ABS MITSUBISHI COLT 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 107 of 364

CONTROLLER AREA NETWORK (CAN)

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-13

CONTROLLER AREA NETWORK (CAN)

M2132019000292

Establishing communication without fail is designed

by CAN communication protocol. Refer to Group

54C-CAN

P.54C-2 for the details about CAN.

The signals input into engine-ECU

engine-CVT-ECU

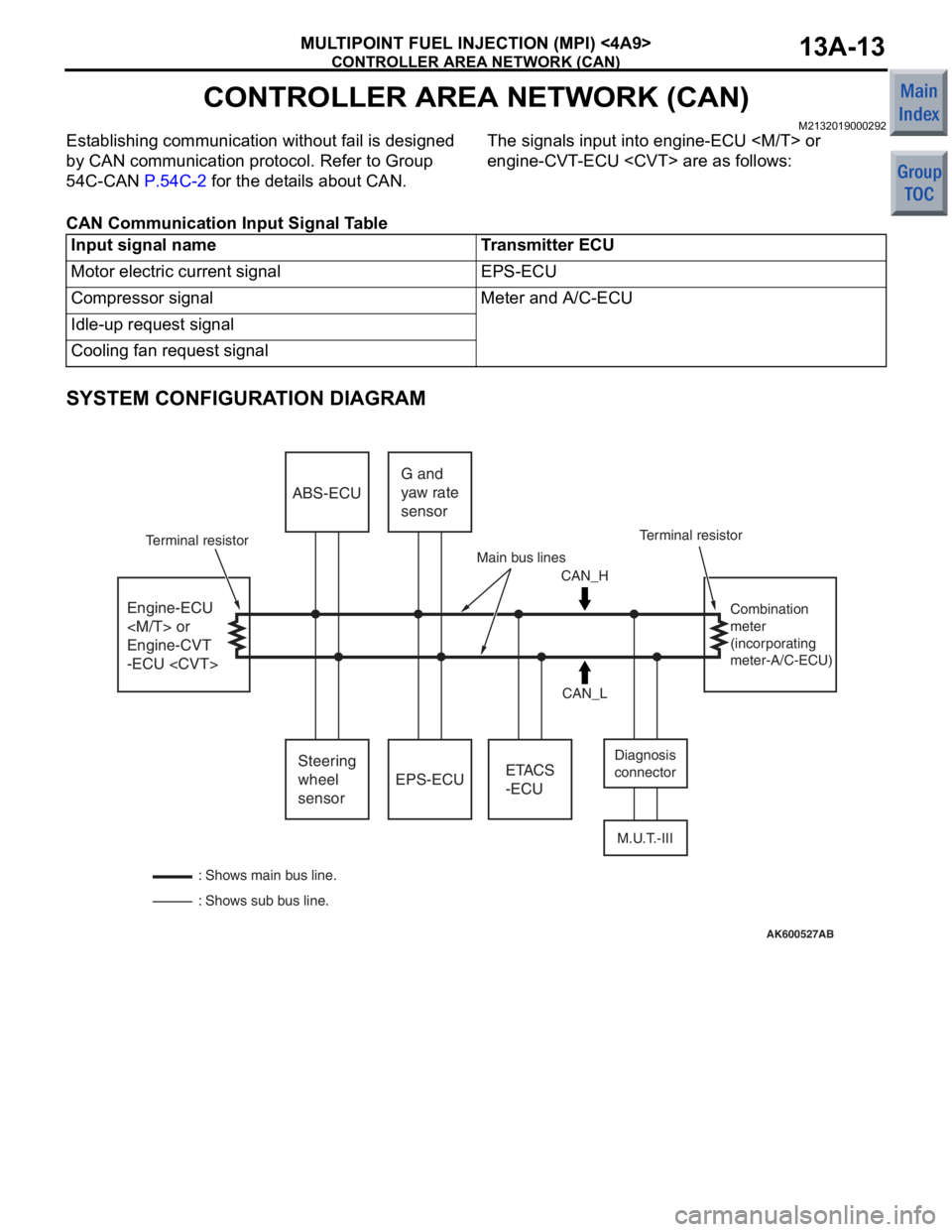

CAN Communication Input Signal Table

Input signal nameTransmitter ECU

Motor electric current signalEPS-ECU

Compressor signalMeter and A/C-ECU

Idle-up request signal

Cooling fan request signal

SYSTEM CONFIGURATION DIAGRAM

AK600527AB

Engine-ECU

Engine-CVT

-ECU

M.U.T.-III

EPS-ECU ETACS

-ECU

Steering

wheel

sensor G and

yaw rate

sensor

ABS-ECU

CAN_H

CAN_L Diagnosis

connector Combination

meter

(incorporating

meter-A/C-ECU)

