air condition MITSUBISHI 380 2005 Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 238 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-238

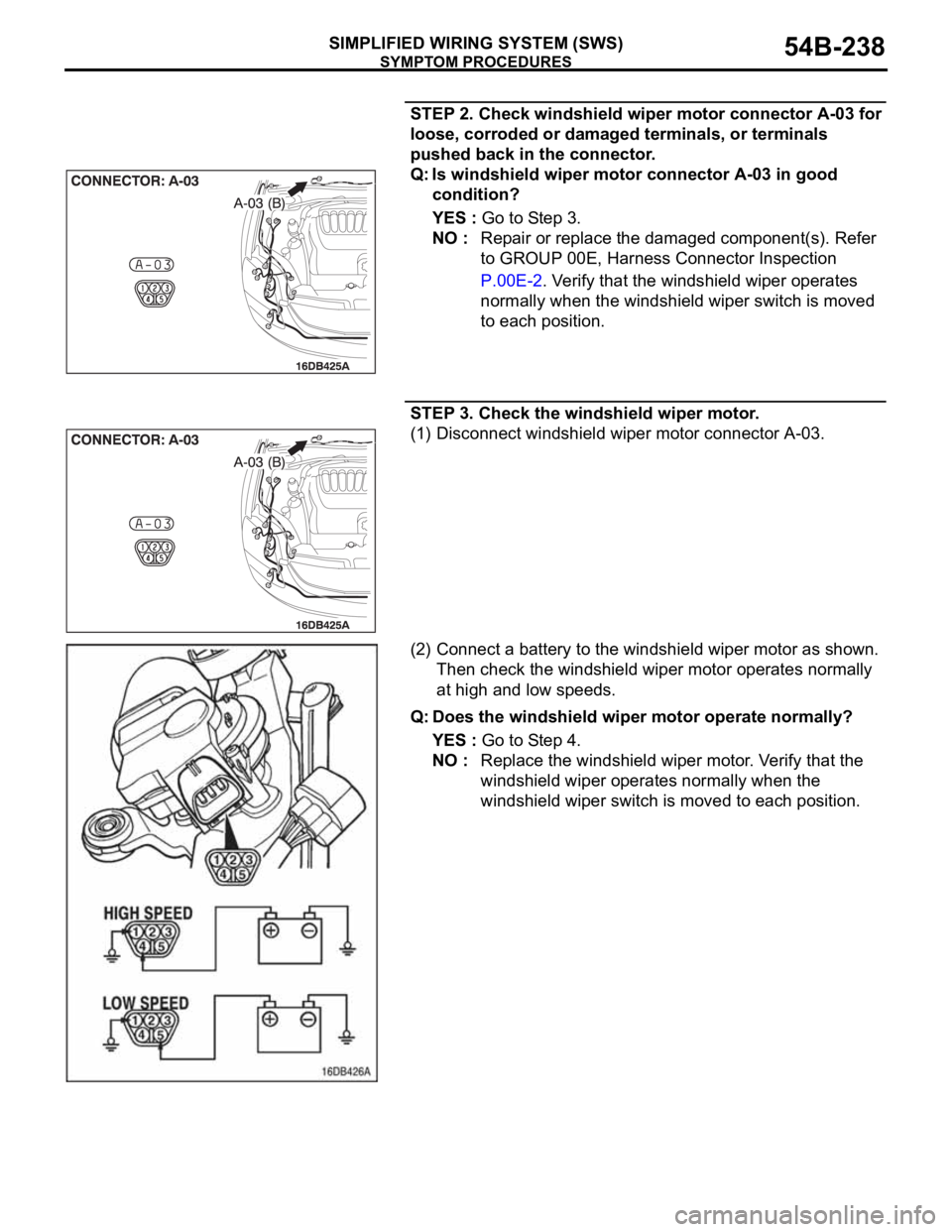

STEP 2. Check windshield wiper motor connector A-03 for

loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is windshield wiper motor connector A-03 in good

condition?

YES : Go to Step 3.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the windshield wiper operates

normally when the windshield wiper switch is moved

to each position.

STEP 3. Check the windshield wiper motor.

(1) Disconnect windshield wiper motor connector A-03.

(2) Connect a battery to the windshield wiper motor as shown.

Then check the windshield wiper motor operates normally

at high and low speeds.

Q: Does the windshield wiper motor operate normally?

YES : Go to Step 4.

NO : Replace the windshield wiper motor. Verify that the

windshield wiper operates normally when the

windshield wiper switch is moved to each position.

