ECU MITSUBISHI COLT 2006 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 12 of 364

CONSTRUCTION DESCRIPTION

ANTI-SKID BRAKE SYSTEM (ABS)35B-12

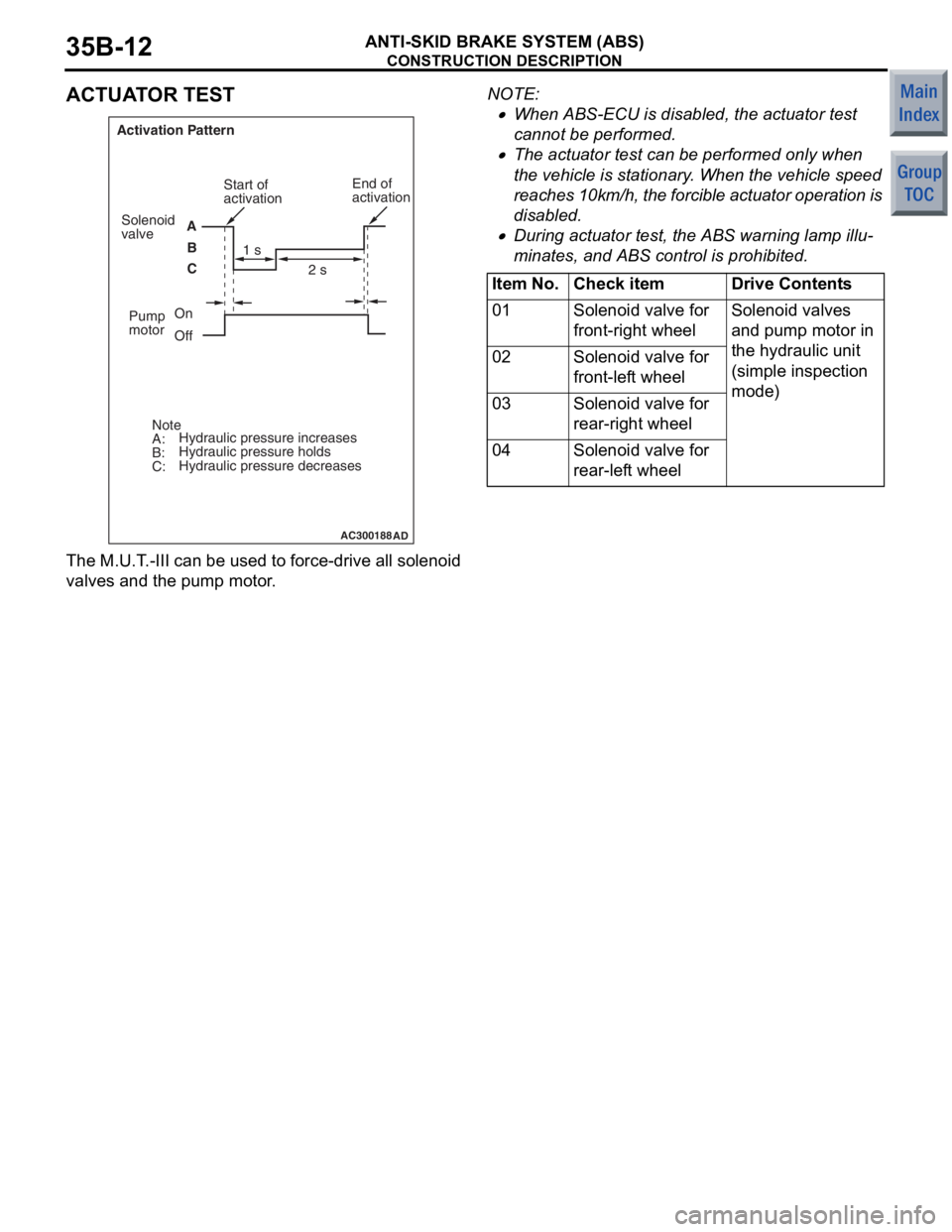

ACTUATOR TEST

AC300188AD

Activation PatternAB

C Start of

activation

1 s 2 s

On

Off

Note

A:

B:

C: Hydraulic pressure increases

Hydraulic pressure holds

Hydraulic pressure decreases End of

activation

Solenoid

valve

Pump

motor

The M.U.T . -III can be u s ed to force-drive a ll sole noid

valves and th

e pump mo tor .

NOTE: .

•Whe n ABS-ECU is disabled, the actu ator te st

cannot b

e perfo rmed.

•The actu ator test can be p e rformed on ly whe n

the

veh i cle is st a t iona ry . Whe n the ve hicle speed

rea

c h e s 10km/h, the f o rcible a c t uator operation is

disabled.

•During actuator test, the ABS warning lamp illu-

minates , an d ABS contro l is proh ibit ed.

