MITSUBISHI COLT 2006 Service Service Manual

COLT 2006

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57093/w960_57093-0.png

MITSUBISHI COLT 2006 Service Service Manual

Trending: brake sensor, tow bar, panel, rear motor, remote start, door, suspension

Page 41 of 364

EXHAUST SYSTEM

INTAKE AND EXHAUST15-5

EXHAUST SYSTEM

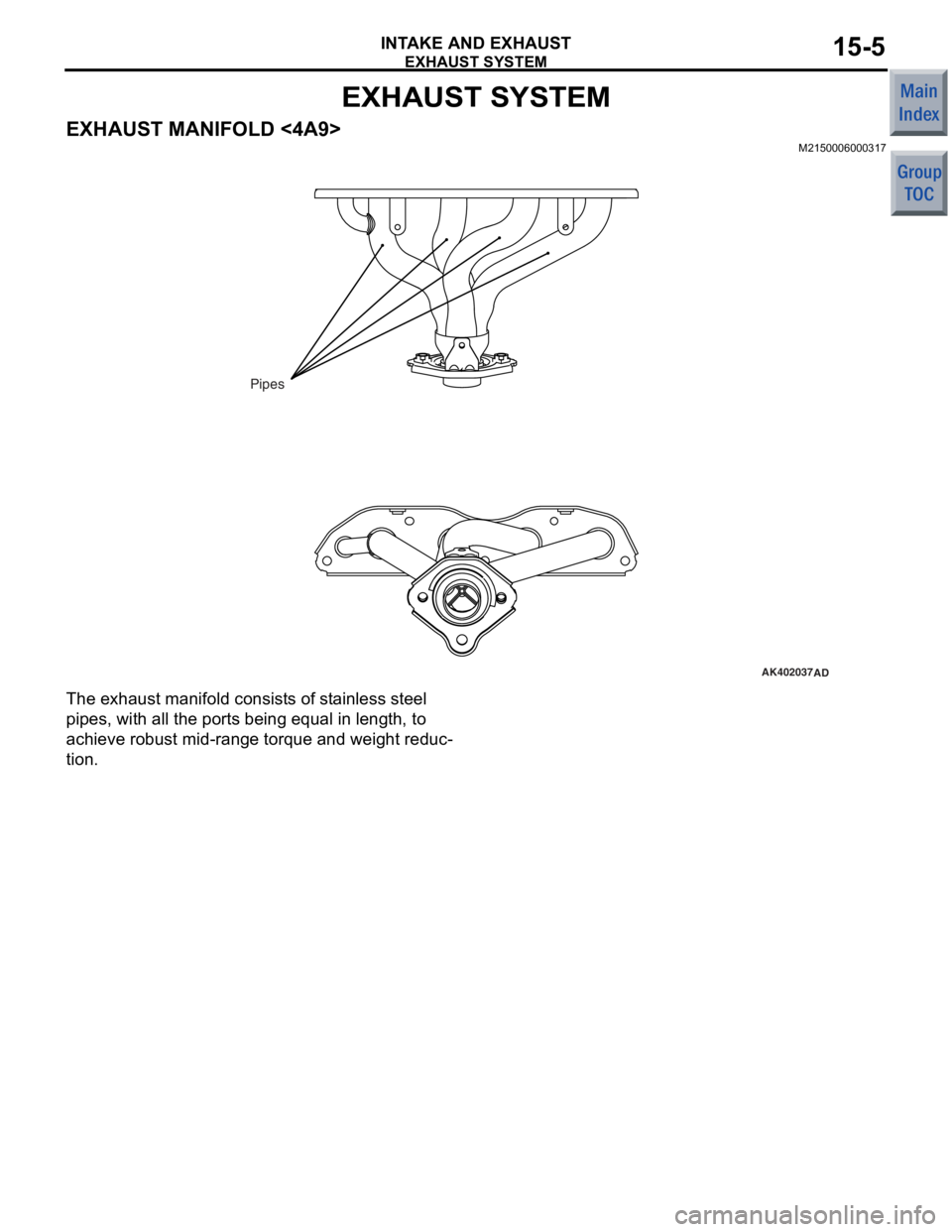

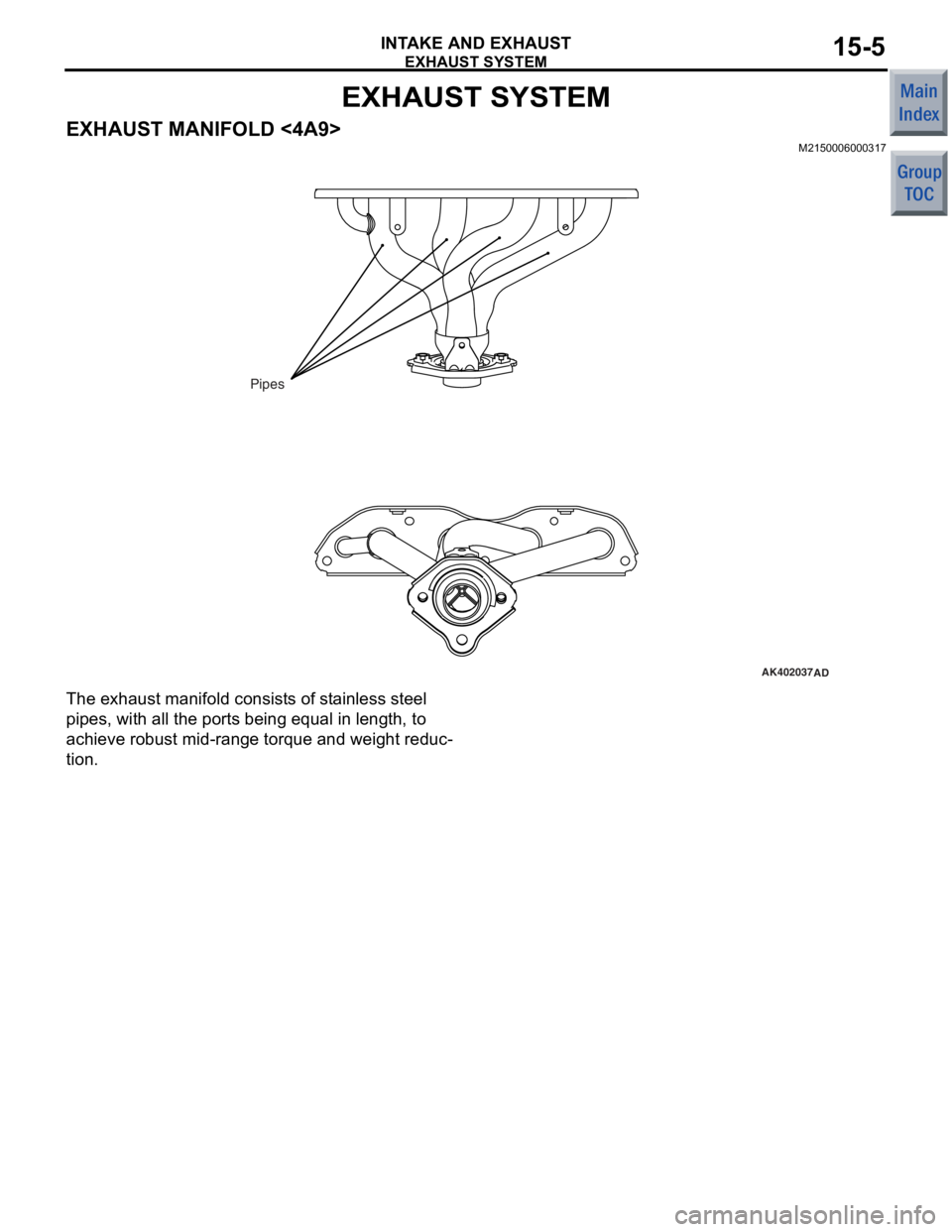

EXHAUST MANIFOLD <4A9>M2150006000317

AK402037

Pipes

AD

The exhaust manifold co nsist s of st ain l ess st eel

pipes, with

all the po rt s bein g equa l in leng th, to

achieve

robust mid-range torque and weight red u c

-

tion.

