Oil MITSUBISHI 380 2005 Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1434 of 1500

DRIVE SHAFT ASSEMBLY

FRONT AXLE26-17

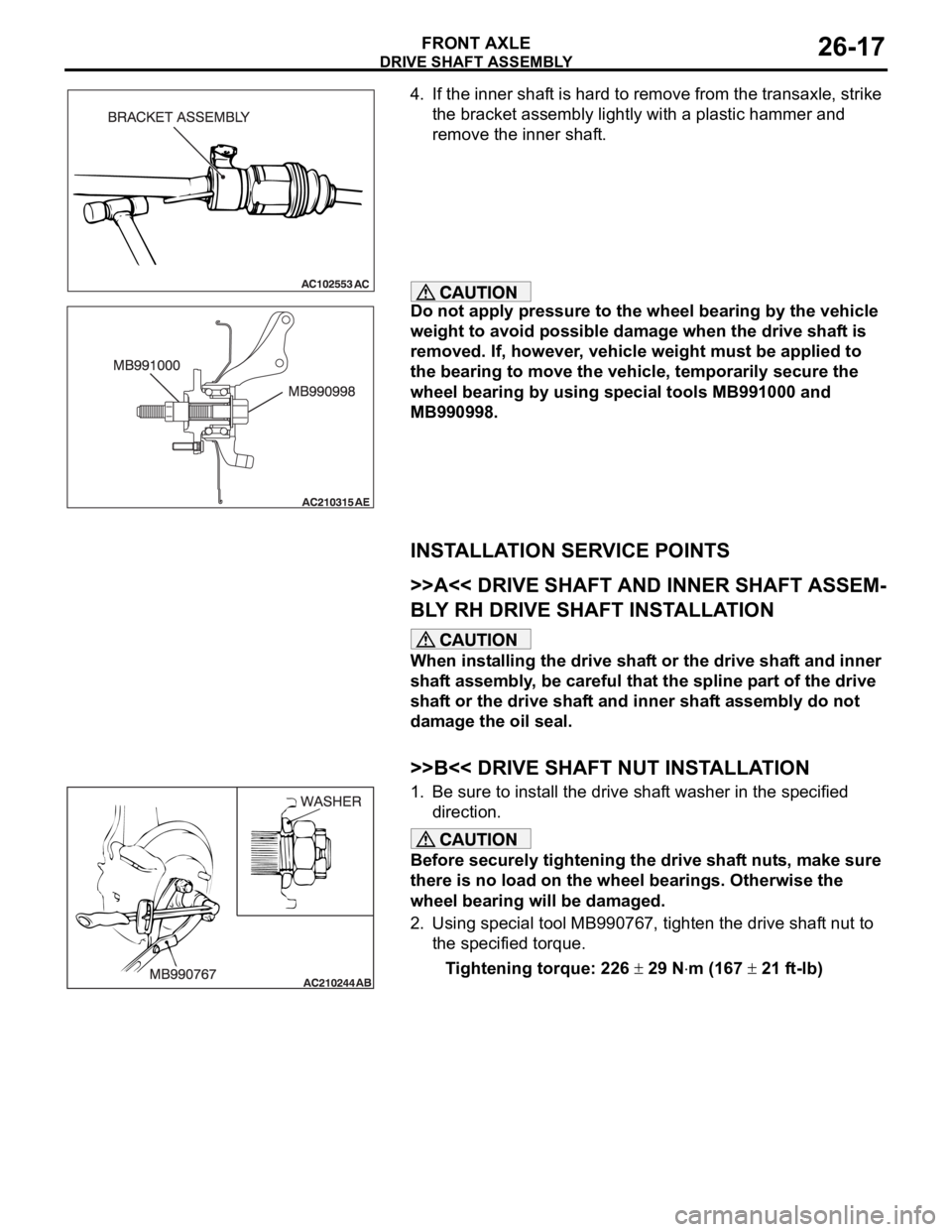

4. If the inner shaft is hard to remove from the transaxle, strike

the bracket assembly lightly with a plastic hammer and

remove the inner shaft.

Do not apply pressure to the wheel bearing by the vehicle

weight to avoid possible damage when the drive shaft is

removed. If, however, vehicle weight must be applied to

the bearing to move the vehicle, temporarily secure the

wheel bearing by using special tools MB991000 and

MB990998.

INSTALLATION SERVICE POINTS

.

>>A<< DRIVE SHAFT AND INNER SHAFT ASSEM-

BLY RH DRIVE SHAFT INSTALLATION

When installing the drive shaft or the drive shaft and inner

shaft assembly, be careful that the spline part of the drive

shaft or the drive shaft and inner shaft assembly do not

damage the oil seal.

.

>>B<< DRIVE SHAFT NUT INSTALLATION

1. Be sure to install the drive shaft washer in the specified

direction.

Before securely tightening the drive shaft nuts, make sure

there is no load on the wheel bearings. Otherwise the

wheel bearing will be damaged.

2. Using special tool MB990767, tighten the drive shaft nut to

the specified torque.

