MITSUBISHI 380 2005 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 861 of 1500

SENSORS

HEATER, AIR CONDITIONING AND VENTILATION55-160

SENSORS

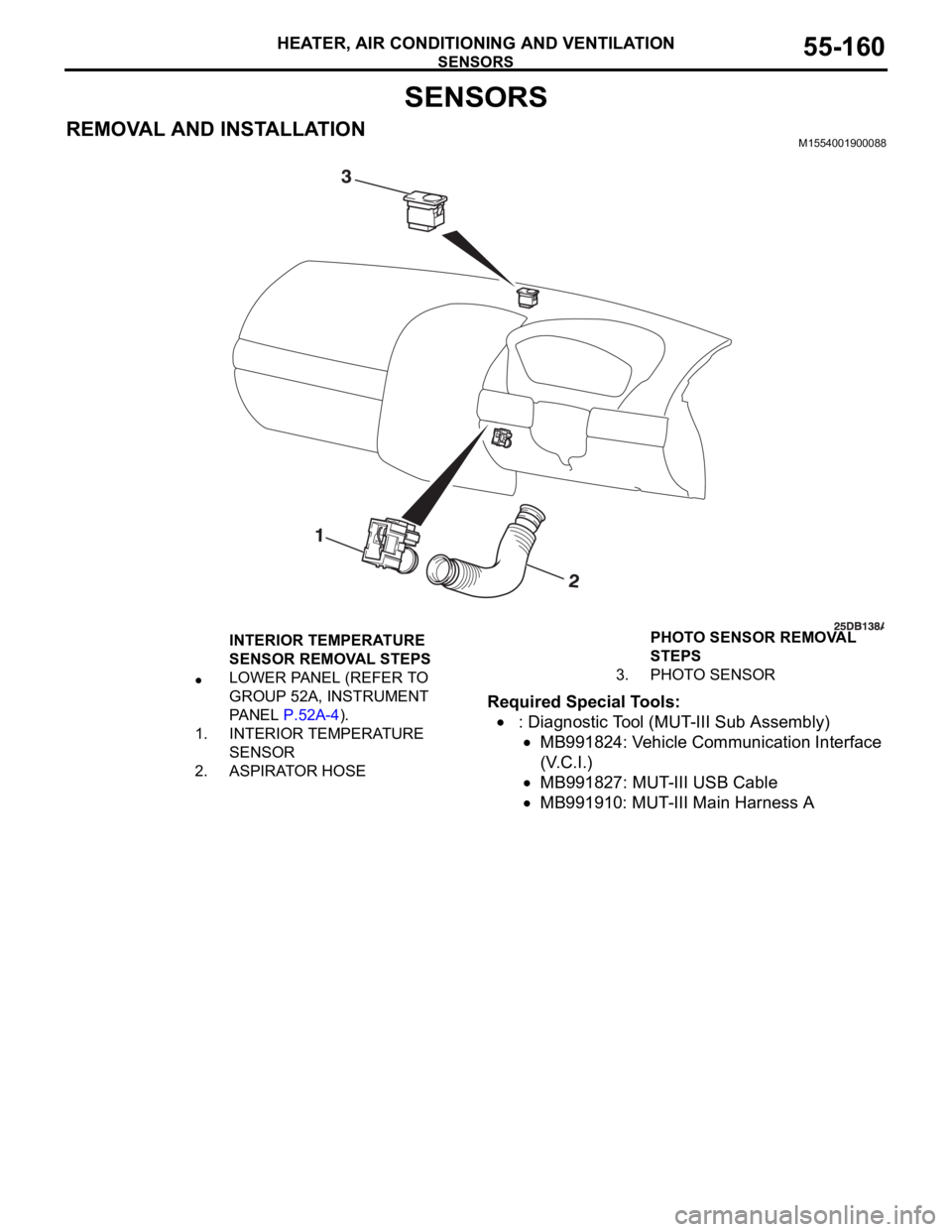

REMOVAL AND INSTALLATIONM1554001900088

Required Special Tools:

: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface

(V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

INTERIOR TEMPERATURE

SENSOR REMOVAL STEPS

LOWER PANEL (REFER TO

GROUP 52A, INSTRUMENT

PA N E L P.52A-4).

1. INTERIOR TEMPERATURE

SENSOR

2. ASPIRATOR HOSEPHOTO SENSOR REMOVAL

STEPS

3. PHOTO SENSOR

Page 862 of 1500

SENSORS

HEATER, AIR CONDITIONING AND VENTILATION55-161

INSPECTIONM1554002000130.

