MITSUBISHI 380 2005 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 971 of 1500

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-12

REMOVAL SERVICE POINTS

.

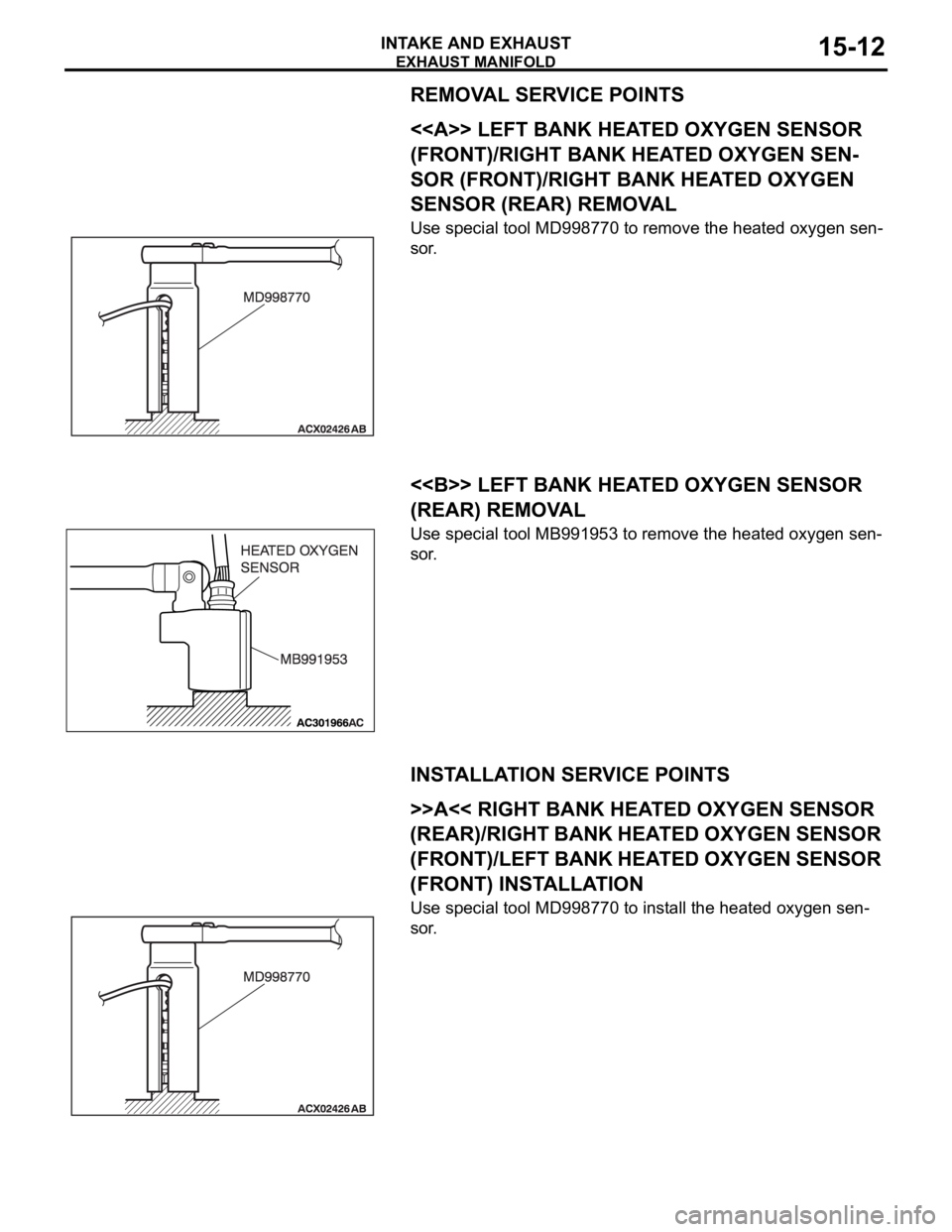

<> LEFT BANK HEATED OXYGEN SENSOR

(FRONT)/RIGHT BANK HEATED OXYGEN SEN-

SOR (FRONT)/RIGHT BANK HEATED OXYGEN

SENSOR (REAR) REMOVAL

Use special tool MD998770 to remove the heated oxygen sen-

sor.

.