: Shows sub bus line. : Shows main bus line. Terminal resistor

Terminal resistor

Main bus lines

Page 108 of 364

DIAGNOSIS SYSTEM

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-14

DIAGNOSIS SYSTEM

M2132009000882

Engine-ECU

been provided with the following functions for easier

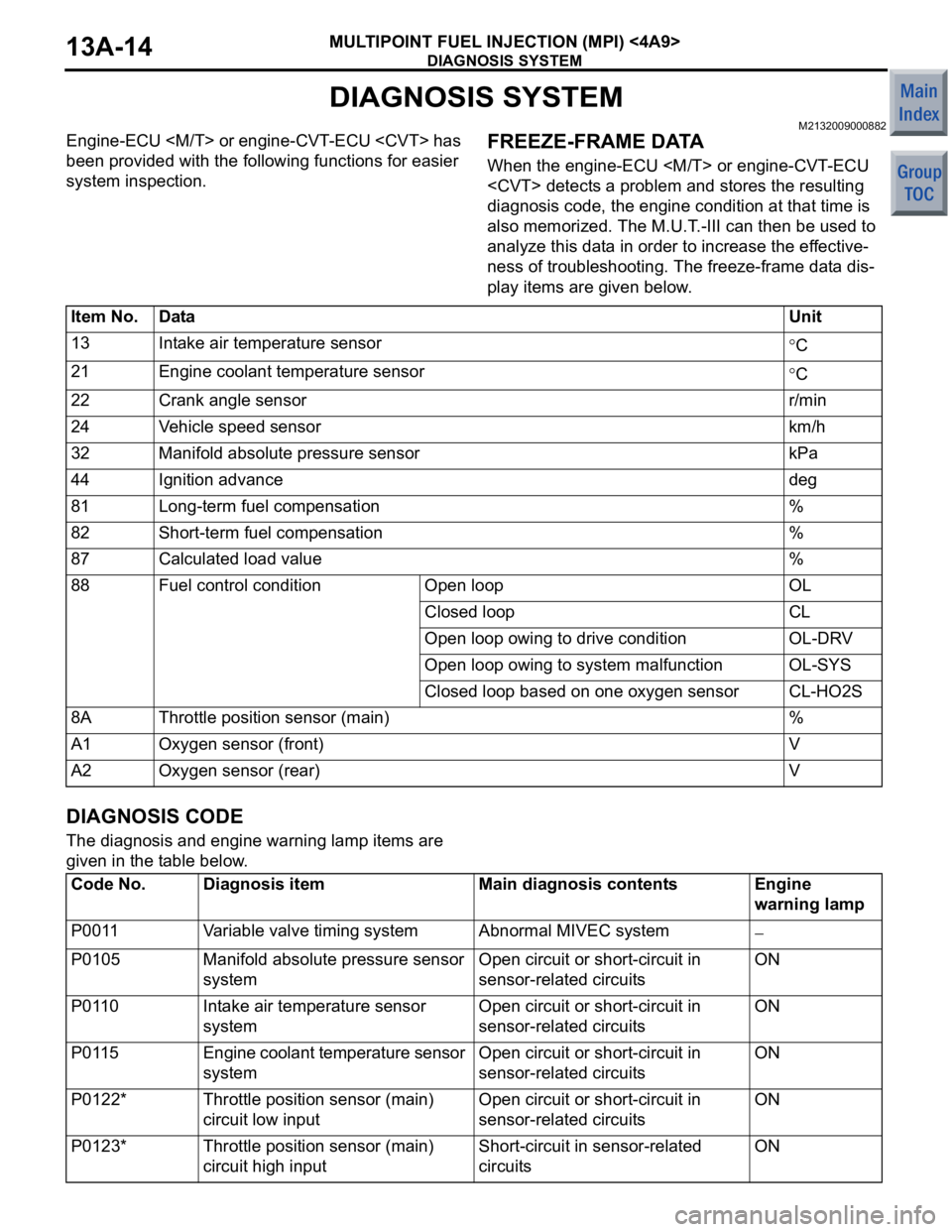

system inspection.FREEZE-FRAME DATA

When the engine-ECU

diagnosis code, the engine condition at that time is

also memorized. The M.U.T.-III can then be used to

analyze this data in order to increase the effective

-

ness of troubleshooting. The freeze-frame data dis-

play items are given below.

Item No.DataUnit

13Intake air temperature sensor°C

21Engine coolant temperature sensor°C

22Crank angle sensorr/min

24Vehicle speed sensorkm/h

32Manifold absolute pressure sensorkPa

44Ignition advancedeg

81Long-term fuel compensation%

82Short-term fuel compensation%

87Calculated load value%

88Fuel control conditionOpen loopOL

Closed loopCL

Open loop owing to drive conditionOL-DRV

Open loop owing to system malfunctionOL-SYS

Closed loop based on one oxygen sensorCL-HO2S

8AThrottle position sensor (main)%

A1Oxygen sensor (front)V

A2Oxygen sensor (rear)V

DIAGNOSIS CODE

The diagnosis and engine warning lamp items are

given in the table below.

Code No.Diagnosis itemMain diagnosis contentsEngine

warning lamp

P0011Variable valve timing systemAbnormal MIVEC system−

P0105Manifold absolute pressure sensor

systemOpen circuit or short-circuit in

sensor-related circuitsON

P0110Intake air temperature sensor

systemOpen circuit or short-circuit in

sensor-related circuitsON

P0115Engine coolant temperature sensor

systemOpen circuit or short-circuit in

sensor-related circuitsON

P0122*Throttle position sensor (main)

circuit low inputOpen circuit or short-circuit in

sensor-related circuitsON

P0123*Throttle position sensor (main)