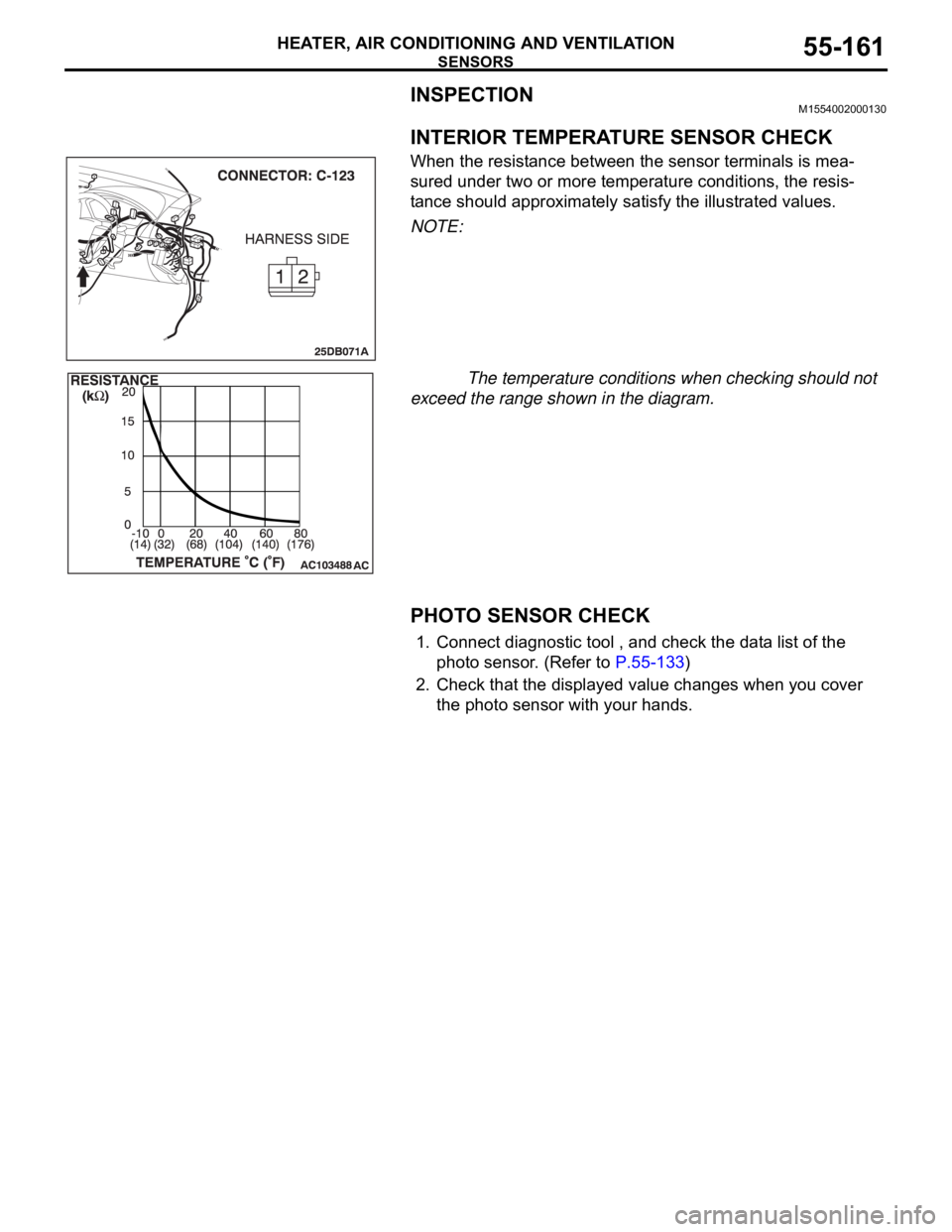

INTERIOR TEMPERATURE SENSOR CHECK

When the resistance between the sensor terminals is mea-

sured under two or more temperature conditions, the resis-

tance should approximately satisfy the illustrated values.

NOTE:

The temperature conditions when checking should not

exceed the range shown in the diagram.

.

PHOTO SENSOR CHECK

1. Connect diagnostic tool , and check the data list of the

photo sensor. (Refer to P.55-133)

2. Check that the displayed value changes when you cover

the photo sensor with your hands.