Item No.Check itemDrive Contents

01Solenoid valve for

front-right wheelSolenoid valves

and pump motor in

the hydraulic unit

(simple inspection

mode)

02Solenoid valve for

front-left wheel

03Solenoid valve for

rear-right wheel

04Solenoid valve for

rear-left wheel

Page 22 of 364

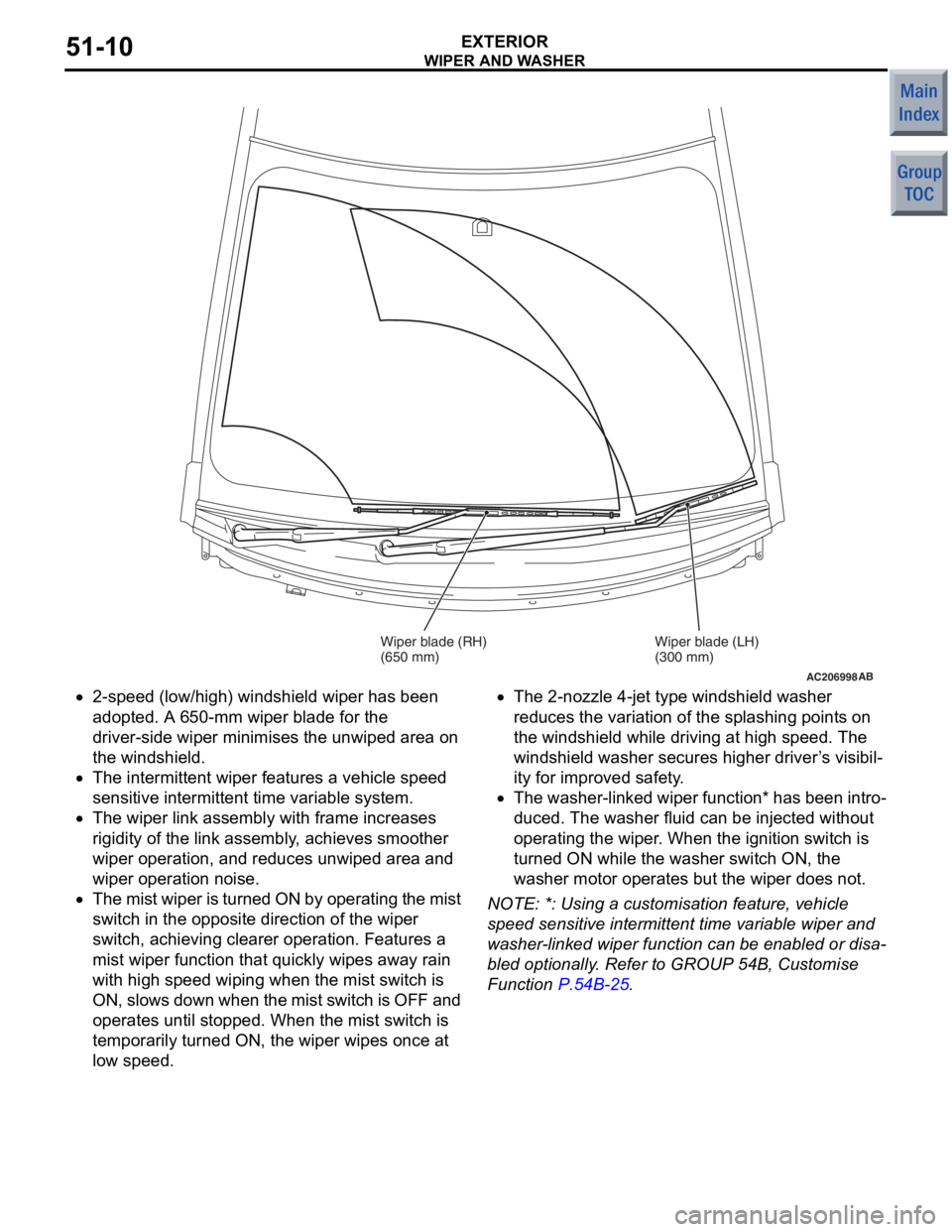

AC206998AB

Wiper blade (RH)

(650 mm)Wiper blade (LH)

(300 mm)

WIPE

R AN D W A SHER

EXTERIOR51-10

•2-speed (low/high) wind shield wip e r has been

ado

pted. A 6 50-mm wipe r blad e for th e

driver-side

wiper minimises the unwiped are a on

the

windshield.

•The intermitte nt wipe r feature s a vehicle spe ed

se

nsitive inte rmit tent time varia b le system.

•The wiper link assemb ly with frame in creases

rig

i dit y of t he link a s sembly , achieves smo o ther

wipe

r operat ion, a nd red u ces unwip ed area and

wipe

r operat ion n o ise.

•The mist wip e r is tu rned ON by o pera t ing the mist

switch in the

opposite direction of the wiper

switch,

achieving cleare r operat ion. F eatures a

mist wiper fun

c tio n that quickly wipe s away rain

with

high spee d wiping when t he mist switch is

ON,

slows down whe n th e mist switch is OFF and

ope

rates until sto pped. When th e mist switch is

temporarily turned

ON, the wiper wip e s o n ce a t

lo

w speed .

•The 2-nozzle 4-je t type windshield wash er

redu

ces the varia t ion of the spla shing point s on

the

windshield while dr iving at high speed. The

wind

shield washer secu res h i gher driver ’ s visibil

-

ity for impro v ed safe ty .

