MITSUBISHI 380 2005 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 961 of 1500

GENERAL DESCRIPTION

INTAKE AND EXHAUST15-2

GENERAL DESCRIPTIONM1151000100446

The exhaust pipe is divided into four parts.

INTAKE AND EXHAUST DIAGNOSIS

INTRODUCTIONM1151006900321

Intake leaks usually create driveability issues that

are not obviously related to the intake system.

Exhaust leaks or abnormal noise is caused by

cracks, gaskets and fittings, or by exhaust pipe or

muffler damage due to impacts during travel. The

exhaust leaks from these sections and causes the

exhaust noise to increase. There may be cases

when the system contacts the body and vibration

noise is generated.

TROUBLESHOOTING STRATEGYM1151007000321

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will be sure that you

have exhausted most of the possible ways to find an

intake or exhaust system fault.

1. Gather information from the customer.2. Verify that the condition described by the

customer exists.

3. Find the malfunction by following the Symptom

Chart.

4. Verify malfunction is eliminated.

SYMPTOM CHARTM1151007100328

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: Exhaust Leakage

DIAGNOSIS

STEP 1. Start the engine. Have an assistant stay

in the driver’s seat. Raise the vehicle on a hoist.

Have the assistant rev the engine while

searching for exhaust leaks.

Q: Is the exhaust leaking?

YES :

Go to Step 2.

NO : The procedure is complete.

STEP 2. Check the gasket for cracks, damage.

Q: Is the gasket damaged?

YES :

Replace the gasket, then go Step 1.

NO : Go to Step 3.

STEP 3. Check for loose coupling sections.

Q: Are there any loose each sections?

YES :

Tighten, then go to Step 1.

NO : There is no action to be taken. SYMPTOM INSPECTION PROCEDURE REFERENCE PAGE

Exhaust Leakage 1

P.15-2

Abnormal Noise 2

P.15-3

Page 962 of 1500

SPECIAL TOOLS

INTAKE AND EXHAUST15-3

INSPECTION PROCEDURE 2: Abnormal Noise

DIAGNOSIS

STEP 1. Start the engine. Have an assistant stay

in the drivers seat. Raise the vehicle on a hoist.

Have the assistant rev the engine while

searching for exhaust leaks.

Q: Is any abnormal noise generated?

YES :

Go to Step 2.

NO : The procedure is complete.

STEP 2. Check for missing parts in the muffler.

Tap the muffler lightly to check for loose baffles,

etc.

Q: Are there any missing parts in the muffler?

YES :

Replace, then go to Step 1.

NO : Go to Step 3.

STEP 3. Check the hanger for cracks.

Q: Is the hanger cracked?

YES :

Replace, then go to Step 1.

NO : Go to Step 4.

STEP 4. Check for interference of the pipes and

muffler with the body.

Q: Are the pipes and muffler interfering with the

body?

YES :

Repair, then go to Step 1.

NO : Go to Step 5.

STEP 5. Check the heat protectors.

Q: Are any heat protectors loose or damaged?

YES :

Tighten or replace, then go to Step 1.

NO : Go to Step 6.

STEP 6. Check the pipes and muffler for damage.

Q: Are the pipes and muffler damaged?

YES :

Replace, then go to Step 1.

NO : There is no action to be taken.

