service MITSUBISHI 380 2005 Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 865 of 1500

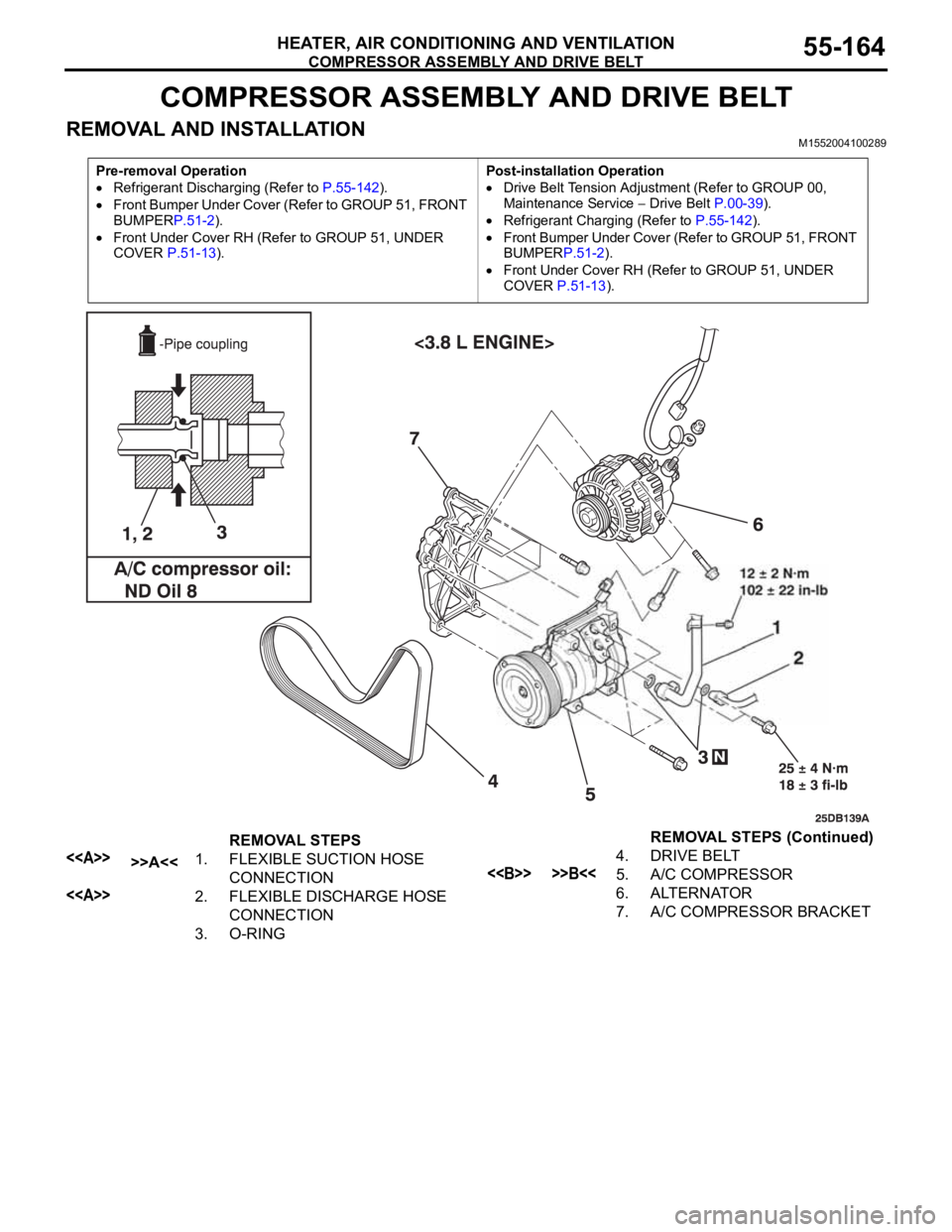

COMPRESSOR ASSEMBLY AND DRIVE BELT

HEATER, AIR CONDITIONING AND VENTILATION55-164

COMPRESSOR ASSEMBLY AND DRIVE BELT

REMOVAL AND INSTALLATIONM1552004100289

Pre-removal Operation

Refrigerant Discharging (Refer to P.55-142).