•The washer-linke d wiper function * has b een int r o-

duced. The wash er flu i d can be injected withou t

ope

rating the wip e r . Whe n the ignition switch is

turn

ed ON while t he wash er switch ON, the

washer mo

tor ope rates but th e wiper d oes not.

NOTE: *: Using a cust omisation fea t ure, vehicle

spee

d sen s it ive intermitte nt time variab le wip e r and

wa

sher

-lin ked wiper fun c tio n ca n be e nable d or disa

-

bled optio nally . Refer to GROUP 54 B, Cu stomise

Funct

i on

P.54B-25.

Page 24 of 364

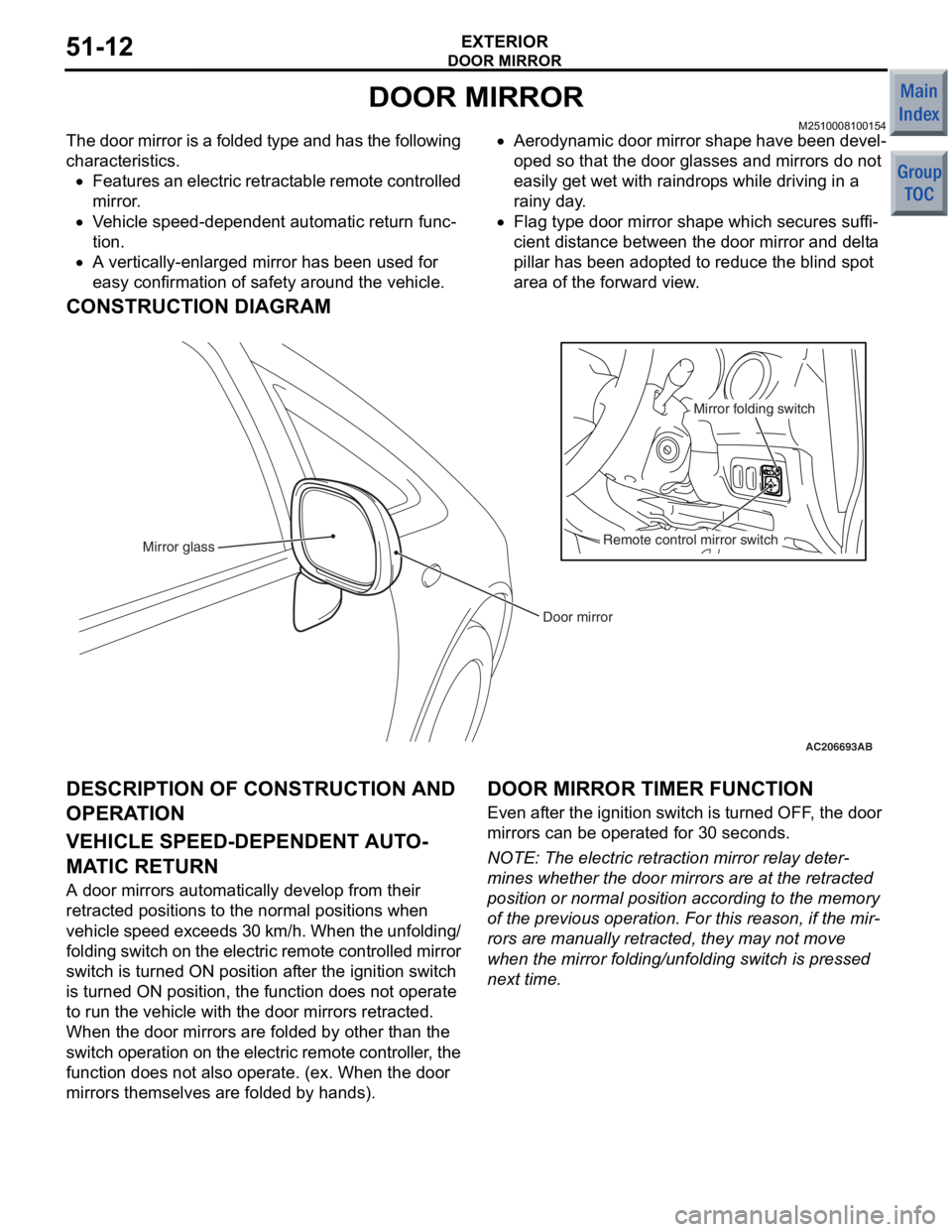

DOOR MIRROR

EXTERIOR51-12

DOOR MIRROR

M2510008100154

The door mirror is a folded type and has the following

characteristics.

•Features an electric retractable remote controlled

mirror.

•Vehicle speed-dependent automatic return func-

tion.

•A vertically-enlarged mirror has been used for

easy confirmation of safety around the vehicle.

•Aerodynamic door mirror shape have been devel-

oped so that the door glasses and mirrors do not

easily get wet with raindrops while driving in a

rainy day.

•Flag type door mirror shape which secures suffi-

cient distance between the door mirror and delta

pillar has been adopted to reduce the blind spot

area of the forward view.

