air conditioning MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 43 of 1500

DIAGNOSTIC TROUBLE CODE PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-43

DTC 013 (U1110): A/C-ECU Time-out.

If DTC 013 (U1110) is set in the ETACS-ECU,

always diagnose the CAN main bus line.

Whenever the ECU is replaced, ensure that the

communication circuit is normal.

.

TROUBLE JUDGMENT

The ETACS-ECU receives air conditioning sys-

tem-related signal from the A/C-ECU. If an air condi-

tioning control system-related signal cannot be

received, DTC 013 (U1110) will be set.

.

TECHNICAL DESCRIPTION (COMMENT)

Current trouble

Connector(s) or wiring harness in the CAN bus

lines between the A/C-ECU and the

ETACS-ECU, the power supply system to the

A/C-ECU, the A/C-ECU, or the ETACS-ECU may

be defective.

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80Past trouble

If DTC 013 (U1110) is stored as a past trouble,

carry out diagnosis with particular emphasis on

wiring and connector(s) in the CAN bus line

between the A/C-ECU and the ETACS-ECU, and

the power supply system to the A/C-ECU. For

diagnosis procedures, refer to "How to cope with

past trouble" (Refer to GROUP 00, How to treat

past trouble P.00-16).

NOTE: You cannot find a past trouble, by the

MUT-III CAN bus diagnostics even if there is a

failure in CAN bus lines. In this case, refer to

GROUP 00, How to Cope with Intermittent Mal-

function P.00-14 and check the CAN bus lines.

You can narrow down the possible cause of the

trouble by referring to the DTC, which is set

regarding the CAN communication-linked ECUs

(Refer to GROUP 54C, Explanation about the

diagnostic tool (MUT-III) CAN BUS diagnostics

P.54C-6).

.

TROUBLESHOOTING HINTS

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The A/C-ECU may be defective

The ETACS-ECU may be defective

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991958: DIAGNOSTIC TOOL (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

Page 44 of 1500

DIAGNOSTIC TROUBLE CODE PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-44