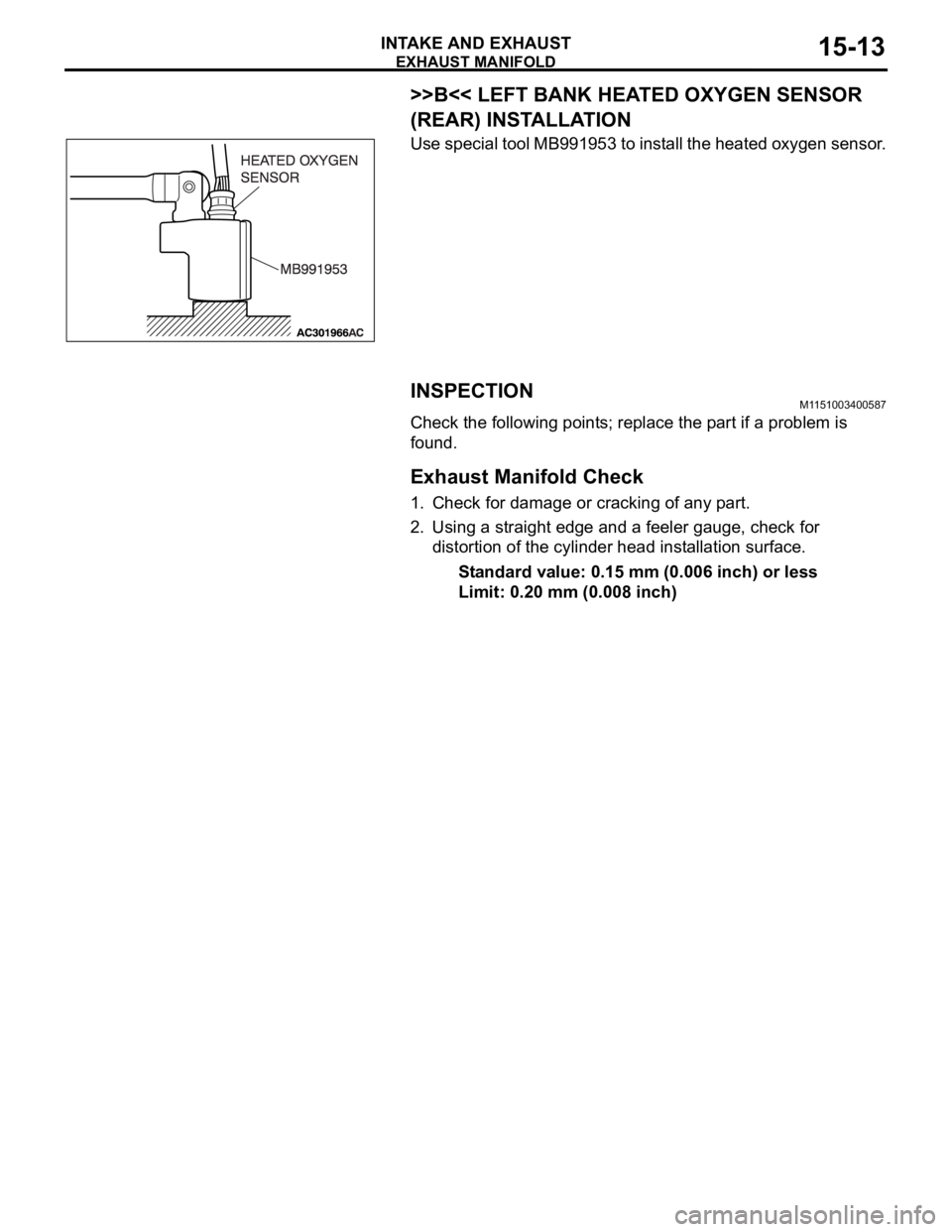

<> LEFT BANK HEATED OXYGEN SENSOR

(REAR) REMOVAL

Use special tool MB991953 to remove the heated oxygen sen-

sor.

INSTALLATION SERVICE POINTS

.

>>A<< RIGHT BANK HEATED OXYGEN SENSOR

(REAR)/RIGHT BANK HEATED OXYGEN SENSOR

(FRONT)/LEFT BANK HEATED OXYGEN SENSOR

(FRONT) INSTALLATION

Use special tool MD998770 to install the heated oxygen sen-

sor.

.

Page 972 of 1500

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-13

>>B<< LEFT BANK HEATED OXYGEN SENSOR

(REAR) INSTALLATION

Use special tool MB991953 to install the heated oxygen sensor.

INSPECTIONM1151003400587

Check the following points; replace the part if a problem is

found.

.

Exhaust Manifold Check

1. Check for damage or cracking of any part.

2. Using a straight edge and a feeler gauge, check for

distortion of the cylinder head installation surface.

Standard value: 0.15 mm (0.006 inch) or less

Limit: 0.20 mm (0.008 inch)