CONSTRUCTION DIAGRAM

AC206693AB

Door mirror

Mirror glass

Remote control mirror switchMirror folding switch

DESCRIPTION OF CONSTRUCTION AND

OPERA

T ION

VEHICLE SPEED-DEPENDENT AUT O-

MATIC RETURN

A d oor mirrors automatically d e velop fro m the i r

retract

ed positions to the norma l positions wh en

ve

h i cle spe e d exce ed s 3 0 km/ h . Wh en t h e un fo ldin g/

fold

in g switch on t h e e l ectr ic re mo te co nt ro lled mirr or

switch is turned

ON po sition af ter the ig nition switch

is tu

rned ON positio n, the funct i on d oes n o t ope rate

to run th

e ve hicle with the do or mirrors retracted.

When th

e door mirro rs are fold ed by other t han th e

s

w itc h ope rat i on o n th e ele c t r i c rem o t e c o n t rol l er , th e

funct

i on d oes n o t also op erate. (ex. W hen the door

mirro

rs the m selve s are fold ed by hands).

DOOR MIRROR TIMER FUNCTION

Even after the ignition swit ch is turned OFF , the d oor

mirro

rs can be operate d for 30 seconds.

NOTE: The electric retraction mirror rela y de ter-

mine s whet her the door mirrors are a t the re tracte d

position

or normal p o sition accordin g to the memory

of the p

r evious operation. F o r this reason, if the mir

-

rors ar e man ually ret r acte d, they ma y not move

wh

en the mirro r fold ing/u n fold ing switch is pressed

next time

.

Page 25 of 364

GROUP 55

HEATER, AIR

CONDITIONER AND

VENTILATION

CONTENTS

GENERAL INFORMATIO N . . . . . . . .55-2

HEATER UNIT . . . . . . . . . . . . . . . . . .55-5

HEATER CONTROL . . . . . . . . . . . . .55-7

A/C-ECU . . . . . . . . . . . . . . . . . . . . . . .55-8

DUCTS . . . . . . . . . . . . . . . . . . . . . . . .55-11

VENTILATION SYSTEM . . . . . . . . . . .55-12

Page 26 of 364

GENERAL INFORMATION

HEATER, AIR CONDITIONER AND VENTILATION55-2

GENERAL INFORMATION

M2551000100759

For the heater and A/C system, the heater, the

blower and the cooling unit are integrated as one unit

to reduce weight and size. For A/C system, the man

-

ual A/C has been adopted.

FEATURES

IMPROVEMENTS IN COMFORT

•Adoption of low noise, large air volume heater

and A/C system

•Adoption of smaller air intake box for larger pas-

senger leg space.

•Optimising the areas of the outside air induction

hole and the air outlet improves ventilation per

-

formance as well as the quietness of the room

•Adoption of clean air filter with deodorant function

for cleaner air in the compartment.

IMPROVEMENTS IN OPERATION

PERFORMANCE

•Inside/outside air selection switch has been

changed to a pushbutton switch.

•Improved operation ability by the enlarged tab on

the dial knob

•Air amount and temperature only are controlled

automatically for easier operation.

RELIABLE VISUAL FIELD

(IMPROVEMENT IN SAFETY)

•Current type defroster nozzle has been adopted

to improve defogging performance (Shortens

windshield fogging time).

•Defroster vents have been integrated to secure

better defogging pattern.

•Black coin drop prevention ribs are used on the

defroster to prevent its reflection on the wind

-

shield, providing sufficient field of vision for safety

IMPROVEMENTS IN FUEL ECONOMY

•Wider condenser area reduces load to the A/C

and improves fuel consumption.

•Energy conservation control using outside air

temperature sensor is adopted for vehicles with

manual A/C as well.

•A small-size, highly-efficient compressor has

been adopted.

•Simpler wiring and weight reduction are achieved

by installation of CAN communication system

GLOBAL ENVIRONMENT PROTECTION

Adoption of HFC134a for refrigerant.

IMPROVEMENTS IN SERVICE QUALITY

•Reduction of refrigerant gas leakage and

improvement in serviceability by incorporating

condenser and receiver

•The layout of refrigerant line for better workability

is adopted.

RESPONSIBILITY IMPROVEMENT

Reliable information transmission is achieved by

connecting A/C-ECU and each ECU via CAN com

-

munication.

Page 32 of 364

A/C-ECU

HEATER, AIR CONDITIONER AND VENTILATION55-8

A/C-ECU

M2551001200179

CONTROL SYSTEM

The manual and automatic A/Cs have the following

control functions.

ControlManual A/CAutomatic A/C

Automatic wind temperature change controlApplicableApplicable

Automatic outside/inside air selection controlApplicableApplicable

Idle-up controlApplicableApplicable

Cooling fun load controlApplicableApplicable

Cooling controlApplicableApplicable

Detection control for refrigerant leaksApplicableApplicable

MAX A/C controlNot applicableApplicable

Estimation control for compressor torqueApplicableApplicable

Defroster linked controlNot applicableApplicable

AUTOMATIC CHANGE CONTROL OF

BLOW WIND TEMPERATURE

(COMPRESSOR

ENERGY-CONSERVATION CONTROL)

Optimum ON/OFF control of the compressor is

achieved according to the outside/inside air mode,

air temperature (air temperature sensor), and insula

-

tion.