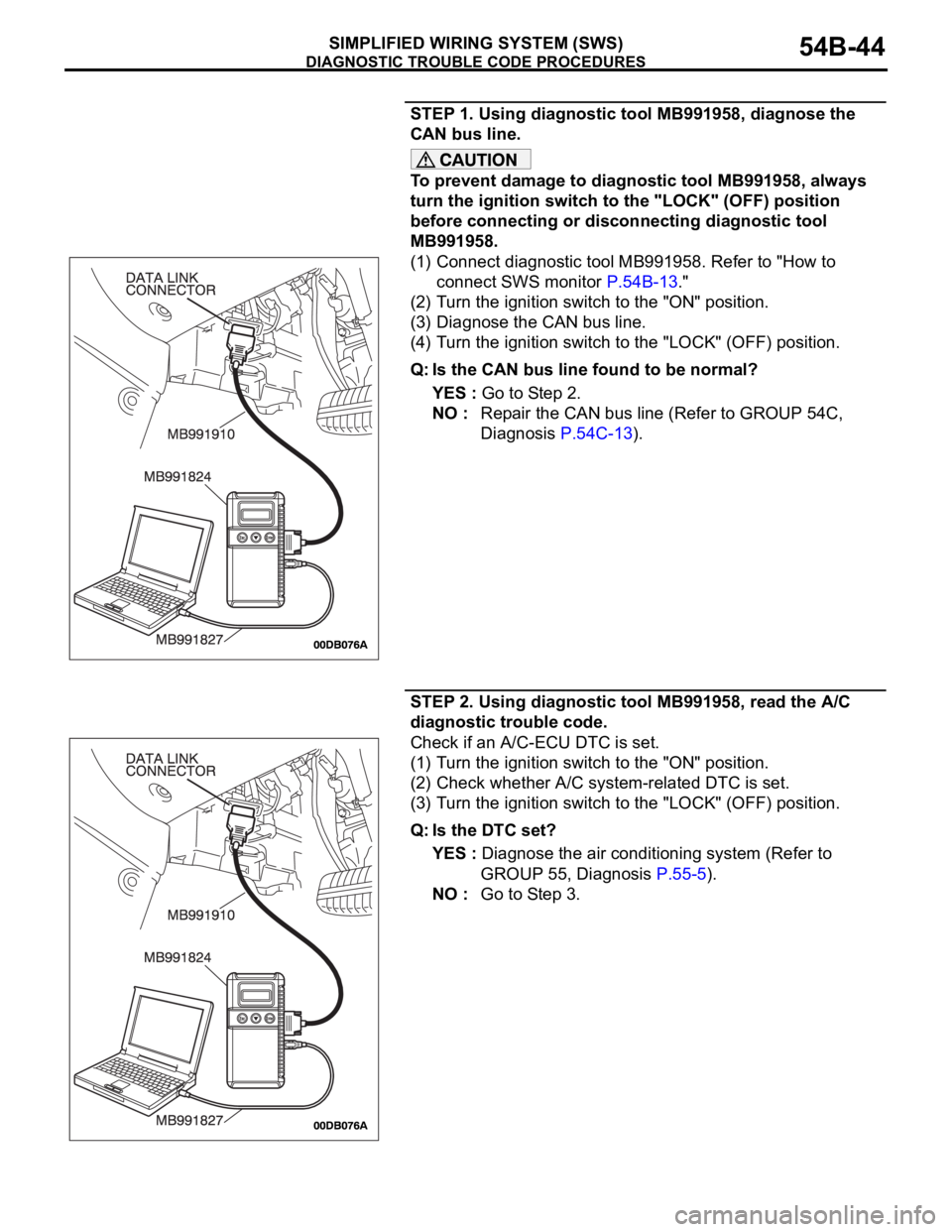

STEP 1. Using diagnostic tool MB991958, diagnose the

CAN bus line.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect diagnostic tool MB991958. Refer to "How to

connect SWS monitor P.54B-13."

(2) Turn the ignition switch to the "ON" position.

(3) Diagnose the CAN bus line.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the CAN bus line found to be normal?

YES : Go to Step 2.

NO : Repair the CAN bus line (Refer to GROUP 54C,

Diagnosis P.54C-13).

STEP 2. Using diagnostic tool MB991958, read the A/C

diagnostic trouble code.

Check if an A/C-ECU DTC is set.

(1) Turn the ignition switch to the "ON" position.

(2) Check whether A/C system-related DTC is set.

(3) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the DTC set?

YES : Diagnose the air conditioning system (Refer to

GROUP 55, Diagnosis P.55-5).

NO : Go to Step 3.