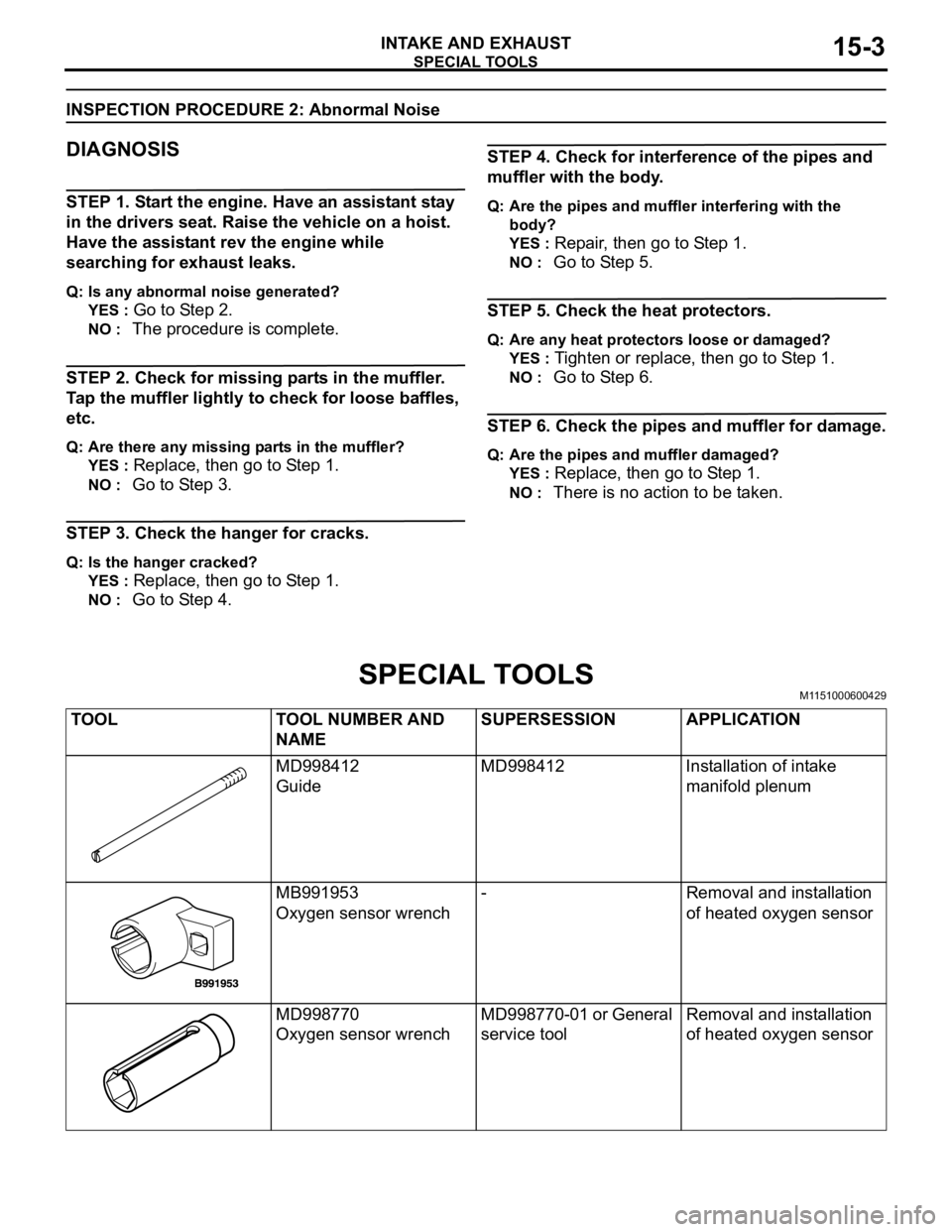

SPECIAL TOOLSM1151000600429

TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

MD998412

GuideMD998412 Installation of intake

manifold plenum

MB991953

Oxygen sensor wrench- Removal and installation

of heated oxygen sensor

MD998770

Oxygen sensor wrenchMD998770-01 or General

service toolRemoval and installation

of heated oxygen sensor

Page 963 of 1500

AIR CLEANER

INTAKE AND EXHAUST15-4

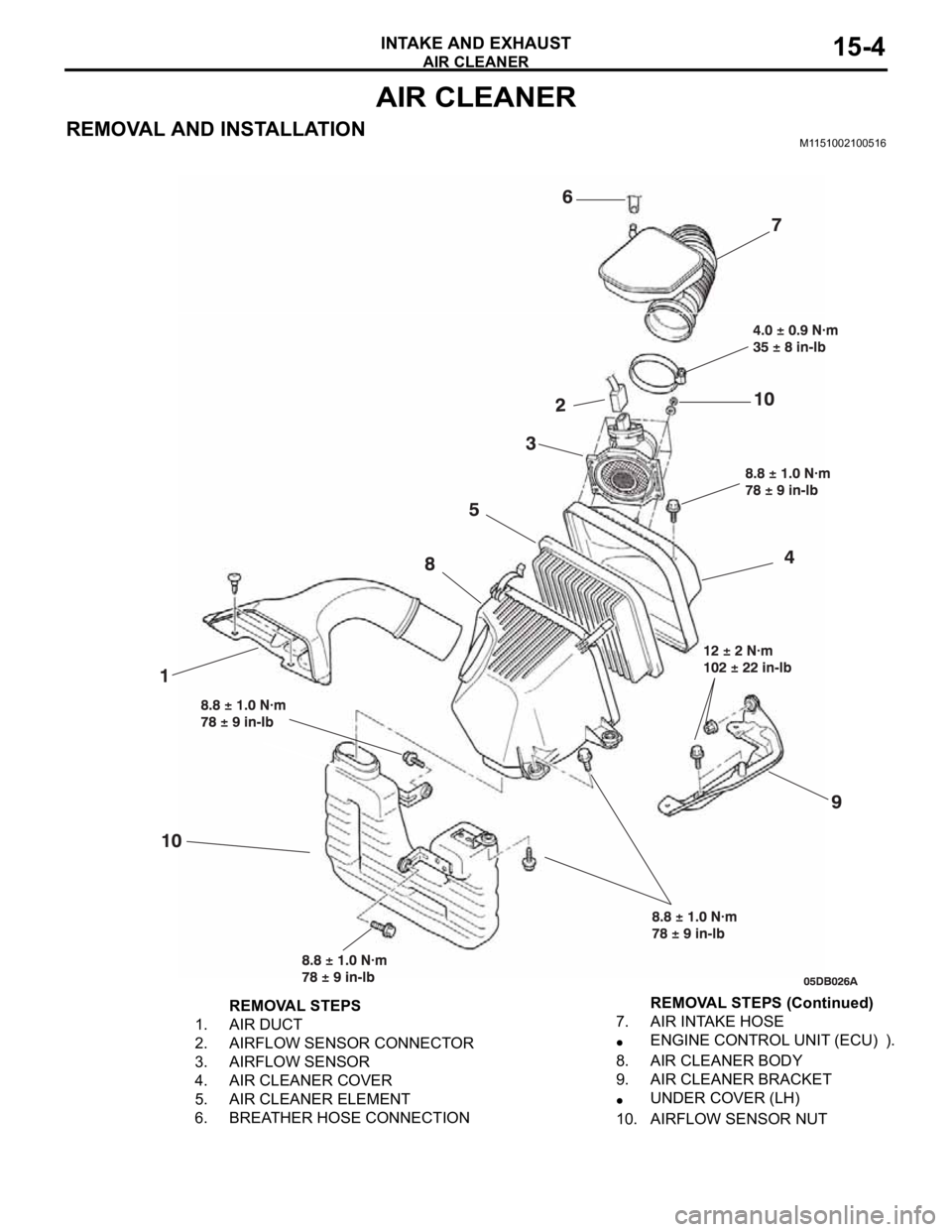

AIR CLEANER

REMOVAL AND INSTALLATIONM1151002100516

REMOVAL STEPS

1. AIR DUCT

2. AIRFLOW SENSOR CONNECTOR

3. AIRFLOW SENSOR

4. AIR CLEANER COVER

5. AIR CLEANER ELEMENT

6. BREATHER HOSE CONNECTION7. AIR INTAKE HOSE

ENGINE CONTROL UNIT (ECU) ).