Page 42 of 364

EXHAUST SYSTEM

INTAKE AND EXHAUST15-6

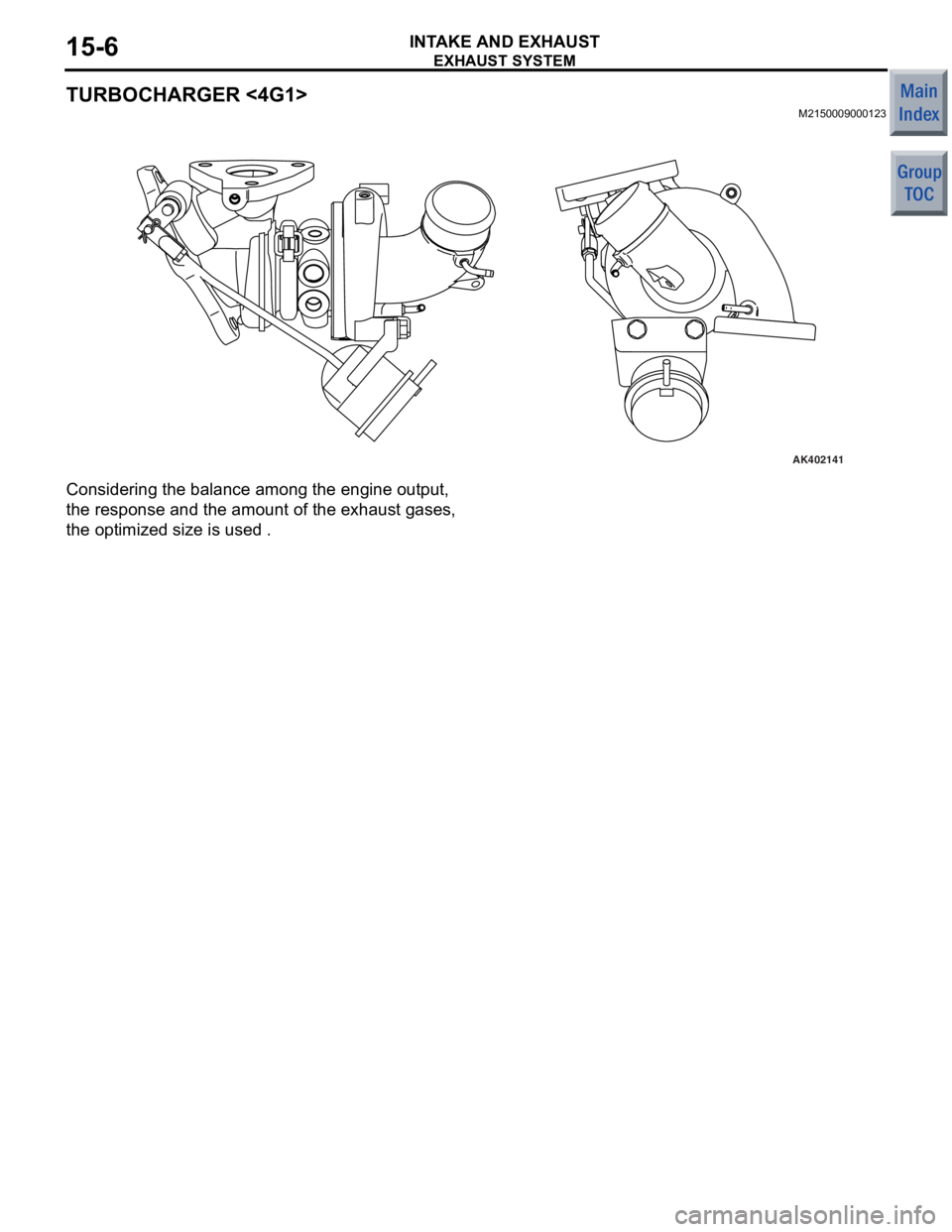

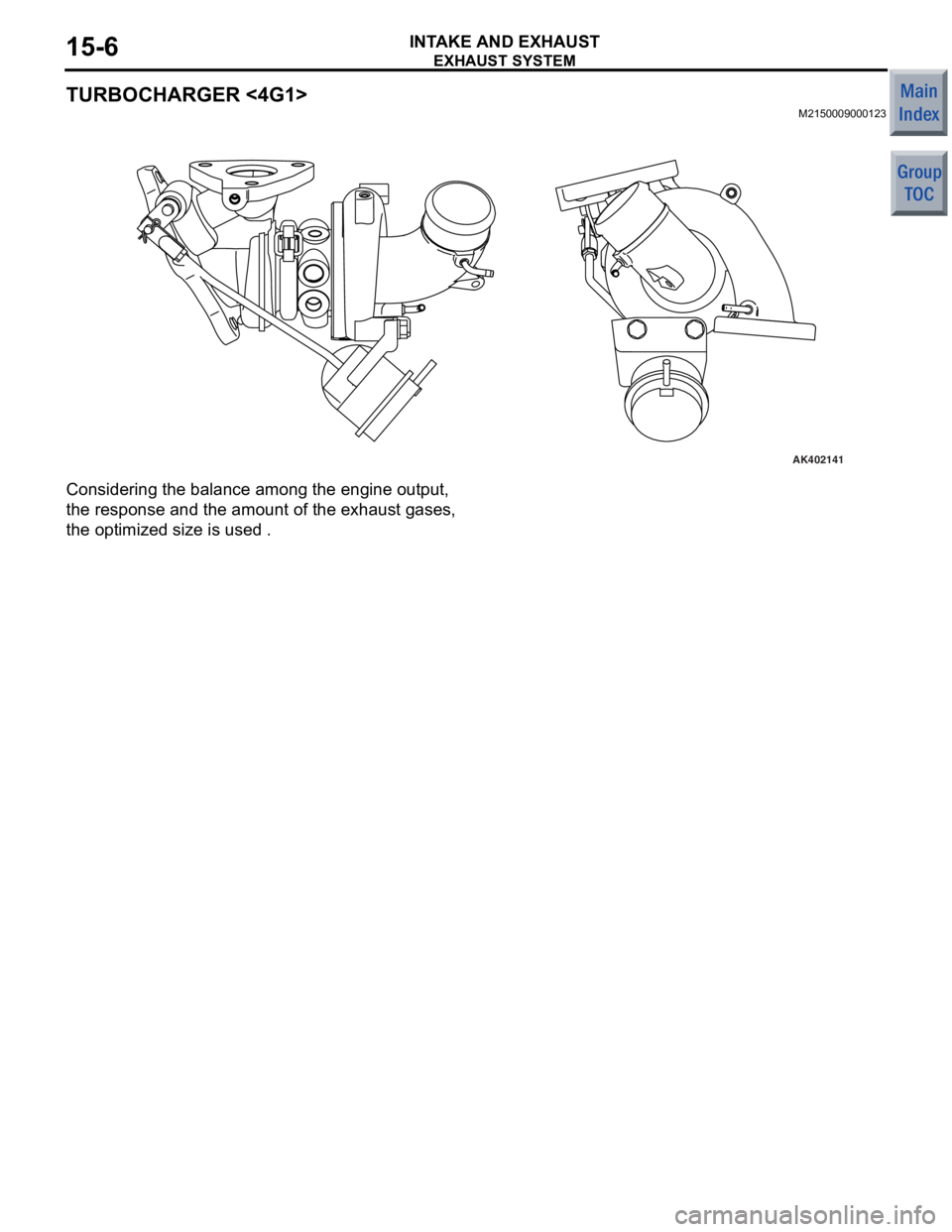

TURBOCHARGER <4G1>

M2150009000123

AK402141

Cons id ering the ba lance among t he eng ine o u tput,

the response and

the amount of the exha ust g a ses,

the opt

imized size is used .