Page 863 of 1500

AMBIENT TEMPERATURE SENSOR

HEATER, AIR CONDITIONING AND VENTILATION55-162

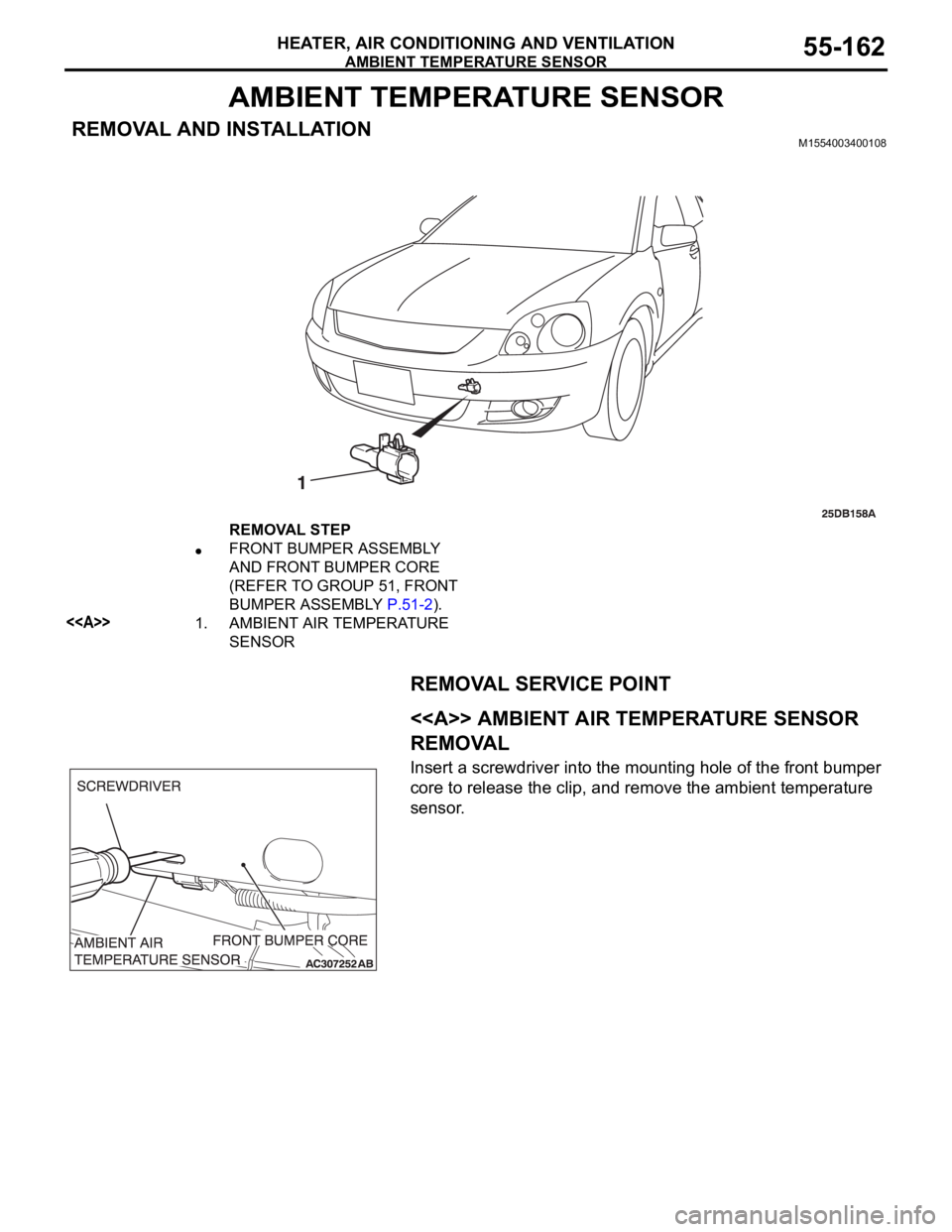

AMBIENT TEMPERATURE SENSOR

REMOVAL AND INSTALLATIONM1554003400108

REMOVAL SERVICE POINT

.

<> AMBIENT AIR TEMPERATURE SENSOR

REMOVAL

Insert a screwdriver into the mounting hole of the front bumper

core to release the clip, and remove the ambient temperature

sensor.

REMOVAL STEP

FRONT BUMPER ASSEMBLY

AND FRONT BUMPER CORE

(REFER TO GROUP 51, FRONT

BUMPER ASSEMBLY P.51-2).

<>1. AMBIENT AIR TEMPERATURE

SENSOR

Page 864 of 1500

AMBIENT TEMPERATURE SENSOR

HEATER, AIR CONDITIONING AND VENTILATION55-163

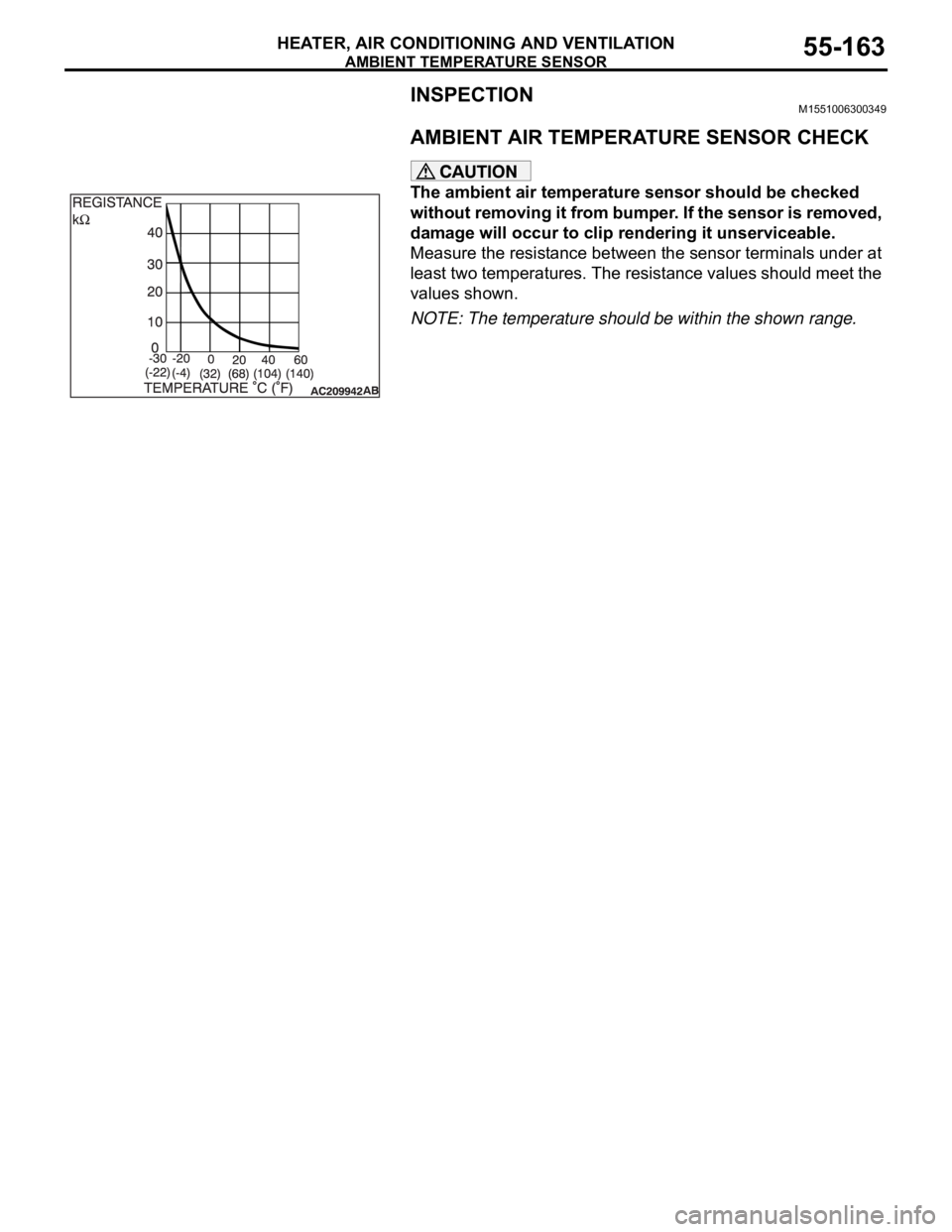

INSPECTIONM1551006300349.