Page 973 of 1500

EXHAUST PIPE AND MAIN MUFFLER

INTAKE AND EXHAUST15-14

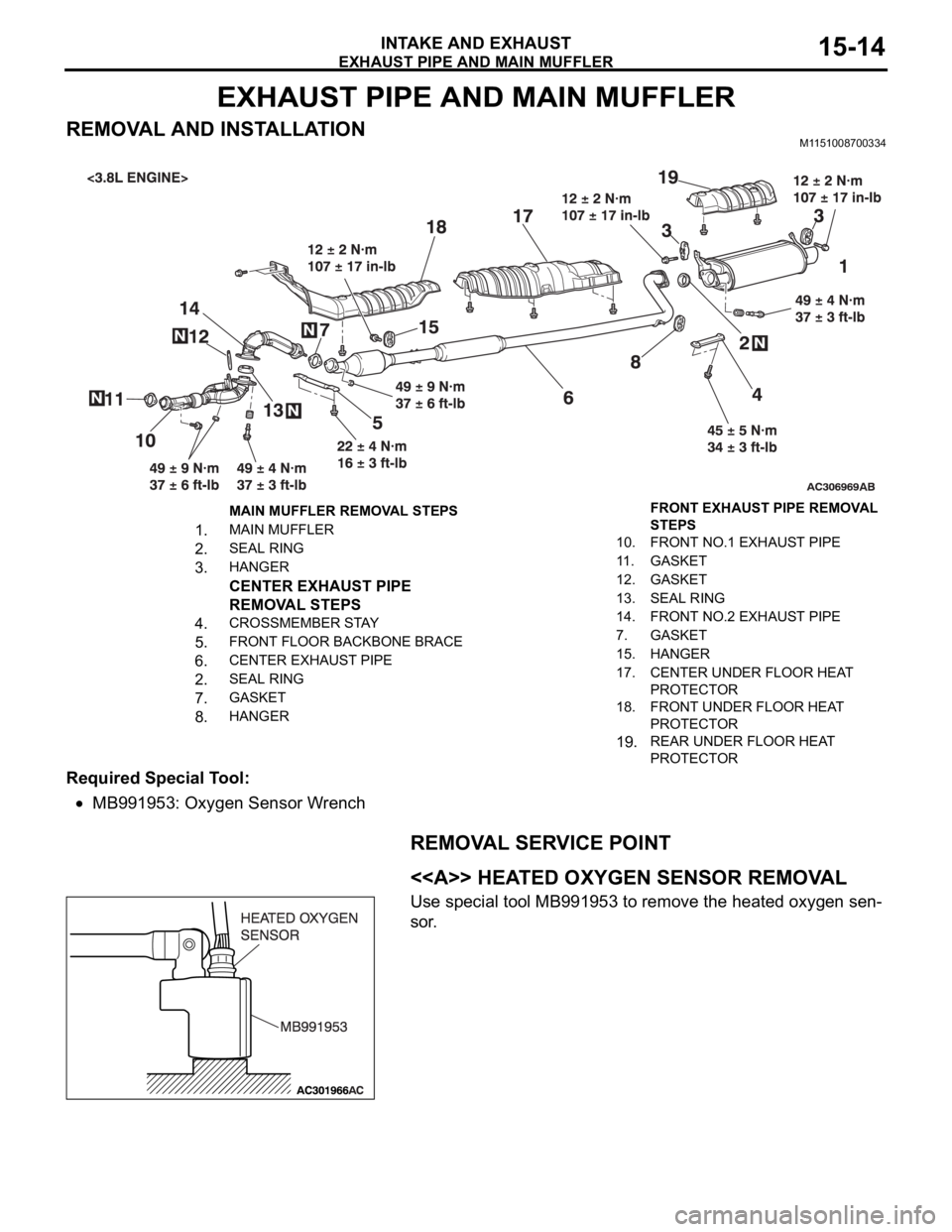

EXHAUST PIPE AND MAIN MUFFLER

REMOVAL AND INSTALLATIONM1151008700334

Required Special Tool:

MB991953: Oxygen Sensor Wrench

REMOVAL SERVICE POINT

.

<> HEATED OXYGEN SENSOR REMOVAL

Use special tool MB991953 to remove the heated oxygen sen-

sor.

MAIN MUFFLER REMOVAL STEPS

1.MAIN MUFFLER

2.SEAL RING

3.HANGER

CENTER EXHAUST PIPE

REMOVAL STEPS

4.

CROSSMEMBER STAY

5.FRONT FLOOR BACKBONE BRACE

6.CENTER EXHAUST PIPE

2.SEAL RING

7.GASKET

8.HANGERFRONT EXHAUST PIPE REMOVAL

STEPS

10. FRONT NO.1 EXHAUST PIPE

11. GASKET

12. GASKET

13. SEAL RING

14. FRONT NO.2 EXHAUST PIPE

7. GASKET

15. HANGER

17. CENTER UNDER FLOOR HEAT

PROTECTOR

18. FRONT UNDER FLOOR HEAT

PROTECTOR

19.REAR UNDER FLOOR HEAT

PROTECTOR

Page 974 of 1500

EXHAUST PIPE AND MAIN MUFFLER

INTAKE AND EXHAUST15-15

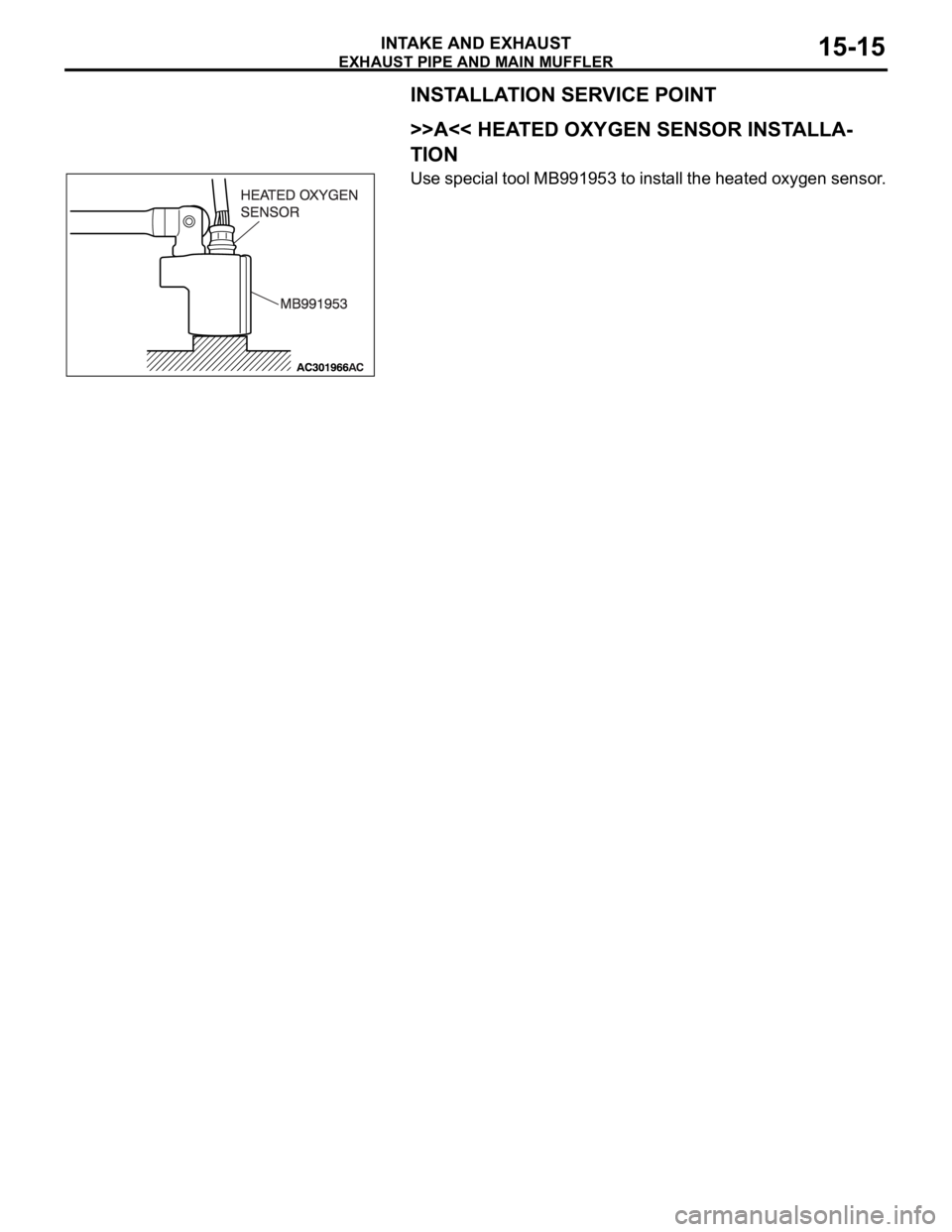

INSTALLATION SERVICE POINT

.