Front Bumper Under Cover (Refer to GROUP 51, FRONT

BUMPERP.51-2).

Front Under Cover RH (Refer to GROUP 51, UNDER

COVER P.51-13).Post-installation Operation

Drive Belt Tension Adjustment (Refer to GROUP 00,

Maintenance Service

Drive Belt P.00-39).

Refrigerant Charging (Refer to P.55-142).

Front Bumper Under Cover (Refer to GROUP 51, FRONT

BUMPERP.51-2).

Front Under Cover RH (Refer to GROUP 51, UNDER

COVER P.51-13).

REMOVAL STEPS

<>>>A<<1. FLEXIBLE SUCTION HOSE

CONNECTION

<>2. FLEXIBLE DISCHARGE HOSE

CONNECTION

3. O-RING4. DRIVE BELT

<> >>B<<5. A/C COMPRESSOR

6. ALTERNATOR

7. A/C COMPRESSOR BRACKETREMOVAL STEPS (Continued)

Page 866 of 1500

Page 869 of 1500

Page 872 of 1500

Page 873 of 1500

REFRIGERANT LINE

HEATER, AIR CONDITIONING AND VENTILATION55-172

O-RING AND PIPE SERVICE POINT

.

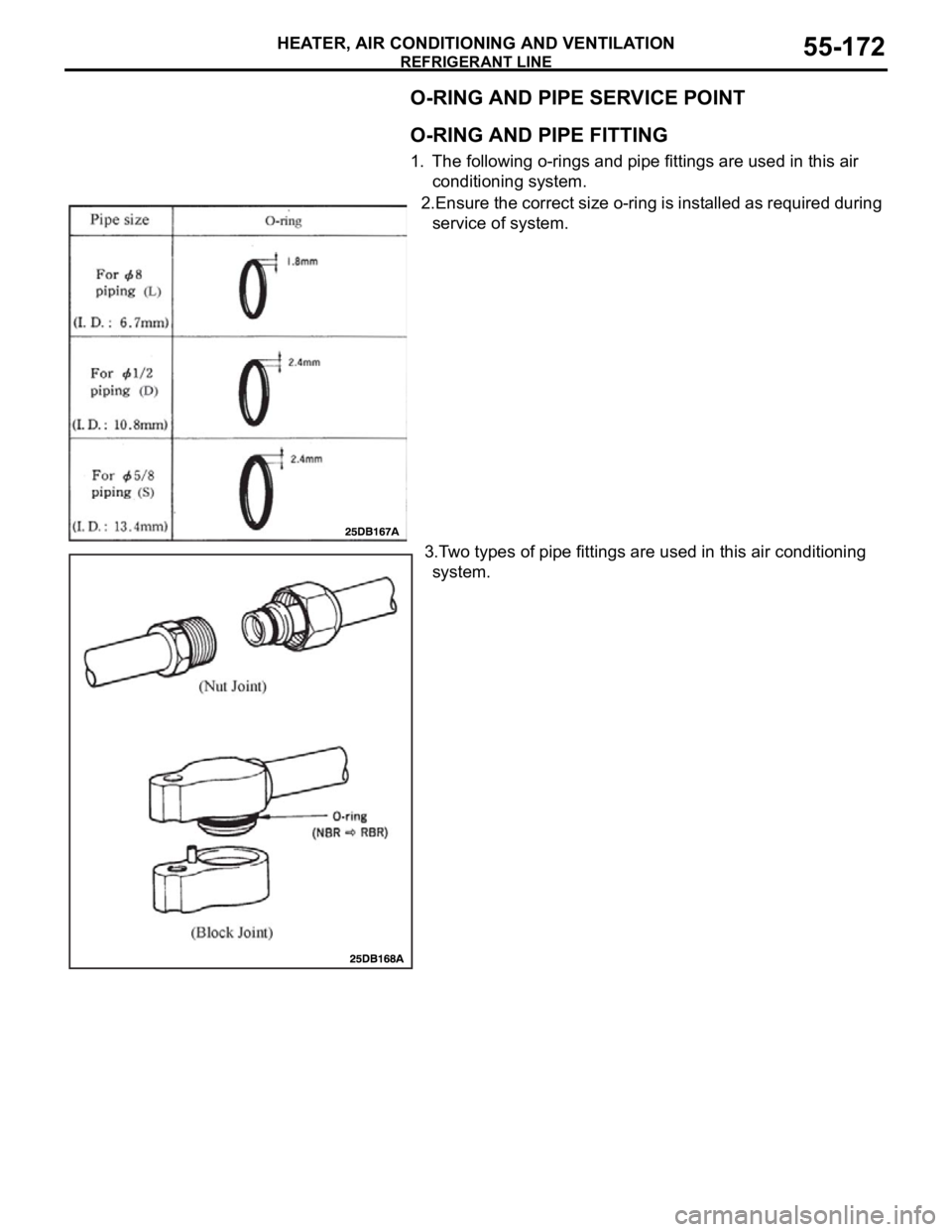

O-RING AND PIPE FITTING

1. The following o-rings and pipe fittings are used in this air

conditioning system.

2.Ensure the correct size o-ring is installed as required during

service of system.

3.Two types of pipe fittings are used in this air conditioning

system.

.