Page 43 of 364

EXHAUST SYSTEM

INTAKE AND EXHAUST15-7

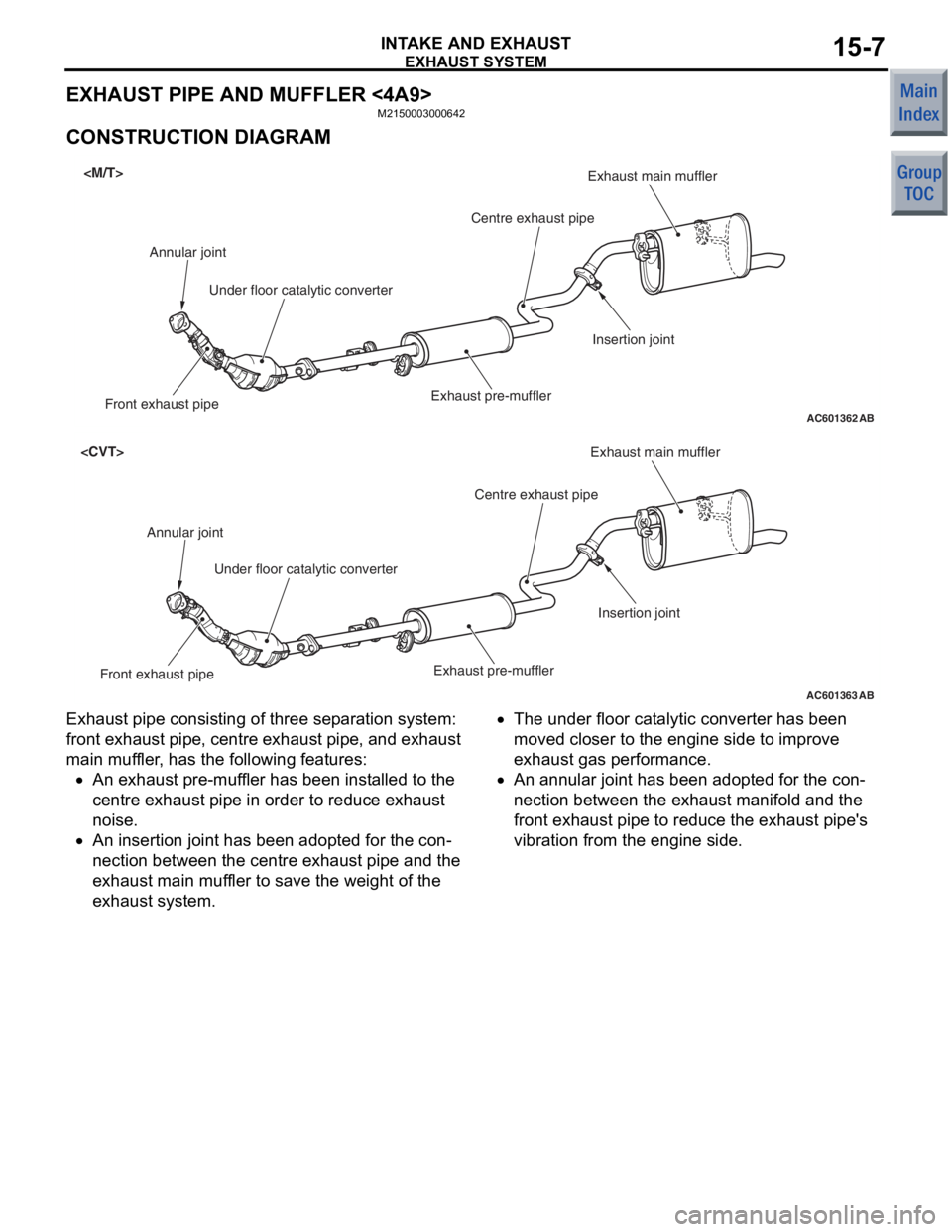

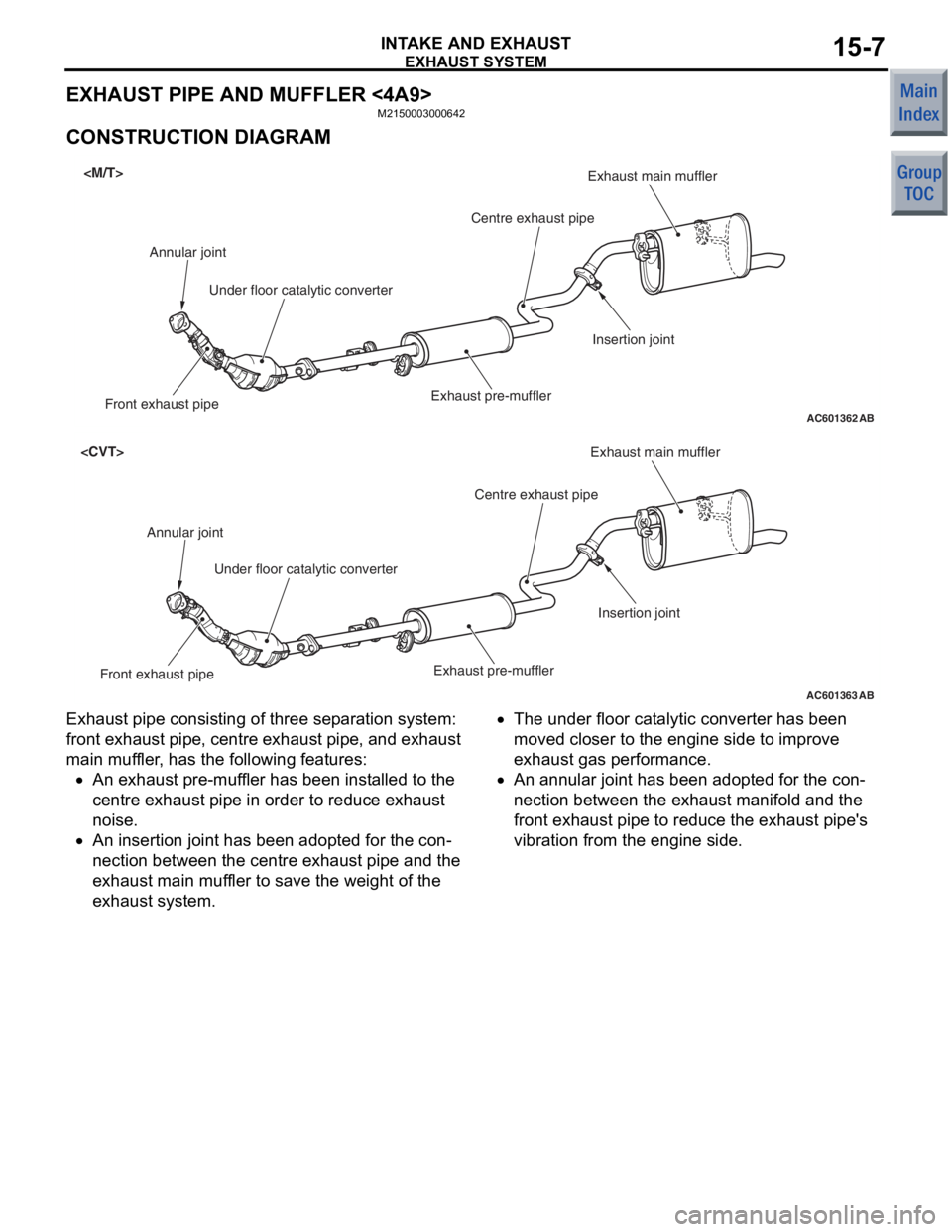

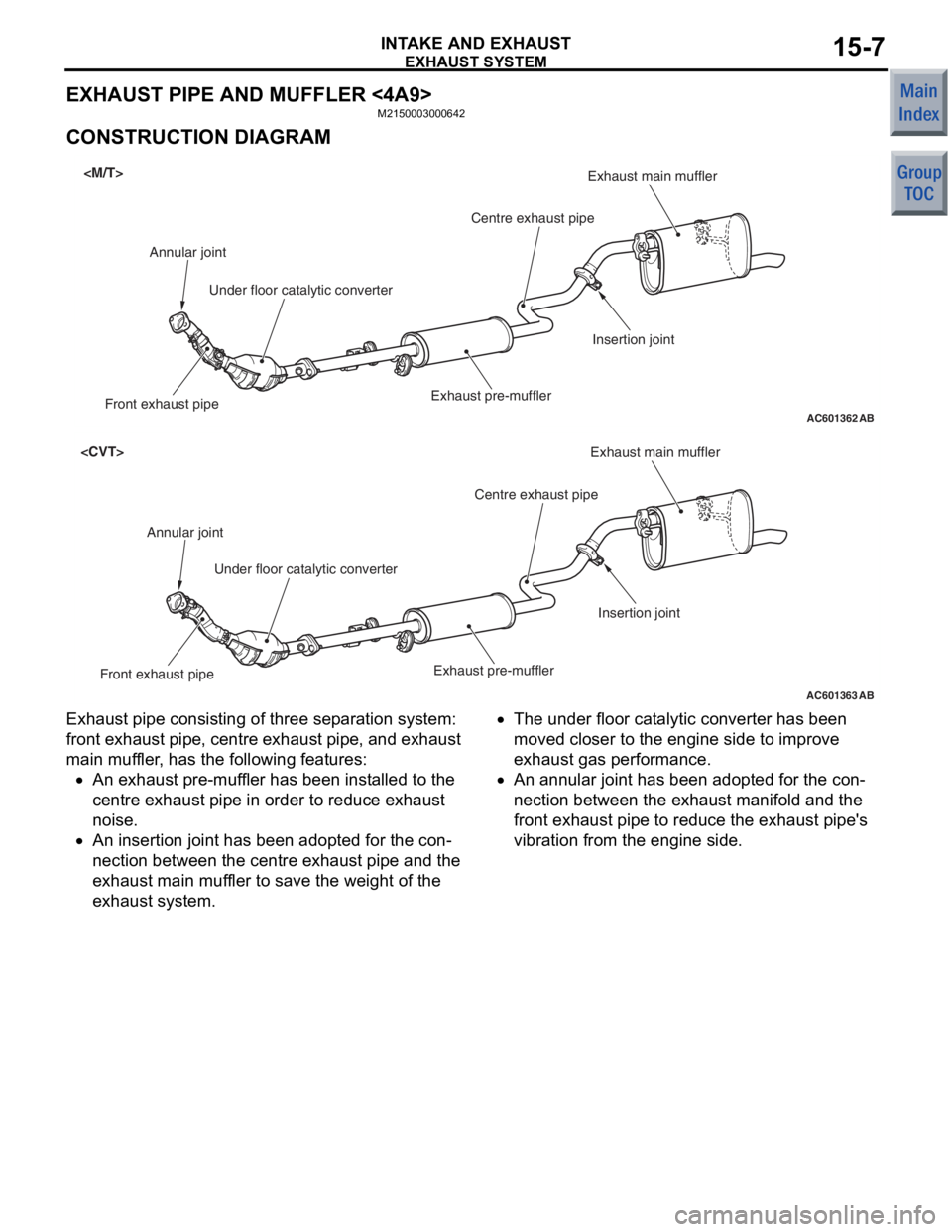

EXHAUST PIPE AND MUFFLER <4A9>

M2150003000642

CONSTRUCTION DIAGRAM

AC601362AB

Centre exhaust pipeExhaust main muffler

Front exhaust pipeAnnular joint

Under floor catalytic converter

Exhaust pre-muffler

Insertion joint

AC601363AB

Centre exhaust pipeExhaust main muffler

Front exhaust pipeAnnular joint

Under floor catalytic converter

Exhaust pre-muffler

Insertion joint

Exhaust pipe consisting of th ree sep a ratio n system:

front exhaust pipe,

centre e x hau st pip e , and exhaust

main muf

f ler , has the fo llowing fea t ures:

•An exhaust pre-muff ler ha s be en in st alled to th e

ce

ntre exhaust pipe in order t o reduce exhaust

noise.

•An insertion joint has b een a dopted for the con-

nection between the centre exha ust p i pe and the

exhaust ma

in muf f ler to save the weight of the

exhaust system.

