MITSUBISHI COLT 2006 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 191 of 364

TECHNICAL FEATURES

GENERAL00-6

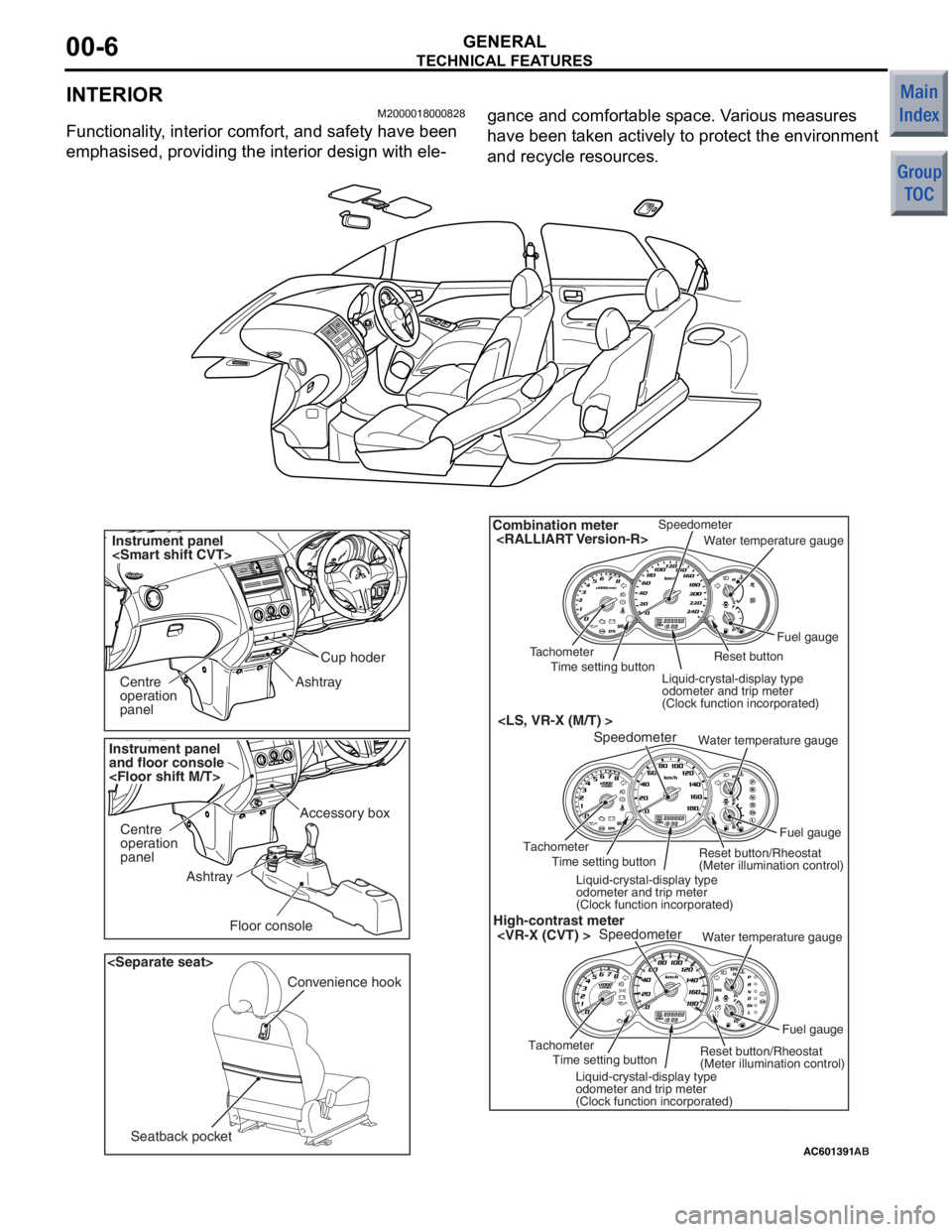

INTERIOR

M2000018000828

Functionality, interior comfort, and safety have been

emphasised, providing the interior design with ele

-

gance and comfortable space. Various measures

have been taken actively to protect the environment

and recycle resources.

AC601391AB

Centre

operation

panelAshtray

Instrument panel

Instrument panel

and floor console

Accessory box

Ashtray

Floor console

Cup hoder

Centre

operation

panel

Convenience hook

Seatback pocket Combination meter

High-contrast meter

Time setting buttonReset button

Water temperature gauge

Fuel gauge

Speedometer

Tachometer Liquid-crystal-display type

odometer and trip meter

(Clock function incorporated)

Tachometer

SpeedometerWater temperature gauge

Fuel gauge

Liquid-crystal-display type

odometer and trip meter

(Clock function incorporated)

Time setting button Reset button/Rheostat

(Meter illumination control)

Tachometer

SpeedometerWater temperature gauge

Fuel gauge

Liquid-crystal-display type

odometer and trip meter

(Clock function incorporated)

Time setting buttonReset button/Rheostat

(Meter illumination control)

Page 192 of 364

TECHNICAL FEATURES

GENERAL00-7

FEATURES

Quality improvement

•Full interior trim

•Two-tone interior

•Cloth covered part door trim

Usability improvement

•Movable ashtray

•Front RECARO seat (Option)

•Cup holder of right/left separation type (for front

seats)

•Convenience hook (passenger’s side)