Page 498 of 1500

INSTRUMENT PANEL ASSEMBLY

INTERIOR52A-9

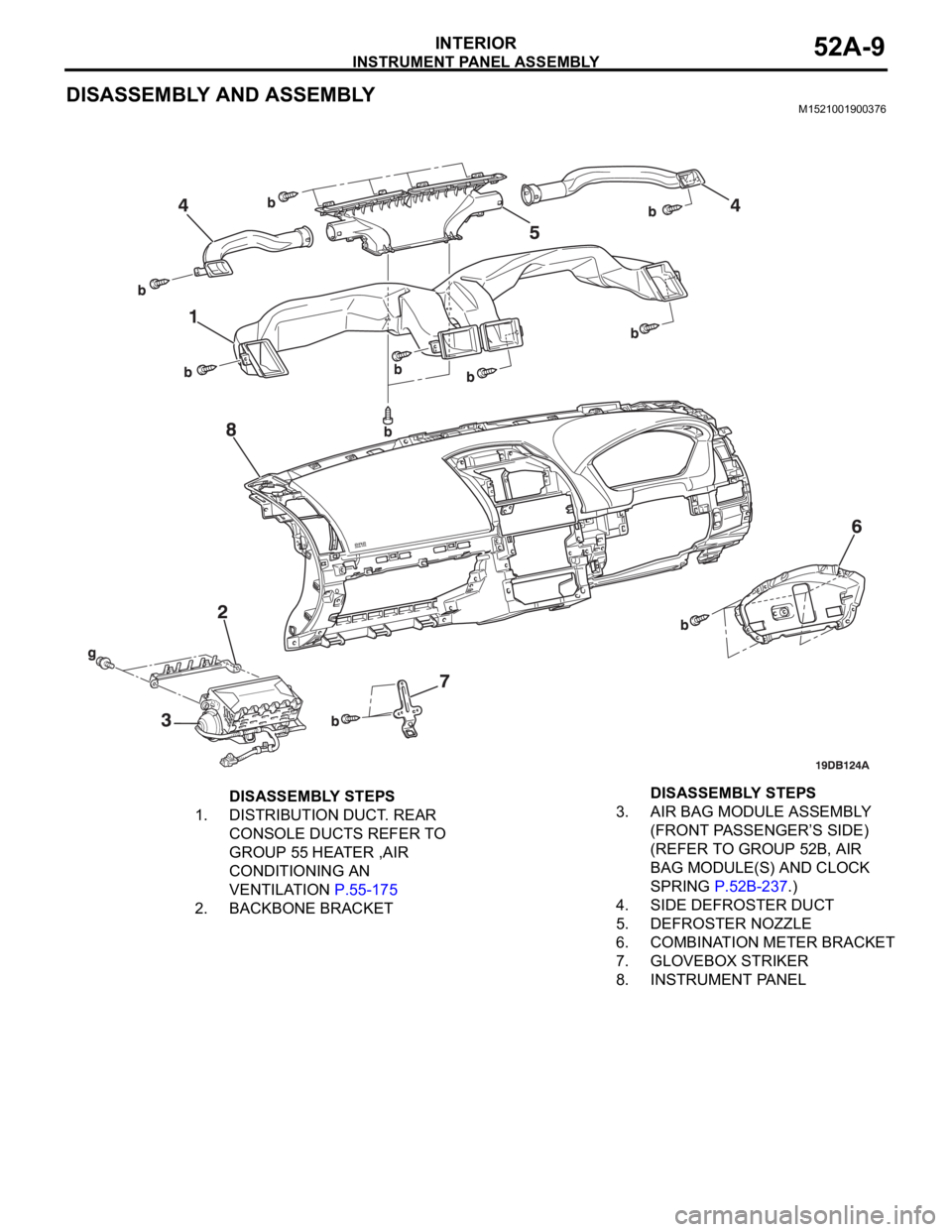

DISASSEMBLY AND ASSEMBLYM1521001900376

DISASSEMBLY STEPS

1. DISTRIBUTION DUCT. REAR

CONSOLE DUCTS REFER TO

GROUP 55 HEATER ,AIR

CONDITIONING AN

VENTILATION P.55-175

2. BACKBONE BRACKET3. AIR BAG MODULE ASSEMBLY

(FRONT PASSENGER’S SIDE)

(REFER TO GROUP 52B, AIR

BAG MODULE(S) AND CLOCK

SPRING P.52B-237.)

