ECU MITSUBISHI COLT 2006 Service Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 131 of 364

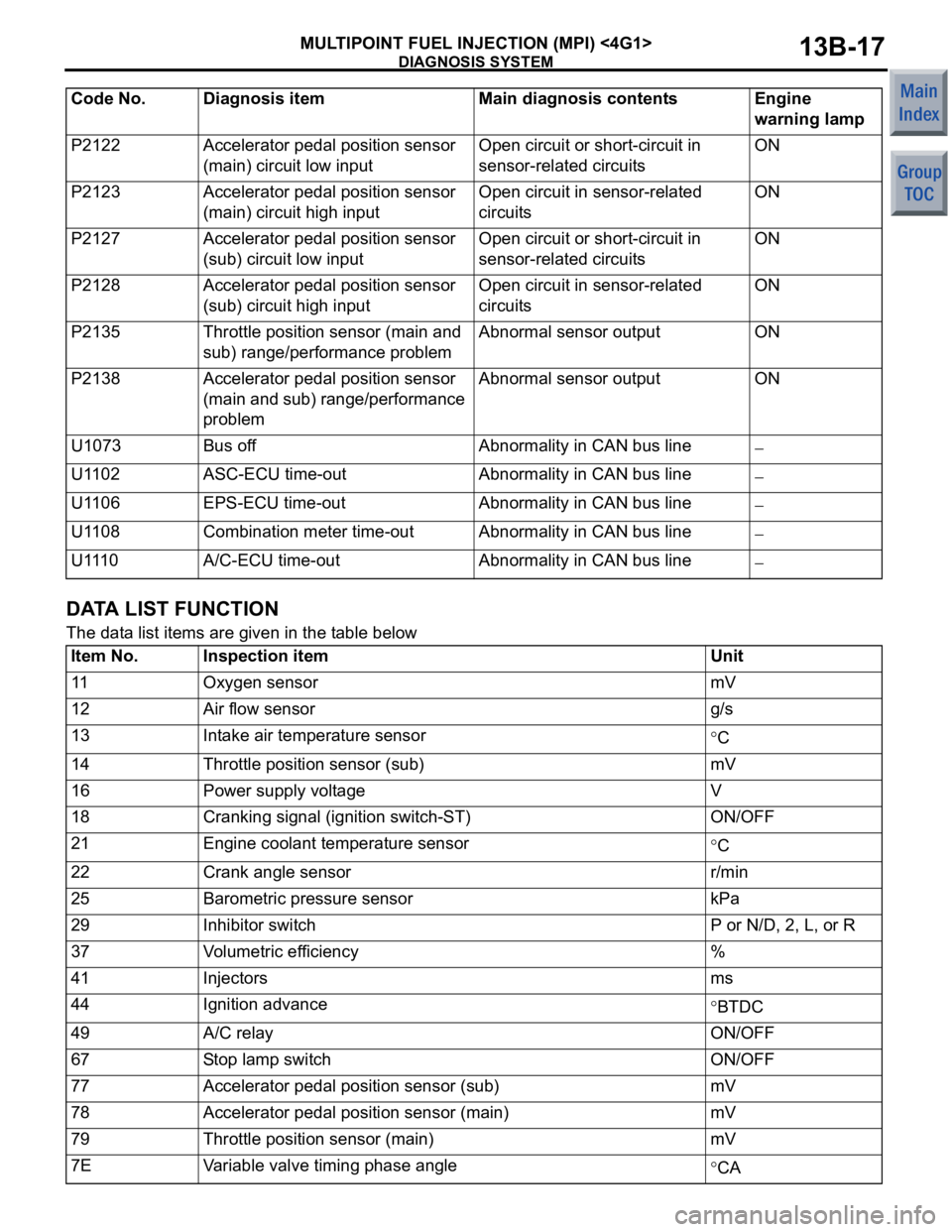

DIAGNOSIS SYSTEM

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-17

DATA LIST FUNCTION

The data list items are given in the table below

P2122Accelerator pedal position sensor

(main) circuit low inputOpen circuit or short-circuit in

sensor-related circuitsON

P2123Accelerator pedal position sensor

(main) circuit high inputOpen circuit in sensor-related

circuitsON

P2127Accelerator pedal position sensor

(sub) circuit low inputOpen circuit or short-circuit in

sensor-related circuitsON

P2128Accelerator pedal position sensor

(sub) circuit high inputOpen circuit in sensor-related

circuitsON

P2135Throttle position sensor (main and

sub) range/performance problemAbnormal sensor outputON

P2138Accelerator pedal position sensor

(main and sub) range/performance

problemAbnormal sensor outputON

U1073Bus offAbnormality in CAN bus line−

U1102ASC-ECU time-outAbnormality in CAN bus line−

U1106EPS-ECU time-outAbnormality in CAN bus line−

U1108Combination meter time-outAbnormality in CAN bus line−

U 111 0A/C-ECU time-outAbnormality in CAN bus line−

Code No. Diagnosis item Main diagnosis contents Engine

warning lamp

Item No.Inspection itemUnit

11Oxygen sensormV

12Air flow sensorg/s

13Intake air temperature sensor°C

14Throttle position sensor (sub)mV

16Power supply voltageV

18Cranking signal (ignition switch-ST)ON/OFF

21Engine coolant temperature sensor°C

22Crank angle sensorr/min

25Barometric pressure sensorkPa

29Inhibitor switchP or N/D, 2, L, or R

37Volumetric efficiency%

41Injectorsms

44Ignition advance°BTDC

49A/C relayON/OFF