OUTSIDE/INSIDE AIR AUTO SWITCHING

CONTROL

When the A/C is turned on in high ambient tempera-

ture, the recirculation function is automatically acti-

vated to cool down the passenger compartment and

improve fuel consumption.

COOLING FUN LOAD CONTROL

Depending on the A/C load, the cooling fan cycle

time is controlled and the exterior noise in the inter

-

mediary stage is decreased. Also, the load of the

alternator is decreased to improve the fuel economy.

COOLING CONTROL

If air temperature is high, the CVT rotates at a high

speed to prevent deterioration in cooling perform

-

ance.

DETECTION CONTROL FOR

REFRIGERANT LEAKS

When it is judged from the air temperature (air tem-

perature sensor) and the refrigerant pressure (A/C

pressure sensor) that the refrigerant amount is the

specified value or less, or the refrigerant pressure is

abnormal, the compressor is forced to be cut off to

protect the A/C system.

MAX A/C CONTROL

When MAX COOL position is set, automatically the

mode is changed to the inside air mode before the

A/C is turned ON, thereby facilitating the operation

for obtaining maximum cooling performance.

ESTIMATION CONTROL FOR

COMPRESSOR TORQUE

Communication between the engine⋅CVT-ECU and

A/C-ECU is made to control the engine according to

the compressor torque for higher drivability and

reduction in fuel consumption.

FORCIBLE DEFROSTER CONTROL

When the defroster vents are selected, the A/C is

automatically turned ON. At this time, the out

-

side/inside air selection damper is operated to the

fresh-air position to defrost the windshield glass

quickly.

Page 33 of 364

A/C-ECU

HEATER, AIR CONDITIONER AND VENTILATION55-9

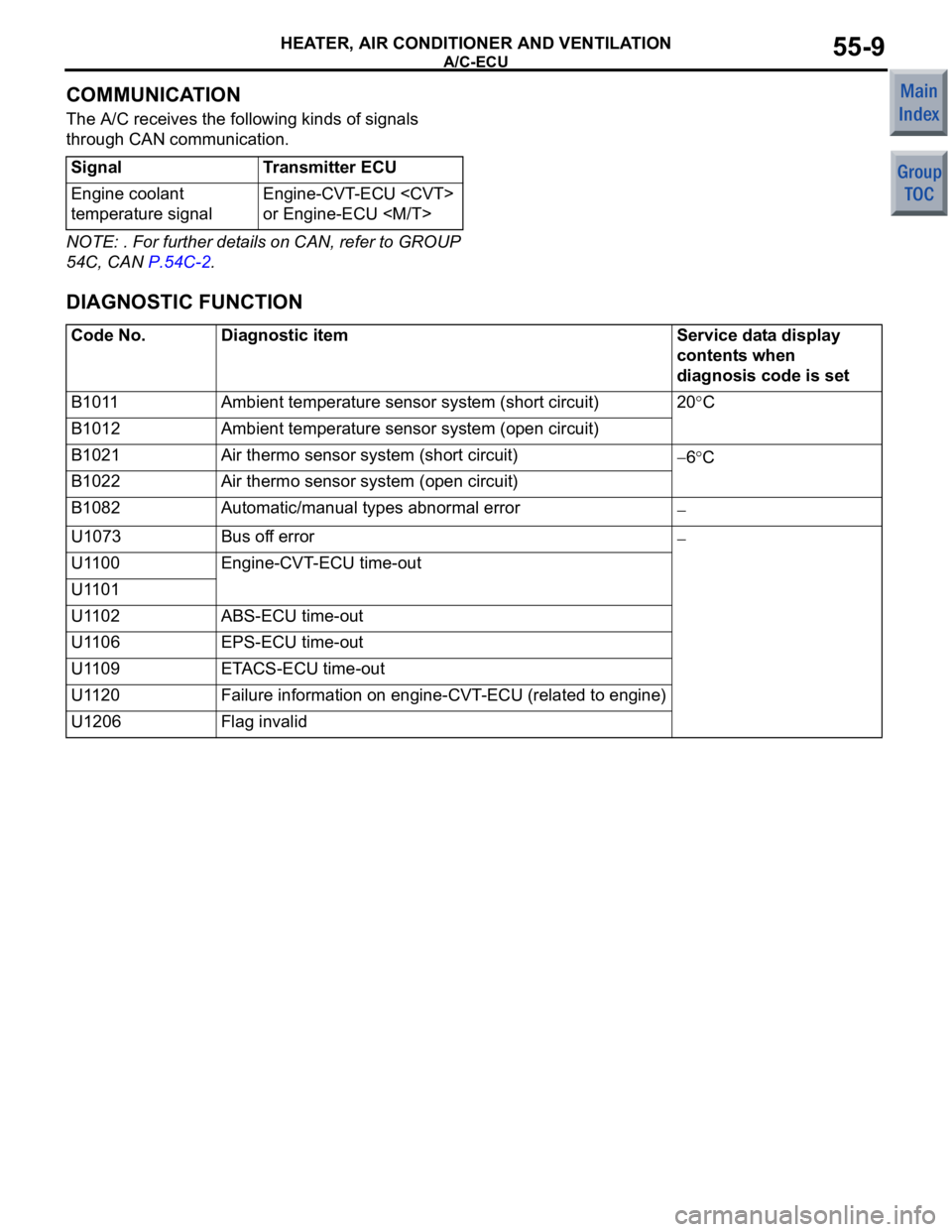

COMMUNICATION

The A/C receives the following kinds of signals

through CAN communication.