8. AIR CLEANER BODY

9. AIR CLEANER BRACKET

UNDER COVER (LH)

10. AIRFLOW SENSOR NUTREMOVAL STEPS (Continued)

Page 964 of 1500

INTAKE MANIFOLD PLENUM

INTAKE AND EXHAUST15-5

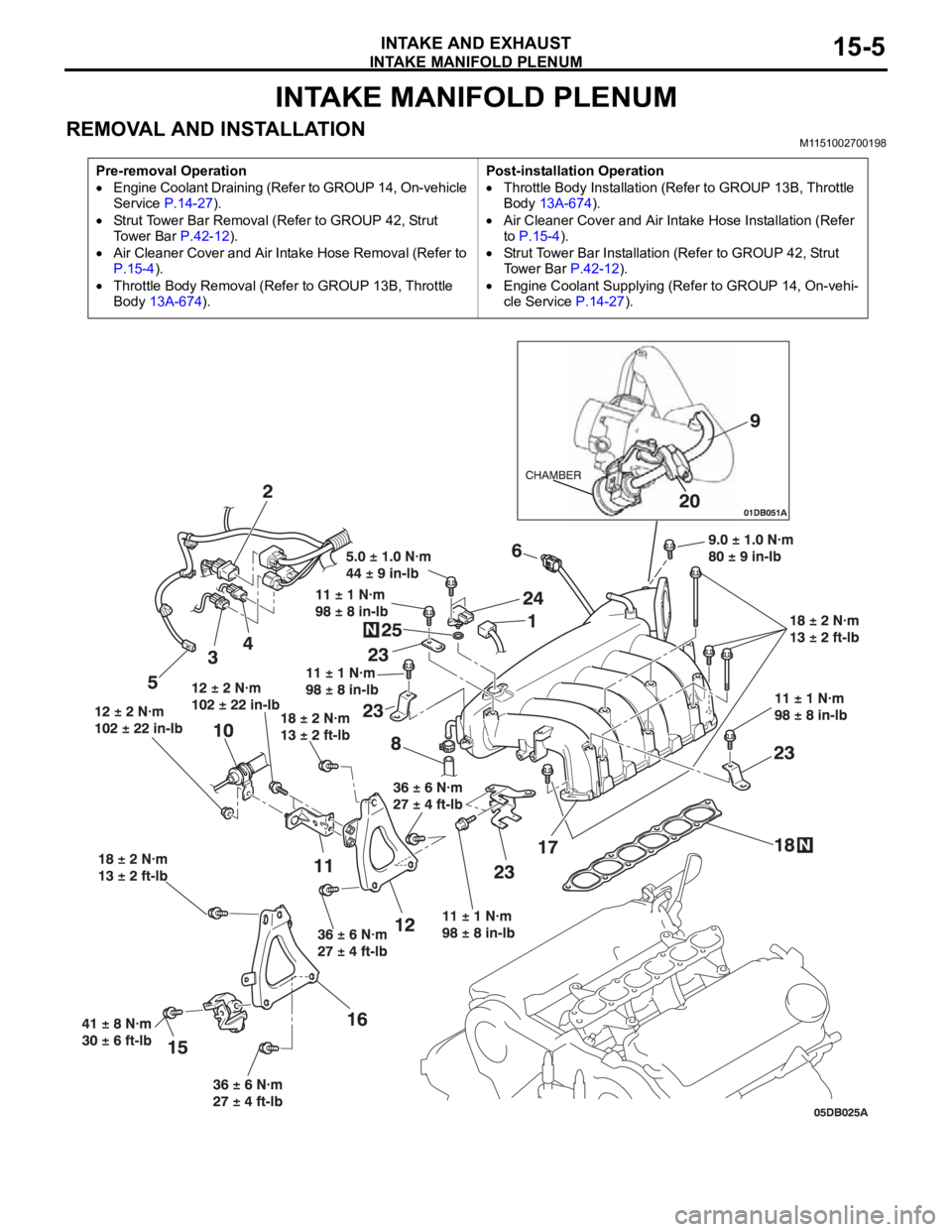

INTAKE MANIFOLD PLENUM

REMOVAL AND INSTALLATION M1151002700198

Pre-removal Operation

Engine Coolant Draining (Refer to GROUP 14, On-vehicle

Service P.14-27).

Strut Tower Bar Removal (Refer to GROUP 42, Strut

To w e r B a r P.42-12).

Air Cleaner Cover and Air Intake Hose Removal (Refer to

P.15-4).

Throttle Body Removal (Refer to GROUP 13B, Throttle

Body 13A-674).Post-installation Operation

Throttle Body Installation (Refer to GROUP 13B, Throttle

Body 13A-674).

Air Cleaner Cover and Air Intake Hose Installation (Refer

to P.15-4).

Strut Tower Bar Installation (Refer to GROUP 42, Strut

Tower Bar P.42-12).

Engine Coolant Supplying (Refer to GROUP 14, On-vehi-

cle Service P.14-27).

