brake sensor MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 25 of 408

.

1-26 GENERALINFORMATIONAND MAINTENANCE

TDC of the compression stroke. If this happens, the

piston WIII be at the beginning of the power stroke

just as the compressed and ignited air/fuel mixture

forces the piston down and turns the crankshaft. Be-

cause it takes a fraction of a second for the spark

plug to ignite the mixture in the cylinder, the spark

plug must fire a little before the piston reaches TDC.

Otherwise, the mixture will not be completely ignited

as the piston passes TDC and the full power of the

explosion will not be used by the engine.

The timing measurement is given in degrees of

crankshaft rotation before the piston reaches TDC

(BTDC). If the setting for the ignition timing is 10”

BTDC, each spark plug must fire 10 degrees before

each piston reaches TDC. This only holds true, how-

ever, when the engine is at idle speed. The combus-

tion process must be complete by 23”ATDC to main-

tain proper engine performance, fuel mileage, and

low emissions.

As the engine speed increases, the pistons go

faster. The spark plugs have to ignite the fuel even

sooner if it IS to be completely ignited when the pis-

ton reaches TDC. If the ignition is set too far ad-

vanced (BTDC), the ignition and expansion of the fuel

in the cylinder wtll occur too soon and tend to force

the piston down while it is still traveling up. Thus

causes pre ignition or “knockmg and pinging”. If the

ignition spark is set too far retarded, or after TDC

(ATDC), the piston will have already started on its

way down when the fuel is ignited. The piston will be

forced down for only a portion of its travel, resulting

in poor engine performance and lack of power.

Timing marks or scales can be found on the rim of

the crankshaft pulley and the timing cover. The marks

on the pulley correspond to the posrtion of the piston

in the No. 1 cylinder. A stroboscopic (dynamic) tim-

ing light is hooked onto the No. 1 cylinder spark plug

wrre. Every time the spark plug fires, the timing light

flashes. By aiming the light at the timing marks while

the engine is running, the exact position of the piston

within the cylinder can be easily read (the flash of

light makes the mark on the pulley appear to be

standing still). Proper timing is indicated when the

mark and scale are in specified alignment.

When checking timing with the engine run-

ning, take care not to get the timing light

wires tangled in the tan blades and/or drive

belts.

INSPECTION &ADJUSTMENT

1990-96 Models

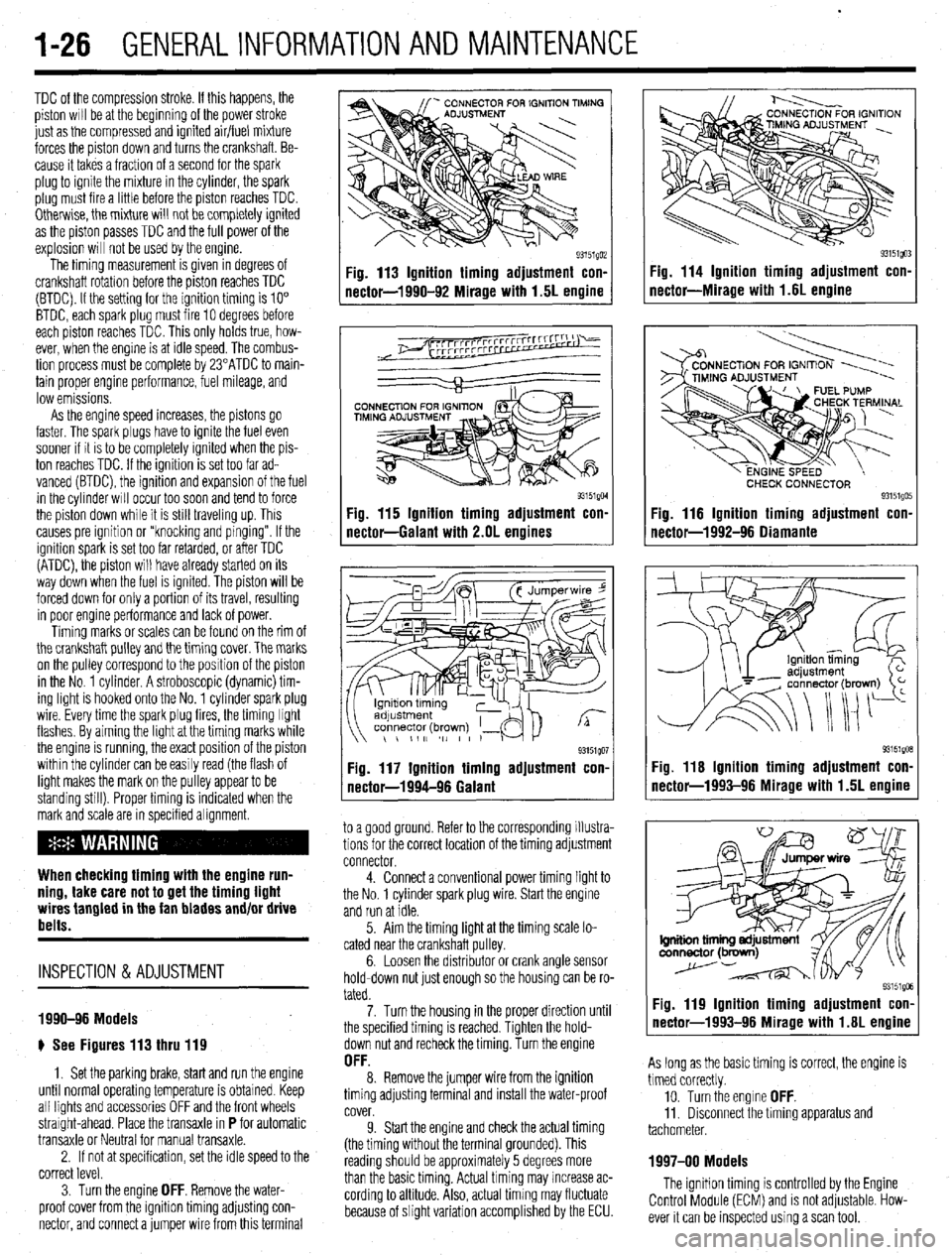

e See Figures 113 thru 119

1. Set the parking brake, start and run the engine

until normal operating temperature is obtained. Keep

all lights and accessories OFF and the front wheels

straight-ahead. Place the transaxle in

P for automatic

transaxle or Neutral for manual transaxle.

2. If not at specification, set the idle speed to the

correct level.

