warning MITSUBISHI 380 2005 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 690 of 1500

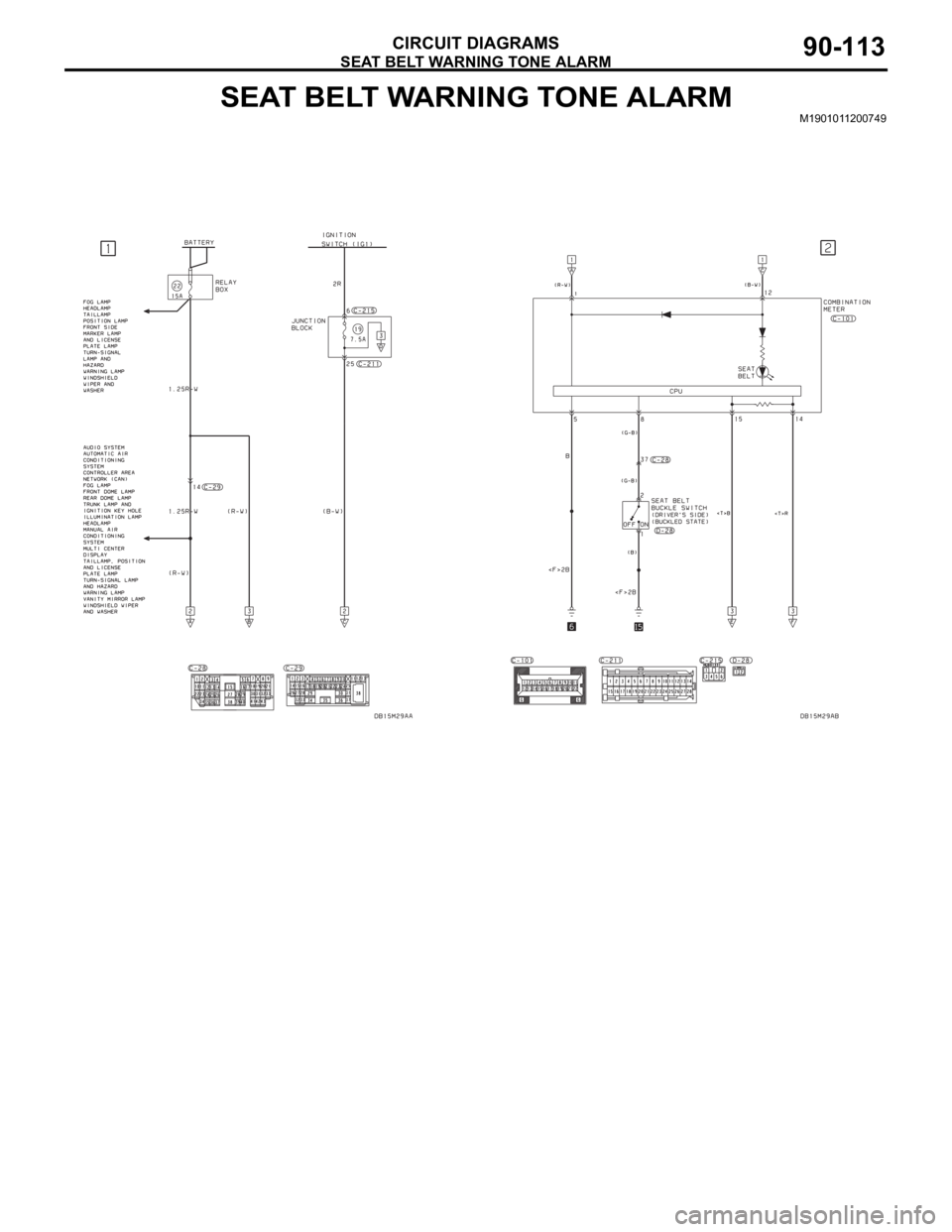

SEAT BELT WARNING TONE ALARM

CIRCUIT DIAGRAMS90-113