Tightening torque: 226

29 Nm (167 21 ft-lb)

Page 1449 of 1500

GENERAL DESCRIPTION

REAR AXLE27-2

GENERAL DESCRIPTIONM1271000100326

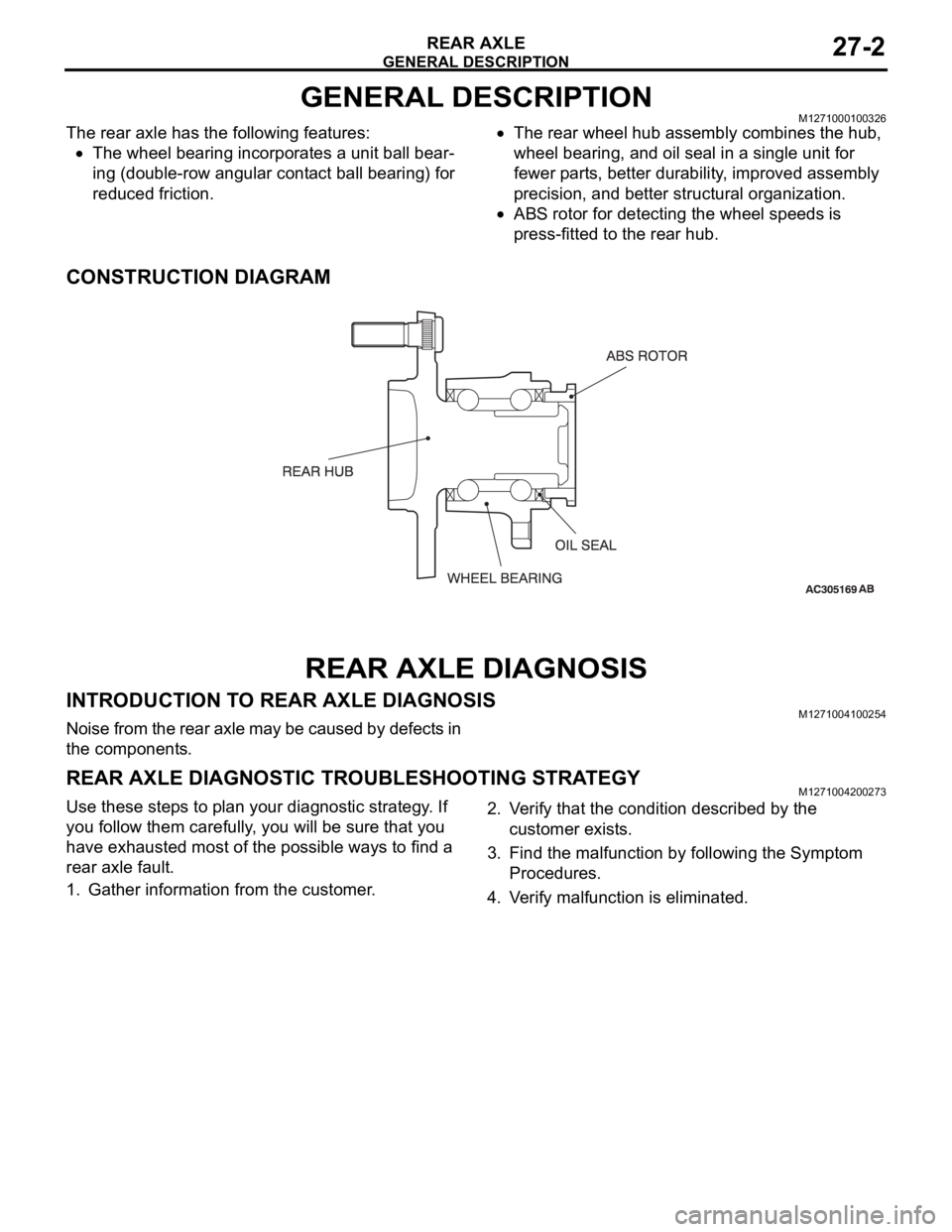

The rear axle has the following features:

The wheel bearing incorporates a unit ball bear-

ing (double-row angular contact ball bearing) for

reduced friction.

The rear wheel hub assembly combines the hub,

wheel bearing, and oil seal in a single unit for

fewer parts, better durability, improved assembly

precision, and better structural organization.

ABS rotor for detecting the wheel speeds is

press-fitted to the rear hub.

CONSTRUCTION DIAGRAM

REAR AXLE DIAGNOSIS

INTRODUCTION TO REAR AXLE DIAGNOSISM1271004100254

Noise from the rear axle may be caused by defects in

the components.

REAR AXLE DIAGNOSTIC TROUBLESHOOTING STRATEGYM1271004200273

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will be sure that you

have exhausted most of the possible ways to find a

rear axle fault.

1. Gather information from the customer.2. Verify that the condition described by the

customer exists.

3. Find the malfunction by following the Symptom

Procedures.