>>A<< HEATED OXYGEN SENSOR INSTALLA-

TION

Use special tool MB991953 to install the heated oxygen sensor.

Page 975 of 1500

SPECIFICATIONS

INTAKE AND EXHAUST15-16

SPECIFICATIONS

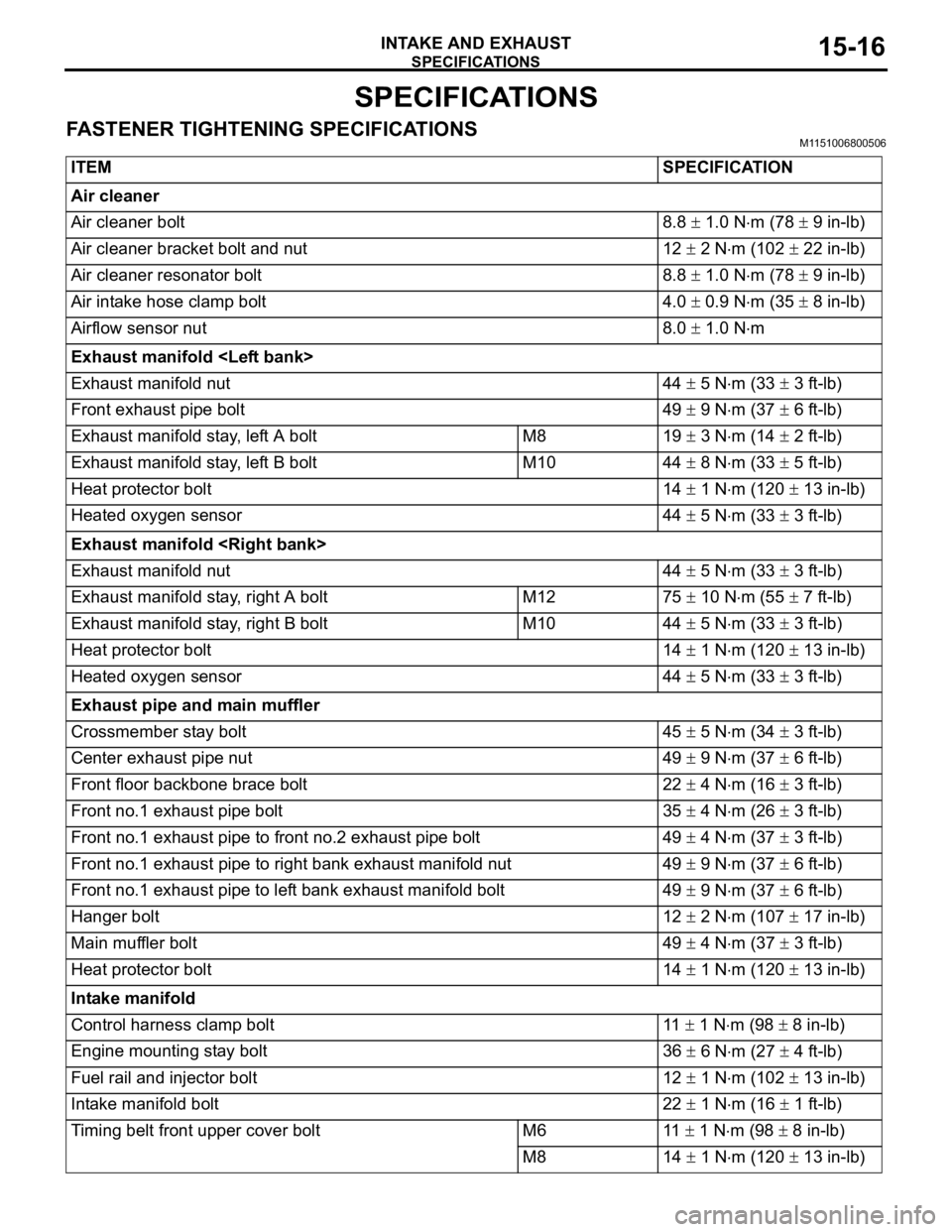

FASTENER TIGHTENING SPECIFICATIONSM1151006800506

ITEMSPECIFICATION

Air cleaner

Air cleaner bolt 8.8

1.0 Nm (78 9 in-lb)

Air cleaner bracket bolt and nut 12

2 Nm (102 22 in-lb)

Air cleaner resonator bolt 8.8

1.0 Nm (78 9 in-lb)

Air intake hose clamp bolt 4.0

0.9 Nm (35 8 in-lb)

Airflow sensor nut 8.0

1.0 Nm

Exhaust manifold

Exhaust manifold nut 44

5 Nm (33 3 ft-lb)

Front exhaust pipe bolt 49

9 Nm (37 6 ft-lb)

Exhaust manifold stay, left A bolt M8 19

3 Nm (14 2 ft-lb)

Exhaust manifold stay, left B bolt M10 44

8 Nm (33 5 ft-lb)

Heat protector bolt 14

1 Nm (120 13 in-lb)

Heated oxygen sensor 44

5 Nm (33 3 ft-lb)

Exhaust manifold

Exhaust manifold nut 44

5 Nm (33 3 ft-lb)

Exhaust manifold stay, right A bolt M12 75

10 Nm (55 7 ft-lb)

Exhaust manifold stay, right B bolt M10 44

5 Nm (33 3 ft-lb)

Heat protector bolt 14

1 Nm (120 13 in-lb)

Heated oxygen sensor 44

5 Nm (33 3 ft-lb)

Exhaust pipe and main muffler

Crossmember stay bolt 45

5 Nm (34 3 ft-lb)

Center exhaust pipe nut 49

9 Nm (37 6 ft-lb)

Front floor backbone brace bolt 22

4 Nm (16 3 ft-lb)

Front no.1 exhaust pipe bolt 35

4 Nm (26 3 ft-lb)

Front no.1 exhaust pipe to front no.2 exhaust pipe bolt 49

4 Nm (37 3 ft-lb)

Front no.1 exhaust pipe to right bank exhaust manifold nut 49