•The under floor cat a lytic con v erter has been

moved

clo s er to the e ngine side to impro v e

exhaust gas perfo

rmance.

•An annula r joint has been adopt ed for th e co n-

nection between the exhau st manifo ld an d the

fron

t exh aust pipe to redu ce th e exhaust pipe 's

vibration from the

engine side.

Page 44 of 364

EXHAUST SYSTEM

INTAKE AND EXHAUST15-8

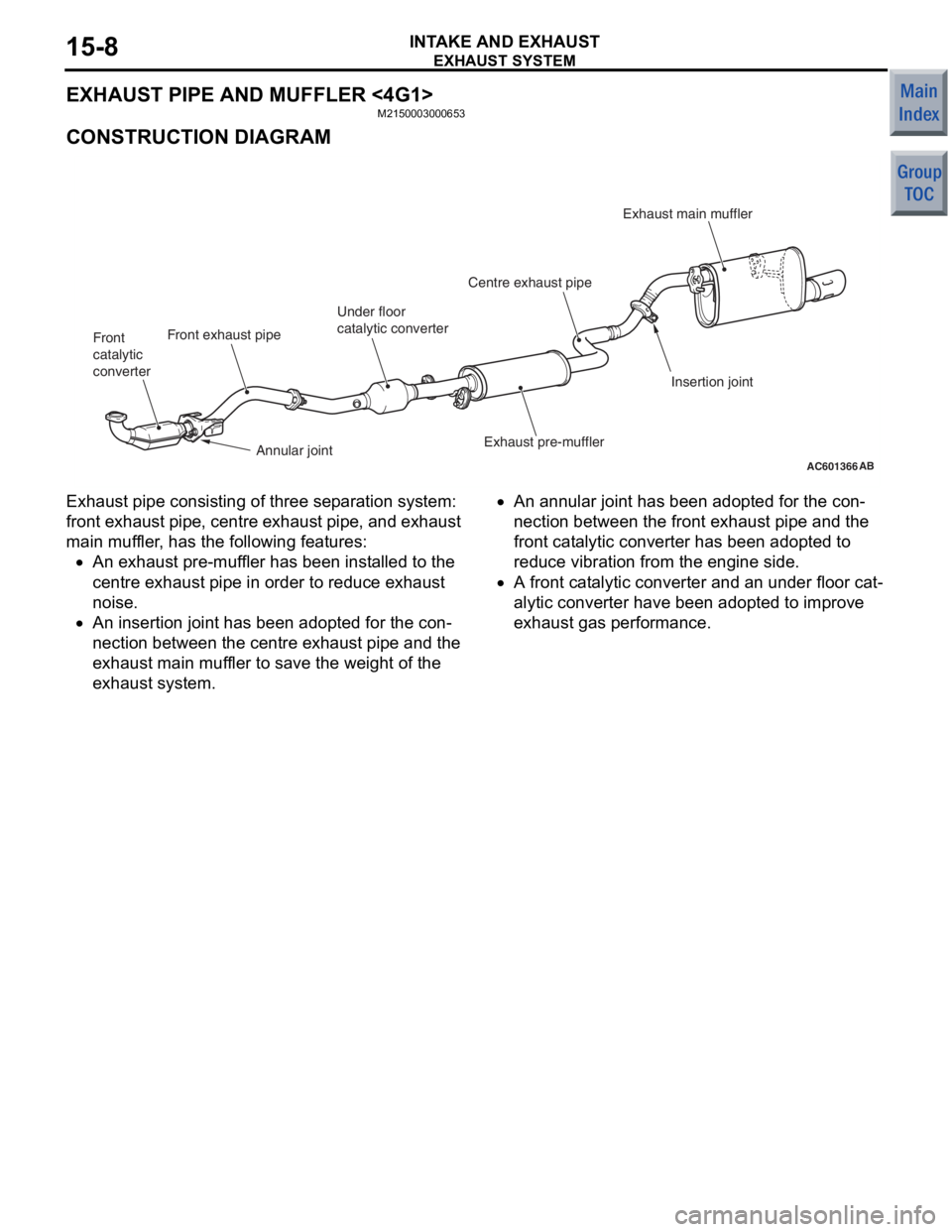

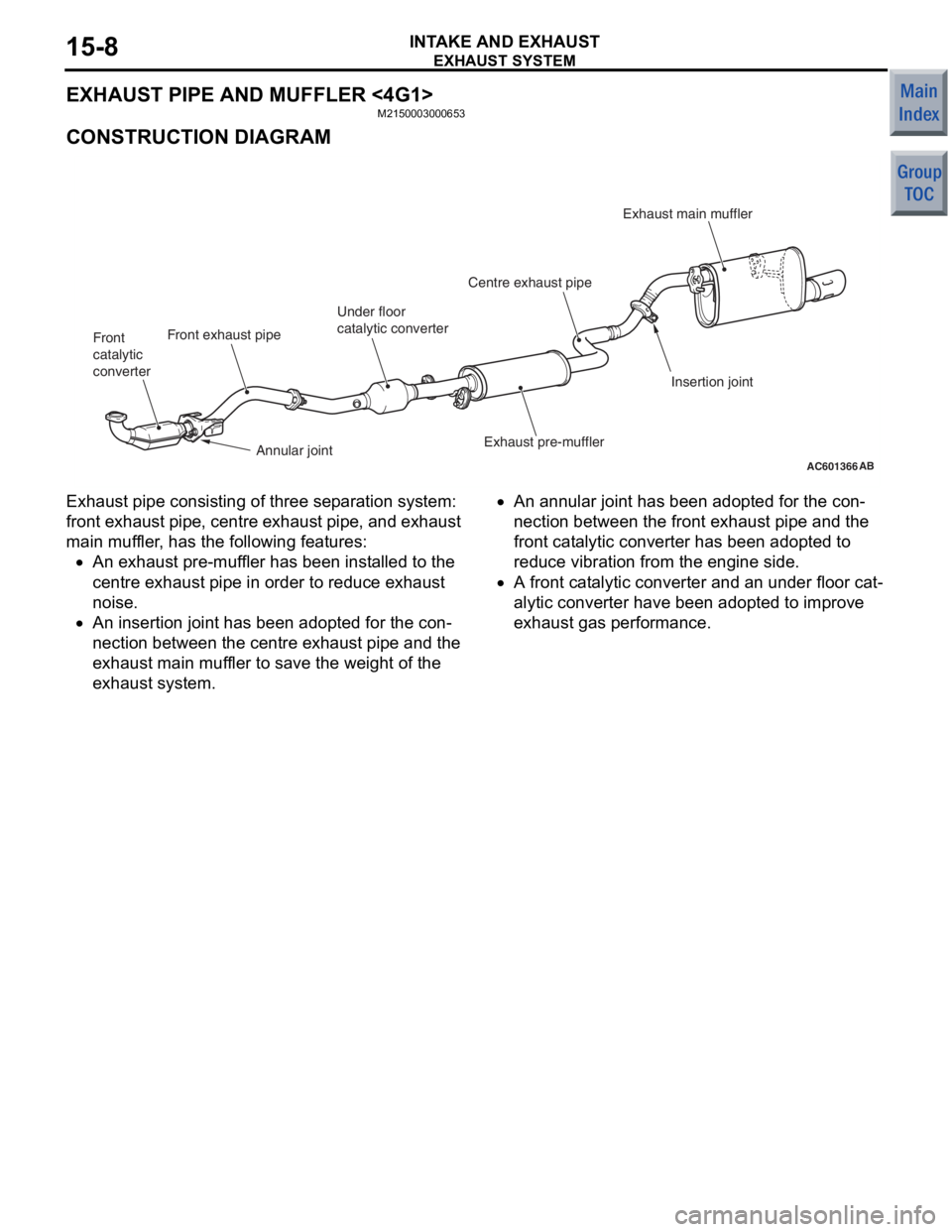

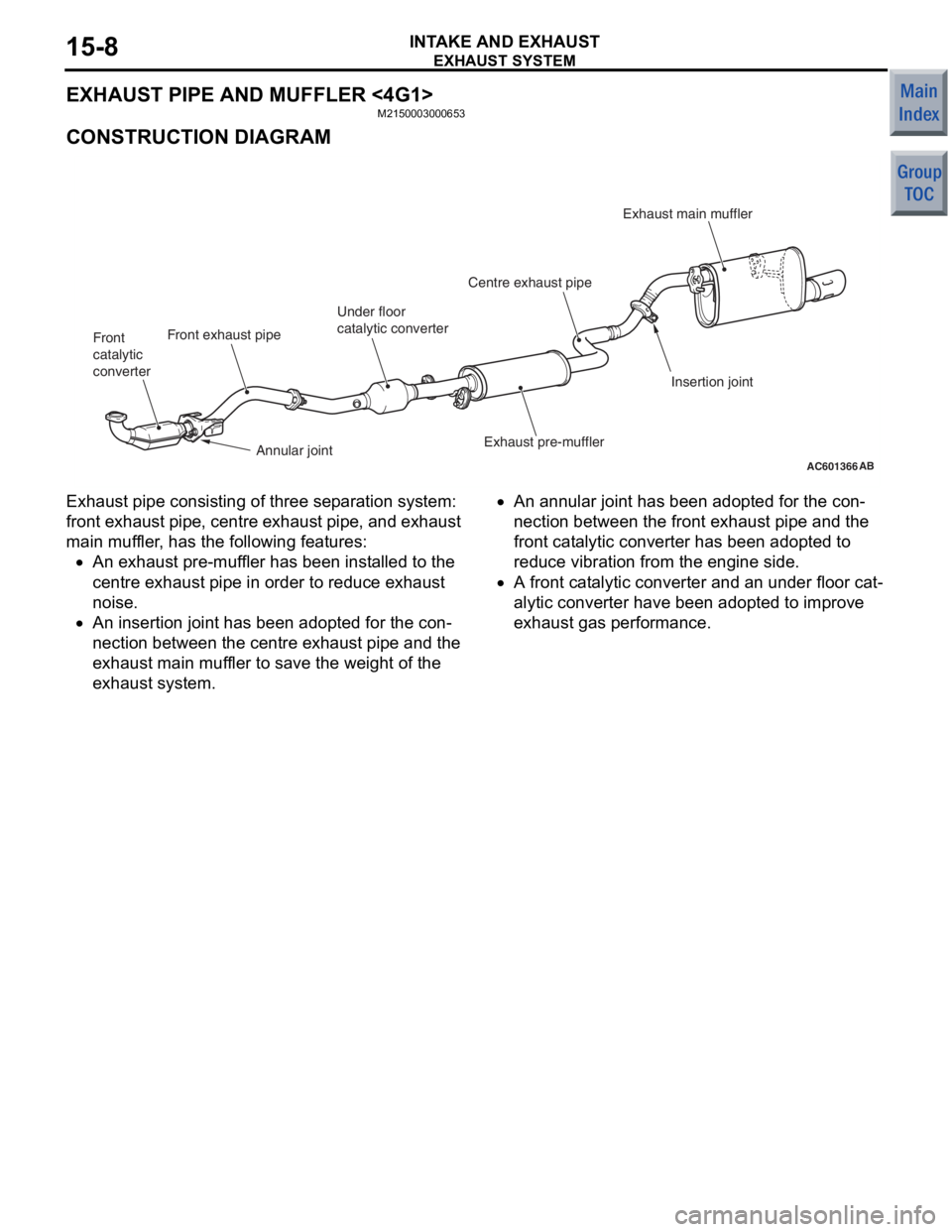

EXHAUST PIPE AND MUFFLER <4G1>

M2150003000653

CONSTRUCTION DIAGRAM

AC601366AB

Centre exhaust pipeExhaust main muffler

Front exhaust pipe

Under floor

catalytic converter

Exhaust pre-muffler

Front

catalytic

converter

Insertion joint

Annular joint

Exhaust pipe co

nsisting of th ree sep a ratio n system:

front exhaust pipe,

centre e x hau st pip e , and exhaust

main muf

f ler , has the fo llowing fea t ures:

•An exhaust pre-muff ler ha s be en in st alled to th e

ce

ntre exhaust pipe in order t o reduce exhaust

noise.

•An insertion joint has b een a dopted for the con-

nection between the centre exha ust p i pe and the

exhaust ma

in muf f ler to save the weight of the

exhaust system.

•An annula r joint has been adopt ed for th e co n-

nection between the fro n t exhaust pip e and the

fron

t cat a lytic co nvert e r has been adopt ed to

redu

ce vibra t ion from th e eng ine side .

•A front cat a lytic co nvert e r and an und er floo r cat-

alytic conver ter have bee n adop ted to imp r ove

exhaust gas perfo

rmance.