Page 965 of 1500

INTAKE MANIFOLD PLENUM

INTAKE AND EXHAUST15-6

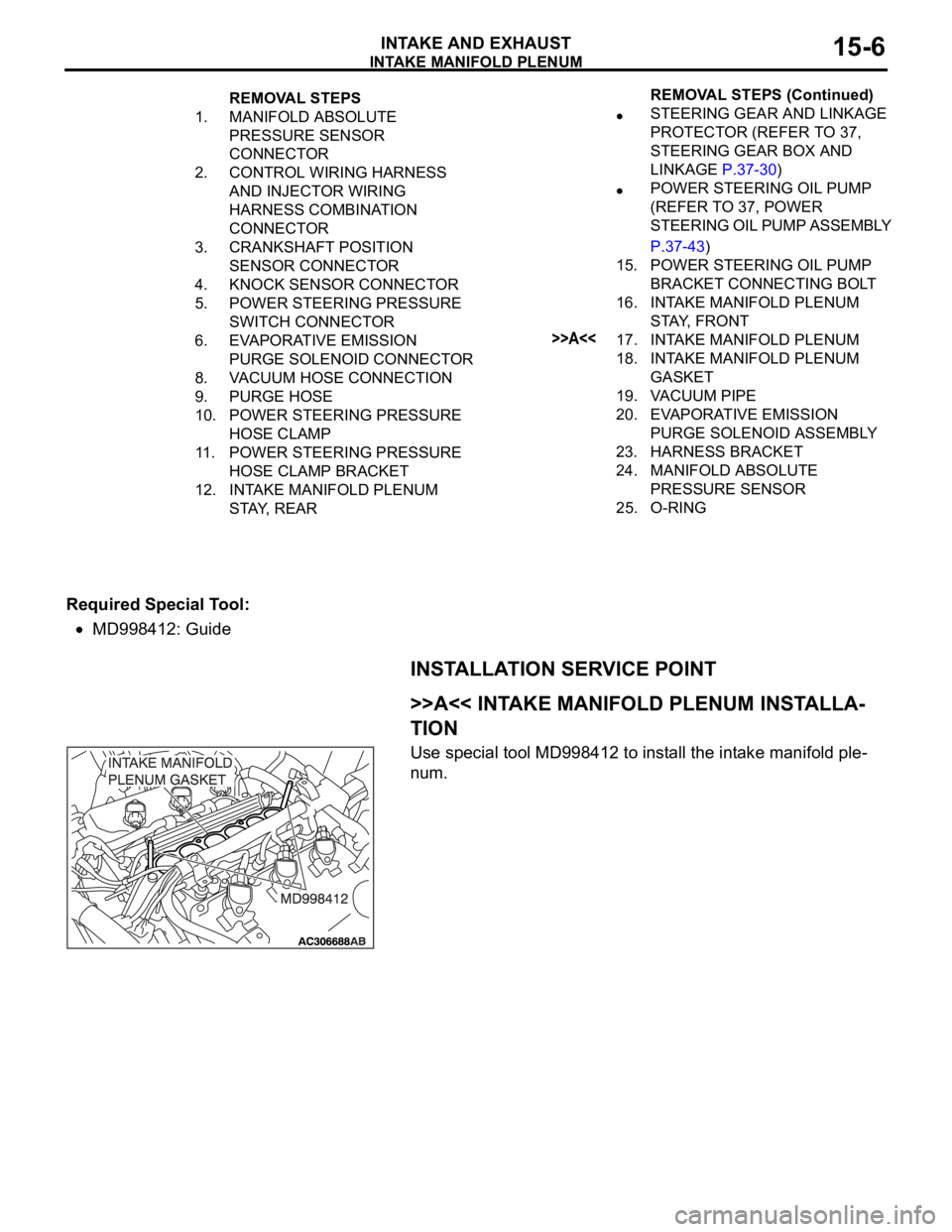

Required Special Tool:

MD998412: Guide

INSTALLATION SERVICE POINT

.

>>A<< INTAKE MANIFOLD PLENUM INSTALLA-

TION

Use special tool MD998412 to install the intake manifold ple-

num.

REMOVAL STEPS

1. MANIFOLD ABSOLUTE

PRESSURE SENSOR

CONNECTOR

2. CONTROL WIRING HARNESS

AND INJECTOR WIRING

HARNESS COMBINATION

CONNECTOR

3. CRANKSHAFT POSITION

SENSOR CONNECTOR

4. KNOCK SENSOR CONNECTOR

5. POWER STEERING PRESSURE

SWITCH CONNECTOR

6. EVAPORATIVE EMISSION

PURGE SOLENOID CONNECTOR

8. VACUUM HOSE CONNECTION

9. PURGE HOSE

10. POWER STEERING PRESSURE

HOSE CLAMP

11. POWER STEERING PRESSURE

HOSE CLAMP BRACKET

12. INTAKE MANIFOLD PLENUM

STAY, REARSTEERING GEAR AND LINKAGE

PROTECTOR (REFER TO 37,

STEERING GEAR BOX AND

LINKAGE P.37-30)

POWER STEERING OIL PUMP

(REFER TO 37, POWER

STEERING OIL PUMP ASSEMBLY

P.37-43)