•Wide variety of seat arrangement

•Reclining adjustment, slide adjustment

•Luggage hook

•High-contrast meter

•Combination meter of 240km/h scale

Convenient boxes

•Centre panel box

•Glove box

•Seatback pocket

•Bottle holder (front door trim)

•Door pocket (front door trim)

Safety improvement

•ELR three-point seat belt (front)

•Front seat belt with force limiter mechanism

•ELR three-point seat belt/child seat fastening

mechanism (ALR) switching seat belt (rear)

•Floor carpet with heel stopper structure

•Instrument panel and trims which adopt

fire-retarding materials

Consideration for the optimum driving position

•Seat height adjustment (driver’s seat)

•Head restraint with height adjustment (front, rear)

•One-touch adjustable seat belt anchor (front seat

belt)

Measures for resource recycling

Aggressively use PP materials that are easy to recy-

cle and easy to stamp material symbols on the plas-

tic (resin) parts.

Page 193 of 364

TECHNICAL FEATURES

GENERAL00-8

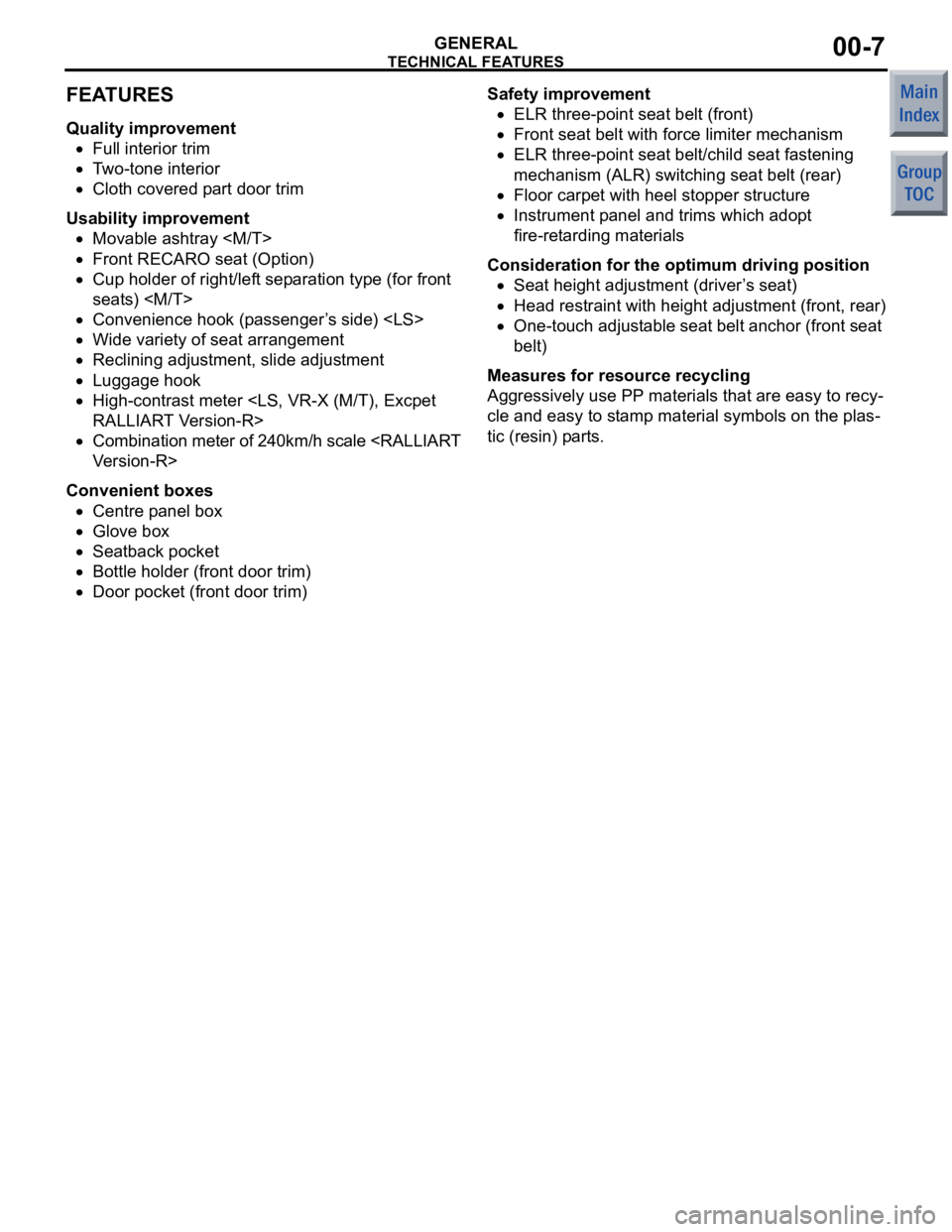

SPACIOUS CABIN

M2000000400230

AC313513

8

7 2

4

3

6

1

10

9

5

AB

•S

pa cio us interior sp ace leading the comp act car

fie ld•

No.ItemDimension mm

1Front shoulder room1,340

2Interior effective length1,805

3Head roomFront920/875*

4Rear855/850*

5Hip-point heightFront325

6Rear375

7Seating ground clearanceFront600

8Rear650

9Brake pedal room900

10Hip point couple805

Seating gro und clearance of fering ea sy access

NOTE: .