SEAT BELT WARNING TONE ALARMM1901011200749

Page 691 of 1500

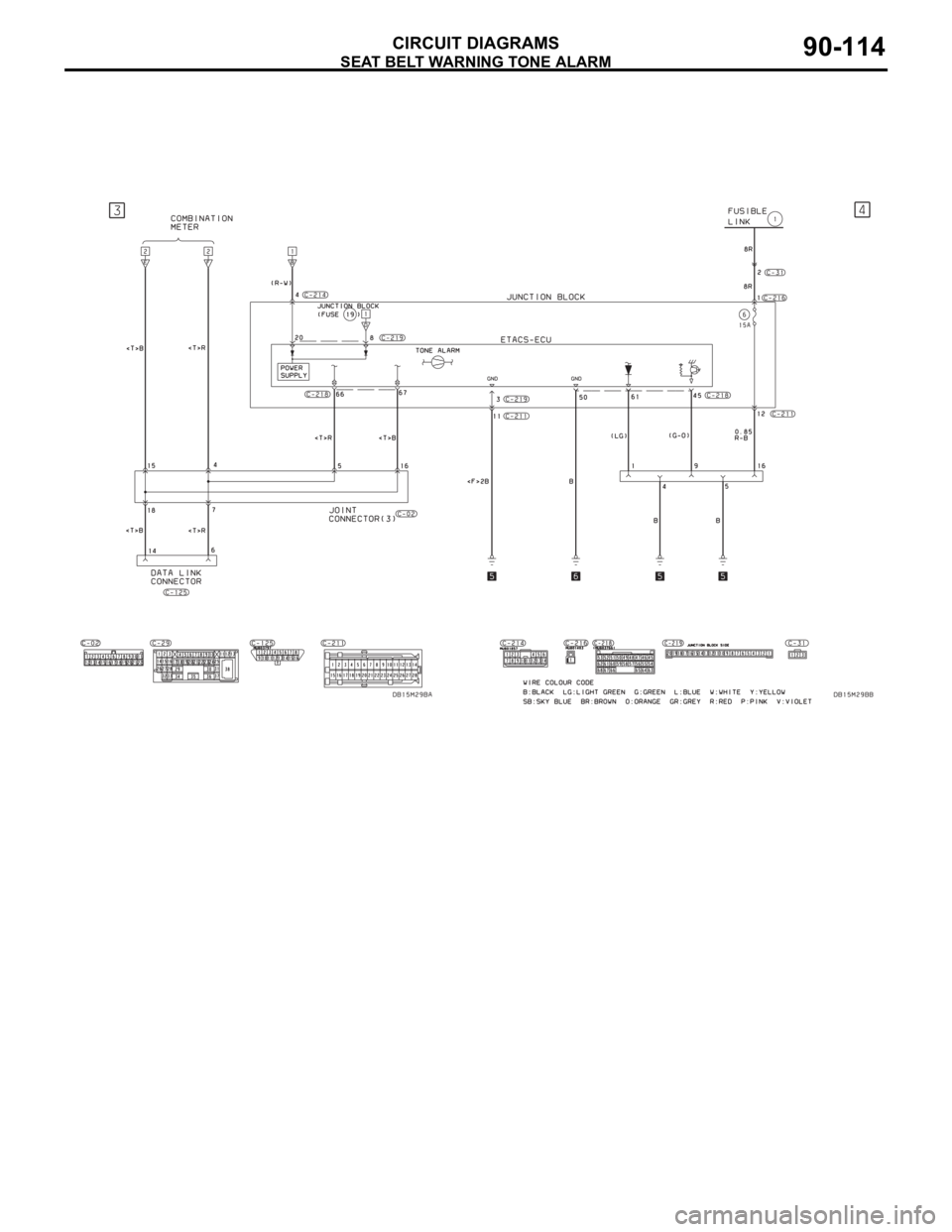

SEAT BELT WARNING TONE ALARM

CIRCUIT DIAGRAMS90-114

Page 692 of 1500

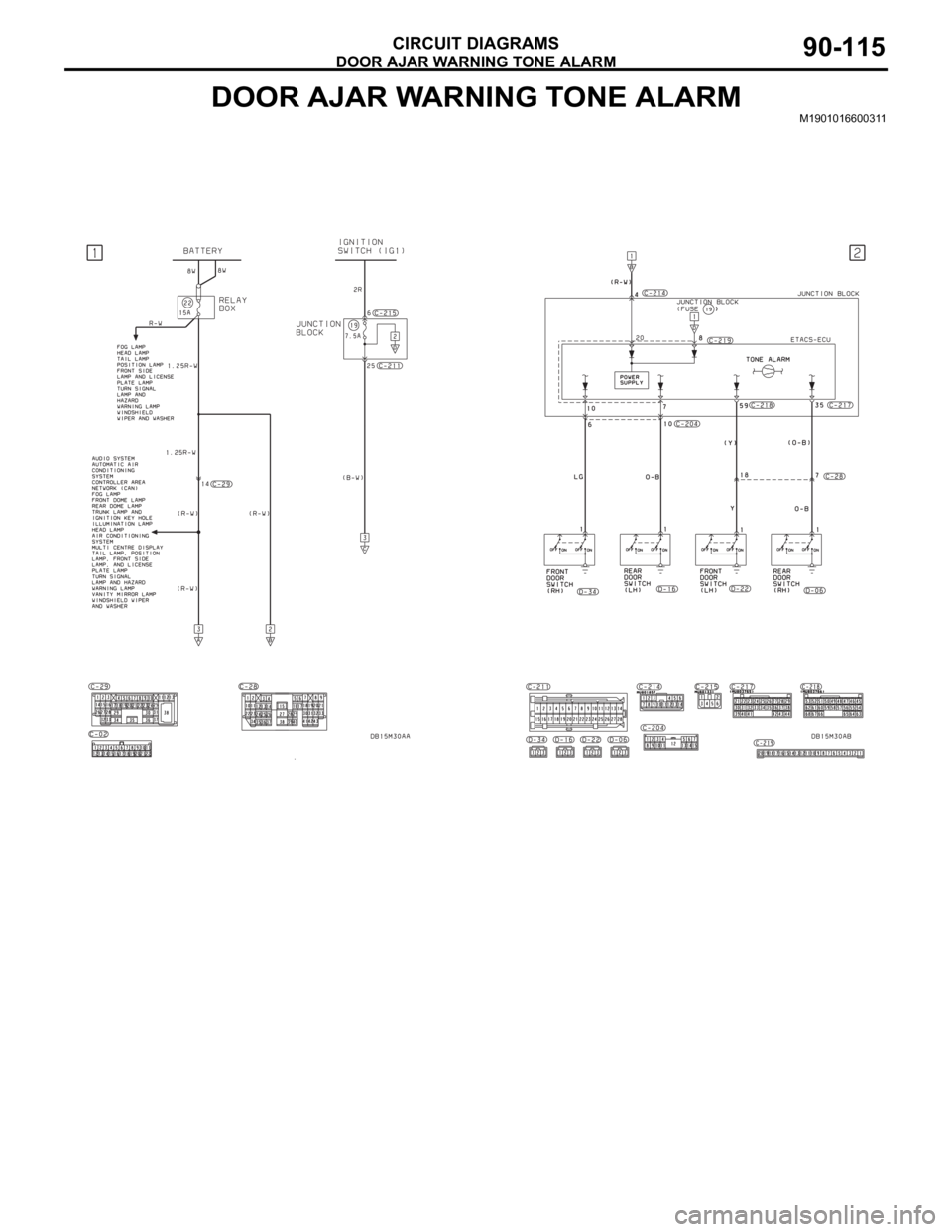

