engine MITSUBISHI COLT 2006 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 117 of 364

![MITSUBISHI COLT 2006 Service Manual PDF

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-3

SYSTEM BLOCK DIAGRAM

AK600528

Barometric pressure sensorEngine control unitEngine-ECU

[1] Fuel injection control

[2] Throttle valve open MITSUBISHI COLT 2006 Service Manual PDF

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-3

SYSTEM BLOCK DIAGRAM

AK600528

Barometric pressure sensorEngine control unitEngine-ECU

[1] Fuel injection control

[2] Throttle valve open](/img/19/57093/w960_57093-116.png)

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-3

SYSTEM BLOCK DIAGRAM

AK600528

Barometric pressure sensorEngine control unitEngine-ECU

[1] Fuel injection control

[2] Throttle valve opening control

and idle speed control

[3] MIVEC (Mitsubishi Innovative

Valve timing Electronic

control system)

[4] Ignition timing control

[5] Engine control relay control

[6] Throttle valve control servo

relay control

[7] Fuel pump relay control

[8] Oxygen sensor (front) heater

control

[9] Oxygen sensor (rear) heater

control

[10] Fuel pressure control

[11] Waste gate control

[12] Fan relay control

[13] A/C compressor relay

control

[14] Alternator control

[15] Purge control

[16] Diagnostic output

[17] RAM data transmission Throttle valve control unit

Throttle opening feedback control

Engine coolant

temperature sensor Intake air temperature sensor Air flow sensor

Accelerator pedal

position sensor (main) Throttle position sensor (sub)

Camshaft position sensor

Crank angle sensor

Oxygen sensor (front)

Oxygen sensor (rear)

Alternator FR terminal

Clutch switch

Detonation sensor

Ignition switch-IG

Ignition switch-ST

Stop lamp switch

Power supply

Throttle position sensor (main)

Accelerator pedel

position sensor (sub)

Throttle valve control servo No.1 injector

No.2 injector

No.3 injector

No.4 injector

No.1 Ignition coil

No.2 Ignition coil

No.3 Ignition coil

No.4 Ignition coil

Engine control relay

Throttle valve control servo relay

Waste gate solenoid valve

A/C compressor relay

Fuel pump relay

Alternator G terminal

Cooling fan control relay (Hi, Lo)

Purge control solenoid valve

Diagnostic output terminal

Oxygen sensor (front) heater

Oxygen sensor (rear) heater Oil feeder control valve

(for MIVEC)

Fuel pressure control

solenoid valve

AB

Page 118 of 364

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-4

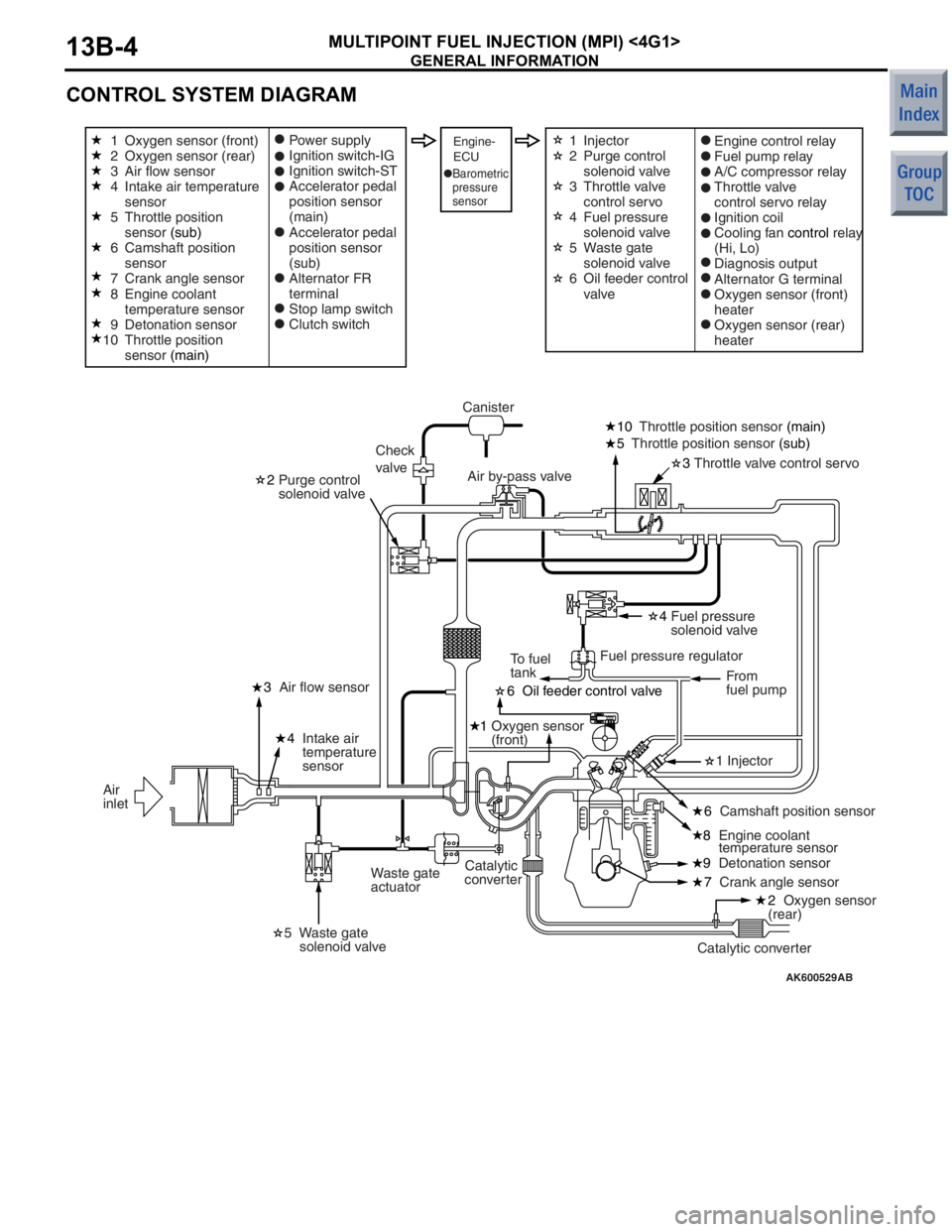

CONTROL SYSTEM DIAGRAM

AK600529AB

6 Oil feeder control valve

1 Oxygen sensor

(front)