Page 45 of 364

GROUP 11B

ENGINE

MECHANICAL

<4G1>

CONTENTS

GENERAL INFORMATIO N . . . . . . . .11B-2BASE ENGINE . . . . . . . . . . . . . . . . . .11B-3

Page 46 of 364

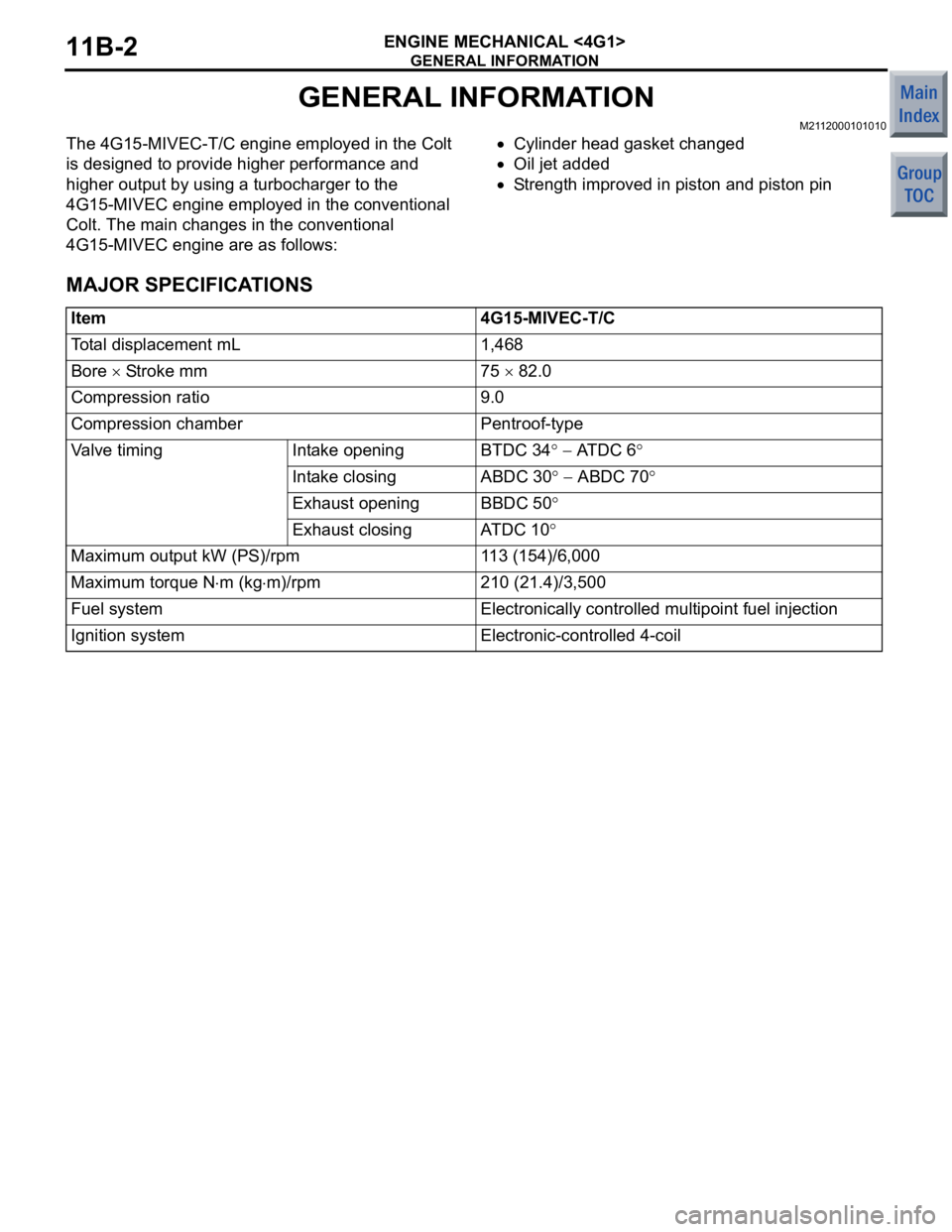

GENERAL INFORMATION

ENGINE MECHANICAL <4G1>11B-2

GENERAL INFORMATION

M2112000101010

The 4G15-MIVEC-T/C engine employed in the Colt

is designed to provide higher performance and

higher output by using a turbocharger to the

4G15-MIVEC engine employed in the conventional

Colt. The main changes in the conventional

4G15-MIVEC engine are as follows:•Cylinder head gasket changed

•Oil jet added

•Strength improved in piston and piston pin

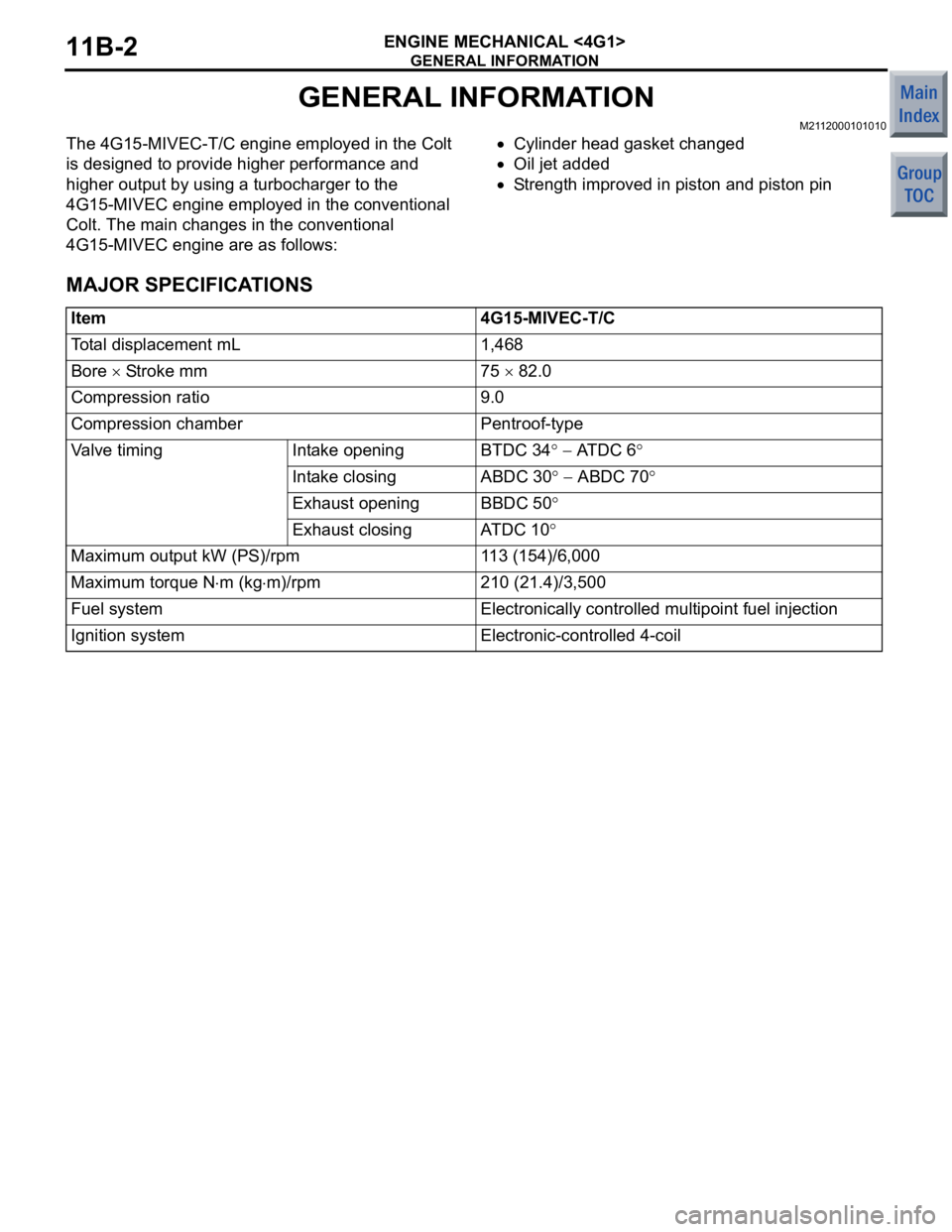

MAJOR SPECIFICATIONS

Item4G15-MIVEC-T/C

Total displacement mL1,468