Page 239 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-239

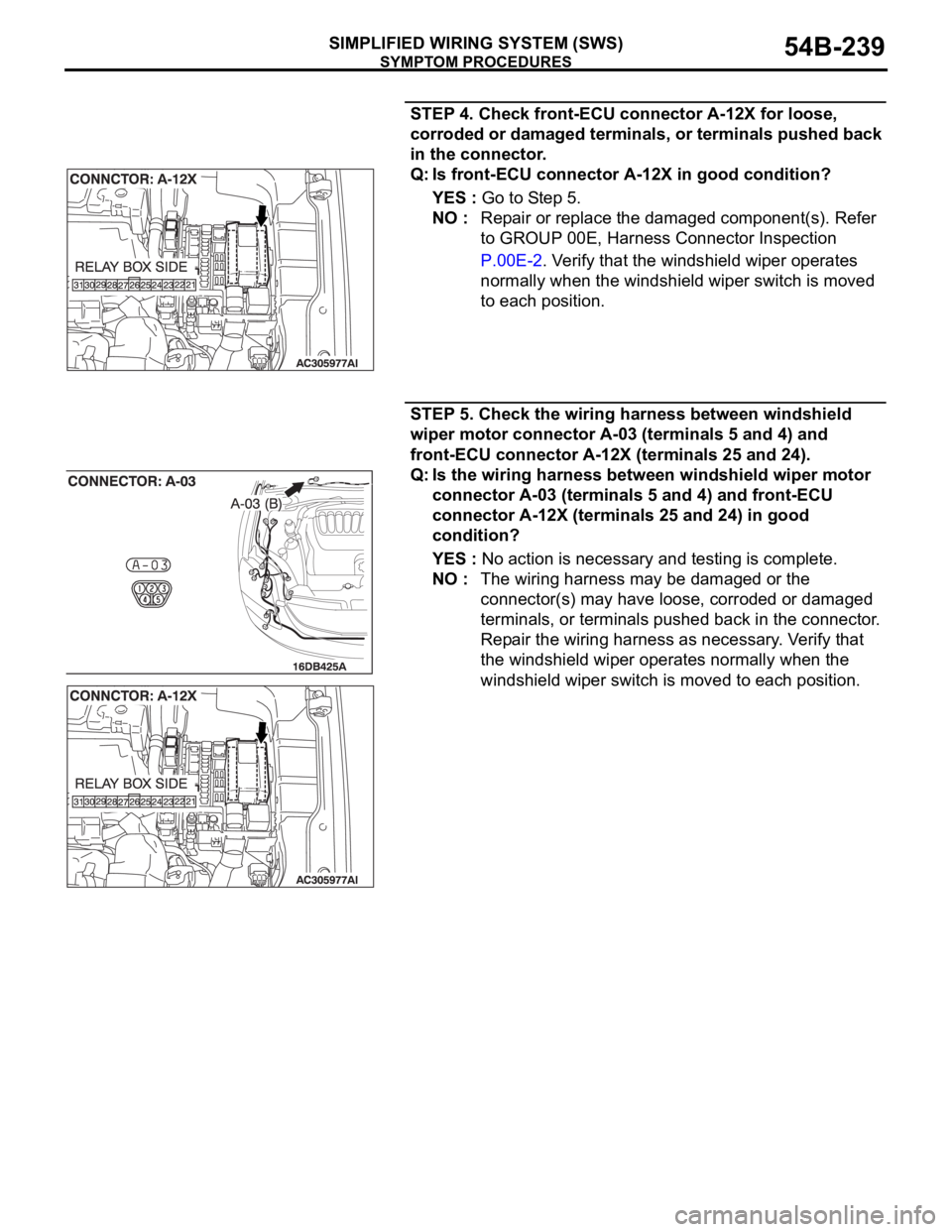

STEP 4. Check front-ECU connector A-12X for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is front-ECU connector A-12X in good condition?

YES : Go to Step 5.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the windshield wiper operates

normally when the windshield wiper switch is moved

to each position.

STEP 5. Check the wiring harness between windshield

wiper motor connector A-03 (terminals 5 and 4) and

front-ECU connector A-12X (terminals 25 and 24).

Q: Is the wiring harness between windshield wiper motor

connector A-03 (terminals 5 and 4) and front-ECU

connector A-12X (terminals 25 and 24) in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the windshield wiper operates normally when the

windshield wiper switch is moved to each position.

