ignition MITSUBISHI DIAMANTE 1900 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 44 of 408

GENERALINFORMATIONAND MAINTENANCE 1-45

SLING TYPE

WHEEL LIFT TYPE

cles

SUNG TYPE

WHEEL LIFT TYPE

FLAT BED TYPE

Fig. 220 Rear towing position-FWD vehi

cles

personal injury. Remember that batteries contain a

small amount of explosive hydrogen gas which is a

by-product of battery charging. Sparks should always

be avoided when working around batteries, especially

when attaching jumper cables. To minimize the pos-

sibility of accidental sparks, follow the procedure

carefully.

NEVER hook the batteries up in a series cir-

cuit or the entire electrical system will go up

in smoke. includino the starter!

Vehicles equipped with a diesel engine may utilize

two 12 volt batteries. If so, the batteries are con-

nected in a parallel circuit (positive terminal to posi-

tive terminal, negative terminal to negative terminal).

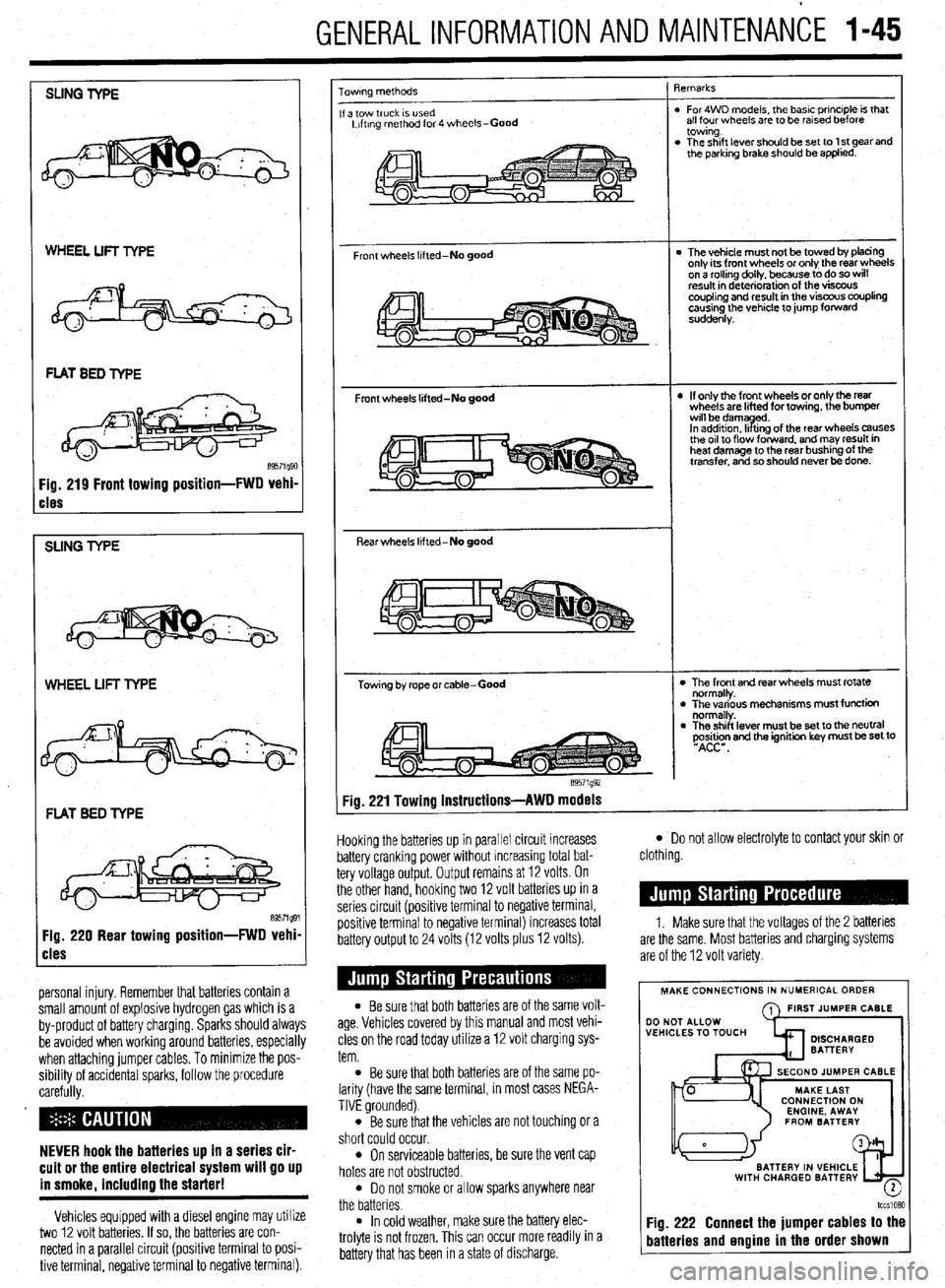

owrng methods

a tow truck IS used

Lrftrng method for 4 wheels-Good

Front wheels lifted-No good

Front wheels lifted-No good

Rear wheels lifted-No good

Towing by rope or cable-Good

e9571g92 qemarks

. For4WD models, the basic principle is that

all four wheels are to be rarsed before

towing.

. The shift lever should be set to 1 st gear and

the parking brake should be applied.

l The vehicle must not be towed by tofacing

only its front wheels or only the rear wheels

on a rollino dollv, because to do so will

result in d&e&ration of the visfx~s

coupling and result in the viscous coupling

causing the vehicle to jump forward

suddenly.

l If only the front wheels or only the rear

wheels are lifted for towing, the bumper

wrll bedamyd.

In addrtron. II trng of the rear wheels causes

the or1 to flow forward. and may result in

heat damage to the rear bushing of the

transfer, and so should never be done.

l The front and rear wheels must rotate

normally.

l The various mechanisms must function

normally.

l The shift lever must be set to the neutral

~Asi&n and the ignition key must be set to

Fig. 221 Towing instructions-AWD models

Hooking the batteries up in parallel circuit increases

battery cranking power without increasing total bat-

tery voltage output. Output remains at 12 volts. On

the other hand, hooking two 12 volt batteries up in a

series circuit (positive terminal to negative terminal,

positive terminal to negative terminal) increases total

battery output to 24 volts (12 volts plus 12 volts).

l Be sure that both batteries are of the same volt-

age. Vehicles covered by this manual and most vehi-

cles on the road today utilize a 12 volt charging sys-

tem.

l Be sure that both batteries are of the same po-

larity (have the same terminal, in most cases NEGA-

TIVE grounded).

l Be sure that the vehicles are not touching or a

short could occur.

l On serviceable batteries, be sure the vent cap

holes are not obstructed.

l Do not smoke or allow sparks anywhere near

the batteries.

l In cold weather, make sure the battery elec-

trolyte is not frozen, This can occur more readily in a

battery that has been in a state of discharge.

l Do not allow electrolyte to contact your skin or

clothing.

1. Make sure that the voltages of the 2 batteries

are the same. Most batteries and charging systems

are of the 12 volt variety.

MAKE CONNECTIONS IN NUMERICAL ORDER

A FIRST JUMPER CABLE

WITH CHARGED BATTERY

-

lccslQ?,Q

Fig. 222 Connect the jumper cables to the

batteries and engine in the order shown

Page 45 of 408

.

I-46 GENERALINFORMATIONAND MAINTENANCE

2. Pull the jumping vehicle (with the good bat-

tery) into a position so the jumper cables can reach

the dead battery and that vehicle’s engine. Make sure

that the vehicles do NOT touch.

3. Place the transmissions/transaxles of both ve-

hicles in Neutral (MT) or P (AT), as applicable, then

firmly set their parking brakes.

*ff necessary for safety reasons, the hazard

lights on both vehicles may be operated

throughout the entire procedure without sig-

nificantiy increasing the diff icuity of jumping

the dead battery.

4. Turn all lights and accessories OFF on both

vehicles. Make sure the ignition switches on both ve-

hicles are turned to the OFF position.

5. Cover the battery cell caps with a rag, but do

not cover the terminals.

6. Make sure the terminals on both batteries are

clean and free of corrosion or proper electrical con-

nection will be impeded. If necessary, clean the bat-

tery terminals before proceeding.

7. Identify the positive (+) and negative (-) termi-

nals on both batteries.

8. Connect the first jumper cable to the positive

(t) terminal of the dead battery, then connect the

other end of that cable to the positive (t) terminal of

the booster (good) battery.

9. Connect one end of the other jumper cable to

the negative (−) terminal on the booster bat-

tery and the final cable clamp to an engine bolt head,

alternator bracket or other solid, metallic point on the

engine with the dead battery. Try to pick a ground on

the engine that is positioned away from the battery in

order to minimize the possibility of the 2 clamps

touching should one loosen during the procedure.

DO NOT connect this clamp to the negative (-) termi-

nal of the bad battery. cable on the donor battery. Disconnect the positive

cable from the donor battery and finally, disconnect

the positive cable from the formerly dead battery. Be

careful when disconnecting the cables from the posi-

tive terminals not to allow the alligator clips to touch

any metal on either vehicle or a short and sparks will

occur.