15. POWER STEERING OIL PUMP

BRACKET CONNECTING BOLT

16. INTAKE MANIFOLD PLENUM

STAY, FRONT

>>A<<17. INTAKE MANIFOLD PLENUM

18. INTAKE MANIFOLD PLENUM

GASKET

19. VACUUM PIPE

20. EVAPORATIVE EMISSION

PURGE SOLENOID ASSEMBLY

23. HARNESS BRACKET

24. MANIFOLD ABSOLUTE

PRESSURE SENSOR

25. O-RINGREMOVAL STEPS (Continued)

Page 966 of 1500

INTAKE MANIFOLD

INTAKE AND EXHAUST15-7

INTAKE MANIFOLD

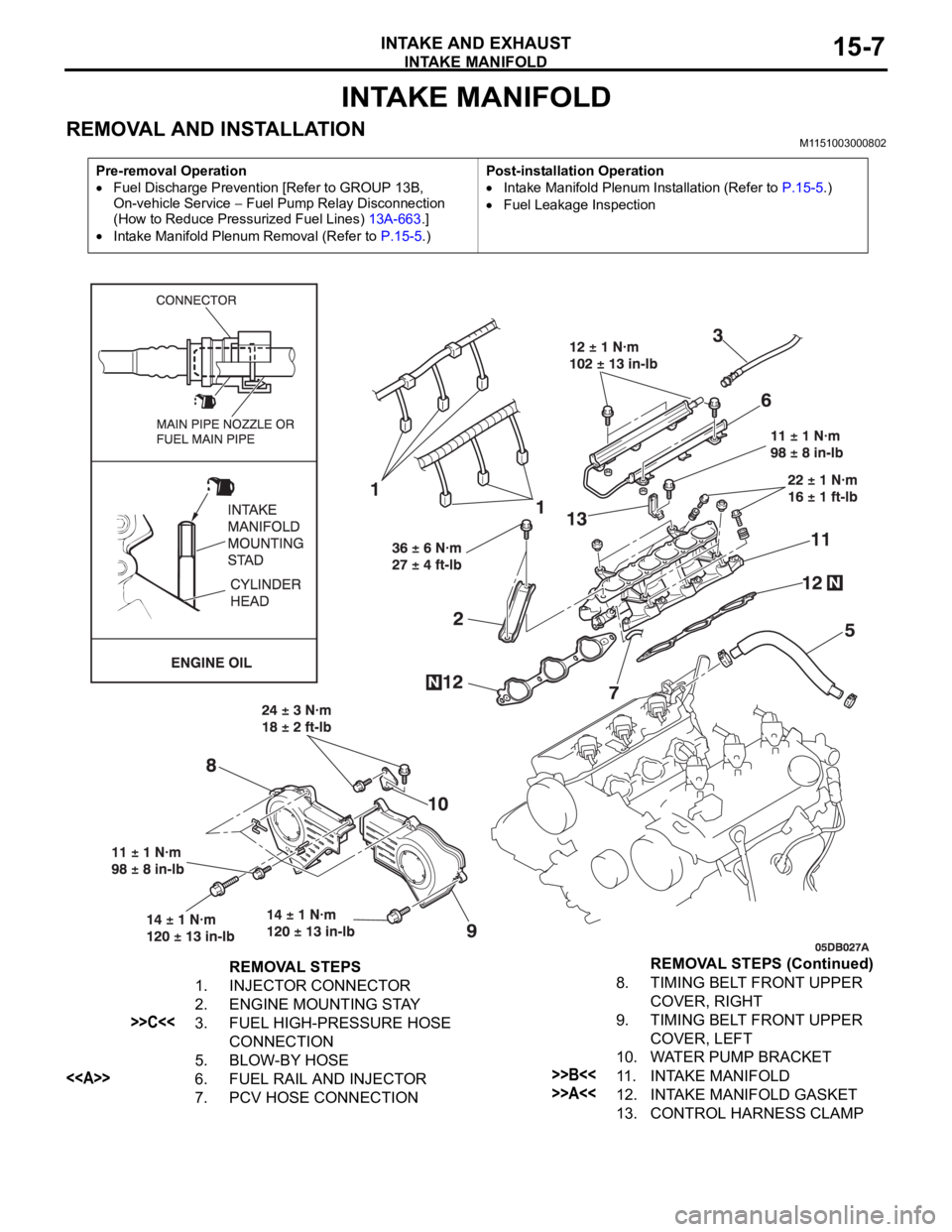

REMOVAL AND INSTALLATION M1151003000802

Pre-removal Operation

Fuel Discharge Prevention [Refer to GROUP 13B,

On-vehicle Service

Fuel Pump Relay Disconnection

(How to Reduce Pressurized Fuel Lines) 13A-663.]

Intake Manifold Plenum Removal (Refer to P.15-5.)Post-installation Operation

Intake Manifold Plenum Installation (Refer to P.15-5.)