Page 241 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-241

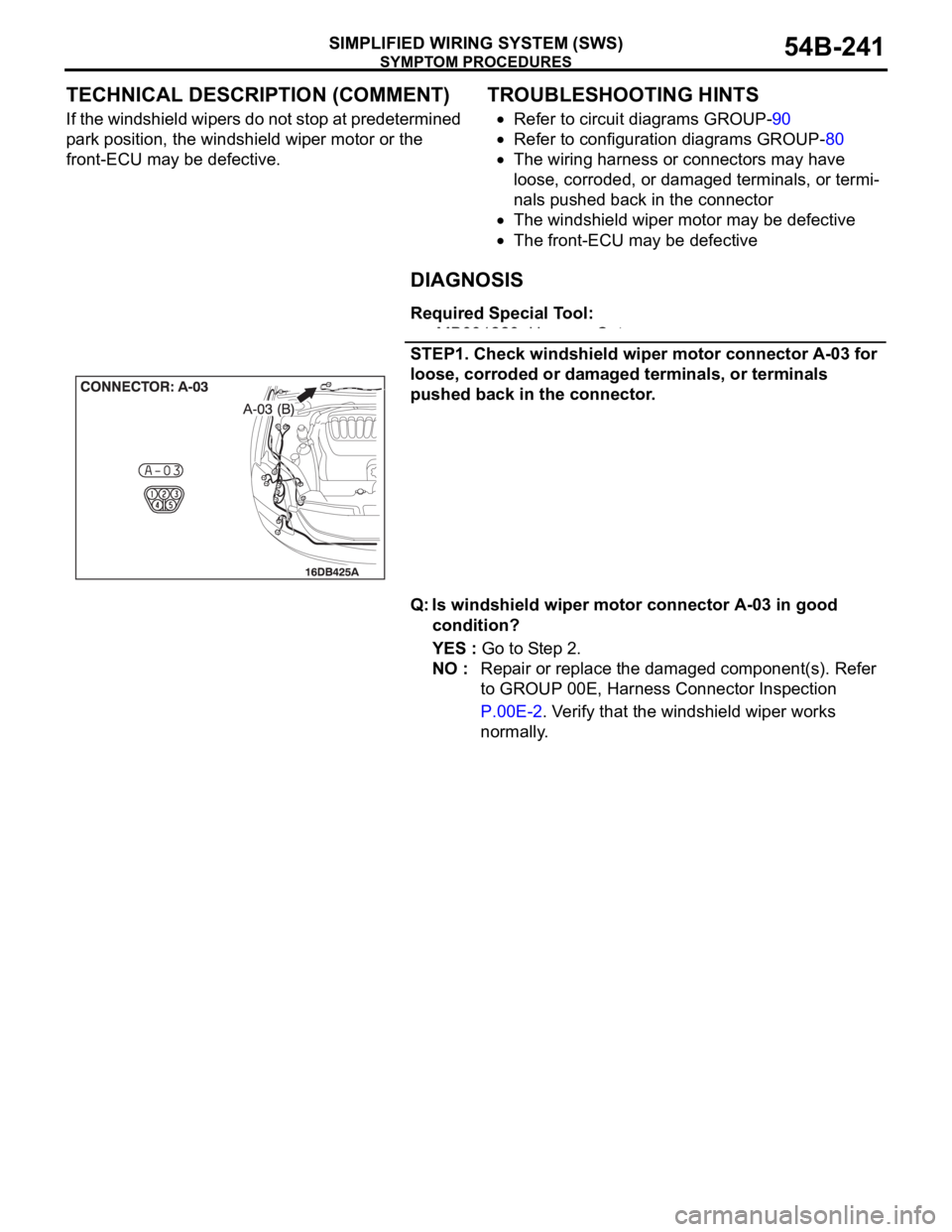

TECHNICAL DESCRIPTION (COMMENT)

If the windshield wipers do not stop at predetermined

park position, the windshield wiper motor or the

front-ECU may be defective.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The windshield wiper motor may be defective

The front-ECU may be defective

DIAGNOSIS

Required Special Tool:

MB991223: Harness Set

STEP1. Check windshield wiper motor connector A-03 for

loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is windshield wiper motor connector A-03 in good

condition?

YES : Go to Step 2.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the windshield wiper works

normally.

Page 244 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-244

NOTE: Also check intermediate connector C-29 for loose, cor-

roded, or damaged terminals, or terminals pushed back in the

connector. If intermediate connector C-29 is damaged, repair or

replace the damaged component(s) as described in GROUP

00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between windshield wiper motor

connector A-03 (terminal 3) and the ignition switch

(ACC) in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the windshield wiper works normally.

STEP 5. Check front-ECU connector A-12X for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is front-ECU connector A-12X in good condition?

YES : Go to Step 6.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. The windshield wiper should stop at the

predetermined park position.