8 Engine coolant

temperature sensor

3

Throttle valve control servo

10

Throttle position sensor (main)

5 Throttle position sensor (sub)

2 Purge control

solenoid valve

4 Fuel pressure

solenoid valve

7 Crank angle sensor

9

Detonation sensor

4

Intake air

temperature

sensor

3

Air flow sensor

Waste gate

actuator Canister

Check

valve Air by-pass valve

Fuel pressure regulatorFrom

fuel pump

To fuel

tank

Catalytic converter

Catalytic

converter

Air

inlet

Oxygen sensor (front)

Oxygen sensor (rear)

Air flow sensor

Intake air temperature

sensor

Throttle position

sensor

(sub)

Camshaft position

sensor

Crank angle sensor

Engine coolant

temperature sensor

Detonation sensor

Throttle position

sensor (main) Power supply

Ignition switch-IG

Ignition switch-ST

Accelerator pedal

position sensor

(main)

Accelerator pedal

position sensor

(sub)

Alternator FR

terminal

Stop lamp switch

Clutch switchEngine-

ECUEngine control relay

Fuel pump relay

A/C compressor relay

Throttle valve

control servo relay

Ignition coil

Cooling fan

control relay

(Hi, Lo)

Diagnosis output

Alternator G terminal

Oxygen sensor (front)

heater

Oxygen sensor (rear)

heater

Barometric

pressure

sensor

1 Injector

5 Waste gate

solenoid valve

2 Oxygen sensor

(rear)