•*:Vehicles with sunroo f

•Refer to P.00-31

Page 194 of 364

TECHNICAL FEATURES

GENERAL00-9

ENGINE

M2000020000579

<4A9>

The newly-developed 4A9 engine has been installed

to realise small-size, light-weight, high-performance,

and better fuel economy with the state-of-the-art

technologies such as the aluminium die-cast cylinder

block, direct attack driven-type DOHC MIVEC, timing

chain-type cam drive, and rear exhaust.

MAJOR SPECIFICATIONS

Item4A91

Total displacement mL1,499

Bore × Stro ke mm75 × 84.8

Compression ratio10.0

Compression chamberPentroof-type

Va l v e t i m i n gIntake openingBTDC 31° − ATDC 19°

Intake closingABDC 21° − ABDC 71°

Exhaust openingBBDC 39°

Exhaust closingATDC 5°

Maximum output kW (PS)/rpm77 (105)/6,000

Maximum torque N⋅m (kg⋅m)/rpm141 (14.4)/4,000

Fuel systemElectronically controlled multipoint fuel injection

Ignition systemElectronic-controlled 4-coil

<4G1>

Based on the 4G1 engine fitted on the existing COLT,

the power performance leading the compact car field

has been secured by Turbocharger.

MAJOR SPECIFICATIONS

Item4G15 (with Intercooler Turbocharger)

Total displacement mL1,468

Bore × Stro ke mm75 × 82.0

Compression ratio9.0

Compression chamberPentroof-type

Va l v e t i m i n gIntake openingBTDC 34° − ATDC 6°

Intake closingABDC 30° − ABDC 70°

Exhaust openingBBDC 50°

Exhaust closingATDC 10°

Maximum output kW (PS)/rpm113 (154)/6,000

Maximum torque N⋅m (kg⋅m)/rpm210 (21.4)/3,500

Fuel systemElectronically controlled multipoint fuel injection

Ignition systemElectronic-controlled 4-coil

Page 195 of 364

TECHNICAL FEATURES

GENERAL00-10

TRANSMISSION

M2000021000594

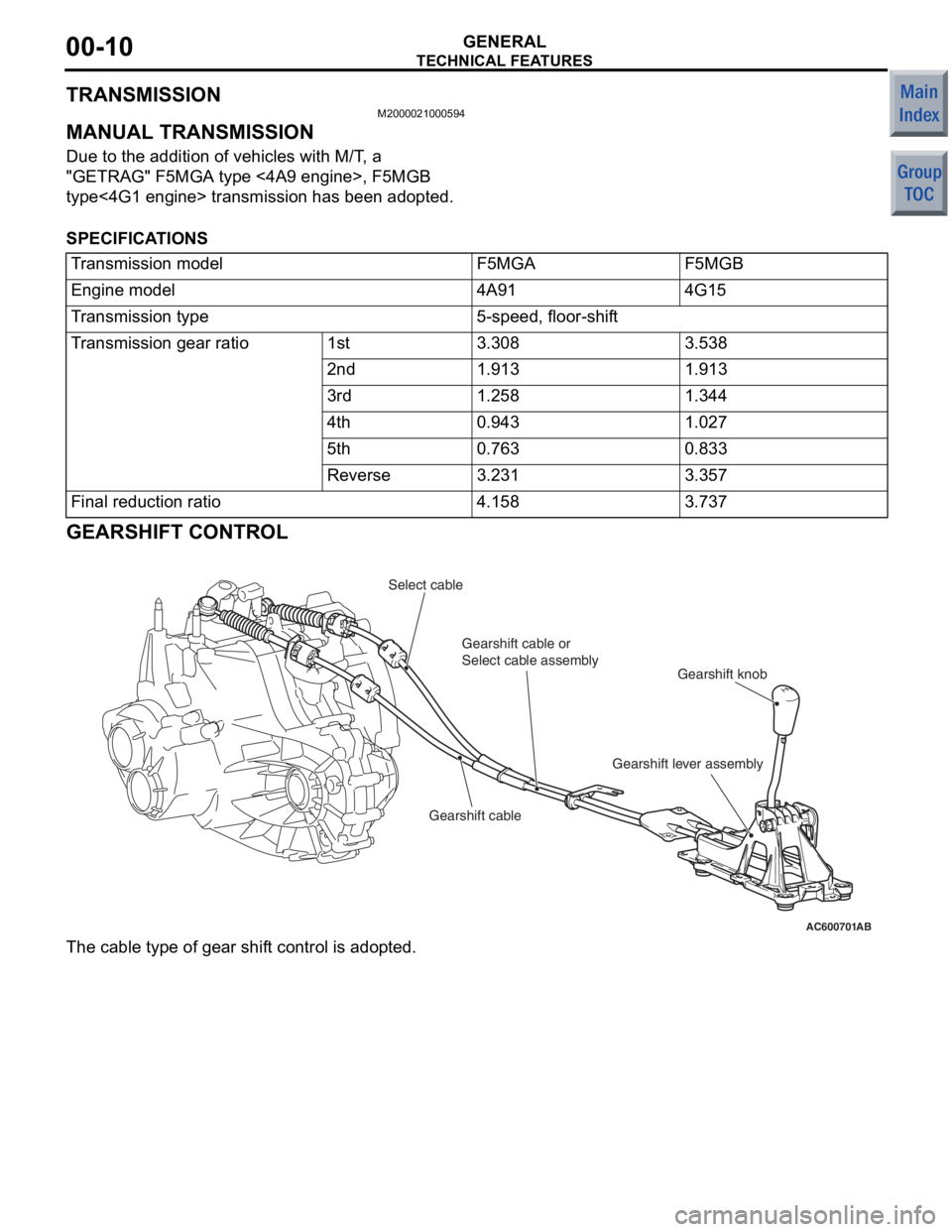

MANUAL TRANSMISSION

Due to the addition of vehicles with M/T, a

"GETRAG" F5MGA type <4A9 engine>, F5MGB

type<4G1 engine> transmission has been adopted.