Page 245 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-245

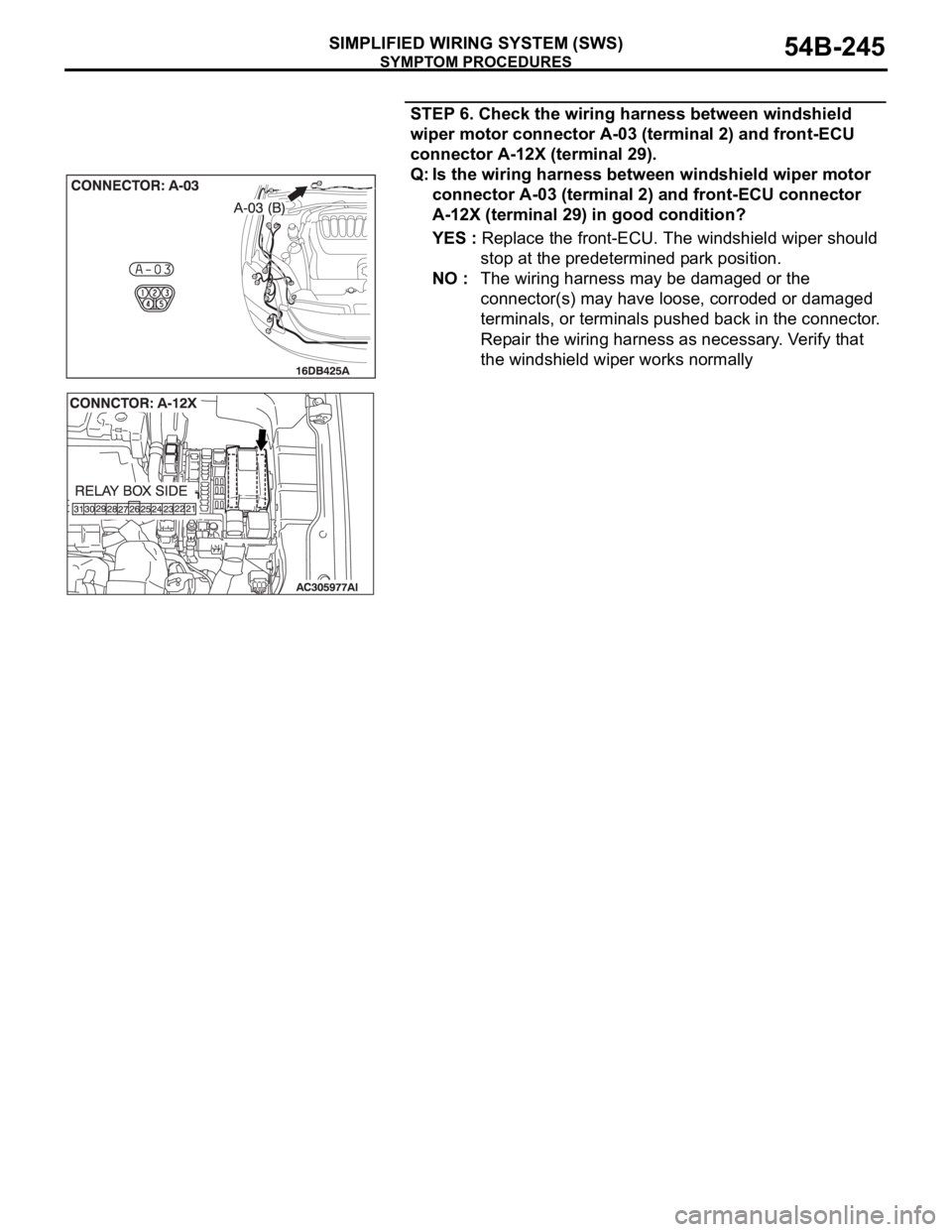

STEP 6. Check the wiring harness between windshield

wiper motor connector A-03 (terminal 2) and front-ECU

connector A-12X (terminal 29).

Q: Is the wiring harness between windshield wiper motor

connector A-03 (terminal 2) and front-ECU connector

A-12X (terminal 29) in good condition?

YES : Replace the front-ECU. The windshield wiper should

stop at the predetermined park position.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the windshield wiper works normally