3. Turn the engine

OFF. Remove the water-

proof cover from the igmtion timing adjusting con-

nector, and connect a jumper wire from this terminal

Fig. 113 Ignition timing adjustment con-

nector-1990-92 Mirage with 1.5L engine

93151QM Fig. 115 Ignition timing adjustment con-

nectar-Galant with 2.OL engines

93151QO1 Fig. 117 Ignition timing adjustment con.

nectar-1994-96 Galant

to a good ground. Refer to the corresponding illustra-

tions for the correct location of the timing adjustment

connector.

4. Connect a conventional power timing light to

the No. 1 cylinder spark plug wire. Start the engine

and run at idle.

5. Aim the timing light at the timing scale lo-

cated near the crankshaft pulley.

6. Loosen the distributor or crank angle sensor

hold-down nut just enough so the housing can be ro-

tated.

7. Turn the housing in the proper direction until

the specified timing is reached. Tighten the hold-

down nut and recheck the timing. Turn the engine

OFF. 8. Remove the jumper wire from the ignition

timing adjusting terminal and install the water-proof

cover.

9. Start the engine and check the actual timing

(the timing without the terminal grounded). This

reading should be approximately 5 degrees more

than the basic timing. Actual timing may increase ac-

cording to altitude. Also, actual timing may fluctuate

because of slight variation accomplished by the ECU.

Fig. 114 Ignition timing adjustment con-

nectar-Miracle with 1.6L enaine

CHECK CONNECTOR 93151QO! Fig. 116 Ignition timing adjustment con.

nectar-1992-96 Oiamante

93151gOB Fig. 116 Ignition timing adjustment con-

nector-1993-96 Mirage with 1.5L engine

Fig. 119 Ignition timing adjustment con-

nector-1993-96 Mirage with 1.6L engine

As long as the basic timing is correct, the engine is

timed correctly.

10. Turn the engine

OFF. 11. Disconnect the timing apparatus and

tachometer.

1997-00 Models

The ignition timing is controlled by the Engine

Control Module (ECM) and is not adjustable. How-

ever it can be inspected using a scan tool.

Page 63 of 408

3-2 ENGINEANDENGINEOVERHAUL

REMOVAL &INSTALLATION

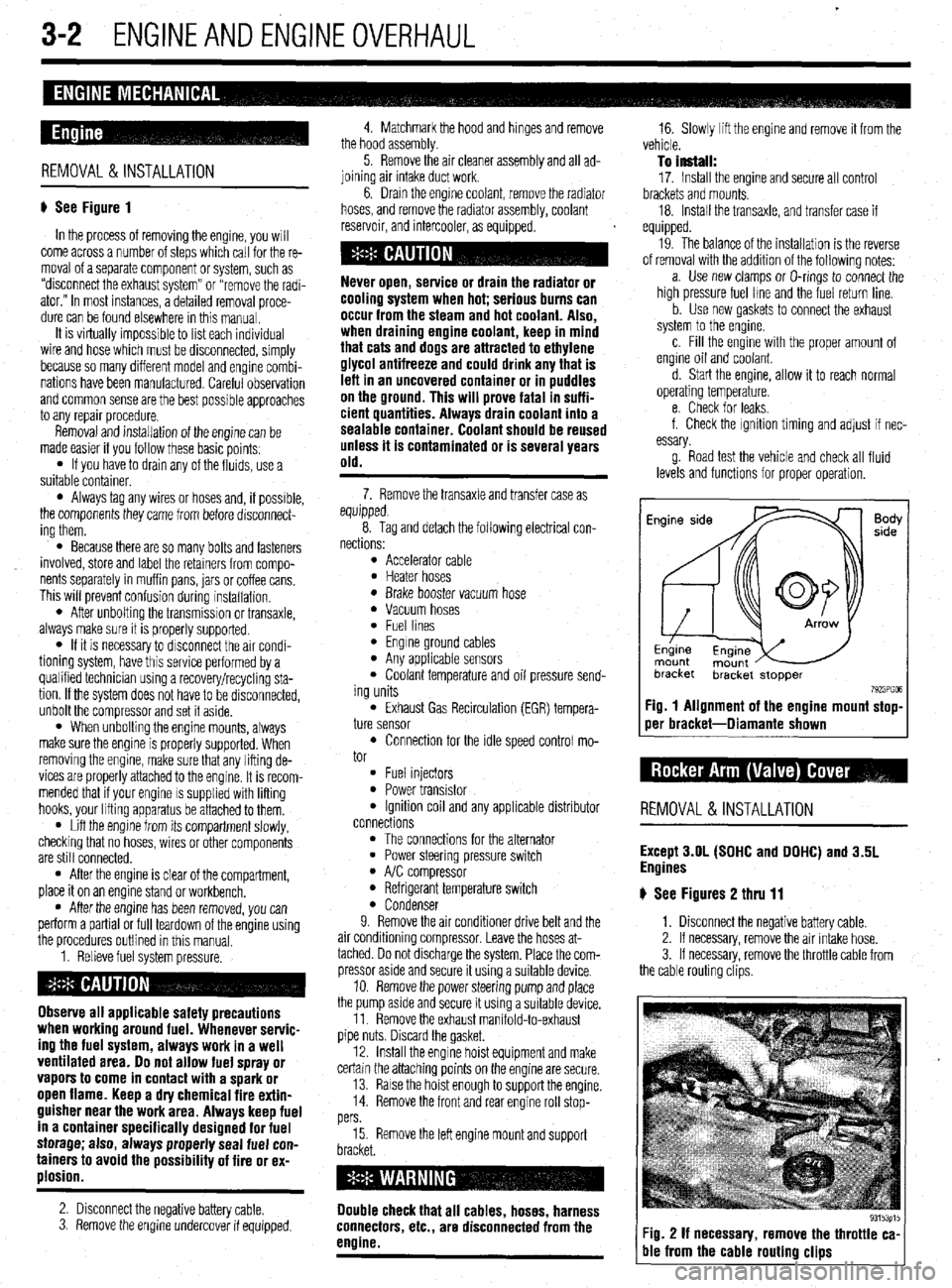

# See Figure 1

In the process of removing the engine, you will

come across a number of steps which call for the re-

moval of a separate component or system, such as

“disconnect the exhaust system” or “remove the radi-

ator.” In most instances, a detailed removal proce-

dure can be found elsewhere in this manual.

It is virtually impossible to list each individual

wire and hose which must be disconnected, simply

because so many different model and engrne combi-

nations have been manufactured Careful observation

and common sense are the best possible approaches

to any repair procedure.