4. Verify malfunction is eliminated.

Page 1461 of 1500

AUTOMATIC TRANSMISSION23A-2

SPECIAL TOOLS . . . . . . . . . . . . . . . .23A-286

ON-VEHICLE SERVICE. . . . . . . . . . .23A-289

A/T CONTROL COMPONENT LAYOUT . . 23A-289

ESSENTIAL SERVICE . . . . . . . . . . . . . . . . 23A-291

TRANSMISSION FLUID CHECK . . . . . . . . 23A-291

TRANSMISSION FLUID CHANGE . . . . . . . 23A-292

OIL COOLER FLOW CHECK . . . . . . . . . . . 23A-294

TRANSMISSION RANGE SWITCH

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23A-294

TRANSMISSION RANGE SWITCH AND

CONTROL CABLE ADJUSTMENT. . . . . . . 23A-294

AUTOMATIC TRANSMISSION CONTROL

COMPONENT CHECK . . . . . . . . . . . . . . . . 23A-295

CRANKSHAFT POSITION SENSOR

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23A-295

TRANSMISSION FLUID TEMPERATURE

SENSOR CHECK . . . . . . . . . . . . . . . . . . . . 23A-296

TRANSMISSION RANGE SWITCH

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23A-296

STOPLIGHT SWITCH CHECK . . . . . . . . . . 23A-296

A/T CONTROL RELAY CHECK . . . . . . . . . 23A-296

SOLENOID VALVE CHECK . . . . . . . . . . . . 23A-298SELECTOR LEVER OPERATION

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23A-299

TRANSMISSION CONTROL CABLE

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 23A-299

TRANSMISSION CONTROL* . . . . . . .23A-300

REMOVAL AND INSTALLATION . . . . . . . . 23A-300

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 23A-301

DISASSEMBLY AND ASSEMBLY . . . . . . . 23A-302

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 23A-303

TRANSMISSION ASSEMBLY . . . . . .23A-304

REMOVAL AND INSTALLATION . . . . . . . . 23A-304

TRANSMISSION FLUID COOLER,

HOSE AND PIPE . . . . . . . . . . . . . . . .23A-312

REMOVAL AND INSTALLATION . . . . . . . . 23A-312

SPECIFICATIONS . . . . . . . . . . . . . . .23A-313

FASTENER TIGHTENING

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . 23A-313

SERVICE SPECIFICATIONS . . . . . . . . . . . 23A-313

LUBRICANT . . . . . . . . . . . . . . . . . . . . . . . . 23A-314

Page 1465 of 1500

GENERAL DESCRIPTION

AUTOMATIC TRANSMISSION23A-6

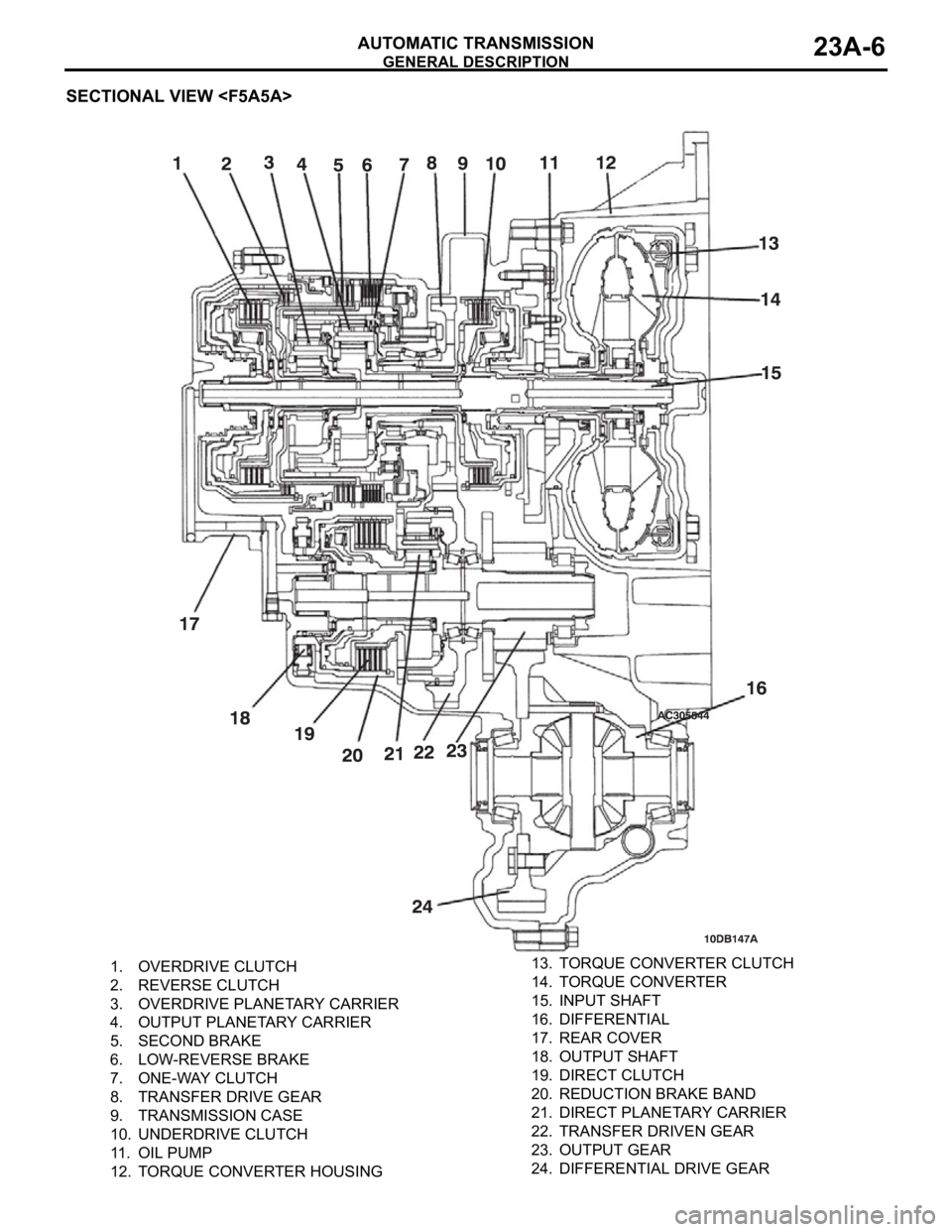

SECTIONAL VIEW

1. OVERDRIVE CLUTCH

2. REVERSE CLUTCH

3. OVERDRIVE PLANETARY CARRIER

4. OUTPUT PLANETARY CARRIER

5. SECOND BRAKE

6. LOW-REVERSE BRAKE

7. ONE-WAY CLUTCH

8. TRANSFER DRIVE GEAR

9. TRANSMISSION CASE

10. UNDERDRIVE CLUTCH

11. OIL PUMP

12. TORQUE CONVERTER HOUSING13. TORQUE CONVERTER CLUTCH

14. TORQUE CONVERTER

15. INPUT SHAFT

16. DIFFERENTIAL

17. REAR COVER

18. OUTPUT SHAFT

19. DIRECT CLUTCH

20. REDUCTION BRAKE BAND

21. DIRECT PLANETARY CARRIER

22. TRANSFER DRIVEN GEAR

23. OUTPUT GEAR

24. DIFFERENTIAL DRIVE GEAR

Page 1486 of 1500

![MITSUBISHI 380 2005 Manual Online AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-27