6 Camshaft position sensor

1

2

3

4

5

6

7

8

9

10 Injector

Purge control

solenoid valve

Throttle valve

control servo

Fuel pressure

solenoid valve

Waste gate

solenoid valve

Oil feeder control

valve

1

2

3

4

5

6

Page 119 of 364

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-5

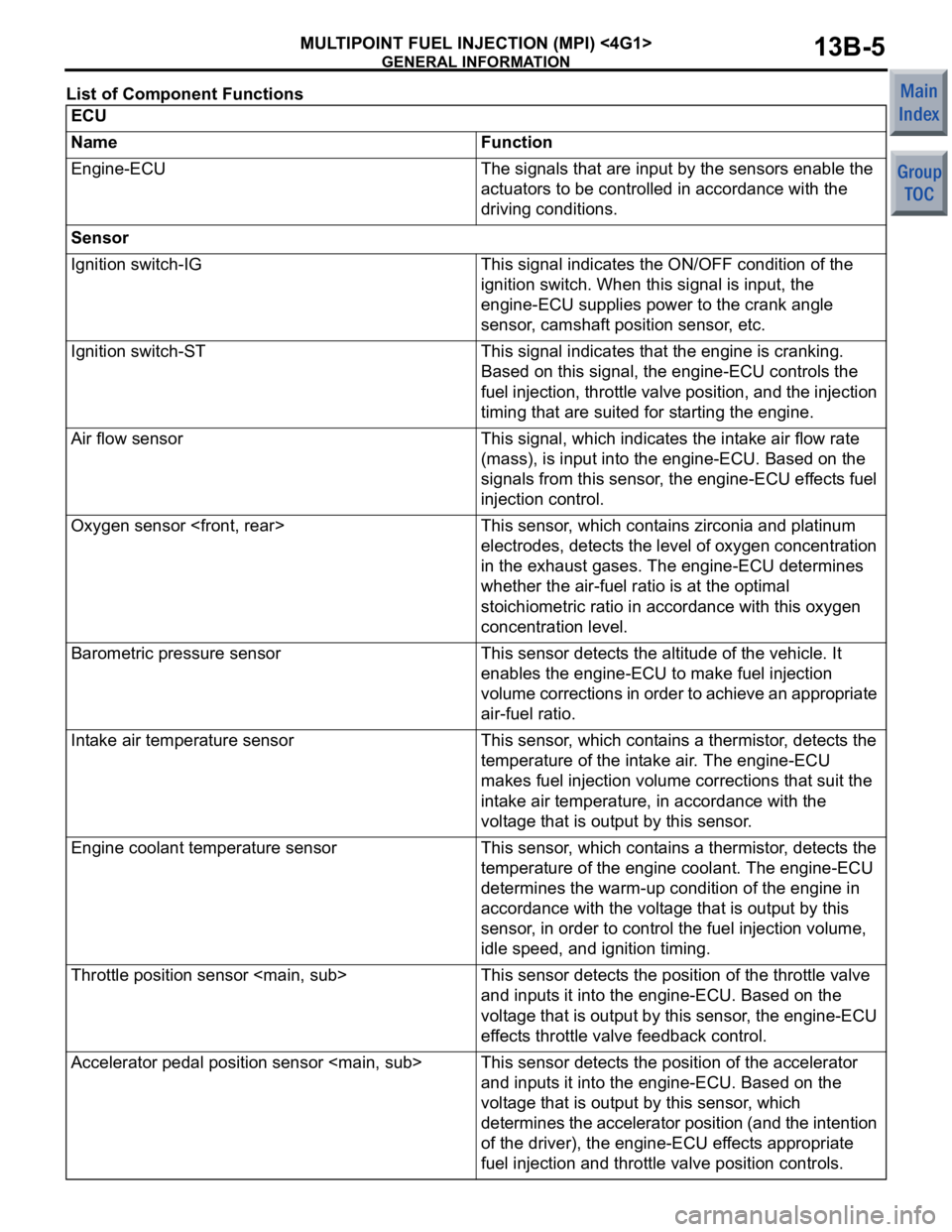

List of Component Functions

ECU

NameFunction

Engine-ECUThe signals that are input by the sensors enable the

actuators to be controlled in accordance with the

driving conditions.

Sensor

Ignition switch-IGThis signal indicates the ON/OFF condition of the

ignition switch. When this signal is input, the

engine-ECU supplies power to the crank angle

sensor, camshaft position sensor, etc.

Ignition switch-STThis signal indicates that the engine is cranking.

Based on this signal, the engine-ECU controls the

fuel injection, throttle valve position, and the injection

timing that are suited for starting the engine.

Air flow sensor This signal, which indicates the intake air flow rate

(mass), is input into the engine-ECU. Based on the

signals from this sensor, the engine-ECU effects fuel

injection control.

Oxygen sensor

electrodes, detects the level of oxygen concentration

in the exhaust gases. The engine-ECU determines

whether the air-fuel ratio is at the optimal

stoichiometric ratio in accordance with this oxygen

concentration level.

Barometric pressure sensorThis sensor detects the altitude of the vehicle. It

enables the engine-ECU to make fuel injection

volume corrections in order to achieve an appropriate

air-fuel ratio.

Intake air temperature sensorThis sensor, which contains a thermistor, detects the

temperature of the intake air. The engine-ECU

makes fuel injection volume corrections that suit the

intake air temperature, in accordance with the

voltage that is output by this sensor.

Engine coolant temperature sensorThis sensor, which contains a thermistor, detects the

temperature of the engine coolant. The engine-ECU

determines the warm-up condition of the engine in

accordance with the voltage that is output by this

sensor, in order to control the fuel injection volume,

idle speed, and ignition timing.

Throttle position sensor

and inputs it into the engine-ECU. Based on the

voltage that is output by this sensor, the engine-ECU

effects throttle valve feedback control.

Accelerator pedal position sensor

and inputs it into the engine-ECU. Based on the

voltage that is output by this sensor, which

determines the accelerator position (and the intention

of the driver), the engine-ECU effects appropriate

fuel injection and throttle valve position controls.