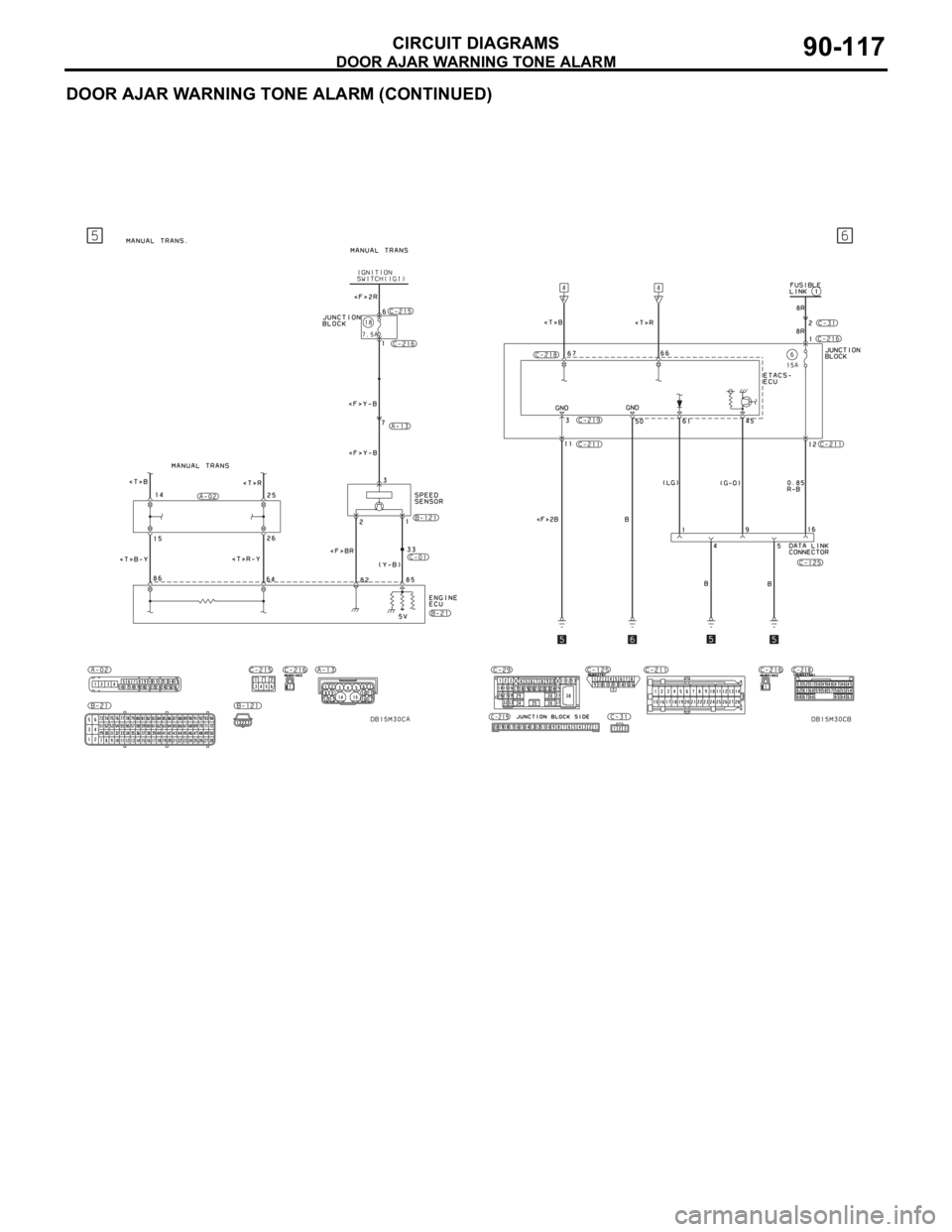

DOOR AJAR WARNING TONE ALARM

CIRCUIT DIAGRAMS90-115

DOOR AJAR WARNING TONE ALARMM1901016600311

Page 693 of 1500