3. Connect the special tools (3.0 MPa (427 psi) oil pressure

gauge [MD998330] and adapters [MD998332, MD998900])

to each pressure discha MITSUBISHI 380 2005 Manual Online AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-27

3. Connect the special tools (3.0 MPa (427 psi) oil pressure

gauge [MD998330] and adapters [MD998332, MD998900])

to each pressure discha](/img/19/57086/w960_57086-1485.png)

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-27

3. Connect the special tools (3.0 MPa (427 psi) oil pressure

gauge [MD998330] and adapters [MD998332, MD998900])

to each pressure discharge port.

NOTE: .

2ND: Second brake pressure port

UD: Underdrive clutch pressure port

LR: Low-reverse brake pressure port

DR: Torque converter release pressure port

DA: Torque converter apply pressure port

RV: Reverse clutch pressure port

OD: Overdrive clutch pressure port

DIR: Direct clutch pressure port

RED: Reduction clutch pressure port

4. Restart the engine.

5. Check that there are no leaks around the special tool port

adapters.

6. Measure the hydraulic pressure at each port under the

conditions given in the standard hydraulic pressure table,

and check that the measured values are within the standard

value ranges.

7. If the pressure is not within the standard value, stop the

engine and refer to the hydraulic pressure test diagnosis

table.

8. Remove the O-ring from the port plug and replace it.

9. Remove the special tool, and install the plugs to the

hydraulic pressure ports.

10.Start the engine and check that there are no leaks around

the plugs.

Page 1487 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-28

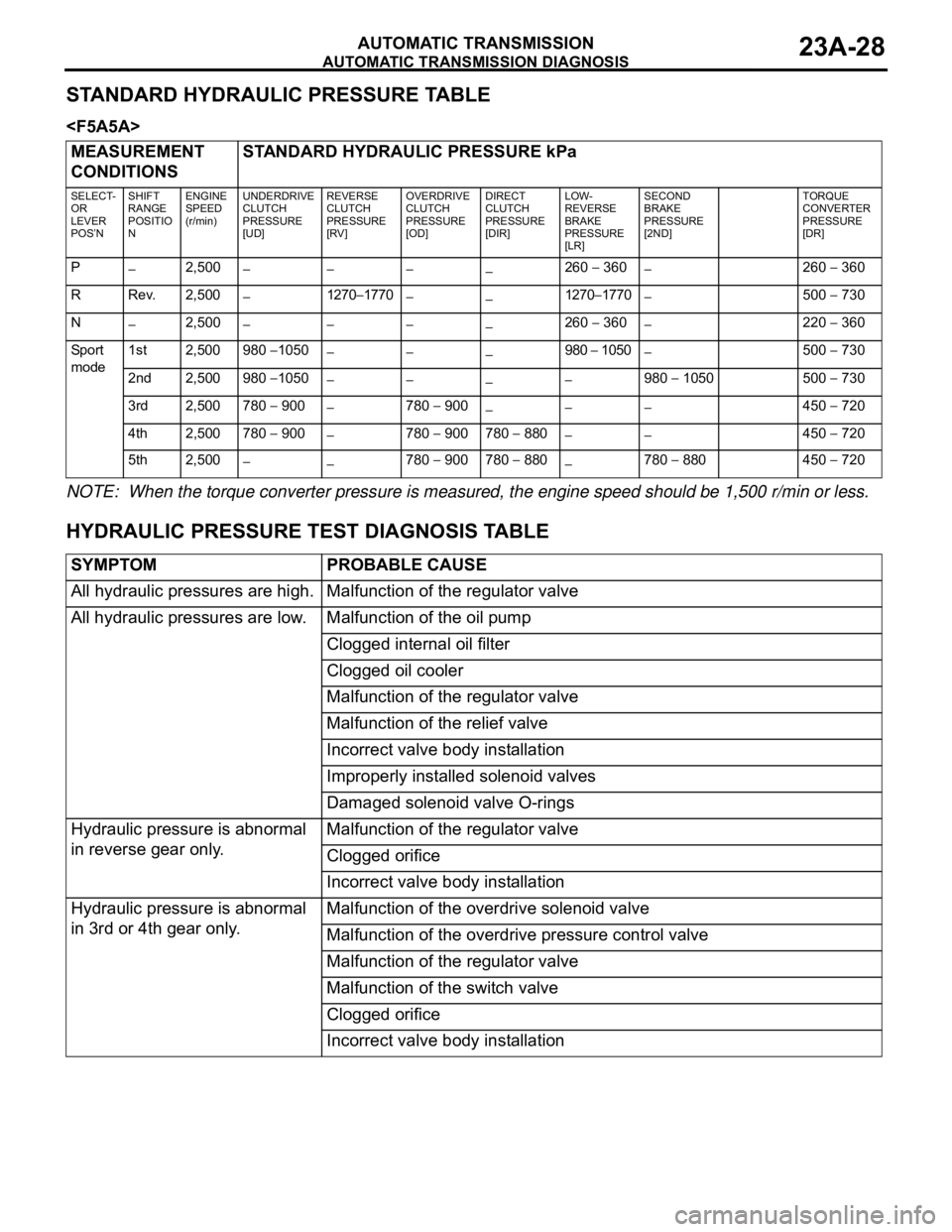

STANDARD HYDRAULIC PRESSURE TABLE

NOTE: When the torque converter pressure is measured, the engine speed should be 1,500 r/min or less.