Bore × Stro ke mm75 × 82.0

Compression ratio9.0

Compression chamberPentroof-type

Va l v e t i m i n gIntake openingBTDC 34° − AT D C 6°

Intake closingABDC 30° − ABDC 70°

Exhaust openingBBDC 50°

Exhaust closingATDC 10°

Maximum output kW (PS)/rpm113 (154)/6,000

Maximum torque N⋅m (kg⋅m)/rpm210 (21.4)/3,500

Fuel systemElectronically controlled multipoint fuel injection

Ignition systemElectronic-controlled 4-coil

Page 47 of 364

BASE ENGINE

ENGINE MECHANICAL <4G1>11B-3

BASE ENGINE

M2112001000886

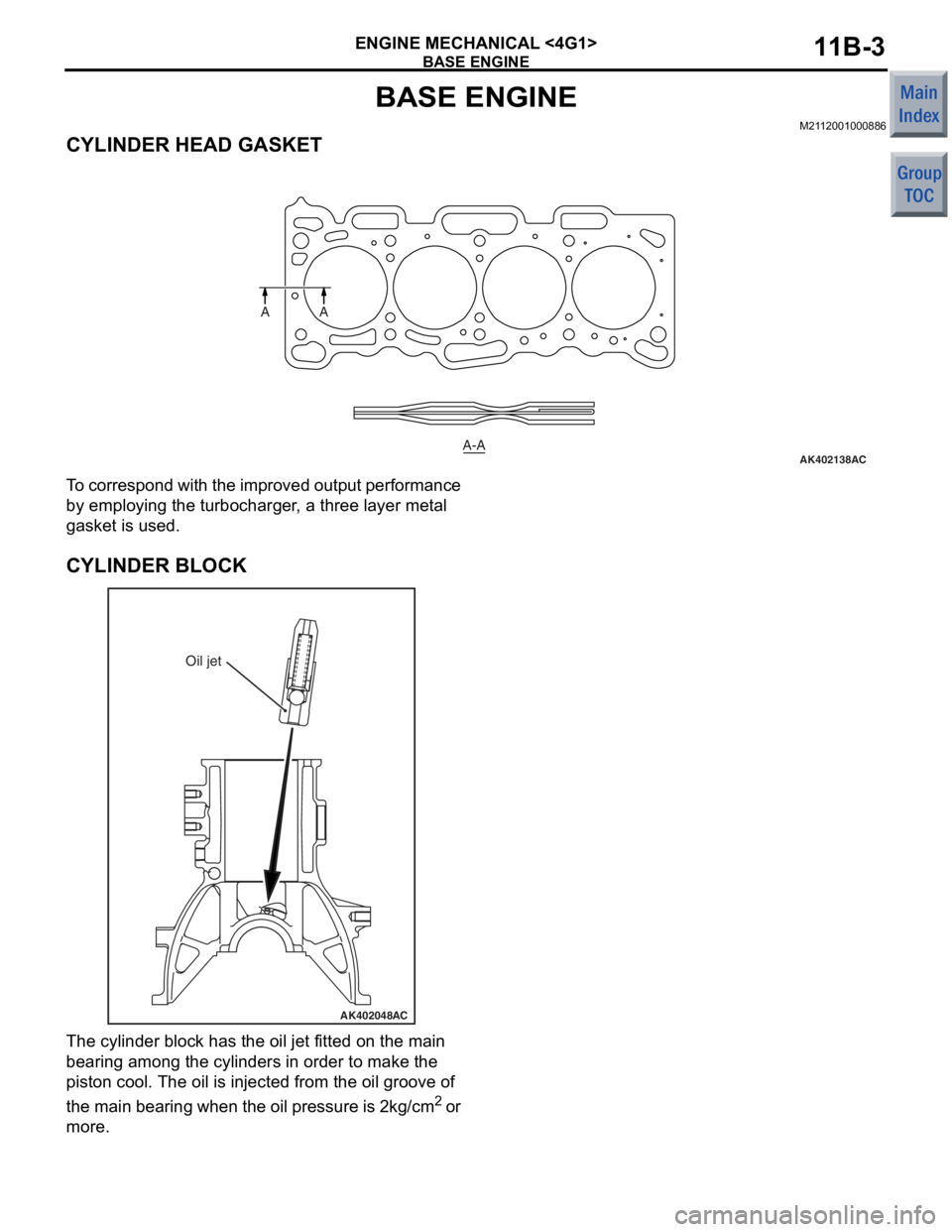

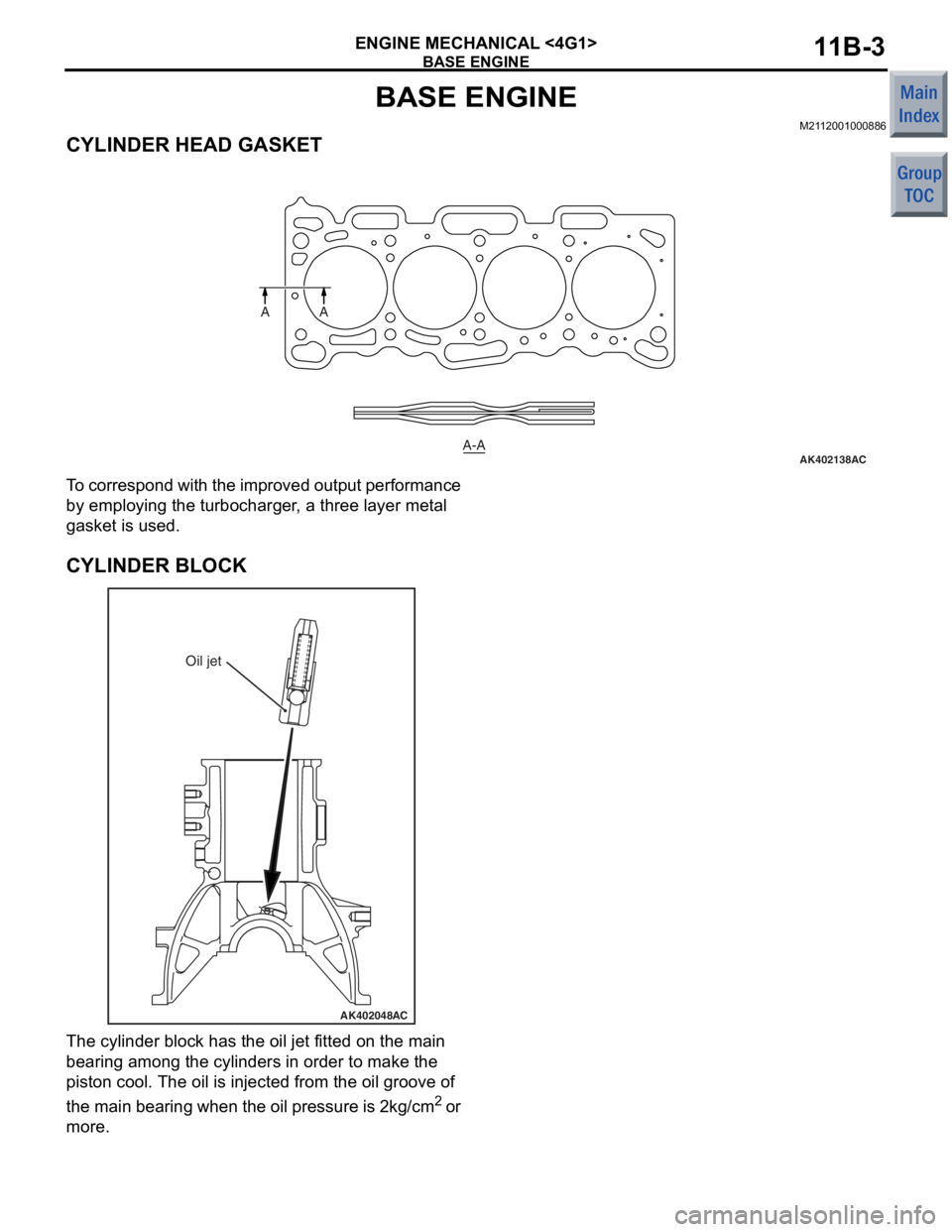

CYLINDER HEAD GASKET

AK402138

A

AC

AA-A

To co rrespo nd wi th the imp r ove d o u t put pe rfo r ma nce

by emplo

y in g the t u rbocharger , a three layer me t a l

gasket is used.