circuit high inputShort-circuit in sensor-related

circuitsON

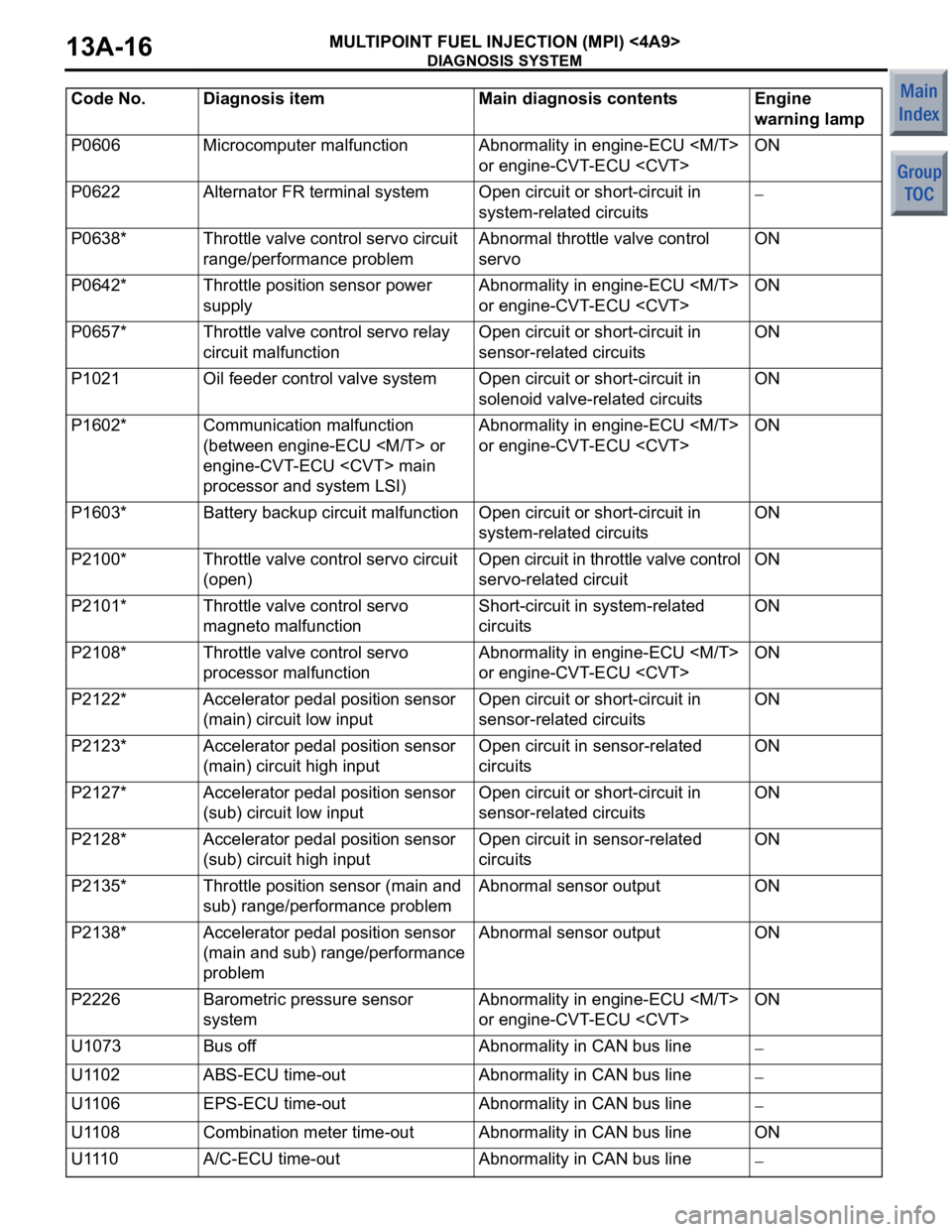

Page 110 of 364

DIAGNOSIS SYSTEM

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-16

P0606Microcomputer malfunctionAbnormality in engine-ECU

or engine-CVT-ECU

P0622Alternator FR terminal systemOpen circuit or short-circuit in

system-related circuits−

P0638*Throttle valve control servo circuit

range/performance problemAbnormal throttle valve control

servoON

P0642*Throttle position sensor power

supplyAbnormality in engine-ECU

or engine-CVT-ECU

P0657*Throttle valve control servo relay

circuit malfunctionOpen circuit or short-circuit in

sensor-related circuitsON

P1021Oil feeder control valve systemOpen circuit or short-circuit in

solenoid valve-related circuitsON

P1602*Communication malfunction

(between engine-ECU

engine-CVT-ECU

processor and system LSI)Abnormality in engine-ECU

or engine-CVT-ECU

P1603*Battery backup circuit malfunctionOpen circuit or short-circuit in

system-related circuitsON

P2100*Throttle valve control servo circuit

(open)Open circuit in throttle valve control

servo-related circuitON

P2101*Throttle valve control servo

magneto malfunctionShort-circuit in system-related

circuitsON

P2108*Throttle valve control servo

processor malfunctionAbnormality in engine-ECU

or engine-CVT-ECU

P2122*Accelerator pedal position sensor

(main) circuit low inputOpen circuit or short-circuit in

sensor-related circuitsON

P2123*Accelerator pedal position sensor

(main) circuit high inputOpen circuit in sensor-related

circuitsON

P2127*Accelerator pedal position sensor

(sub) circuit low inputOpen circuit or short-circuit in

sensor-related circuitsON

P2128*Accelerator pedal position sensor

(sub) circuit high inputOpen circuit in sensor-related

circuitsON

P2135*Throttle position sensor (main and

sub) range/performance problemAbnormal sensor outputON

P2138*Accelerator pedal position sensor

(main and sub) range/performance

problemAbnormal sensor outputON

P2226Barometric pressure sensor

systemAbnormality in engine-ECU

or engine-CVT-ECU

U1073Bus offAbnormality in CAN bus line−

U1102ABS-ECU time-outAbnormality in CAN bus line−

U1106EPS-ECU time-outAbnormality in CAN bus line−

U1108Combination meter time-outAbnormality in CAN bus lineON

U 111 0A/C-ECU time-outAbnormality in CAN bus line−

Code No. Diagnosis item Main diagnosis contents Engine

warning lamp

Page 111 of 364

DIAGNOSIS SYSTEM

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-17

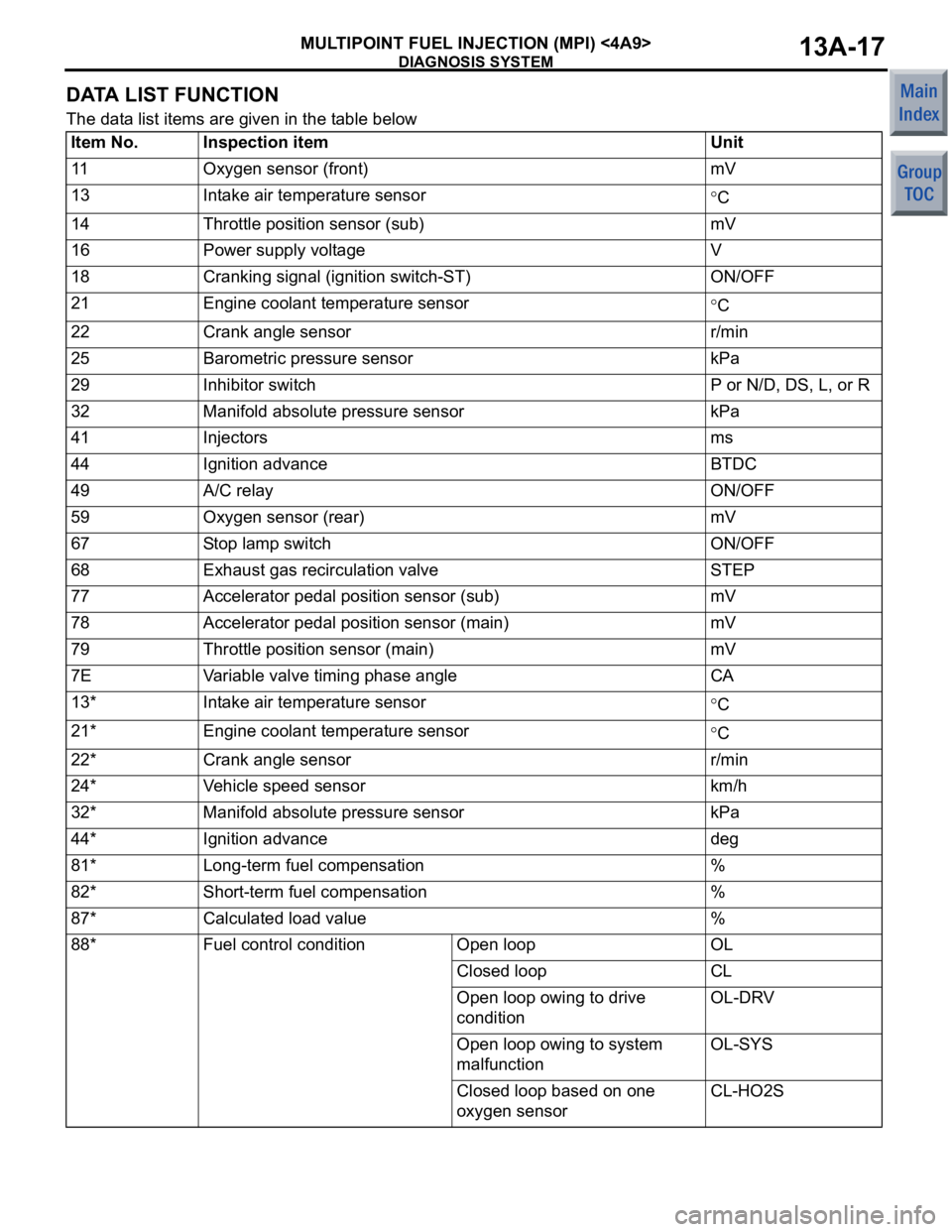

DATA LIST FUNCTION

The data list items are given in the table below

Item No.Inspection itemUnit

11Oxygen sensor (front)mV

13Intake air temperature sensor°C

14Throttle position sensor (sub)mV

16Power supply voltageV

18Cranking signal (ignition switch-ST)ON/OFF

21Engine coolant temperature sensor°C

22Crank angle sensorr/min

25Barometric pressure sensorkPa

29Inhibitor switchP or N/D, DS, L, or R

32Manifold absolute pressure sensorkPa

41Injectorsms

44Ignition advanceBTDC

49A/C relayON/OFF

59Oxygen sensor (rear)mV

67Stop lamp switchON/OFF

68Exhaust gas recirculation valveSTEP

77Accelerator pedal position sensor (sub)mV

78Accelerator pedal position sensor (main)mV

79Throttle position sensor (main)mV

7EVariable valve timing phase angleCA

13*Intake air temperature sensor°C

21*Engine coolant temperature sensor°C

22*Crank angle sensorr/min

24*Vehicle speed sensorkm/h

32*Manifold absolute pressure sensorkPa

44*Ignition advancedeg

81*Long-term fuel compensation%

82*Short-term fuel compensation%

87*Calculated load value%

88*Fuel control conditionOpen loopOL

Closed loopCL

Open loop owing to drive

conditionOL-DRV

Open loop owing to system

malfunctionOL-SYS

Closed loop based on one

oxygen sensorCL-HO2S

Page 130 of 364

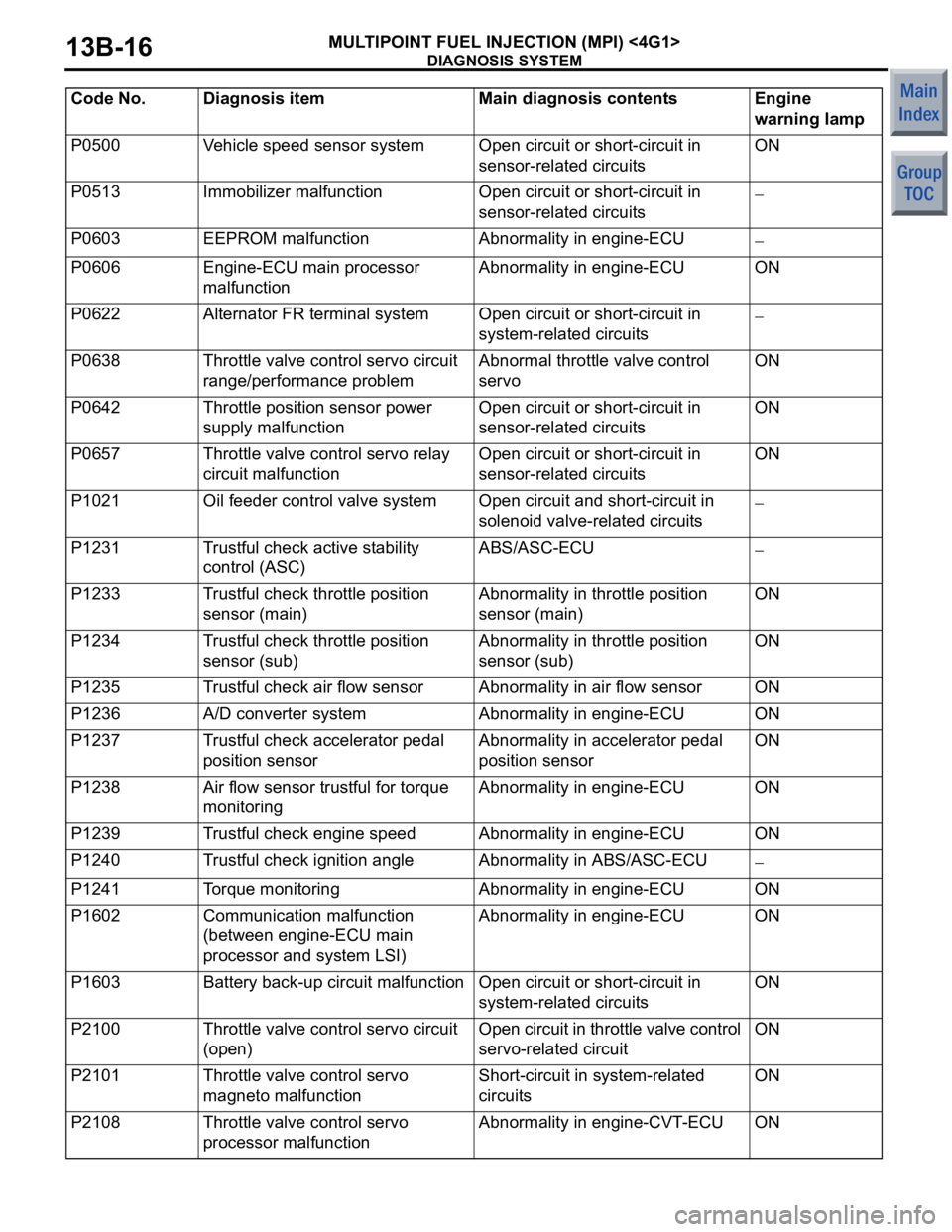

DIAGNOSIS SYSTEM

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-16

P0500Vehicle speed sensor systemOpen circuit or short-circuit in

sensor-related circuitsON

P0513Immobilizer malfunctionOpen circuit or short-circuit in

sensor-related circuits−

P0603EEPROM malfunctionAbnormality in engine-ECU−

P0606Engine-ECU main processor

malfunctionAbnormality in engine-ECUON

P0622Alternator FR terminal systemOpen circuit or short-circuit in

system-related circuits−

P0638Throttle valve control servo circuit

range/performance problemAbnormal throttle valve control

servoON

P0642Throttle position sensor power

supply malfunctionOpen circuit or short-circuit in

sensor-related circuitsON

P0657Throttle valve control servo relay

circuit malfunctionOpen circuit or short-circuit in

sensor-related circuitsON

P1021Oil feeder control valve systemOpen circuit and short-circuit in

solenoid valve-related circuits−

P1231Trustful check active stability

control (ASC)ABS/ASC-ECU−

P1233Trustful check throttle position

sensor (main)Abnormality in throttle position

sensor (main)ON

P1234Trustful check throttle position

sensor (sub)Abnormality in throttle position

sensor (sub)ON

P1235Trustful check air flow sensorAbnormality in air flow sensorON

P1236A/D converter systemAbnormality in engine-ECUON

P1237Trustful check accelerator pedal

position sensorAbnormality in accelerator pedal

position sensorON

P1238Air flow sensor trustful for torque

monitoringAbnormality in engine-ECUON

P1239Trustful check engine speedAbnormality in engine-ECUON

P1240Trustful check ignition angleAbnormality in ABS/ASC-ECU−

P1241Torque monitoringAbnormality in engine-ECUON

P1602Communication malfunction

(between engine-ECU main

processor and system LSI)Abnormality in engine-ECUON

P1603Battery back-up circuit malfunctionOpen circuit or short-circuit in

system-related circuitsON

P2100Throttle valve control servo circuit

(open)Open circuit in throttle valve control

servo-related circuitON

P2101Throttle valve control servo

magneto malfunctionShort-circuit in system-related

circuitsON

P2108Throttle valve control servo

processor malfunctionAbnormality in engine-CVT-ECUON

Code No. Diagnosis item Main diagnosis contents Engine

warning lamp

Page 137 of 364

GROUP 35

SERVICE BRAKE

CONTENTS

BASIC BRAKE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35A

ANTI-SKID BRAKE SYSTEM (ABS) . . . . . . . . . . . . . . . . . . . . .35B

ACTIVE STABILITY CONTROL SYSTEM (ASC). . . . . . . . . . . .35C

Page 140 of 364

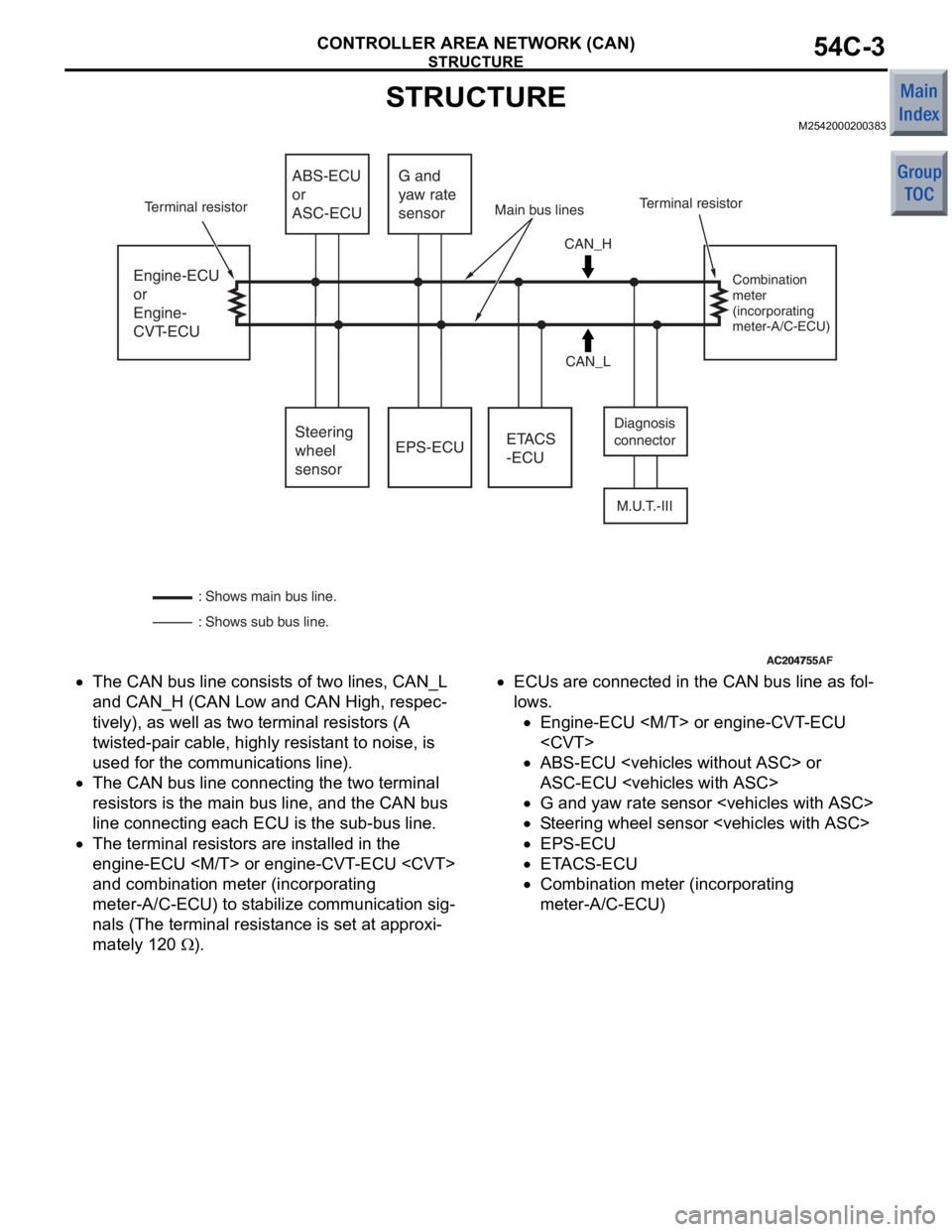

STRUCTURE

CONTROLLER AREA NETWORK (CAN)54C-3

STRUCTURE

M2542000200383

AC204755AC204755AF

Engine-ECU

or

Engine-

CVT-ECUEPS-ECU

M.U.T.-III

ETACS

-ECU

ABS-ECU

or

ASC-ECU

Steering

wheel

sensor G and

yaw rate

sensor

CAN_H

CAN_L Diagnosis

connector

Combination

meter

(incorporating

meter-A/C-ECU)

: Shows sub bus line. : Shows main bus line. Terminal resistor

Terminal resistor Main bus lines

•The CAN bu s line consist s of two lines, CAN_L

and

CAN_H (CAN Low and CAN Hig h , respec

-

tively), as well as two terminal re sistors (A

twisted-p

a ir cable, highly resist ant to noise, is

used for

the communicatio n s line) .

•The CAN bu s line connectin g the two terminal

resist

ors is th e main bus line, an d the CAN bus

line connecting

each ECU is th e su b-bus lin e.

•The terminal resistors are inst alled in the

eng

ine-ECU

and

combin ation mete r (incorpora t ing

meter-A/C-ECU) to st

abi lize co mmunicatio n sig

-

nals (The terminal resist ance is se t at ap proxi-

mately 120 Ω).

•ECUs are conn ected in th e CAN bus line as fo l-

lows.

•En gine -ECU

•ABS-ECU

A

S C-ECU

•G and ya w ra te se nsor

•St e e ring wh eel sensor

•EPS-ECU

•E T ACS-ECU

•Co mbinatio n me ter (in c orpo rating

meter-A/C-ECU)

Page 147 of 364

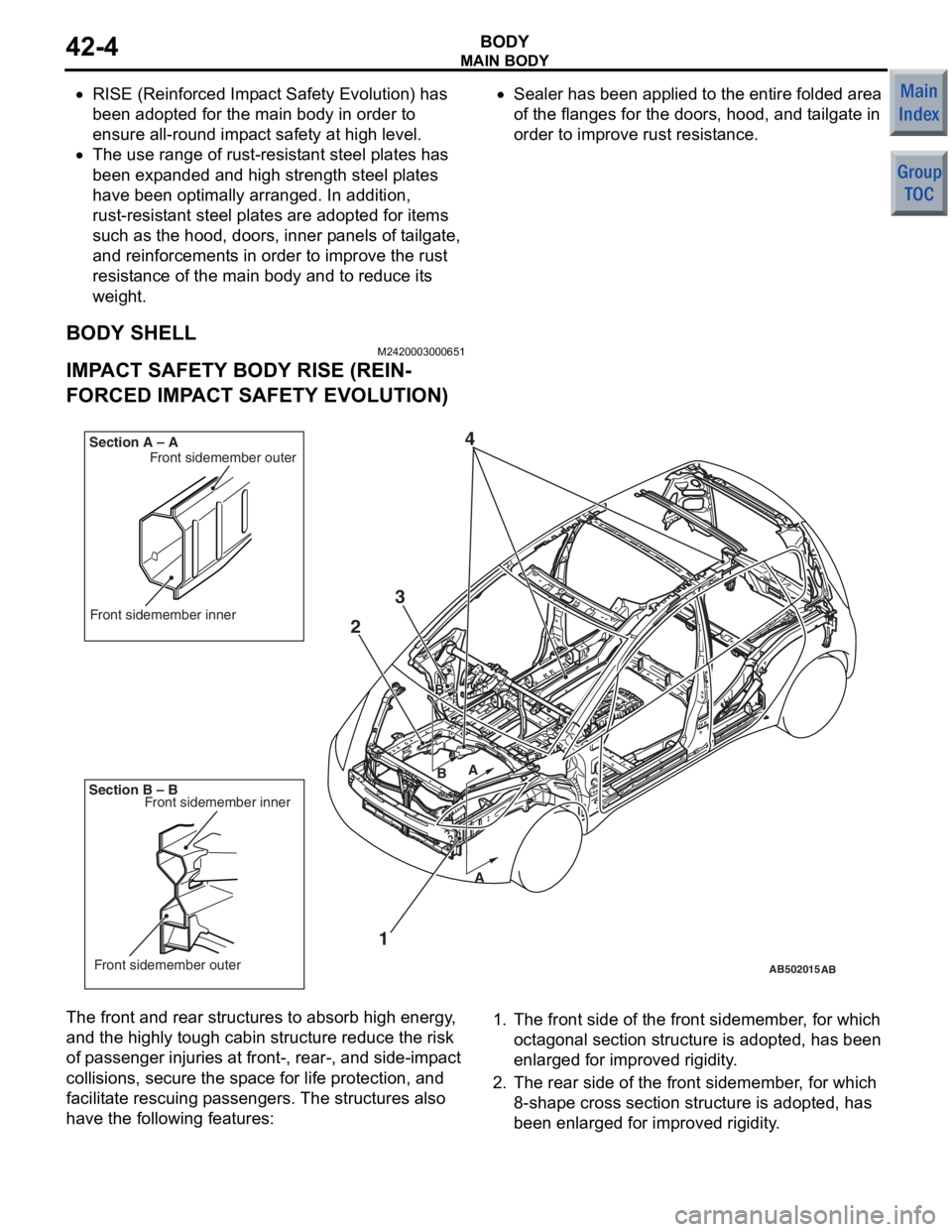

MAIN BODY

BODY42-4

•RISE (Reinforced Impact Safety Evolution) has

been adopted for the main body in order to

ensure all-round impact safety at high level.

•The use range of rust-resistant steel plates has

been expanded and high strength steel plates

have been optimally arranged. In addition,

rust-resistant steel plates are adopted for items

such as the hood, doors, inner panels of tailgate,

and reinforcements in order to improve the rust

resistance of the main body and to reduce its

weight.

•Sealer has been applied to the entire folded area

of the flanges for the doors, hood, and tailgate in

order to improve rust resistance.

BODY SHELL

M2420003000651

IMPACT SAFETY BODY RISE (REIN-

FORCED IMPACT SAFETY EVOLUTION)

AB201266

AB201267AB502015

AB400214

AB

1

2

4

Front sidemember inner

Front sidemember outer

B AA

B

Section B – B Section A – A

Front sidemember inner

Front sidemember outer

3

The fron

t and re ar st ructure s to abso r b hig h ener gy ,

and the

high ly tough cabin str u cture reduce the risk

of p

a ssenger inju ries at fron t-, rear-, and side-imp a ct

collisions, se

cure the sp a c e fo r life protection , and

facilit

ate rescuing p a sse ngers. The structures also

have

the followin g feat ures:1.The front side of the front sidemember , for wh ich

oct a gonal section stru cture is a dopted , has been

enlarged for improved rigidity .

2.The rear side o f the fr ont sidememb e r , for which

8-shape cross section struct ure is adop ted, ha s

bee n enlarged for improved rig i dity .

Page 162 of 364

WINDOW GLASS

BODY42-19

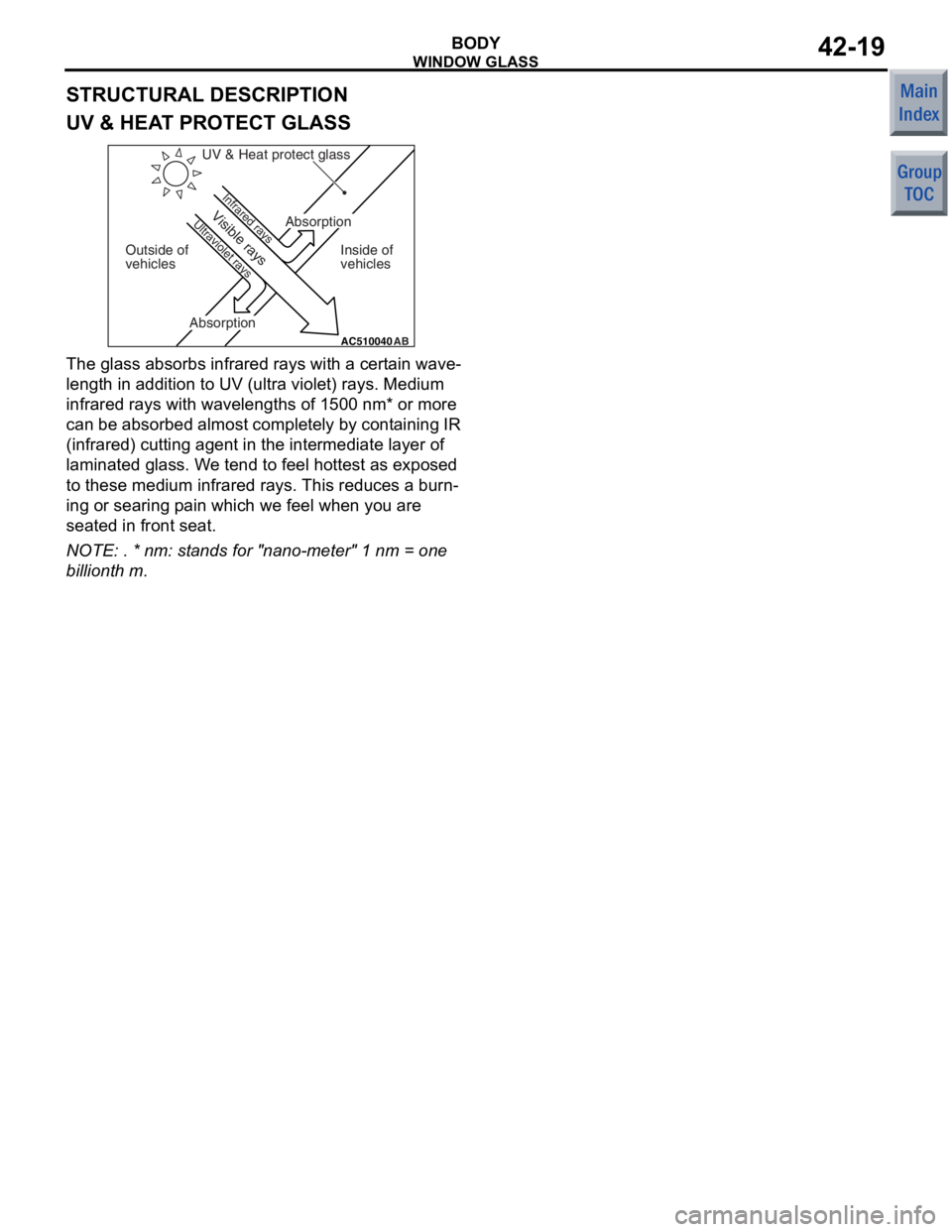

STRUCTURAL DESCRIPTION

UV & HEAT PROTECT GLASS

AC510040AB

UV & Heat protect glass

Outside of

vehicles Inside of

vehicles

Infrared rays

Ultraviolet rays

Absorption

AbsorptionVisible rays

The glass absorbs infrare d rays with a ce rt ain wave-

length in a ddition to UV (u ltra violet) rays. Medium

infrare

d rays with wa velengths of 15 00 nm* or mo re

can

be absorbed almost comple tely by cont aining IR

(infrare

d) cu tting agent in the inte rmediate layer of

laminate

d gla ss. W e te nd to f eel h o ttest as expo sed

to these medium in

frared ra ys. This reduces a burn

-

ing or searing p a in which we feel when you ar e

seate

d in front seat.

NOTE: . * nm: stand s for "nano-meter" 1 nm = one

billiont

h m.

Page 174 of 364

DIAGNOSIS SYSTEM

CHASSIS ELECTRICAL54A-3

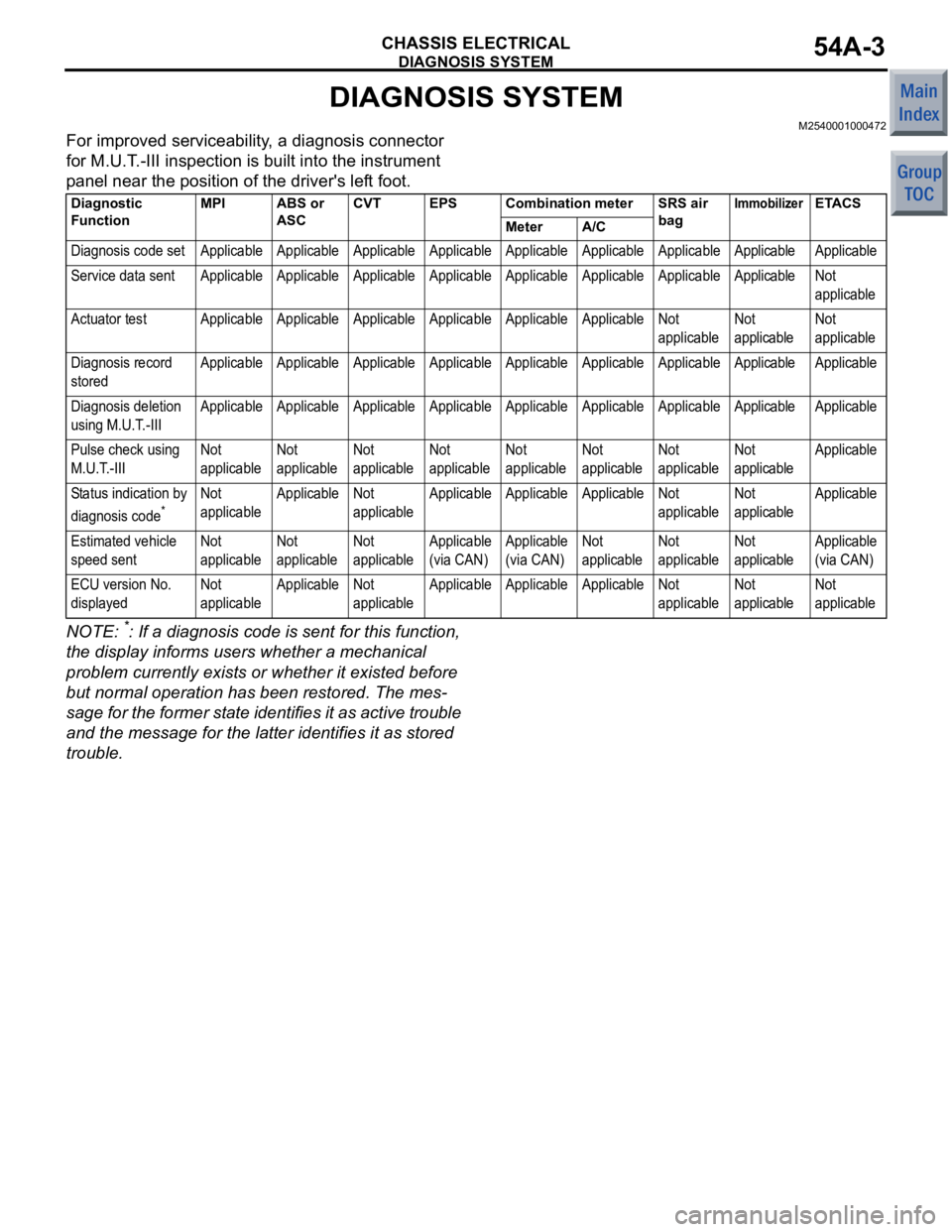

DIAGNOSIS SYSTEM

M2540001000472

For improved serviceability, a diagnosis connector

for M.U.T.-III inspection is built into the instrument

panel near the position of the driver's left foot.

Diagnostic

FunctionMPIABS or

ASCCVTEPSCombination meterSRS air

bagImmobilizerETACS

MeterA/C

Diagnosis code setApplicableApplicableApplicableApplicableApplicableApplicableApplicableApplicableApplicable

Service data sentApplicableApplicableApplicableApplicableApplicableApplicableApplicableApplicableNot

applicable

Actuator testApplicableApplicableApplicableApplicableApplicableApplicableNot

applicableNot

applicableNot

applicable

Diagnosis record

storedApplicableApplicableApplicableApplicableApplicableApplicableApplicableApplicableApplicable

Diagnosis deletion

using M.U.T.-IIIApplicableApplicableApplicableApplicableApplicableApplicableApplicableApplicableApplicable

Pulse check using

M.U.T.-IIINot

applicableNot

applicableNot

applicableNot

applicableNot

applicableNot

applicableNot

applicableNot

applicableApplicable

Status indication by

diagnosis code

*

Not

applicableApplicableNot

applicableApplicableApplicableApplicableNot

applicableNot

applicableApplicable

Estimated vehicle

speed sentNot

applicableNot

applicableNot

applicableApplicable

(via CAN)Applicable

(via CAN)Not

applicableNot

applicableNot

applicableApplicable

(via CAN)

ECU version No.

displayedNot

applicableApplicableNot

applicableApplicableApplicableApplicableNot

applicableNot

applicableNot

applicable

NOTE: *: If a diagnosis code is sent for this function,

the display informs users whether a mechanical

problem currently exists or whether it existed before

but normal operation has been restored. The mes

-

sage for the former state identifies it as active trouble

and the message for the latter identifies it as stored

trouble.