HYDRAULIC PRESSURE TEST DIAGNOSIS TABLE

MEASUREMENT

CONDITIONSSTANDARD HYDRAULIC PRESSURE kPa

SELECT-

OR

LEVER

POS’N SHIFT

RANGE

POSITIO

NENGINE

SPEED

(r/min)UNDERDRIVE

CLUTCH

PRESSURE

[UD]REVERSE

CLUTCH

PRESSURE

[RV]OVERDRIVE

CLUTCH

PRESSURE

[OD]DIRECT

CLUTCH

PRESSURE

[DIR]LOW-

REVERSE

BRAKE

PRESSURE

[LR]SECOND

BRAKE

PRESSURE

[2ND]TORQUE

CONVERTER

PRESSURE

[DR]

P2,500260 360260 360

R Rev. 2,500

12701770 12701770 500 730

N

2,500260 360 220 360

Spo rt

mode1st 2,500 980

1050 980 1050 500 730

2nd 2,500 980

1050 980 1050 500 730

3rd 2,500 780

900 780 900 450 720

4th 2,500 780

900 780 900 780 880 450 720

5th 2,500

780 900 780 880 780 880 450 720

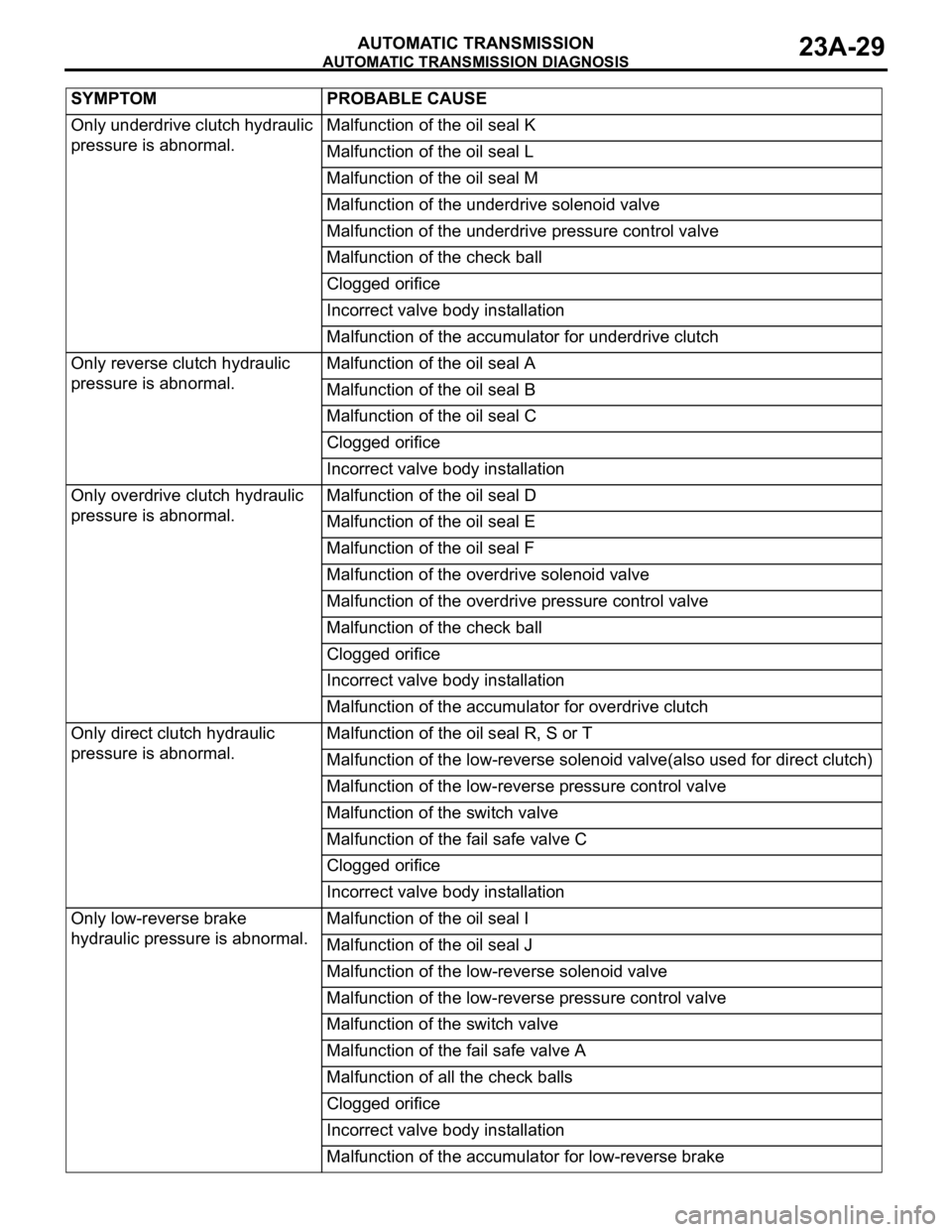

SYMPTOM PROBABLE CAUSE

All hydraulic pressures are high. Malfunction of the regulator valve

All hydraulic pressures are low. Malfunction of the oil pump

Clogged internal oil filter

Clogged oil cooler

Malfunction of the regulator valve

Malfunction of the relief valve

Incorrect valve body installation

Improperly installed solenoid valves

Damaged solenoid valve O-rings

Hydraulic pressure is abnormal

in reverse gear only.Malfunction of the regulator valve

Clogged orifice

Incorrect valve body installation

Hydraulic pressure is abnormal

in 3rd or 4th gear only.Malfunction of the overdrive solenoid valve

Malfunction of the overdrive pressure control valve

Malfunction of the regulator valve

Malfunction of the switch valve

Clogged orifice

Incorrect valve body installation

Page 1488 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-29

Only underdrive clutch hydraulic

pressure is abnormal.Malfunction of the oil seal K

Malfunction of the oil seal L

Malfunction of the oil seal M

Malfunction of the underdrive solenoid valve

Malfunction of the underdrive pressure control valve

Malfunction of the check ball

Clogged orifice

Incorrect valve body installation

Malfunction of the accumulator for underdrive clutch

Only reverse clutch hydraulic

pressure is abnormal.Malfunction of the oil seal A

Malfunction of the oil seal B

Malfunction of the oil seal C

Clogged orifice

Incorrect valve body installation

Only overdrive clutch hydraulic

pressure is abnormal.Malfunction of the oil seal D

Malfunction of the oil seal E

Malfunction of the oil seal F

Malfunction of the overdrive solenoid valve

Malfunction of the overdrive pressure control valve

Malfunction of the check ball

Clogged orifice

Incorrect valve body installation

Malfunction of the accumulator for overdrive clutch

Only direct clutch hydraulic

pressure is abnormal.Malfunction of the oil seal R, S or T

Malfunction of the low-reverse solenoid valve(also used for direct clutch)