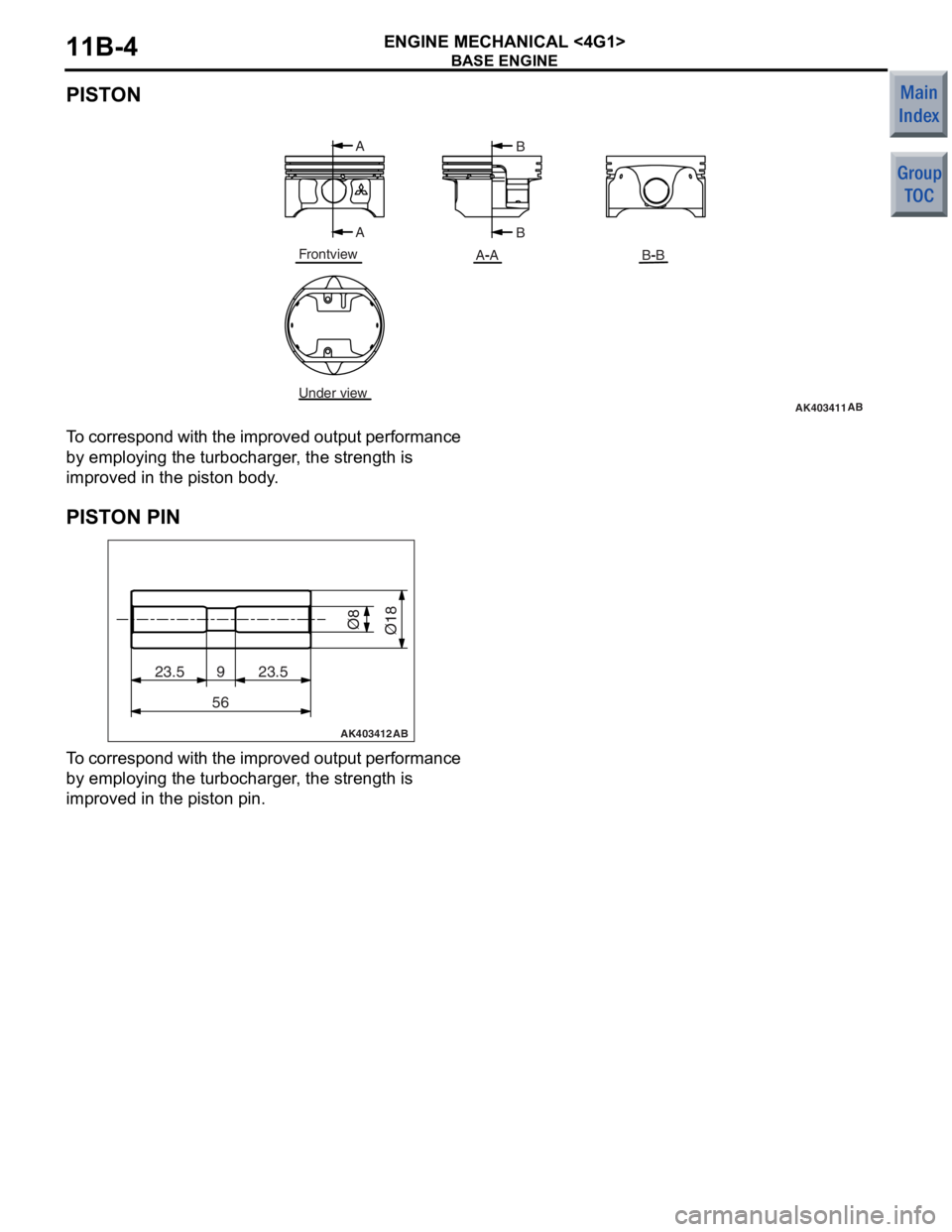

CYLINDER BLOCK

AK402048AC

Oil jet

The cylinder bl ock has the oil jet fitted o n the main

bearin

g among th e cylin ders in ord e r to make the

pist

on cool. T he oil is injecte d from the o il g r oove of

the main b

earin g when th e oil pressure is 2kg/ cm

2 or

more.