Fuel Leakage Inspection

REMOVAL STEPS

1. INJECTOR CONNECTOR

2. ENGINE MOUNTING STAY

>>C<<3. FUEL HIGH-PRESSURE HOSE

CONNECTION

5. BLOW-BY HOSE

<>6. FUEL RAIL AND INJECTOR

7. PCV HOSE CONNECTION8. TIMING BELT FRONT UPPER

COVER, RIGHT

9. TIMING BELT FRONT UPPER

COVER, LEFT

10. WATER PUMP BRACKET>>B<<11. INTAKE MANIFOLD

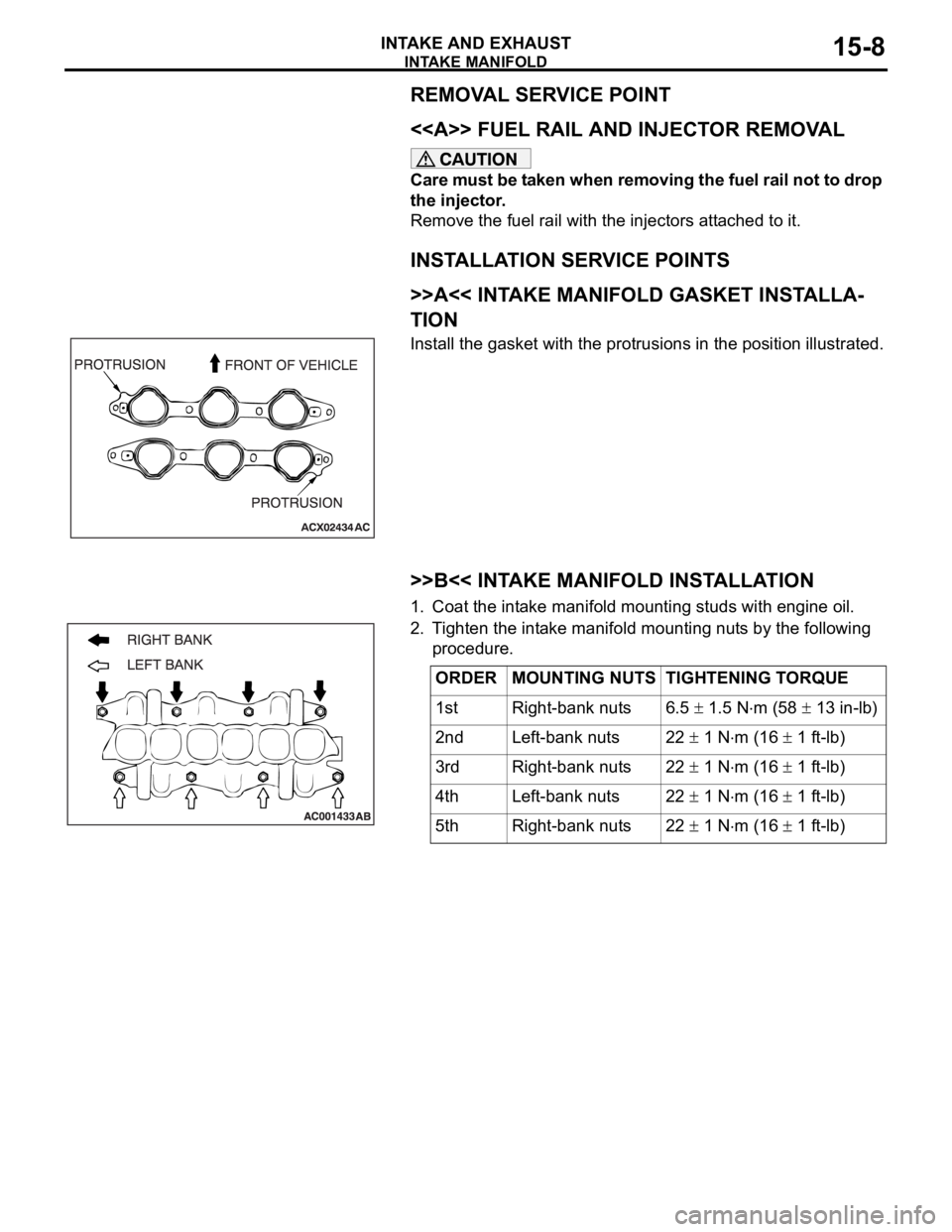

>>A<<12. INTAKE MANIFOLD GASKET

13. CONTROL HARNESS CLAMPREMOVAL STEPS (Continued)

Page 967 of 1500

Page 968 of 1500

INTAKE MANIFOLD

INTAKE AND EXHAUST15-9

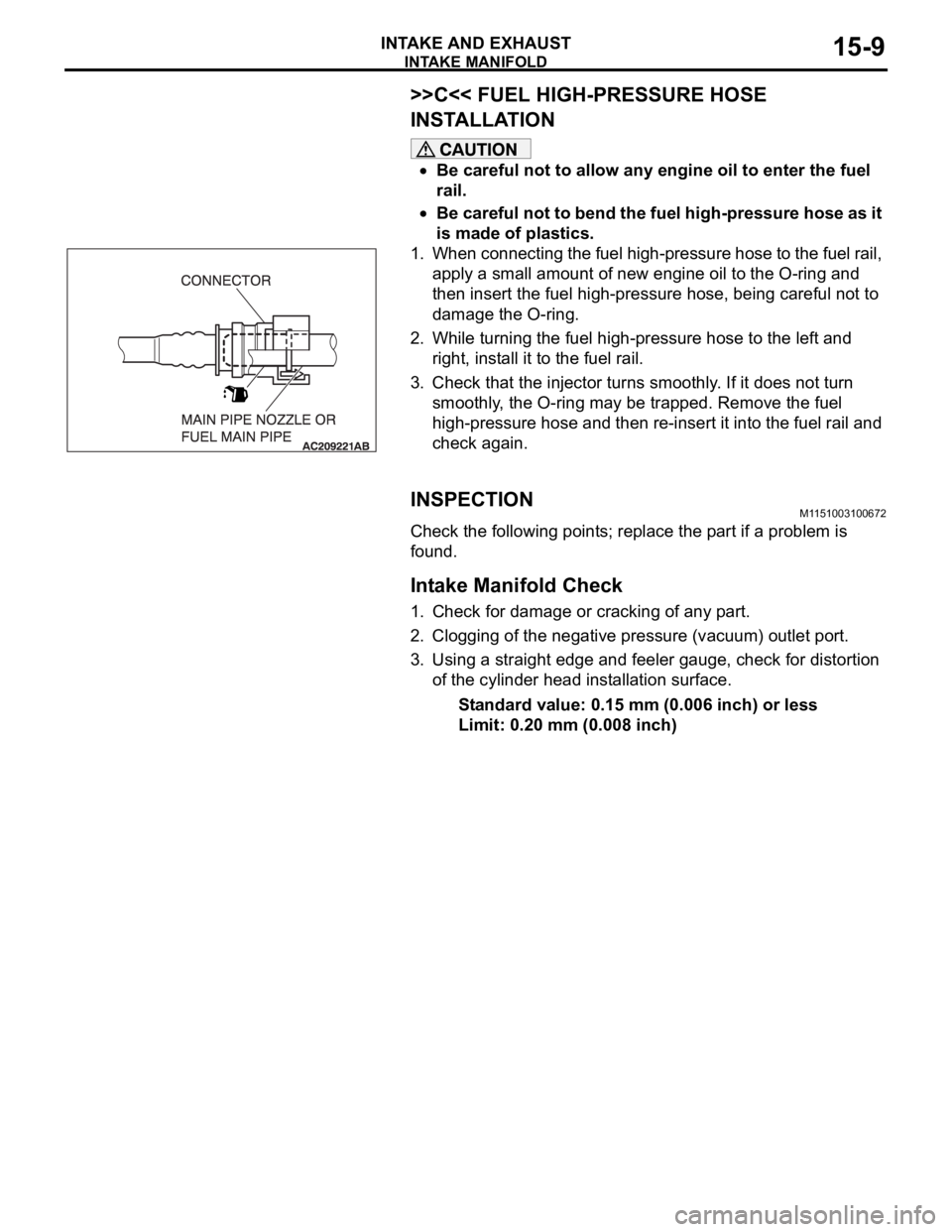

>>C<< FUEL HIGH-PRESSURE HOSE

INSTALLATION

Be careful not to allow any engine oil to enter the fuel

rail.