Malfunction of the low-reverse pressure control valve

Malfunction of the switch valve

Malfunction of the fail safe valve C

Clogged orifice

Incorrect valve body installation

Only low-reverse brake

hydraulic pressure is abnormal.Malfunction of the oil seal I

Malfunction of the oil seal J

Malfunction of the low-reverse solenoid valve

Malfunction of the low-reverse pressure control valve

Malfunction of the switch valve

Malfunction of the fail safe valve A

Malfunction of all the check balls

Clogged orifice

Incorrect valve body installation

Malfunction of the accumulator for low-reverse brake SYMPTOM PROBABLE CAUSE

Page 1489 of 1500

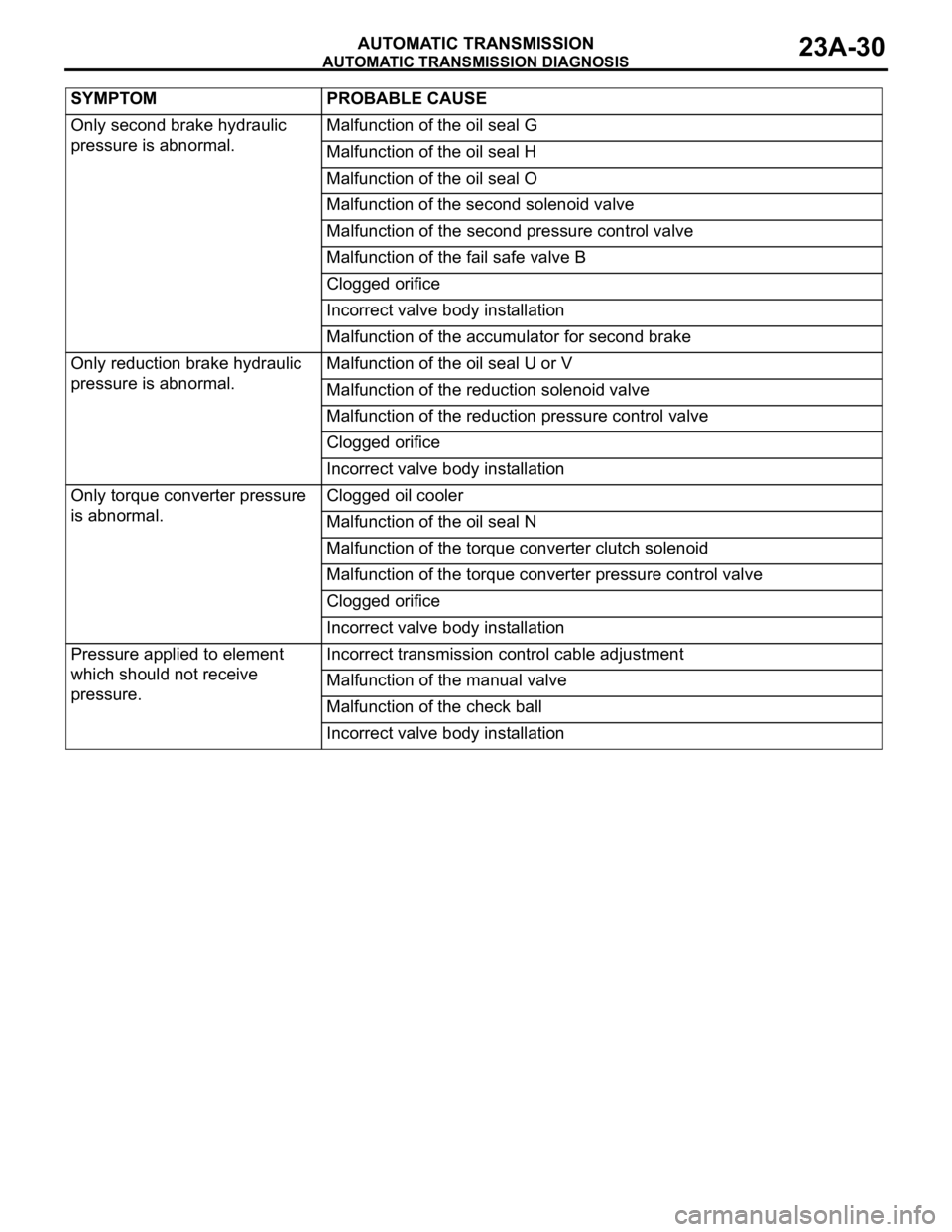

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-30

Only second brake hydraulic

pressure is abnormal.Malfunction of the oil seal G

Malfunction of the oil seal H

Malfunction of the oil seal O

Malfunction of the second solenoid valve

Malfunction of the second pressure control valve

Malfunction of the fail safe valve B