Page 48 of 364

BASE ENGINE

ENGINE MECHANICAL <4G1>11B-4

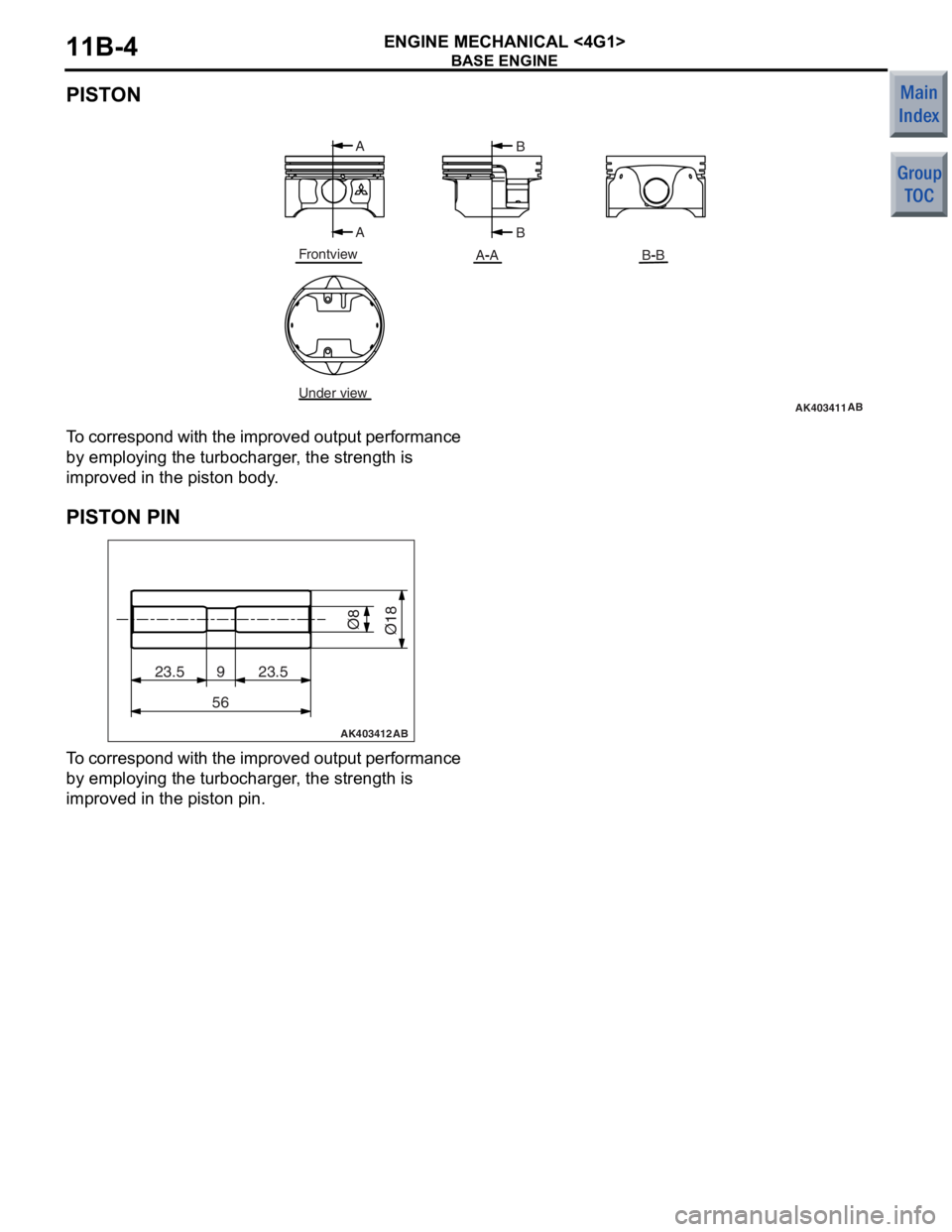

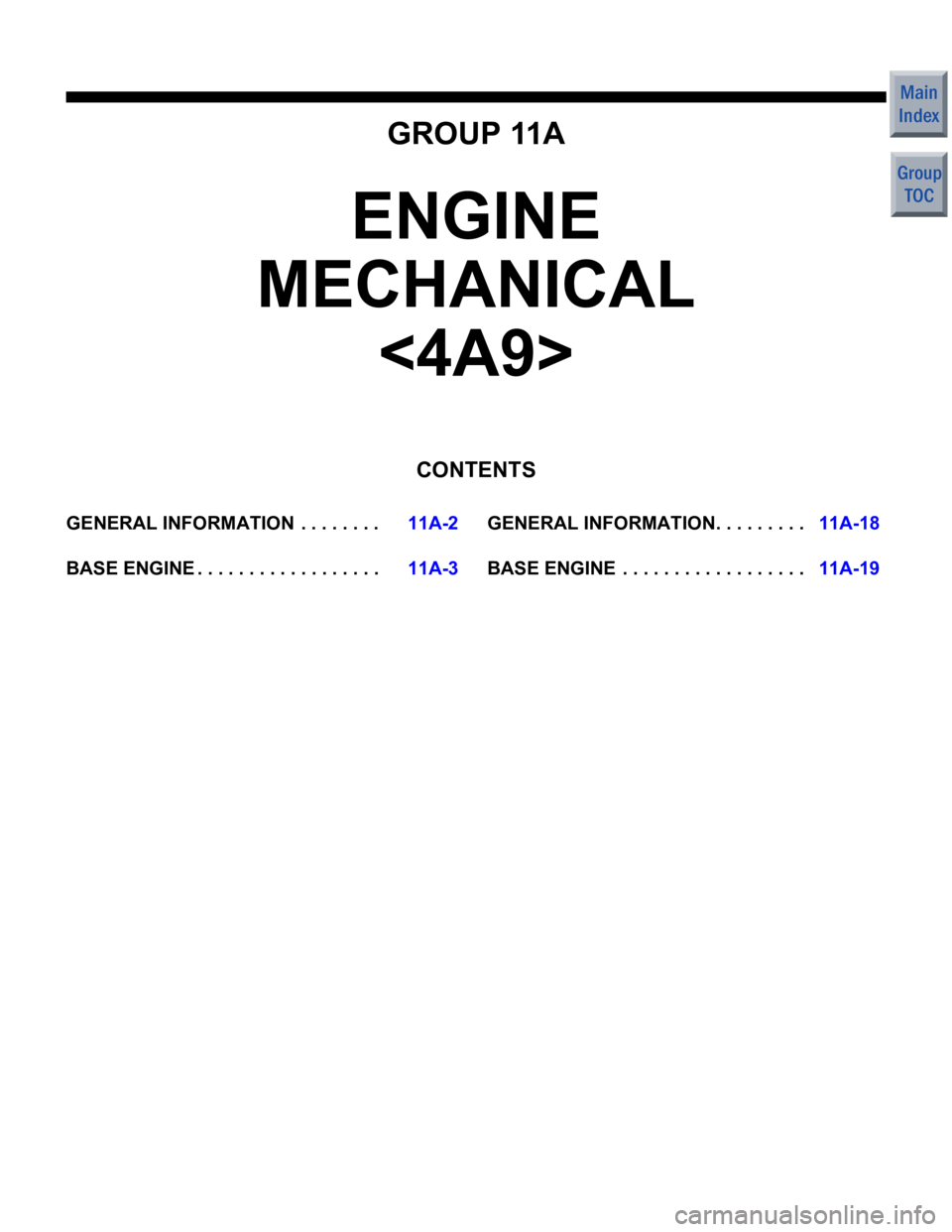

PISTON

AK403411

Frontview

Under view

A-AB -B

A

A B

B

AB

T

o co rrespo nd wi th the imp r ove d o u t put pe rfo r ma nce

by emplo

y in g the t u rbocharger , the strength is

imp

r oved in th e piston b ody .

PISTON PIN

AK403412

56

Ø8

Ø18

23.523.5 9

AB

T o co rrespo nd wi th the imp r ove d o u t put pe rfo r ma nce

by emplo

y in g the t u rbocharger , the strength is

imp

r oved in th e piston p i n.

Page 49 of 364

GROUP 11A

ENGINE

MECHANICAL

<4A9>

CONTENTS

GENERAL INFORMATIO N . . . . . . . .11A-2

BASE ENGINE . . . . . . . . . . . . . . . . . .11A-3

GENERAL INFORMATION. . . . . . . . .11A-18

BASE ENGINE . . . . . . . . . . . . . . . . . .11A-19

Page 50 of 364

GENERAL INFORMATION

ENGINE MECHANICAL <4A9>11A-2

GENERAL INFORMATION

M2112000100697

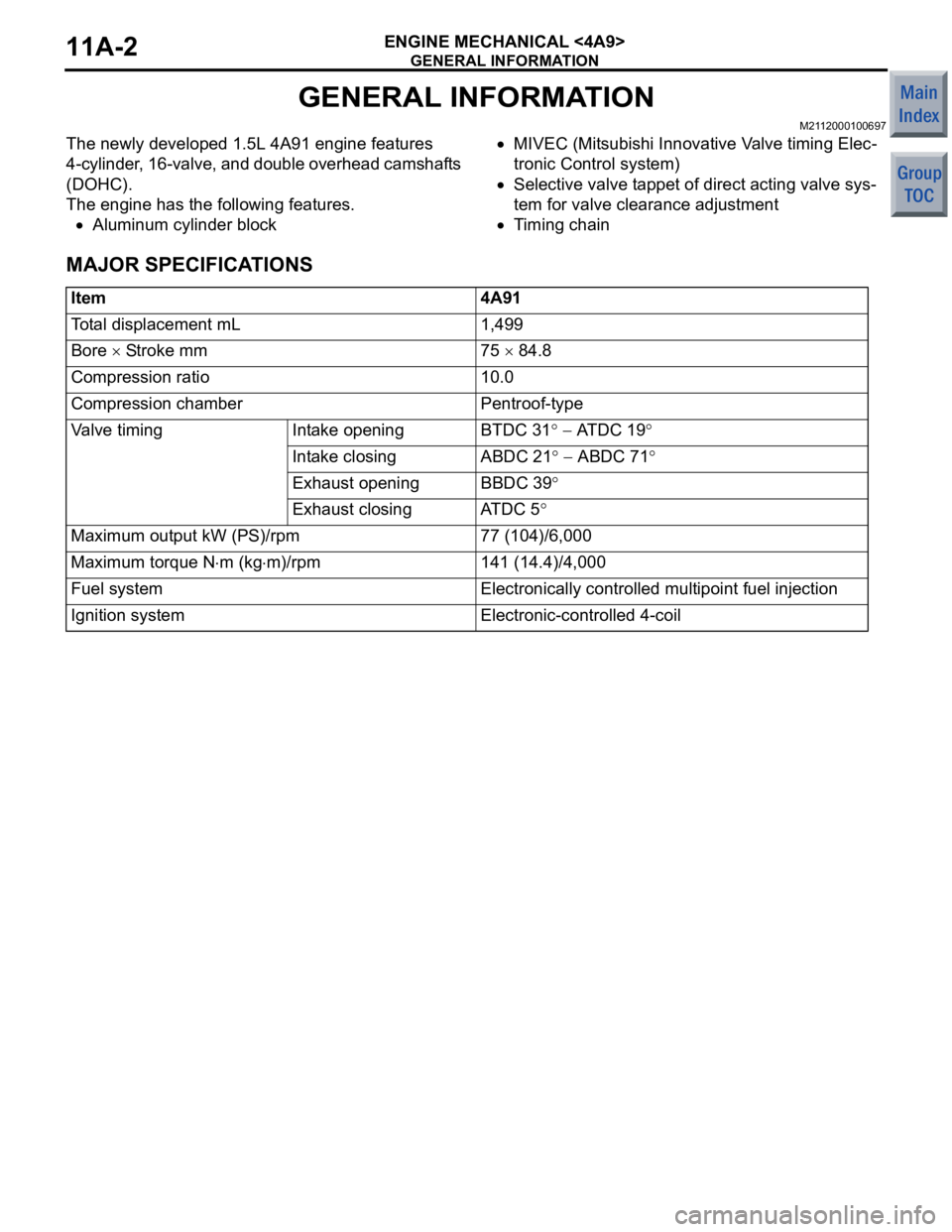

The newly developed 1.5L 4A91 engine features

4-cylinder, 16-valve, and double overhead camshafts

(DOHC).

The engine has the following features.

•Aluminum cylinder block

•MIVEC (Mitsubishi Innovative Valve timing Elec-

tronic Control system)

•Selective valve tappet of direct acting valve sys-

tem for valve clearance adjustment

•Timing chain

MAJOR SPECIFICATIONS

Item4A91

Total displacement mL1,499

Bore × Stro ke mm75 × 84.8

Compression ratio10.0

Compression chamberPentroof-type

Va l v e t i m i n gIntake openingBTDC 31° − AT D C 1 9°

Intake closingABDC 21° − ABDC 71°

Exhaust openingBBDC 39°

Exhaust closingATDC 5°

Maximum output kW (PS)/rpm77 (104)/6,000

Maximum torque N⋅m (kg⋅m)/rpm141 (14.4)/4,000

Fuel systemElectronically controlled multipoint fuel injection

Ignition systemElectronic-controlled 4-coil

Trending: technical specifications, crankshaft, key, latch, low beam, gearbox, airbag off