Be careful not to bend the fuel high-pressure hose as it

is made of plastics.

1. When connecting the fuel high-pressure hose to the fuel rail,

apply a small amount of new engine oil to the O-ring and

then insert the fuel high-pressure hose, being careful not to

damage the O-ring.

2. While turning the fuel high-pressure hose to the left and

right, install it to the fuel rail.

3. Check that the injector turns smoothly. If it does not turn

smoothly, the O-ring may be trapped. Remove the fuel

high-pressure hose and then re-insert it into the fuel rail and

check again.

INSPECTIONM1151003100672

Check the following points; replace the part if a problem is

found.

.

Intake Manifold Check

1. Check for damage or cracking of any part.

2. Clogging of the negative pressure (vacuum) outlet port.

3. Using a straight edge and feeler gauge, check for distortion

of the cylinder head installation surface.

Standard value: 0.15 mm (0.006 inch) or less

Limit: 0.20 mm (0.008 inch)

Page 969 of 1500

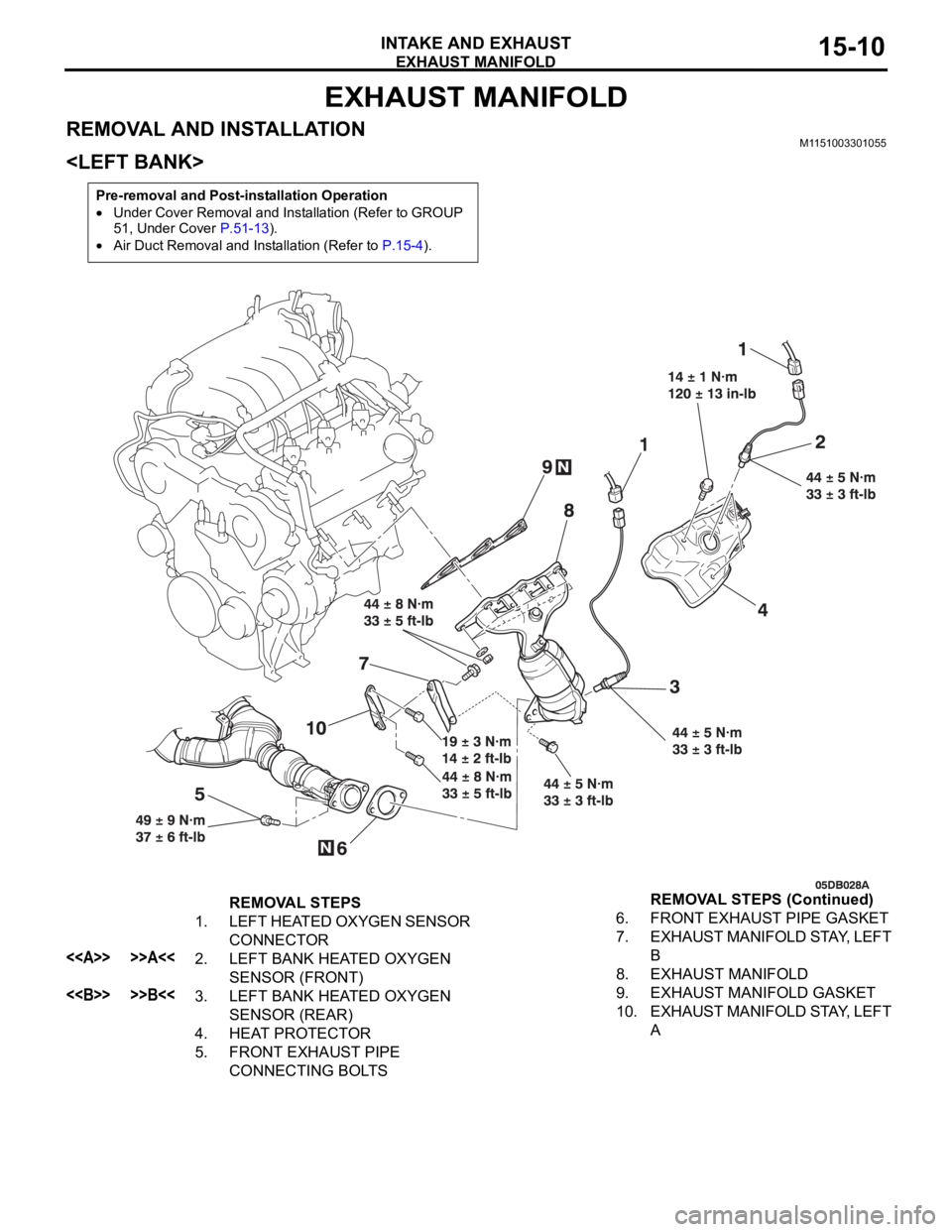

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-10

EXHAUST MANIFOLD

REMOVAL AND INSTALLATION M1151003301055

Pre-removal and Post-installation Operation

Under Cover Removal and Installation (Refer to GROUP

51, Under Cover P.51-13).

Air Duct Removal and Installation (Refer to P.15-4).