67Stop lamp switchON/OFF

77Accelerator pedal position sensor (sub)mV

78Accelerator pedal position sensor (main)mV

79Throttle position sensor (main)mV

7EVariable valve timing phase angle°CA

Page 133 of 364

DIAGNOSIS SYSTEM

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-19

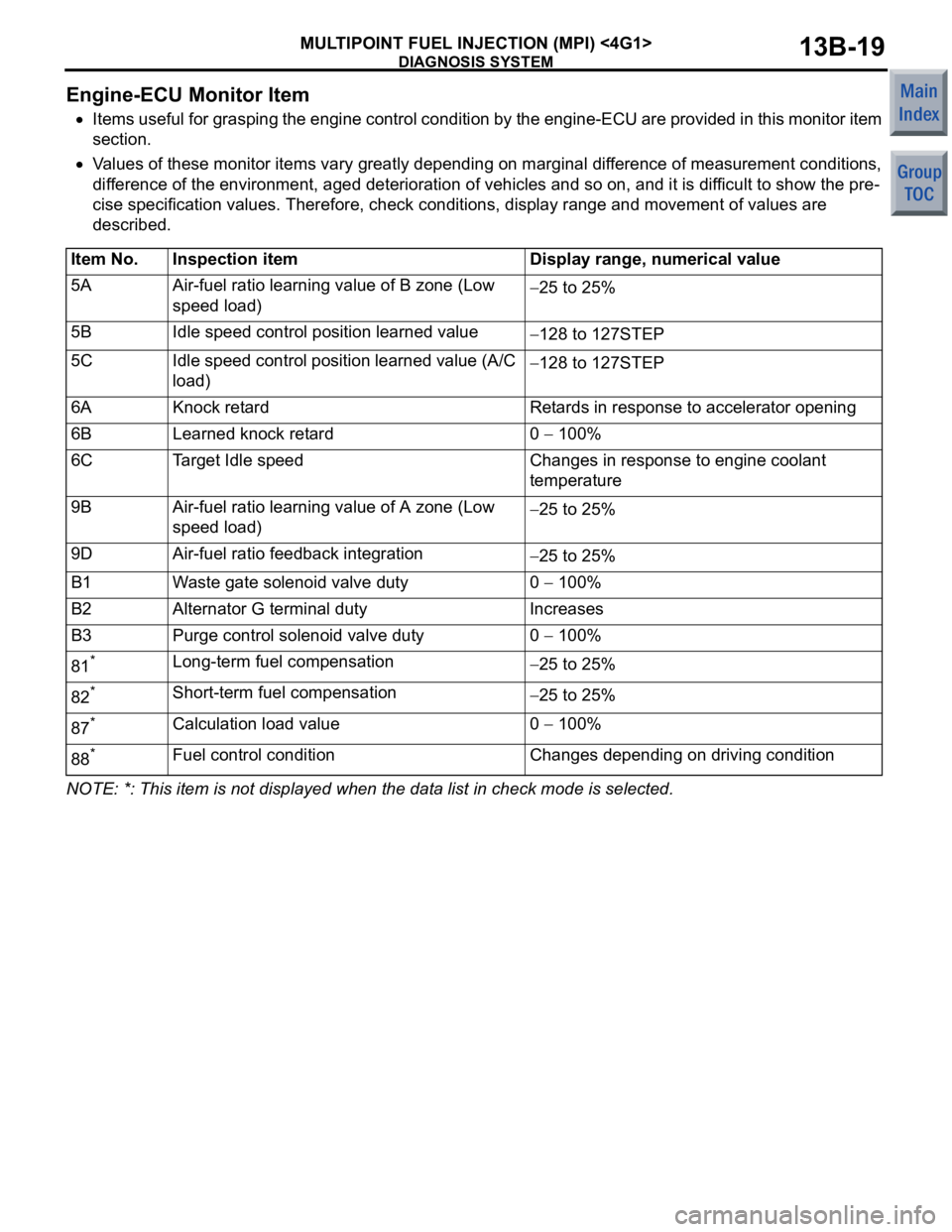

Engine-ECU Monitor Item

•Items useful for grasping the engine control condition by the engine-ECU are provided in this monitor item

section.

•Values of these monitor items vary greatly depending on marginal difference of measurement conditions,

difference of the environment, aged deterioration of vehicl es and so on, and it is difficult to show the pre

-

cise specification values. Therefore, check conditions, display range and movement of values are

described.

Item No.Inspection itemDisplay range, numerical value

5AAir-fuel ratio learning value of B zone (Low

speed load)−25 to 25%

5BIdle speed control position learned value−128 to 127STEP

5CIdle speed control position learned value (A/C

load)−128 to 127STEP

6AKnock retardRetards in response to accelerator opening

6BLearned knock retard0 − 100%

6CTarget Idle speedChanges in response to engine coolant

temperature

9BAir-fuel ratio learning value of A zone (Low

speed load)−25 to 25%

9DAir-fuel ratio feedback integration−25 to 25%

B1Waste gate solenoid valve duty0 − 100%

B2Alternator G terminal dutyIncreases

B3Purge control solenoid valve duty0 − 100%

81*Long-term fuel compensation−25 to 25%

82*Short-term fuel compensation−25 to 25%

87*Calculation load value0 − 100%

88*Fuel control conditionChanges depending on driving condition

NOTE: *: This item is not displayed when the data list in check mode is selected.