SignalTransmitter ECU

Engine coolant

temperature signalEngine-CVT-ECU

or Engine-ECU

NOTE: . For further details on CAN, refer to GROUP

54C, CAN

P.54C-2.

DIAGNOSTIC FUNCTION

Code No.Diagnostic itemService data display

contents when

diagnosis code is set

B1011Ambient temperature sensor system (short circuit)20°C

B1012Ambient temperature sensor system (open circuit)

B1021Air thermo sensor system (short circuit)−6°C

B1022Air thermo sensor system (open circuit)

B1082Automatic/manual types abnormal error−

U1073Bus off error−

U1100Engine-CVT-ECU time-out

U1101

U1102ABS-ECU time-out

U1106EPS-ECU time-out

U1109ETACS-ECU time-out

U1120Failure information on engine-CVT-ECU (related to engine)

U1206Flag invalid

Page 34 of 364

A/C-ECU

HEATER, AIR CONDITIONER AND VENTILATION55-10

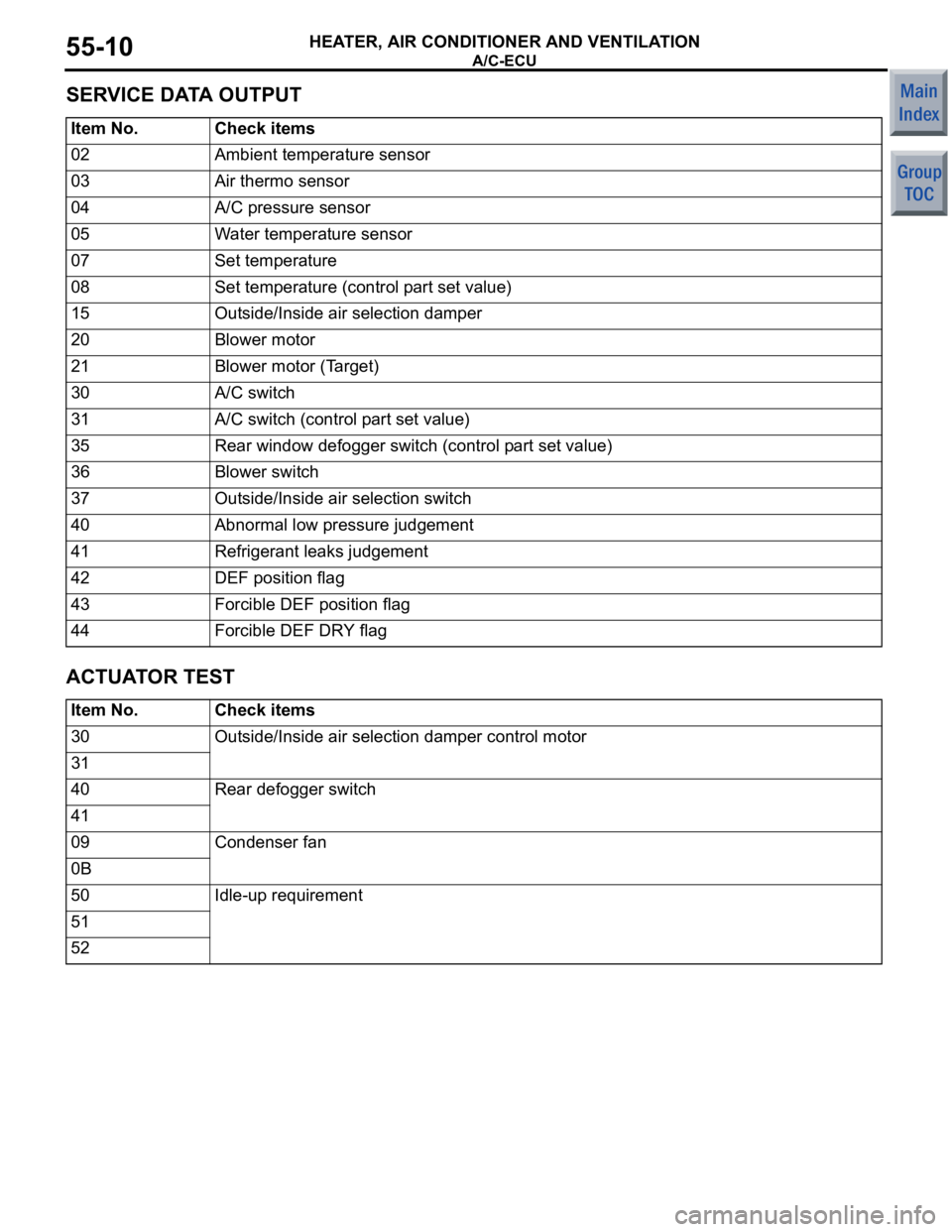

SERVICE DATA OUTPUT

Item No.Check items

02Ambient temperature sensor

03Air thermo sensor

04A/C pressure sensor

05Water temperature sensor

07Set temperature

08Set temperature (control part set value)