Removal and installation of the engine can be

made easier if you follow these basic points:

l If you have to drain any of the fluids, use a

suitable container.

l Always tag any wires or hoses and, if possrble,

the components they came from before disconnect-

ing them.

l Because there are so many bolts and fasteners

involved, store and label the retainers from compo-

nents separately in muffin pans, jars or coffee cans.

This will prevent confusion during installatron.

l After unbolting the transmisston or transaxle,

always make sure it is properly supported.

l If it is necessary to disconnect the air condi-

tioning system, have this service performed by a

qualified technician using a recovery/recycling sta-

tion If the system does not have to be disconnected,

unbolt the compressor and set it aside.

l When unbolting the engine mounts, always

make sure the engine is properly supported. When

removing the engine, make sure that any lifting de-

vices are properly attached to the engine. It is recom-

mended that if your engine IS supplied with lifting

hooks, your lifting apparatus be attached to them.

l Lift the engine from its compartment slowly,

checking that no hoses, wires or other components

are still connected.

l After the engine is clear of the compartment,

place it on an engine stand or workbench.

l After the engine has been removed, you can

perform a partial or full teardown of the engine using

the procedures outlined in this manual.

1. Relieve fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect the negative battery cable.

3. Remove the engine undercover if equipped. 4. Matchmark the hood and hinges and remove

the hood assembly.

5. Remove the air cleaner assembly and all ad-

joining air intake duct work.

6. Drain the engine coolant, remove the radiator

hoses, and remove the radiator assembly, coolant

reservoir, and intercooler, as equipped.

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

7. Remove the transaxle and transfer case as

equipped.

8. Tag and detach the following electrical con-

nections:

l Accelerator cable l Heater hoses l Brake booster vacuum hose l Vacuum hoses l Fuel lines l Engine ground cables l Any applicable sensors l Coolant temperature and oil pressure send-

ing units

l Exhaust Gas Recirculation (EGR) tempera-

ture sensor

l Connection for the idle speed control mo-

tor

l Fuel injectors l Power transistor l Ignition coil and any applicable distributor

connections

l The connections for the alternator l Power steering pressure switch l A/C compressor l Refrigerant temperature switch l Condenser

9. Remove the air conditioner drive belt and the

air conditioning compressor. Leave the hoses at-

tached. Do not discharge the system. Place the com-

pressor aside and secure it using a suitable device.

10. Remove the power steering pump and place

the pump asrde and secure it using a surtable device.

11. Remove the exhaust manifold-to-exhaust

pipe nuts. Discard the gasket.

12. Install the engine hoist equipment and make

certain the attaching points on the engine are secure.

13. Raise the hoist enough to support the engine.

14. Remove the front and rear engine roll stop-

pers

15. Remove the left engine mount and support

Double check that all cables, hoses, harness

connectors, etc., are disconnected from the

engine.

16. Slowly lift the engine and remove it from the

vehicle.

To install:

17. Install the engine and secure all control

brackets and mounts.

18. Install the transaxle, and transfer case if

equipped.

19. The balance of the installation is the reverse

of removal with the addition of the following notes:

a. Use new clamps or O-rings to connect the

high pressure fuel lme and the fuel return line.

b. Use new gaskets to connect the exhaust

system to the engine.

c. Fill the engine with the proper amount of

engine oil and coolant.

d. Start the engine, allow it to reach normal

operating temperature.

e. Check for leaks.

f. Check the ignition timing and adjust if nec-

essary.

g. Road test the vehicle and check all fluid

levels and functions for proper operation.

Fig. 1 Alignment of the engine mount stop-

oer bracket-Diamante shown

REMOVAL &INSTALLATION

Except 3.OL (SOHC and DOHC) and 3.5L

Engines

# See Figures 2 thru 11

1. Disconnect the negative battery cable.

2. If necessary, remove the air intake hose.

3. If necessary, remove the throttle cable from

the cable routing clips.