AMBIENT AIR TEMPERATURE SENSOR CHECK

The ambient air temperature sensor should be checked

without removing it from bumper. If the sensor is removed,

damage will occur to clip rendering it unserviceable.

Measure the resistance between the sensor terminals under at

least two temperatures. The resistance values should meet the

values shown.

NOTE: The temperature should be within the shown range.

Page 865 of 1500

COMPRESSOR ASSEMBLY AND DRIVE BELT

HEATER, AIR CONDITIONING AND VENTILATION55-164

COMPRESSOR ASSEMBLY AND DRIVE BELT

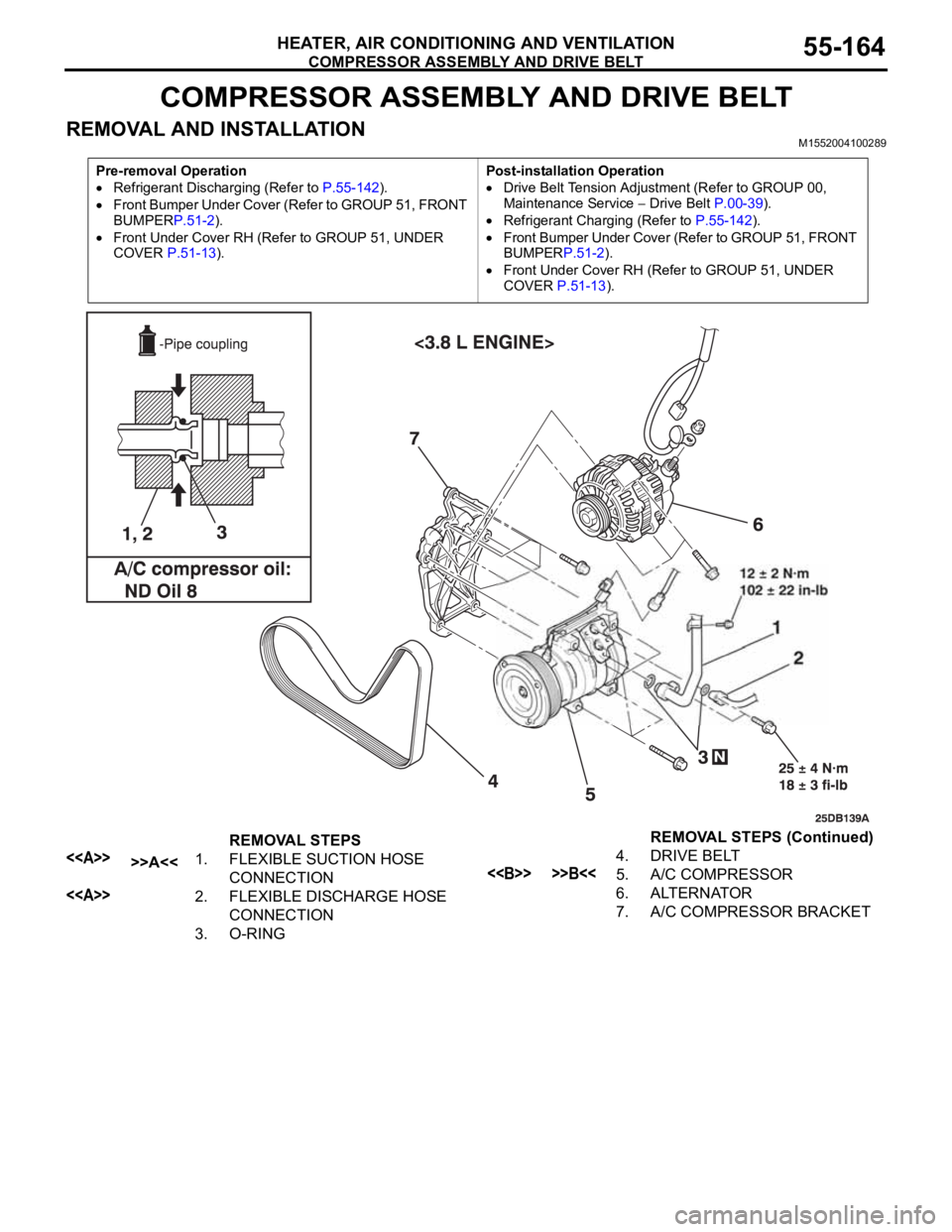

REMOVAL AND INSTALLATIONM1552004100289

Pre-removal Operation

Refrigerant Discharging (Refer to P.55-142).

Front Bumper Under Cover (Refer to GROUP 51, FRONT

BUMPERP.51-2).

Front Under Cover RH (Refer to GROUP 51, UNDER

COVER P.51-13).Post-installation Operation

Drive Belt Tension Adjustment (Refer to GROUP 00,

Maintenance Service

Drive Belt P.00-39).