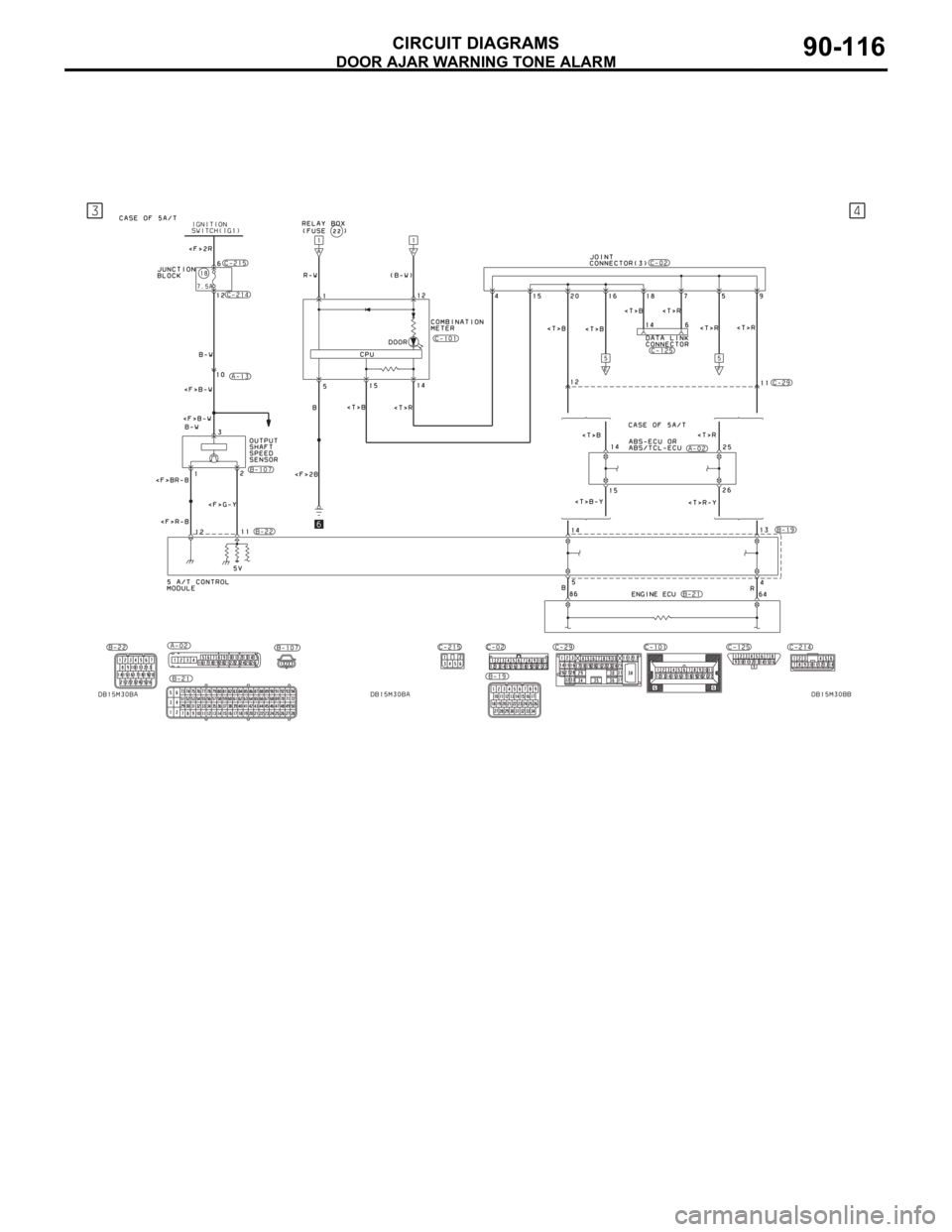

DOOR AJAR WARNING TONE ALARM

CIRCUIT DIAGRAMS90-116

Page 694 of 1500

DOOR AJAR WARNING TONE ALARM

CIRCUIT DIAGRAMS90-117

DOOR AJAR WARNING TONE ALARM (CONTINUED)