Fig. 2 If necessary, remove the throttle ca-

ble from the cable routing clips

Page 69 of 408

3-8' ENGINEANDENGINEOVERHAUL

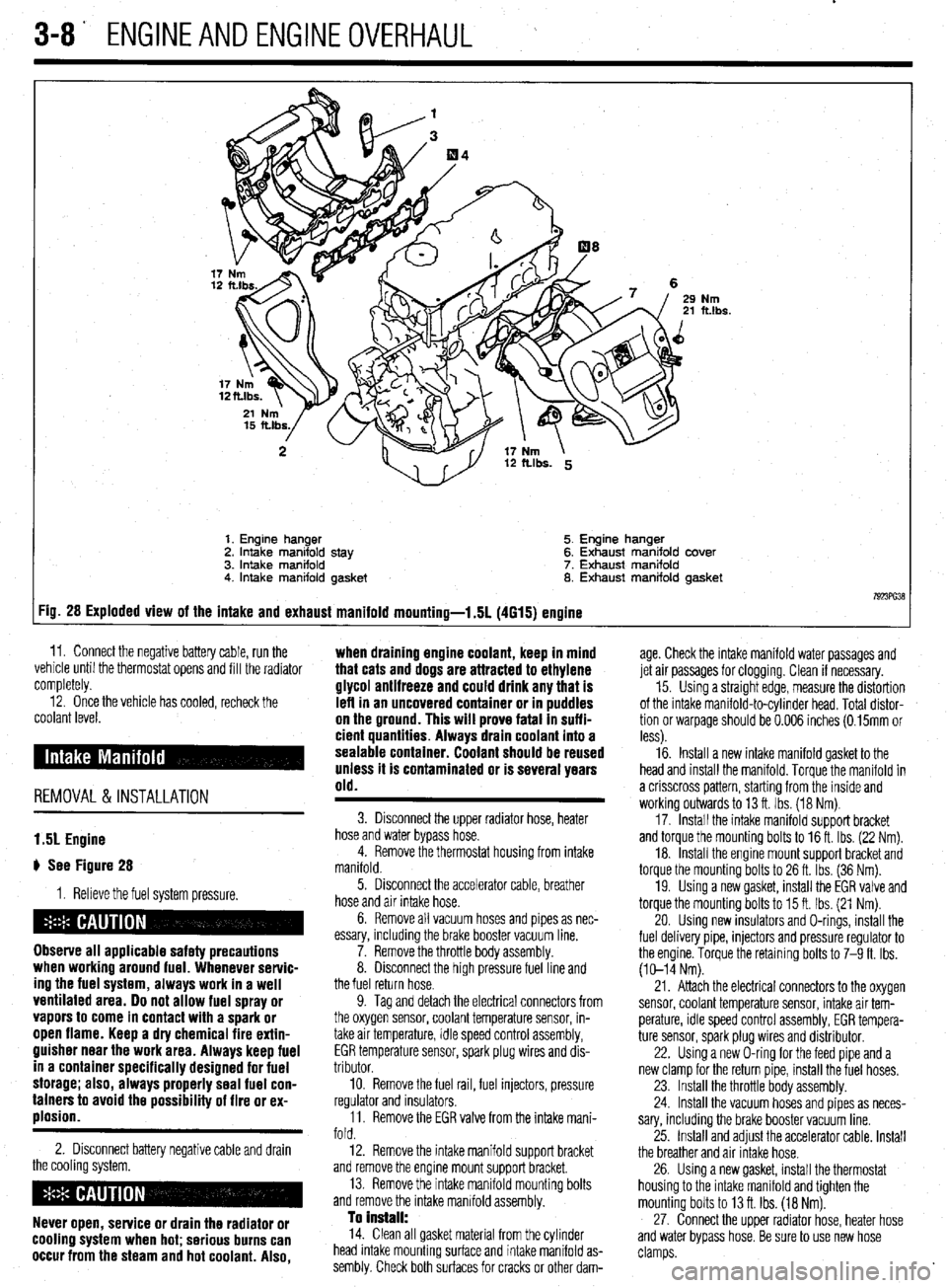

Nm ft.lbs.

1. Engine hanger 5. Engine hanger

2. Intake manifold stay 6. Exhaust manifold cover

3. intake manifold 7. Exhaust manifold

4. Intake manifold gasket 8. Exhaust manifold gasket

7923ffi38 :ig. 28 Exploded view of the intake and exhaust manifold mounting-l .5L (4615) engine

11. Connect the negative battery cable, run the ,. . . .

vemcie unnl me tnermostat opens ano till the radiator

completely. age. Check the intake manifold water passages and

jet air passages for clogging. Clean if necessary.

12. Once the vehicle has cooled, recheck the

coolant level.

REMOVAL &INSTALLATION when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal In suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

15. Using a straight edge, measure the distortion

of the intake manifold-to-cylinder head. Total distor-

tion or warpage should be 0.006 inches (0.15mm or

less).

16. Install a new intake manifold gasket to the

head and install the manifold. Torque the manifold in

a crisscross pattern, starting from the inside and

working outwards to 13 ft. Ibs. (18 Nm).

17. Install the intake manifold support bracket

and torque the mounting bolts to 16 ft. Ibs. (22 Nm).

18. Install the engine mount support bracket and

torque the mounting bolts to 26 ft. Ibs. (36 Nm).

19. Using a new gasket, install the EGR valve and

torque the mounting bolts to 15 ft. Ibs. (21 Nm).

20. Using new insulators and O-rings, install the

fuel delivery pipe, injectors and pressure regulator to

the engine. Torque the retaining bolts to 7-9 ft. Ibs.

(10-14 Nm).

1.51 Engine

# See Figure 28

1. Relieve the fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect battery negative cable and drain

the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

3. Disconnect the upper radiator hose, heater

hose and water bypass hose.

4. Remove the thermostat housing from intake

manifold.

5. Disconnect the accelerator cable, breather

hose and air intake hose.

6. Remove all vacuum hoses and pipes as nec-

essary, including the brake booster vacuum line.

7. Remove the throttle body assembly.

8. Disconnect the high pressure fuel line and

the fuel return hose.

9. Tag and detach the electrical connectors from

the oxygen sensor, coolant temperature sensor, in-

take air temperature, idle speed control assembly,

EGR temperature sensor, spark plug wires and dis-

tributor.

10. Remove the fuel rail, fuel injectors, pressure

regulator and insulators.

11. Remove the EGR valve from the intake mani-

fold.

12. Remove the intake manifold support bracket

and remove the engine mount support bracket.

13. Remove the intake manifold mounting bolts

and remove the intake manifold assembly.

To Install: 14. Clean all gasket material from the cylinder

head intake mounting surface and intake manifold as-

sembly. Check both surfaces for cracks or other dam- 21. Attach the electrical connectors to the oxygen

sensor, coolant temperature sensor, intake air tem-

perature, idle speed control assembly, EGR tempera-

ture sensor, spark plug wires and distributor.

22. Using a new O-ring for the feed pipe and a

new clamp for the return pipe, install the fuel hoses.

23. Install the throttle body assembly.

24. Install the vacuum hoses and pipes as neces-

sary, including the brake booster vacuum line.

25. Install and adjust the accelerator cable. Install

the breather and air Intake hose.

26. Using a new gasket, install the thermostat

housing to the intake manifold and tighten the

mounting bolts to 13 ft. Ibs. (18 Nm).

27. Connect the upper radiator hose, heater hose

and water bypass hose. Be sure to use new hose

clamps.

Page 70 of 408

ENGINEANDENGINEOVERHAUL 3-9

28. Fill the system with coolant.

29. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

completely.

30. Check and adjust the idle speed and ignition

timing.

31. Once the vehicle has cooled, recheck the

coolant level.