15Outside/Inside air selection damper

20Blower motor

21Blower motor (Target)

30A/C switch

31A/C switch (control part set value)

35Rear window defogger switch (control part set value)

36Blower switch

37Outside/Inside air selection switch

40Abnormal low pressure judgement

41Refrigerant leaks judgement

42DEF position flag

43Forcible DEF position flag

44Forcible DEF DRY flag

ACTUATOR TEST

Item No.Check items

30Outside/Inside air selection damper control motor

31

40Rear defogger switch

41

09Condenser fan

0B

50Idle-up requirement

51

52

Page 36 of 364

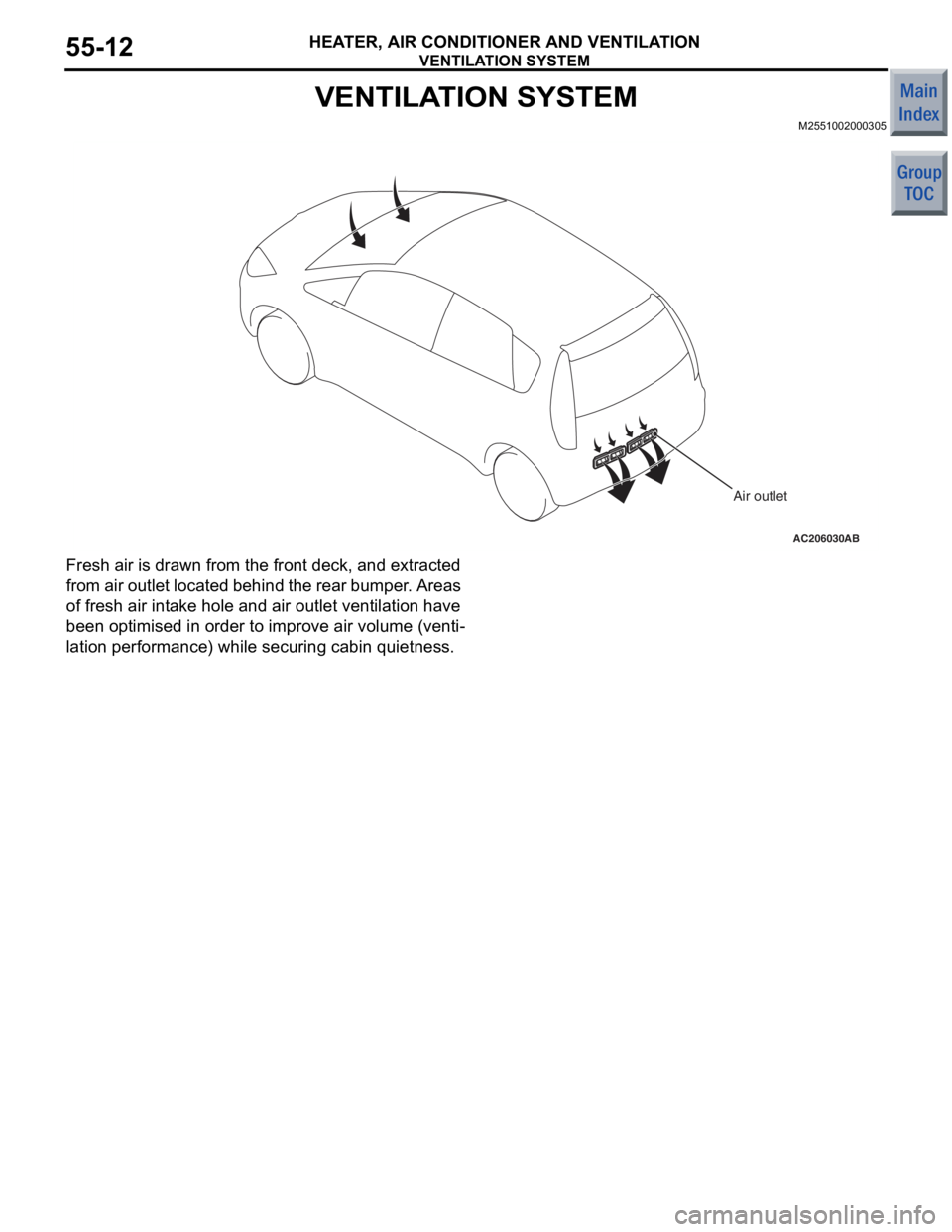

VENTILATION SYSTEM

HEATER, AIR CONDITIONER AND VENTILATION55-12

VENTILATION SYSTEM

M2551002000305

AC206030AB

Air outlet

Fresh ai r is drawn fro m the f r ont deck, a nd extracte d

fro

m air ou tlet lo cate d be hind th e re ar bu mp er . Area s

of fresh

air int a ke h o le and a i r outlet vent ilat i on have

been o

p timise d in order to imp r ove air volume (venti

-

lation perfo rman ce) while secu ring cabin quietness.