REMOVAL STEPS

1. LEFT HEATED OXYGEN SENSOR

CONNECTOR

<> >>A<<2. LEFT BANK HEATED OXYGEN

SENSOR (FRONT)

<> >>B<<3. LEFT BANK HEATED OXYGEN

SENSOR (REAR)

4. HEAT PROTECTOR

5. FRONT EXHAUST PIPE

CONNECTING BOLTS6. FRONT EXHAUST PIPE GASKET

7. EXHAUST MANIFOLD STAY, LEFT

B

8. EXHAUST MANIFOLD

9. EXHAUST MANIFOLD GASKET

10. EXHAUST MANIFOLD STAY, LEFT

A REMOVAL STEPS (Continued)

Page 970 of 1500

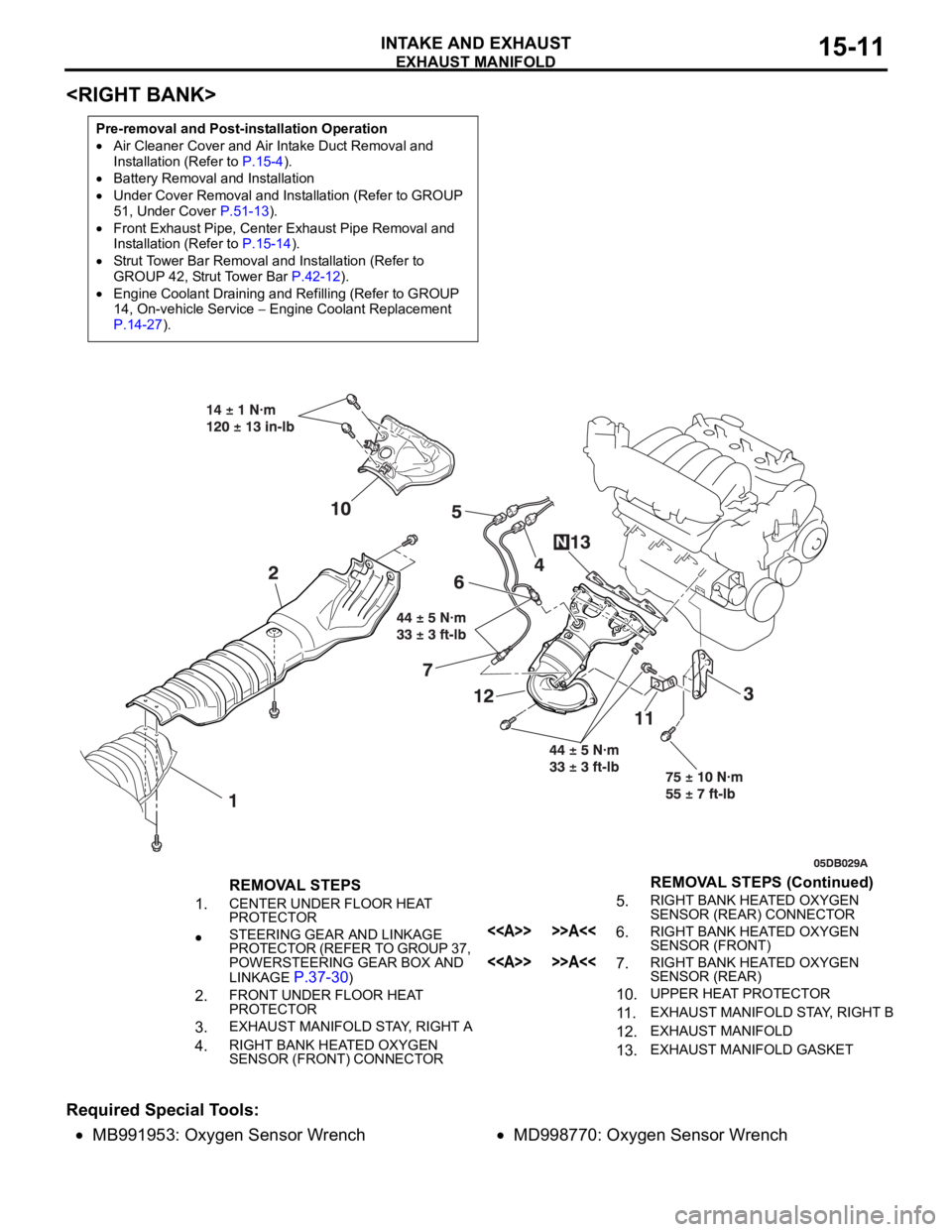

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-11

Required Special Tools:

MB991953: Oxygen Sensor WrenchMD998770: Oxygen Sensor Wrench

Pre-removal and Post-installation Operation

Air Cleaner Cover and Air Intake Duct Removal and

Installation (Refer to P.15-4).

Battery Removal and Installation

Under Cover Removal and Installation (Refer to GROUP

51, Under Cover P.51-13).

Front Exhaust Pipe, Center Exhaust Pipe Removal and

Installation (Refer to P.15-14).

Strut Tower Bar Removal and Installation (Refer to

GROUP 42, Strut Tower Bar P.42-12).

Engine Coolant Draining and Refilling (Refer to GROUP

14, On-vehicle Service Engine Coolant Replacement

P.14-27).

REMOVAL STEPS

1.

CENTER UNDER FLOOR HEAT

PROTECTOR

STEERING GEAR AND LINKAGE

PROTECTOR (REFER TO GROUP 37,

POWERSTEERING GEAR BOX AND

LINKAGE

P.37-30)

2.FRONT UNDER FLOOR HEAT

PROTECTOR

3.EXHAUST MANIFOLD STAY, RIGHT A

4.RIGHT BANK HEATED OXYGEN

SENSOR (FRONT) CONNECTOR

5.RIGHT BANK HEATED OXYGEN

SENSOR (REAR) CONNECTOR

<> >>A<<6.RIGHT BANK HEATED OXYGEN

SENSOR (FRONT)

<> >>A<<7.RIGHT BANK HEATED OXYGEN

SENSOR (REAR)

10.UPPER HEAT PROTECTOR

11 .EXHAUST MANIFOLD STAY, RIGHT B

12.EXHAUST MANIFOLD

13.EXHAUST MANIFOLD GASKET

REMOVAL STEPS (Continued)