Page 139 of 364

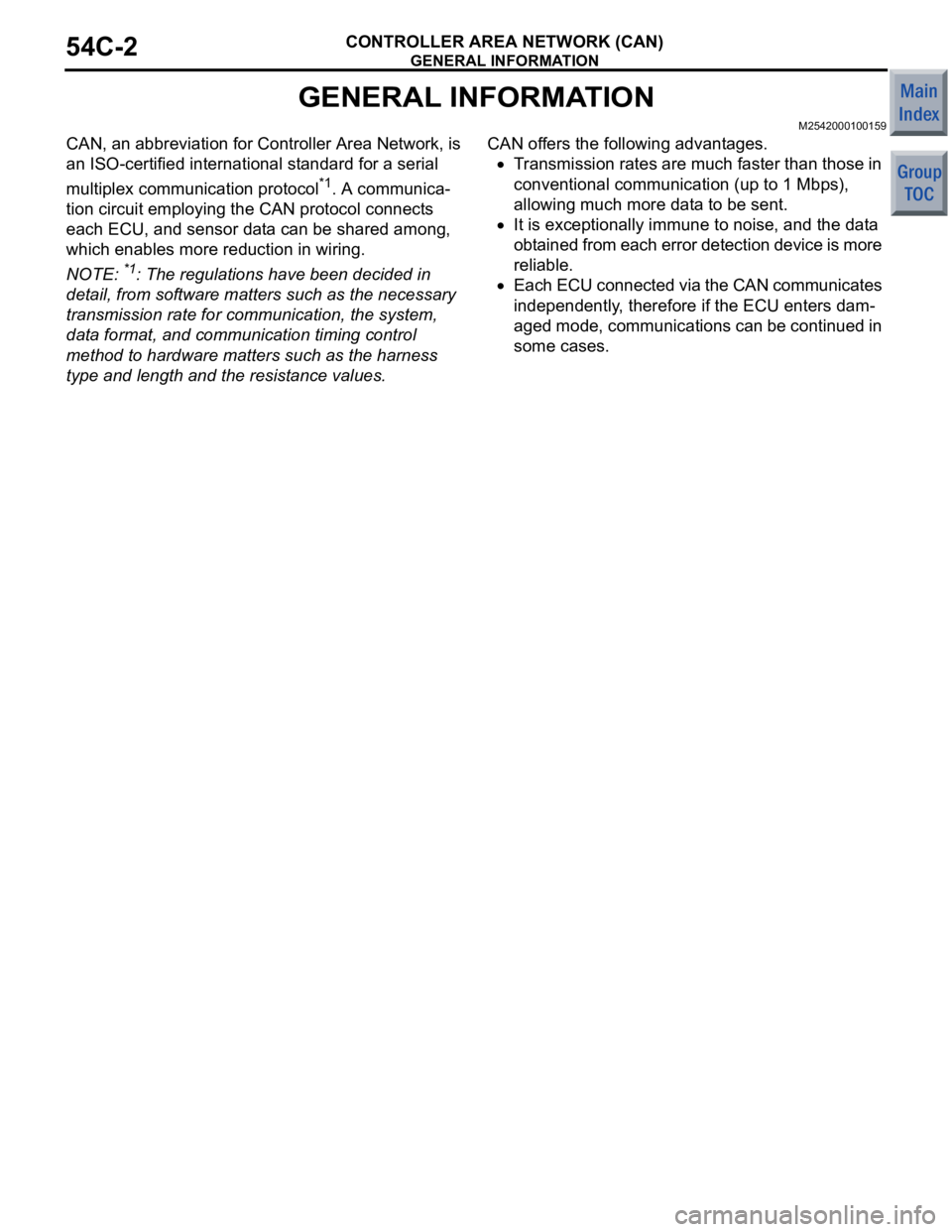

GENERAL INFORMATION

CONTROLLER AREA NETWORK (CAN)54C-2

GENERAL INFORMATION

M2542000100159

CAN, an abbreviation for Controller Area Network, is

an ISO-certified international standard for a serial

multiplex communication protocol

*1. A communica-

tion circuit employing the CAN protocol connects

each ECU, and sensor data can be shared among,

which enables more reduction in wiring.

NOTE: *1: The regulations have been decided in

detail, from software matters such as the necessary

transmission rate for communication, the system,

data format, and communication timing control

method to hardware matters such as the harness

type and length and the resistance values.

CAN offers the following advantages.

•Transmission rates are much faster than those in

conventional communication (up to 1 Mbps),

allowing much more data to be sent.

•It is exceptionally immune to noise, and the data

obtained from each error detection device is more

reliable.

•Each ECU connected via the CAN communicates

independently, therefore if the ECU enters dam

-

aged mode, communications can be continued in

some cases.

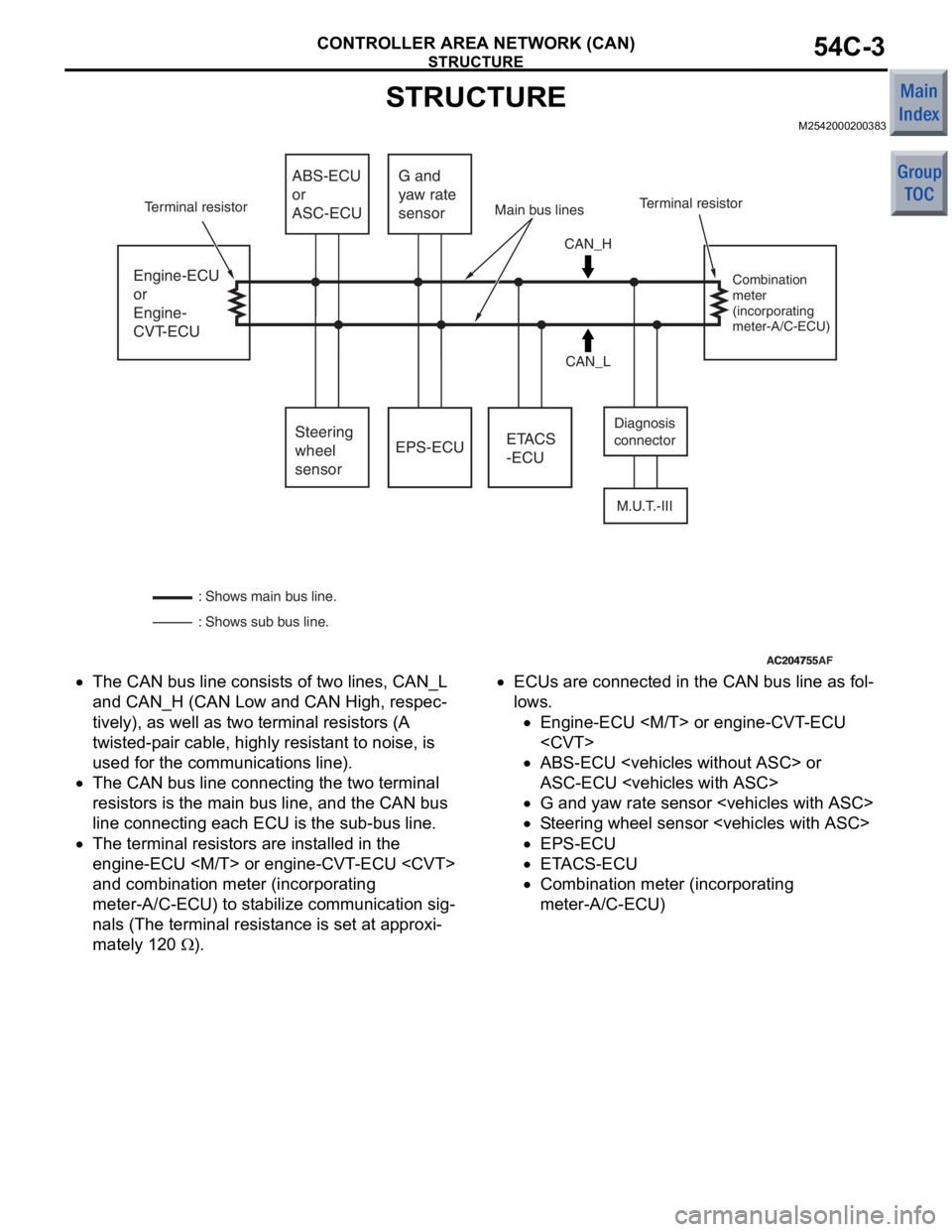

Page 140 of 364

STRUCTURE

CONTROLLER AREA NETWORK (CAN)54C-3

STRUCTURE

M2542000200383

AC204755AC204755AF

Engine-ECU

or

Engine-

CVT-ECUEPS-ECU

M.U.T.-III

ETACS

-ECU

ABS-ECU

or

ASC-ECU

Steering

wheel

sensor G and

yaw rate

sensor

CAN_H

CAN_L Diagnosis

connector

Combination

meter

(incorporating

meter-A/C-ECU)

: Shows sub bus line. : Shows main bus line. Terminal resistor

Terminal resistor Main bus lines

•The CAN bu s line consist s of two lines, CAN_L

and

CAN_H (CAN Low and CAN Hig h , respec

-

tively), as well as two terminal re sistors (A

twisted-p

a ir cable, highly resist ant to noise, is

used for

the communicatio n s line) .