Page 120 of 364

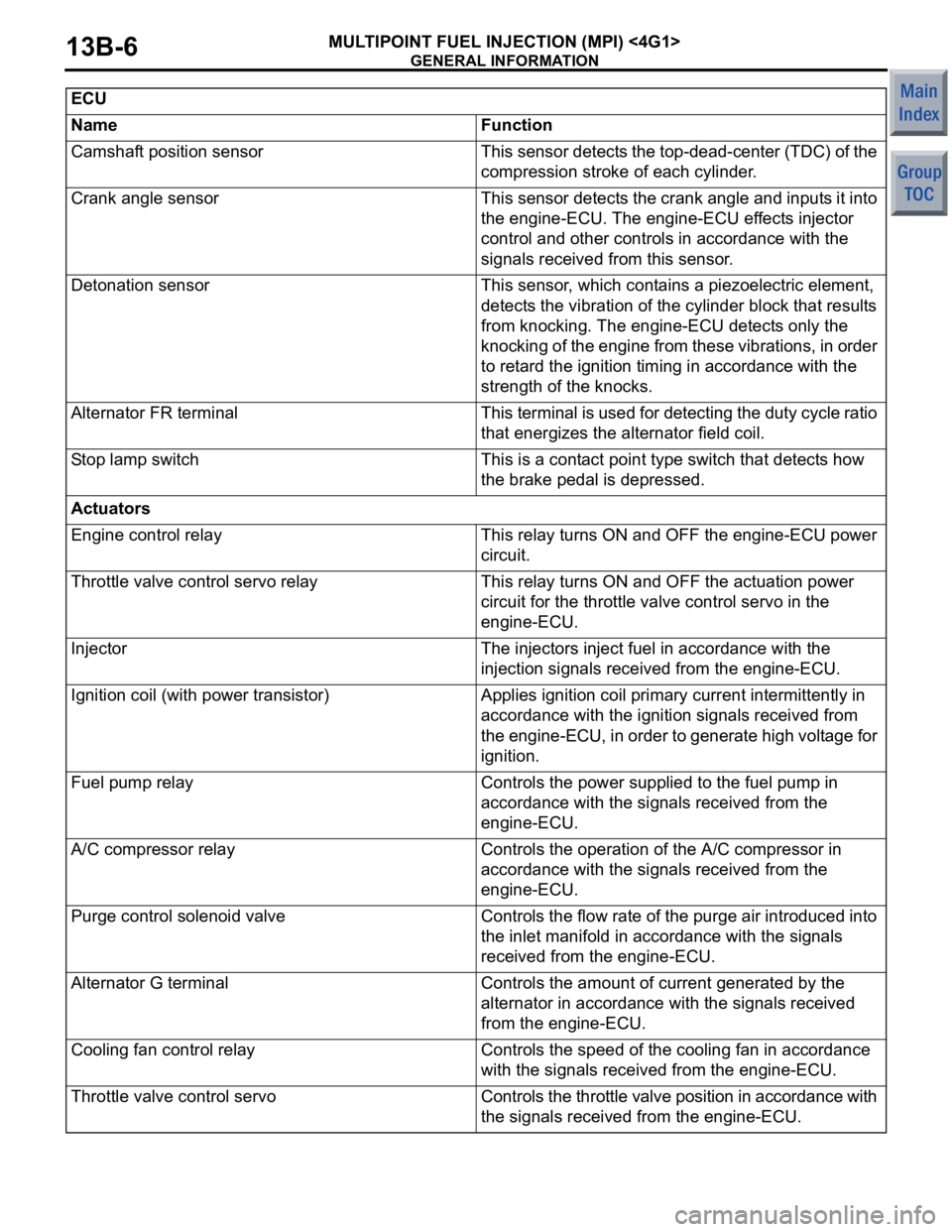

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-6

Camshaft position sensorThis sensor detects the top-dead-center (TDC) of the

compression stroke of each cylinder.

Crank angle sensorThis sensor detects the crank angle and inputs it into

the engine-ECU. The engine-ECU effects injector

control and other controls in accordance with the

signals received from this sensor.

Detonation sensorThis sensor, which contains a piezoelectric element,

detects the vibration of the cylinder block that results

from knocking. The engine-ECU detects only the

knocking of the engine from these vibrations, in order

to retard the ignition timing in accordance with the

strength of the knocks.

Alternator FR terminalThis terminal is used for detecting the duty cycle ratio

that energizes the alternator field coil.

Stop lamp switchThis is a contact point type switch that detects how

the brake pedal is depressed.

Actuators

Engine control relayThis relay turns ON and OFF the engine-ECU power

circuit.

Throttle valve control servo relayThis relay turns ON and OFF the actuation power

circuit for the throttle valve control servo in the

engine-ECU.

InjectorThe injectors inject fuel in accordance with the

injection signals received from the engine-ECU.

Ignition coil (with power transistor)Applies ignition coil primary current intermittently in

accordance with the ignition signals received from

the engine-ECU, in order to generate high voltage for

ignition.

Fuel pump relayControls the power supplied to the fuel pump in

accordance with the signals received from the

engine-ECU.

A/C compressor relayControls the operation of the A/C compressor in

accordance with the signals received from the

engine-ECU.

Purge control solenoid valveControls the flow rate of the purge air introduced into

the inlet manifold in accordance with the signals

received from the engine-ECU.

Alternator G terminalControls the amount of current generated by the

alternator in accordance with the signals received

from the engine-ECU.

Cooling fan control relayControls the speed of the cooling fan in accordance

with the signals received from the engine-ECU.

Throttle valve control servoControls the throttle valve position in accordance with

the signals received from the engine-ECU.