Clogged orifice

Incorrect valve body installation

Malfunction of the accumulator for second brake

Only reduction brake hydraulic

pressure is abnormal.Malfunction of the oil seal U or V

Malfunction of the reduction solenoid valve

Malfunction of the reduction pressure control valve

Clogged orifice

Incorrect valve body installation

Only torque converter pressure

is abnormal.Clogged oil cooler

Malfunction of the oil seal N

Malfunction of the torque converter clutch solenoid

Malfunction of the torque converter pressure control valve

Clogged orifice

Incorrect valve body installation

Pressure applied to element

which should not receive

pressure.Incorrect transmission control cable adjustment

Malfunction of the manual valve

Malfunction of the check ball

Incorrect valve body installation SYMPTOM PROBABLE CAUSE

Page 1490 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

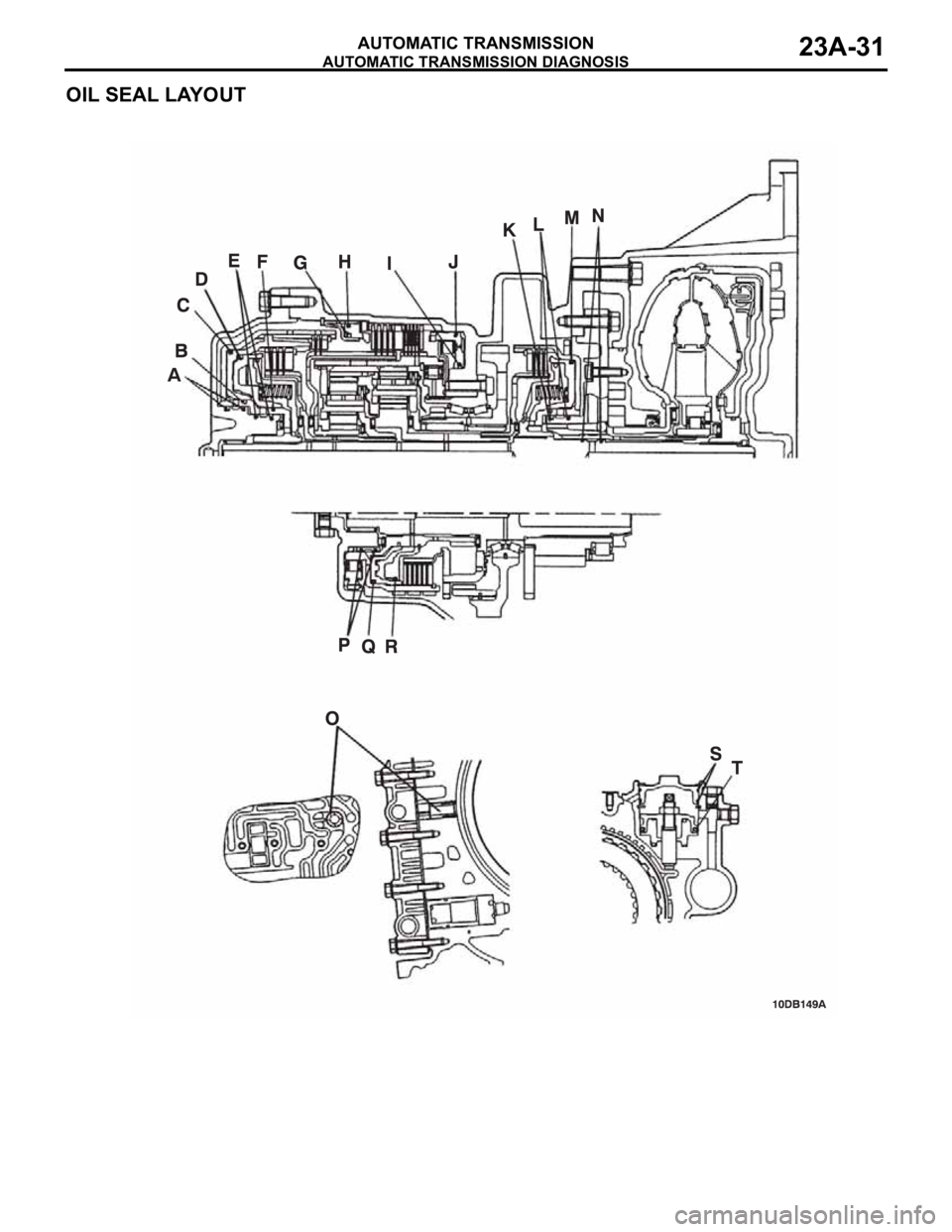

AUTOMATIC TRANSMISSION23A-31

OIL SEAL LAYOUT

Page 1491 of 1500