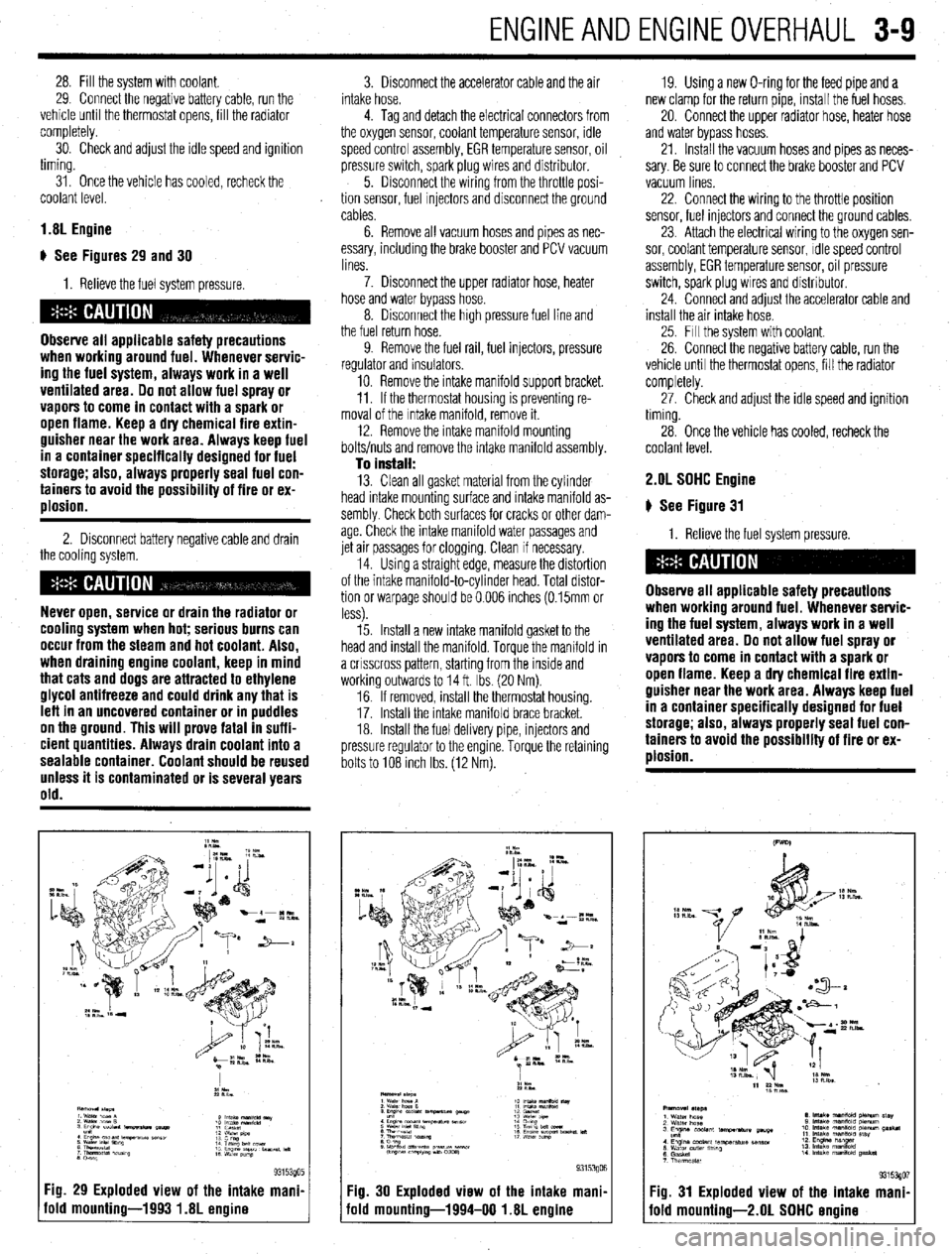

1.8L Engine

) See Figures 29 and 30

I. Relieve the fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect battery negative cable and drain

the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

leff in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

Fig. 29 Exploded view of the intake mani.

old mounting-1993 1.8L engine

3. Disconnect the accelerator cable and the air

intake hose.

4. Tag and detach the electrical connectors from

the oxygen sensor, coolant temperature sensor, idle

speed control assembly, EGR temperature sensor, oil

pressure switch, spark plug wires and distributor.

5. Disconnect the wiring from the throttle posi-

tion sensor, fuel Injectors and disconnect the ground

cables.

6. Remove all vacuum hoses and pipes as nec-

essary, including the brake booster and PCV vacuum

lines.

7. Disconnect the upper radiator hose, heater

hose and water bypass hose.

8. Disconnect the high pressure fuel line and

the fuel return hose.

9. Remove the fuel rail, fuel injectors, pressure

regulator and insulators.

10. Remove the intake manifold support bracket.

11. If the thermostat housing is preventing re-

moval of the Intake manifold, remove it.

12. Remove the intake manifold mounting

bolts/nuts and remove the intake manifold assembly.

To install: 13. Clean all gasket material from the cylinder

head intake mounting surface and intake manifold as-

sembly Check both surfaces for cracks or other dam-

age. Check the intake manifold water passages and

jet air passages for clogging. Clean if necessary.

14. Using a straight edge, measure the distortion

of the intake manifold-to-cylinder head. Total distor-

tion or warpage should be 0.006 inches (0.15mm or

less).

15. Install a new intake manifold gasket to the

head and install the manifold. Torque the manifold in

a crrsscross pattern, starting from the inside and

working outwards to 14 ft. Ibs. (20 Nm).

16. If removed, install the thermostat housing.

17. Install the Intake manifold brace bracket.

18. Install the fuel delivery pipe, injectors and

pressure regulator to the engine. Torque the retaining

bolts to 108 Inch Ibs. (12 Nm). 19. Using a new O-ring for the feed pipe and a

new clamp for the return pipe, install the fuel hoses,

20. Connect the upper radiator hose, heater hose

and water bypass hoses.

21. Install the vacuum hoses and pipes as neces-

sary. Be sure to connect the brake booster and PCV

vacuum lines

22. Connect the wiring to the throttle position

sensor, fuel injectors and connect the ground cables,

23. Attach the electrical wiring to the oxygen sen-

sor, coolant temperature sensor, Idle speed control

assembly, EGR temperature sensor, oil pressure

switch, spark plug wires and distributor.

24. Connect and adjust the accelerator cable and

install the air intake hose.

25. Fill the system with coolant.

26. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

completely.

27. Check and adjust the idle speed and ignition

timing.

28. Once the vehicle has cooled, recheck the

coolant level. 2.OL SOHC Engine

# See Figure 31

1. Relieve the fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

Fig. 30 Exploded view of the intake mani,

iold mounting-1994-00 1.8L engine Fig. 31 Exploded view of the intake mani

fold mounting-2.01 SOHC ermine

Page 71 of 408

3-10 ENGINEANDENGINEOVERHAUL

2. Disconnect the battery negative cable.

3. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

4 Disconnect the accelerator cable and air in-

take hose.

5. Disconnect the upper radiator hose, heater

hose and water bypass hose.

6. Unplug the vacuum connection at the power

brake booster and the PCV valve if still connected.

Disconnect all remaining vacuum hoses and pipes as

necessary.

7. Disconnect the high pressure fuel line, fuel

return hose and remove throttle control cable brack-

ets

8. Tag and detach the electrical connectors from

the oxygen sensor, coolant temperature sensor,

therm0 switch, idle speed control assembly, EGR

temperature sensor, distributor, fuel injectors and

spark plug wires. Position the engine wiring harness

aside.

9. Matchmark the distributor housing to the in-

take manifold, and remove the distributor.

10. Remove the intake manifold bracket and the

engine hanger.

11. If the thermostat housing is preventing re-

moval of the intake manifold, remove it.

12. Remove the intake manifold mounting bolts

and remove the intake manifold assembly. Drsassem-

ble manifold from the Intake plenum on a work bench

as required

To install: 13. Clean all gasket material from the cylinder

head intake mounting surface and intake manifold as-

sembly. Check both surfaces for cracks or other dam-

age. Check the intake manifold water passages and

jet air passages for clogging. Clean if necessary.