Page 253 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-253

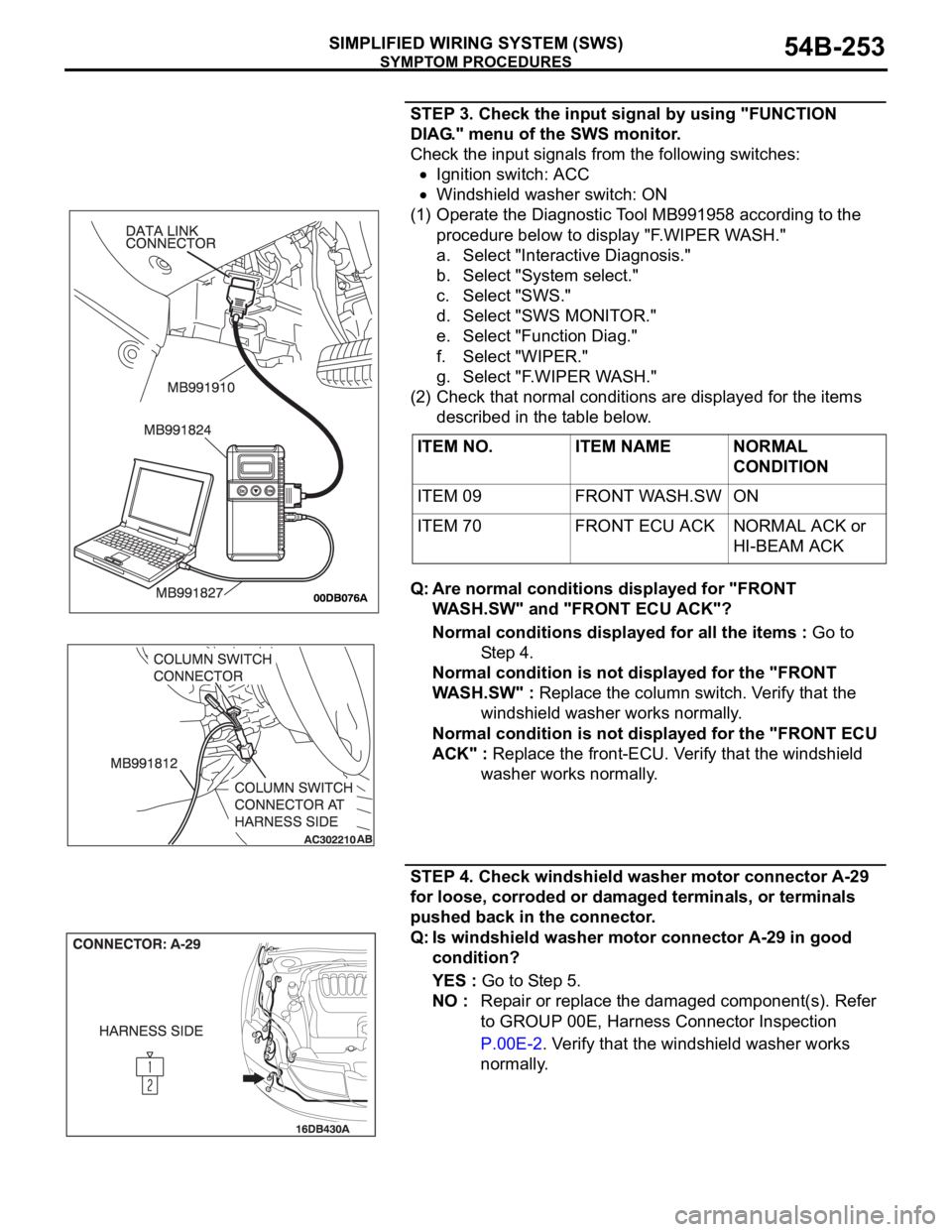

STEP 3. Check the input signal by using "FUNCTION

DIAG." menu of the SWS monitor.

Check the input signals from the following switches:

Ignition switch: ACC

Windshield washer switch: ON

(1) Operate the Diagnostic Tool MB991958 according to the

procedure below to display "F.WIPER WASH."

a. Select "Interactive Diagnosis."

b. Select "System select."

c. Select "SWS."

d. Select "SWS MONITOR."

e. Select "Function Diag."

f. Select "WIPER."

g. Select "F.WIPER WASH."

(2) Check that normal conditions are displayed for the items

described in the table below.

Q: Are normal conditions displayed for "FRONT

WASH.SW" and "FRONT ECU ACK"?

Normal conditions displayed for all the items : Go to

St e p 4 .

Normal condition is not displayed for the "FRONT

WASH.SW" : Replace the column switch. Verify that the

windshield washer works normally.

Normal condition is not displayed for the "FRONT ECU

ACK" : Replace the front-ECU. Verify that the windshield

washer works normally.

STEP 4. Check windshield washer motor connector A-29

for loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is windshield washer motor connector A-29 in good

condition?

YES : Go to Step 5.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the windshield washer works

