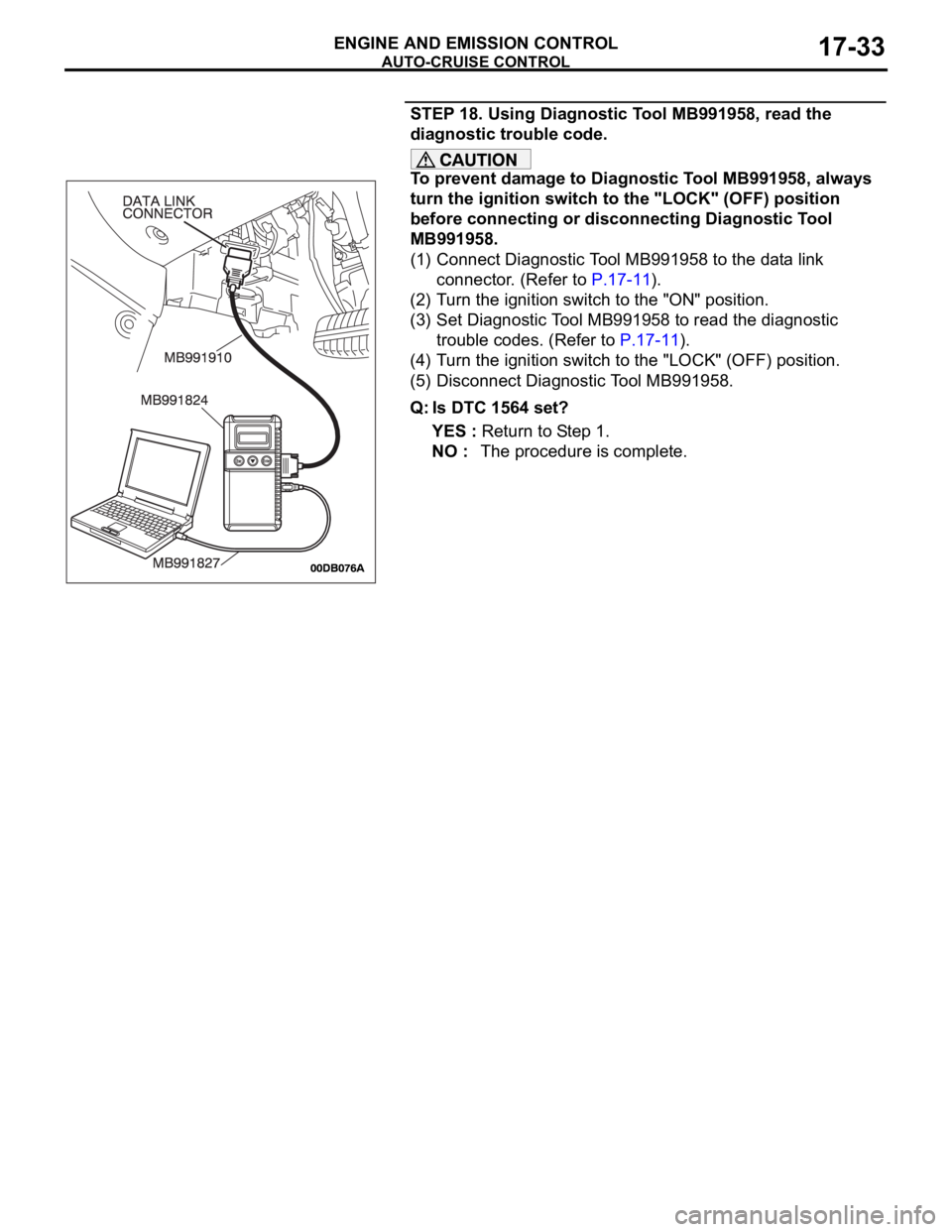

STEP 18. Using Diagnostic Tool MB991958, read the

diagnostic trouble code.

To prevent damage to Diagnostic Tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting Diagnostic Tool

MB991958.

(1) Connect Diagnostic Tool MB991958 to the data link

connector. (Refer to P.17-11).

(2) Turn the ignition switch to the "ON" position.

(3) Set Diagnostic Tool MB991958 to read the diagnostic

trouble codes. (Refer to P.17-11).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect Diagnostic Tool MB991958.

Q: Is DTC 1564 set?

YES : Return to Step 1.

NO : The procedure is complete.

Page 1365 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-34

DTC 1575: Cancel Latch Signal System

.

DTC SET CONDITIONS

The Engine ECU communicates cancellation reten-

tion information between the two microprocessors.

This DTC is set when cancellation retention informa-

tion contains inconsistency.

.

TROUBLESHOOTING HINTS (THE MOST

LIKELY CAUSES FOR THIS CODE TO BE

SET ARE:)

Malfunction of the Engine ECU.

Circuit drawings

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Refer to component locations GROUP-70

DIAGNOSIS

Replace the Engine ECU.[Refer to GROUP 13A, Engine ECU

13A-675] . Then check that diagnostic trouble code P1575 is

not set.