14 Assemble the intake manifold assembly using

all new gaskets. Torque air intake plenum bolts to

11-14ff. Ibs. (15-19 Nm).

15. Install a new intake manifold gasket to the

head and install the manifold. Torque the manifold in

a crrsscross pattern, starting from the inside and

working outwards to 11-14 ff. Ibs. (15-19 Nm).

16. Install the fuel delivery pipe, injectors and

pressure regulator to the engine. Torque the retaining

bolts to 4 ft. Ibs (6 Nm).

17. install the thermostat housing, intake mani-

fold brace bracket, and engine hanger bracket.

18 Connect or install all hoses, cables and elec-

trical connectors that were removed or disconnected

during the removal procedure.

19. Align the distributor matchmarks and install

the distributor.

20. Fill the system with coolant,

21. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

completely. 22. Adjust the accelerator cable. Check and ad-

just the idle speed and ignition timing.

23. Once the vehicle has cooled, recheck the

coolant level.

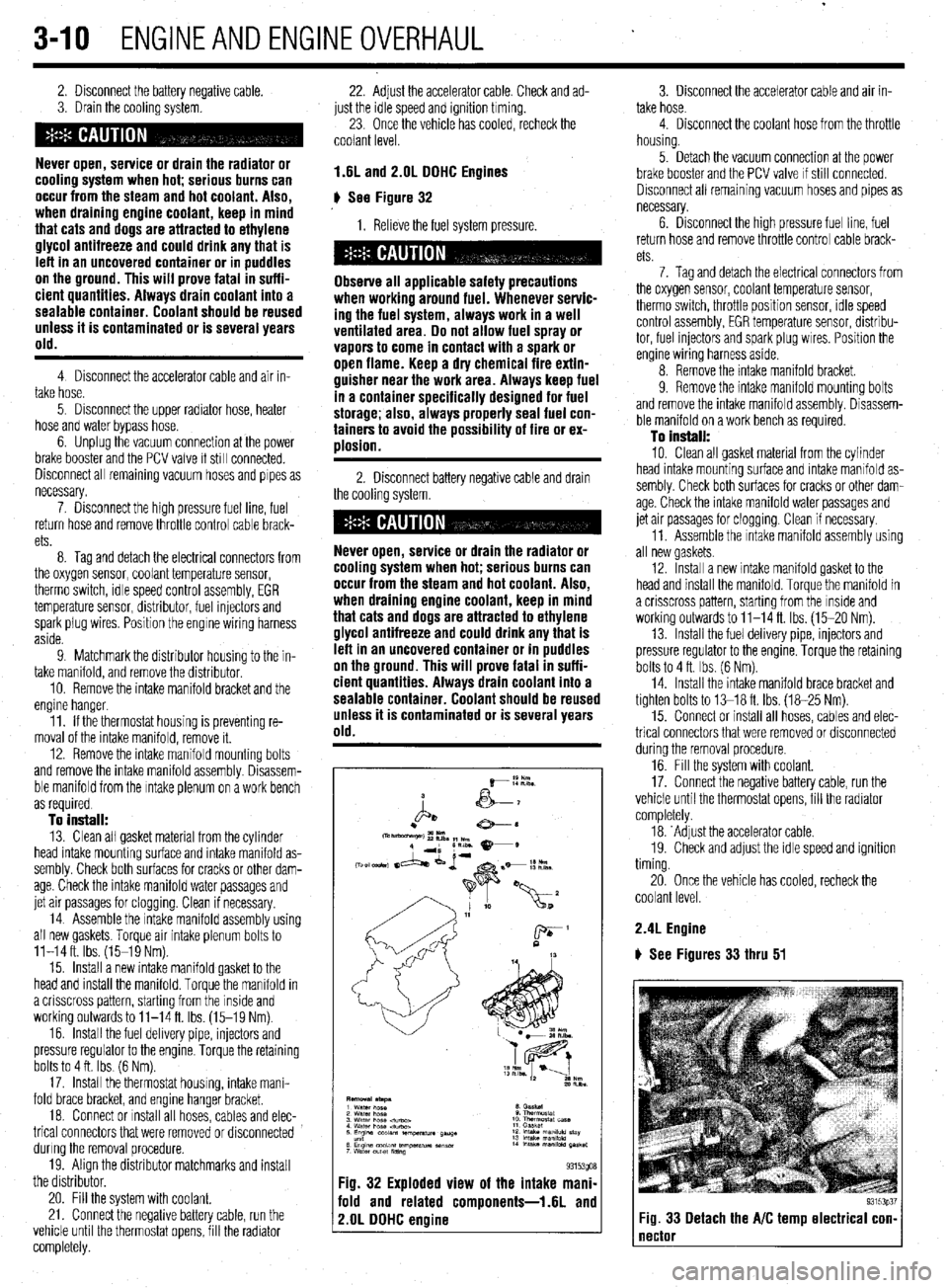

1.6L and 2.OL DDHC Engines

# See Figure 32

1. Relieve the fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

ulosion.

2. Disconnect battery negative cable and drain

the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

Fig. 32 Exploded view of the intake mani-

fold and related components-1.6L and

2.OL DDHC engine

3. Disconnect the accelerator cable and air in-

take hose.

4. Disconnect the coolant hose from the throttle

housing.

5. Detach the vacuum connection at the power

brake booster and the PCV valve If still connected.

Disconnect all remaining vacuum hoses and pipes as

necessary.

6. Drsconnect the high pressure fuel line, fuel

return hose and remove throttle control cable brack-

ets

7. Tag and detach the electrical connectors from

the oxygen sensor, coolant temperature sensor,

therm0 switch, throttle position sensor, rdle speed

control assembly, EGR temperature sensor, distribu-

tor, fuel injectors and spark plug wires. Position the

engine wiring harness aside.

8. Remove the intake manifold bracket.

9. Remove the intake mamfold mounting bolts

and remove the intake manifold assembly. Disassem-

ble manifold on a work bench as required.

To install:

10. Clean all gasket material from the cylinder

head intake mounting surface and intake manifold as-

sembly. Check both surfaces for cracks or other dam-

age. Check the intake manifold water passages and

jet air passages for clogging. Clean if necessary.

11. Assemble the Intake manifold assembly using

all new gaskets.

12. Install a new intake manifold gasket to the

head and install the manifold. Torque the manifold in

a crisscross pattern, starting from the inside and

working outwards to 11-14 ft. Ibs. (15-20 Nm).

13. Install the fuel delivery pipe, injectors and

pressure regulator to the engine. Torque the retaining

bolts to 4 ft. Ibs. (6 Nm).