Page 1134 of 1500

KEYLESS ENTRY SYSTEM

BODY42-67

KEYLESS ENTRY SYSTEM

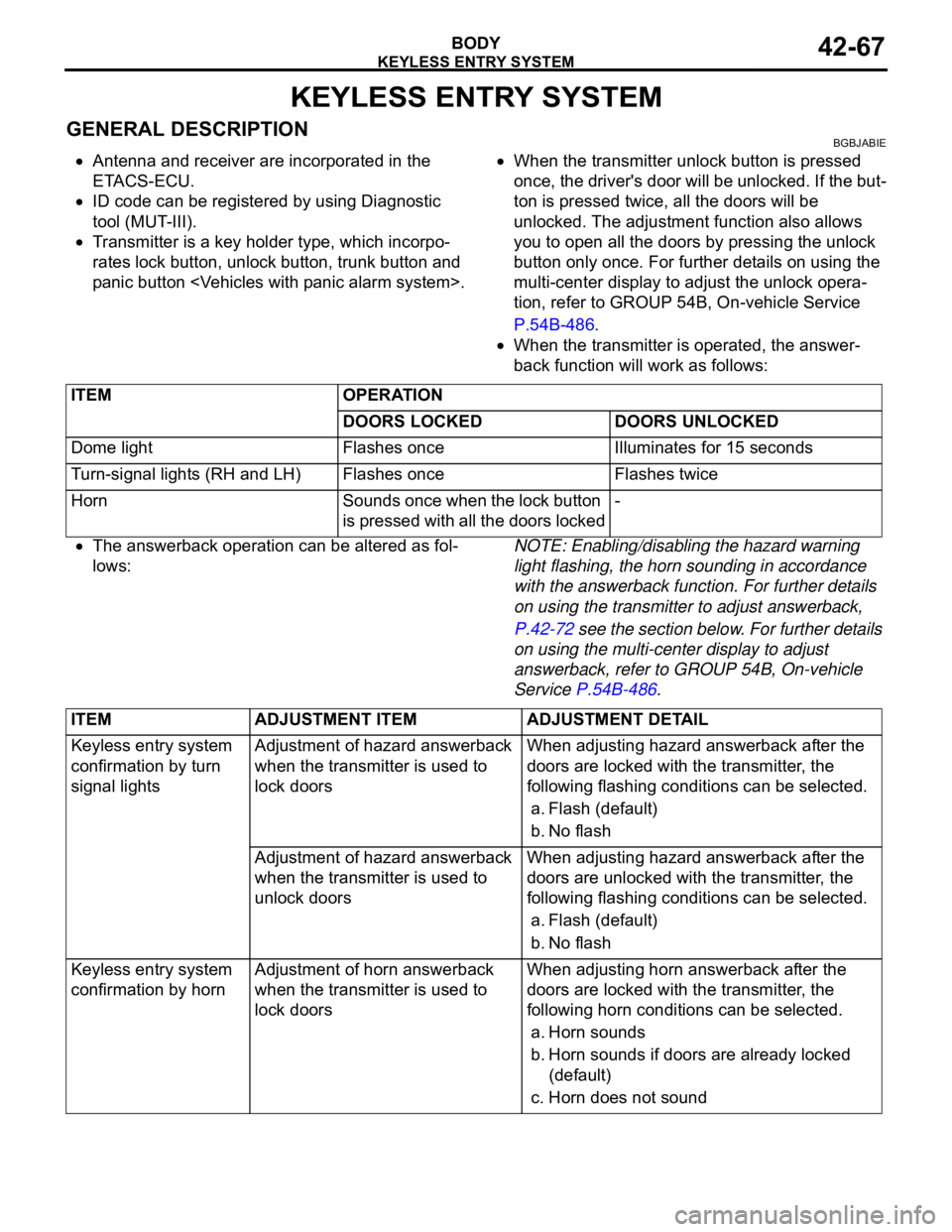

GENERAL DESCRIPTIONBGBJABIE

Antenna and receiver are incorporated in the

ETACS-ECU.