Page 879 of 1500

SPECIFICATIONS

HEATER, AIR CONDITIONING AND VENTILATION55-178

SPECIFICATIONS

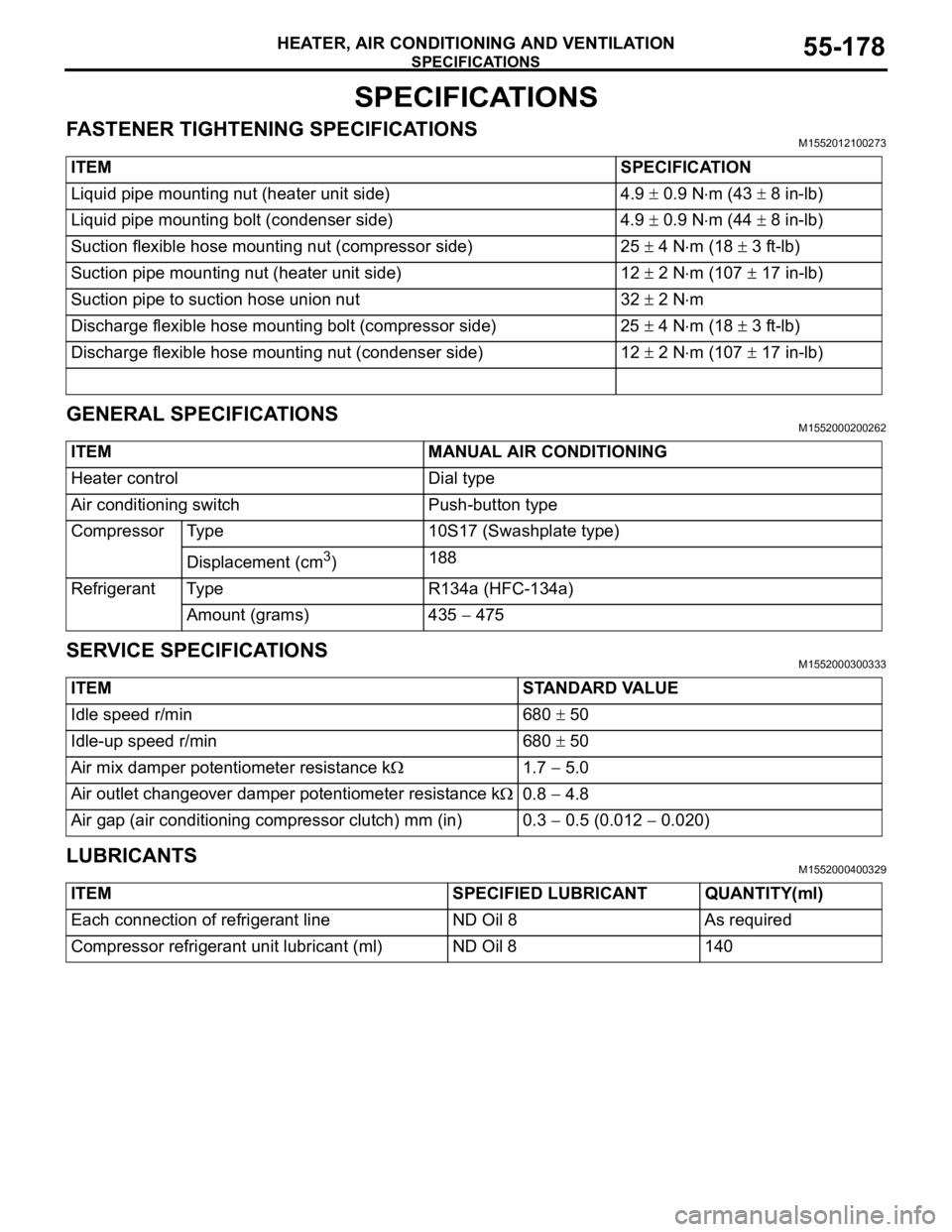

FASTENER TIGHTENING SPECIFICATIONSM1552012100273

GENERAL SPECIFICATIONSM1552000200262

SERVICE SPECIFICATIONSM1552000300333

LUBRICANTSM1552000400329

ITEM SPECIFICATION

Liquid pipe mounting nut (heater unit side) 4.9

0.9 Nm (43 8 in-lb)

Liquid pipe mounting bolt (condenser side) 4.9

0.9 Nm (44 8 in-lb)

Suction flexible hose mounting nut (compressor side) 25

4 Nm (18 3 ft-lb)

Suction pipe mounting nut (heater unit side) 12

2 Nm (107 17 in-lb)

Suction pipe to suction hose union nut 32

2 Nm

Discharge flexible hose mounting bolt (compressor side) 25

4 Nm (18 3 ft-lb)

Discharge flexible hose mounting nut (condenser side) 12

2 Nm (107 17 in-lb)

ITEM MANUAL AIR CONDITIONING

Heater control Dial type

Air conditioning switch Push-button type

Compressor Type 10S17 (Swashplate type)

Displacement (cm

3)188

Refrigerant Type R134a (HFC-134a)

Amount (grams) 435

475

ITEM STANDARD VALUE

Idle speed r/min 680

50

Idle-up speed r/min 680

50

Air mix damper potentiometer resistance k

1.7 5.0

Air outlet changeover damper potentiometer resistance k

0.8 4.8

Air gap (air conditioning compressor clutch) mm (in) 0.3

0.5 (0.012 0.020)

ITEM SPECIFIED LUBRICANT QUANTITY(ml)