14. Install the intake manifold brace bracket and

tighten bolts to 13-18 ft. Ibs. (18-25 Nm).

15. Connect or install all hoses, cables and elec-

trical connectors that were removed or disconnected

during the removal procedure.

16. Fill the system with coolant.

17. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

completely.

18. ‘Adjust the accelerator cable.

19. Check and adjust the idle speed and ignition

timing.

20. Once the vehicle has cooled, recheck the

coolant level.

2.4L Engine

) See Figures 33 thru 51

93153p37 Fig. 33 Detach the A/C temp electrical con- 1

Page 73 of 408

.

3-12 ENGINEANDENGINEOVERHAUL

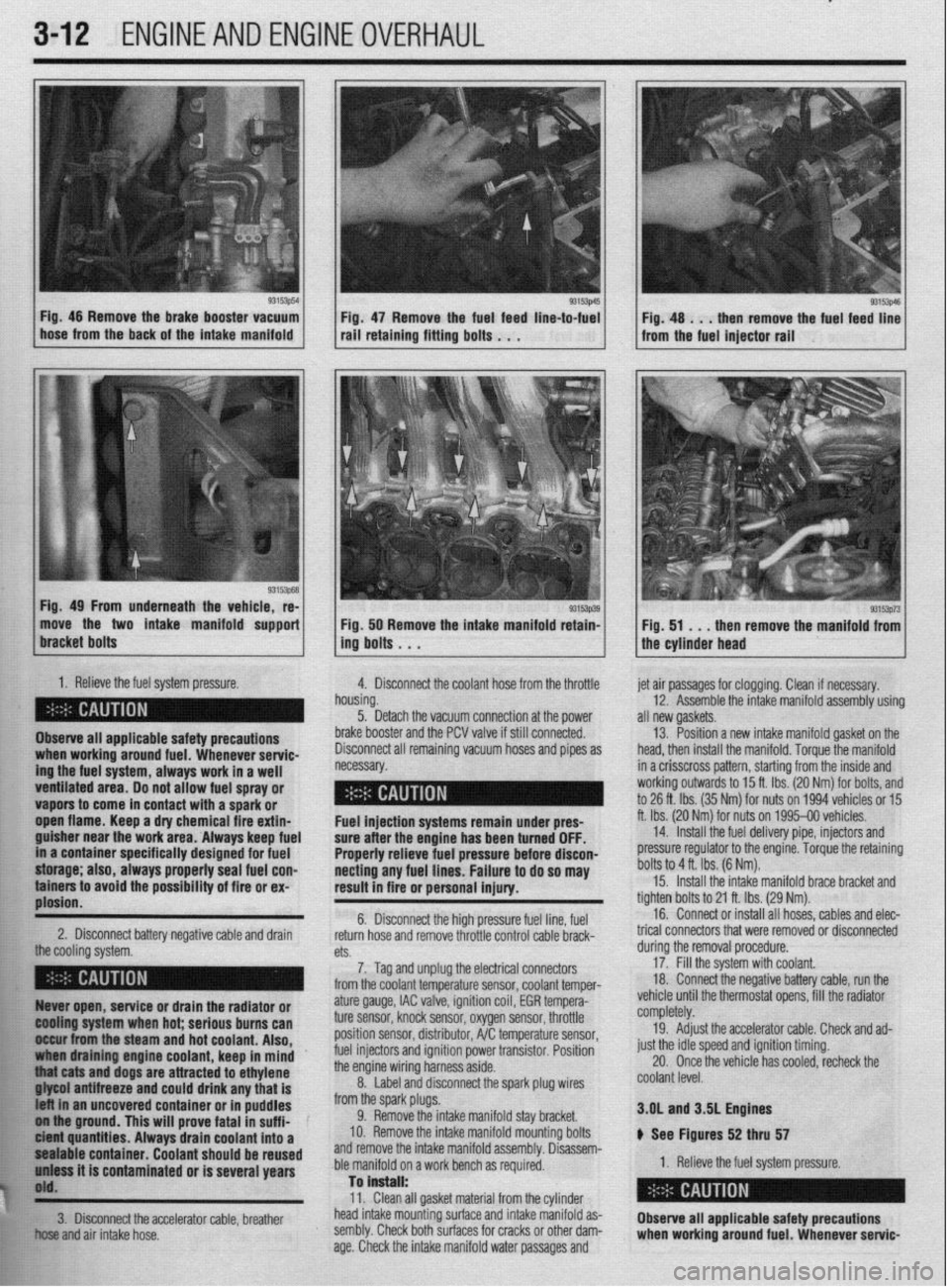

93153p54

1

L Fig. 46 Remove the brake booster vacuum

hose from the back of the intake manifold Fig 47 Remove the fuel feed line-to-fuel rail’retaini”g fitti”g bo,ts . . .

Fig. 49 From underneath the vehicle, re-

move the two intake manifold support

1. Relieve the fuel system pressure.

4. Disconnect the coolant hose from the throttle

Observe all applicable safety precautions

ing the fuel system, always work in a well when working around fuel. Whenever servic-

ventilated area. Do not allow fuel spray or - __.

vapors to come in contact with a spark or

._

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect battery negative cable and drain

the cooling rtfctnm 93153p39 Fig. 50 Remove the intake manifold retain-

ing bolts . . .

h

n ousing.

5. Detach the vacuum connection at the power

b

rake booster and the PCV valve if still connected.

C lisconnect all remaining vacuum hoses and pipes as

ecessary. et air passages for clogging. Clean if necessary.

12. Assemble the intake manifold assembly using

III new gaskets.

13. Position a new intake manifold gasket on the

lead, then install the manifold. Torque the manifold

n a crisscross pattern, starting from the inside and

vorking outwards to 15 ft. Ibs. (20 Nm) for bolts, and

o 26 ft. Ibs. (35 Nm) for nuts on 1994 vehicles or 15

t. Ibs. (20 Nr$ for nuts on 1995-00 vehicles.

14. Install the fuel delivery pipe, injectors and

xessure regulator to the engine. Torque the retaining

)olts to 4 ft. Ibs. (6 Nm). Fuel injection systems remain under pres- f

sure after the engine has been turned OFF.

Properly relieve fuel pressure before discon-

necting any fuel lines. Failure to do so may [

result in fire or personal injury.

t 6. Disconnect the high pressure fuel line, fuel

return hose and remove throttle control cable brack- t

n+C.

cm. durino the removal orocedure. 15. Install the intake manifold brace bracket and

ighten bolts to 21 ft. Ibs. (29 Nm).