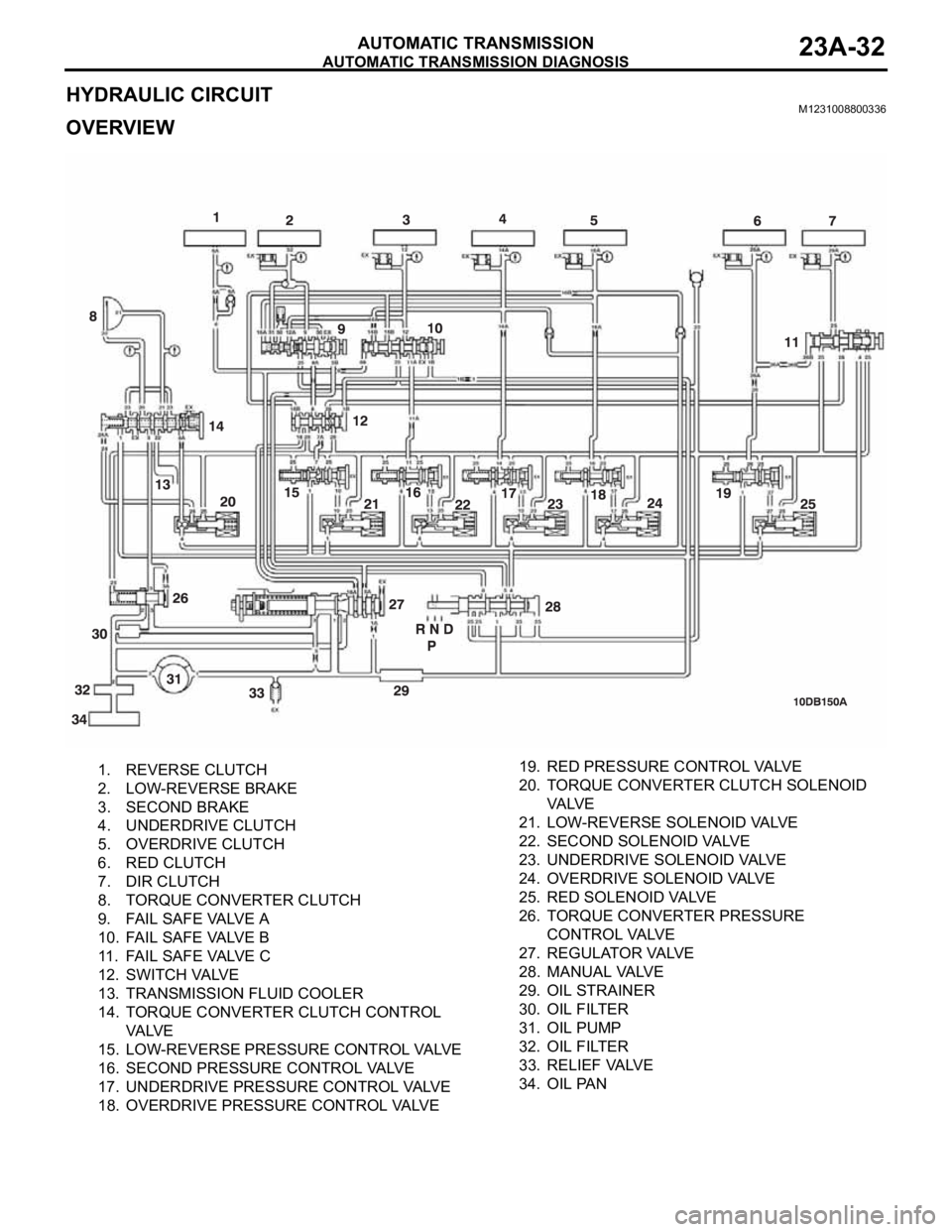

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-32

HYDRAULIC CIRCUITM1231008800336

OVERVIEW

1. REVERSE CLUTCH

2. LOW-REVERSE BRAKE

3. SECOND BRAKE

4. UNDERDRIVE CLUTCH

5. OVERDRIVE CLUTCH

6. RED CLUTCH

7. DIR CLUTCH

8. TORQUE CONVERTER CLUTCH

9. FAIL SAFE VALVE A

10. FAIL SAFE VALVE B

11. FAIL SAFE VALVE C

12. SWITCH VALVE

13. TRANSMISSION FLUID COOLER

14. TORQUE CONVERTER CLUTCH CONTROL

VA LV E

15. LOW-REVERSE PRESSURE CONTROL VALVE

16. SECOND PRESSURE CONTROL VALVE

17. UNDERDRIVE PRESSURE CONTROL VALVE

18. OVERDRIVE PRESSURE CONTROL VALVE 19. RED PRESSURE CONTROL VALVE

20. TORQUE CONVERTER CLUTCH SOLENOID

VA LV E

21. LOW-REVERSE SOLENOID VALVE

22. SECOND SOLENOID VALVE

23. UNDERDRIVE SOLENOID VALVE

24. OVERDRIVE SOLENOID VALVE

25. RED SOLENOID VALVE

26. TORQUE CONVERTER PRESSURE

CONTROL VALVE

27. REGULATOR VALVE

28. MANUAL VALVE

29. OIL STRAINER

30. OIL FILTER

31. OIL PUMP

32. OIL FILTER

33. RELIEF VALVE

34. OIL PAN