Each connection of refrigerant line ND Oil 8 As required

Compressor refrigerant unit lubricant (ml) ND Oil 8 140

Page 916 of 1500

14-1

GROUP 14

ENGINE COOLING

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .14-2

SPECIAL TOOL . . . . . . . . . . . . . . . . .14-2

ENGINE COOLING DIAGNOSIS . . . .14-2

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . 14-2

TROUBLESHOOTING STRATEGY . . . . . . 14-2

SYMPTOM CHART. . . . . . . . . . . . . . . . . . . 14-3

SYMPTOM PROCEDURES . . . . . . . . . . . . 14-3

ON-VEHICLE SERVICE . . . . . . . . . . .14-26

ENGINE COOLANT LEAK CHECK . . . . . . 14-26

RADIATOR CAP PRESSURE CHECK . . . . 14-27

ENGINE COOLANT REPLACEMENT . . . . 14-27

ENGINE COOLANT CONCENTRATION TEST14-29

FAN CONTROLLER CHECK . . . . . . . . . . . 14-29

FAN CONTROL RELAY CONTINUITY CHECK14-31

RADIATOR . . . . . . . . . . . . . . . . . . . . .14-32

REMOVAL AND INSTALLATION . . . . . . . . 14-32

THERMOSTAT . . . . . . . . . . . . . . . . . .14-35

REMOVAL AND INSTALLATION . . . . . . . . 14-35

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 14-38

WATER PUMP . . . . . . . . . . . . . . . . . .14-39

REMOVAL AND INSTALLATION . . . . . . . . 14-39

WATER HOSE AND WATER PIPE . .14-40

REMOVAL AND INSTALLATION . . . . . . . . 14-40

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 14-41

SPECIFICATIONS . . . . . . . . . . . . . . .14-42

FASTENER TIGHTENING

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . 14-42

SERVICE SPECIFICATION . . . . . . . . . . . . 14-43

CAPACITIES . . . . . . . . . . . . . . . . . . . . . . . . 14-43

SEALANTS . . . . . . . . . . . . . . . . . . . . . . . . . 14-43

Page 917 of 1500

GENERAL DESCRIPTION

ENGINE COOLING14-2

GENERAL DESCRIPTIONM1141000100401

The cooling system is designed to keep every

part of the engine at appropriate temperature in

whatever condition the engine may be operated.

The cooling method is of the water-cooled, pres-

sure forced circulation type in which the water

pump pressurizes coolant and circulates it

throughout the engine. If the coolant temperature exceeds the prescribed temperature, the thermo-

stat opens to circulate the coolant through the

radiator as well so that the heat absorbed by the

coolant may be radiated into the air. The water

pump is of the centrifugal type and is driven by

the drive belt from the crankshaft. The radiator is

the corrugated fin, down flow type.

SPECIAL TOOLM1141000600279

ENGINE COOLING DIAGNOSIS

INTRODUCTIONM1141005300347

The system cools the engine so that it does not over-

heat and maintains the engine at an optimum tem-

perature. The system components are the radiator,

water pump, thermostat, condenser and fan assem-

blies. Possible faults include low coolant, contamina-

tion, belt loosening and component damage.

TROUBLESHOOTING STRATEGYM1141005200340

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will be sure to find

most of the engine cooling faults.

1. Gather information from the customer.2. Verify that the condition described by the

customer exists.

3. Find and repair the malfunction by following the

SYMPTOM CHART.

4. Verify that the malfunction is eliminated. TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

MB991871

LLC changerGeneral service tool Coolant refilling

Page 919 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-4

INSPECTION PROCEDURE 2: Engine Overheating

DIAGNOSIS

STEP 1. Remove the radiator cap and check for coolant

contamination.

Q: Is the coolant contaminated with rust and oil?

YES : Replace it. Refer to P.14-27.

NO : There is no action to be taken. Go to Step 2.