Refrigerant Charging (Refer to P.55-142).

Front Bumper Under Cover (Refer to GROUP 51, FRONT

BUMPERP.51-2).

Front Under Cover RH (Refer to GROUP 51, UNDER

COVER P.51-13).

REMOVAL STEPS

<>>>A<<1. FLEXIBLE SUCTION HOSE

CONNECTION

<>2. FLEXIBLE DISCHARGE HOSE

CONNECTION

3. O-RING4. DRIVE BELT

<> >>B<<5. A/C COMPRESSOR

6. ALTERNATOR

7. A/C COMPRESSOR BRACKETREMOVAL STEPS (Continued)

Page 866 of 1500

Page 867 of 1500

COMPRESSOR ASSEMBLY AND DRIVE BELT

HEATER, AIR CONDITIONING AND VENTILATION55-166

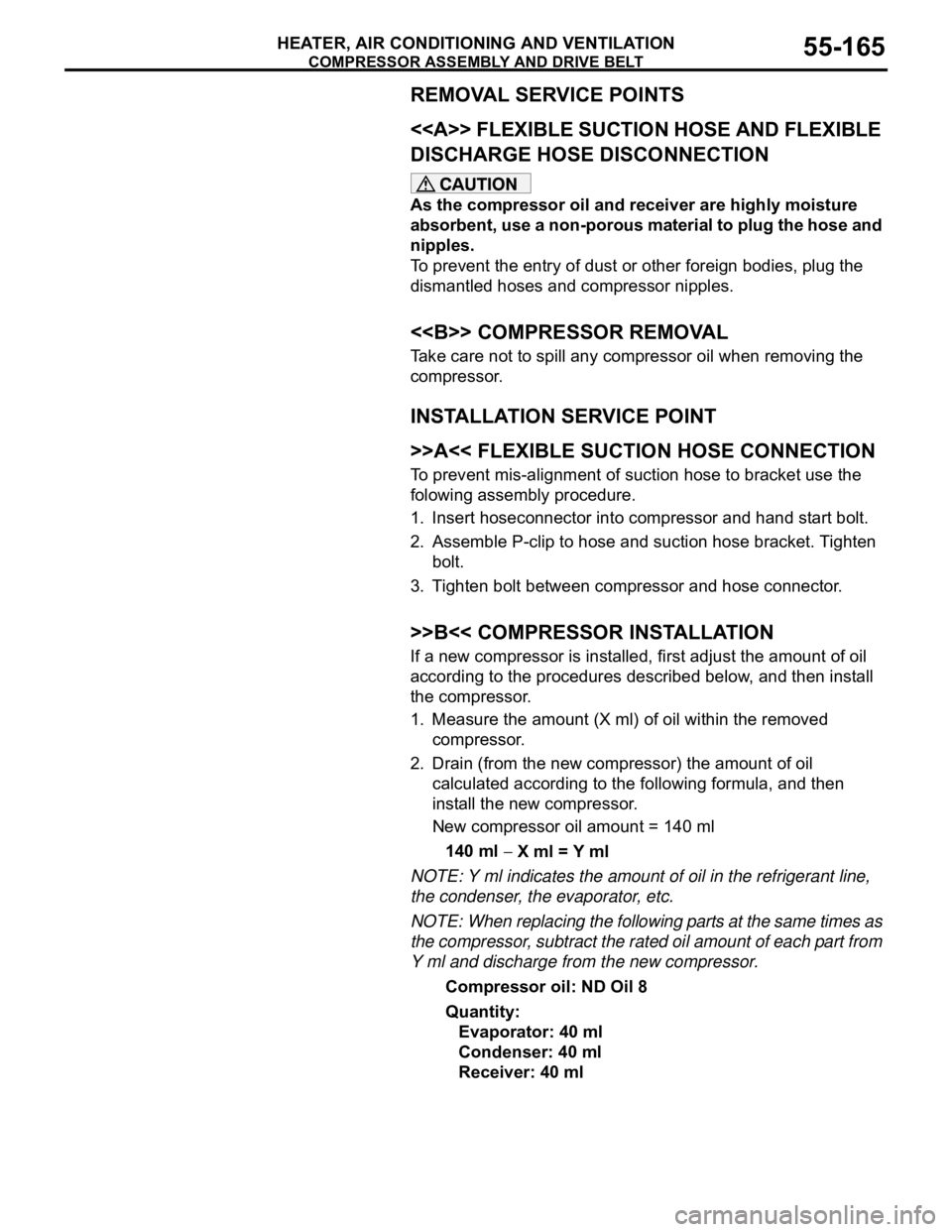

INSPECTIONM1552014301083

COMPRESSOR AIR CONDITIONING

COMPRESSOR CLUTCH OPERATION CHECK

Connect the compressor connector terminal to the battery posi-

tive (+) terminal and ground the battery’s negative (-) terminal

to the compressor unit. At that time, the air conditioning com-

pressor clutch should make a definite operating sound.

.

AIR GAP ADJUSTMENT

Check whether or not the air gap of the clutch is within the stan-

dard value.

Standard value:

0.35

0.60mm

NOTE: If there is a deviation of the air gap from the standard

value, assess the operation of the clutch and replace the com-

pressor assembly as required.