ECU

Name Function

Page 121 of 364

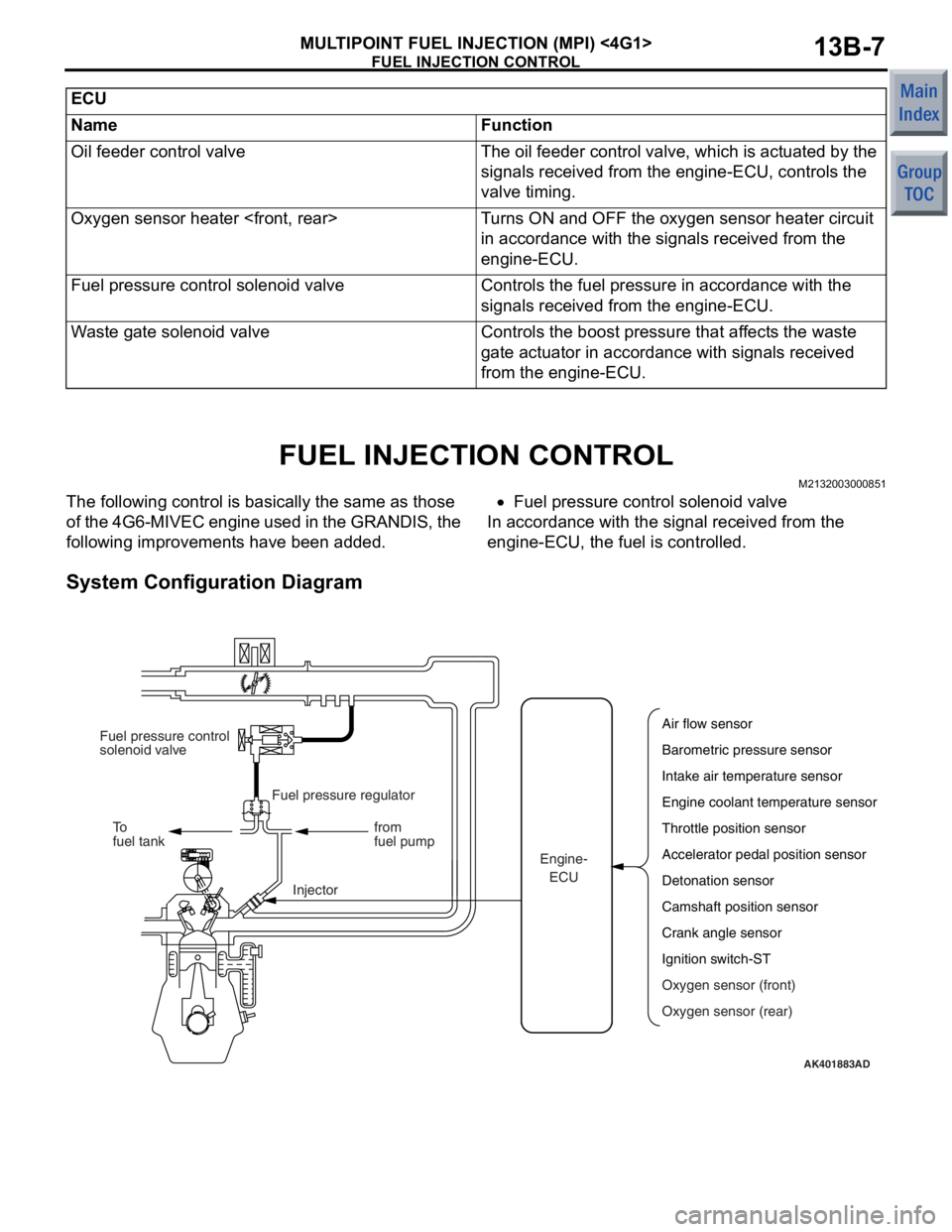

FUEL INJECTION CONTROL

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-7

FUEL INJECTION CONTROL

M2132003000851

The following control is basically the same as those

of the 4G6-MIVEC engine used in the GRANDIS, the

following improvements have been added.•Fuel pressure control solenoid valve

In accordance with the signal received from the

engine-ECU, the fuel is controlled.

System Configuration Diagram

AK401883AD

Air flow sensor

Barometric pressure sensor

Intake air temperature sensor

Engine coolant temperature sensor

Throttle position sensor

Accelerator pedal position sensor

Detonation sensor

Camshaft position sensor

Crank angle sensor

Ignition switch-ST

Oxygen sensor (front)

Oxygen sensor (rear)

Engine-

ECU

Injector from

fuel pump

To

fuel tank Fuel pressure regulator

Fuel pressure control

solenoid valve

Oil feed

er con t rol valveThe oil fee der control va lve , which is actuate d by the

signals re

ceived f r om th e eng ine-ECU, co ntrols the

valve timing.

Oxygen sensor he ater

in

accordan ce wit h the sign als rece ive d from the

en

gine-ECU.

Fuel p r essure control solenoid va lveControls the fue l pressure in a cco rdance with the

signals re

ceived f r om th e eng ine-ECU.

Wa ste g a te solen o id valveControls the boo st pre s sure tha t af fe ct s th e waste

ga

te actuator in accord ance with signals re ceived

from the

engin e -ECU.