SPECIFICATIONS

Transmission modelF5MGAF5MGB

Engine model4A914G15

Transmission type5-speed, floor-shift

Transmission gear ratio1st3.3083.538

2nd1.9131.913

3rd1.2581.344

4th0.9431.027

5th0.7630.833

Reverse3.2313.357

Final reduction ratio4.1583.737

GEARSHIFT CONTROL

AC600701

Gearshift knob

AB

Select cable

Gearshift lever assembly

Gearshift cable or

Select cable assembly

Gearshift cable

The cable type of gea r shift contro l is adop ted.

Page 196 of 364

TECHNICAL FEATURES

GENERAL00-11

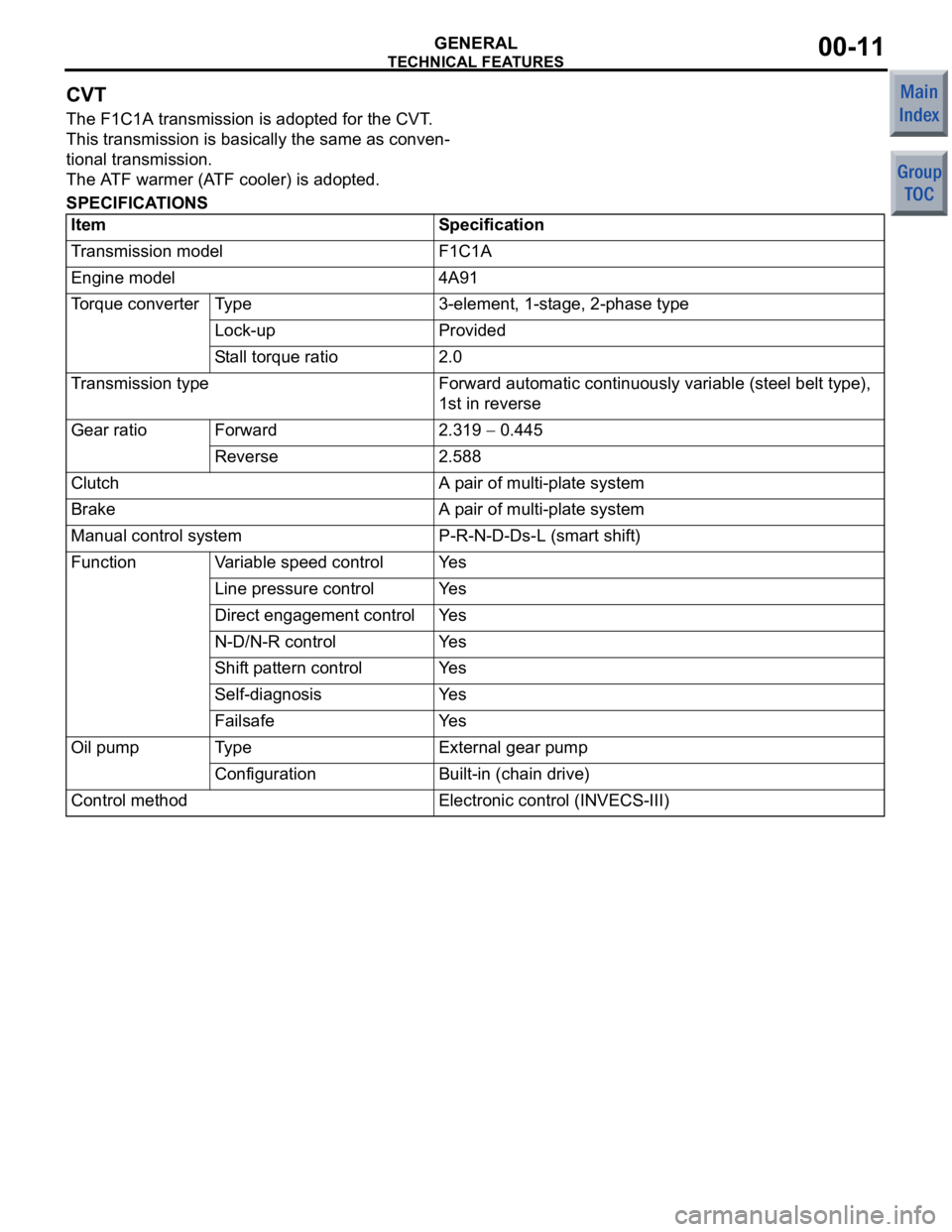

CVT

The F1C1A transmission is adopted for the CVT.

This transmission is basically the same as conven

-

tional transmission.

The ATF warmer (ATF cooler) is adopted.