9 Nm (37 6 ft-lb)

Front no.1 exhaust pipe to left bank exhaust manifold bolt 49

9 Nm (37 6 ft-lb)

Hanger bolt 12

2 Nm (107 17 in-lb)

Main muffler bolt 49

4 Nm (37 3 ft-lb)

Heat protector bolt 14

1 Nm (120 13 in-lb)

Intake manifold

Control harness clamp bolt 11

1 Nm (98 8 in-lb)

Engine mounting stay bolt 36

6 Nm (27 4 ft-lb)

Fuel rail and injector bolt 12

1 Nm (102 13 in-lb)

Intake manifold bolt 22

1 Nm (16 1 ft-lb)

Timing belt front upper cover bolt M6 11

1 Nm (98 8 in-lb)

M8 14

1 Nm (120 13 in-lb)

Page 976 of 1500

SPECIFICATIONS

INTAKE AND EXHAUST15-17

Water pump bracket bolt 24 3 Nm (18 2 ft-lb) ITEMSPECIFICATION

Page 977 of 1500

SPECIFICATIONS

INTAKE AND EXHAUST15-18

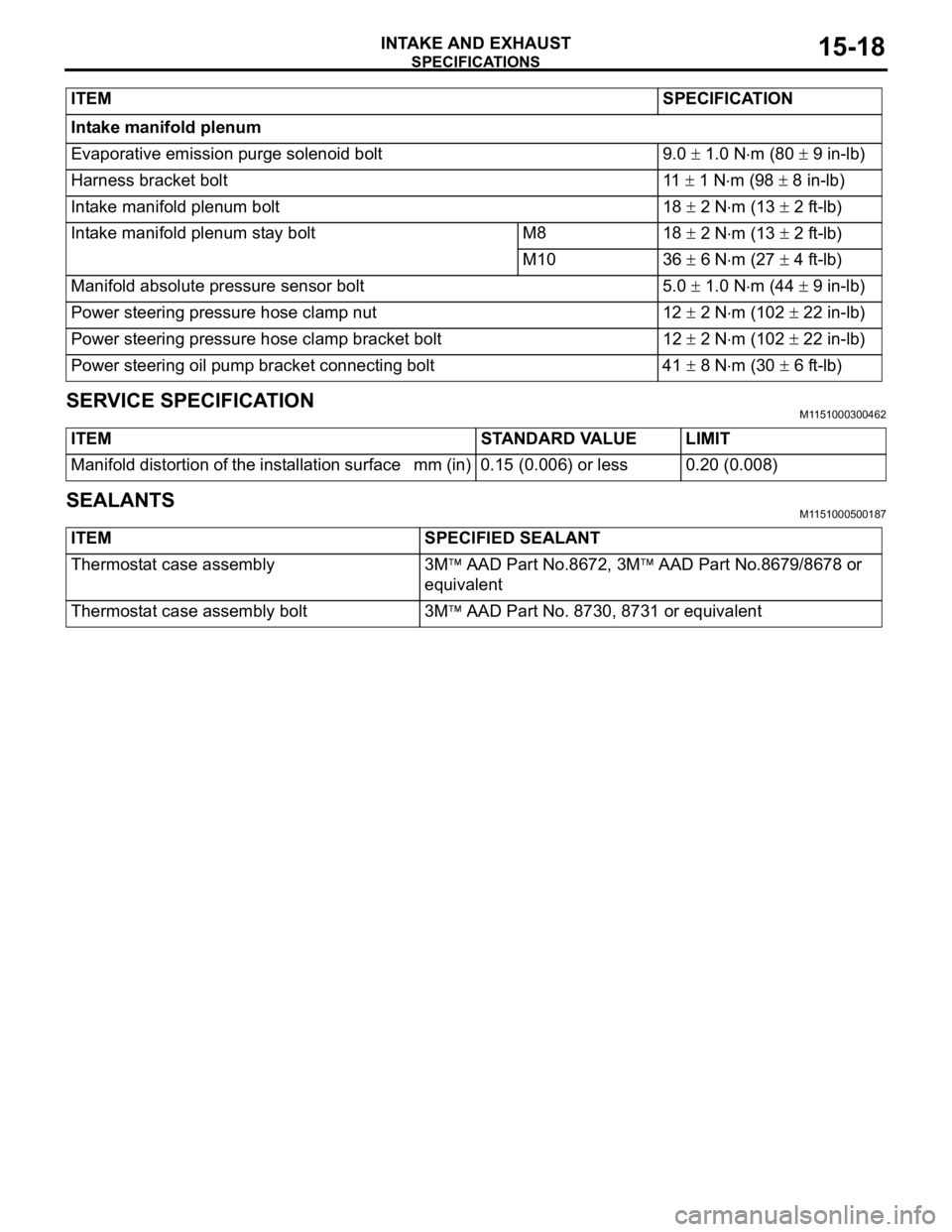

SERVICE SPECIFICATIONM1151000300462

SEALANTSM1151000500187

Intake manifold plenum

Evaporative emission purge solenoid bolt 9.0

1.0 Nm (80 9 in-lb)

Harness bracket bolt 11

1 Nm (98 8 in-lb)

Intake manifold plenum bolt 18

2 Nm (13 2 ft-lb)

Intake manifold plenum stay bolt M8 18

2 Nm (13 2 ft-lb)

M10 36

6 Nm (27 4 ft-lb)

Manifold absolute pressure sensor bolt 5.0

1.0 Nm (44 9 in-lb)

Power steering pressure hose clamp nut 12

2 Nm (102 22 in-lb)

Power steering pressure hose clamp bracket bolt 12

2 Nm (102 22 in-lb)

Power steering oil pump bracket connecting bolt 41

8 Nm (30 6 ft-lb) ITEMSPECIFICATION

ITEM STANDARD VALUE LIMIT

Manifold distortion of the installation surface mm (in) 0.15 (0.006) or less 0.20 (0.008)