ECU

Nam

e Func tion

Page 122 of 364

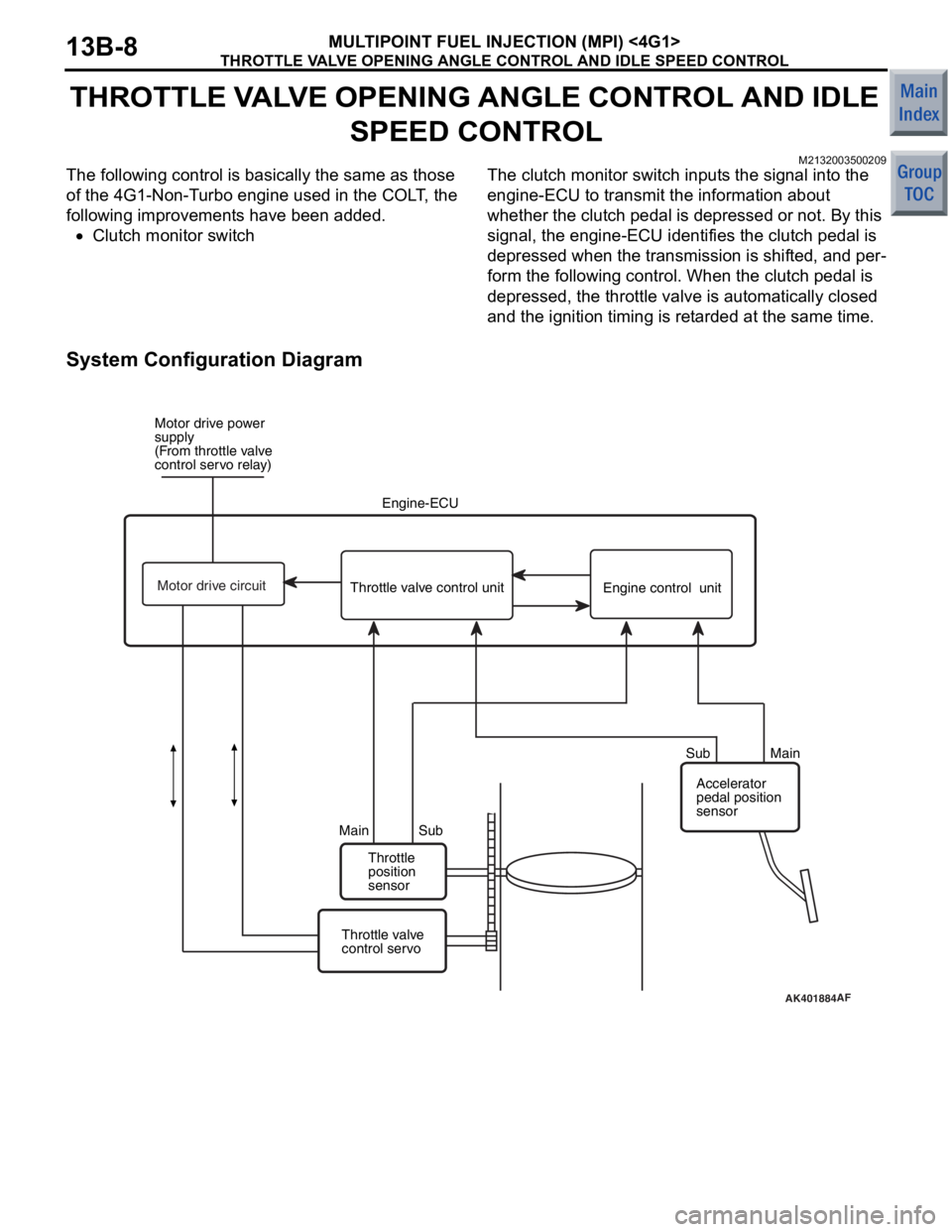

THROTTLE VALVE OPENING ANGLE CONTROL AND IDLE SPEED CONTROL

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-8

THROTTLE VALVE OPENING ANGLE CONTROL AND IDLE

SPEED CONTROL

M2132003500209

The following control is basically the same as those

of the 4G1-Non-Turbo engine used in the COLT, the

following improvements have been added.

•Clutch monitor switch

The clutch monitor switch inputs the signal into the

engine-ECU to transmit the information about

whether the clutch pedal is depressed or not. By this

signal, the engine-ECU identifies the clutch pedal is

depressed when the transmission is shifted, and per

-

form the following control. When the clutch pedal is

depressed, the throttle valve is automatically closed

and the ignition timing is retarded at the same time.

System Configuration Diagram

AK401884AF

Motor drive power

supply

(From throttle valve

control servo relay)

Engine-ECU

Throttle

position

sensor

Main Sub Sub Main

Throttle valve

control servo Accelerator

pedal position

sensor

Throttle valve control unit

Engine control unit

Motor drive circuit

Page 123 of 364

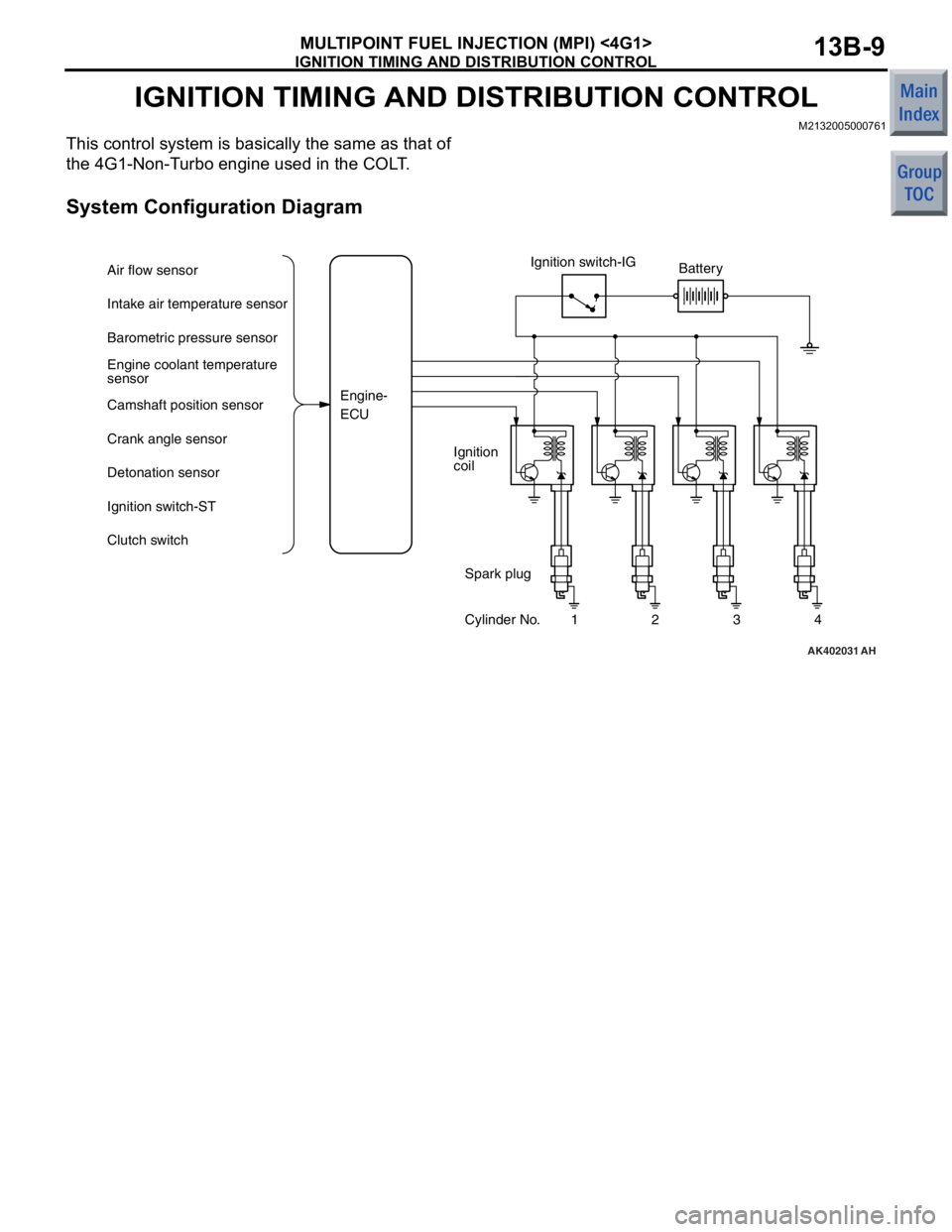

IGNITION TIMING AND DISTRIBUTION CONTROL

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-9

IGNITION TIMING AND DISTRIBUTION CONTROL

M2132005000761

This control system is basically the same as that of

the 4G1-Non-Turbo engine used in the COLT.