I

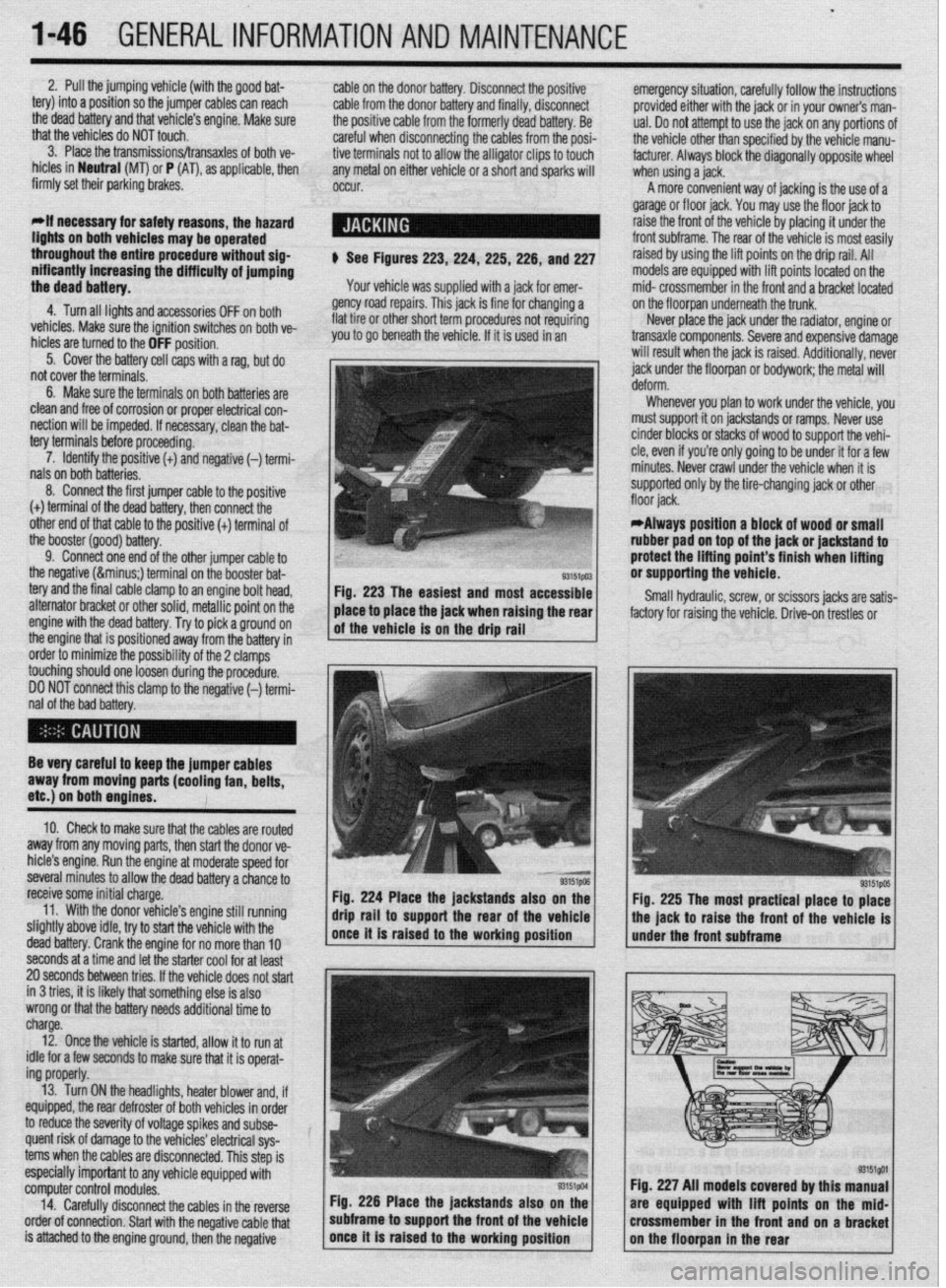

$ See Figures 223,224, 225,226, and 227

Your vehicle was supplied with a jack for emer-

gency road repairs. This jack is fine for changing a

flat tire or other short term procedures not requiring

you to go beneath the vehicle. If it is used in an emergency situation, carefully follow the instructions

provided either with the jack or in your owners man-

ual. Do not attempt to use the jack on any portions of

the vehicle other than specified by the vehicle manu-

facturer. Always block the diagonally opposite wheel

when using a jack.

A more convenient way of jacking is the use of a

garage or floor jack. You may use the floor jack to

raise the front of the vehicle by placing it under the

front subframe. The rear of the vehicle is most easily

raised by using the lift points on the drip rail. All

models are equipped with lift points located on the

mid- crossmember in the front and a bracket located

on the floorpan underneath the trunk.

Never place the jack under the radiator, engine or

transaxle components. Severe and expensive damage

will result when the jack is raised. Additionally, never

jack under the floorpan or

bodywork; the

metal will

Whenever you plan to work under the vehicle, you

must support it on jackstands or ramps. Never use

cinder blocks or stacks of wood to support the vehi-

cle, even if you’re only going to be under it for a few

minutes. Never crawl under the vehicle when it is

supported only by the tire-changing jack or other

*Always position a block of wood or small

rubber pad on top of the jack or jackstand to

protect the lifting point’s finish when lifting

or supporting the vehicle.

Small hydraulic, screw, or scissors jacks are satis-

factory for raising the vehicle. Drive-on trestles or

Be very careful to keep the jumper cables

away from moving parts (cooling fan, belts,

etc.) on both engines.

10. Check to make sure that the cables are routed

away from any moving parts, then start the donor ve-

hicle’s engine. Run the engine at moderate speed for

several minutes to allow the dead battery a chance to

receive some initial charge.

11. With the donor vehicle’s engine still running

slightly above idle, try to start the vehicle with the

dead battery. Crank the engine for no more than 10 &stands also on the

Fig. 225 The most practical place to place

front of the vehicle is

seconds at a time and let the starter cool for at least

20 seconds between tries. If the vehicle does not start

in 3 tries, it is likely thatsomething else is also

wrong or that the battery needs additional time to

charge.

12. Once the vehicle is started, allow it to run at

idle for a few seconds to make sure that it is operat-

ing properly.

13. Turn ON the headlights, heater blower and, if

equipped, the rear defroster of both vehicles in order

to reduce the severity of voltage spikes and subse-

quent risk of damage to the vehicles’ electrical sys-

tems when the cables are disconnected. This step is

especially important to any vehicle equipped with

computer control modules.

14. Carefully disconnect the cables in the’reverse

order of connection. Start with the negative cable that

is attached to the engine ground, then the negative Fig. 226 Place the jackstands also