ITEM SPECIFIED SEALANT

Thermostat case assembly 3M

AAD Part No.8672, 3M AAD Part No.8679/8678 or

equivalent

Thermostat case assembly bolt 3M

AAD Part No. 8730, 8731 or equivalent

Page 978 of 1500

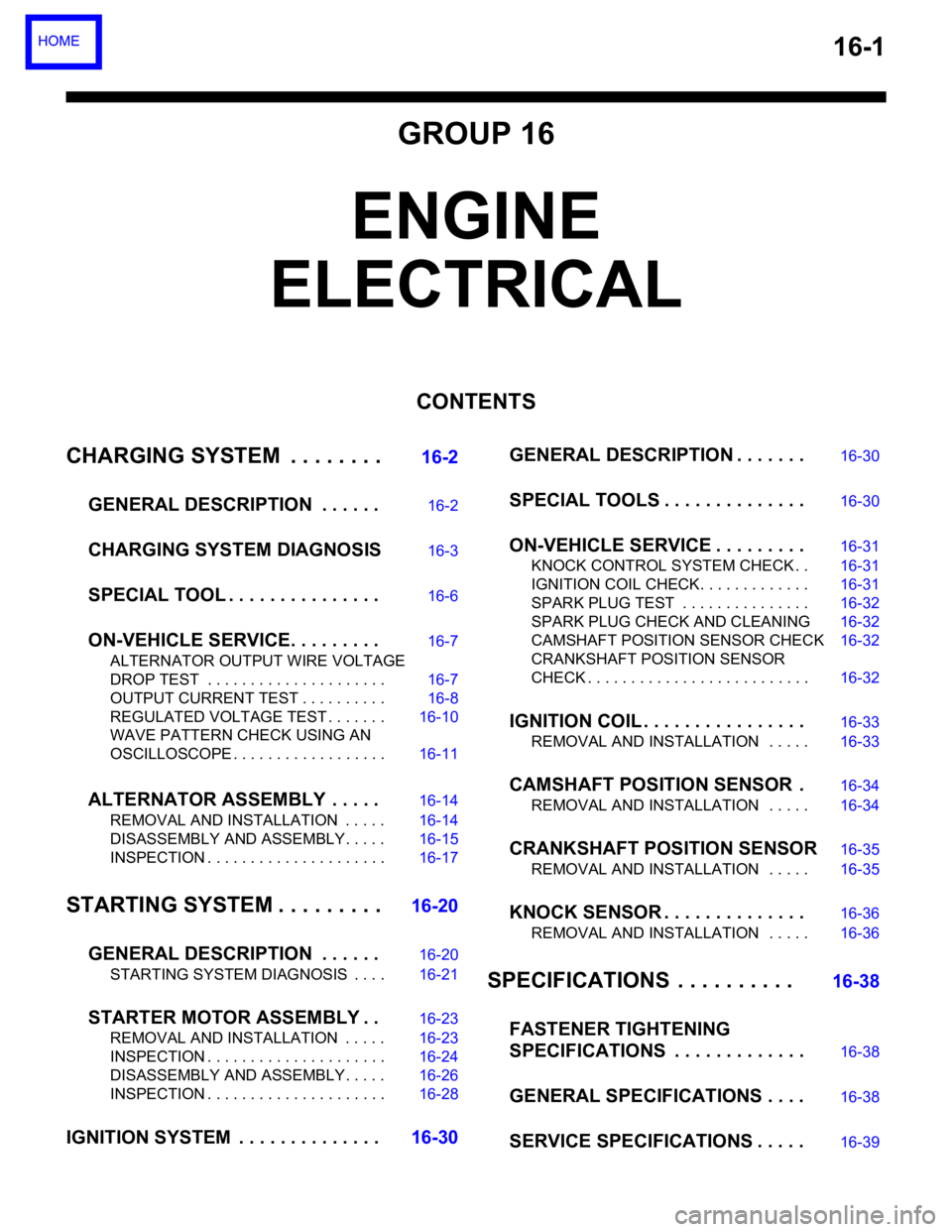

16-1

GROUP 16

ENGINE

ELECTRICAL

CONTENTS

CHARGING SYSTEM . . . . . . . .

16-2

GENERAL DESCRIPTION . . . . . .

16-2

CHARGING SYSTEM DIAGNOSIS16-3

SPECIAL TOOL . . . . . . . . . . . . . . .16-6

ON-VEHICLE SERVICE. . . . . . . . .16-7

ALTERNATOR OUTPUT WIRE VOLTAGE

DROP TEST . . . . . . . . . . . . . . . . . . . . . 16-7

OUTPUT CURRENT TEST . . . . . . . . . . 16-8

REGULATED VOLTAGE TEST . . . . . . . 16-10

WAVE PATTERN CHECK USING AN

OSCILLOSCOPE . . . . . . . . . . . . . . . . . . 16-11

ALTERNATOR ASSEMBLY . . . . .16-14

REMOVAL AND INSTALLATION . . . . . 16-14

DISASSEMBLY AND ASSEMBLY. . . . . 16-15

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-17

STARTING SYSTEM . . . . . . . . .16-20

GENERAL DESCRIPTION . . . . . .

16-20

STARTING SYSTEM DIAGNOSIS . . . . 16-21

STARTER MOTOR ASSEMBLY . .16-23

REMOVAL AND INSTALLATION . . . . . 16-23

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-24

DISASSEMBLY AND ASSEMBLY. . . . . 16-26

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-28

IGNITION SYSTEM . . . . . . . . . . . . . .16-30GENERAL DESCRIPTION . . . . . . .