4. SIDE DEFROSTER DUCT

5. DEFROSTER NOZZLE

6. COMBINATION METER BRACKET

7. GLOVEBOX STRIKER

8. INSTRUMENT PANELDISASSEMBLY STEPS

Page 576 of 1500

55-1

GROUP 55

HEATER, AIR

CONDITIONING AND

VENTILATION

CONTENTS

HEATER, AIR CONDITIONING AND VENTILATION. . . . . . . . .55

Page 579 of 1500

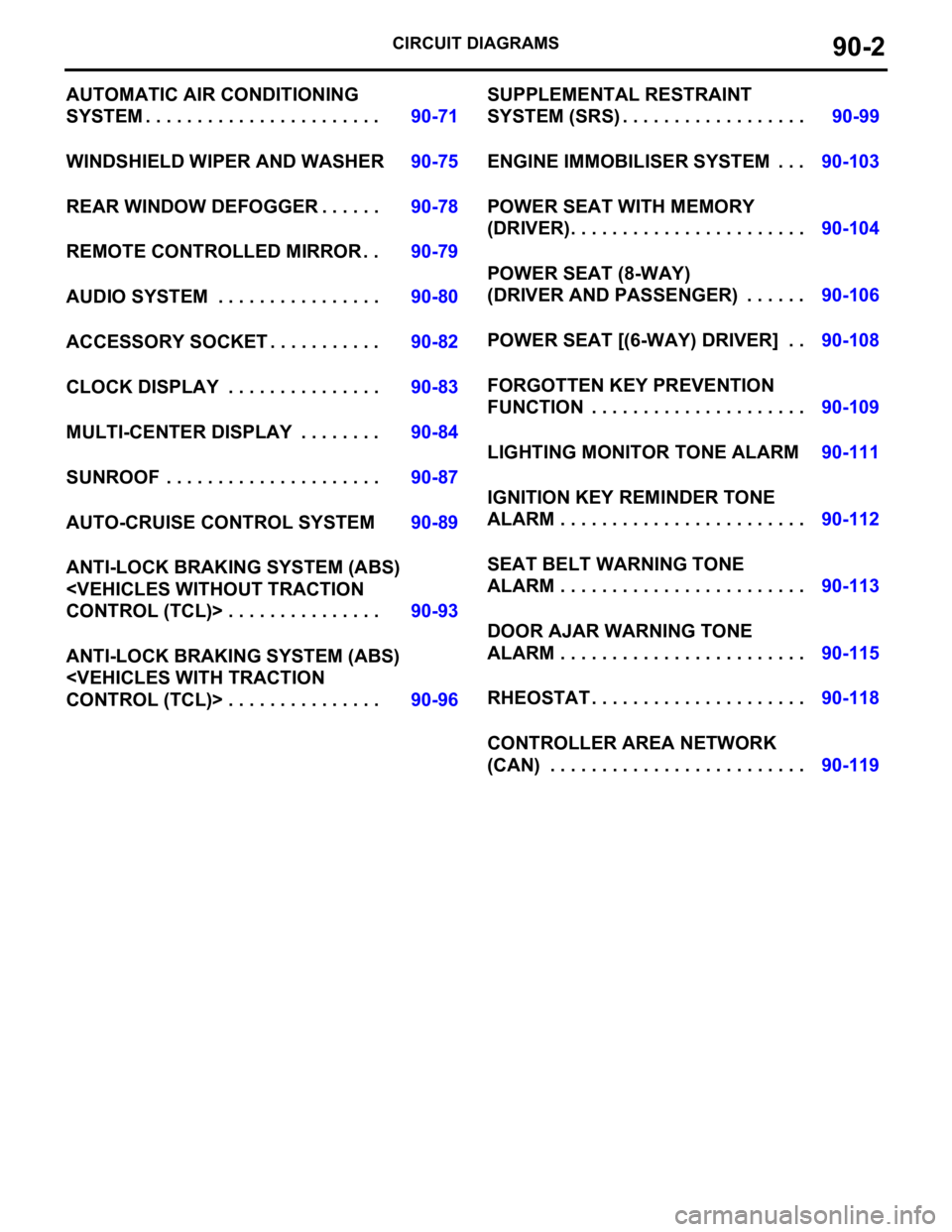

CIRCUIT DIAGRAMS90-2

AUTOMATIC AIR CONDITIONING

SYSTEM . . . . . . . . . . . . . . . . . . . . . . .90-71

WINDSHIELD WIPER AND WASHER90-75

REAR WINDOW DEFOGGER . . . . . .90-78

REMOTE CONTROLLED MIRROR . .90-79

AUDIO SYSTEM . . . . . . . . . . . . . . . .90-80

ACCESSORY SOCKET . . . . . . . . . . .90-82

CLOCK DISPLAY . . . . . . . . . . . . . . .90-83

MULTI-CENTER DISPLAY . . . . . . . .90-84

SUNROOF . . . . . . . . . . . . . . . . . . . . .90-87

AUTO-CRUISE CONTROL SYSTEM90-89

ANTI-LOCK BRAKING SYSTEM (ABS)

ANTI-LOCK BRAKING SYSTEM (ABS)

SYSTEM (SRS) . . . . . . . . . . . . . . . . . .90-99

ENGINE IMMOBILISER SYSTEM . . .90-103

POWER SEAT WITH MEMORY

(DRIVER). . . . . . . . . . . . . . . . . . . . . . .90-104

POWER SEAT (8-WAY)