subframe to support the front of the Fig. 227 All models covered by this

are equipped with lift points on t

crossmember in the front and on a

Page 48 of 408

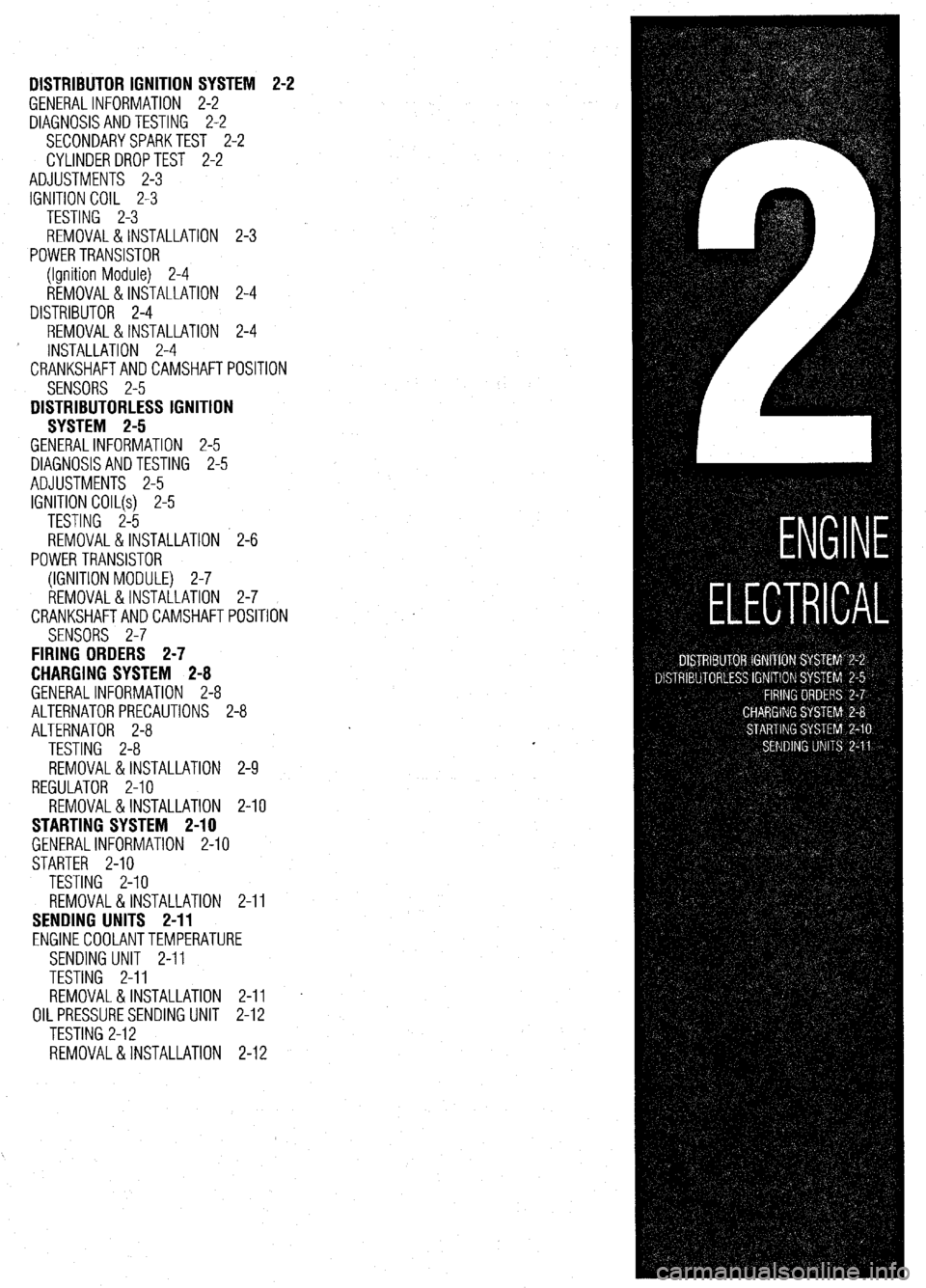

DISTRIBUTOR IGNITION SYSTEM

GENERALINFORMATION 2-2

DIAGNOSISANDTESTING 2-2

SECONDARYSPARKTEST 2-2

CYLINDERDROPTEST 2-2

ADJUSTMENTS 2-3

IGNITION COIL 2-3

TESTING 2-3

REMOVAL&INSTALLATION 2-3

POWERTRANSISTOR

(Ignition Module) 2-4

REMOVAL&INSTALLATION 2-4

DISTRIBUTOR 2-4

REMOVAL&INSTALLATION 2-4 2-2

INSTALLATION 2-4

CRANKSHAFTANDCAMSHAFTPOSITION

SENSORS 2-5

DISTRIBUTORLESS IGNITION

SYSTEM 2-5

GENERALINFORMATION 2-5

DIAGNOSISANDTESTING 2-5

ADJUSTMENTS 2-5

IGNITION COIL(s) 2-5

TESTING 2-5

REMOVAL&INSTALLATION 2-6

POWERTRANSISTOR

(IGNITION MODULE) 2-7

REMOVAL&INSTALLATION 2-7

CRANKSHAFTANDCAMSHAFTPOSITION

SENSORS 2-7

FIRING ORDERS 2-7

CHARGING SYSTEM 2-8

GENERALINFORMATION 2-8

ALTERNATORPRECAUTIONS 2-8

ALTERNATOR 2-8

TESTING 2-8 I

REMOVAL&INSTALLATION 2-9

REGULATOR 2-10

REMOVAL&INSTALLATION 2-10

STARTING SYSTEM 2-10

GENERALINFORMATION 2-10

STARTER 2-10

TESTING 2-10

REMOVAL&INSTALLATION 2-11

SENDING UNITS 2-11

ENGINECOOLANTTEMPERATURE

SENDING UNIT 2-11

TESTING 2-11

REMOVAL&INSTALLATION 2-11

OIL PRESSURESENDING UNIT 2-12

TESTING 2-12

REMOVAL&INSTALLATION 2-12

Page 49 of 408

.~ P.X I_ - “, .- I .-., IS ” .~.I .r

2-2 ENGINE ELECTRICAL

nn

ity and trouble: shooting electrical circuits,

please refer to Section 6 of this manual.

I

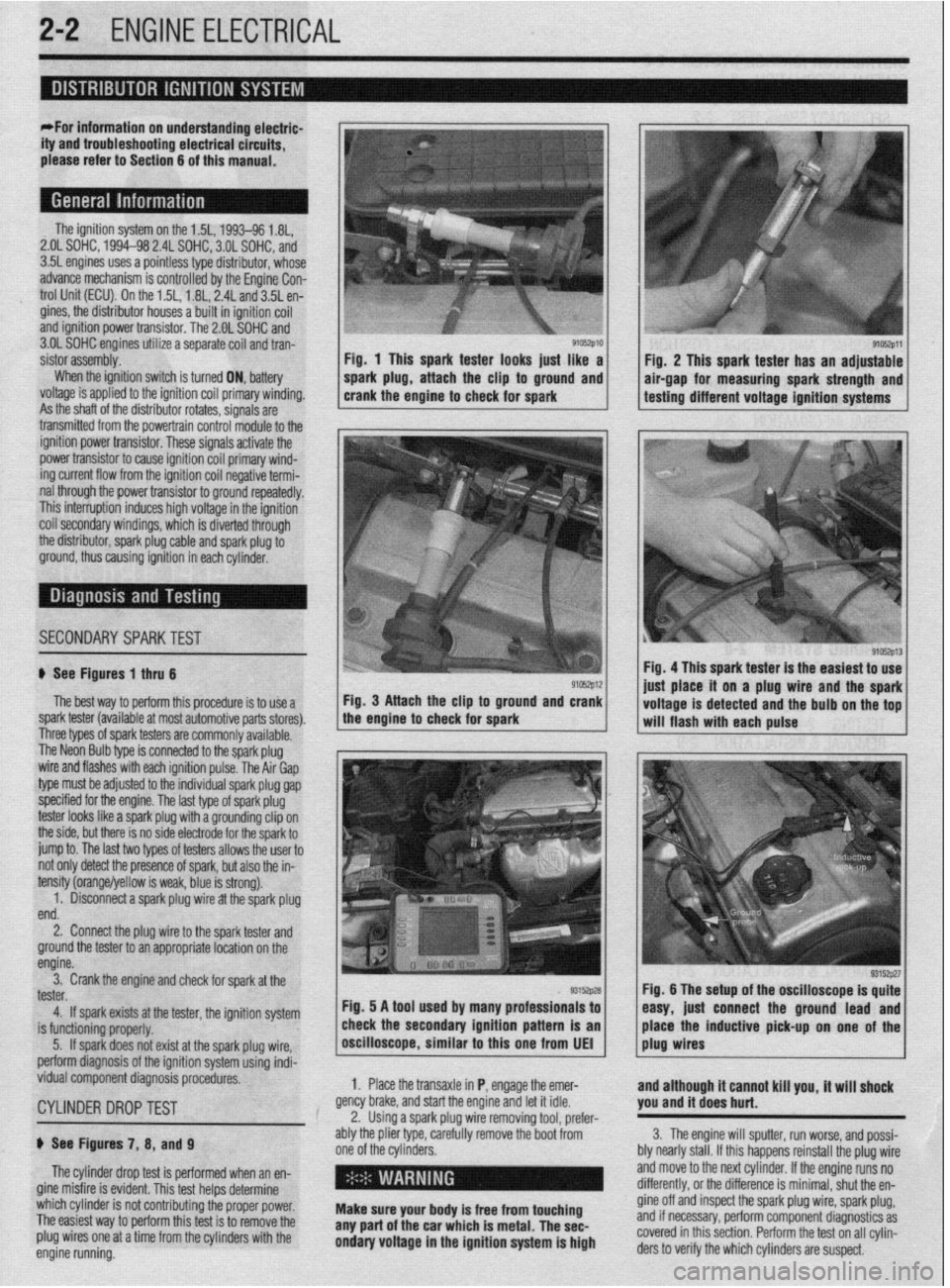

The ignition system on the 1.5L, 1993-96 1.8L,

2.OL SOHC, 1994-98 2.4L SOHC, 3.OL SOHC, and

3.5L engines uses a pointless type distributor, whose

advance mechanism is controlled by the Engine Con-

trol Unit (ECU). On the 1.5L, 1.8L, 2.4L and 3.5L en-

gines, the distributor houses a built in ignition coil

and ignition power transistor. The 2.8L SOHC and

3.OL SOHC engines utilize a separate coil and tran-

sister assemblv.

When the ignition switch is turned ON, battery

voltage is applied to the ignition coil primary winding.

As the shaft of the distributor rotates, signals are

transmitted from the oowertrain control module to the

9105zp11 Fig. 1 This spark tester looks iust like a

Fiu. 2 This spark tester has an adjustable

spark plug, attach the clip to ground and air-gap for measuring spark strength and

crank the engine to check for spark testing different voltage ignition systems

.

ignition power trar rsistor. These signals activate the

power transistor to cause ignition coil primary wind-

ing current flow from the ignition coil negative termi-

nal through the power transistor to ground repeatedly.

This interruption induces high voltage in the ignition

coil secondarv windinas, which is diverted throuah

the distributor, spark plug cable and spark plug 6

ground, thus causing ignition in each cylinder.

I

SECONDARYSPARKTEST l;h.4-

! ,L ".~

'$ >,%

If See Figures 1 thru 6

91rJszp12 Fig. 4 This spark tester is the easiest to use

iust alace it on a plug wire and the spark

The best way to perform this procedure is to use a Fig. 3 Attach the clip to ground and crank

spark tester (available at most automotive parts stores). the engine to check for spark

I I voltage is detected and the bulb on the tof

-. will flash with each pulse

I nree types ot spark testers are commonly available.

The Neon Bulb type is connected to the spark plug

wire and flashes with each ignition pulse. The Air Gap

type must be adjusted to the individual spark plug gap

specified for the engine. The last type of spark plug

tester looks like a spark plug with a grounding clip on

the side, but there is no side electrode for the spark to

jump to. The last two types of testers allows the user to

not only detect the presence of spark, but also the in-

tensity (orange/yellow is weak, blue is strong).

1. Disconnect a spark plug wire at the spark plug

end.

2. Connect the plug wire to the spark tester and

ground the tester to an appropriate location on the

engine.

3. Crank the engine and check for spark at the

tester.

4. If spark exists at the tester, the ignition system

is functioning properly.

5. If spark does not exist at the spark plug wire,

perform diagnosis of the ignition system using indi-

vidual component diagnosis procedures,

CYLINDER DROPTEST

p See Figures 7, 8, and 9

The cylinder drop test is performed when an en-

gine misfire is evident. This test helps determine

which cylinder is not contributing the proper power.

The easiest way to perform this test is to remove the

plug wires one at a time from the cylinders with the

engine running. 1. Place the transaxle in P, engage the emer-

gency brake, and start the engine and let it idle.

2. Using a spark plug wire removing tool, prefer-

ably the plier type, carefully remove the boot from

one of the cylinders.

i ’

Make sure your body is free from touching

any part of the car which is metal. The sec-

ondary voltage in the ignition system is high and although it cannot kill you, it will shock

you and it does hurt.

3. The engine will sputter, run worse, and possi-

bly nearly stall. If this happens reinstall the plug wire

and move to the next cylinder. If the engine runs no

differently, or the difference is minimal, shut the en-

gine off and inspect the spark plug wire, spark plug,

and if necessary, perform component diagnostics as

covered in this section. Perform the test on all cylin-

ders to verify the which cylinders are suspect.

Page 50 of 408

ENGINEELECTRICAL 2-3

91c6zp16 Fig. 9. . . note the idle speed and idle char-

acteristics of the engine. The cylinder(s)

with the least drag is the non-contributing

cyltnder(s) -

1

There are no adjustments to the distributor ignition

system other than the ignition timing adjustment. Re-

fer to section 1 for ignition timing adjustment.

TESTING

1.5L, 1.8L, 2.41, and 3.51 Englnes

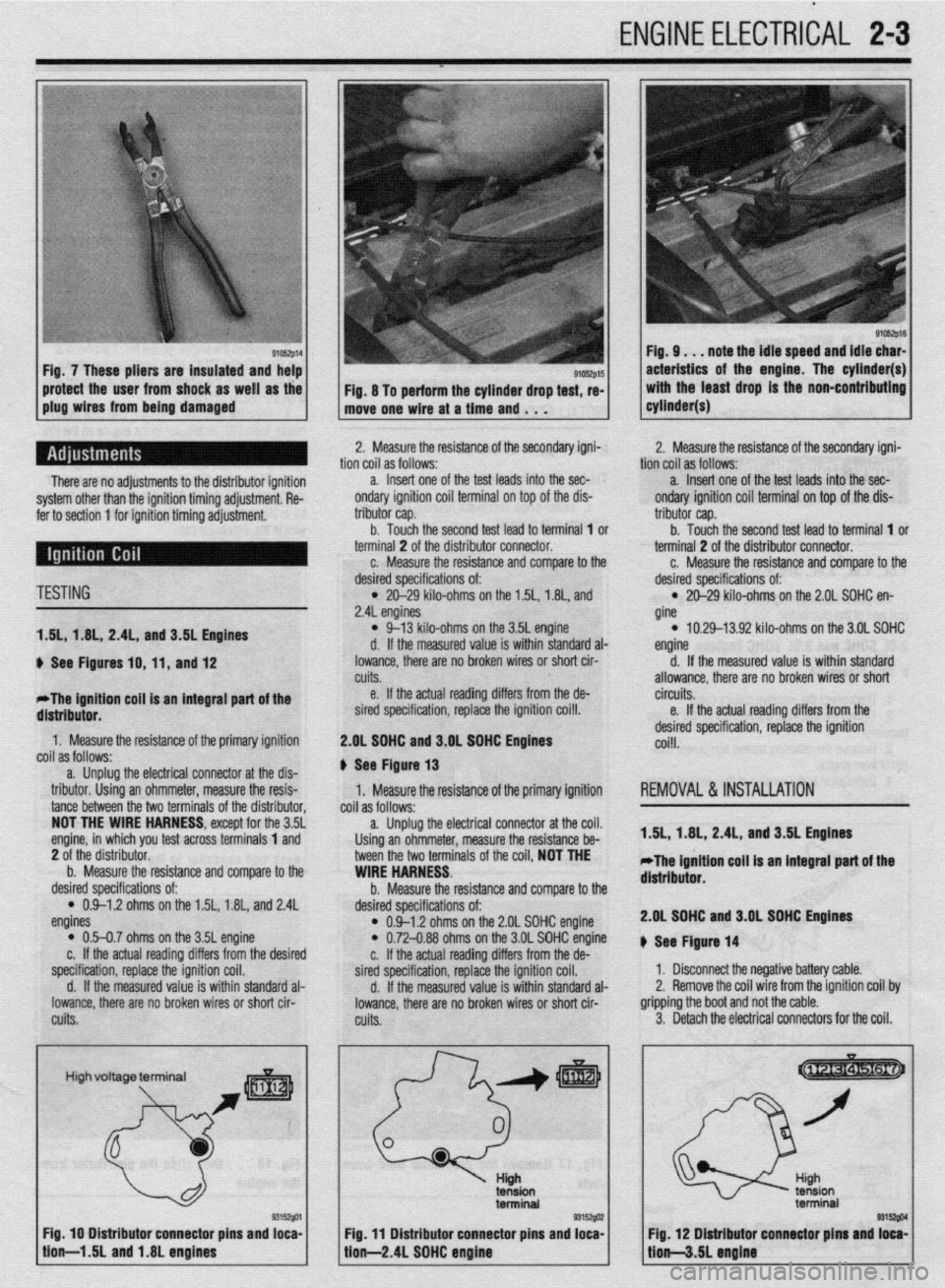

u See Figures 10, 11, and 12

*The ignition cog is an integral part of the

distributor.

1. Measure the resistance of the primary ignition

coil as follows:

a. Unplug the electrical connector at the dis-

tributor. Using an ohmmeter, measure the resis-

tance between the two terminals of the distributor,

NOT THE WIRE HARNESS, except for the 3.5L

engine, in which you test across terminals 1 and

2 of the distributor.

b. Measure the resistance and compare to the

desired specifications of:

l 0.9-1.2 ohms on the 1.5L, 1.8L, and 2.4L

engines

l 0.5-0.7 ohms on the 35L engine

c. If the actual reading differs from the desired

specification, replace the ignition coil.

d. If the measured value is within standard al-

lowance, there are no broken wires or short cir-

cuits. 2. Measure the resistance of the secondary igni-

desired specifications of: tion coil as follows:

l 21329 kilo-ohms on the 1.5L, 1.8L, and

2.4L engines a. Insert one of the test leads into the sec-

ondary ignition coil terminal on top of the dis-

l 9-13 kilo-ohms on the 3.5L engine tributor cap.

d. If the measured value is within standard al- b. Touch the second test lead to terminal 1 or

terminal 2 of the distributor connector.

lowance, there are no broken wires or short cir-

cuits. c. Measure the resistance and comnare to the

e. If the actual reading differs from the de

sired specification, replace the ignition coi!l.

2.OL SOHC and 3.OL SOHC Engines

# See Figure 13

1. Measure the resistance of the primary ignition

coil as follows:

a. Unplug the electrical connector at the coil.

Using an ohmmeter, measure the resistance be-

tween the two terminals of the coil, NOT THE

WIRE HARNESS.

b. Measure the resistance and compare to the

desired specifications of:

l 0.9-1.2 ohms on the 2.OL SOHC engine l 0.72-0.88 ohms on the 3.OL SOHC engine

c. If the actual reading differs from the de-

sired specification, replace the ignition coil.

d. If the measured value is within standard al-

lowance, there are no broken wires or short cir-

cuits. 2.

desired specifications of: Measure the resistance of the secondary igni-

tion coil as follows:

l 20-29 kilo-ohms on the 2.OL SOHC en-

gine a. Insert one of the test leads into the sec-

ondary ignition coil terminal on top of the dis-

l 10.29-13.92 kilo-ohms on the 3.01 SOHC tributor cap.

engine b. Touch the second test lead to terminal 1 or

terminal 2 of the distributor connector.

d. If the measured value is within standard

allowance, there are no broken wires or short c. Measure the resistance and comoare to the

circuits.

e. If the actual reading differs from the

desired specification, replace the ignition

coi!l.

REMOVAL&INSTALLATION

1.5L, 1.8L, 2.4L, and 3.5L Engines

*The ignition coil is an tntegral part of the

distributor.

2.OL SOHC and 3.OL SDHC Engines

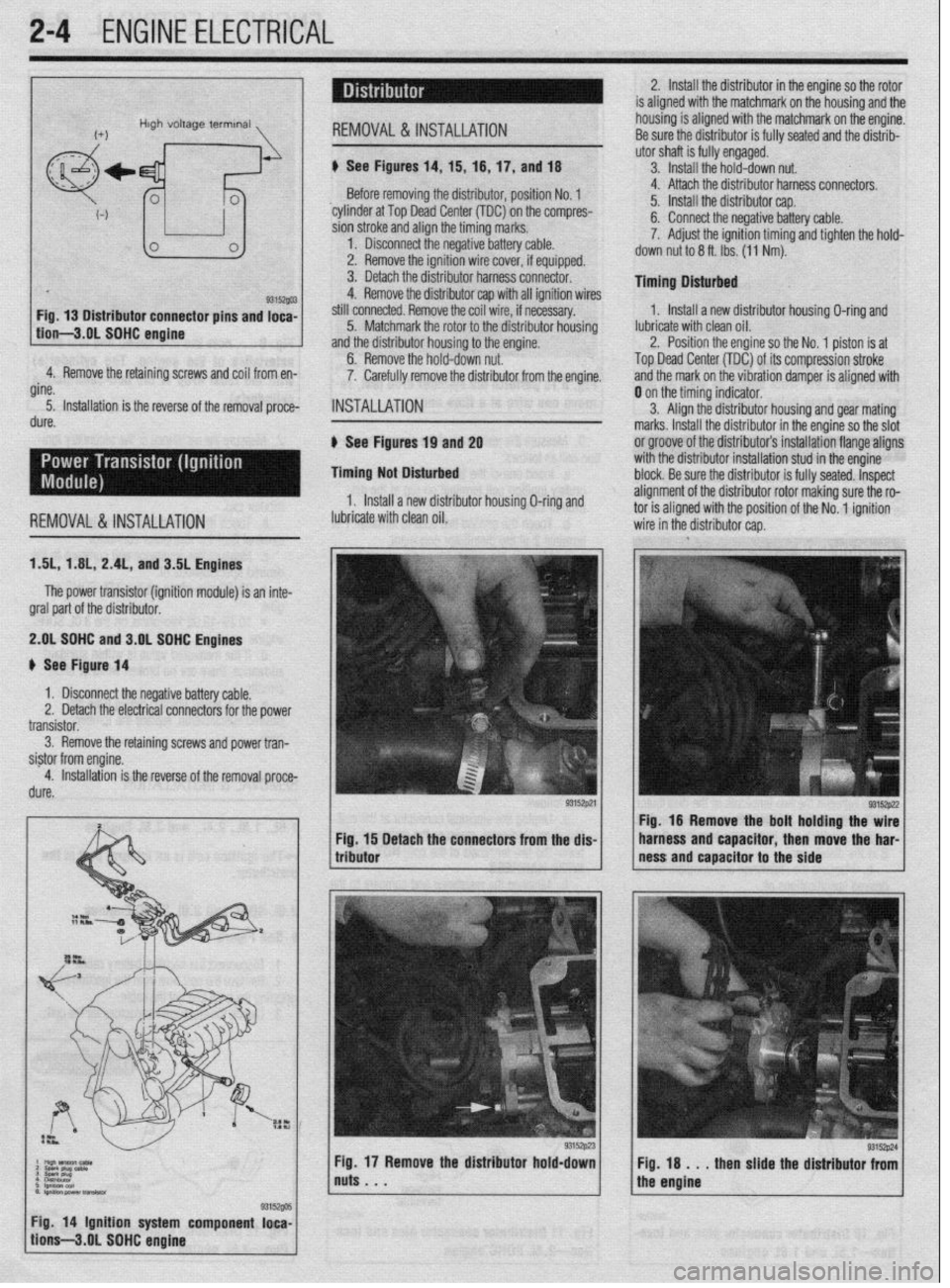

u See Figure 14

1. Disconnect the negative battery cable.

2. Remove the coil wire from the ignition coil by

gripping the boot and not the cable.

3. Detach the electrical connectors for the coil.

High voltage terminal -r

I Q3 ‘I u,

/ - Blm/ I L tflgn

tension

terminal

,

3=%@ @l&M Fig. IO Distributor connector pins and loca-

Fig. 11 Distributor connector pins and loca- Fig. 12 Dlstrfbufor connector plus and loca-

tiou-l.LL and 1.8L engines

lion-2.4L SOHC engtne tio&.5L engine

Page 51 of 408

2-4 ENGINEELECTRICAL

2. Install the distributor in the engine so the rotor

is aligned with the matchmark on the housing and the

housing is aligned with the matchmark on the engine.

4.‘ Remove the retaining screws and coil from en-

gine.

5. Installation is the reverse of the removal proce-

dure. Before removing the distributor, position No. 1

‘cylinder at Top Dead Center (TDC) on the compres-

sion stroke and align the timing marks.

1. Disconnect the negative battery cable.

2. Remove the ignition wire cover, if equipped.

3. Detach the distributor harness connector.

4. Remove the distributor cap with all ignition wires

still connected. Remove the coil wire, if necessary.

5. Matchmark the rotor to the distributor housing

and the distributor housing to the engine.

6. Remove the hold-down nut.

7. Carefully remove the distributor from the engine.

INSTALLATION

6 See Figures 19 and 2g

Timing Not Disturbed

1, Install a new distributor housing O-ring and 4. Attach the distributor harness connectors.

5. Install the distributor cap.

6. Connect the negative battery cable.

7. Adjust the ignition timing and tighten the hold-

down nut to 6 ft. Ibs. (11 Nm).

Timing Dlsturbed

1. Install a new distributor housing O-ring and

lubricate with clean oil.

2. Position the engine so the No. 1 piston is at

Top Dead Center (TDC) of its compression stroke

and the mark on the vibration damper is aligned with

REMOVALS& INSTALLATION lubricate with clean oil. 0 on the timing indicator.

3. Align the distributor housing and gear mating

marks. Install the distributor in the engine so the slot

or groove of the distributor’s installation flange aligns

with the distributor installation stud in the engine

block. Be sure the distributor is fully seated. Inspect

alignment of the distributor rotor making sure the ro- tnr ic dinnnd with thn qn,c$nn of the Nn innitinn

ISL, 1 AIL, 2.4L, and 3.5L Engines

The power transistor (ignition module) is an inte-

gral part of the distributor.

2.gL SDHC and 3.OL SOHC Engines

# See Figure 14

1 x Disconnect the negative battery cable.

Remove the retaining screws and power tran-

Detach the connectors from the dis- Fig. 16 Remove the bolt holding the wire

harness and capacitor, then move the har-

ness and capacitor to the side

Fig. 18 . . . then slide the distributor from

the engine

/ tion’s-3.gL SOHC engine g3is~@ 1 Fig 14 Ignition system component loca-

Page 52 of 408

ENGlNEELECTRliAL 2-5

Fig. 19 Adjusting the distributor-1.5L en-

gine shown, others similar

4. Install the hold-down nut.

5. Attach the distributor harness connectors.

6. Install the distributor cap.

7. Connect the negative battery cable.

8. Adjust the ignition timing and tighten the hold-

down nut to 8 ft. Ibs. (11 Nm).

For procedures on the position sensors, please re-

fer to Section 4 in this manual.

The ignition system found on the 1.6L, 1997-60

1.8L, 2.OL DOHC, 1999-00 2.4L SOHC, 2.4L DOHC,

and 3.OL DOHC engines is a distributorless type.

The advance of this system, like the distributor type

ignition, is controlled by the Engine Control Unit

(ECU) or Powertrain Control Module (PCM). The

distributorless ignition system contains a crank an-

gle/position sensor which detects the crank angle or

position to each cylinder and converts this data into

pulse signals. These signals are sent to the

ECLVPCM, which calculates the engine rpm and

regulates the fuel injection and ignition timing ac-

cordingly. The system also contains a top dead cen-

ter sensor which detects the top dead center position

of each cylinder and converts this data into pulse

signals. These signals are then sent to the

ECU/PCM, which calculates the sequence of fuel in-

jection and engine rpm.

When the ignition switch is turned ON, battery

voltage is applied to the ignition coil primary wind-

ing. As the crank angle sensor shaft rotates, ignition

signals are transmitted from the multi port injection

control unit to the power transistor. These signals

activate the power transistor to cause ignition coil

primary winding current to flow from the ignition

coil negative terminal through the power transistor

to ground or be interrupted, repeatedly. This action

induces high voltage in the secondary winding of

the ignition coil. From the ignitron coil, the sec-

ondary winding current produced flows through the

spark plug to ground, thus causing ignition in each

cylinder.

Refer to Diagnosis and Testing under Distributor

Ignition in this section,

There are no adjustments to the distributorless ig-

nition system other than the ignition timing adjust-

ment. Refer to section 1 for ignition timing adjust-

ment.