16-30

SPECIAL TOOLS . . . . . . . . . . . . . .16-30

ON-VEHICLE SERVICE . . . . . . . . .16-31

KNOCK CONTROL SYSTEM CHECK . . 16-31

IGNITION COIL CHECK. . . . . . . . . . . . . 16-31

SPARK PLUG TEST . . . . . . . . . . . . . . . 16-32

SPARK PLUG CHECK AND CLEANING16-32

CAMSHAFT POSITION SENSOR CHECK16-32

CRANKSHAFT POSITION SENSOR

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . 16-32

IGNITION COIL . . . . . . . . . . . . . . . .16-33

REMOVAL AND INSTALLATION . . . . . 16-33

CAMSHAFT POSITION SENSOR .16-34

REMOVAL AND INSTALLATION . . . . . 16-34

CRANKSHAFT POSITION SENSOR16-35

REMOVAL AND INSTALLATION . . . . . 16-35

KNOCK SENSOR . . . . . . . . . . . . . .16-36

REMOVAL AND INSTALLATION . . . . . 16-36

SPECIFICATIONS . . . . . . . . . . 16-38

FASTENER TIGHTENING

SPECIFICATIONS . . . . . . . . . . . . .

16-38

GENERAL SPECIFICATIONS . . . .16-38

SERVICE SPECIFICATIONS . . . . .16-39

Page 979 of 1500

16-2

CHARGING SYSTEM

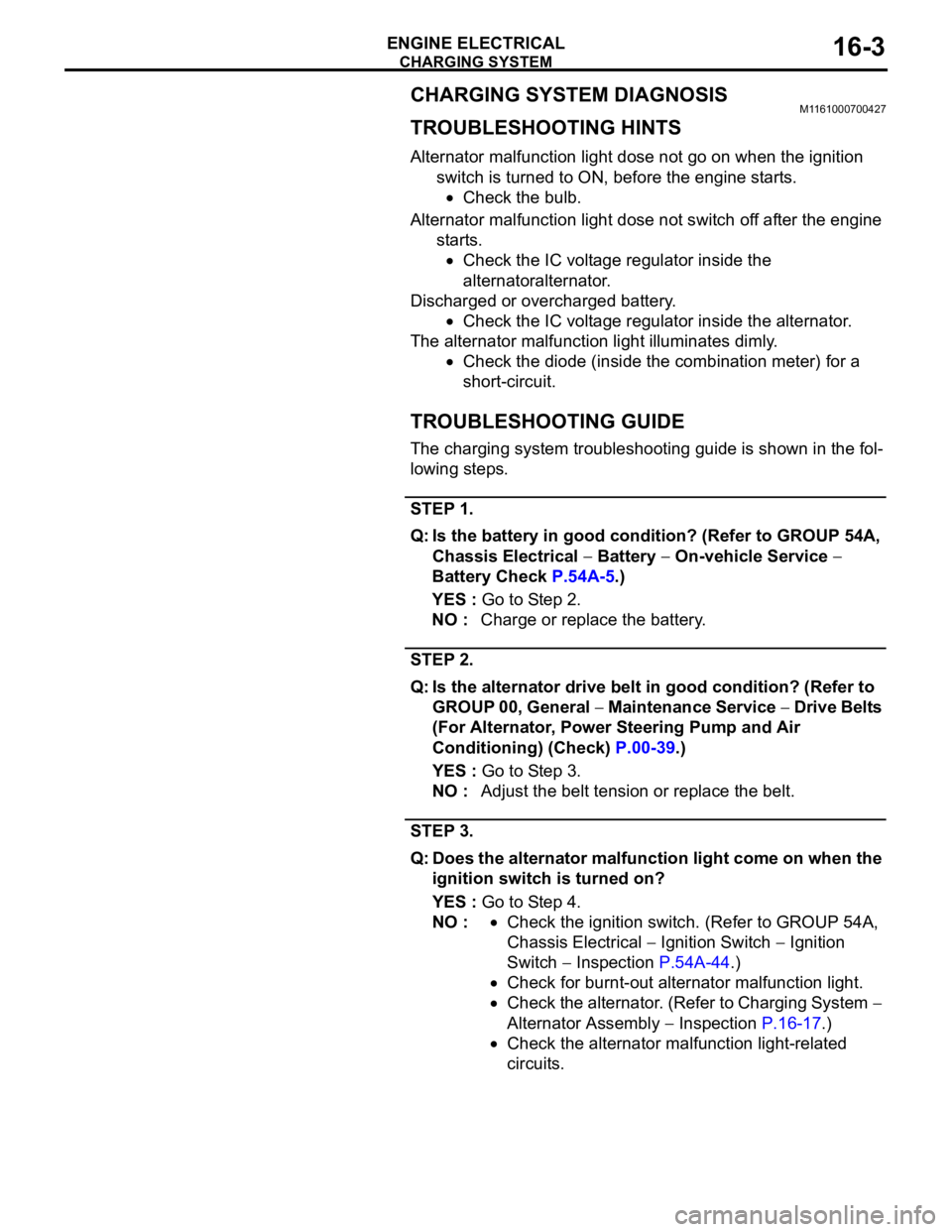

GENERAL DESCRIPTIONM1161000100629

The charging system charges the battery with the

alternator output to keep the battery charged at a

constant level during varying electrical load.