(DRIVER AND PASSENGER) . . . . . .90-106

POWER SEAT [(6-WAY) DRIVER] . .90-108

FORGOTTEN KEY PREVENTION

FUNCTION . . . . . . . . . . . . . . . . . . . . .90-109

LIGHTING MONITOR TONE ALARM90-111

IGNITION KEY REMINDER TONE

ALARM . . . . . . . . . . . . . . . . . . . . . . . .90-112

SEAT BELT WARNING TONE

ALARM . . . . . . . . . . . . . . . . . . . . . . . .90-113

DOOR AJAR WARNING TONE

ALARM . . . . . . . . . . . . . . . . . . . . . . . .90-115

RHEOSTAT . . . . . . . . . . . . . . . . . . . . .90-118

CONTROLLER AREA NETWORK

(CAN) . . . . . . . . . . . . . . . . . . . . . . . . .90-119

Page 648 of 1500

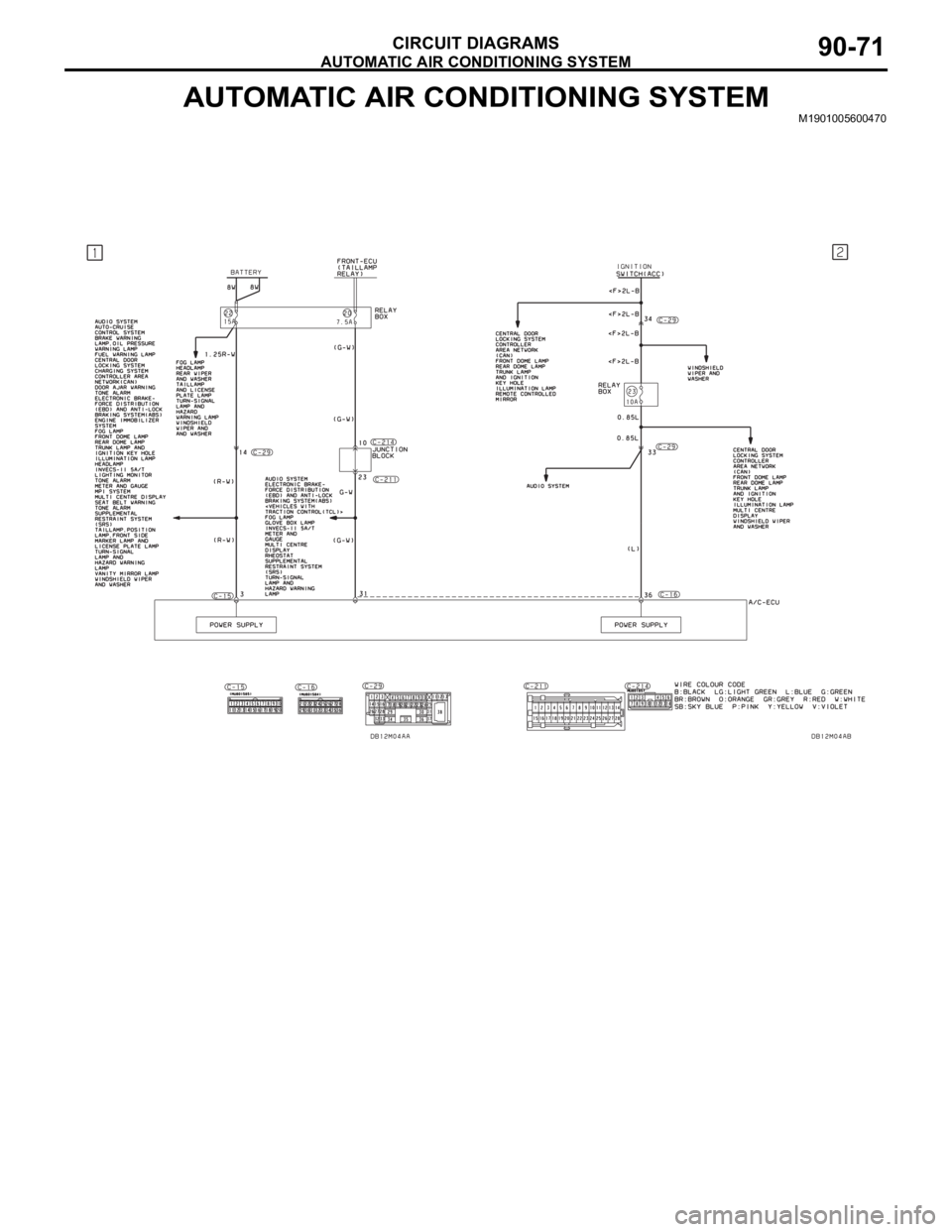

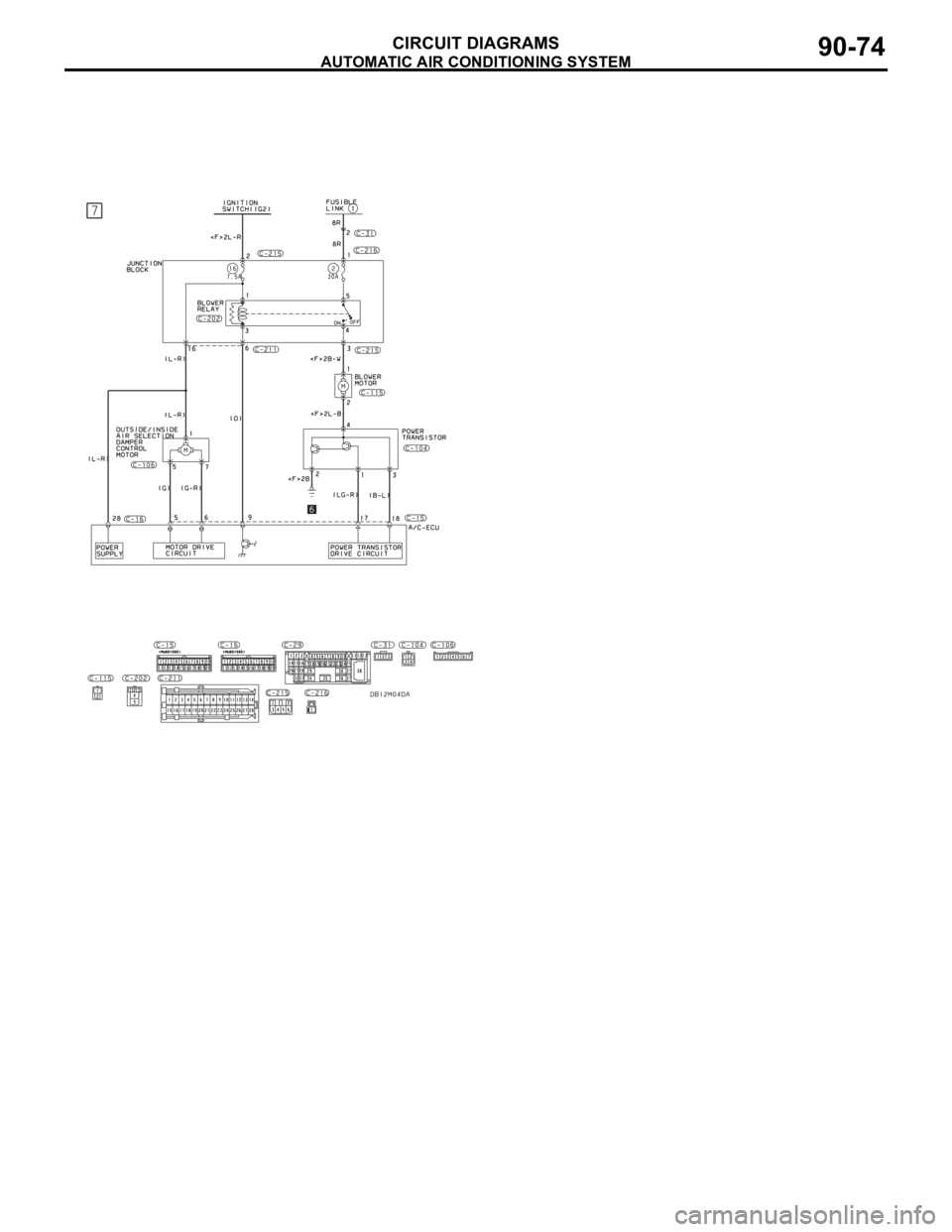

AUTOMATIC AIR CONDITIONING SYSTEM

CIRCUIT DIAGRAMS90-71

AUTOMATIC AIR CONDITIONING SYSTEMM1901005600470

Page 649 of 1500

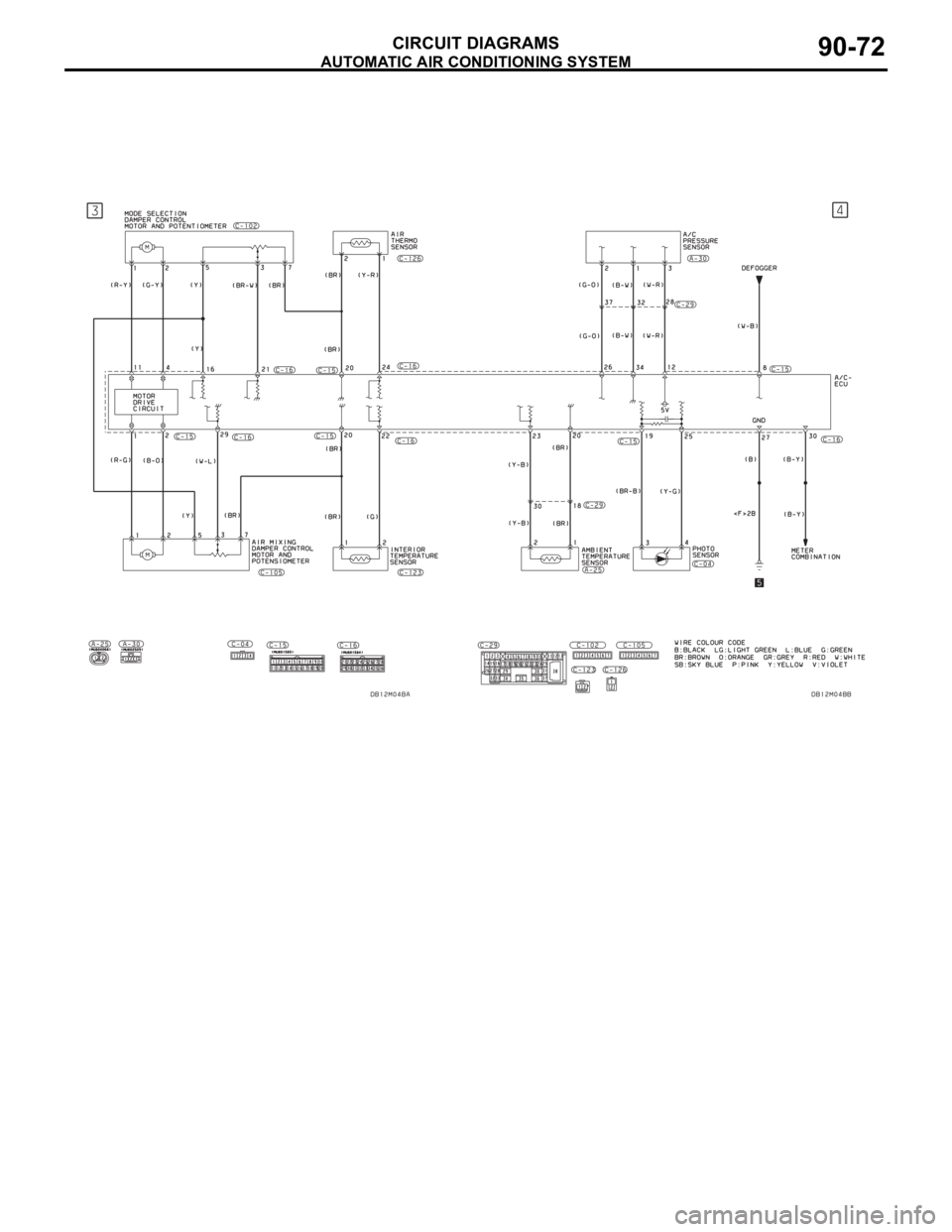

AUTOMATIC AIR CONDITIONING SYSTEM