TESTING

1.6L and 1990 2.OL DOHC Engines

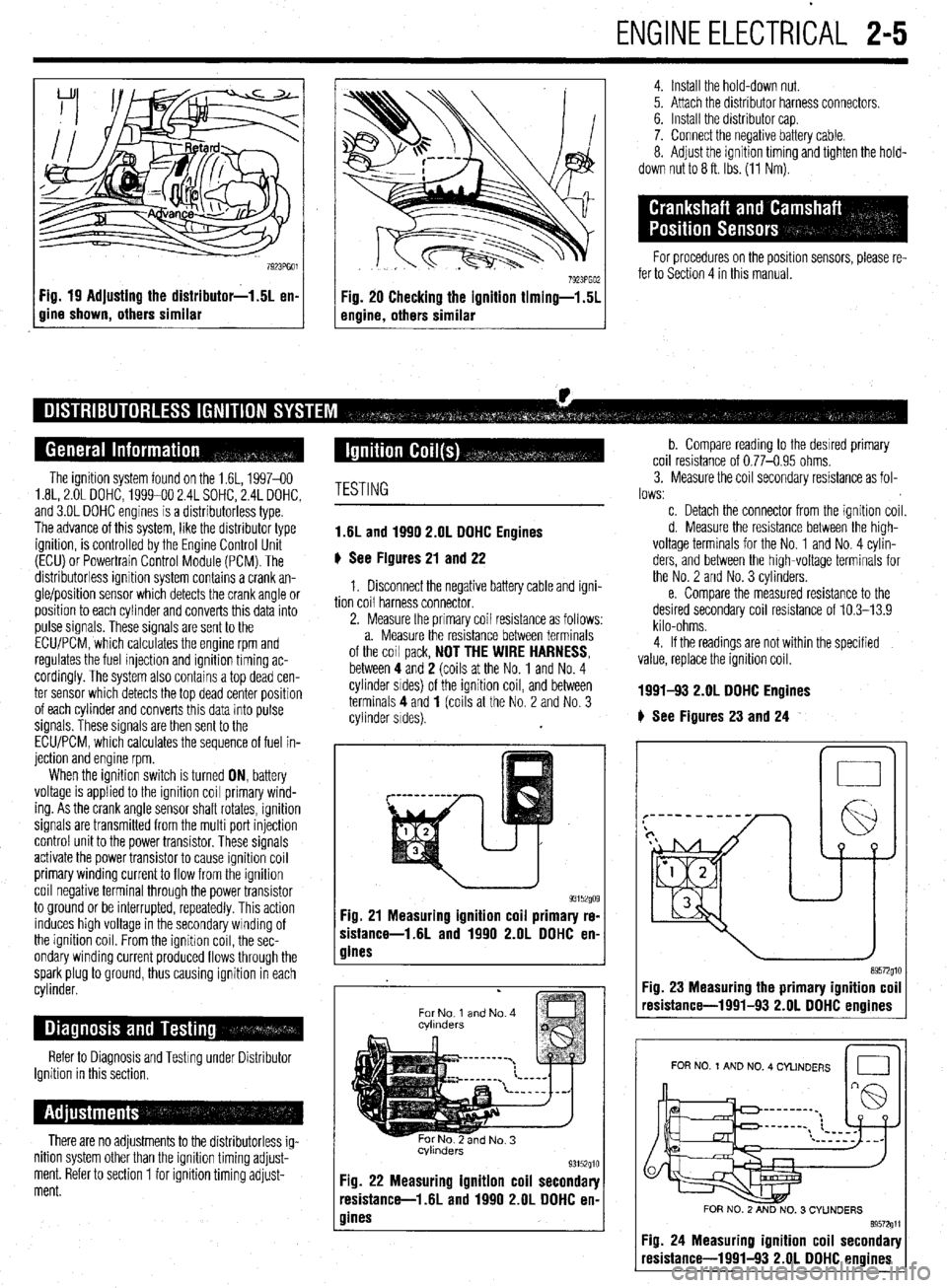

6 See Figures 21 and 22

1. Disconnect the negative battery cable and igni-

tion coil harness connector.

2. Measure the primary coil resistance as follows:

a. Measure the resistance between terminals

of the coil pack,

NOT THE WIRE HARNESS, between 4 and 2 (coils at the No. 1 and No. 4

cylinder srdes) of the ignition coil, and between

terminals 4 and

1 (coils at the No. 2 and No. 3

cylinder sides).

93152go9 Fig. 21 Measuring ignition coil primary re-

sistance-1.6L and 1990 2.OL DDHC en-

gines

.

For No 1 and No. 4

cvlmders

Fig. 22 Measuring ignition coil secondary

resistance-l .6L and 1990 2.OL DOHC en-

gines

b. Compare reading to the desrred primary

coil resistance of 0.77-0.95 ohms.

3. Measure the coil secondary resistance as fol-

lows:

c. Detach the connector from the ignition coil.

d. Measure the resistance between the high-

voltage terminals for the No. 1 and No. 4 cylin-

ders, and between the high-voltage terminals for

the No. 2 and No. 3 cylinders.

e. Compare the measured resistance to the

desired secondary coil resistance of 10.3-13.9

kilo-ohms.

4. If the readings are not within the specified

value, replace the ignition coil.

1991-!I3 2.OL DDHC Engines

# See Figures 23 and 24

n 0

Fig. 23 Measuring the primary ignition coil

resistance-1991-93 2.OL DOHC enoines

I I

FOR NO 1 AND NO. 4 CYLINDERS

Id

FOR NO. 2 AND NO. 3 CYUNDERS

89572611

Fig. 24 Measuring ignition coil secondary

resistance-1991-93 2.OL DOHC engines

Page 53 of 408

2-6 ENGINEELECTRICAL

Fig. 26 Measuring ignition coil secondary

resistance-1997-00 1.8L and 1994-00

2.4L SOHC engines

1. Disconnect the negative battery cable and igni-

tion coil harness connector. 89572914

89572g13

Fig. 28 Measure the primary coil resistance Fig. 27 Measure the secondary resistance

between the connector terminals-2.4L between the towers of the coil-2.4L DOHC

DOHC enaine engine

3. To check the secondary coil resistance, per-

. .

term the tollowmg:

a. Tag and disconnect the spark plug wires

from the ignition coil.

b. Measure the secondary resistance of the

coil between the towers of each individual coil.

c. If the resistance is not between 20.1-27.3

kilo-ohms, replace the ignition coil. 2. Measure the primary coil resistance as follows:

a. Measure the resistance between terminals

3 and 2 (coils at the No. 1 and No. 4 cylinder

sides) of the ignition coil, and between terminals

3 and 1 (coils at the No. 2 and No. 3 cylinder

sides).

b. Compare reading to the desired primary

coil resistance of 0.70-0.86 ohms.

3. Measure the coil secondary resistance as fol-

lows: 3.OL DOHC Engine

c. Detach the connector from the ignition coil.

d. Measure the resistance between the high-

voltage terminals for the No. 1 and No. 4 cylin-

ders, and between the high-voltage terminals for

the No. 2 and No. 3 cylinders.

e. The desired secondary coil resistance is

11.3-15.3 kilo-ohms.

4. If the readings are not within the specified

value, replace the ignition coil.

1997-00 1.8L and 1999-00 2.4L SOHC

Engines

+ See Figure 25 6 See Figures 28 and 29

1. Measure the resistance of the primary ignition

coil as follows:

a. Unplug the electrical connector at the coil

pack. Using an ohmmeter, measure the resis-

tance between the terminals of the coil pack,

NOT THE WIRE HARNESS. Measure the re-

sistance between terminals:

l 2-3 for Coil A l l-3 for Coil B l 4-3 for Coil C

b. Measure the resistance and compare to the

desired specifications of 0.67-0.81 ohms.

1. Measure the resistance of the secondarv iani-

tion coil as follows: , -

a. Insert one of the test leads into the sec-

ondary ignition coil terminal of the coil.

b. Touch the second test lead to terminal 1 or

terminal 2 of the coil connector.

c. Measure the resistance and compare to

the desired specifications of 9.4-12.8 kilo-

ohms.

d. If the measured value is within standard al-

lowance, there are no broken wires or short cir-

cuits.

e. If the actual reading differs from the de-

sired specification, replace the ignition coil.

2.4L DDHC Engines

# See Figures 26 and 27

1. Disconnect the negative battery cable.

2. To check the primary coil resistance, perform

the following:

a. Detach the electrical connector from the

coil pack.

b. Using an ohmmeter, measure the resis-

tance between the two terminals of the coil, NOT

THE WIRE HARNESS.

c. If the resistance is not between 0.74-0.90

ohms, replace the ignition coil. c. If the actual reading differs from the de-

sired specification, replace the ignition coil.

Fig. 28 Measuring ignition coil primary re-

sistance-3.01 DOHC engine

Fig. 29 Measuring ignition coil secondary

resistance-3.01 DOHC enaine d. If the measured value is within standard al-

lowance, there are no broken wires or short cir-

cuits.

2. Measure the resistance of the secondary igni-

tion coil as follows:

3. Insert the lead of the ohmmeter between coil

pack cylinder terminals:

l Between coil terminals l-4 for Co11 A l Between coil terminals 2-5 for Coil B l Between coil terminals 3-6 for Coil C

e. Measure the resistance and compare to the

desired specifications of 11.3-l 5.3 kilo-ohms.

f. If the measured value is within standard al-

lowance, there are no broken wires or short cir-

cuits.

g. If the actual reading differs from the de-

sired specification, replace the ignition coil pack.

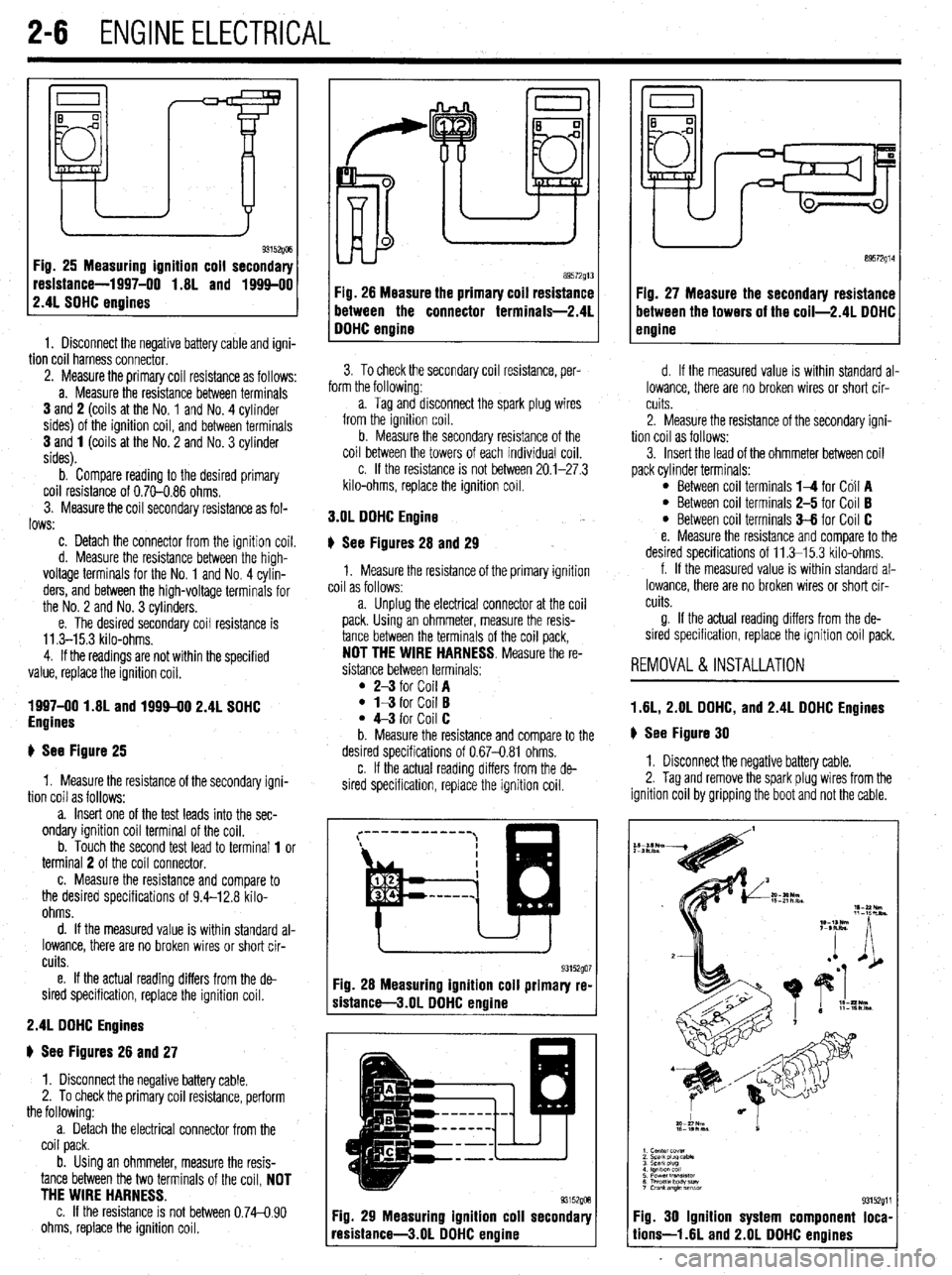

REMOVAL&INSTALLATION

1.6L, 2.OL DOHC, and 2.4L DOHC Engines

# See Figure 30

1. Disconnect the negative battery cable.

2. Tag and remove the spark plug wires from the

ignition coil by gripping the boot and not the cable.

I

~::::L “1

I cemer Cwer

2 Scabpiwcabk

3 SPaark piug

I lgnlllancoll

5 Powertran3lrtor

6 ThrotflsDcnv*w

I Crankangle lmsm

93152g11

Fig. 30 Ignition system component loca-

lions-l .6L and 2.OL DOHC engines

Page 54 of 408

ENGINEELECTRICAL 2-7

3. Detach the electrical connectors for the COIL

4. Remove the retaining screws and coil from en-

gine.

5. Installation is the reverse of the removal proce-

dure.

1997-00 1.81 and 1994-00 2.4L Engines

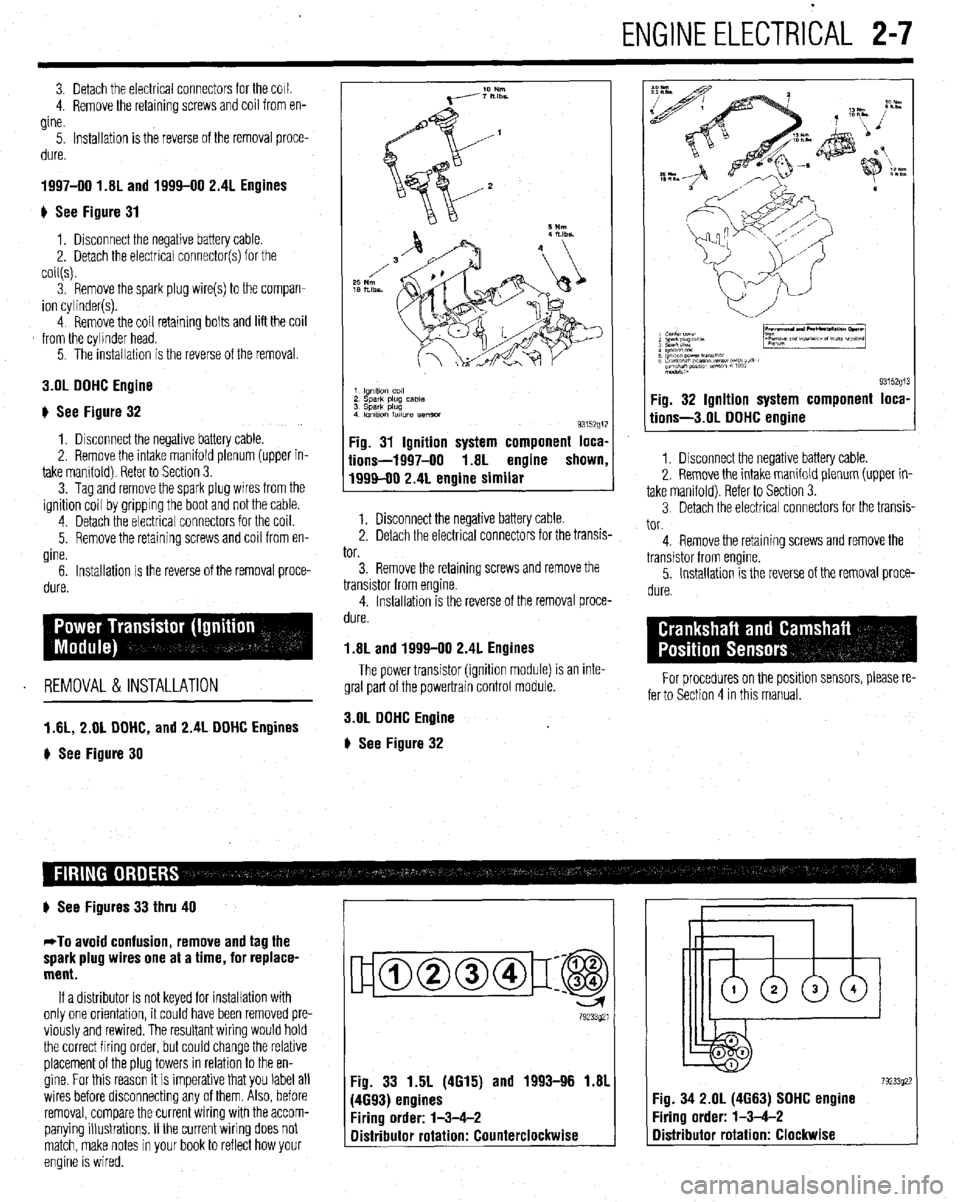

) See Figure 31

1, Disconnect the negative battery cable.

2. Detach the electrical connector(s) for the

coil(s).

3. Remove the spark plug wire(s) to the compan-

ion cylinder(s).

4 Remove the coil retaining bolts and lift the coil

from the cylinder head.

5. The installation is the reverse of the removal.

3.OL DOHC Engine

# See Figure 32

1, Disconnect the negative battery cable.

2. Remove the intake manifold plenum (upper in-

take mamfold) Refer to Section 3.

3. Tag and remove the spark plug wires from the

ignition coil by gripping the boot and not the cable.

4 Detach the electrical connectors for the coil.

5. Remove the retaining screws and coil from en-

gine.

6. Installation is the reverse of the removal proce-

dure.

REMOVAL &INSTALLATION

1 AL, 2.01 DOHC, and 2.4L DOHC Engines

) See Figure 30

1 lgnltlo” co,,

2 sparlt plug case

3 Spark plug

4 Imltlon fatlure semm

93152g1:

Fig. 31 Ignition system component loca,

iions-1997-00 1.8L engine shown

1999-00 2.4L engine similar

1. Disconnect the negative battery cable.

2. Detach the electrical connectors for the transis-

tor.

3. Remove the retaining screws and remove the

transistor from engine.

4. Installation is the reverse of the removal proce-

dure.

1.8L and 1999-00 2.4L Engines

The power transistor (ignition module) is an inte-

gral part of the powertrain control module.

3.OL DOHC Engine

# See Figure 32

9315291 Fig. 32 Ignition system component loca,

tions-3.01 DOHC engine

1. Disconnect the negative battery cable.

2. Remove the intake manifold plenum (upper in-

take manifold). Refer to Section 3.

3 Detach the electrical connectors for the transis-

tor.

4. Remove the retaining screws and remove the

transistor from engine.

5. Installation is the reverse of the removal proce-

dure.

For procedures on the positlon sensors, please re-

fer to Section 4 in this manual.

# See Figures 33 thru 40

*To avoid confusion, remove and tag the

spark plug wires one at a time, for replace-

ment.

If a distributor is not keyed for installation with

only one orientation, it could have been removed pre-

viously and rewired. The resultant wiring would hold

the correct firing order, but could change the relative

placement of the plug towers in relation to the en-

gine. For this reason it is imperative that you label all

wires before disconnecting any of them. Also, before

removal, compare the current wiring with the accom-

panying illustrations. If the current wiring does not

match, make notes in your book to reflect how your

engine is wired.

ujamm-p:@

79233921

Fig. 33 1.5L (4615) and 1993-96 1.81

(4693) engines

Firing order: l-3-4-2

Distributor rotation: Counterclockwise 7923392: :ig. 34 2.OL (4663) SOHC engine

‘iring order: l-3-4-2

Distributor rotation: Clockwise

Page 55 of 408

.

2-8 ENGINEELECTRICAL

Front

of the

Vehicle

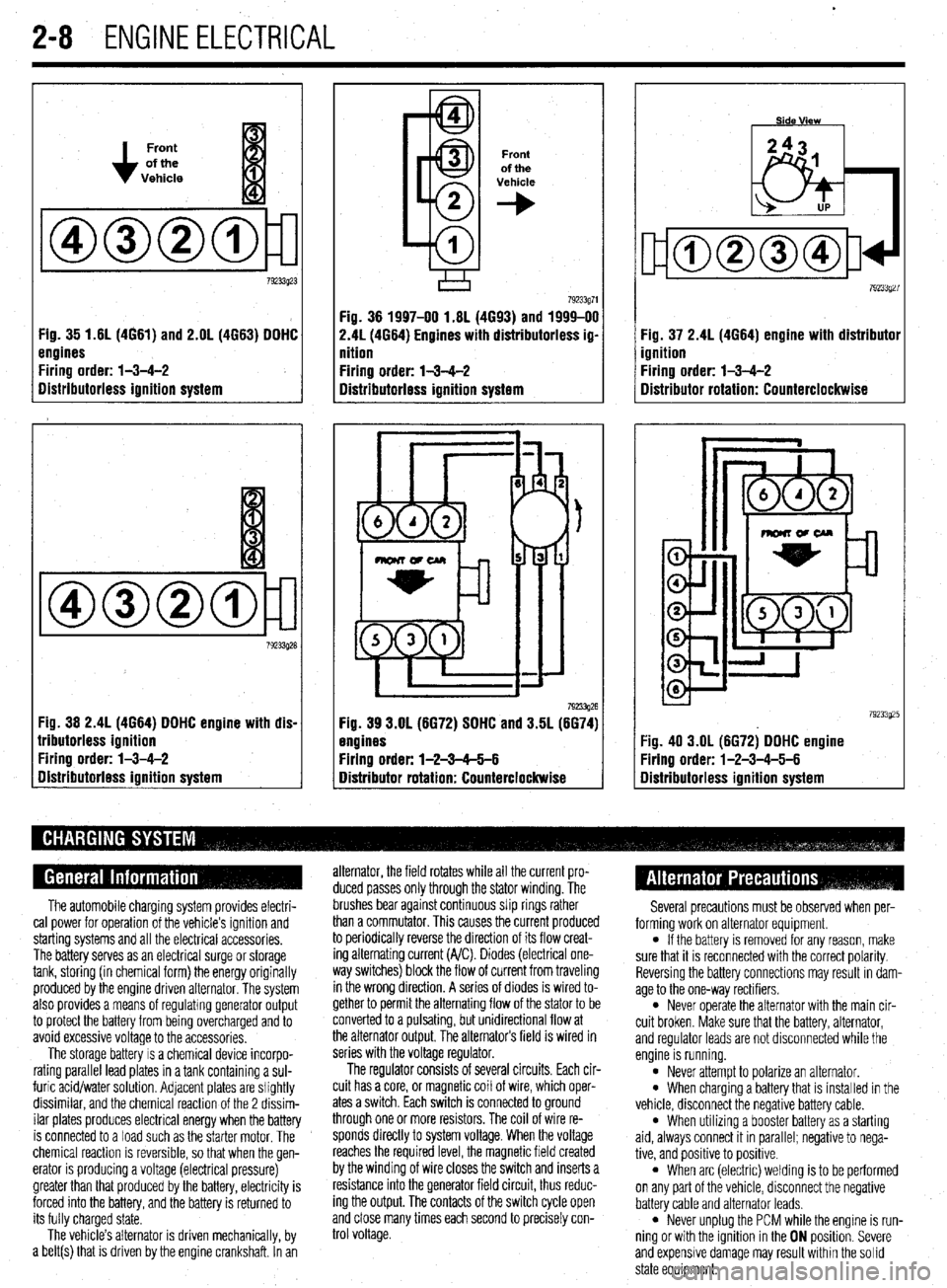

Fig. 35 1.61(4661) and 2.OL (4663) DDHC

engines

Firing order: l-3-4-2

Distributorless ignition system

Fig. 36 2.4L (4664) DDHC engine with dis-

lributorless ignition

Firing order: l-3-4-2

gistributorless ignition system

Front

of the

Vehicle

+

Fig. 36 1997-00 1.6L (4693) and 1999-00

2.41(4664) Engines with distributorless ig-

nition

Firing order: l-3-4-2

Distributorless ignition system

792!33g26 Fig. 39 3.OL (6672) SDHC and 3.5L (6674)

engines

Firing order: l-2-3-65-6

Distributor rotation: Counterclockwise Fig. 37 2.4L (4664) engine with distributor

ignition

Firing order: l-3-4-2

Distributor rotation: Counterclockwise

:ig. 40 3.OL (6672) DDHC engine

Yring order: l-2-3-4-5-6

Iistributorless ignition system

The automobile charging system provides electri-

cal power for operation of the vehicle’s ignition and

starting systems and all the electrical accessories.

The battery serves as an electrical surge or storage

tank, storing (in chemical form) the energy originally

produced by the engine driven alternator. The system

also provides a means of regulating generator output

to protect the battery from being overcharged and to

avoid excessive voltage to the accessories.

The storage battery IS a chemical device incorpo-

rating parallel lead plates in a tank containing a sul-

furic acid/water solution. Adjacent plates are slightly

dissimilar, and the chemical reaction of the 2 dissim-

ilar plates produces electrical energy when the battery

is connected to a load such as the starter motor. The

chemical reaction is reversible, so that when the gen-

erator IS producing a voltage (electrical pressure)

greater than that produced by the battery, electricity is

forced into the battery, and the battery is returned to

its fully charged state.

The vehicle’s alternator is driven mechanically, by

a belt(s) that is driven by the engine crankshaft. In an alternator, the field rotates while all the current pro-

duced passes only through the stator winding. The

brushes bear against continuous slip rings rather

than a commutator. This causes the current produced

to periodically reverse the direction of its flow creat-

ing alternating current (A/C). Diodes (electrical one-

way switches) block the flow of current from traveling

in the wrong direction. A series of diodes is wired to-

gether to permit the alternating flow of the stator to be

converted to a pulsating, but unidirectional flow at

the alternator output, The alternators field is wired in

series with the voltage regulator.

The regulator consists of several circuits. Each cir-

cuit has a core, or magnetic coil of wire, which oper-

ates a switch. Each switch is connected to ground

through one or more resistors. The coil of wire re-

sponds directly to system voltage. When the voltage

reaches the required level, the magnetic field created

by the winding of wire closes the switch and inserts a

resistance into the generator field circuit, thus reduc-

ing the output. The contacts of the switch cycle open

and close many times each second to precisely con-

trol voltage. Several precautions must be observed when per-

forming work on alternator equipment.

l If the battery is removed for any reason, make

sure that it is reconnected with the correct polarity.

Reversing the battery connections may result In dam-

age to the one-way rectifiers.

l Never operate the alternator with the main cir-

cuit broken. Make sure that the battery, alternator,

and regulator leads are not disconnected while the

engine is running.

l Never attempt to polarize an alternator. l When charging a battery that is installed in the

vehicle, disconnect the negative battery cable.

l When utilizing a booster battery as a starting

aid, always connect it in parallel; negatrve to nega-

tive, and positive to positrve.

l When arc (electric) welding is to be performed

on any part of the vehicle, disconnect the negative

battery cable and alternator leads.

l Never unplug the PCM while the engine is run-

ning or with the ignition in the ON position. Severe

and expensive damage may result within the solid

state equipment.