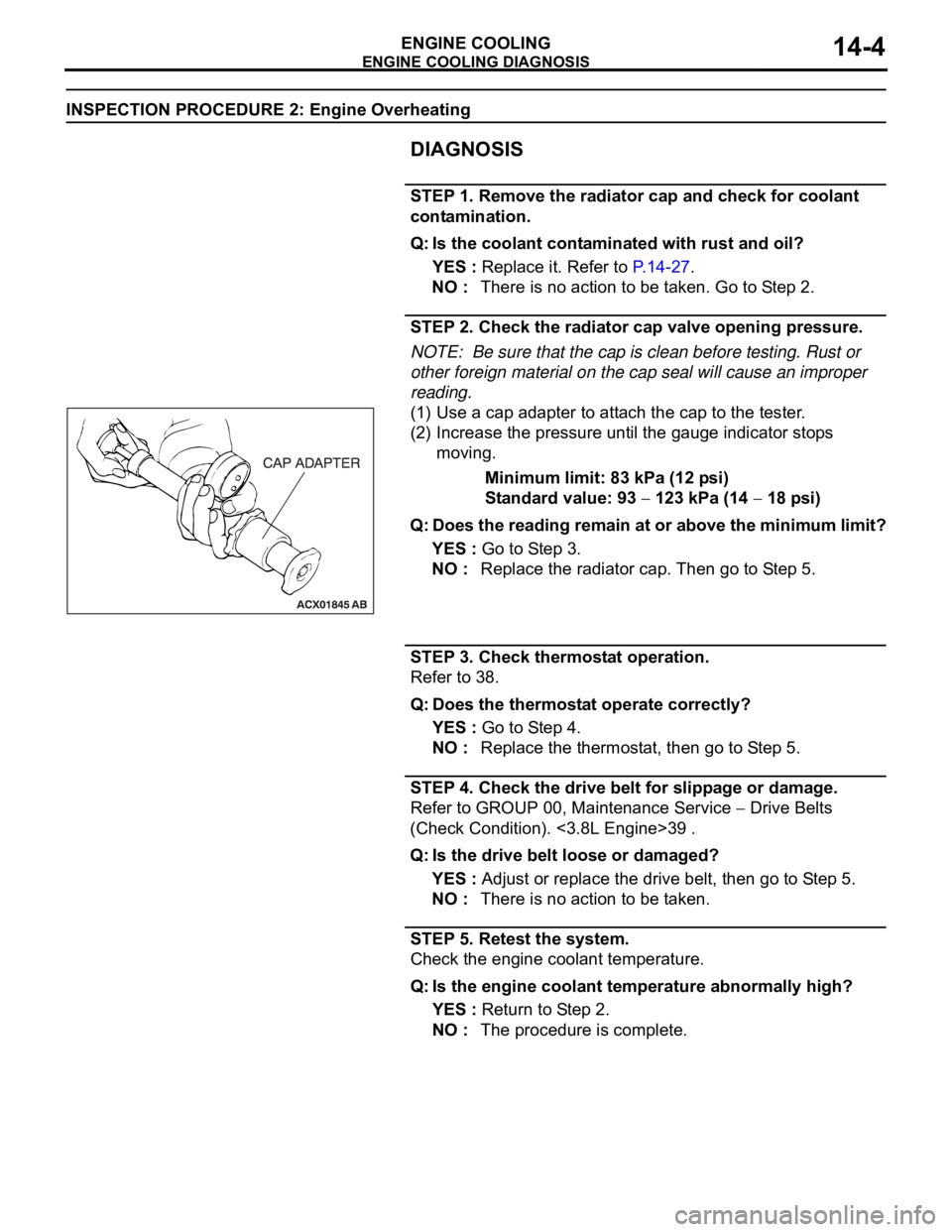

STEP 2. Check the radiator cap valve opening pressure.

NOTE: Be sure that the cap is clean before testing. Rust or

other foreign material on the cap seal will cause an improper

reading.

(1) Use a cap adapter to attach the cap to the tester.

(2) Increase the pressure until the gauge indicator stops

moving.

Minimum limit: 83 kPa (12 psi)

Standard value: 93

123 kPa (14 18 psi)

Q: Does the reading remain at or above the minimum limit?

YES : Go to Step 3.

NO : Replace the radiator cap. Then go to Step 5.

STEP 3. Check thermostat operation.

Refer to 38.

Q: Does the thermostat operate correctly?

YES : Go to Step 4.

NO : Replace the thermostat, then go to Step 5.

STEP 4. Check the drive belt for slippage or damage.

Refer to GROUP 00, Maintenance Service

Drive Belts

(Check Condition). <3.8L Engine>39 .

Q: Is the drive belt loose or damaged?

YES : Adjust or replace the drive belt, then go to Step 5.

NO : There is no action to be taken.

STEP 5. Retest the system.

Check the engine coolant temperature.

Q: Is the engine coolant temperature abnormally high?

YES : Return to Step 2.

NO : The procedure is complete.

Page 941 of 1500

ON-VEHICLE SERVICE

ENGINE COOLING14-26

DIAGNOSIS

STEP 1. Check the condenser fan motor.

Condenser fan motor check. (Refer to GROUP 55, Condenser

and Condenser Fan Motor.

Q: Is the condenser fan motor in good condition?

YES : Go to Step 2.

NO : Replace the condenser fan motor, then go to Step 3.

STEP 2. Check the fan controller.

Refer to 29.

Q: Is the fan controller in good condition?

YES : Go to Step 3.

NO : Replace the fan motor and fan controller (Refer to

14-25). Then go to Step 3.

STEP 3. Check the symptoms.

Q: Do the condenser fan operate?

YES : This symptom is complete.

NO : Return to Step 1.