CIRCUIT DIAGRAMS90-72

Page 650 of 1500

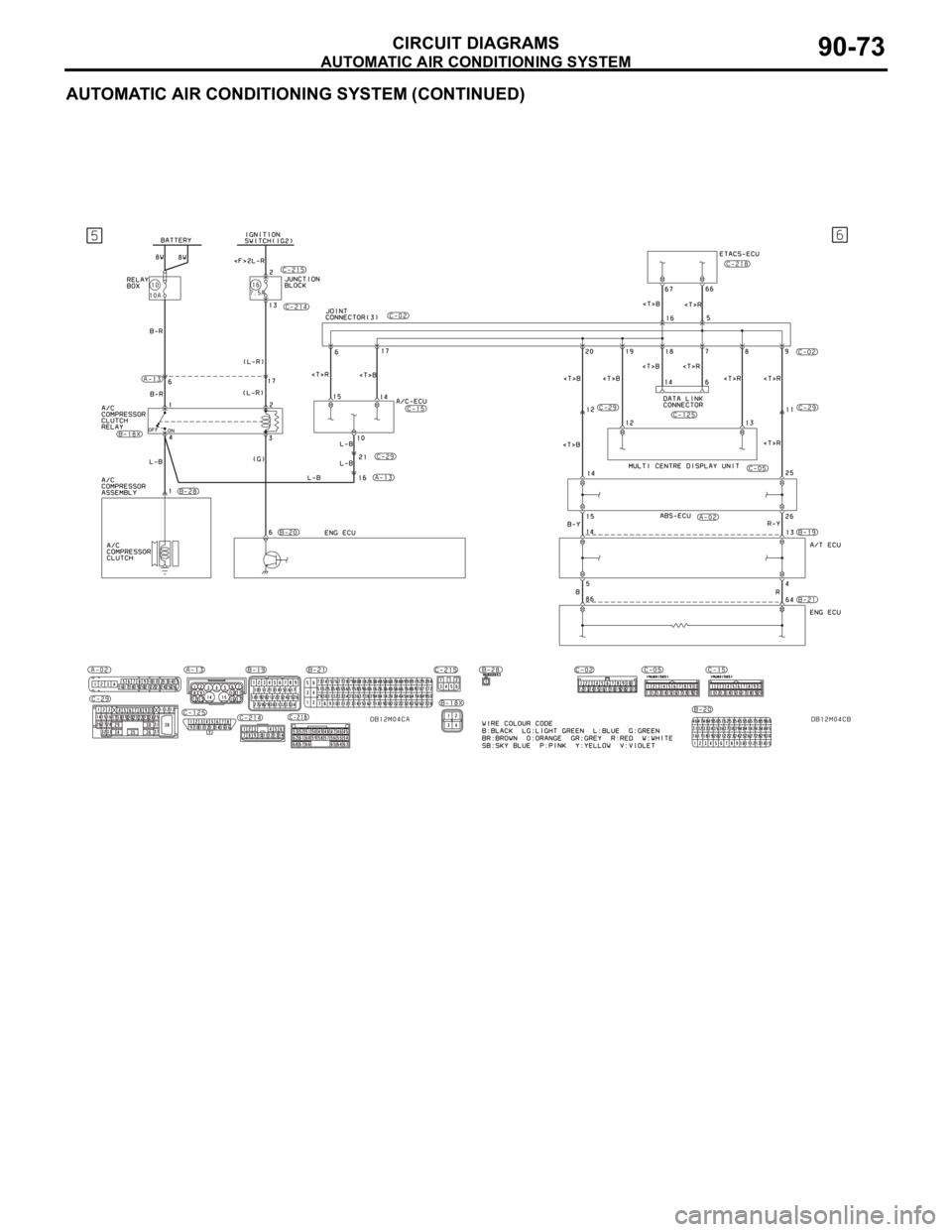

AUTOMATIC AIR CONDITIONING SYSTEM

CIRCUIT DIAGRAMS90-73

AUTOMATIC AIR CONDITIONING SYSTEM (CONTINUED)

Page 651 of 1500

AUTOMATIC AIR CONDITIONING SYSTEM

CIRCUIT DIAGRAMS90-74

Page 702 of 1500

HEATER, AIR CONDITIONING AND VENTILATION55-1

GROUP 55

HEATER, AIR

CONDITIONING AND

VENTILATION

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .55-3

AUTO A/C DIAGNOSIS . . . . . . . . . . .55-5

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . 55-5

AUTOMATIC AIR CONDITIONING

TROUBLESHOOTING STRATEGY . . . . . . 55-5

DIAGNOSTIC FUNCTION . . . . . . . . . . . . . 55-5

DIAGNOSTIC TROUBLE CODE CHART . 55-9

DIAGNOSTIC TROUBLE CODE

PROCEDURES . . . . . . . . . . . . . . . . . . . . . . 55-10

SYMPTOM CHART . . . . . . . . . . . . . . . . . . 55-68

SYMPTOM PROCEDURES . . . . . . . . . . . . 55-69

DATA LIST REFERENCE TABLE . . . . . . . 55-133

ACTUATOR TEST REFERENCE . . . . . . . . 55-136

CHECK AT A/C-ECU TERMINAL . . . . . . . . 55-137

SPECIAL TOOLS . . . . . . . . . . . . . . . .55-139

ON-VEHICLE SERVICE . . . . . . . . . . .55-141

REFRIGERANT LEVEL TEST . . . . . . . . . . 55-141

A/C COMPRESSOR CLUTCH TEST . . . . . 55-141

SIMPLE INSPECTION OF THE A/C

PRESSURE SENSOR . . . . . . . . . . . . . . . . 55-141

COMPRESSOR DRIVE BELT

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 55-142

CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . 55-142

PERFORMANCE TEST . . . . . . . . . . . . . . . 55-143

REFRIGERANT LEAK INSPECTION

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 55-144A/C NOISE TEST . . . . . . . . . . . . . . . . . . . . 55-146

POWER RELAY CHECK . . . . . . . . . . . . . . . 55-148

IDLE-UP OPERATION CHECK . . . . . . . . . . 55-149

HEATER CONTROL ASSEMBLY AND

A/C SWITCH . . . . . . . . . . . . . . . . . . . .55-150

REMOVAL AND INSTALLATION . . . . . . . . 55-150

HEATER UNIT, HEATER CORE,

BLOWER ASSEMBLY AND

EVAPORATOR UNIT . . . . . . . . . . . . .55-151

REMOVAL AND INSTALLATION . . . . . . . . 55-151

REMOVAL AND INSTALLATION . . . . . . . . 55-153

DISASSEMBLY AND ASSEMBLY . . . . . . . 55-154

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 55-155

BLOWER ASSEMBLY DISASSEMBLY

AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . 55-156

MOTORS AND TRANSISTOR . . . . . .55-157

REMOVAL AND INSTALLATION . . . . . . . . 55-157

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 55-158

SENSORS . . . . . . . . . . . . . . . . . . . . . .55-160

REMOVAL AND INSTALLATION . . . . . . . . 55-160

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 55-161

Continued on next page