SPECIFICATIONS

ItemSpecification

Transmission modelF1C1A

Engine model4A91

Torque converterTy p e3-element, 1-stage, 2-phase type

Lock-upProvided

Stall torque ratio2.0

Transmission typeForward automatic continuously variable (steel belt type),

1st in reverse

Gear ratioForward2.319 − 0.445

Reverse2.588

ClutchA pair of multi-plate system

BrakeA pair of multi-plate system

Manual control systemP-R-N-D-Ds-L (smart shift)

FunctionVariable speed controlYe s

Line pressure controlYe s

Direct engagement controlYe s

N-D/N-R controlYe s

Shift pattern controlYe s

Self-diagnosisYe s

FailsafeYe s

Oil pumpTy p eExternal gear pump

ConfigurationBuilt-in (chain drive)

Control methodElectronic control (INVECS-III)

Page 197 of 364

TECHNICAL FEATURES

GENERAL00-12

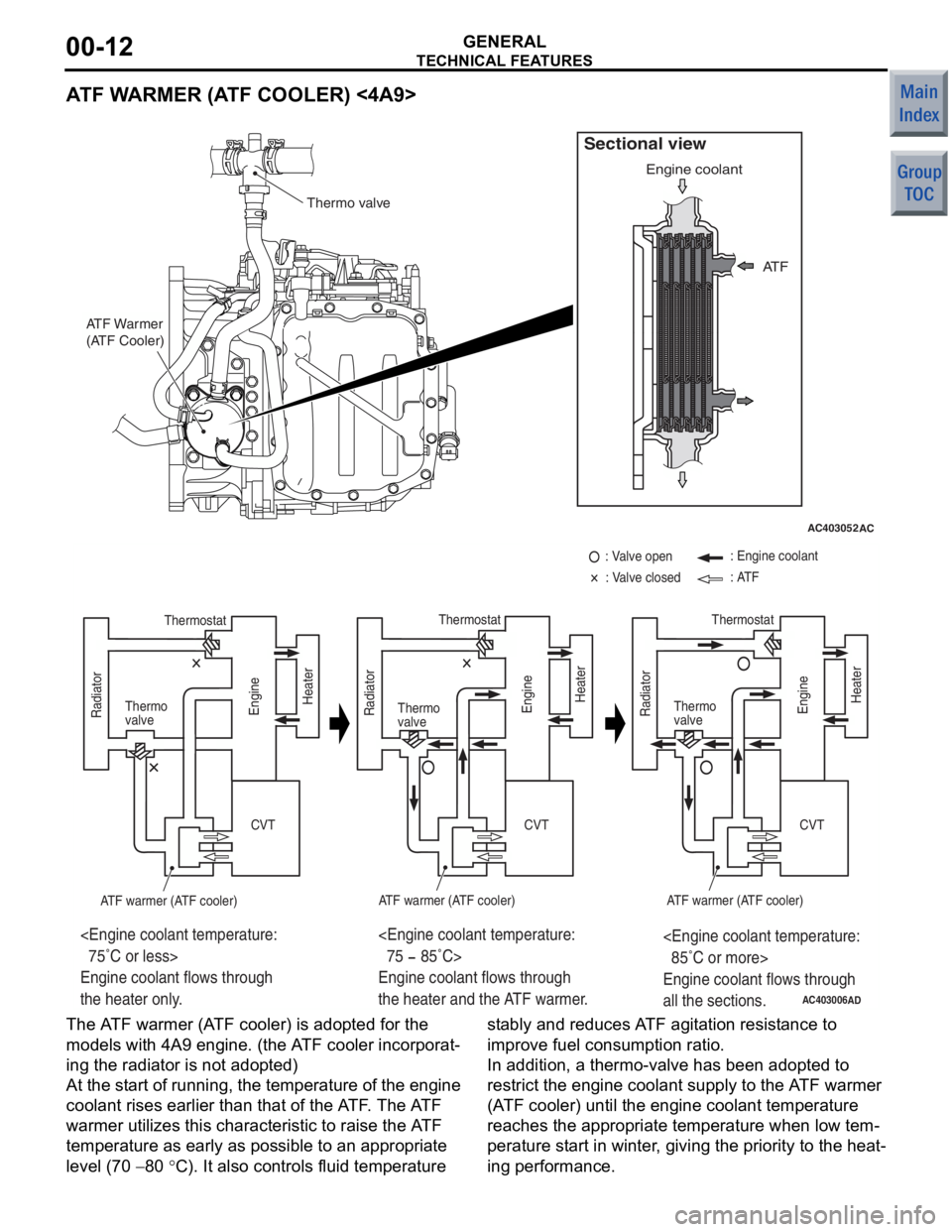

ATF WARMER (ATF COOLER) <4A9>

AC403052AC

AT F

Engine coolant

Sectional view

ATF Warmer

(ATF Cooler)

Thermo valve

AC403006

CVT CVT CVT

Thermostat

Thermo

valve

ATF warmer (ATF cooler)ATF warmer (ATF cooler)

: Engine coolant

: ATF

Engine coolant flows through

all the sections.

- 85˚C>

Engine coolant flows through

the heater and the ATF warmer.

Engine coolant flows through

the heater only.

AD

: Valve open

: Valve closed

Thermostat

Thermo

valve

ATF warmer (ATF cooler)Thermo

valve

Thermostat

Radiator

Engine Heater

Radiator Engine Heater

Radiator

Engine Heater

The A TF warme r (A TF cooler) is adop ted for the

mode ls with 4A9 en gine. (the A TF cooler incorporat

-

ing the radiator is no t adopted)

At the start of runn ing, the tempe rature of th e engine

coolant rises earlier tha n that of the AT F. The A TF

war mer ut ilizes this ch aracteristic to raise the ATF

tempe rature a s ea rly a s po ssible to an a ppropriate

leve l (70

−80 °C). It also co ntrols flu id tempera ture st

ably and reduces A TF agitation resist ance to

imp rove f uel consump tion ra tio.

In addition , a thermo-valve has bee n adopted to

restrict the eng ine coolant supply to the A TF warmer

(A TF coole r) until the engine co olant temperature

reach es th e appro priat e temperature when low tem

-

perature start in winter , giving the priority to th e heat-

ing performance .

Page 198 of 364

TECHNICAL FEATURES

GENERAL00-13

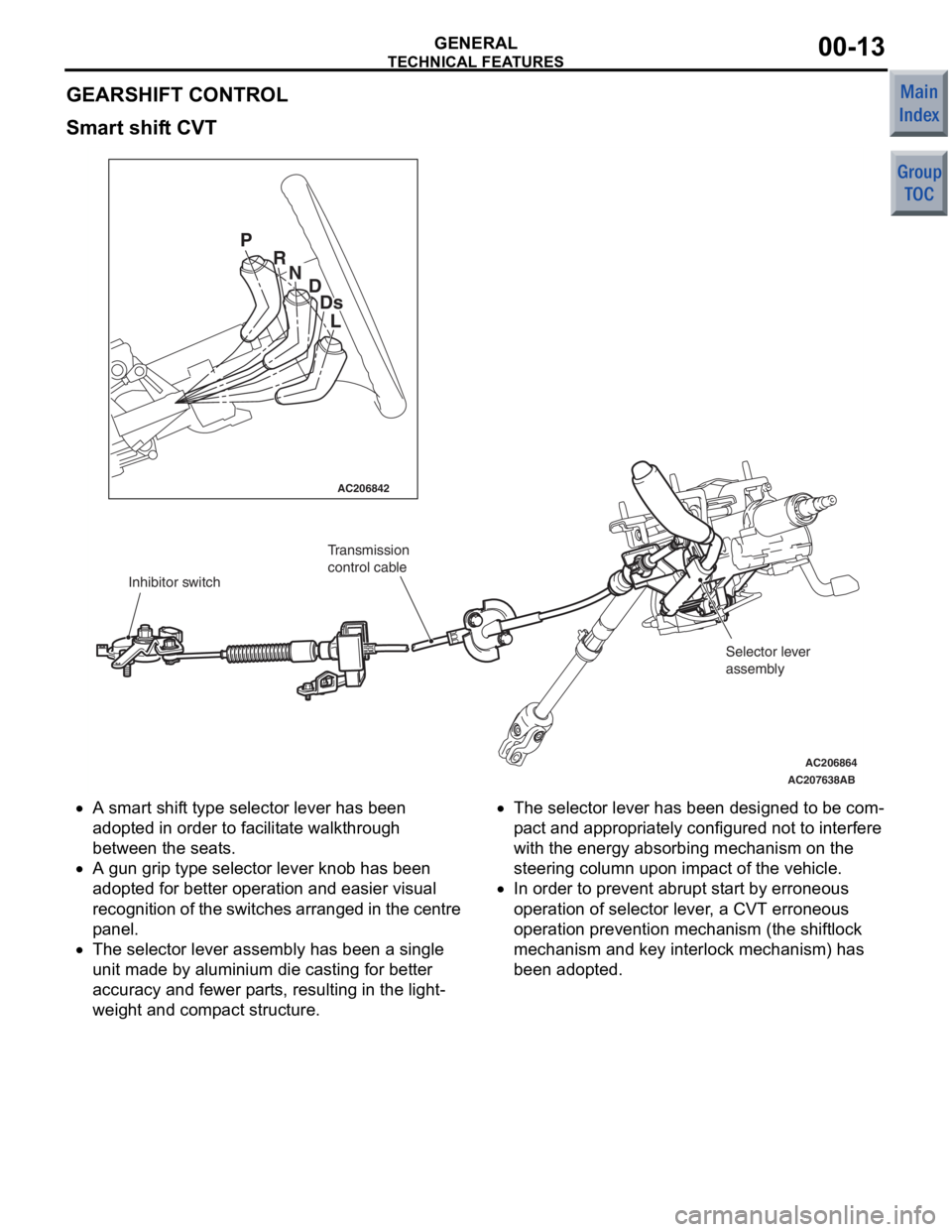

GEARSHIFT CONTROL

Smart shift CVT

AC206842

AC206864

AC207638

AB

P R

ND

Ds

L

Inhibitor switch Transmission

control cable

Selector lever

assembly

•A smart shift type selector lever h as b een

ado pted in orde r to facilitate walkthrou gh

bet wee n the seats.

•A gun grip type selector lever kno b has been

ado pted fo r better operat ion and easier visual

re cog nitio n of th e swit ches ar ra ng ed in th e ce ntre

p anel.

•The selecto r lever assembly has been a single

unit ma de by alu minium die casting f or bette r

accura cy and fewer pa rts, resu lting in the light

-

weig ht and compact struct ure.

•The selecto r lever has been designed to be com-

pa ct a nd appro priate ly configured no t to interf ere

with the en ergy absor bing mechanism on the

steerin g column upon impact of th e vehicle.

•In order to prevent abru pt st art b y erro neous

ope ration of selector lever , a CVT errone ous

ope ration preventio n mechanism (the shiftlock

m echa nis m and key interloc k mech anis m) h as

bee n adop ted.

Page 199 of 364

TECHNICAL FEATURES

GENERAL00-14

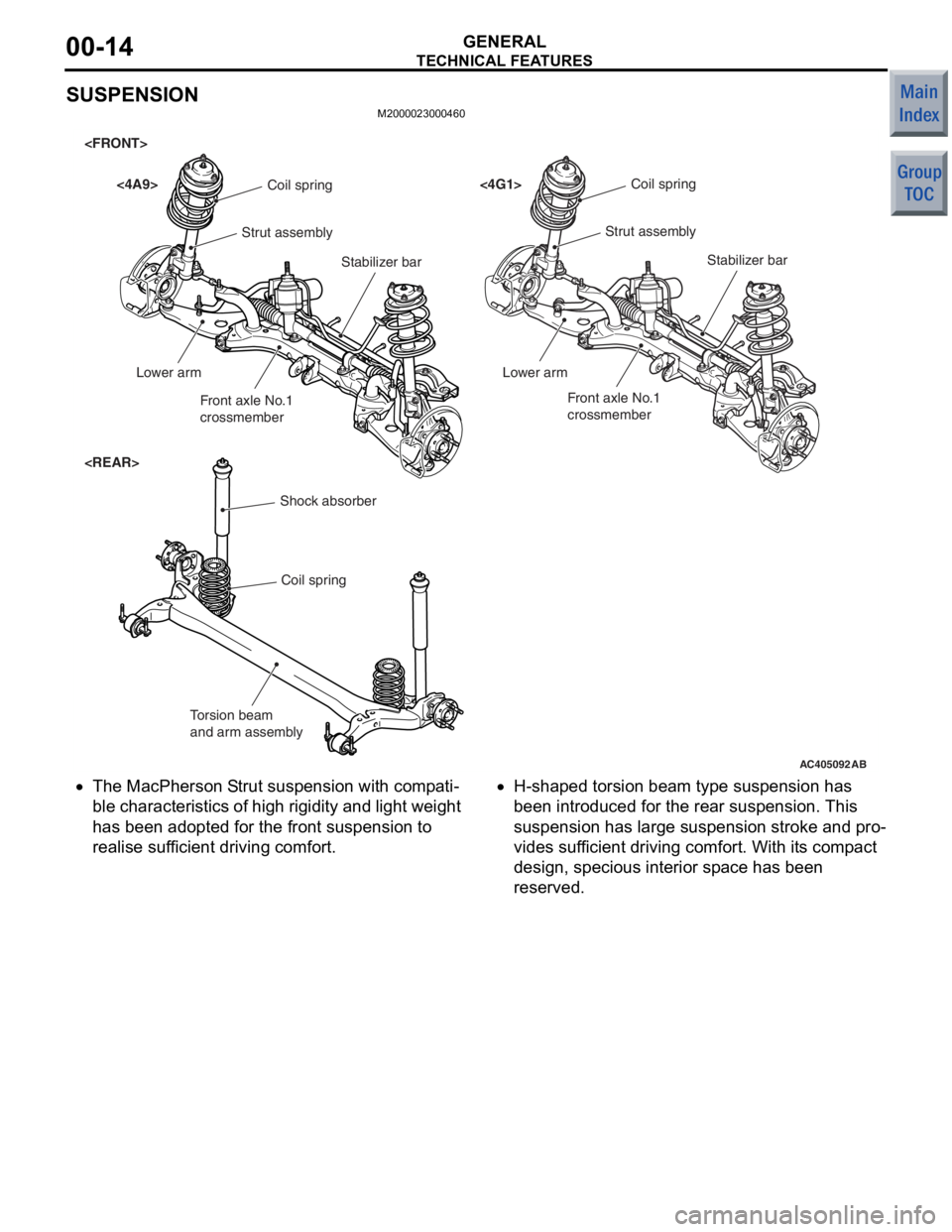

SUSPENSION

M2000023000460

AC405092AB

Front axle No.1

crossmember Stabilizer bar

Coil spring

Strut assembly

Front axle No.1

crossmember

Lower arm Strut assembly

Coil spring

Stabilizer bar

Shock absorber Coil spring

Torsion beam

and arm assembly

<4A9> <4G1>

•The

MacPherso n Strut suspe nsio n with comp ati-

ble characteristics of high rig idity and lig ht weight

has bee n adopted for the fron t suspension to

realise suf ficien t driving comfort.

•H-shaped to rsion bea m type suspe nsion has

bee n int roduced for t he rear suspension. This

suspe nsion has larg e suspen sion stro ke and pro

-

vides suf ficient driving comfort. With it s comp act

design , spe cio us interior sp ace has been

reserved.

Page 200 of 364

TECHNICAL FEATURES

GENERAL00-15

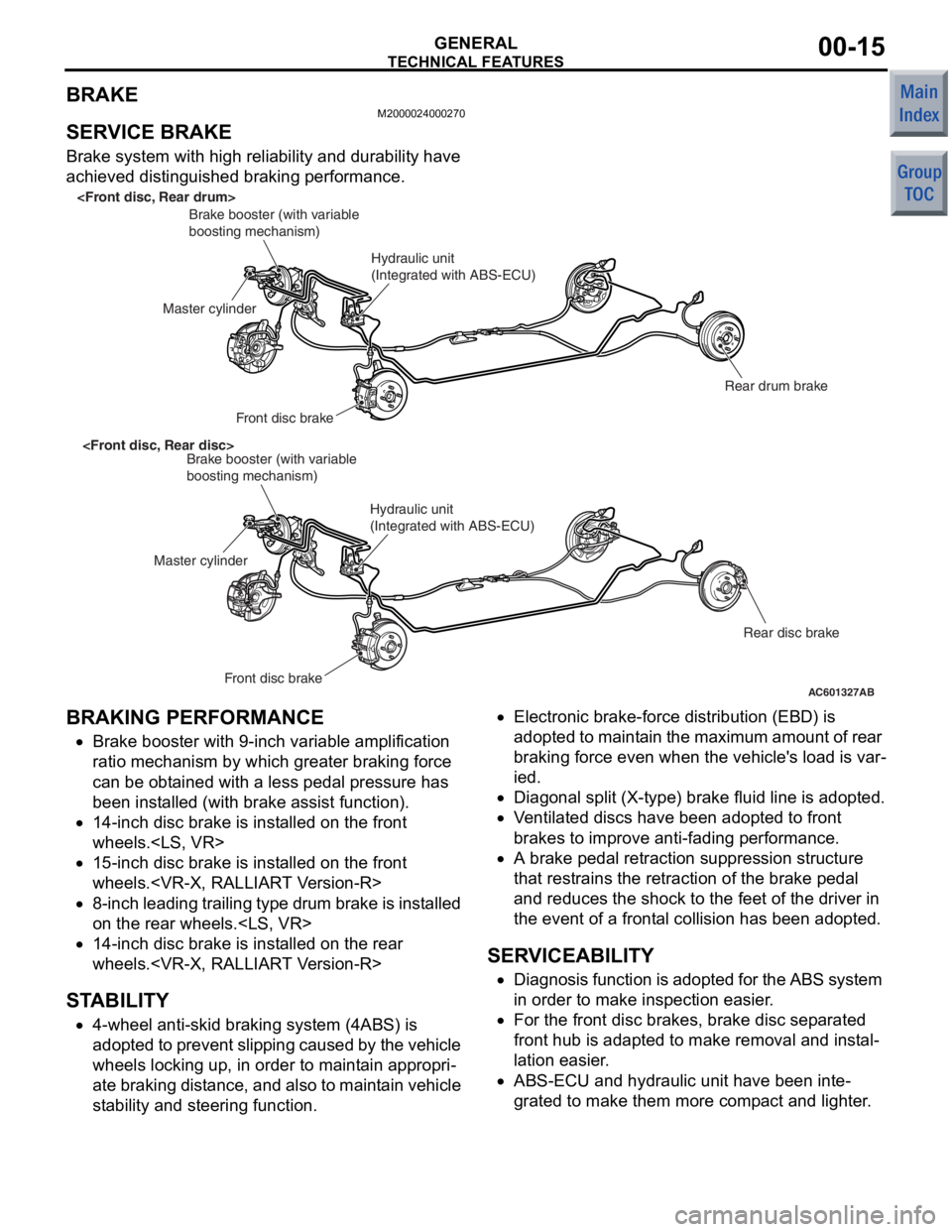

BRAKE

M2000024000270

SERVICE BRAKE

Brake system with high reliability and durability have

achieved distinguished braking performance.

AC601327AB

Brake booster (with variable

boosting mechanism)

Master cylinder Front disc brake

Hydraulic unit

(Integrated with ABS-ECU)

Rear drum brake

Brake booster (with variable

boosting mechanism)

Master cylinder

Front disc brake

Hydraulic unit

(Integrated with ABS-ECU) Rear disc brake

BRAKING PERFORMANCE

•Brake booster with 9-inch variab le amplificatio n

ratio me chanism by which greate r braking f orce

ca n be o bta ined with a less ped al pressure has

bee n inst alled (with b rake assist function).

•14-inch disc bra ke is inst alled on the front

wheels.

•15-inch disc bra ke is inst alled on the front

wheels.

•8-inch leading trailing type drum brake is installed

on the rear wheels.

•14-inch disc bra ke is inst alled on the rear

wheels.

ST ABILITY

•4-wheel anti-skid brak ing system (4ABS) is

ado pted to pre vent slippin g cause d by the vehicle

wheels locking up, in order t o maint ain a ppropri

-

ate bra kin g dist an ce, an d also t o ma inta in ve hicle

st ab ility an d steering function.

•Electronic br ake-force distribution (EBD) is

ad opted to m ain ta in th e max imu m am ount of rea r

braking force even whe n the vehicle's loa d is var

-

ie d.

•Diag onal split (X-type) brake fluid line is adopte d.

•V entilate d discs have bee n adopted to front

brakes to improve anti-fading per formance.

•A brake pe dal retraction suppression structu re

tha t restr ains the re traction of the brake pe dal

and reduces the shock to th e feet of the d rive r in

the even t of a frontal collision ha s been ado pted.

SERVICEABILITY

•Diagnosis function is adopted for the ABS system

in order t o make inspe ctio n easier .

•For the fron t disc bra kes, brake disc separate d

fron t hub is a dapted to make removal a nd instal

-

la tion easier .

•ABS-ECU and hydraulic unit have been inte-

grated to make them mor e comp act and lighte r.