Dash MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 550 of 1500

80-1

GROUP 80

CONFIGURATION

DIAGRAMS

CONTENTS

OVERALL CONFIGURATION

DIAGRAM. . . . . . . . . . . . . . . . . . . . . .80-2

HOW TO READ CONFIGURATION

DIAGRAMS . . . . . . . . . . . . . . . . . . . .80-3

ENGINE COMPARTMENT. . . . . . . . .80-4ENGINE AND TRANSMISSION . . . . .80-6

DASH PANEL . . . . . . . . . . . . . . . . . . .80-10

FLOOR, SEAT AND ROOF . . . . . . . .80-17

DOOR . . . . . . . . . . . . . . . . . . . . . . . . .80-23

LUGGAGE COMPARTMENT . . . . . . .80-24

Page 559 of 1500

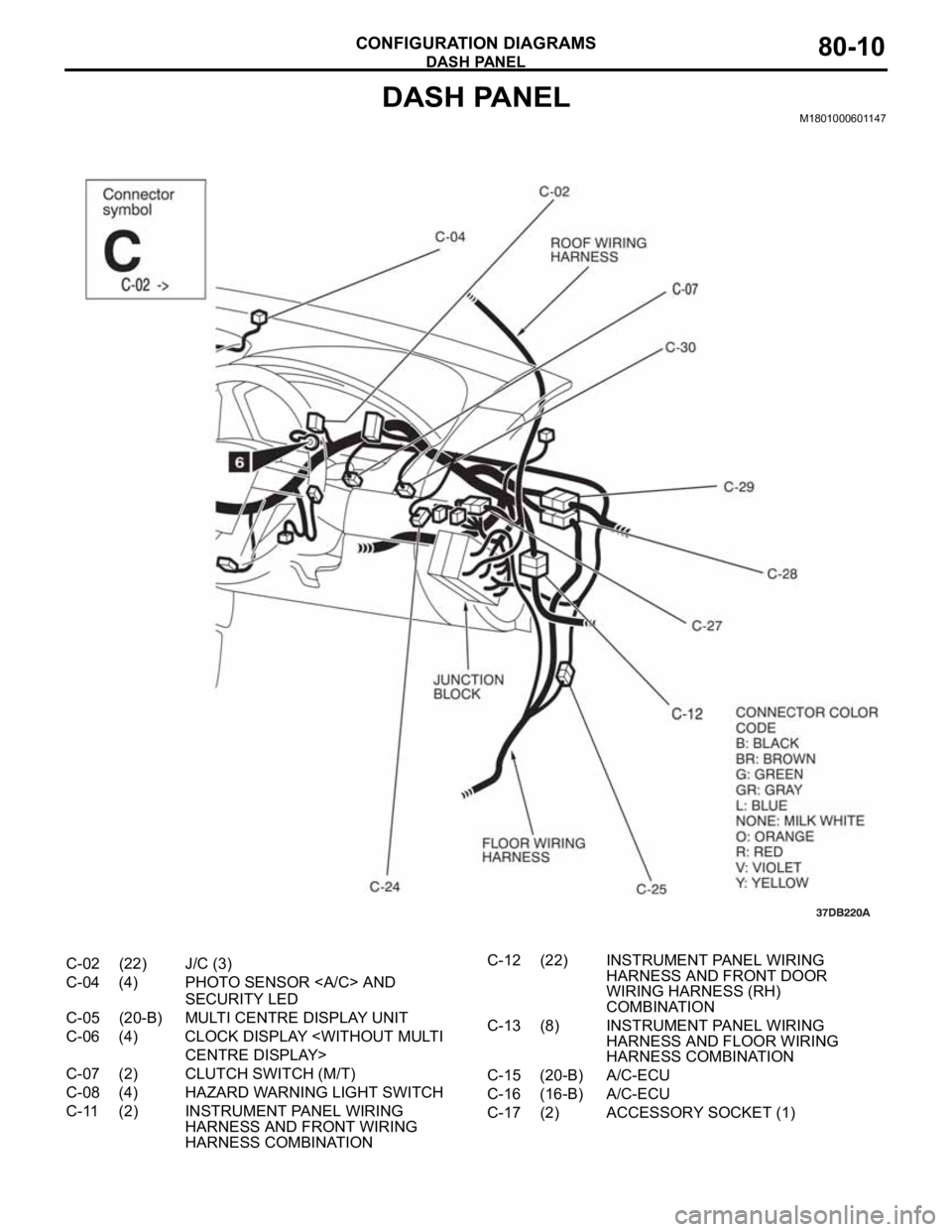

DASH PANEL

CONFIGURATION DIAGRAMS80-10

DASH PANELM1801000601147

C-02 (22) J/C (3)

C-04 (4) PHOTO SENSOR AND

SECURITY LED

C-05 (20-B) MULTI CENTRE DISPLAY UNIT

C-06 (4) CLOCK DISPLAY

C-07 (2) CLUTCH SWITCH (M/T)

C-08 (4) HAZARD WARNING LIGHT SWITCH

C-11 (2) INSTRUMENT PANEL WIRING

HARNESS AND FRONT WIRING

HARNESS COMBINATIONC-12 (22) INSTRUMENT PANEL WIRING

HARNESS AND FRONT DOOR

WIRING HARNESS (RH)

COMBINATION

C-13 (8) INSTRUMENT PANEL WIRING

HARNESS AND FLOOR WIRING

HARNESS COMBINATION

C-15 (20-B) A/C-ECU

C-16 (16-B) A/C-ECU

C-17 (2) ACCESSORY SOCKET (1)

Page 560 of 1500

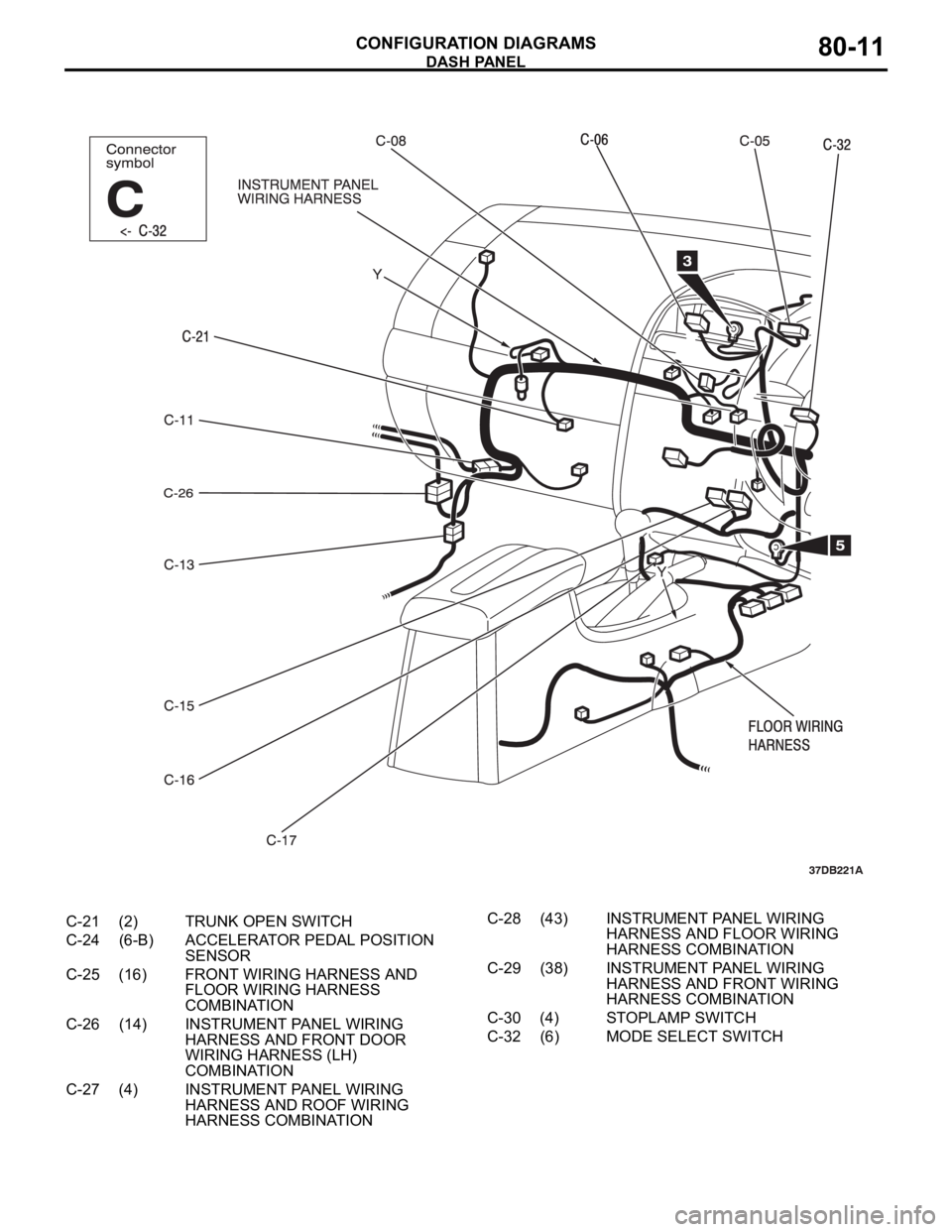

DASH PANEL

CONFIGURATION DIAGRAMS80-11

C-21 (2) TRUNK OPEN SWITCH

C-24 (6-B) ACCELERATOR PEDAL POSITION

SENSOR

C-25 (16) FRONT WIRING HARNESS AND

FLOOR WIRING HARNESS

COMBINATION

C-26 (14) INSTRUMENT PANEL WIRING

HARNESS AND FRONT DOOR

WIRING HARNESS (LH)

COMBINATION

C-27 (4) INSTRUMENT PANEL WIRING

HARNESS AND ROOF WIRING

HARNESS COMBINATIONC-28 (43) INSTRUMENT PANEL WIRING

HARNESS AND FLOOR WIRING

HARNESS COMBINATION

C-29 (38) INSTRUMENT PANEL WIRING

HARNESS AND FRONT WIRING

HARNESS COMBINATION

C-30 (4) STOPLAMP SWITCH

C-32 (6) MODE SELECT SWITCH

Page 561 of 1500

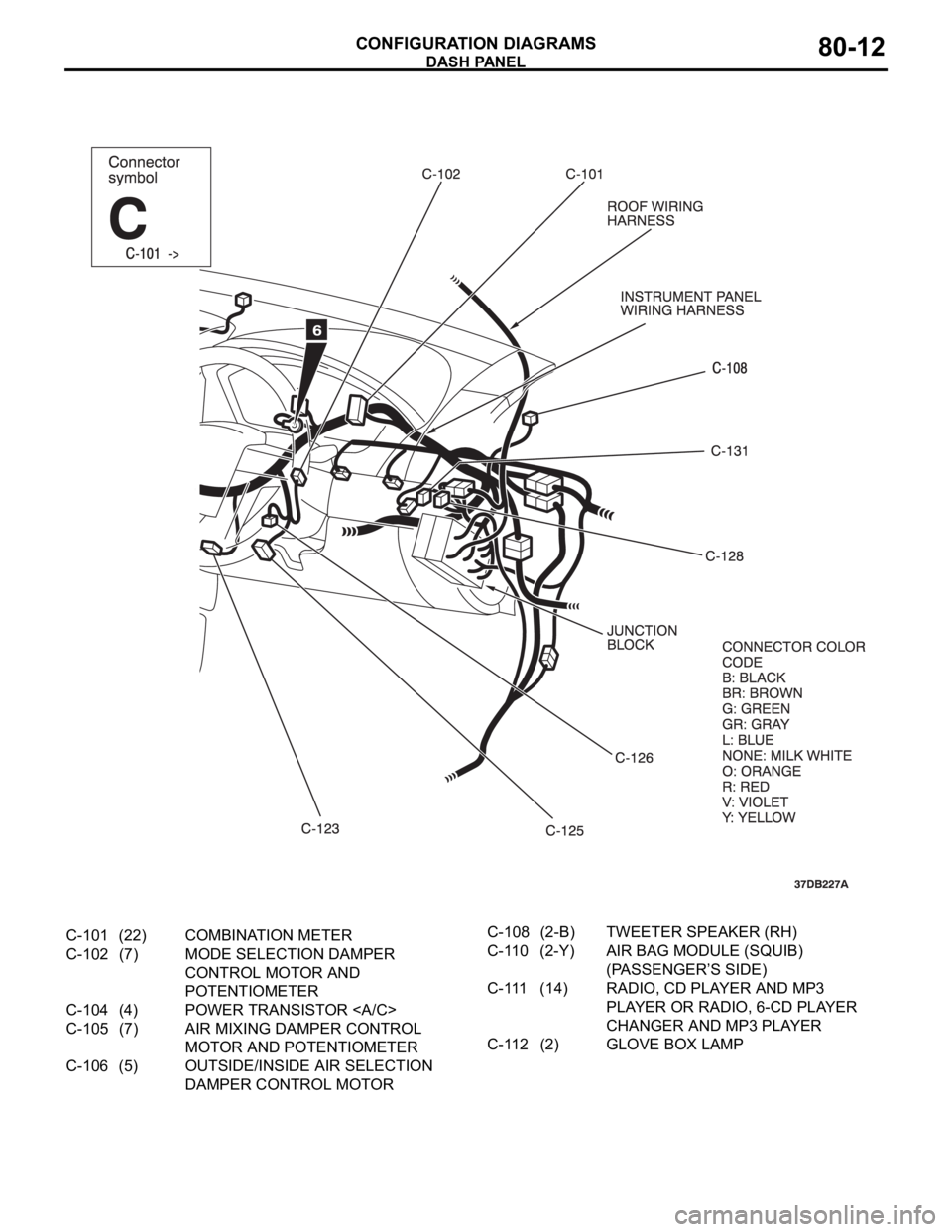

DASH PANEL

CONFIGURATION DIAGRAMS80-12

C-101 (22) COMBINATION METER

C-102 (7) MODE SELECTION DAMPER

CONTROL MOTOR AND

POTENTIOMETER

C-104 (4) POWER TRANSISTOR

C-105 (7) AIR MIXING DAMPER CONTROL

MOTOR AND POTENTIOMETER

C-106 (5) OUTSIDE/INSIDE AIR SELECTION

DAMPER CONTROL MOTORC-108 (2-B) TWEETER SPEAKER (RH)

C-110 (2-Y) AIR BAG MODULE (SQUIB)

(PASSENGER’S SIDE)

C-111 (14) RADIO, CD PLAYER AND MP3

PLAYER OR RADIO, 6-CD PLAYER

CHANGER AND MP3 PLAYER

C-112 (2) GLOVE BOX LAMP

Page 562 of 1500

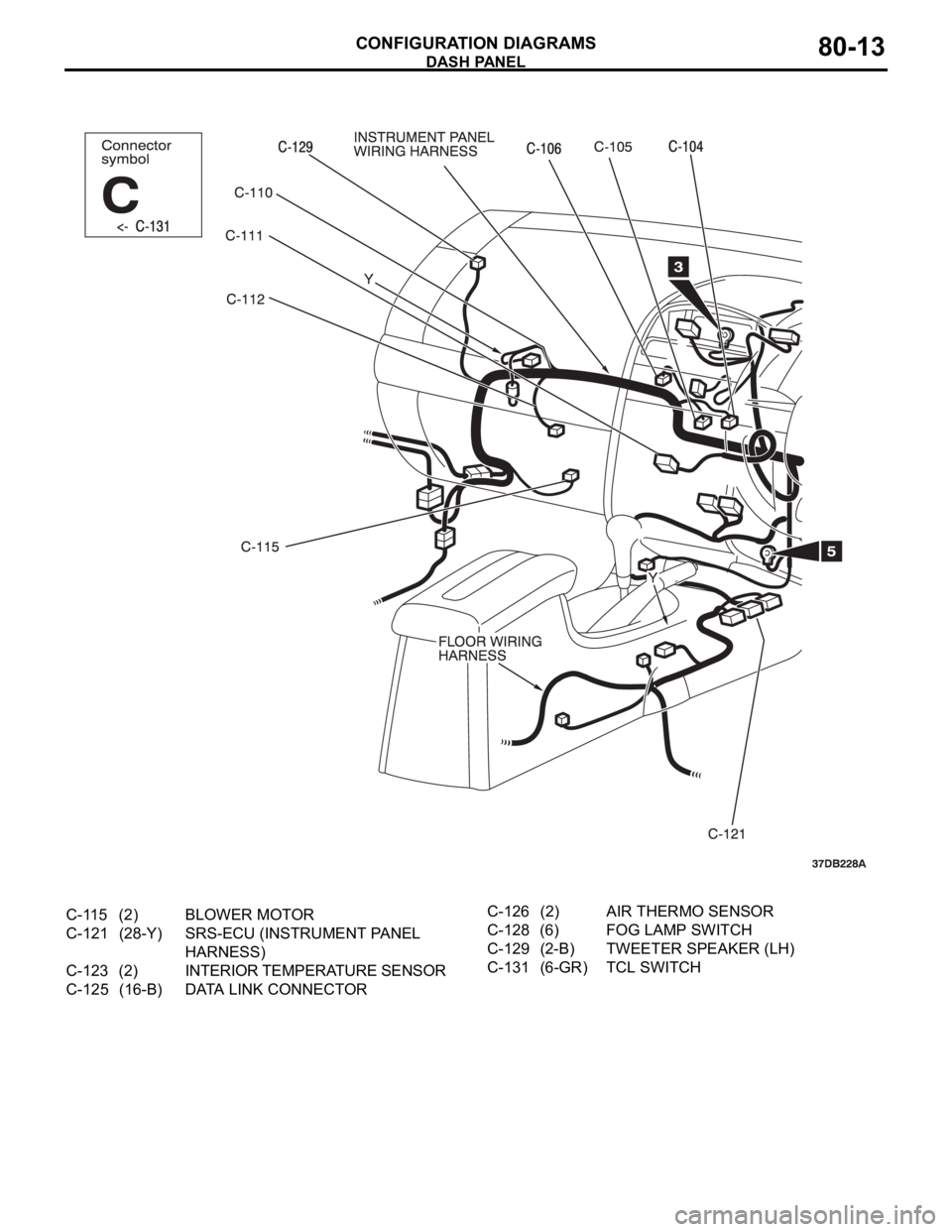

DASH PANEL

CONFIGURATION DIAGRAMS80-13

C-115 (2) BLOWER MOTOR

C-121 (28-Y) SRS-ECU (INSTRUMENT PANEL

HARNESS)

C-123 (2) INTERIOR TEMPERATURE SENSOR

C-125 (16-B) DATA LINK CONNECTORC-126 (2) AIR THERMO SENSOR

C-128 (6) FOG LAMP SWITCH

C-129 (2-B) TWEETER SPEAKER (LH)

C-131 (6-GR) TCL SWITCH

Page 563 of 1500

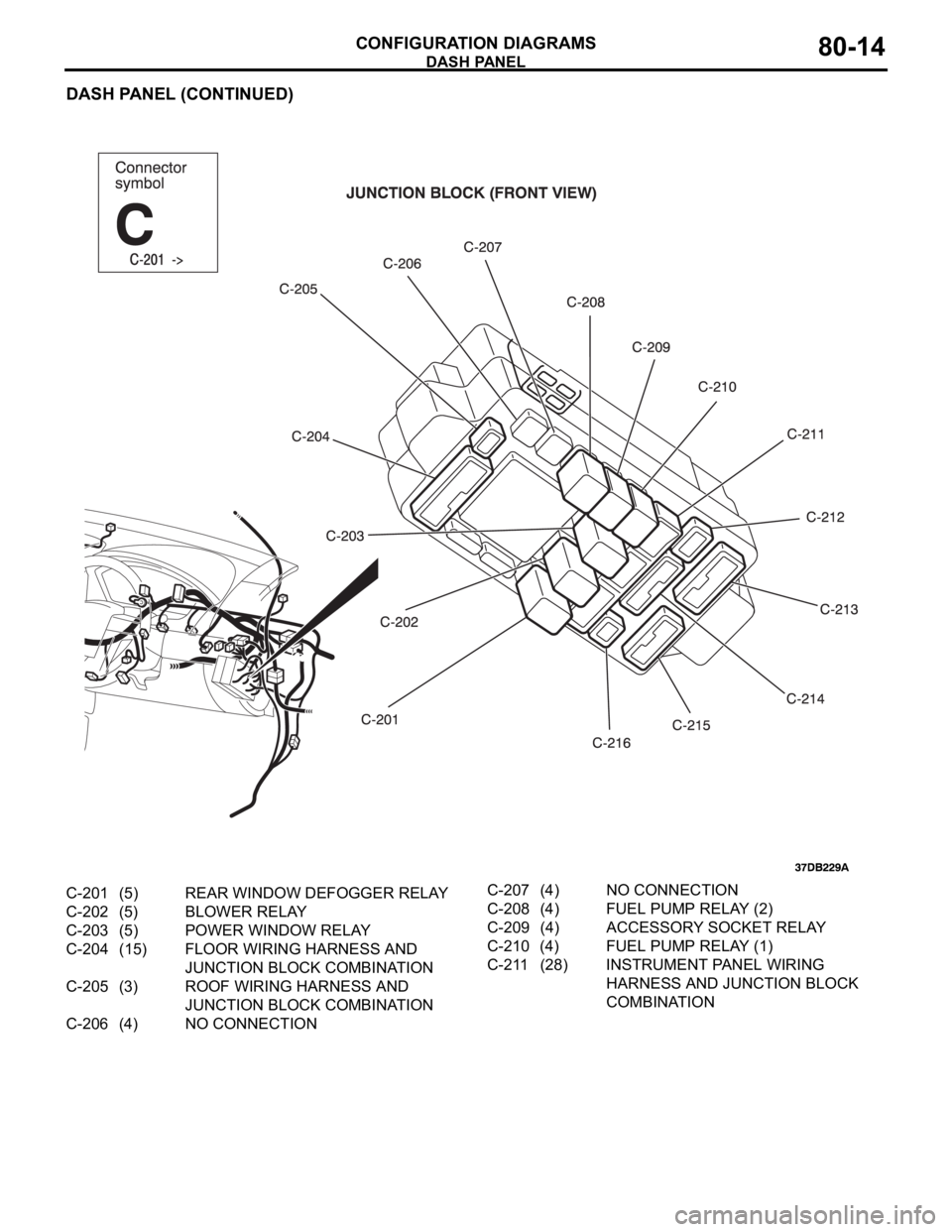

DASH PANEL

CONFIGURATION DIAGRAMS80-14

DASH PANEL (CONTINUED)

C-201 (5) REAR WINDOW DEFOGGER RELAY

C-202 (5) BLOWER RELAY

C-203 (5) POWER WINDOW RELAY

C-204 (15) FLOOR WIRING HARNESS AND

JUNCTION BLOCK COMBINATION

C-205 (3) ROOF WIRING HARNESS AND

JUNCTION BLOCK COMBINATION

C-206 (4) NO CONNECTIONC-207 (4) NO CONNECTION

C-208 (4) FUEL PUMP RELAY (2)

C-209 (4) ACCESSORY SOCKET RELAY

C-210 (4) FUEL PUMP RELAY (1)

C-211 (28) INSTRUMENT PANEL WIRING

HARNESS AND JUNCTION BLOCK

COMBINATION

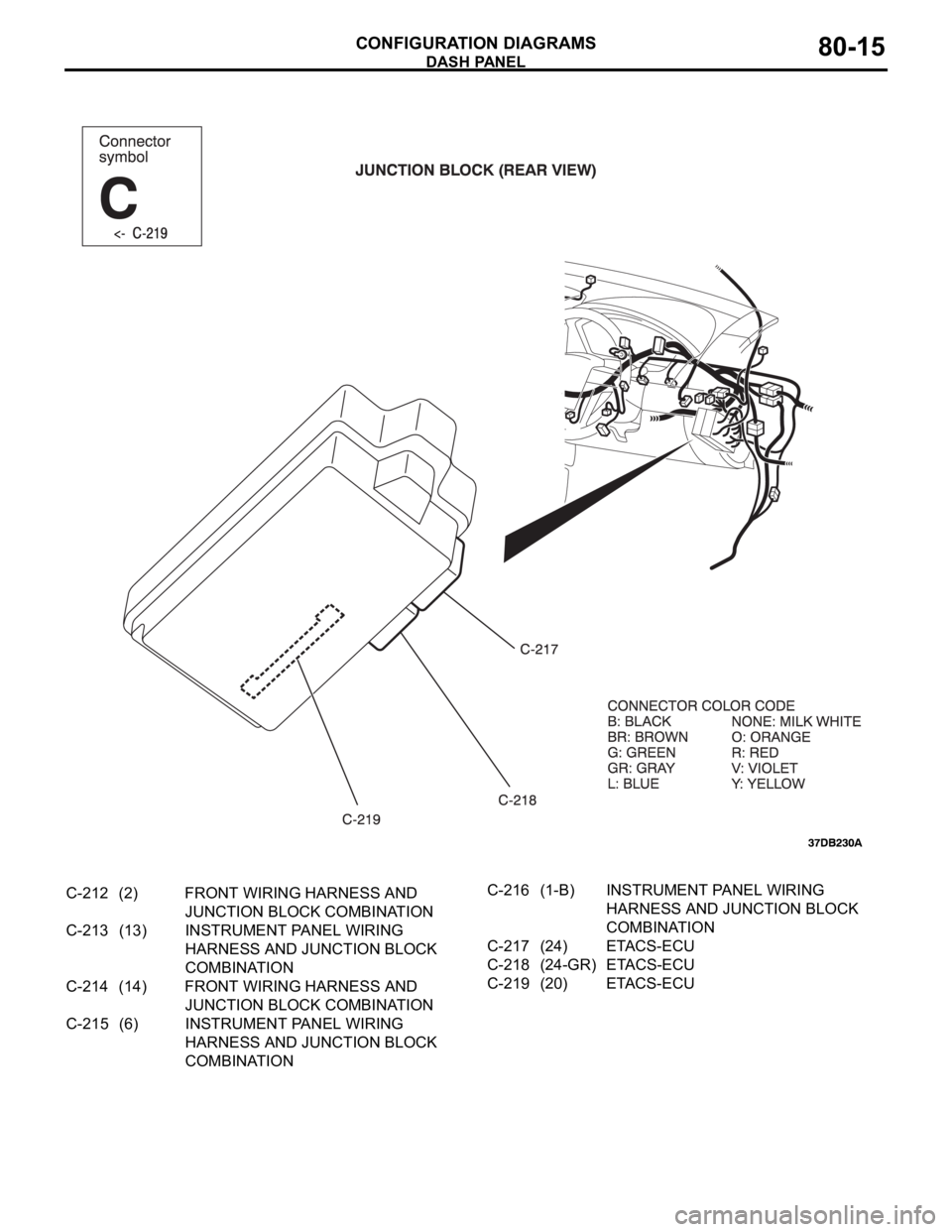

Page 564 of 1500

DASH PANEL

CONFIGURATION DIAGRAMS80-15

C-212 (2) FRONT WIRING HARNESS AND

JUNCTION BLOCK COMBINATION

C-213 (13) INSTRUMENT PANEL WIRING

HARNESS AND JUNCTION BLOCK

COMBINATION

C-214 (14) FRONT WIRING HARNESS AND

JUNCTION BLOCK COMBINATION

C-215 (6) INSTRUMENT PANEL WIRING

HARNESS AND JUNCTION BLOCK

COMBINATIONC-216 (1-B) INSTRUMENT PANEL WIRING

HARNESS AND JUNCTION BLOCK

COMBINATION

C-217 (24) ETACS-ECU

C-218 (24-GR) ETACS-ECU

C-219 (20) ETACS-ECU

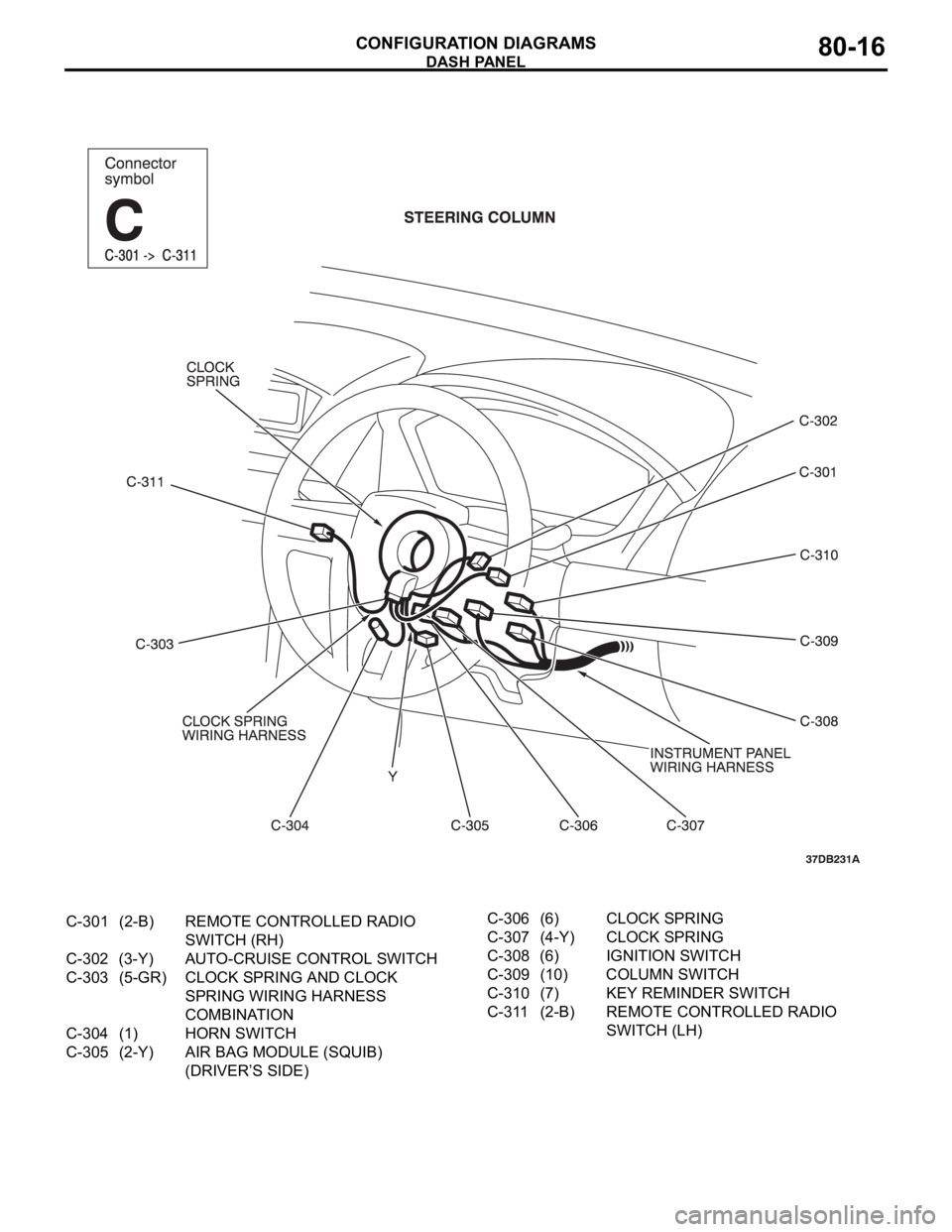

Page 565 of 1500

DASH PANEL

CONFIGURATION DIAGRAMS80-16

C-301 (2-B) REMOTE CONTROLLED RADIO

SWITCH (RH)

C-302 (3-Y) AUTO-CRUISE CONTROL SWITCH

C-303 (5-GR) CLOCK SPRING AND CLOCK

SPRING WIRING HARNESS

COMBINATION

C-304 (1) HORN SWITCH

C-305 (2-Y) AIR BAG MODULE (SQUIB)

(DRIVER’S SIDE)C-306 (6) CLOCK SPRING

C-307 (4-Y) CLOCK SPRING

C-308 (6) IGNITION SWITCH

C-309 (10) COLUMN SWITCH

C-310 (7) KEY REMINDER SWITCH

C-311 (2-B) REMOTE CONTROLLED RADIO

SWITCH (LH)

Page 1178 of 1500

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM35A-13

ON-VEHICLE SERVICE

BRAKE PEDAL CHECK AND ADJUSTMENTM1351000900446

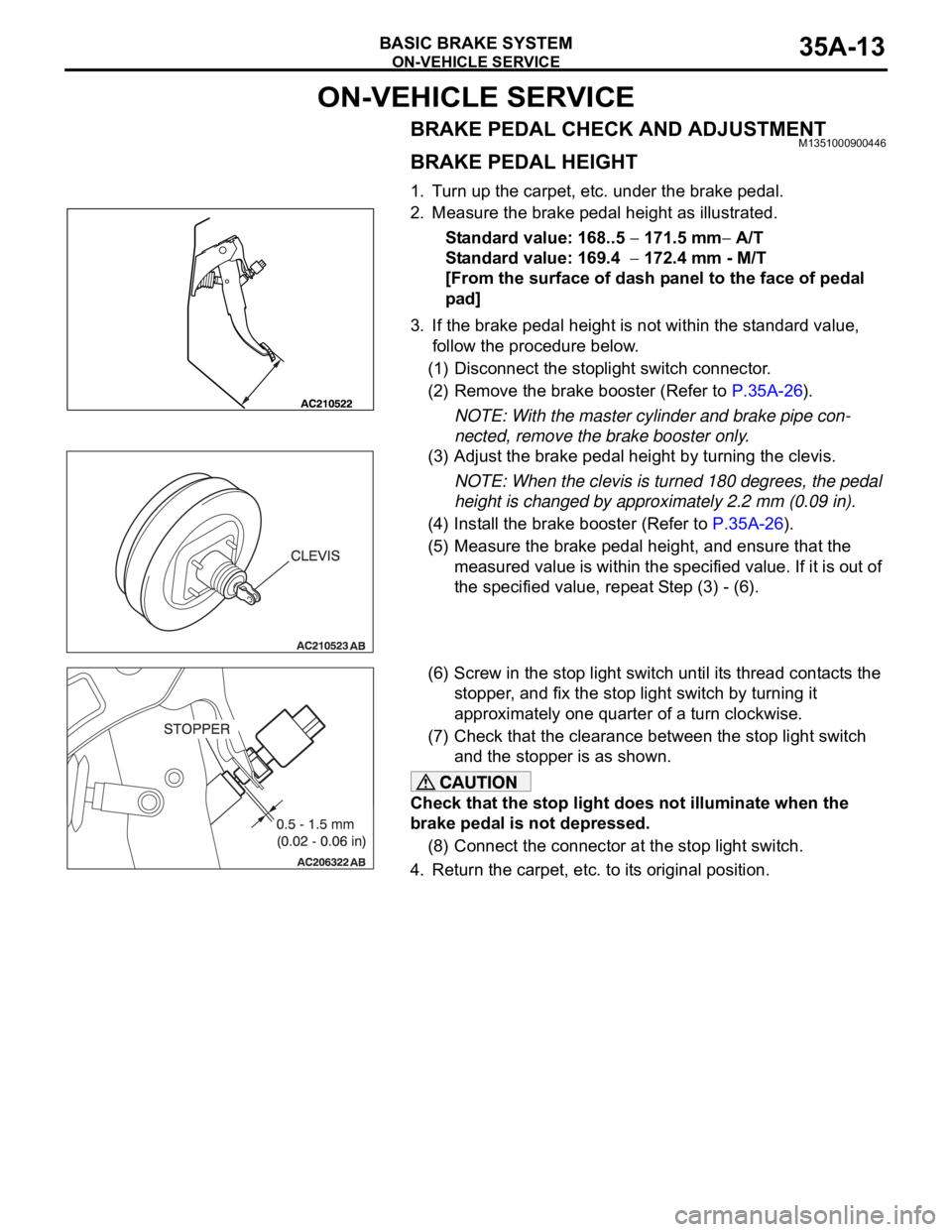

BRAKE PEDAL HEIGHT

1. Turn up the carpet, etc. under the brake pedal.

2. Measure the brake pedal height as illustrated.

Standard value: 168..5

171.5 mm A/T

Standard value: 169.4

172.4 mm - M/T

[From the surface of dash panel to the face of pedal

pad]

3. If the brake pedal height is not within the standard value,

follow the procedure below.

(1) Disconnect the stoplight switch connector.

(2) Remove the brake booster (Refer to P.35A-26).

NOTE: With the master cylinder and brake pipe con-

nected, remove the brake booster only.

(3) Adjust the brake pedal height by turning the clevis.

NOTE: When the clevis is turned 180 degrees, the pedal

height is changed by approximately 2.2 mm (0.09 in).

(4) Install the brake booster (Refer to P.35A-26).

(5) Measure the brake pedal height, and ensure that the

measured value is within the specified value. If it is out of

the specified value, repeat Step (3) - (6).

(6) Screw in the stop light switch until its thread contacts the

stopper, and fix the stop light switch by turning it

approximately one quarter of a turn clockwise.

(7) Check that the clearance between the stop light switch

and the stopper is as shown.

Check that the stop light does not illuminate when the

brake pedal is not depressed.

(8) Connect the connector at the stop light switch.

4. Return the carpet, etc. to its original position.

Page 1179 of 1500

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM35A-14

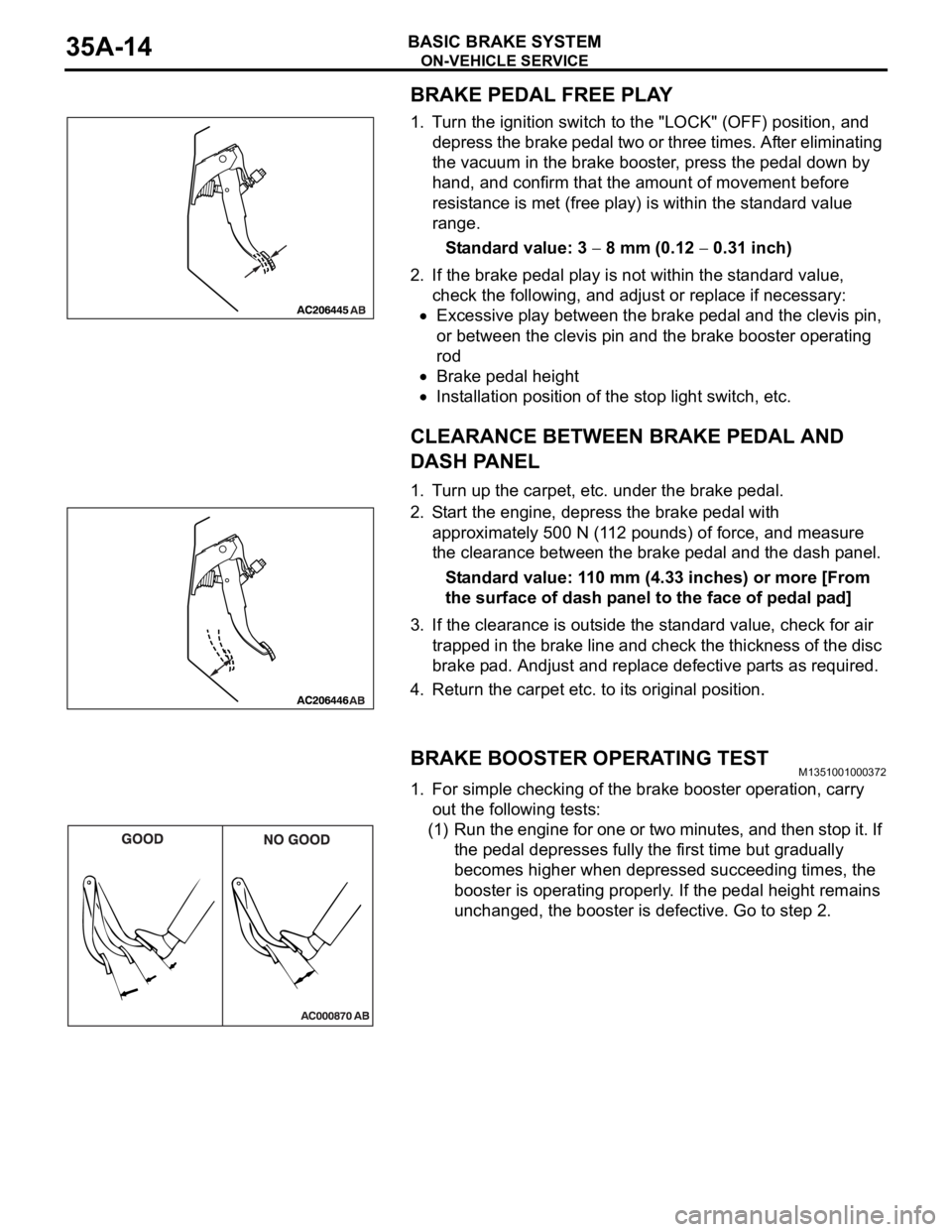

BRAKE PEDAL FREE PLAY

1. Turn the ignition switch to the "LOCK" (OFF) position, and

depress the brake pedal two or three times. After eliminating

the vacuum in the brake booster, press the pedal down by

hand, and confirm that the amount of movement before

resistance is met (free play) is within the standard value

range.

Standard value: 3

8 mm (0.12 0.31 inch)

2. If the brake pedal play is not within the standard value,

check the following, and adjust or replace if necessary:

Excessive play between the brake pedal and the clevis pin,

or between the clevis pin and the brake booster operating

rod

Brake pedal height

Installation position of the stop light switch, etc.

CLEARANCE BETWEEN BRAKE PEDAL AND

DASH PANEL

1. Turn up the carpet, etc. under the brake pedal.

2. Start the engine, depress the brake pedal with

approximately 500 N (112 pounds) of force, and measure

the clearance between the brake pedal and the dash panel.

Standard value: 110 mm (4.33 inches) or more [From

the surface of dash panel to the face of pedal pad]

3. If the clearance is outside the standard value, check for air

trapped in the brake line and check the thickness of the disc

brake pad. Andjust and replace defective parts as required.

4. Return the carpet etc. to its original position.

BRAKE BOOSTER OPERATING TESTM1351001000372

1. For simple checking of the brake booster operation, carry

out the following tests:

(1) Run the engine for one or two minutes, and then stop it. If

the pedal depresses fully the first time but gradually

becomes higher when depressed succeeding times, the

booster is operating properly. If the pedal height remains

unchanged, the booster is defective. Go to step 2.