Page 64 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-16

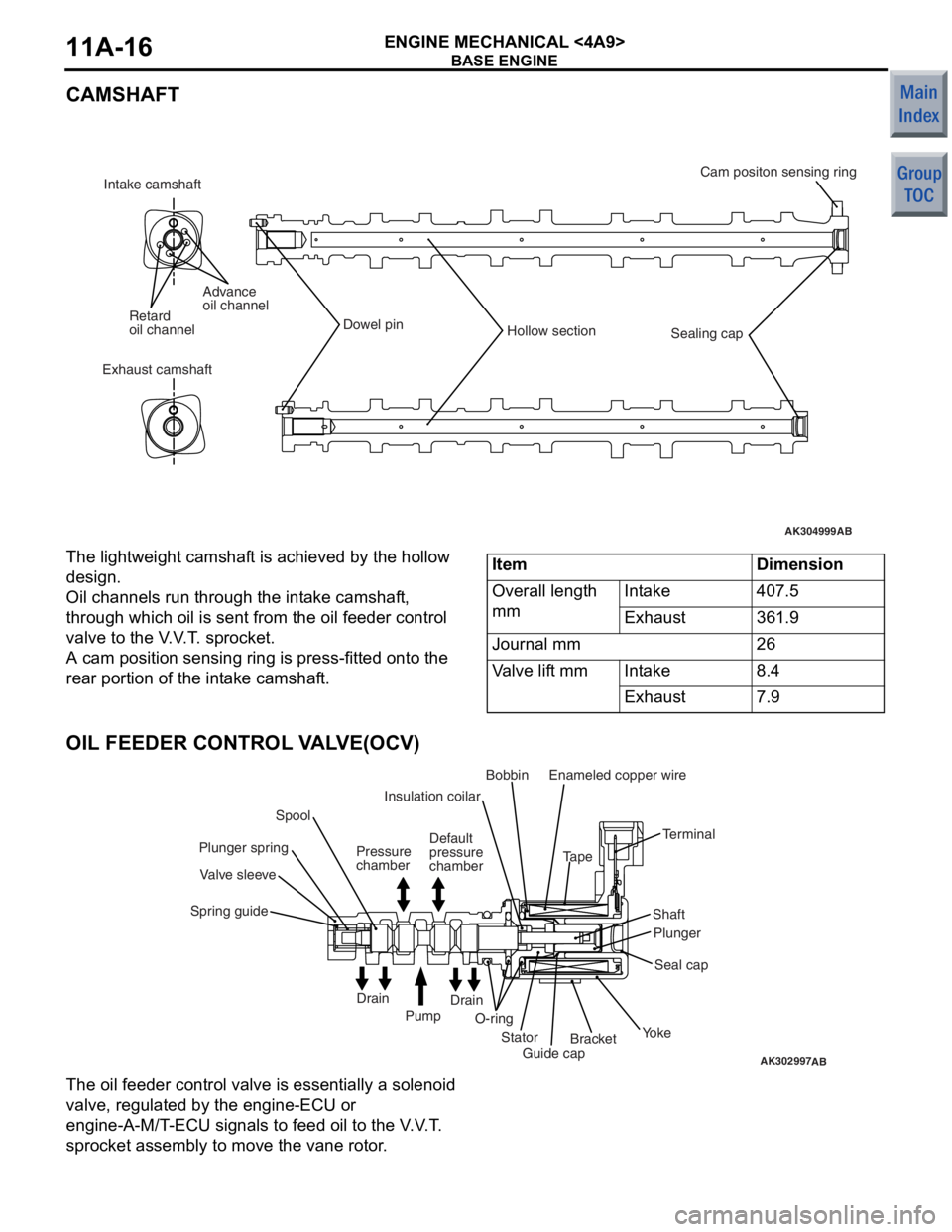

CAMSHAFT

AK304999

Intake camshaft

Exhaust camshaft

AB

Hollow section

Advance

oil channel

Retard

oil channel

Cam positon sensing ring

Dowel pinSealing cap

The lightweight camshaf t is ach i eved by the h o llo w

design.

Oil channels run through the int a ke camshaf t,

through

wh ich oil is sent from t he oil fee der co ntrol

valve to

the V . V . T . sprocket.

A cam position sen s in g ring is press-fitt ed onto the

rear port

i on o f the int a ke camshaf t.

ItemDimension

Overall length

mmIntake407.5

Exhaust361.9

Journal mm26

Valve lift mmIntake8.4

Exhaust7.9

OIL FEEDER CONT ROL V A L V E(OCV)

AK302997AB

Spring guideValve sleeve

Plunger spring Spool

O-ring

Insulation coilar

StatorGuide cap Bracket

Yo k eSeal cap

Plunger

Shaft Terminal

Bobbin

Tape

Enameled copper wire

Drain

Drain

Pump

Pressure

chamber

Default

pressure

chamber

The oil fee

der co ntrol valve is essen t ially a solenoid

valve, re

gulat ed by the en gine -ECU or

engin

e -A-M/T -ECU signals to feed o il to the V . V . T .

sprocket

assemb ly t o move the van e rotor .