Page 1366 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-35

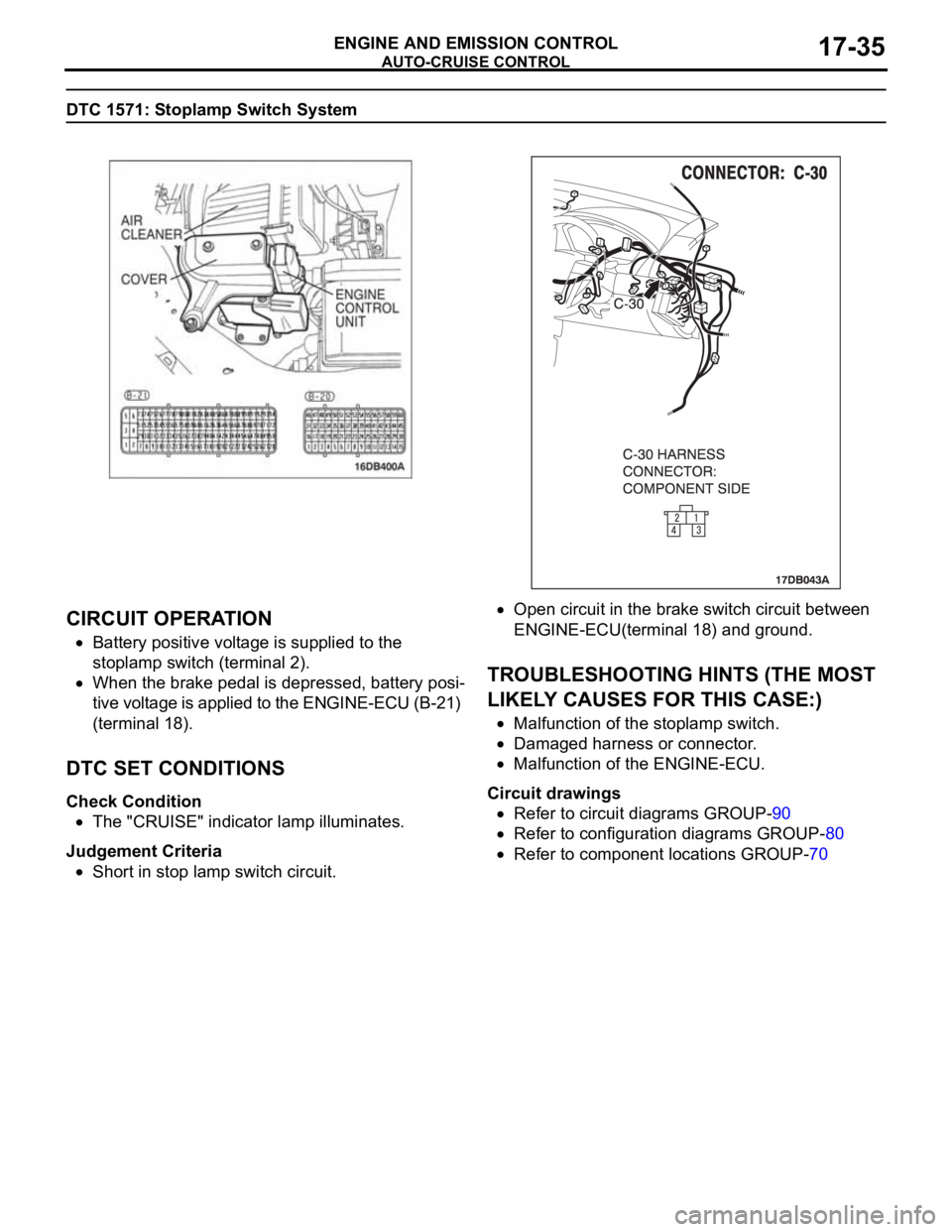

DTC 1571: Stoplamp Switch System

.

CIRCUIT OPERATION

Battery positive voltage is supplied to the

stoplamp switch (terminal 2).

When the brake pedal is depressed, battery posi-

tive voltage is applied to the ENGINE-ECU (B-21)

(terminal 18).

.

DTC SET CONDITIONS

Check Condition

The "CRUISE" indicator lamp illuminates.

Judgement Criteria

Short in stop lamp switch circuit.

Open circuit in the brake switch circuit between

ENGINE-ECU(terminal 18) and ground.

.

TROUBLESHOOTING HINTS (THE MOST

LIKELY CAUSES FOR THIS CASE:)

Malfunction of the stoplamp switch.

Damaged harness or connector.

Malfunction of the ENGINE-ECU.

Circuit drawings

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Refer to component locations GROUP-70

Page 1367 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-36

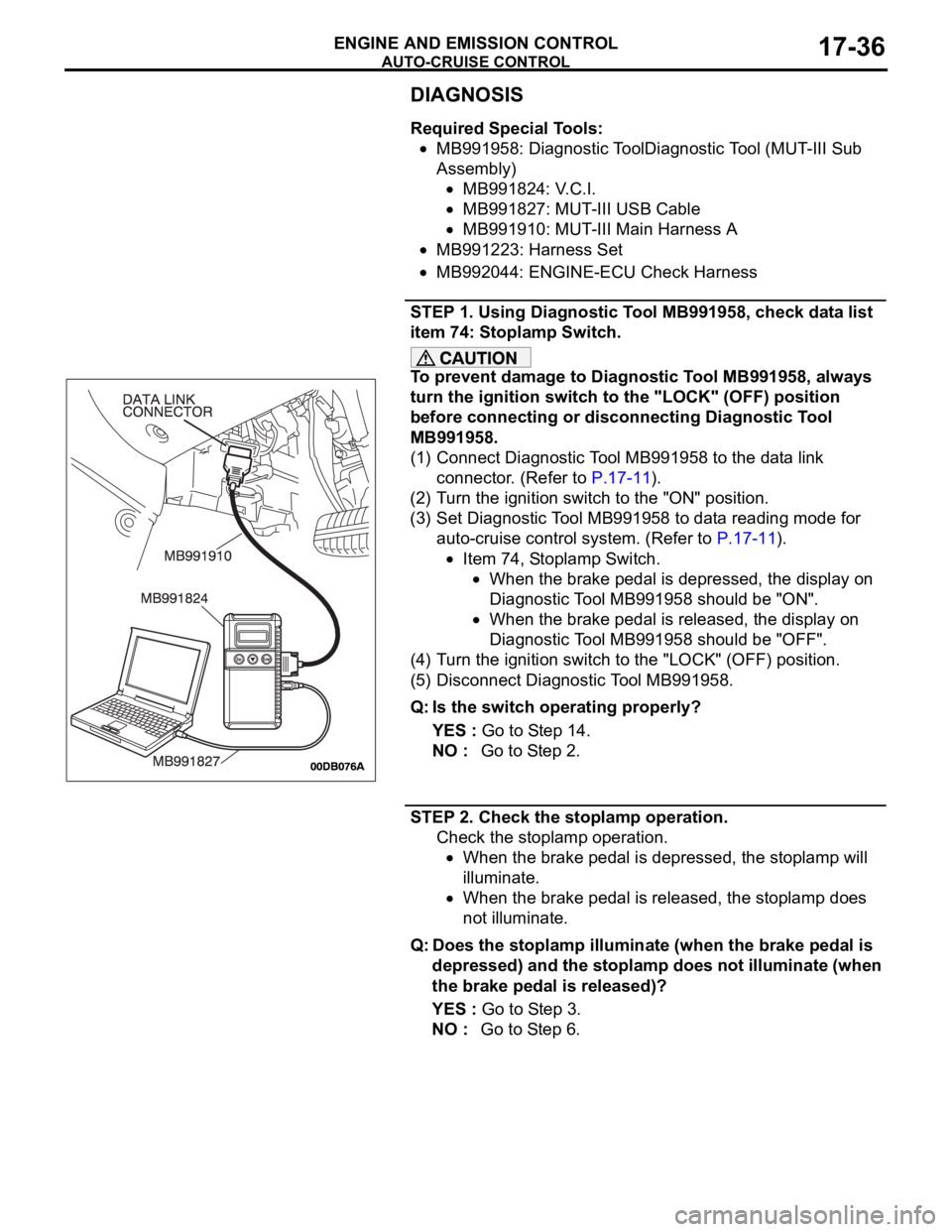

DIAGNOSIS

Required Special Tools:

MB991958: Diagnostic ToolDiagnostic Tool (MUT-III Sub

Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

MB991223: Harness Set

MB992044: ENGINE-ECU Check Harness

STEP 1. Using Diagnostic Tool MB991958, check data list

item 74: Stoplamp Switch.

To prevent damage to Diagnostic Tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting Diagnostic Tool

MB991958.

(1) Connect Diagnostic Tool MB991958 to the data link

connector. (Refer to P.17-11).

(2) Turn the ignition switch to the "ON" position.

(3) Set Diagnostic Tool MB991958 to data reading mode for

auto-cruise control system. (Refer to P.17-11).

Item 74, Stoplamp Switch.

When the brake pedal is depressed, the display on

Diagnostic Tool MB991958 should be "ON".

When the brake pedal is released, the display on

Diagnostic Tool MB991958 should be "OFF".

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect Diagnostic Tool MB991958.

Q: Is the switch operating properly?

YES : Go to Step 14.

NO : Go to Step 2.

STEP 2. Check the stoplamp operation.

Check the stoplamp operation.

When the brake pedal is depressed, the stoplamp will

illuminate.

When the brake pedal is released, the stoplamp does

not illuminate.

Q: Does the stoplamp illuminate (when the brake pedal is

depressed) and the stoplamp does not illuminate (when

the brake pedal is released)?

YES : Go to Step 3.

NO : Go to Step 6.

Page 1368 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-37

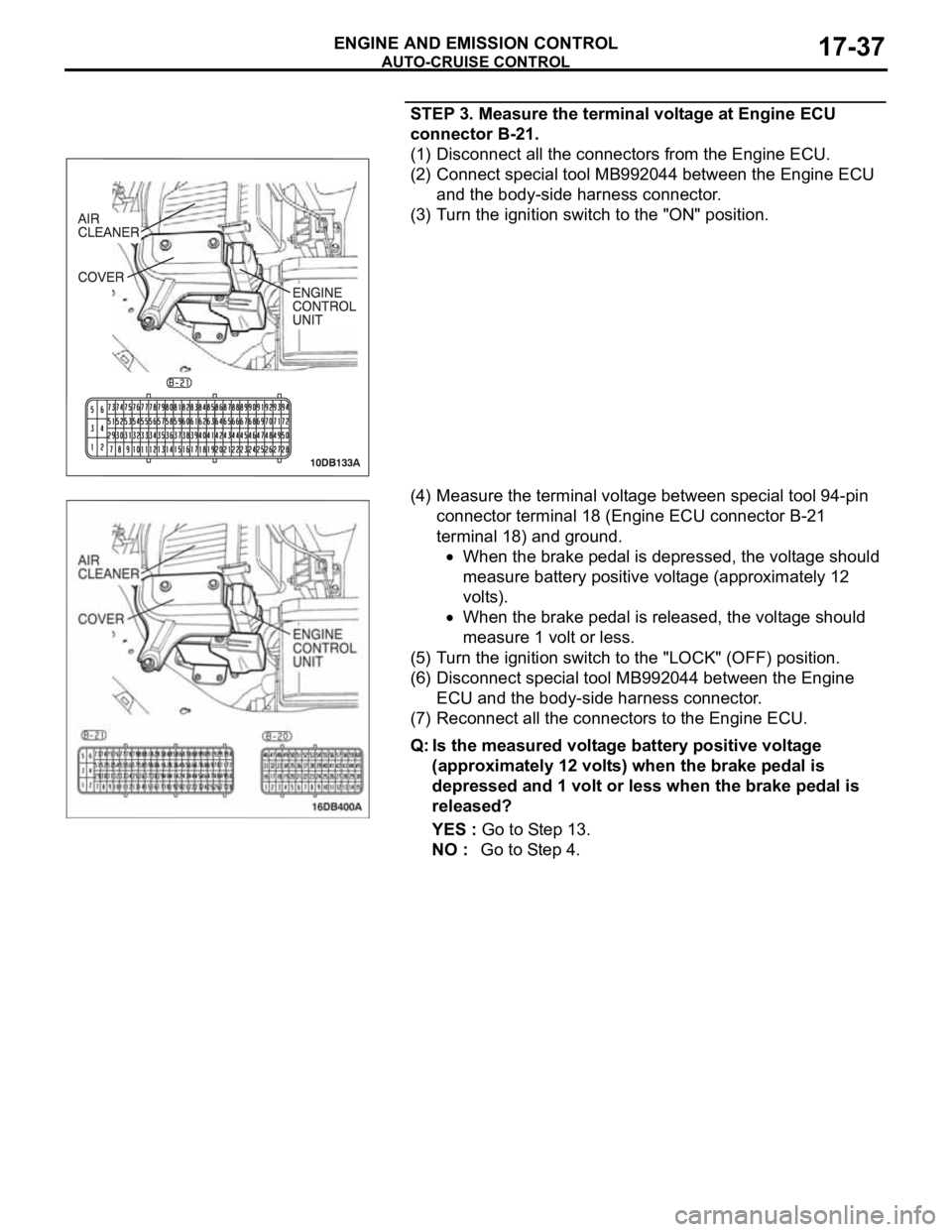

STEP 3. Measure the terminal voltage at Engine ECU

connector B-21.

(1) Disconnect all the connectors from the Engine ECU.

(2) Connect special tool MB992044 between the Engine ECU

and the body-side harness connector.

(3) Turn the ignition switch to the "ON" position.

(4) Measure the terminal voltage between special tool 94-pin

connector terminal 18 (Engine ECU connector B-21

terminal 18) and ground.

When the brake pedal is depressed, the voltage should

measure battery positive voltage (approximately 12

volts).

When the brake pedal is released, the voltage should

measure 1 volt or less.

(5) Turn the ignition switch to the "LOCK" (OFF) position.

(6) Disconnect special tool MB992044 between the Engine

ECU and the body-side harness connector.

(7) Reconnect all the connectors to the Engine ECU.

Q: Is the measured voltage battery positive voltage

(approximately 12 volts) when the brake pedal is

depressed and 1 volt or less when the brake pedal is

released?

YES : Go to Step 13.

NO : Go to Step 4.

Page 1369 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-38

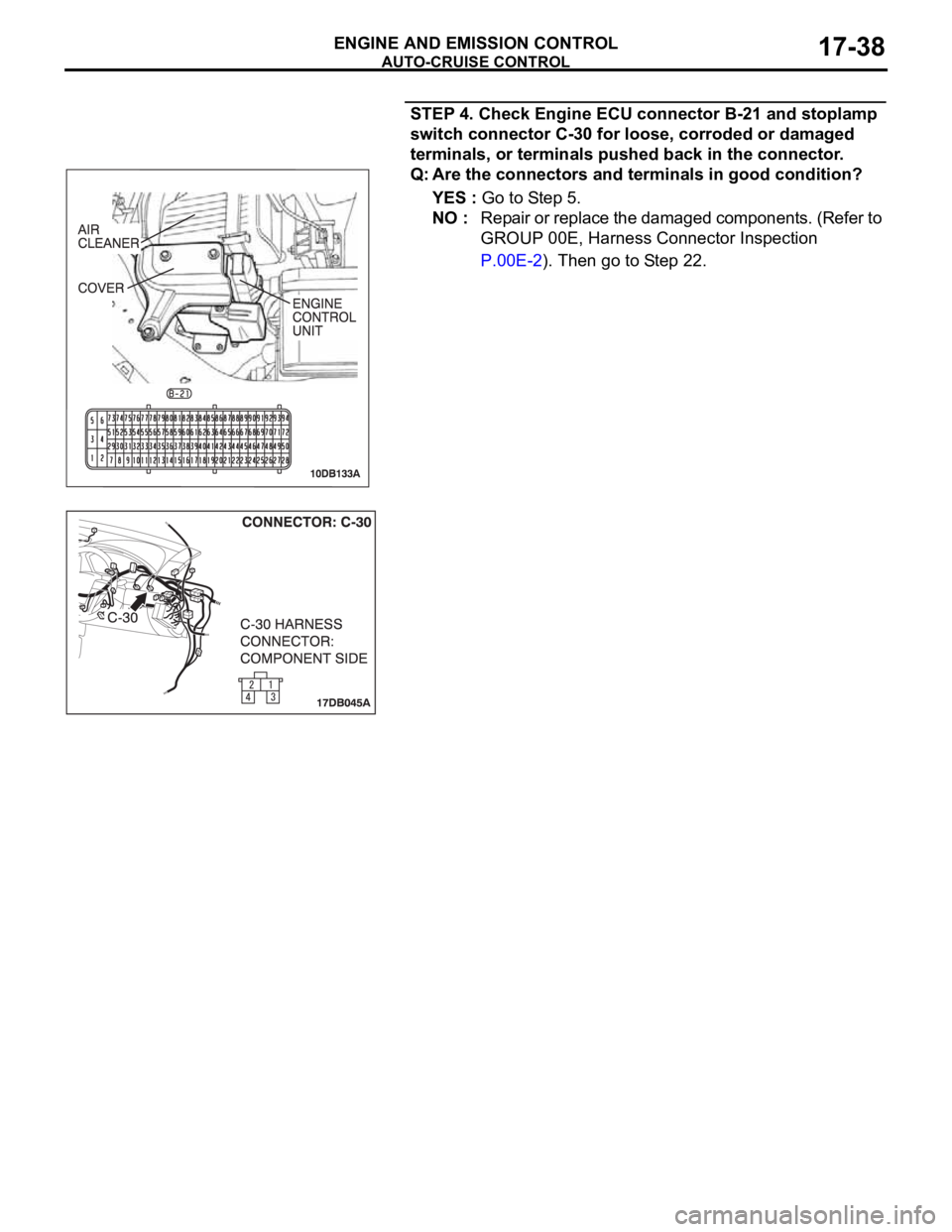

STEP 4. Check Engine ECU connector B-21 and stoplamp

switch connector C-30 for loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Q: Are the connectors and terminals in good condition?

YES : Go to Step 5.

NO : Repair or replace the damaged components. (Refer to

GROUP 00E, Harness Connector Inspection

P.00E-2). Then go to Step 22.

Page 1370 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-39

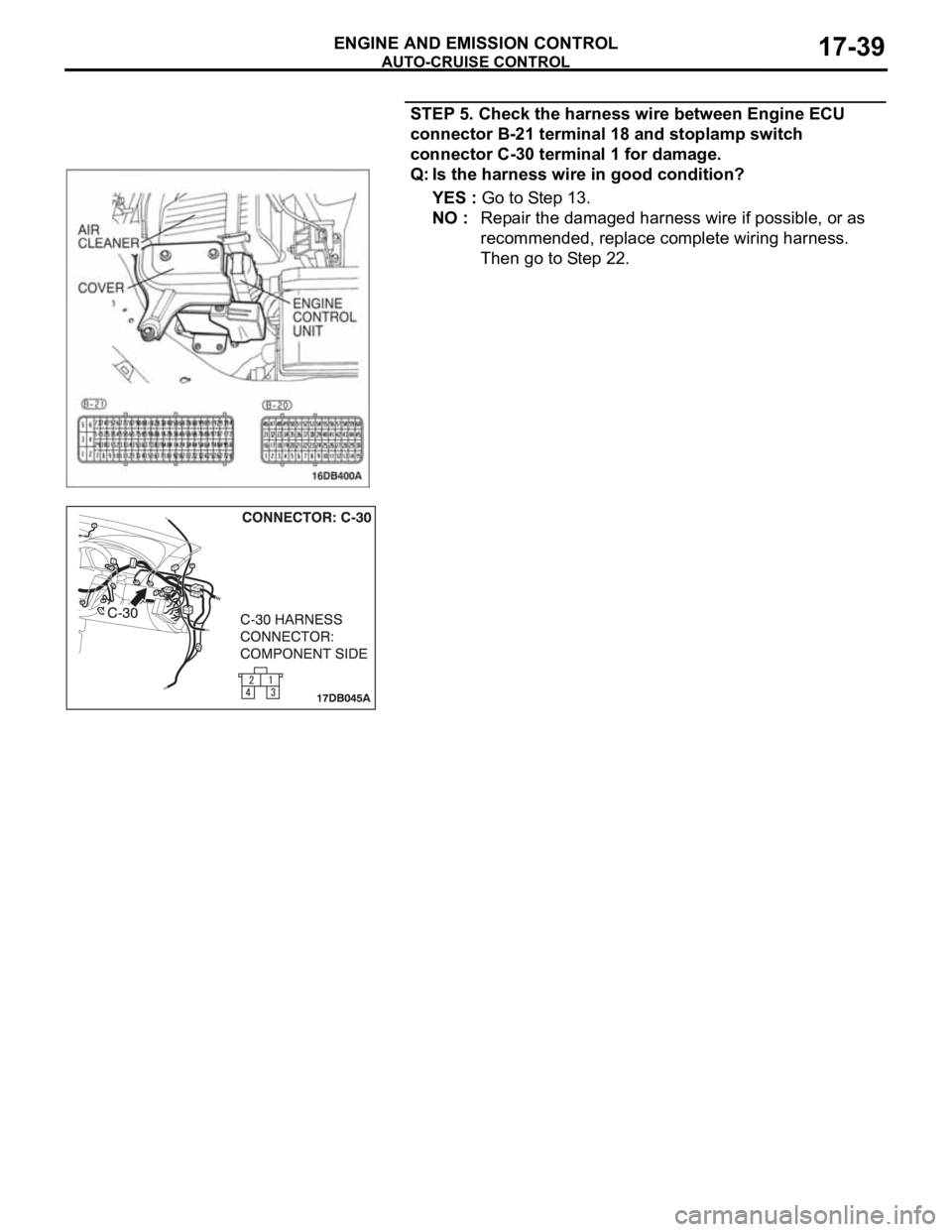

STEP 5. Check the harness wire between Engine ECU

connector B-21 terminal 18 and stoplamp switch

connector C-30 terminal 1 for damage.

Q: Is the harness wire in good condition?

YES : Go to Step 13.

NO : Repair the damaged harness wire if possible, or as

recommended, replace complete wiring harness.

Then go to Step 22.

Page 1371 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-40

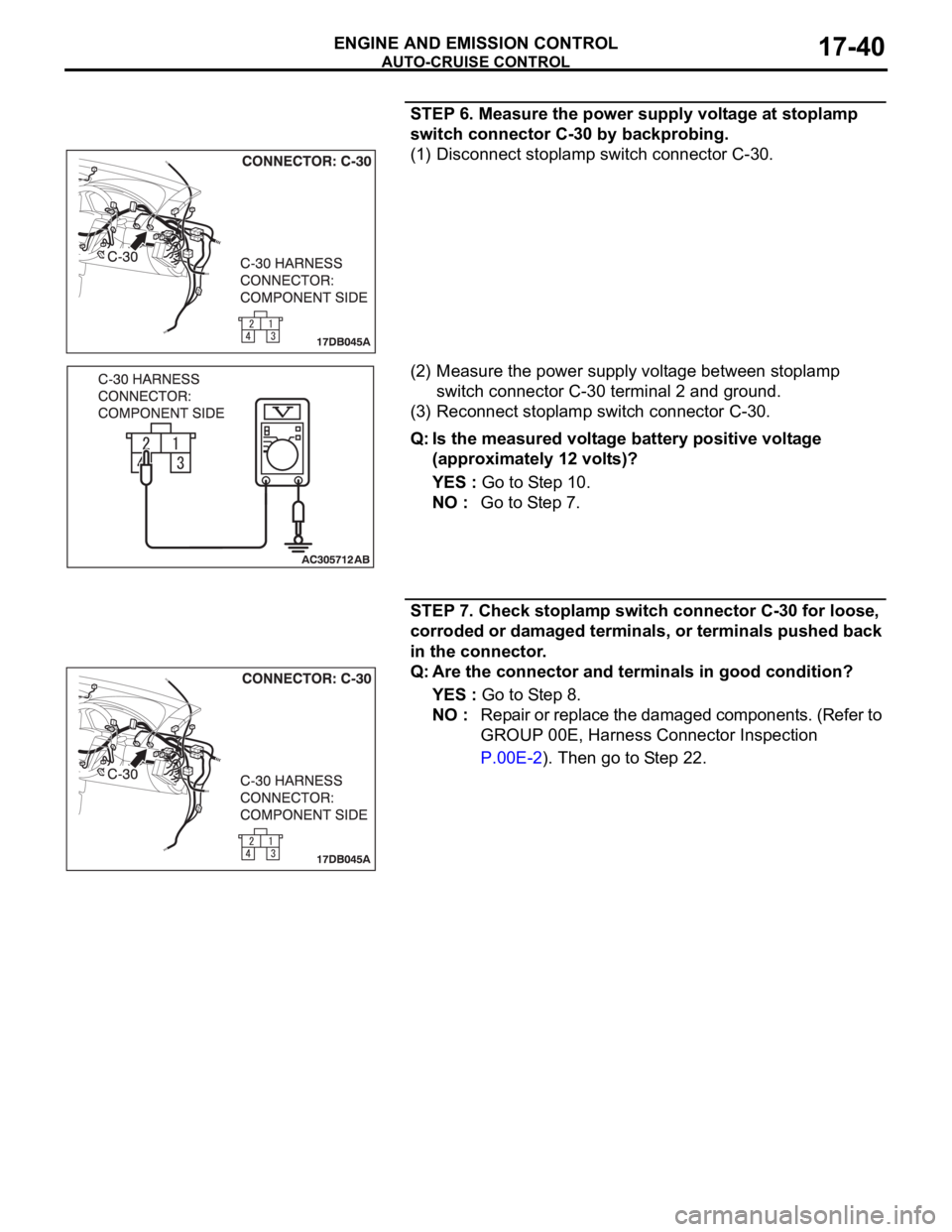

STEP 6. Measure the power supply voltage at stoplamp

switch connector C-30 by backprobing.

(1) Disconnect stoplamp switch connector C-30.

(2) Measure the power supply voltage between stoplamp

switch connector C-30 terminal 2 and ground.

(3) Reconnect stoplamp switch connector C-30.

Q: Is the measured voltage battery positive voltage

(approximately 12 volts)?

YES : Go to Step 10.

NO : Go to Step 7.

STEP 7. Check stoplamp switch connector C-30 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Are the connector and terminals in good condition?

YES : Go to Step 8.

NO : Repair or replace the damaged components. (Refer to

GROUP 00E, Harness Connector Inspection

P.00E-2). Then go to Step 22.

Page 1372 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-41

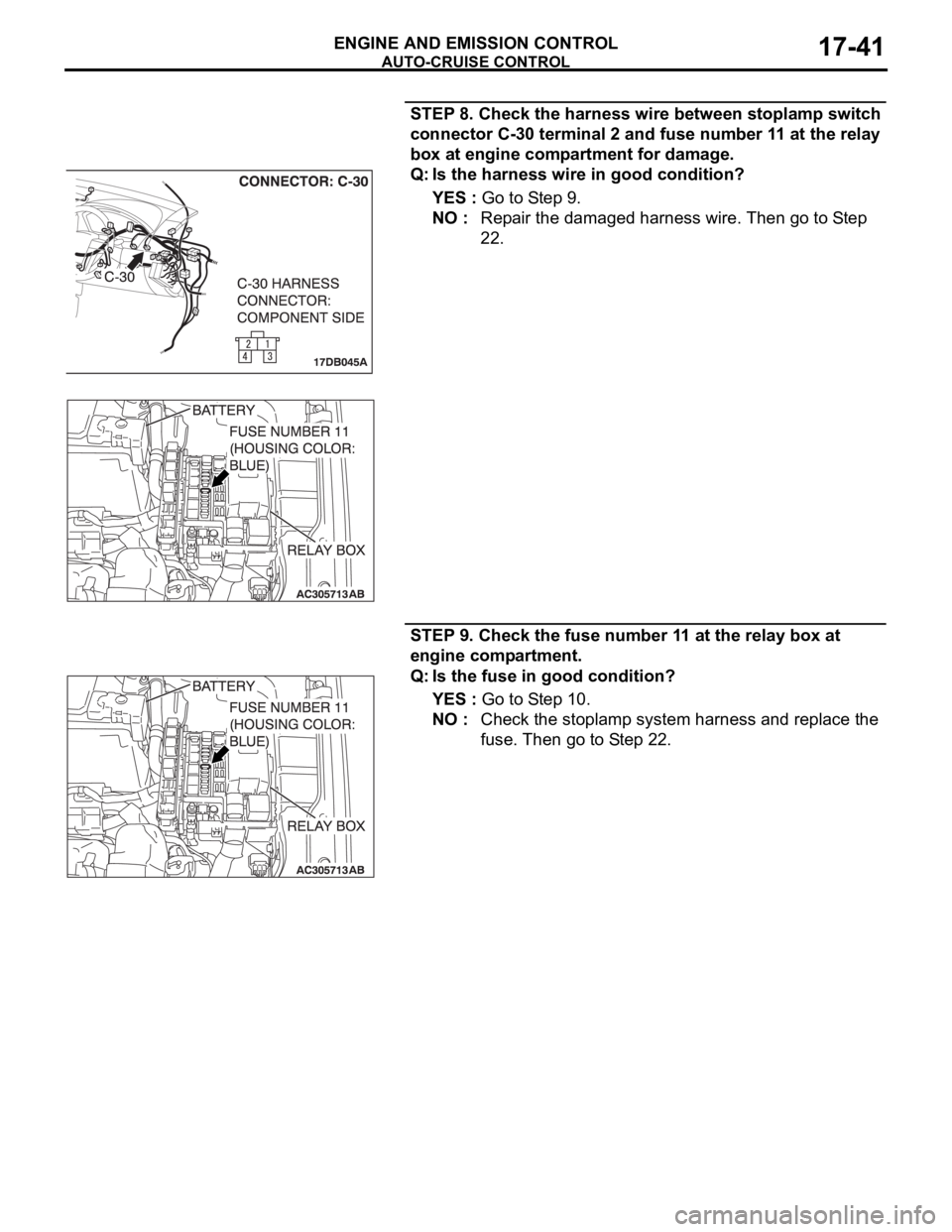

STEP 8. Check the harness wire between stoplamp switch

connector C-30 terminal 2 and fuse number 11 at the relay

box at engine compartment for damage.

Q: Is the harness wire in good condition?

YES : Go to Step 9.

NO : Repair the damaged harness wire. Then go to Step

22.