Page 868 of 1500

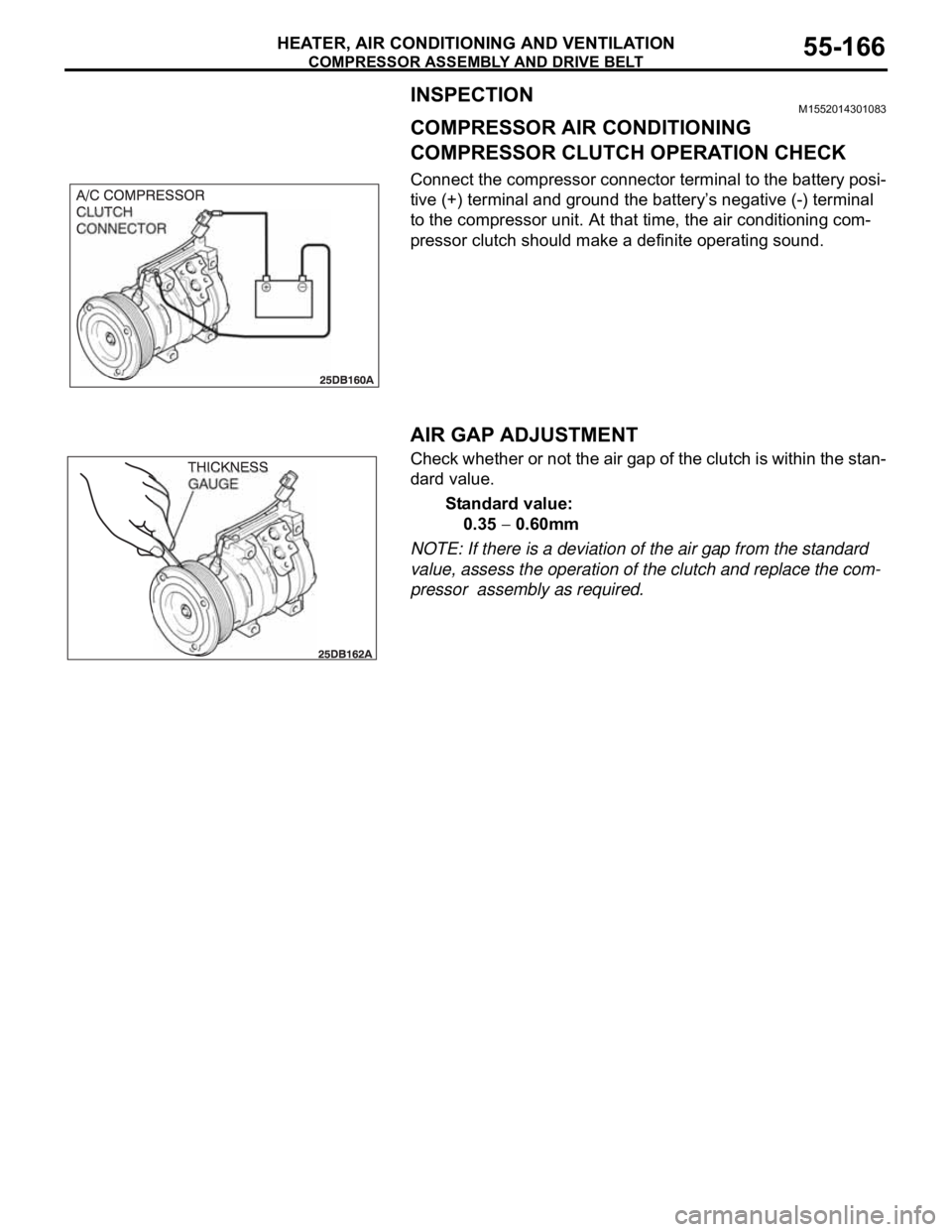

CONDENSER AND CONDENSER FAN

HEATER, AIR CONDITIONING AND VENTILATION55-167

CONDENSER AND CONDENSER FAN

REMOVAL AND INSTALLATIONM1552006700414

Pre-removal and Post-installation Operation

Refrigerant Draining and Refilling (Refer to P.55-142).

Air Duct Removal and Installation (Refer to GROUP 15,

Air Cleaner P.15-4).

Radiator Grilles Removal and Installation (Refer to

GROUP 51, Radiator Grilles P.51-6).

Front End Structure Bar Removal and Installation (Refer

to GROUP 14, Radiator P.14-32).

Cooler tube removal (Refer to GROUP 37, Power steering

P.37-45).