normally. ITEM NO. ITEM NAME NORMAL

CONDITION

ITEM 09 FRONT WASH.SW ON

ITEM 70 FRONT ECU ACK NORMAL ACK or

HI-BEAM ACK

Page 255 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-255

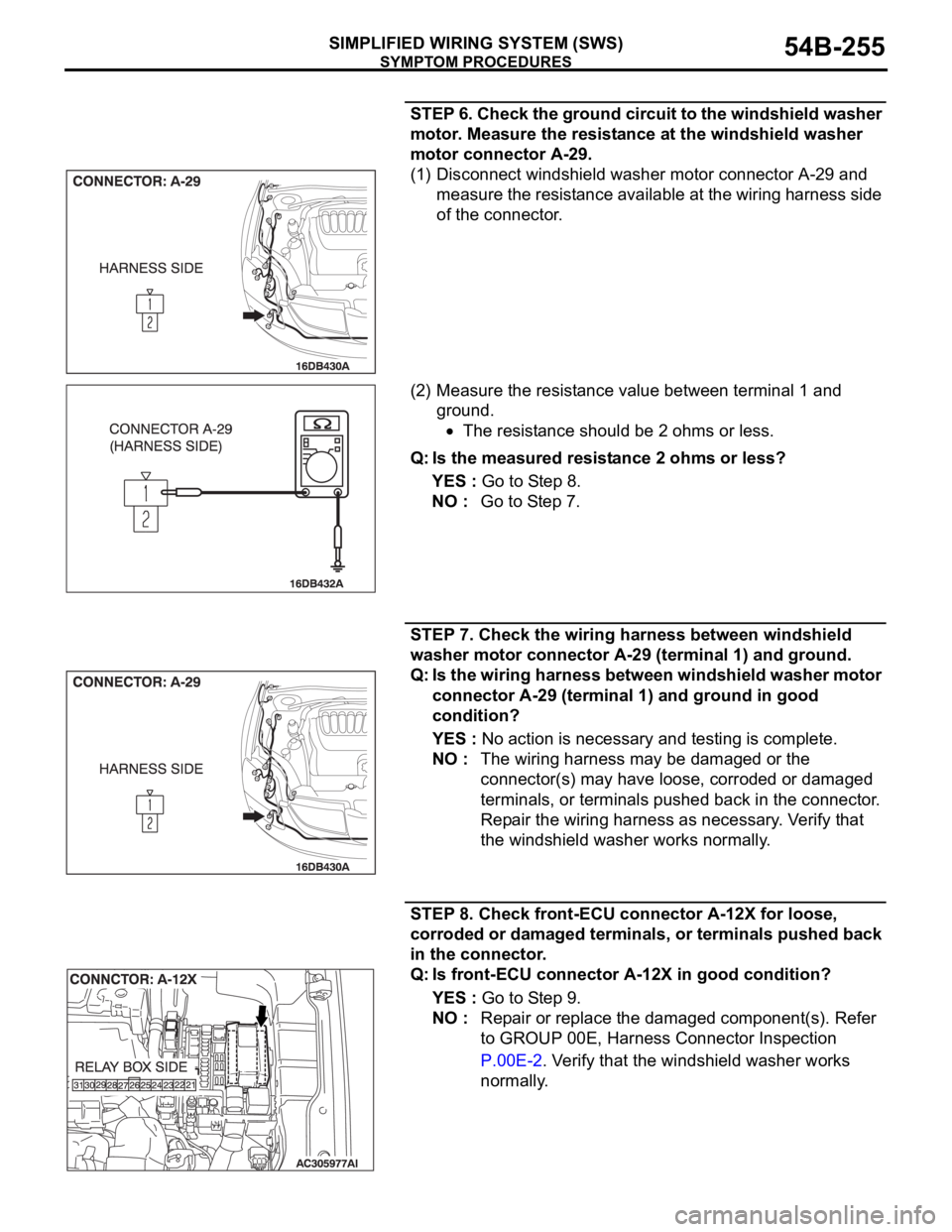

STEP 6. Check the ground circuit to the windshield washer

motor. Measure the resistance at the windshield washer

motor connector A-29.

(1) Disconnect windshield washer motor connector A-29 and

measure the resistance available at the wiring harness side

of the connector.

(2) Measure the resistance value between terminal 1 and

ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to Step 8.

NO : Go to Step 7.

STEP 7. Check the wiring harness between windshield

washer motor connector A-29 (terminal 1) and ground.

Q: Is the wiring harness between windshield washer motor

connector A-29 (terminal 1) and ground in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the windshield washer works normally.

STEP 8. Check front-ECU connector A-12X for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is front-ECU connector A-12X in good condition?

YES : Go to Step 9.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the windshield washer works

normally.

Page 256 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-256

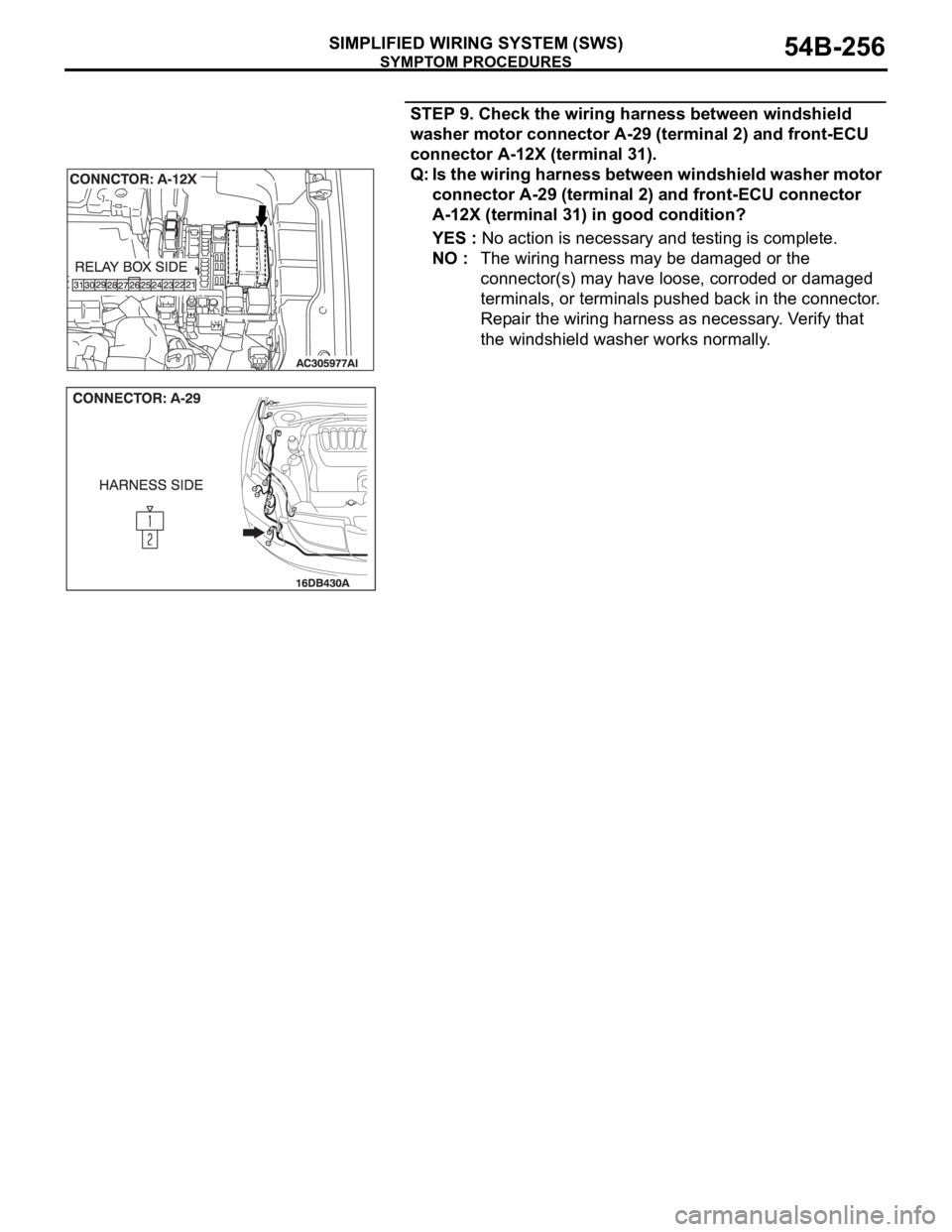

STEP 9. Check the wiring harness between windshield

washer motor connector A-29 (terminal 2) and front-ECU

connector A-12X (terminal 31).