ID code can be registered by using Diagnostic

tool (MUT-III).

Transmitter is a key holder type, which incorpo-

rates lock button, unlock button, trunk button and

panic button

When the transmitter unlock button is pressed

once, the driver's door will be unlocked. If the but-

ton is pressed twice, all the doors will be

unlocked. The adjustment function also allows

you to open all the doors by pressing the unlock

button only once. For further details on using the

multi-center display to adjust the unlock opera-

tion, refer to GROUP 54B, On-vehicle Service

P.54B-486.

When the transmitter is operated, the answer-

back function will work as follows:

The answerback operation can be altered as fol-

lows:NOTE: Enabling/disabling the hazard warning

light flashing, the horn sounding in accordance

with the answerback function. For further details

on using the transmitter to adjust answerback,

P.42-72 see the section below. For further details

on using the multi-center display to adjust

answerback, refer to GROUP 54B, On-vehicle

Service P.54B-486. ITEM OPERATION

DOORS LOCKED DOORS UNLOCKED

Dome light Flashes once Illuminates for 15 seconds

Turn-signal lights (RH and LH) Flashes once Flashes twice

Horn Sounds once when the lock button

is pressed with all the doors locked-

ITEM ADJUSTMENT ITEM ADJUSTMENT DETAIL

Keyless entry system

confirmation by turn

signal lightsAdjustment of hazard answerback

when the transmitter is used to

lock doorsWhen adjusting hazard answerback after the

doors are locked with the transmitter, the

following flashing conditions can be selected.

a. Flash (default)

b. No flash

Adjustment of hazard answerback

when the transmitter is used to

unlock doorsWhen adjusting hazard answerback after the

doors are unlocked with the transmitter, the

following flashing conditions can be selected.

a. Flash (default)

b. No flash

Keyless entry system

confirmation by hornAdjustment of horn answerback

when the transmitter is used to

lock doorsWhen adjusting horn answerback after the

doors are locked with the transmitter, the

following horn conditions can be selected.

a. Horn sounds

b. Horn sounds if doors are already locked

(default)