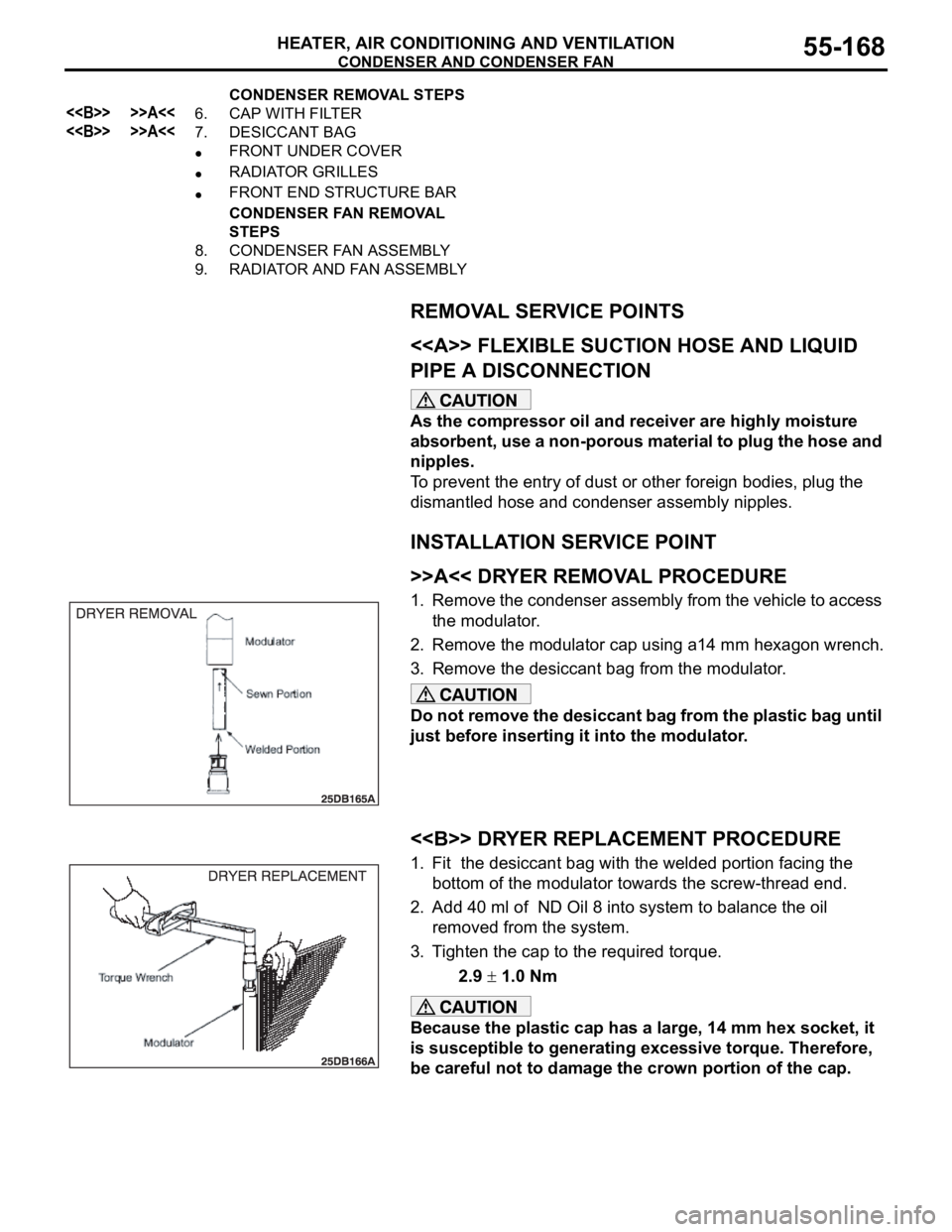

CONDENSER REMOVAL STEPS

<>1. FLEXIBLE DISCHARGE HOSE

CONNECTION

<>2. LIQUID PIPE A CONNECTION3. O-RING

>>B<<4. CONDENSER ASSEMBLY

5. RECEIVER CONDENSER REMOVAL STEPS

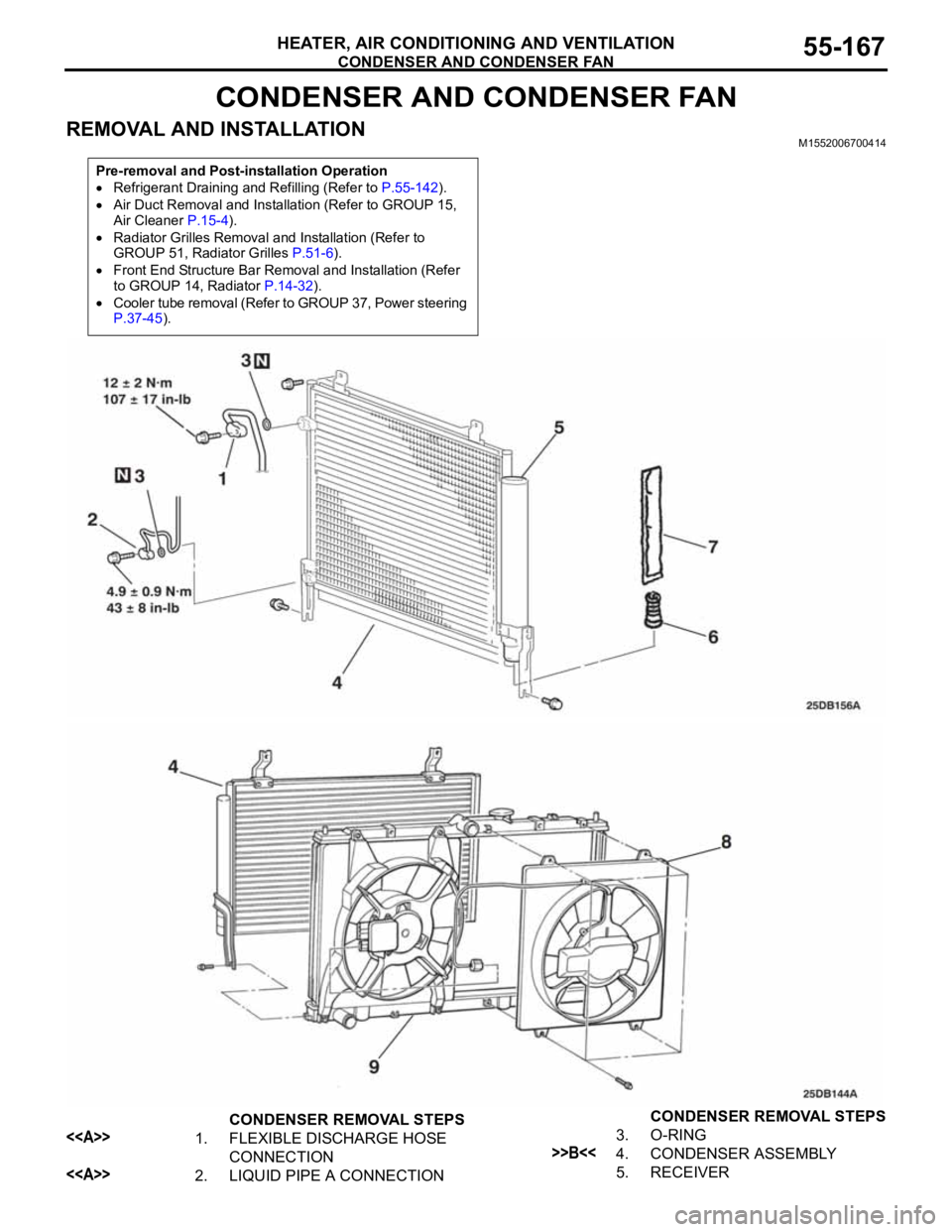

Page 869 of 1500

Page 870 of 1500

CONDENSER AND CONDENSER FAN

HEATER, AIR CONDITIONING AND VENTILATION55-169

>>B<< CONDENSER INSTALLATION