System Configuration Diagram

AK402031

Ignition switch-IG

Ignition

coil Battery

Spark plug

Cylinder No. 1 2 3 4

Air flow sensor

Intake air temperature sensor

Barometric pressure sensor

Engine coolant temperature

sensor

Camshaft position sensor

Crank angle sensor

Detonation sensor

Ignition switch-ST

Clutch switch

Engine-

ECU

AH

Page 124 of 364

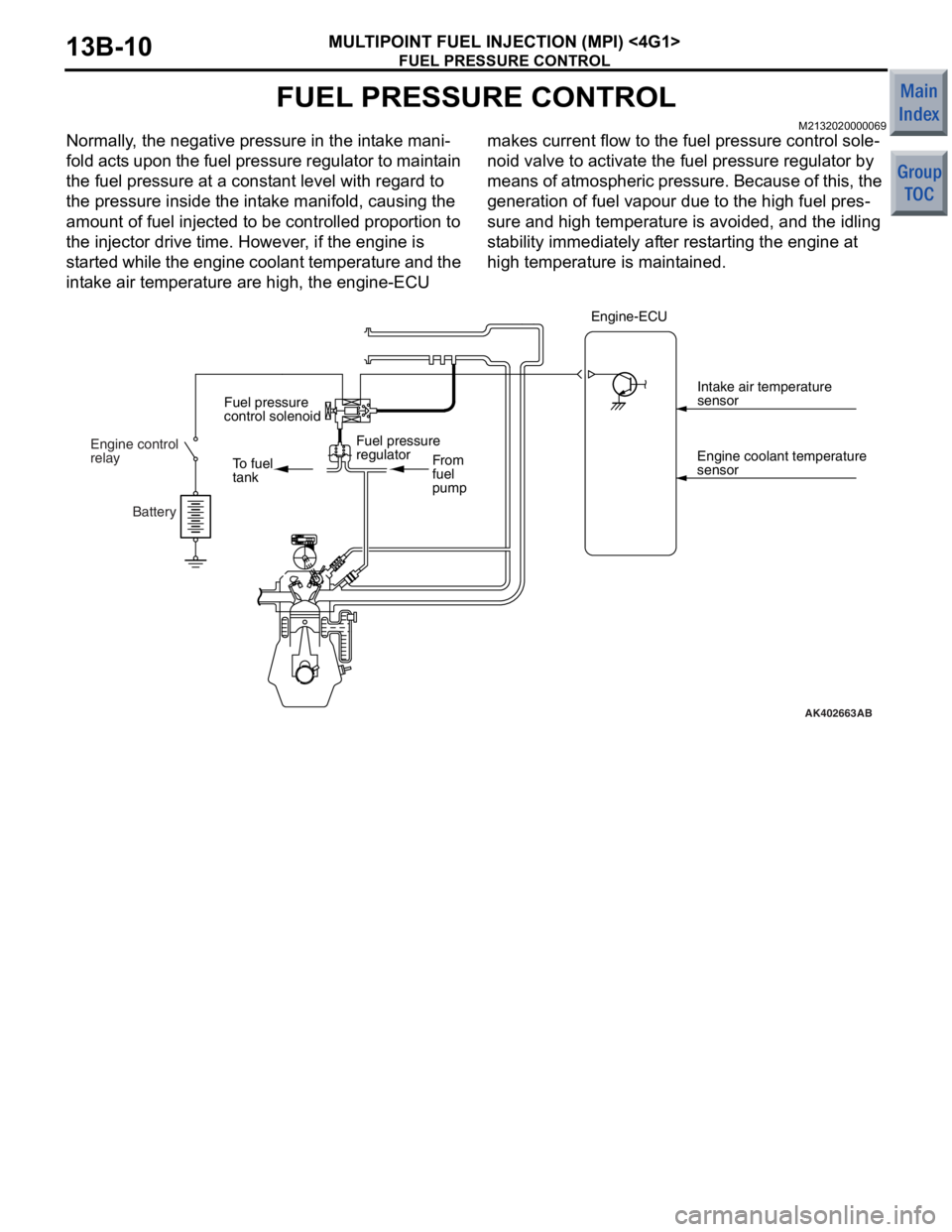

FUEL PRESSURE CONTROL

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-10

FUEL PRESSURE CONTROL

M2132020000069

Normally, the negative pressure in the intake mani-

fold acts upon the fuel pressure regulator to maintain

the fuel pressure at a constant level with regard to

the pressure inside the intake manifold, causing the

amount of fuel injected to be controlled proportion to

the injector drive time. However, if the engine is

started while the engine coolant temperature and the

intake air temperature are high, the engine-ECU makes current flow to the fuel pressure control sole

-

noid valve to activate the fuel pressure regulator by

means of atmospheric pressure. Because of this, the

generation of fuel vapour due to the high fuel pres

-

sure and high temperature is avoided, and the idling

stability immediately after restarting the engine at

high temperature is maintained.

AK402663

To fuel

tank

From

fuel

pump

Fuel pressure

regulator

Fuel pressure

control solenoid

AB

Engine control

relay

Engine coolant temperature

sensorIntake air temperature

sensor

Engine-ECU

Battery

Page 125 of 364

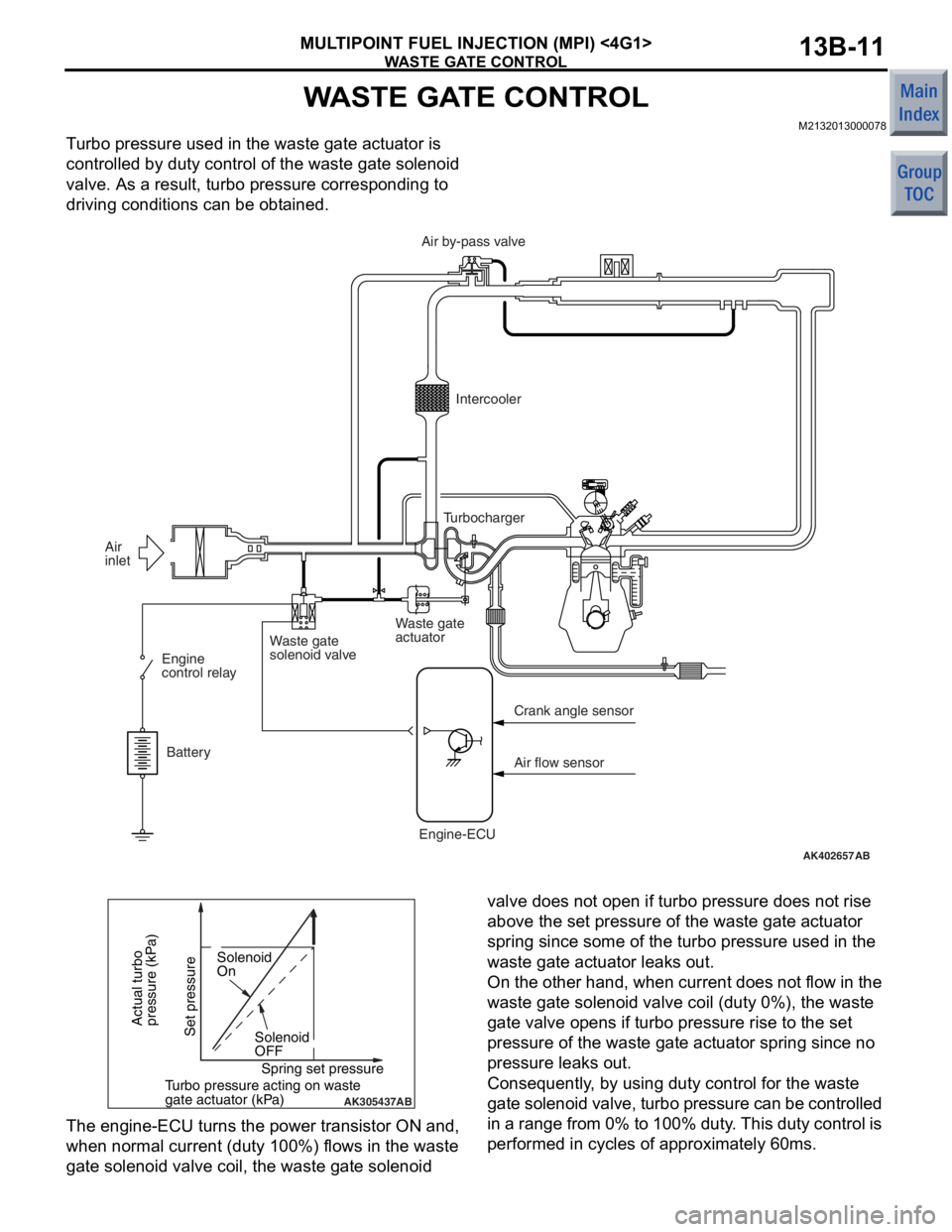

WASTE GATE CONTROL

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-11

WASTE GATE CONTROL

M2132013000078

Turbo pressure used in the waste gate actuator is

controlled by duty control of the waste gate solenoid

valve. As a result, turbo pressure corresponding to

driving conditions can be obtained.

AK402657

Waste gate

solenoid valveWaste gate

actuator

Battery Engine-ECU Crank angle sensor

Engine

control relay

Air flow sensor

Air by-pass valve

Air

inlet Intercooler

Turbocharger

AB

AK305437

Solenoid

On SolenoidSpring set pressure

Set pressure Actual turbo

pressure (kPa)

Turbo pressure acting on waste

gate actuator (kPa)

OFFAB

The eng

ine-ECU turns the power tran sistor ON and,

whe

n normal curren t (duty 100% ) flows in th e waste

gate solen

o id valve coil, the waste gat e solenoid valve do es n o t ope n if tu rbo pre ssu re does not rise

above the set pre s sure of th e waste gate actua t or

spring since some of the turb o pressure used in th e

wa ste g a te actuato r leaks o u t.

On the ot

her hand, when current do es not flow in the

wa

ste g a te soleno id valve co il (d uty 0 % ), the wa ste

gate valve ope

ns if turbo pressure rise to the set

pressure o

f the waste gat e act uator sprin g since no

pressure leaks out

.

Conseq uently , by u s in g duty co ntrol for the waste

g

a te solen o id valve, turbo pressu re can b e con t ro lled

in a range

f r om 0% to 1 00% duty . Th is du ty co ntrol is

performed in cycles of

approximately 60ms.

Page 126 of 364

OTHER CONTROL FUNCTIONS

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-12

OTHER CONTROL FUNCTIONS

M2132010000648

The following controls are basically the same as

those of the 4G1-Non-Turbo engine used in the

COLT.

•ENGINE CONTROL RELAY CONTROL

•THROTTLE VALVE CONTROL SERVO RELAY

CONTROL

•MIVEC (Mitsubishi Innovative Valve Timing Elec-

tronic Control System)

•FUEL PUMP RELAY CONTROL

•OXYGEN SENSOR (front) HEATER CONTROL

•OXYGEN SENSOR (rear) HEATER CONTROL

•FAN RELAY CONTROL

•A/C RELAY CONTROL

•ALTERNATOR CONTROL