•The CAN bu s line connectin g the two terminal

resist

ors is th e main bus line, an d the CAN bus

line connecting

each ECU is th e su b-bus lin e.

•The terminal resistors are inst alled in the

eng

ine-ECU

and

combin ation mete r (incorpora t ing

meter-A/C-ECU) to st

abi lize co mmunicatio n sig

-

nals (The terminal resist ance is se t at ap proxi-

mately 120 Ω).

•ECUs are conn ected in th e CAN bus line as fo l-

lows.

•En gine -ECU

•ABS-ECU

A

S C-ECU

•G and ya w ra te se nsor

•St e e ring wh eel sensor

•EPS-ECU

•E T ACS-ECU

•Co mbinatio n me ter (in c orpo rating

meter-A/C-ECU)

Page 141 of 364

OPERATION

CONTROLLER AREA NETWORK (CAN)54C-4

OPERATION

M2542000300313

AC206267

ECU-1A

AAA

BBB CCA

B

Interval "a"

Interval "b" Interval "c"

CCC BB

AAA

ECU-1

ECU-2

CAN bus

Data frames

AC206267

AD

Transmission

suspended by

mediation

Re-

transmission

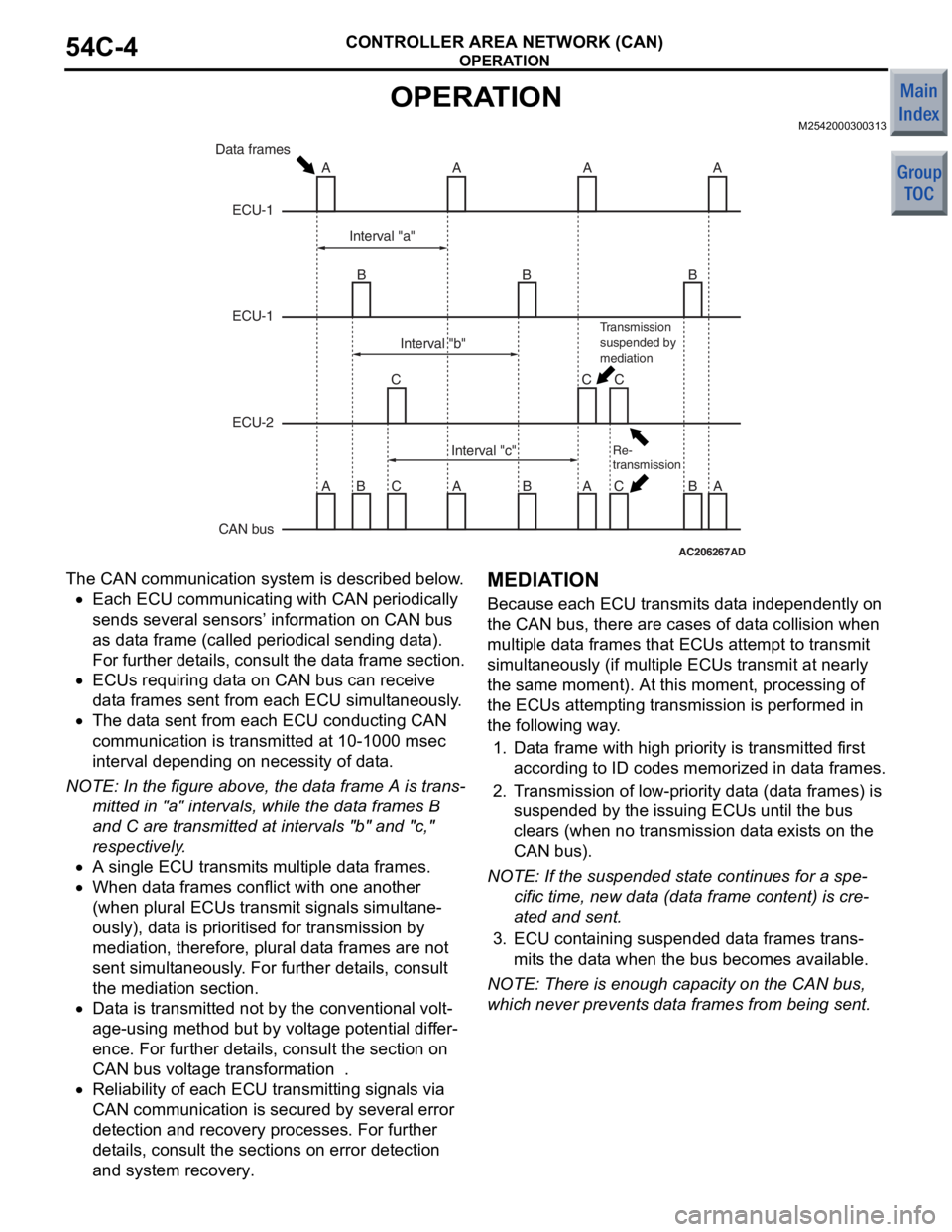

The CAN commun ica t ion system is describe d below .

•Each ECU communicating with CAN pe riodically

se

nds several sensors’ inf o rmation on CAN bu s

as dat

a frame (calle d periodical send ing d a t a ).

For furt

her det ails, co nsult the dat a frame sectio n

.

•ECUs requirin g dat a on CAN bu s can receive

dat

a fra m es sen t from each ECU simult aneo usly .

•The dat a se nt from each ECU condu cting CAN

co

mmunicatio n is transmitted at 10-100 0 msec

in

terva l dep endin g on n e cessity of dat a.

NOTE: In the f i gure ab ove, th e dat a frame A is trans-

mitted in "a" intervals, while the d a t a frames B

and

C are tran smitted at int e rvals "b" and "c,"

respective

ly .

•A single ECU tra n smit s multiple dat a frames.

•When dat a frames conf lict with o ne ano ther

(when

plural ECUs tr ansmit signals simu lt ane

-

ously), data is prioriti sed for transmission b y

mediat

ion, t herefore , plu r al da t a frames are not

se

nt simult aneously . F o r furthe r det ails, consult

the

mediatio n se ctio n

.

•Data is transmitted no t by the conve n tion al volt-

age-using method b u t by volt a ge pot entia l dif f er-

ence. For further det ails, consu l t the section on

CAN

bus volt ag e transformation

.

•Reliability of each ECU transmitting sig nals via

CAN

commun ica t ion is secu red by several error

det

ection and reco very processes. For furth e r

det

ails, consult the sections on error detection

and

sy stem rec o very

.

MEDIA T I O N

Because ea ch ECU transmit s dat a indepe ndently o n

the CAN bus,

there a r e ca ses of da t a collision whe n

multiple dat

a frames that ECUs at temp t to tran smit

simult

ane ously (if mu ltiple ECUs tran smit at n early

the same

moment). At th is moment, p r ocessing of

the ECUs atte

mpting tra n smission is performed in

the followin

g way .