ON-VEHICLE SERVICE

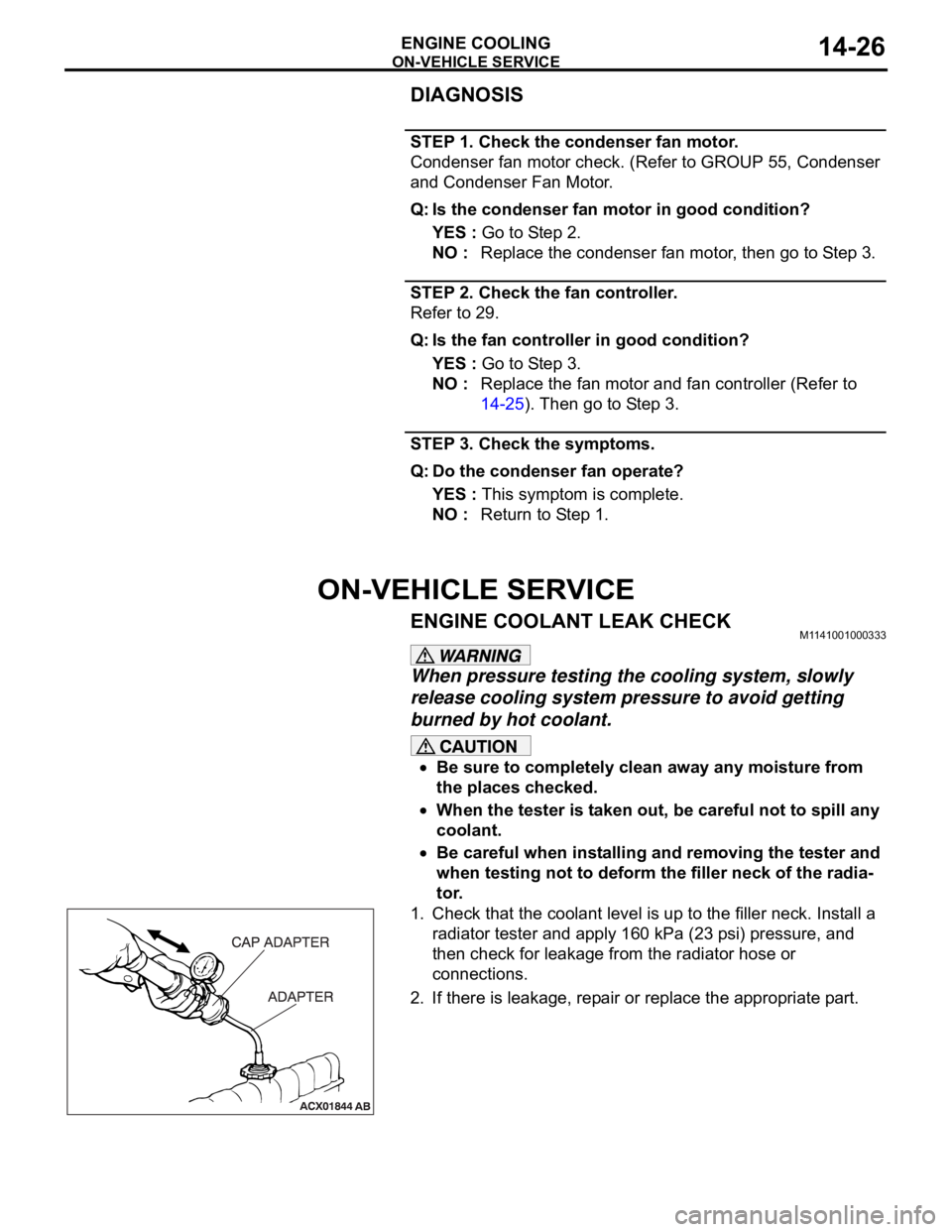

ENGINE COOLANT LEAK CHECKM1141001000333

When pressure testing the cooling system, slowly

release cooling system pressure to avoid getting

burned by hot coolant.

Be sure to completely clean away any moisture from

the places checked.

When the tester is taken out, be careful not to spill any

coolant.

Be careful when installing and removing the tester and

when testing not to deform the filler neck of the radia-

tor.

1. Check that the coolant level is up to the filler neck. Install a

radiator tester and apply 160 kPa (23 psi) pressure, and

then check for leakage from the radiator hose or

connections.

2. If there is leakage, repair or replace the appropriate part.