Q: Is the wiring harness between windshield washer motor

connector A-29 (terminal 2) and front-ECU connector

A-12X (terminal 31) in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the windshield washer works normally.

Page 263 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-263

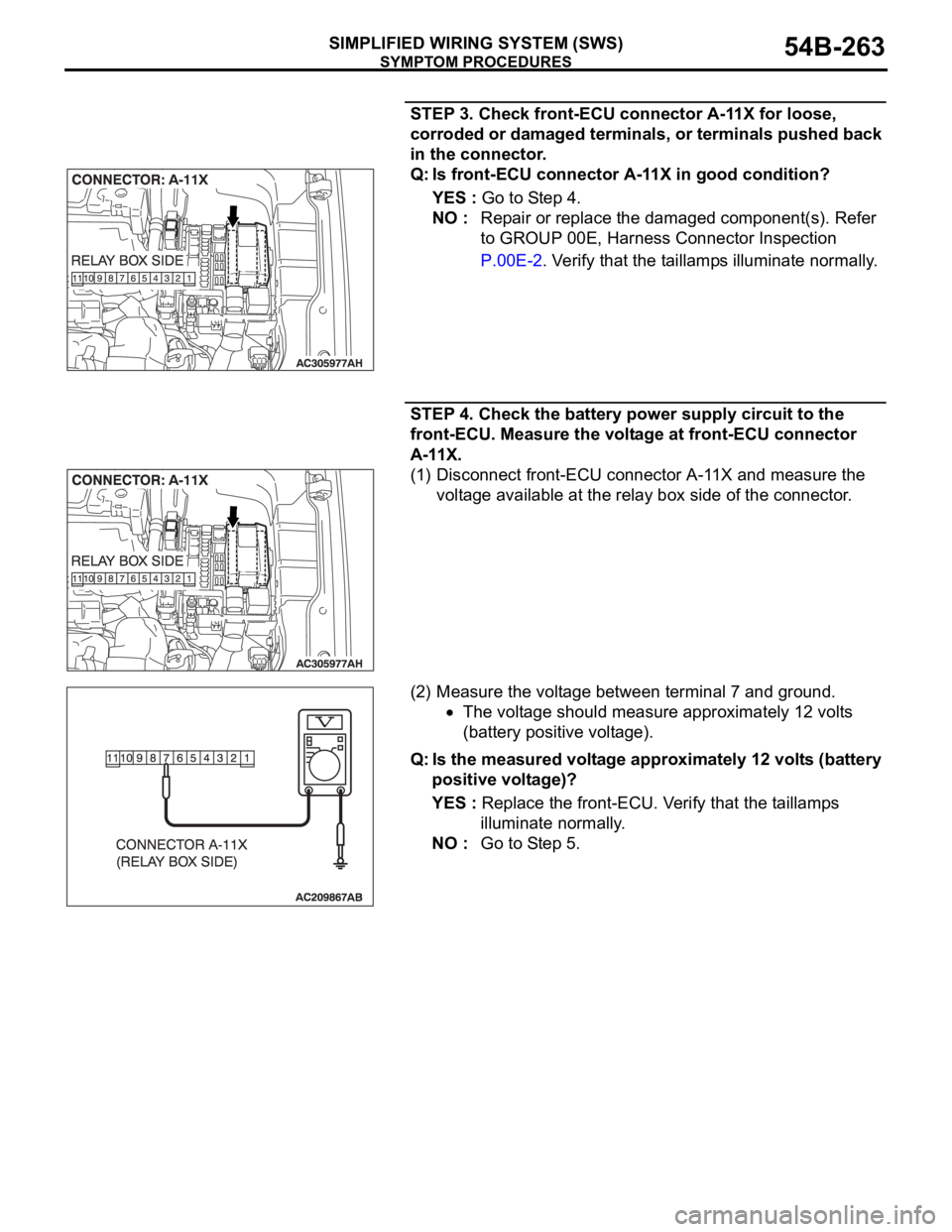

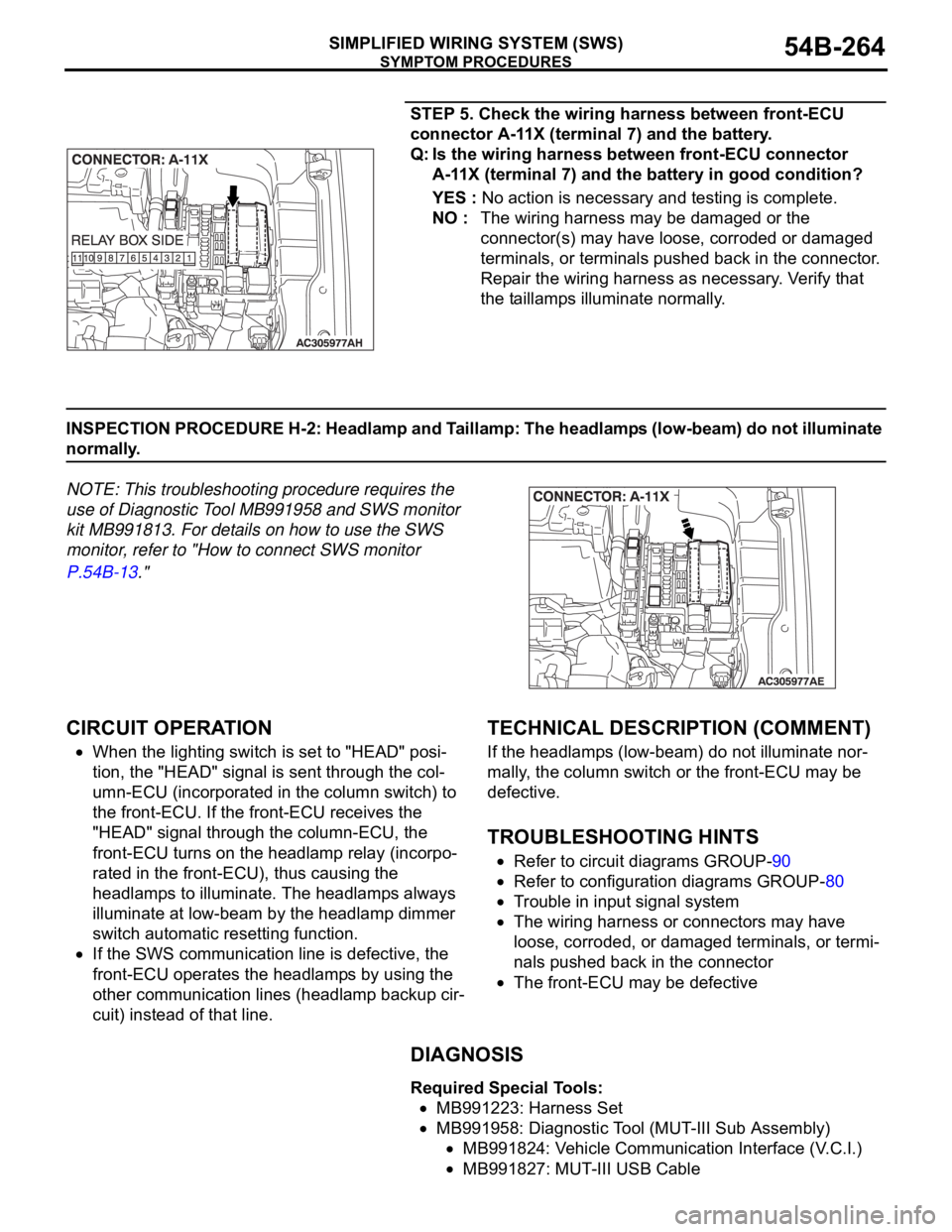

STEP 3. Check front-ECU connector A-11X for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is front-ECU connector A-11X in good condition?

YES : Go to Step 4.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the taillamps illuminate normally.

STEP 4. Check the battery power supply circuit to the

front-ECU. Measure the voltage at front-ECU connector

A-11X.

(1) Disconnect front-ECU connector A-11X and measure the

voltage available at the relay box side of the connector.

(2) Measure the voltage between terminal 7 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Replace the front-ECU. Verify that the taillamps

illuminate normally.

NO : Go to Step 5.

Page 264 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-264

STEP 5. Check the wiring harness between front-ECU

connector A-11X (terminal 7) and the battery.

Q: Is the wiring harness between front-ECU connector

A-11X (terminal 7) and the battery in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the taillamps illuminate normally.

INSPECTION PROCEDURE H-2: Headlamp and Taillamp: The headlamps (low-beam) do not illuminate

normally.

NOTE: This troubleshooting procedure requires the

use of Diagnostic Tool MB991958 and SWS monitor

kit MB991813. For details on how to use the SWS

monitor, refer to "How to connect SWS monitor

P.54B-13."

.

CIRCUIT OPERATION

When the lighting switch is set to "HEAD" posi-

tion, the "HEAD" signal is sent through the col-

umn-ECU (incorporated in the column switch) to

the front-ECU. If the front-ECU receives the

"HEAD" signal through the column-ECU, the

front-ECU turns on the headlamp relay (incorpo-

rated in the front-ECU), thus causing the

headlamps to illuminate. The headlamps always

illuminate at low-beam by the headlamp dimmer

switch automatic resetting function.

If the SWS communication line is defective, the

front-ECU operates the headlamps by using the

other communication lines (headlamp backup cir-

cuit) instead of that line.

.

TECHNICAL DESCRIPTION (COMMENT)

If the headlamps (low-beam) do not illuminate nor-

mally, the column switch or the front-ECU may be

defective.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Trouble in input signal system

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The front-ECU may be defective

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable