ABS MITSUBISHI COLT 2006 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 11 of 364

CONSTRUCTION DESCRIPTION

ANTI-SKID BRAKE SYSTEM (ABS)35B-11

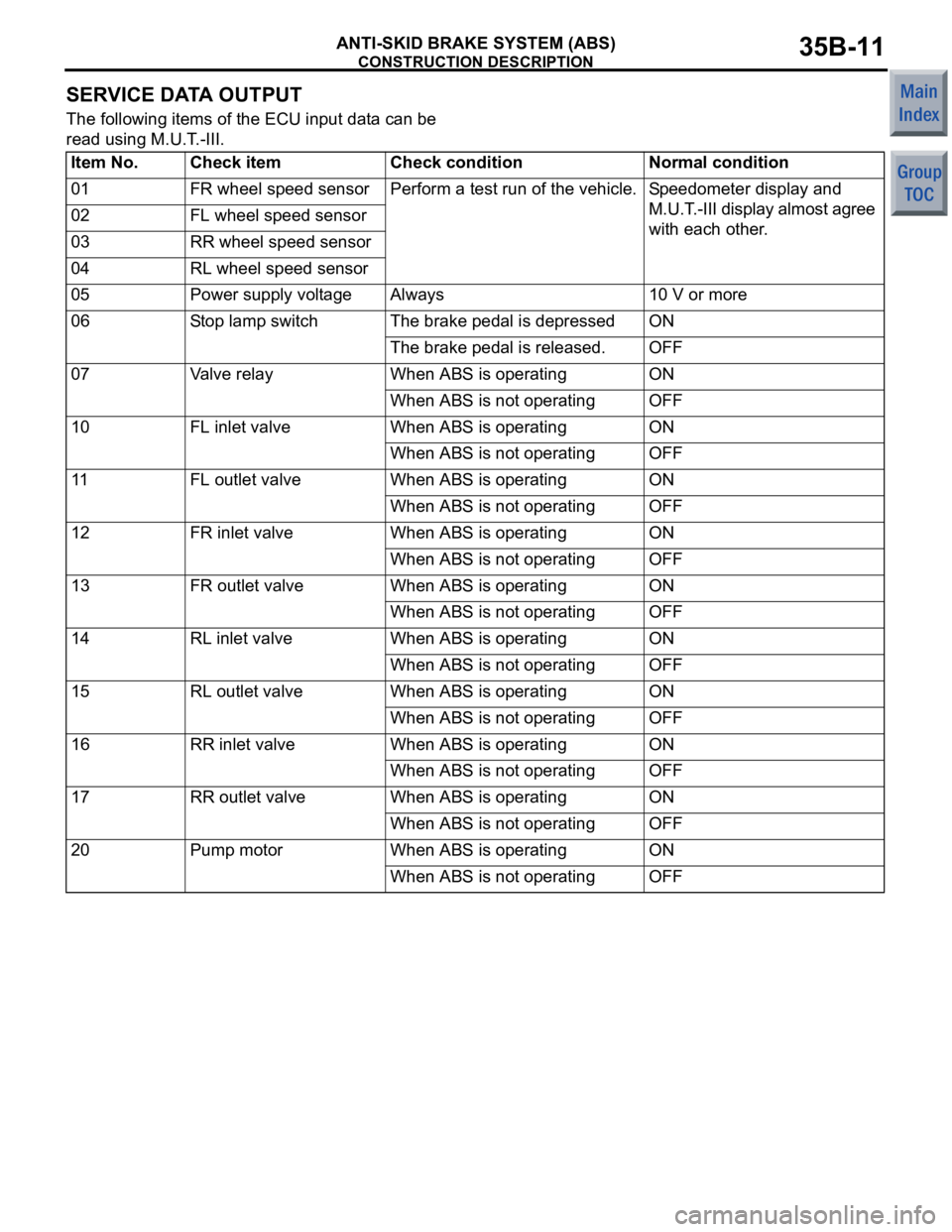

SERVICE DATA OUTPUT

The following items of the ECU input data can be

read using M.U.T.-III.

Item No.Check itemCheck conditionNormal condition

01FR wheel speed sensorPerform a test run of the vehicle.Speedometer display and

M.U.T.-III display almost agree

with each other.

02FL wheel speed sensor

03RR wheel speed sensor

04RL wheel speed sensor

05Power supply voltageAlways10 V or more

06Stop lamp switchThe brake pedal is depressedON

The brake pedal is released.OFF

07Va l v e r e l a yWhen ABS is operatingON

When ABS is not operatingOFF

10FL inlet valve When ABS is operatingON

When ABS is not operatingOFF

11FL outlet valve When ABS is operatingON

When ABS is not operatingOFF

12FR inlet valve When ABS is operatingON

When ABS is not operatingOFF

13FR outlet valve When ABS is operatingON

When ABS is not operatingOFF

14RL inlet valve When ABS is operatingON

When ABS is not operatingOFF

15RL outlet valve When ABS is operatingON

When ABS is not operatingOFF

16RR inlet valve When ABS is operatingON

When ABS is not operatingOFF

17RR outlet valve When ABS is operatingON

When ABS is not operatingOFF

20Pump motorWhen ABS is operatingON

When ABS is not operatingOFF

Page 12 of 364

CONSTRUCTION DESCRIPTION

ANTI-SKID BRAKE SYSTEM (ABS)35B-12

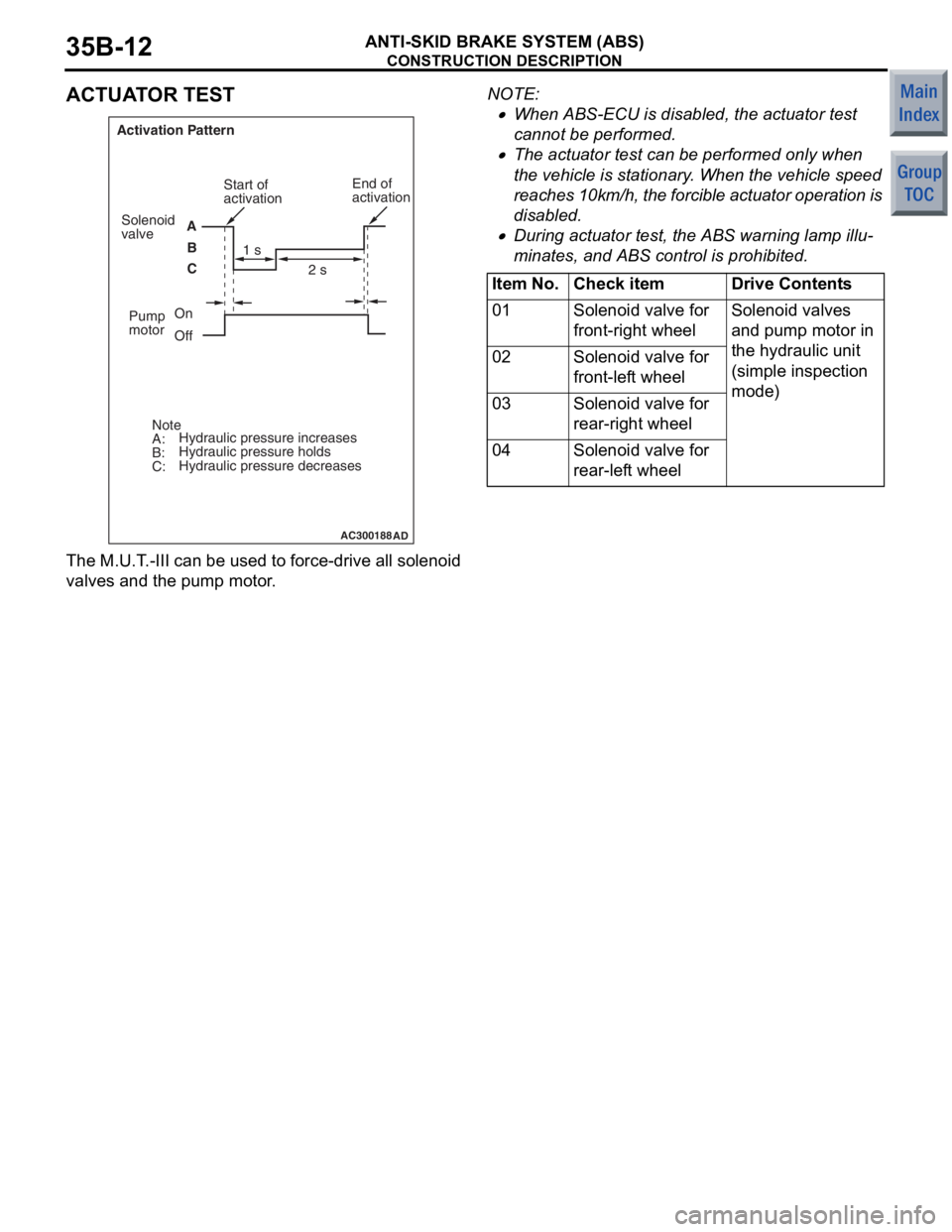

ACTUATOR TEST

AC300188AD

Activation PatternAB

C Start of

activation

1 s 2 s

On

Off

Note

A:

B:

C: Hydraulic pressure increases

Hydraulic pressure holds

Hydraulic pressure decreases End of

activation

Solenoid

valve

Pump

motor

The M.U.T . -III can be u s ed to force-drive a ll sole noid

valves and th

e pump mo tor .

NOTE: .

•Whe n ABS-ECU is disabled, the actu ator te st

cannot b

e perfo rmed.

•The actu ator test can be p e rformed on ly whe n

the

veh i cle is st a t iona ry . Whe n the ve hicle speed

rea

c h e s 10km/h, the f o rcible a c t uator operation is

disabled.

•During actuator test, the ABS warning lamp illu-

minates , an d ABS contro l is proh ibit ed.

Item No.Check itemDrive Contents

01Solenoid valve for

front-right wheelSolenoid valves

and pump motor in

the hydraulic unit

(simple inspection

mode)

02Solenoid valve for

front-left wheel

03Solenoid valve for

rear-right wheel

04Solenoid valve for

rear-left wheel

Page 33 of 364

A/C-ECU

HEATER, AIR CONDITIONER AND VENTILATION55-9

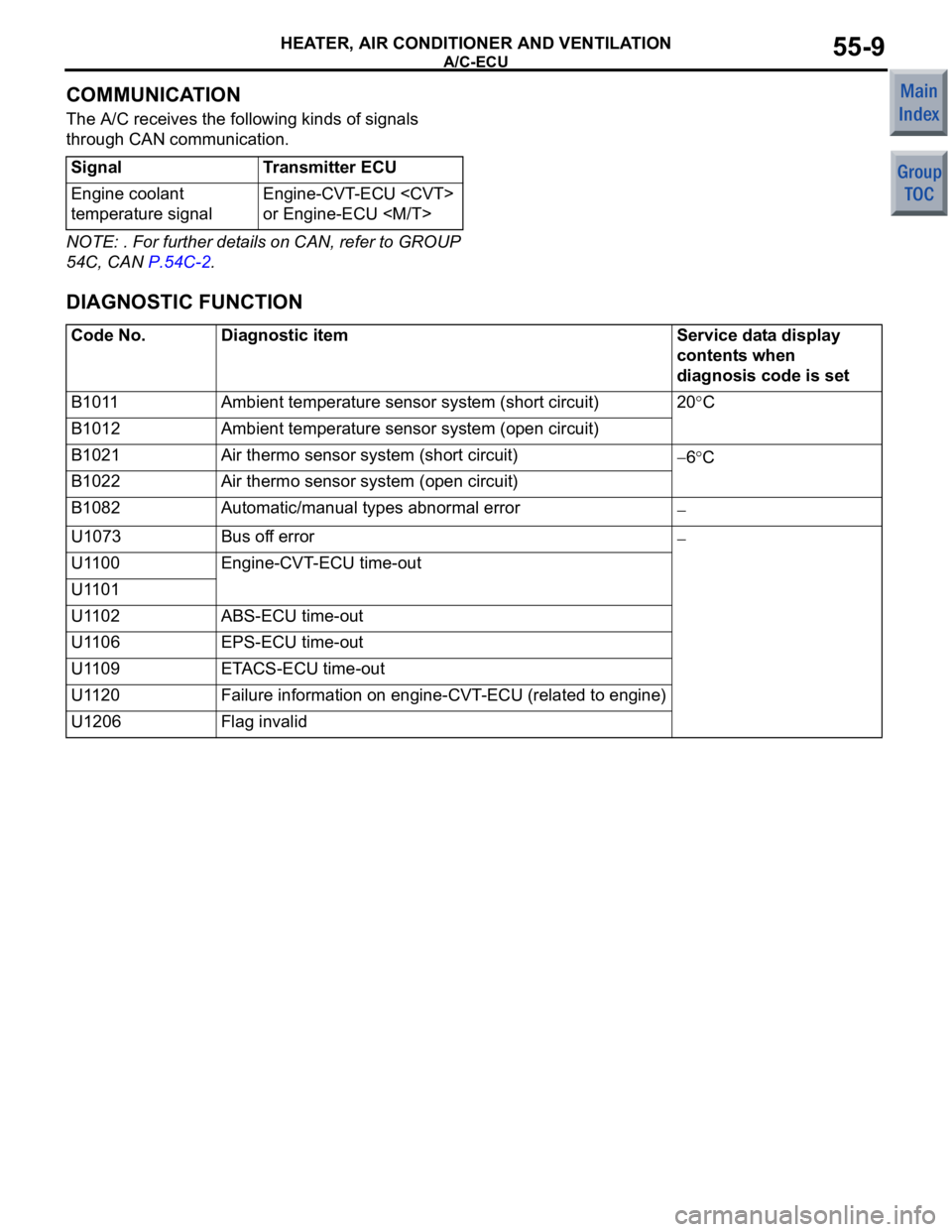

COMMUNICATION

The A/C receives the following kinds of signals

through CAN communication.

SignalTransmitter ECU

Engine coolant

temperature signalEngine-CVT-ECU

or Engine-ECU

NOTE: . For further details on CAN, refer to GROUP

54C, CAN

P.54C-2.

DIAGNOSTIC FUNCTION

Code No.Diagnostic itemService data display

contents when

diagnosis code is set

B1011Ambient temperature sensor system (short circuit)20°C

B1012Ambient temperature sensor system (open circuit)

B1021Air thermo sensor system (short circuit)−6°C

B1022Air thermo sensor system (open circuit)

B1082Automatic/manual types abnormal error−

U1073Bus off error−

U1100Engine-CVT-ECU time-out

U1101

U1102ABS-ECU time-out

U1106EPS-ECU time-out

U1109ETACS-ECU time-out

U1120Failure information on engine-CVT-ECU (related to engine)

U1206Flag invalid

Page 86 of 364

GENERAL INFORMATION

REAR SUSPENSION34-2

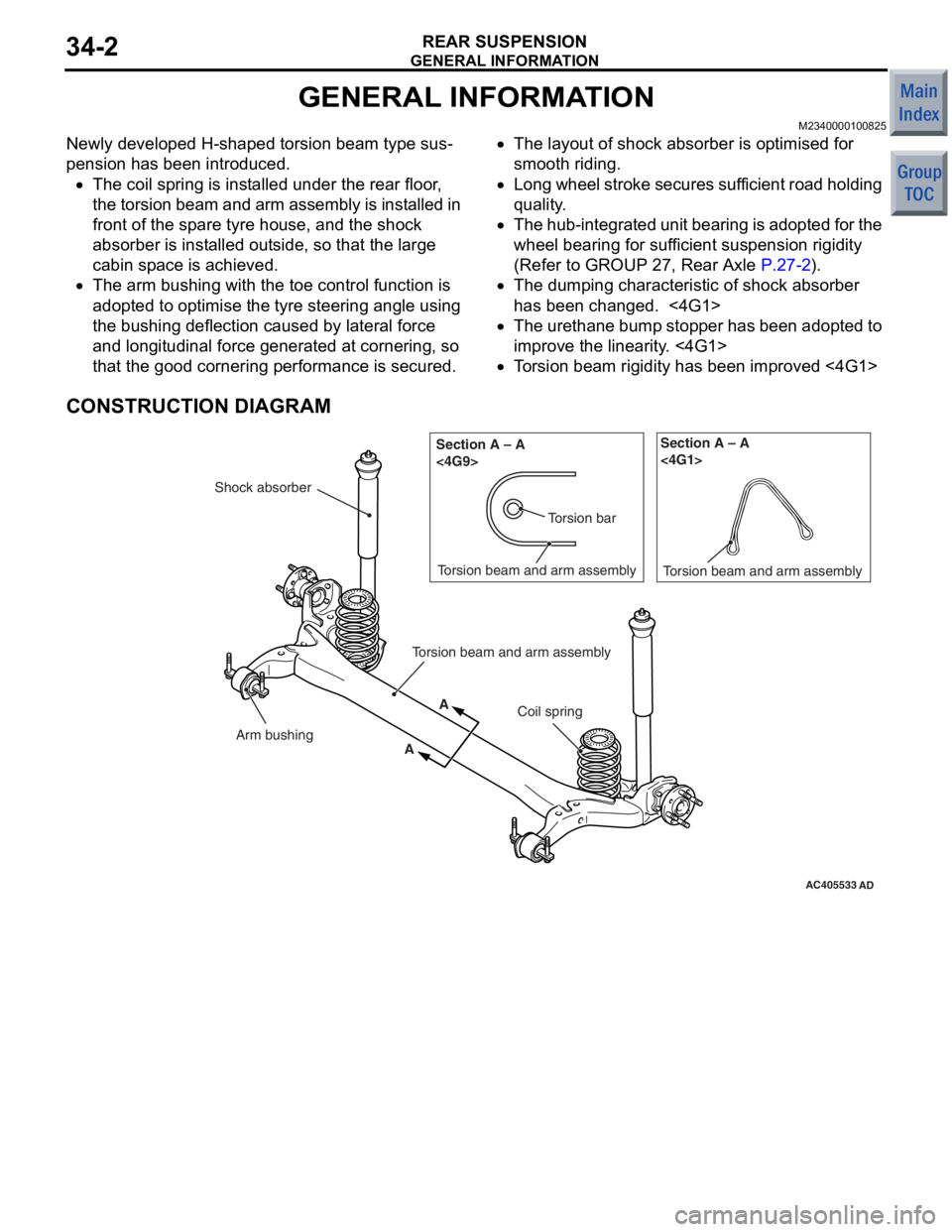

GENERAL INFORMATION

M2340000100825

Newly developed H-shaped torsion beam type sus-

pension has been introduced.

•The coil spring is installed under the rear floor,

the torsion beam and arm assembly is installed in

front of the spare tyre house, and the shock

absorber is installed outside, so that the large

cabin space is achieved.

•The arm bushing with the toe control function is

adopted to optimise the tyre steering angle using

the bushing deflection caused by lateral force

and longitudinal force generated at cornering, so

that the good cornering performance is secured.

•The layout of shock absorber is optimised for

smooth riding.

•Long wheel stroke secures sufficient road holding

quality.

•The hub-integrated unit bearing is adopted for the

wheel bearing for sufficient suspension rigidity

(Refer to GROUP 27, Rear Axle

P.27-2).

•The dumping characteristic of shock absorber

has been changed. <4G1>

•The urethane bump stopper has been adopted to

improve the linearity. <4G1>

•Torsion beam rigidity has been improved <4G1>

CONSTRUCTION DIAGRAM

AC405533AD

Coil spring

Shock absorber

Torsion beam and arm assembly

Arm bushing

Torsion bar

Section A – A

<4G9>

A

A Torsion beam and arm assembly

Section A – A

<4G1>

Torsion beam and arm assembly

Page 97 of 364

GENERAL INFORMATION

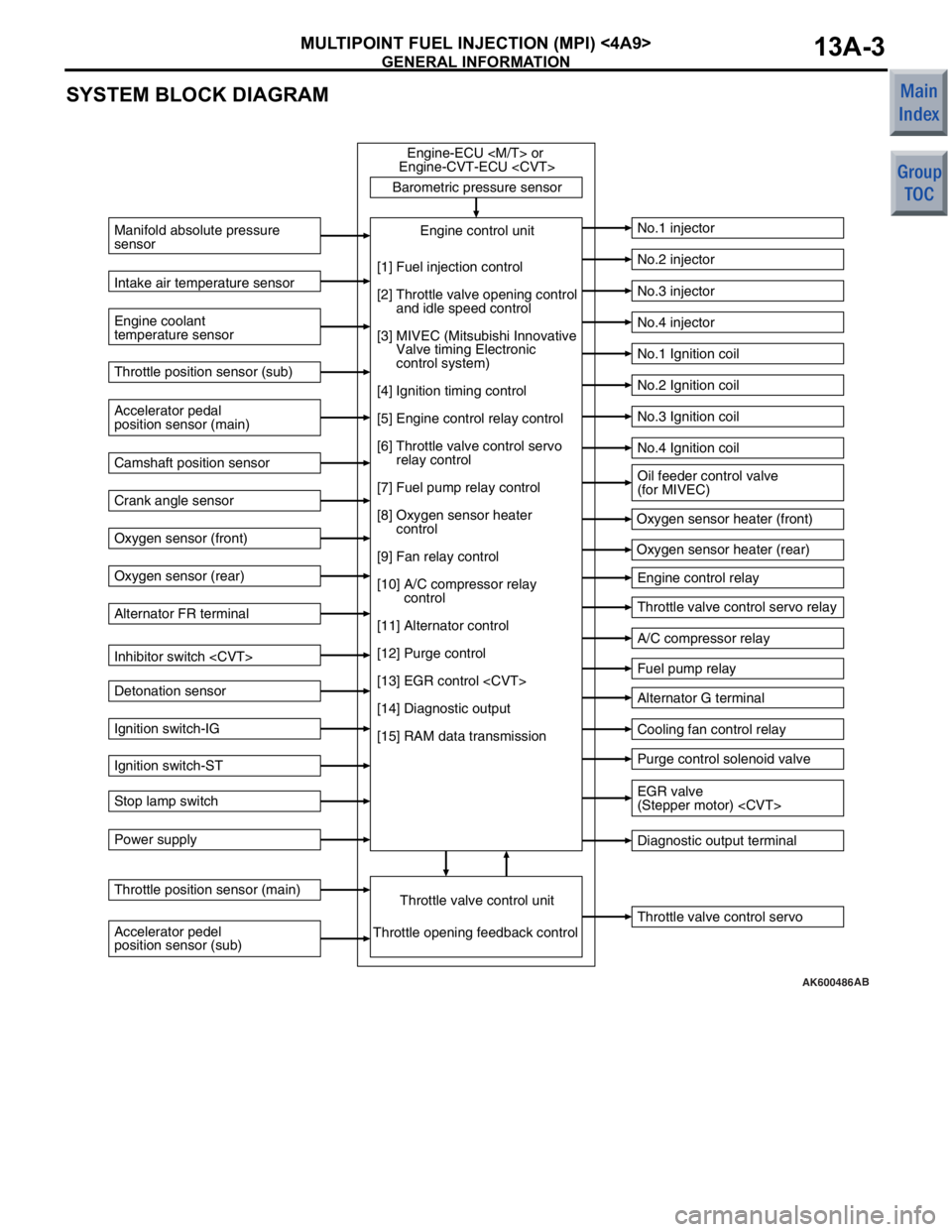

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-3

SYSTEM BLOCK DIAGRAM

AK600486

Barometric pressure sensorThrottle valve control servo

Manifold absolute pressure

sensor

Engine coolant

temperature sensor

No.1 injector

No.2 injector

No.3 injector

No.4 injector

No.1 Ignition coil

No.2 Ignition coil

No.3 Ignition coil

No.4 Ignition coil

Engine control relay

Throttle valve control servo relay

A/C compressor relay

Fuel pump relay

Alternator G terminal

Cooling fan control relay

Purge control solenoid valve

Diagnostic output terminal

Intake air temperature sensor

Accelerator pedal

position sensor (main) Throttle position sensor (sub)

Camshaft position sensor

Crank angle sensor

Oxygen sensor (front)

Oxygen sensor (rear)

Alternator FR terminal

Inhibitor switch

Detonation sensor

Ignition switch-IG

Ignition switch-ST

Stop lamp switch

Power supply

Accelerator pedel

position sensor (sub) Throttle position sensor (main)

Throttle valve control unitEngine control unit

Engine-ECU

Engine-CVT-ECU

Throttle opening feedback control Oxygen sensor heater (front)

Oxygen sensor heater (rear)

[1] Fuel injection control

[2] Throttle valve opening control

and idle speed control

[3] MIVEC (Mitsubishi Innovative

Valve timing Electronic

control system)

[4] Ignition timing control

[5] Engine control relay control

[6] Throttle valve control servo

relay control

[7] Fuel pump relay control

[8] Oxygen sensor heater

control

[9] Fan relay control

[10] A/C compressor relay

control

[11] Alternator control

[12] Purge control

[13] EGR control

[14] Diagnostic output

[15] RAM data transmission

Oil feeder control valve

(for MIVEC)

EGR valve

(Stepper motor)

AB

Page 98 of 364

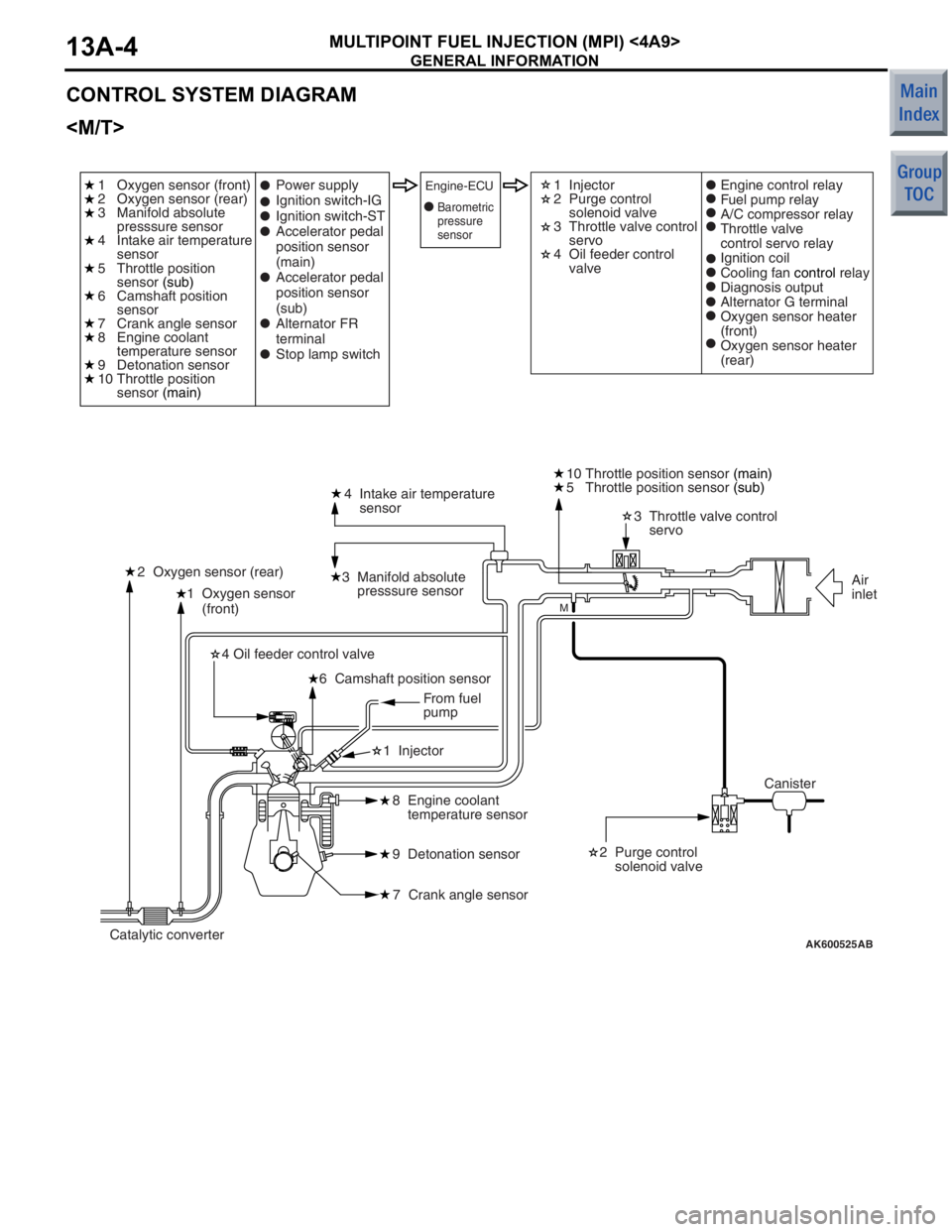

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-4

CONTROL SYSTEM DIAGRAM

AK600525

1 Oxygen sensor

(front)4 Intake air temperature

sensor

3 Manifold absolute

presssure sensor

2 Oxygen sensor (rear) 3 Throttle valve control

servo

10 Throttle position sensor

(main)

2 Purge control

solenoid valve

8 Engine coolant

temperature sensor

9 Detonation sensor

7 Crank angle sensor

6 Camshaft position sensor

4 Oil feeder control valve

1 Injector

AB

M

1 Oxygen sensor (front)

2 Oxygen sensor (rear)

3 Manifold absolute

presssure sensor

4 Intake air temperature

sensor

5 Throttle position

sensor

(sub)

6 Camshaft position

sensor

7 Crank angle sensor

8 Engine coolant

temperature sensor

9 Detonation sensor

10 Throttle position

sensor (main) 1 Injector

2 Purge control

solenoid valve

3 Throttle valve control

servo

4 Oil feeder control

valve

Power supply

Ignition switch-IG

Ignition switch-ST

Accelerator pedal

position sensor

(main)

Accelerator pedal

position sensor

(sub)

Alternator FR

terminal

Stop lamp switchEngine-ECUEngine control relay

Fuel pump relay

A/C compressor relay

Throttle valve

control servo relay

Ignition coil

Cooling fan

control relay

Diagnosis output

Alternator G terminal

Oxygen sensor heater

(front)

Oxygen sensor heater

(rear)

Canister Air

inlet

Catalytic converter From fuel

pump

5 Throttle position sensor

(sub)

Barometric

pressure

sensor

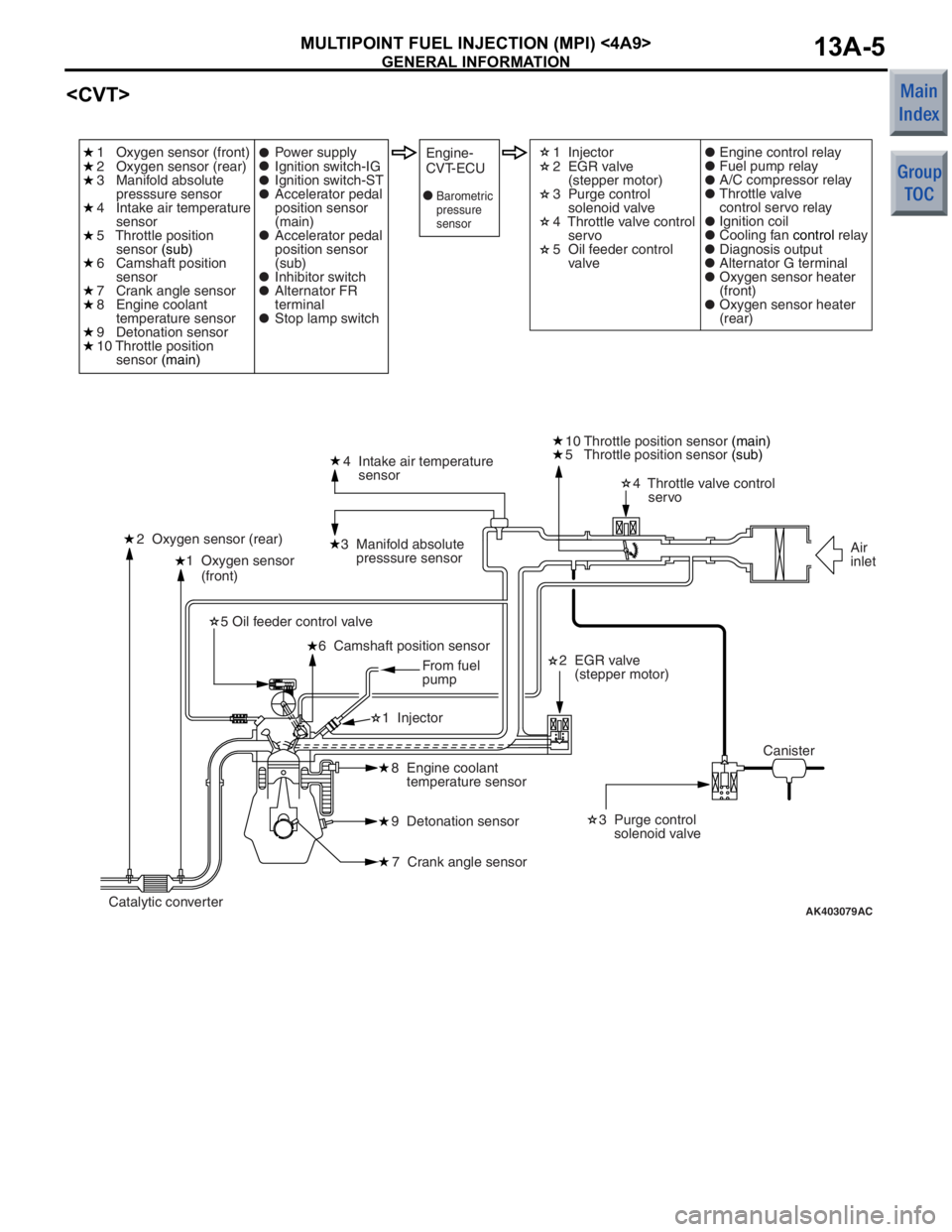

Page 99 of 364

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-5

AK403079

1 Oxygen sensor

(front)4 Intake air temperature

sensor

3 Manifold absolute

presssure sensor

2 Oxygen sensor (rear) 4 Throttle valve control

servo

10 Throttle position sensor

(main)

2 EGR valve

(stepper motor) 3 Purge control

solenoid valve

8 Engine coolant

temperature sensor

9 Detonation sensor

7 Crank angle sensor

6 Camshaft position sensor

5 Oil feeder control valve

1 Injector

AC

1 Oxygen sensor (front)

2 Oxygen sensor (rear)

3 Manifold absolute

presssure sensor

4 Intake air temperature

sensor

5 Throttle position

sensor (sub)

6 Camshaft position

sensor

7 Crank angle sensor

8 Engine coolant

temperature sensor

9 Detonation sensor

10 Throttle position

sensor (main) 1 Injector

2 EGR valve

(stepper motor)

3 Purge control

solenoid valve

4 Throttle valve control

servo

5 Oil feeder control

valve

Power supply

Ignition switch-IG

Ignition switch-ST

Accelerator pedal

position sensor

(main)

Accelerator pedal

position sensor

(sub)

Inhibitor switch

Alternator FR

terminal

Stop lamp switchEngine-

CVT-ECUEngine control relay

Fuel pump relay

A/C compressor relay

Throttle valve

control servo relay

Ignition coil

Cooling fan

control relay

Diagnosis output

Alternator G terminal

Oxygen sensor heater

(front)

Oxygen sensor heater

(rear)

Canister Air

inlet

Catalytic converter From fuel

pump

5 Throttle position sensor

(sub)

Barometric

pressure

sensor

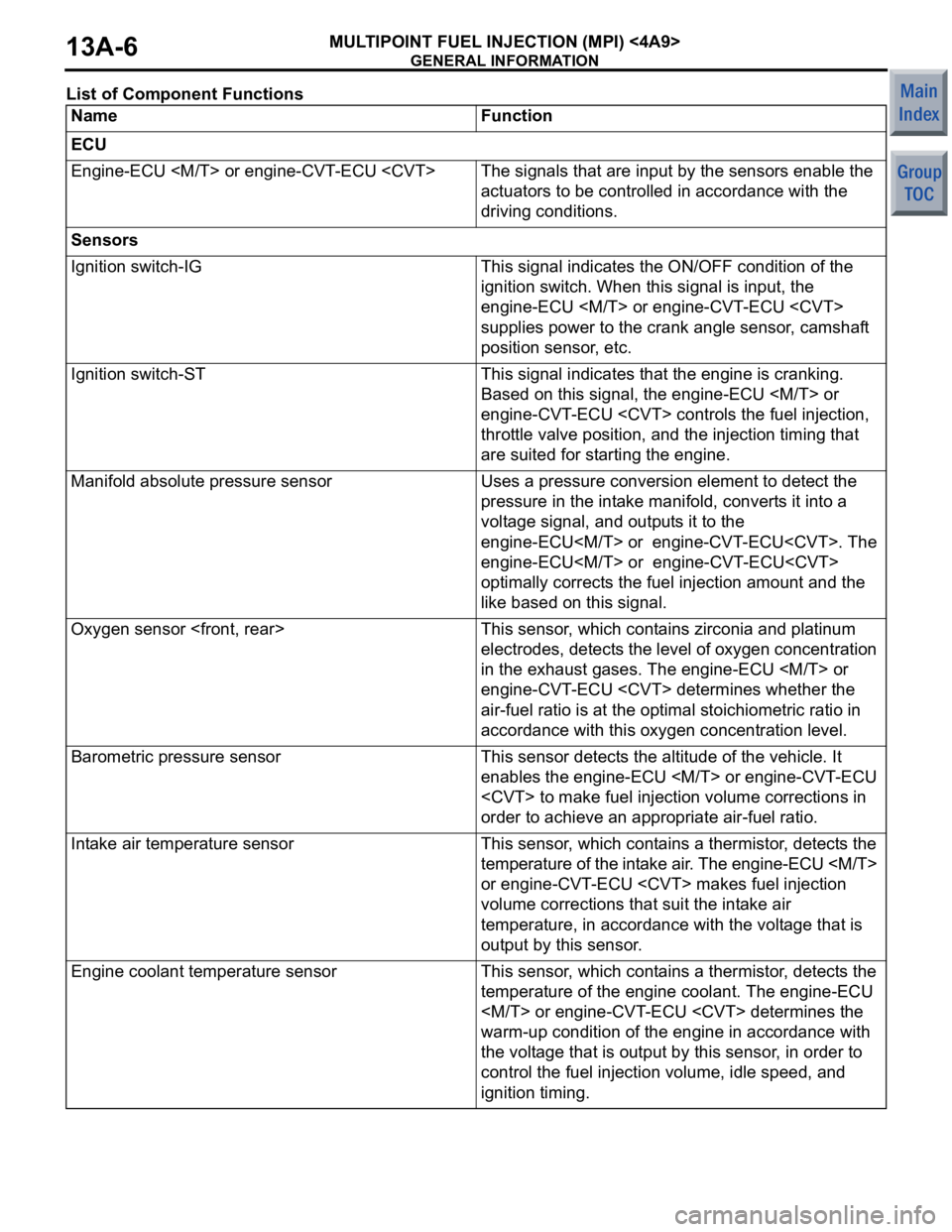

Page 100 of 364

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-6

List of Component Functions

NameFunction

ECU

Engine-ECU

actuators to be controlled in accordance with the

driving conditions.

Sensors

Ignition switch-IGThis signal indicates the ON/OFF condition of the

ignition switch. When this signal is input, the

engine-ECU

supplies power to the crank angle sensor, camshaft

position sensor, etc.

Ignition switch-STThis signal indicates that the engine is cranking.

Based on this signal, the engine-ECU

engine-CVT-ECU

throttle valve position, and the injection timing that

are suited for starting the engine.

Manifold absolute pressure sensor Uses a pressure conversion element to detect the

pressure in the intake manifold, converts it into a

voltage signal, and outputs it to the

engine-ECU

engine-ECU

optimally corrects the fuel injection amount and the

like based on this signal.

Oxygen sensor

electrodes, detects the level of oxygen concentration

in the exhaust gases. The engine-ECU

engine-CVT-ECU

air-fuel ratio is at the optimal stoichiometric ratio in

accordance with this oxygen concentration level.

Barometric pressure sensorThis sensor detects the altitude of the vehicle. It

enables the engine-ECU

order to achieve an appropriate air-fuel ratio.

Intake air temperature sensorThis sensor, which contains a thermistor, detects the

temperature of the intake air. The engine-ECU

or engine-CVT-ECU

volume corrections that suit the intake air

temperature, in accordance with the voltage that is

output by this sensor.

Engine coolant temperature sensorThis sensor, which contains a thermistor, detects the

temperature of the engine coolant. The engine-ECU

warm-up condition of the engine in accordance with

the voltage that is output by this sensor, in order to

control the fuel injection volume, idle speed, and

ignition timing.

Page 103 of 364

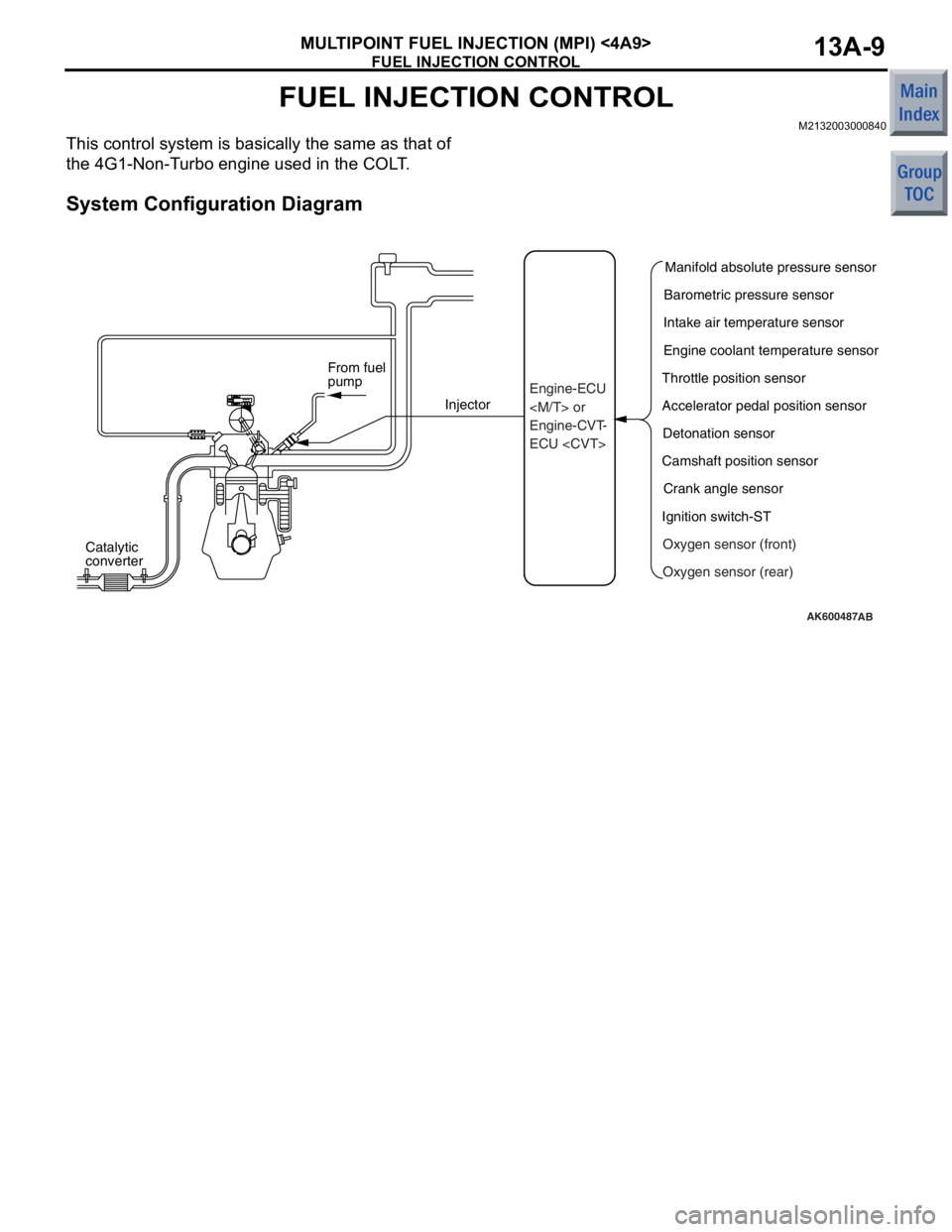

FUEL INJECTION CONTROL

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-9

FUEL INJECTION CONTROL

M2132003000840

This control system is basically the same as that of

the 4G1-Non-Turbo engine used in the COLT.

System Configuration Diagram

AK600487

Catalytic

converterInjector

From fuel

pump

AB

Manifold absolute pressure sensor

Engine-ECU

Engine-CVT-

ECU

Intake air temperature sensor

Engine coolant temperature sensor

Throttle position sensor

Accelerator pedal position sensor Detonation sensor

Camshaft position sensor Crank angle sensor

Ignition switch-ST Oxygen sensor (front)

Oxygen sensor (rear)

Page 105 of 364

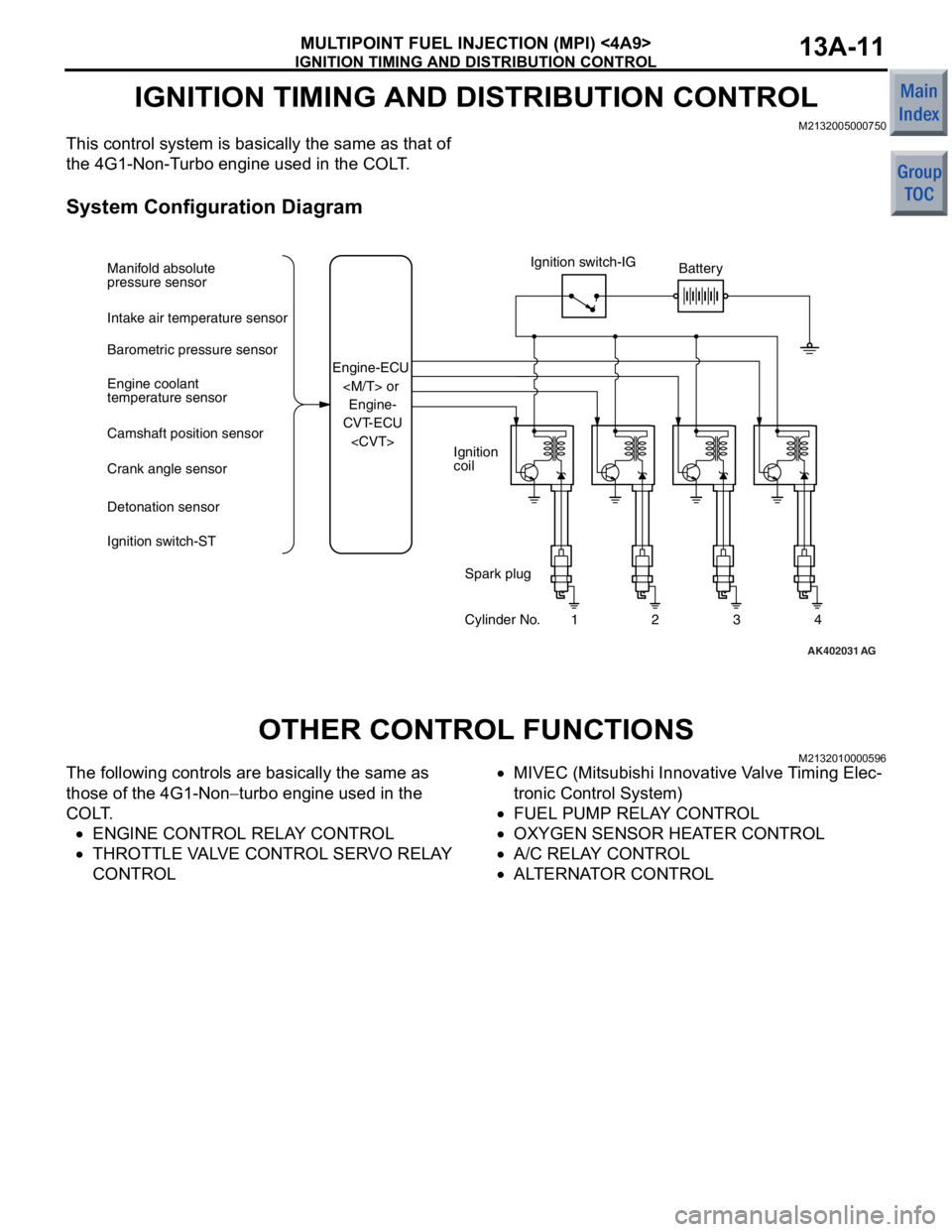

IGNITION TIMING AND DISTRIBUTION CONTROL

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-11

IGNITION TIMING AND DISTRIBUTION CONTROL

M2132005000750

This control system is basically the same as that of

the 4G1-Non-Turbo engine used in the COLT.

System Configuration Diagram

AK402031

Ignition switch-IG

Ignition

coil Battery

Spark plug

Cylinder No. 1 2 3 4

Manifold absolute

pressure sensor

Intake air temperature sensor

Barometric pressure sensor

Engine coolant

temperature sensor

Camshaft position sensor

Crank angle sensor

Detonation sensor

Ignition switch-ST

Engine-ECU

CVT-ECU

AG

OTHER CONTROL FUNCTI O NS

M21320100 0059 6

The following co ntrols are b a sically t he sa me a s

those

of the 4G1 - No n

−turbo eng ine u s ed in the

CO

L

T

.

•ENGINE CONTROL RELA Y CONTROL

•THROTTLE VA L V E C O NTROL SER VO R E LA Y

CONTROL

•MIVEC (Mitsub i sh i Inno vative V a lve T i ming Elec-

tronic Con t rol System)

•FUEL PUMP RELA Y CONTROL

•OXYGEN S E NSOR HEA T E R CONTR O L

•A/C RELAY CONTROL

•ALTER N A T OR CONTROL