c. Horn does not sound

Page 1141 of 1500

KEYLESS ENTRY SYSTEM

BODY42-74

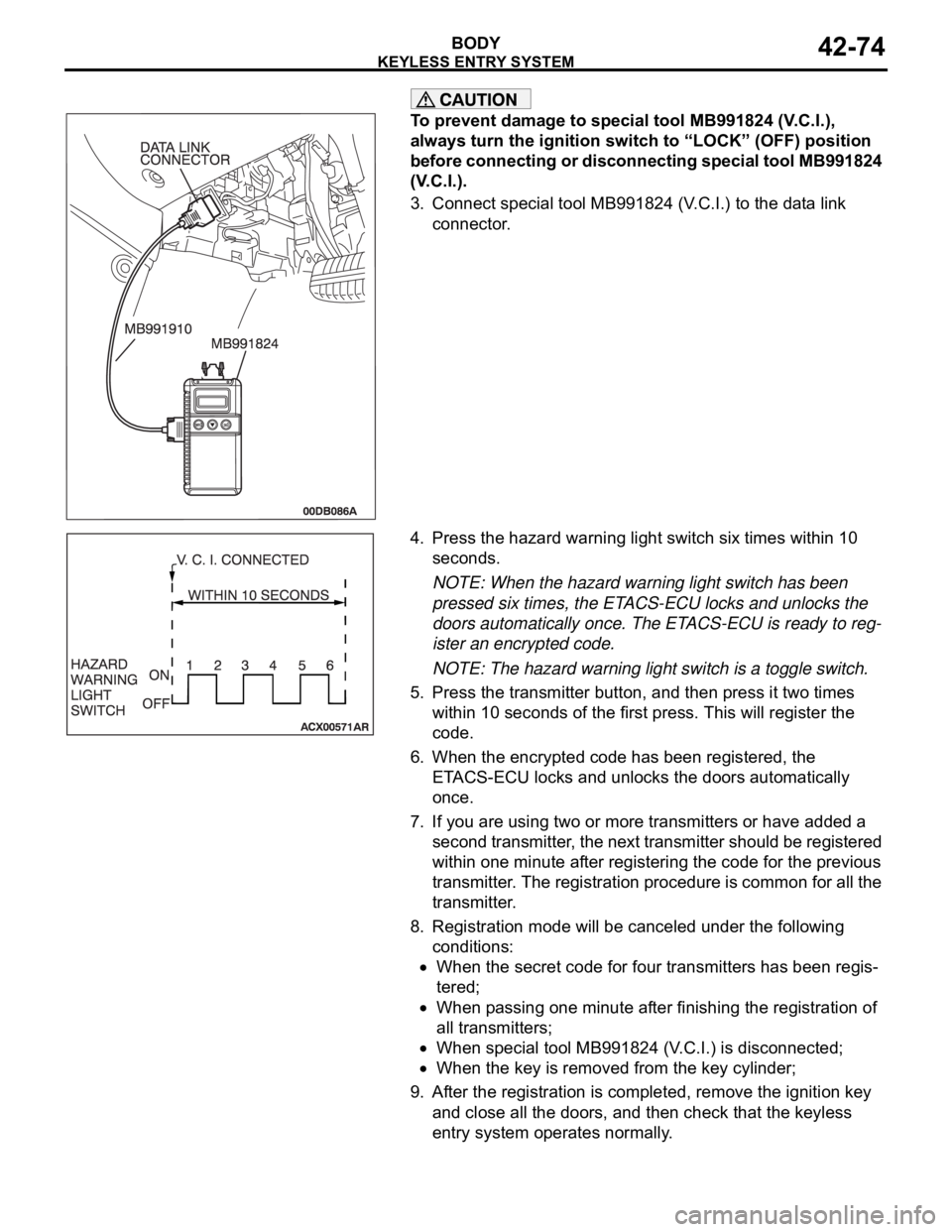

To prevent damage to special tool MB991824 (V.C.I.),

always turn the ignition switch to “LOCK” (OFF) position

before connecting or disconnecting special tool MB991824

(V.C.I.).

3. Connect special tool MB991824 (V.C.I.) to the data link

connector.

4. Press the hazard warning light switch six times within 10

seconds.

NOTE: When the hazard warning light switch has been

pressed six times, the ETACS-ECU locks and unlocks the

doors automatically once. The ETACS-ECU is ready to reg-

ister an encrypted code.

NOTE: The hazard warning light switch is a toggle switch.

5. Press the transmitter button, and then press it two times

within 10 seconds of the first press. This will register the

code.

6. When the encrypted code has been registered, the

ETACS-ECU locks and unlocks the doors automatically

once.

7. If you are using two or more transmitters or have added a

second transmitter, the next transmitter should be registered

within one minute after registering the code for the previous

transmitter. The registration procedure is common for all the

transmitter.

8. Registration mode will be canceled under the following

conditions:

When the secret code for four transmitters has been regis-

tered;

When passing one minute after finishing the registration of

all transmitters;

When special tool MB991824 (V.C.I.) is disconnected;

When the key is removed from the key cylinder;

9. After the registration is completed, remove the ignition key

and close all the doors, and then check that the keyless

entry system operates normally.

Page 1224 of 1500

HOW TO USE THIS MANUAL

GENERAL00-3

HOW TO USE THIS MANUALM1001000100897

MAINTENANCE, REPAIR AND

SERVICING EXPLANATIONS

This manual provides explanations, etc. concerning

procedures for the inspection, maintenance, repair

and servicing of the subject model. Unless otherwise

specified, each service procedure covers all models.

Procedures covering specific models are identified

by the model codes, or similar designation (engine

type, transaxle type, etc). A description of these des-

ignations is covered in this manual under "VEHICLE

IDENTIFICATION."

.

ON-VEHICLE SERVICE

The "ON-VEHICLE SERVICE" section has proce-

dures for performing inspections and adjustments of

particularly important components. These proce-

dures are done with regard to maintenance and ser-

vicing, but other inspections (looseness, play,

cracking, damage, etc.) must also be performed.

.

SERVICE PROCEDURES

The service steps are arranged in numerical order.

Attention to be paid in performing vehicle service are

described in detail in SERVICE POINTS.

DEFINITION OF TERMS

.

STANDARD VALUE

Indicates the value used as the standard for judging

whether or not a part or adjustment is correct.

.

LIMIT

Shows the maximum or minimum value for judging

whether or not a part or adjustment is acceptable.

.

REFERENCE VALUE

Indicates the adjustment value prior to starting the

work (presented in order to facilitate assembly and

adjustment procedures, and so they can be com-

pleted in a shorter time).

.

DANGER, WARNING, AND CAUTION

DANGER, WARNING, and CAUTION call special

attention to a necessary action or to an action that

must be avoided. The differences among DANGER,

WARNING, and CAUTION are as follows:

If a DANGER is not followed, the result is severe

bodily harm or even death.

If a WARNING is not followed, the result could be

bodily injury.

If a CAUTION is not followed, the result could be

damage to the vehicle, vehicle components or

service equipment.

TIGHTENING TORQUE INDICATION

The tightening torque indicates a median and its tol-

erance by a unit of N

m (in-lb.) or Nm (ft.-lb.). For

fasteners with no assigned torque value, refer to

P.00-32.

SPECIAL TOOL NOTE

Only MMC special tool part numbers are called out in

the repair sections of this manual. Please refer to the

special tool cross-reference chart located at the

beginning of each group, for the special tool number

that is available in your market.

ABBREVIATIONS

The following abbreviations are used in this manual

for classification of model types:

A/T:Automatic transaxle, or models equipped with

automatic transaxle.

MPI: Multipoint fuel injection, or engines equipped

with multiport fuel injection.

A/C: Air conditioning.

3.8L engine: 3.8 litre <6G75> engine, or a model

equipped with such an engine.

ABS: Anti-lock Braking System

TCL: Traction Control System

ECU: Electronic Control Unit

V.C.I.: Vehicle Communication Interface

SWS: Simplified Wiring System

CAN: Controller Area Network

M/T: Manual Transmission

SRS: Supplemental Restraint System

Page 1233 of 1500

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE POINTS

GENERAL00-12

IF INSPECTING WITH THE CONNECTOR

DISCONNECTED

Required Special Tool:

MB991219: Inspection Harness (Included in MB991223,

Harness Set)

The special tool MB991219 for connector pin contact pres-

sure should be used. The test probe should never be forc-

ibly inserted, as it may cause a defective contact.

From back side of the connector (SRS-ECU harness side

connector)

Since the SRS-ECU harness connector is plated to improve

conductivity, observe the warning below when checking this

connector.

Insert the test probe tool into the connector from the

harness side, and connect the tester to the test probe

tool. If any tool other than the test probe tool is used,

it may cause damage to the harness and other com-

ponents. Furthermore, measurement should not be

carried out by touching the test probe tool directly

against the terminals from the front of the connector.

The terminals are plated to increase their conductiv-

ity, so that if they are touched directly by the test

probe tool, the plating may break, which will decrease

reliability.

IF INSPECTING WITH THE CONNECTOR

DISCONNECTED

At this time, be careful not to short the connector pins with

the test probes. Doing so may damage the circuits inside

the ECU.

Touch the pin directly with the test probe.

Page 1243 of 1500

PRECAUTIONS BEFORE SERVICE

GENERAL00-22

ENGINE MODEL STAMPING

The engine model is stamped on the cylinder block.

The engine model number is as shown as follow.

The engine serial number is stamped near the engine model

number.

PRECAUTIONS BEFORE SERVICE

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)M1001011600056

1. Items to review when servicing SRS:

(1) Be sure to read GROUP 52B, Supplemental

Restraint System (SRS). For safe operation,

please follow the directions and heed all

warnings.

(2) Wait at least 60 seconds after disconnecting

the battery cable before doing any further

work. The SRS system is designed to retain

enough voltage to deploy the air bag even

after the battery has been disconnected.

Serious injury may result from unintended air

bag deployment if work is done on the SRS

system immediately after the battery cable is

disconnected.

(3) Warning labels must be heeded when

servicing or handling SRS components.

Warning labels can be found in the following

locations.

Front impact sensor

Hood

Sun visor

Instrument panel (passenger ’s side)

SRS-ECU

Steering wheel

Clock spring

Air bag module (Driver's or front

passenger's)

Side-airbag module (Driver's side or front

passenger's side)

Side impact sensor

Seat belt pre-tensioner

(4) Always use the designated special tools and

test equipment.(5) Store components removed from the SRS in a

clean and dry place. The air bag module

should be stored on a flat surface and placed

so that the pad surface is facing upward.

(6) Never attempt to disassemble or repair the

SRS components (SRS-ECU, air bag module

and clock spring). If there is a defect, replace

the defective part.

(7) Whenever you finish servicing the SRS, check

the SRS warning light operation to make sure

that the system functions properly.

(8) Be sure to deploy the air bag before disposing

of the air bag module or disposing of a vehicle

equipped with an air bag (Refer to GROUP

52B, Air Bag Module Disposal Procedures

P.52B-254).

2. Observe the following when carrying out

operations on places where SRS components are

installed, including operations not directly related

to the SRS air bag.

(1) When removing or installing parts, do not allow

any impact or shock to occur to the SRS

components.

(2) If heat damage may occur during paint work,

remove the SRS-ECU, the air bag module,

clock spring, the front impact sensor, the side

impact sensor, and the seat belt pre-tensioner.

a.SRS-ECU, air bag module, clock spring,

front impact sensor, the side impact sensor:

93

C (200F) or more

b.Seat belt pre-tensioner: 90

C (194F) or

more ENGINE MODEL ENGINE DISPLACEMENT

6G75 3828cc