STEP 9. Check the fuse number 11 at the relay box at

engine compartment.

Q: Is the fuse in good condition?

YES : Go to Step 10.

NO : Check the stoplamp system harness and replace the

fuse. Then go to Step 22.

Page 1373 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-42

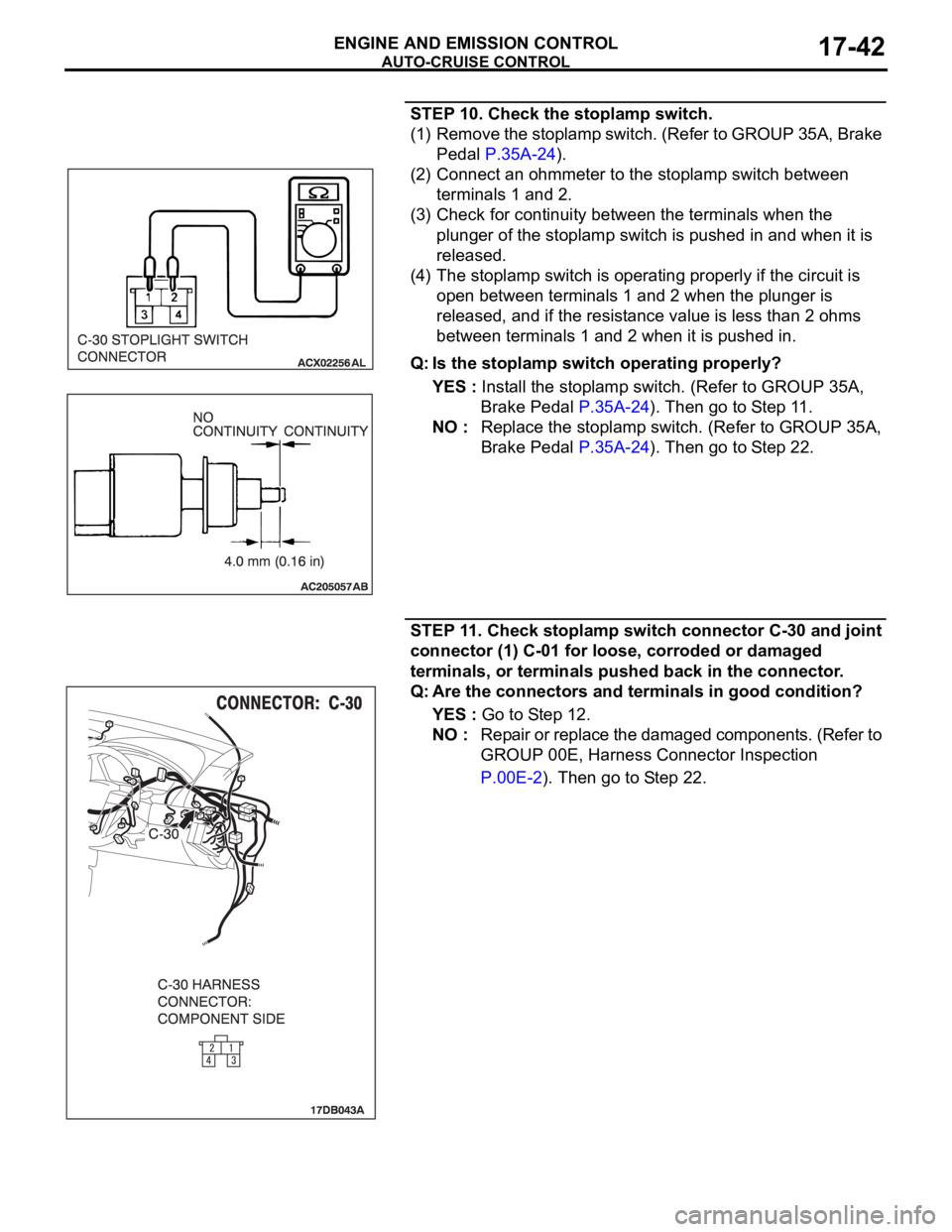

STEP 10. Check the stoplamp switch.

(1) Remove the stoplamp switch. (Refer to GROUP 35A, Brake

Pedal P.35A-24).

(2) Connect an ohmmeter to the stoplamp switch between

terminals 1 and 2.

(3) Check for continuity between the terminals when the

plunger of the stoplamp switch is pushed in and when it is

released.

(4) The stoplamp switch is operating properly if the circuit is

open between terminals 1 and 2 when the plunger is

released, and if the resistance value is less than 2 ohms

between terminals 1 and 2 when it is pushed in.

Q: Is the stoplamp switch operating properly?

YES : Install the stoplamp switch. (Refer to GROUP 35A,

Brake Pedal P.35A-24). Then go to Step 11.

NO : Replace the stoplamp switch. (Refer to GROUP 35A,

Brake Pedal P.35A-24). Then go to Step 22.

STEP 11. Check stoplamp switch connector C-30 and joint

connector (1) C-01 for loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Q: Are the connectors and terminals in good condition?

YES : Go to Step 12.

NO : Repair or replace the damaged components. (Refer to

GROUP 00E, Harness Connector Inspection

P.00E-2). Then go to Step 22.