When replacing the condenser, refill it with a specified amount

of compressor oil and install it to the vehicle.

Compressor oil: ND Oil 8

Quantity: 40 ml

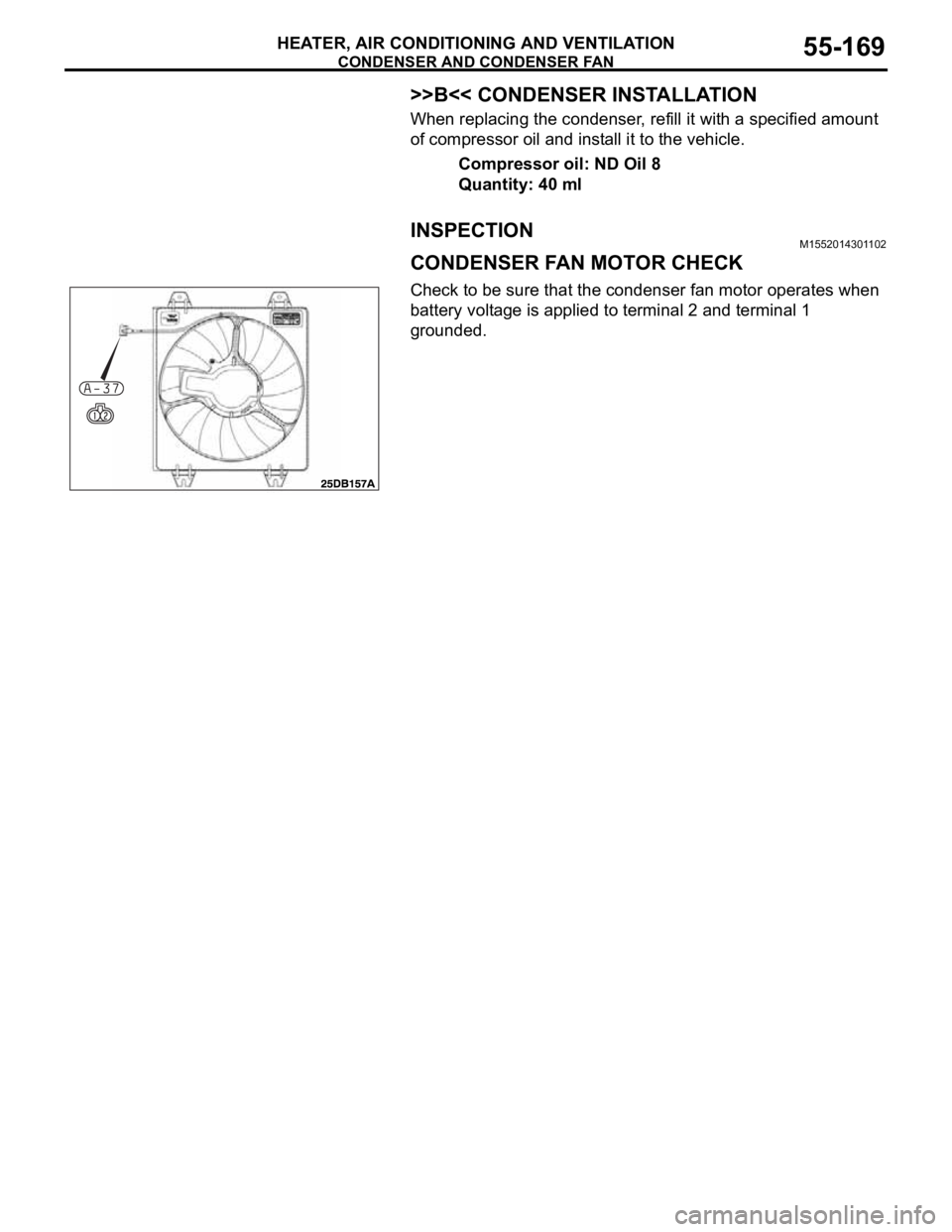

INSPECTIONM1552014301102

CONDENSER FAN MOTOR CHECK

Check to be sure that the condenser fan motor operates when

battery voltage is applied to terminal 2 and terminal 1

grounded.