1.Dat a frame with high priority is tra n smitted first

accord ing to ID cod e s memo rize d in dat a frames.

2.T r ansmission of lo w-p r iori ty dat a (dat a frames) is

suspe nded b y the issuin g ECUs until the bus

clears (when no transmission da t a exist s on the

CAN bus).

NO TE: If th e su spen ded st a t e co ntinu e s fo r a sp e-

cific time, new d a t a (dat a frame content ) is cre-

ated and sent.

3.ECU cont aining suspende d dat a fra m es trans-

mits the dat a when t he bus become s available .

NOTE: The re is enou gh ca p a city on t he CAN bus,

wh

ich

neve r prevent s da t a f r ames from being se nt.

Page 142 of 364

OPERATION

CONTROLLER AREA NETWORK (CAN)54C-5

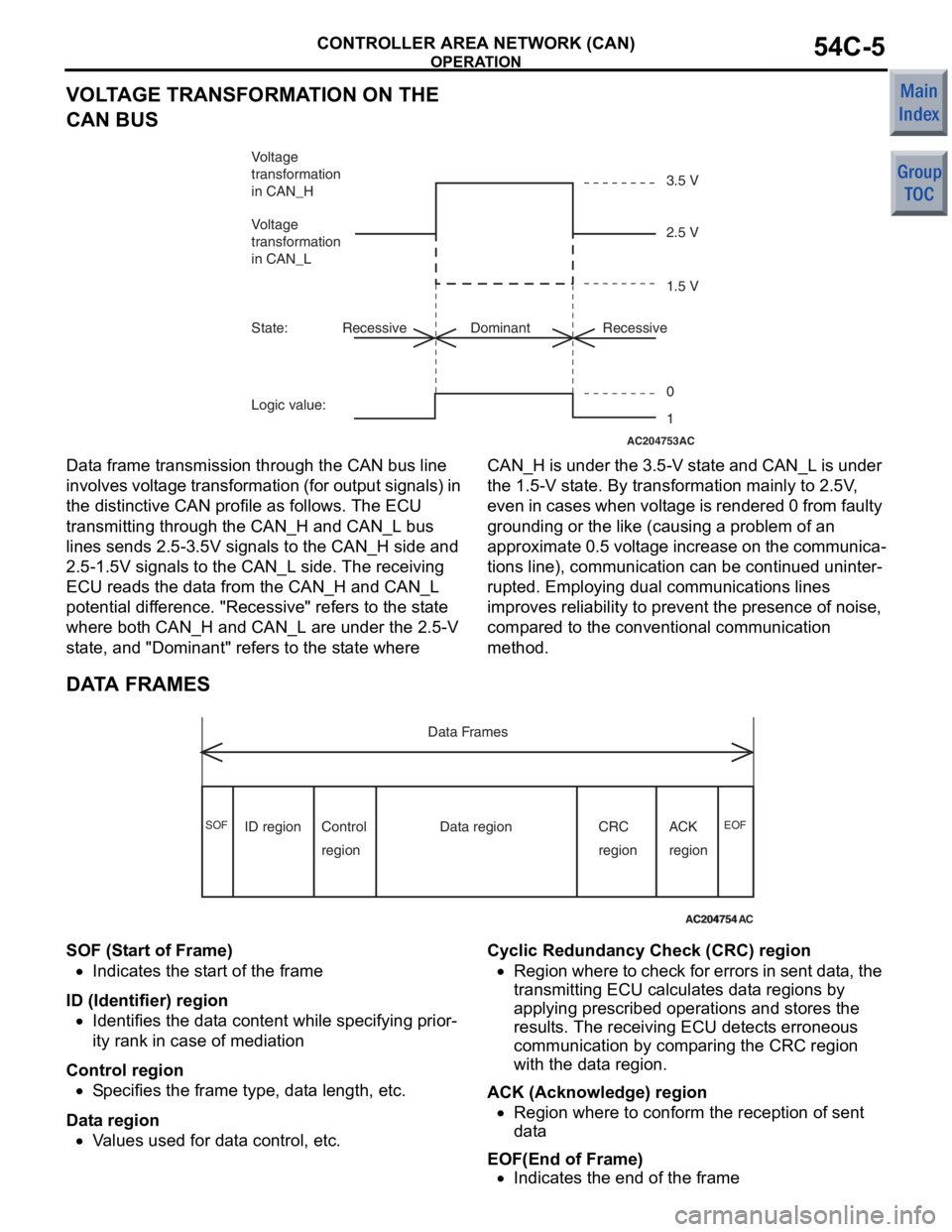

VOLTAGE TRANSFORMATION ON THE

CAN BUS

AC204753

Voltage

transformation

in CAN_L

State:

Logic value:Recessive Recessive

Dominant 3.5 V

2.5 V

1.5 V

0

1

AC

Voltage

transformation

in CAN_H

Dat

a f r ame t r ansmissio n throu gh the CAN bu s line

i

n vo lve s vo lt ag e tran sfo r ma ti on (for o u t p u t sign al s) in

the distinctive CAN profile a

s follows. The ECU

transmitting th

rough t he CAN_ H and CAN_L bus

line

s sends 2.5-3.5 V sig nals to th e CAN_H side and

2.5-1.5V sign

als to the CAN_L sid e . The receivin g

ECU read

s the dat a from the CAN_H and CAN_L

potential d

i f f e r ence . "Recessive" re fers to the st ate

whe

r e both CAN_H an d CAN_ L are u nder th e 2.5-V

st

ate, an d "Dominant" r e fers to the st ate where CAN_H is u nder the 3.5 - V st a t e and CAN_L is un der

the 1.5 - V st ate. By transforma t ion mainly to 2.5V ,

even in cases when volt age is rend ered 0 from fault y

ground ing o r the like (causing a prob lem of an

approximate 0.5 volt ag e incre a se on the co mmu nica

-

tions line), communication ca n be continued unint er-

rupted. Emplo y in g dua l co mmunicatio n s lines

imp

r oves reliability to pre v en t the pre s ence of noise,

comp

a r ed to t he co nven tion al communication

metho

d .

DAT A FRAMES

AC204754

ID region CRC

regionACK

region

Control

region Data region

Data Frames

AC204754AC

SOF

EOF

SOF (St a rt of Fra m e)

•Indi cat e s th e st art o f the fra m e

ID (I dentifier) regi on

•Iden tifies th e dat a content wh ile specifying prior-

ity rank in case of mediation

Cont rol re gion

•Specifies the frame type , dat a le ngth, e t c.

Data region

•Va lues used for d a t a con t rol, e t c.

Cyclic Redun dancy Che ck (CRC) reg i on

•Region wh er e to che c k fo r e r r o rs in se nt da t a , t h e

t

r a n s m it t i ng EC U ca l c u l at e s da t a re g i on s by

app

lying pre s cribed operations and stores the

result

s. The receiving ECU de tect s e rroneou s

communicatio

n by comp a r ing the CRC regio n

with

the da t a r egion .

ACK (Acknowledge) region

•Region where to co nform the reception of sent

dat

a

EOF(End of Fra m e)

•Indi ca tes th e end of the frame

Page 143 of 364

SELF-DIAGNOSIS

CONTROLLER AREA NETWORK (CAN)54C-6

ERROR DETECTION AND RECOVERY

CAN protocol secures its reliability of communication

by providing several error detection function such as

CRC shown in data frame, and the recovery function

(recovery is performed by resending, from abnormal

state such as transmission errors). If an error is

detected but it is not resolved even after recovery,

communication is stopped. This state is called "Bus

Off."

SELF-DIAGNOSIS

M2542000400280

•CAN self-diagnosis is performed by each ECU

connected to the CAN bus.

•diagnosis codes related to communication are

named with the capital letter U, and are called

"U-codes."

•A summary of the CAN self-diagnosis system is

presented below.

TIME-OUT

Each ECU transmits data frames periodically. If the

data frame is not received within the specified period,

the intended receiving ECU transmits a diagnosis

code indicating communication time-out for the ECU

that failed to transmit.

BUS OFF

Related to a communication error that persists even

after the transmitting ECU attempts recovery for a

specified number of attempts or that persists for a

specified period after recovery, communication is

stopped and this diagnostic code is issued.

FA I L U R E D ATA

When the transmitting ECU detects failure of a sen-

sor directly connected to it, this is the pertinent data

used to inform the ECU.

DATA LENGTH ERROR

When the number of data bytes received is different

from the prescribed number of bytes, this diagnosis

code is issued.

DYNAMIC RANGE ERROR

When the data received is more or less than the pre-

scribed range, this diagnosis code is issued.

CAN BUS DIAGNOSTICS

M2542000500179

As ECUs are connected via CAN bus (including

M.U.T.-III), always diagnose CAN bus to confirm its

normality when inspecting. Simply by performing

M.U.T.-III screen operations, the following inspec

-

tions can be performed automatically, and the result

can be used to verify the CAN bus status.

•Voltage measurement between the CAN_L and

CAN_H and the body earthing terminal

•Resistance measurement between the CAN_L

and CAN_H

•Confirmation of communication of all ECUs

Page 150 of 364

MAIN BODY

BODY42-7

DRIVING STABILITY

AB400932

AB400232AB400233

AB400213A

A

Cowl top lower panel

Spring house

panel

Corner of door opening

Corner of tailgate opening

AB

Section A – A1

2

2

4,5

3

Upper frame to

front pillar brace

Front upper

outer plate

Front upper

frame outer

Cowl top extension lower

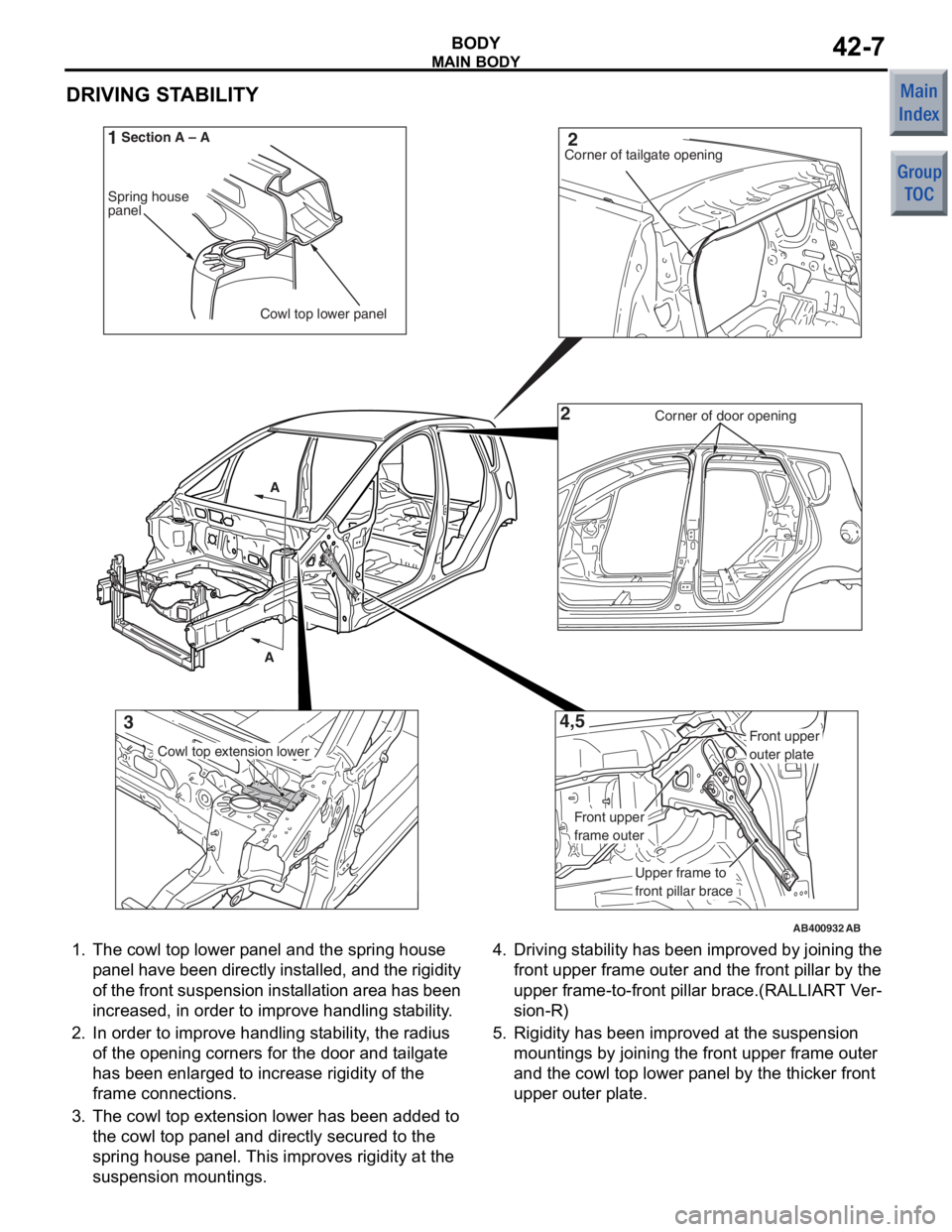

1.

The cowl t op lo we r p a nel a nd the spring ho use

p a n e l h a ve be en dire ct ly inst alled , a n d th e rigidity

of the fro n t suspen sion inst allation area ha s b een

in creased, in orde r to improve han dling st ab ility .

2.In o r der to imp r ove h andling st a b ility , the radius

of t he ope ning corne r s for the do or and t a ilgate

has bee n enlarged t o increase rigidity of th e

frame connection s.

3.The cowl t op extension lower has bee n adde d to

the cowl t op p anel and d i rectly secured t o the

sp ring house p anel. This improves rigidity a t the

su spen sio n mo untin gs.

4.Driving st ability has bee n improved by jo ining the

fron t uppe r frame outer a nd the front p illar by the

upp er frame-to-fro nt pillar b r ace . (RALL I AR T V e r

-

sion-R)

5.Rigidity has been impr ove d at the suspension

mountings b y joining the front u pper fra m e ou ter

and the cowl top lower p a n e l by the t h icker fro n t

upp er oute r plat e.

Page 156 of 364

DOOR

BODY42-13

KEYLESS ENTRY SYSTEM

M2420010000727

The multimode keyless entry system is installed.

There are the following features.

•Transmitter has two buttons (LOCK/UNLOCK).

•The ETACS-ECU is equipped with the integral

receiver and receiving antenna.

•Up to 4 encrypted codes (4 transmitters) can be

registered using M.U.T.-III.

•Answer-back function has been adopted.

•Using the LOCK/UNLOCK buttons, all doors

(including tailgate) can be locked or unlocked and

door mirrors can be retracted or opened.

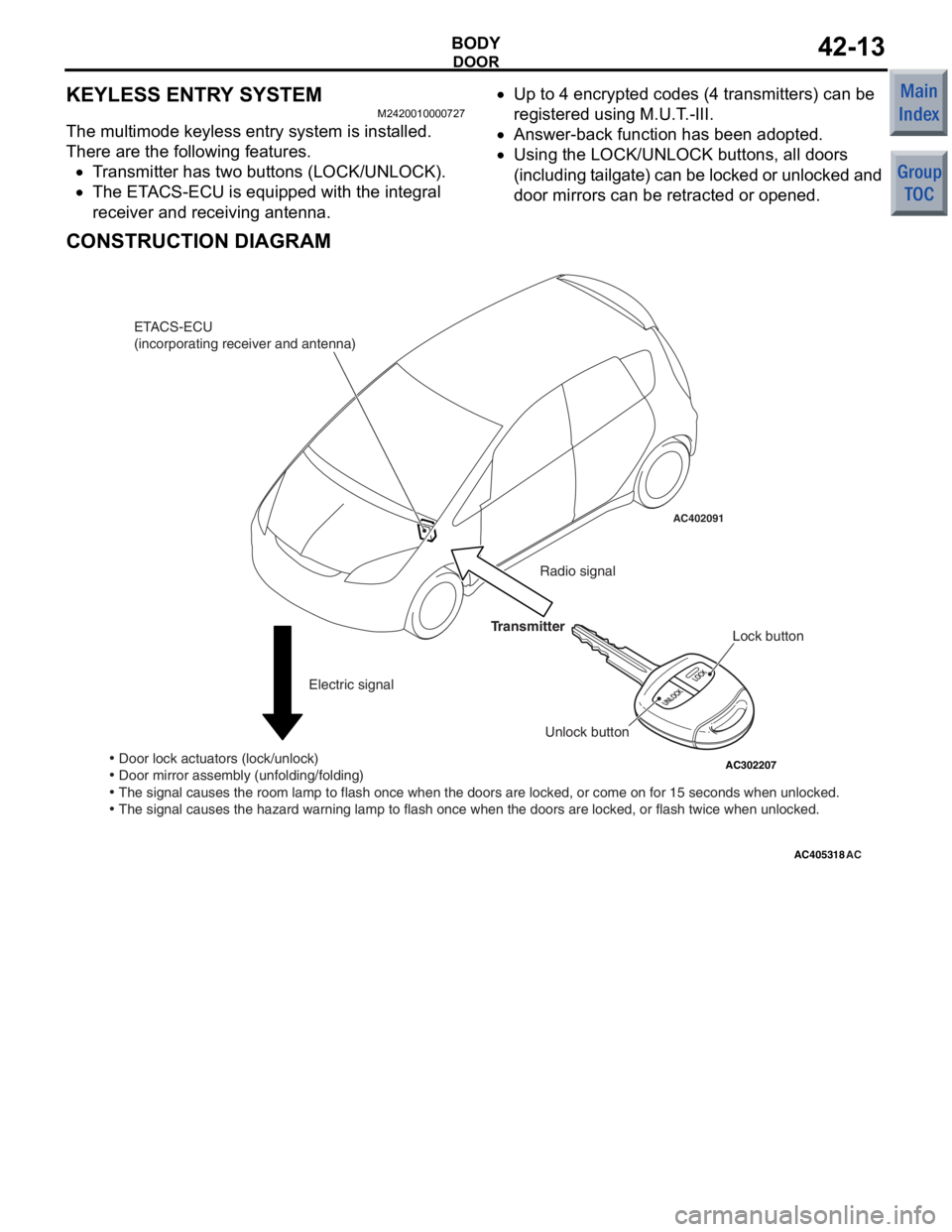

CONSTRUCTION DIAGRAM

AC405318

AC206461

AC302207

AC402091

AC

ETACS-ECU

(incorporating receiver and antenna)

Electric signal Radio signal

Lock button

Unlock button

Transmitter

• Door lock actuators (lock/unlock)

• Door mirror assembly (unfolding/folding)

• The signal causes the room lamp to flash once when the doors are locked\

, or come on for 15 seconds when unlocked.

• The signal causes the hazard warning lamp to flash once when the doors \

are locked, or flash twice when unlocked.

Page 158 of 364

DOOR

BODY42-15

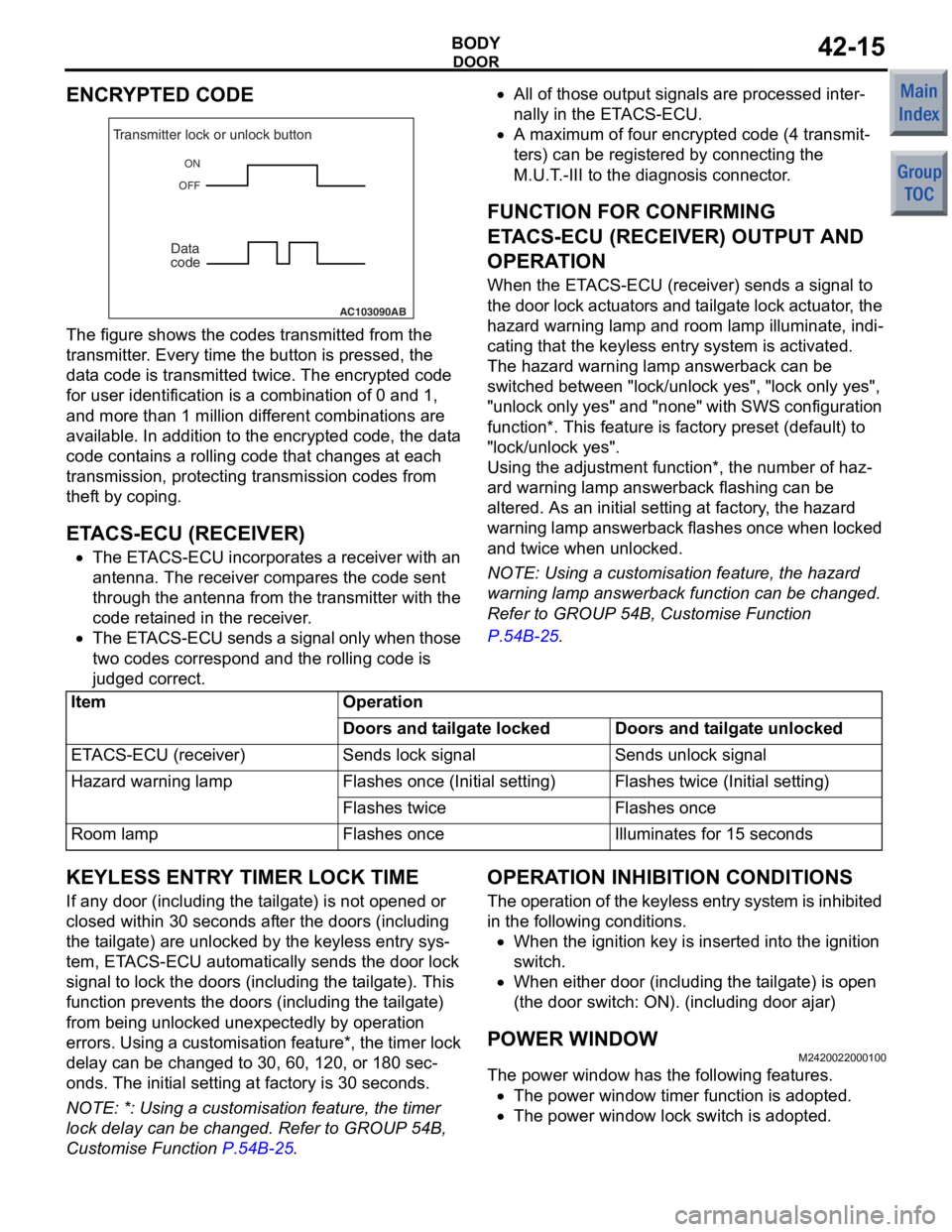

ENCRYPTED CODE

AC103090AB

ON

OFF

Transmitter lock or unlock button

Data

code

The figure shows th e co des transmitte d from the

transmitte

r . Every time the butto n is pressed, the

dat

a cod e is transmitted tw ice. Th e encrypte d co de

for user ide

n tification is a comb ination o f 0 and 1,

and more tha

n 1 million dif f erent comb inations are

available. In a

ddition to t he encrypt ed co de, the dat a

code

cont ains a rolling code t hat change s at e a ch

transmission, prot

ecting tran smission code s from

thef

t by coping.

ETACS-ECU (RECEIVER)

•The ET ACS-ECU incorp orates a receiver with a n

ant

enna. T he receiver co mp ares the code sent

thro

ugh t he an tenna from the transmit t er with the

co

de ret a ined in the re ceiver .

•The ET ACS-ECU send s a si gnal only whe n t hose

two codes corre

spon d and the rollin g co de is

ju

dged correct.

•All of tho s e o u tput sign als are processed inter-

nally in the ETACS-ECU.

•A maximum of fou r encr y pted cod e (4 tran smit-

ters) can be re gistered by co nnecting the

M.U.

T . -III t o the d i agn osis co nnector .

FUNCTION FOR CONFIRMING

ET

ACS-ECU (RECEIVER) OUT P UT AND

OPERA

T ION

When the ET ACS-ECU (receiver) send s a sign al to

the

do or lock actua t o r s an d t a ilga te lo ck actua t or , t h e

haza

r d warnin g lamp an d room lamp illumina te, in di

-

cating that the keyless ent ry syste m is activated.

The hazard warn ing lamp answe rback ca n be

switched b

e tween "lock/unlock yes", "lock o n ly yes",

"unlock o

n ly yes" and "non e" with SW S co nfigurat ion

funct

i on*. Th is f eature is fa ctory preset (de f ault ) to

"lock/unlock ye

s".

Using the ad justment function*, th e number of haz-

ard warning lamp a n swerba ck flashing can be

altere

d. As a n initial set t ing a t factory , the haza r d

wa

rnin g lamp an swerb a ck flashes once wh en locked

and twice when

unlo cke d.

NOTE: Using a cust omisation fea t ure, th e hazard

wa

rning lamp answe rback fun c tio n ca n be change d.

Re

fer to GROUP 54B, Customise Function

P.54B-25.

ItemOperation

Doors and tailgate lockedDoors and tailgate unlocked

ETACS-ECU (receiver)Sends lock signalSends unlock signal

Hazard warning lampFlashes once (I nitial setting)Flashes twice (Initial setting)

Flashes twiceFlashes once

Room lampFlashes onceIlluminates for 15 seconds

KEYLESS ENTR Y TIMER LOCK TIME

If any door (includin g the t a ilgat e) is not op ened or

closed within 3

0 se cond s af ter th e doo rs (in c lu ding

the t

a ilgate) a r e unlocked by the keyless ent ry sys

-

tem, ETACS-ECU aut omatically sen d s th e door lock

sign

al to lock the doors (includ i ng t he t a ilgate). T h is

funct

i on p r even t s the d oors (including the t a ilga te)

from b

e ing unlocke d unex pectedly by opera t ion

errors.

Using a customisa t ion fea t ure*, the timer lock

delay ca

n be chang ed to 3 0 , 60, 120, or 180 sec

-

onds. The initial setting at fa ctory is 30 secon d s.

NOTE: *: Using a custo m isation fea t ure, the timer

lock delay can b e ch anged. Re fer to GROUP 54B,

Customise Function

P.54B-25.

OPERA T ION INHIBITION CONDITIONS

The operation of t he keyless entry system is inhibited

in the

following cond itio ns.

•When the ignition key is inse rted into the ignition

sw

itc h .

•When eit her doo r (including th e t a ilg ate) is ope n

(the

door switch : ON). (includin g doo r ajar)

POWER WI NDOW

M24200220 0010 0

The powe r window ha s the following f eatures.

•The power wind ow timer functio n is adopt ed.

•The power wind ow lock switch is adopte d .