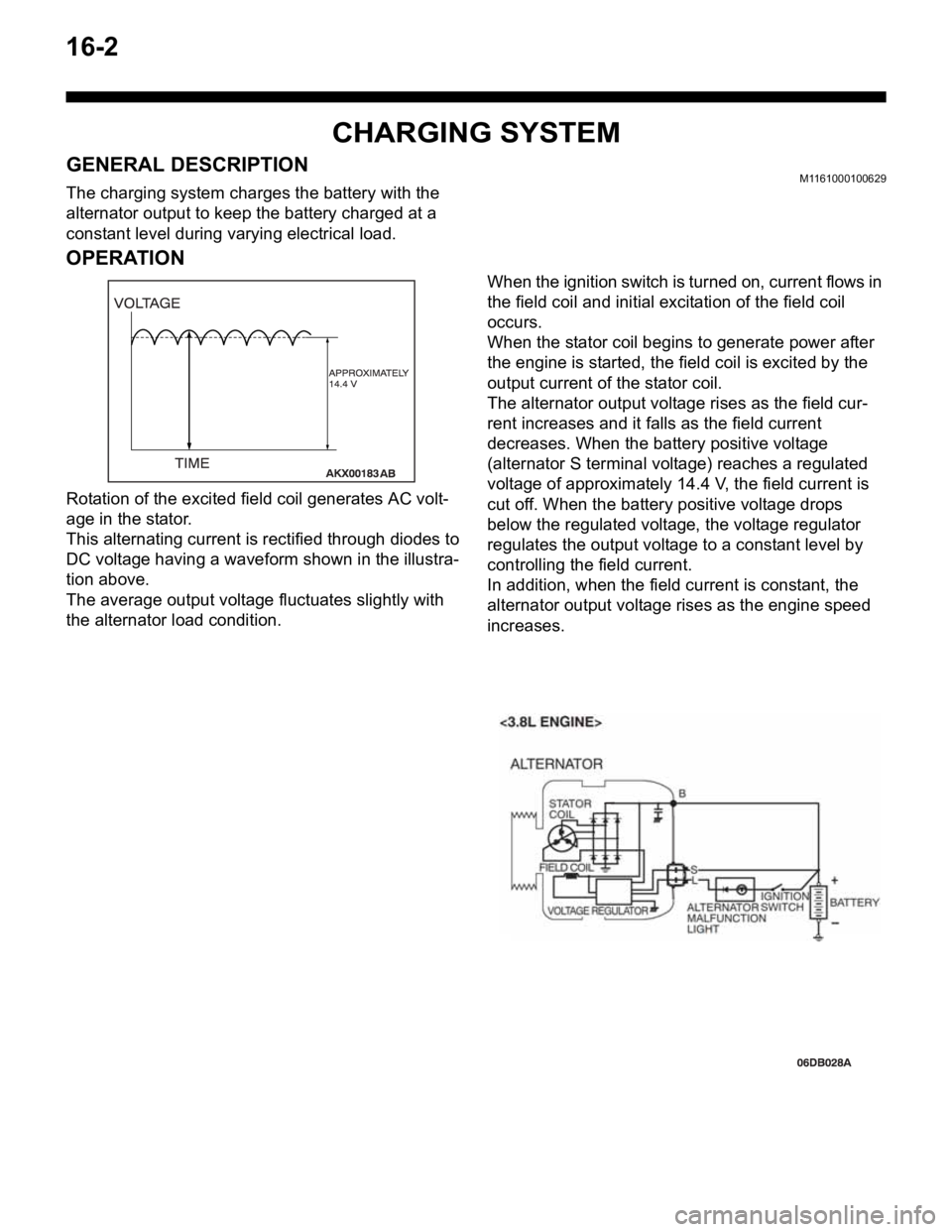

OPERATION

Rotation of the excited field coil generates AC volt-

age in the stator.

This alternating current is rectified through diodes to

DC voltage having a waveform shown in the illustra-

tion above.

The average output voltage fluctuates slightly with

the alternator load condition.When the ignition switch is turned on, current flows in

the field coil and initial excitation of the field coil

occurs.

When the stator coil begins to generate power after

the engine is started, the field coil is excited by the

output current of the stator coil.

The alternator output voltage rises as the field cur-

rent increases and it falls as the field current

decreases. When the battery positive voltage

(alternator S terminal voltage) reaches a regulated

voltage of approximately 14.4 V, the field current is

cut off. When the battery positive voltage drops

below the regulated voltage, the voltage regulator

regulates the output voltage to a constant level by

controlling the field current.

In addition, when the field current is constant, the

alternator output voltage rises as the engine speed

increases.

Page 980 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-3

CHARGING SYSTEM DIAGNOSISM1161000700427

TROUBLESHOOTING HINTS

Alternator malfunction light dose not go on when the ignition

switch is turned to ON, before the engine starts.

Check the bulb.

Alternator malfunction light dose not switch off after the engine

starts.

Check the IC voltage regulator inside the

alternatoralternator.

Discharged or overcharged battery.

Check the IC voltage regulator inside the alternator.

The alternator malfunction light illuminates dimly.

Check the diode (inside the combination meter) for a

short-circuit.

TROUBLESHOOTING GUIDE

The charging system troubleshooting guide is shown in the fol-

lowing steps.

STEP 1.

Q: Is the battery in good condition? (Refer to GROUP 54A,

Chassis Electrical

Battery On-vehicle Service

Battery Check P.54A-5.)

YES : Go to Step 2.

NO : Charge or replace the battery.

STEP 2.

Q: Is the alternator drive belt in good condition? (Refer to

GROUP 00, General

Maintenance Service Drive Belts

(For Alternator, Power Steering Pump and Air

Conditioning) (Check) P.00-39.)

YES : Go to Step 3.

NO : Adjust the belt tension or replace the belt.

STEP 3.

Q: Does the alternator malfunction light come on when the

ignition switch is turned on?

YES : Go to Step 4.

NO :

Check the ignition switch. (Refer to GROUP 54A,

Chassis Electrical

Ignition Switch Ignition

Switch

Inspection P.54A-44.)

Check for burnt-out alternator malfunction light.

Check the alternator. (Refer to Charging System

Alternator Assembly

Inspection P.16-17.)

Check the alternator malfunction light-related

circuits.