16. Connect or install all hoses, cables and elec-

rical connectors that were removed or disconnected

7. Tag and unplug the electrical connectors

from the coolant temperature sensor, coolant temper- 17: Fill the system with coolant.

18 Connect the negative battery cable, run the

, . : .., ,, ., , ,

,,,, ,. ,.

93153p73 Fig. 51 . . .

then remove the manifold from

the cylinder head

Ruver open, service or drain the radiator or

@Ming system when hot; serious burns can

II&ur from the steam and hot coolant. Also,

draining engine coolant, keep in mind ’

j “thiat cats and dogs are attracted to ethylene

. . . ..____ “..” 11_,1 -...... any that is

t uncovered container or in puddles

FE ol iha ground. This will prove fatal in suff i-

k ici?M quantities. Always drain coolant into a

$1 pealable container. Coolant should be reused

h’ uniass it is contaminated or is several years

j$O'd.

**w

ature gauge, IAC valve, ignition coil, EGR tempera-

ture sensor, knock sensor, oxygen sensor, throttle

position sensor, distributor, A/C temperature sensor,

fuel injectors and ignition power transistor. Position

the engine wiring harness aside.

8. Label and disconnect the spark plug wires

from the spark plugs.

9. Remove the intake manifold stay bracket.

IO. Remove the intake manifold mounting bolts

and remove the intake manifold assembly. Disassem-

ble manifold on a work bench as required.

Tan is”.+..ll. vemcle unrn me mermosrar opens, ml tne raalaror

completely.

19. Adjust the accelerator cable. Check and ad-

just the idle speed and ignition timing.

20. Once the vehicle has cooled, recheck the

coolant level.

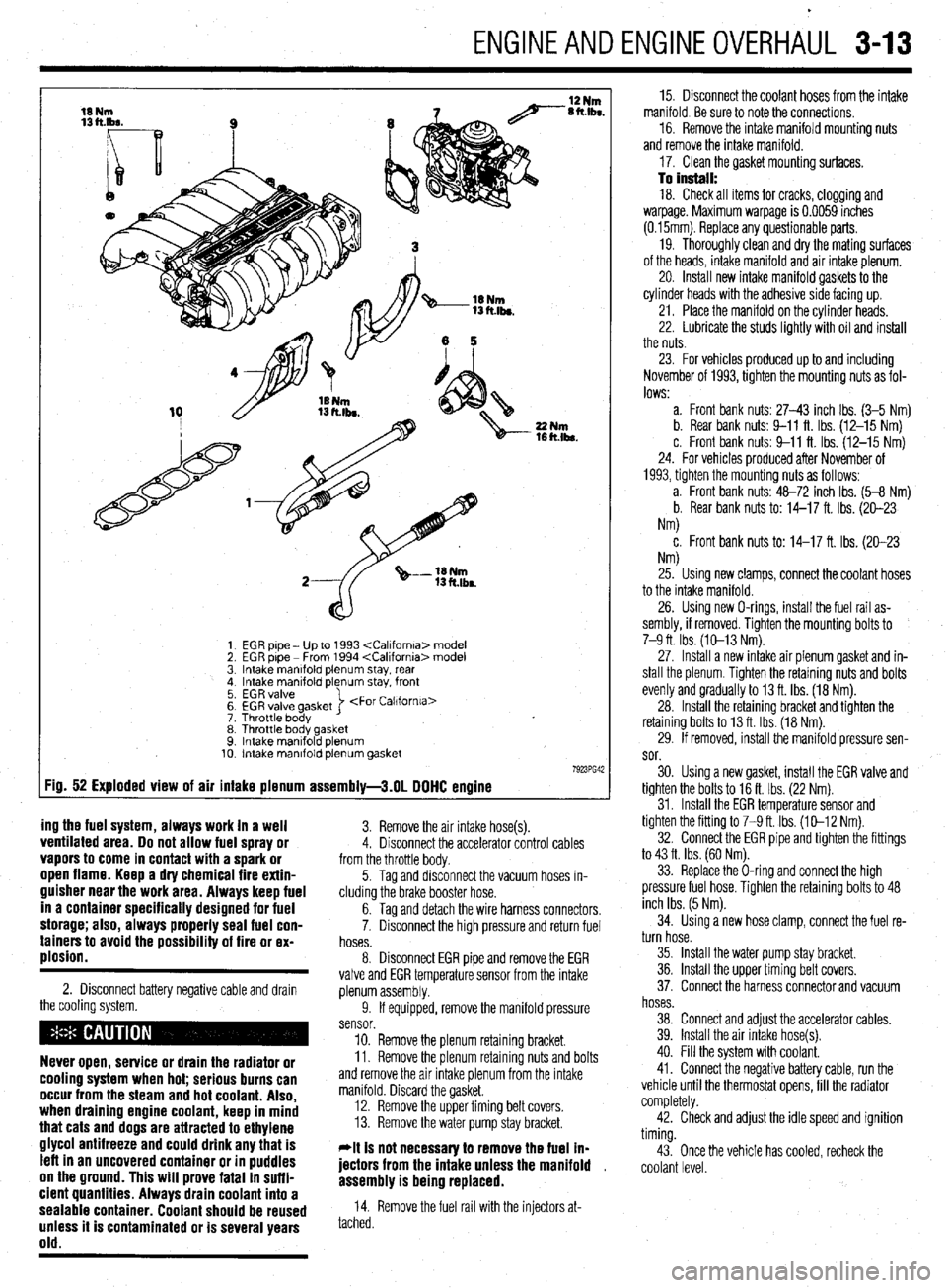

3.OL and 3SL Engines

ti See Figures 52 thru 57

1. Relieve the fuel system pressure.

W.>. Clean all gasket material from the cylinder

!&S head intake mounting surface and intake manifold as-

fir!: 3. Disconnect the accelerator cable, breather

Observe all applicable safety precautions

El .;,

+w..” and air intake hose. sembly. Check both surfaces for cracks or other dam-

age. Check the intake manifold water passages and when working around fuel. Whenever servic-

Page 74 of 408

ENGINEANDENGINEOVERHAUL 3-13

EGR pipe - Up to 1993

EGR pipe - From 1994

Intake manlfold plenum stay, rear

Intake manifold plenum stay. front

EGR valve

EGR valve gasket

Throttle body >

Throttle body gasket

Intake mantfold plenum

Intake manifold plenum gasket

:ig. 52 Exploded view of air intake plenum assembly-3.01 DOHC engine

ing the fuel system, always work in a well

3. Remove the air intake hose(s). ventilated area. Do not allow fuel spray or 4. Disconnect the accelerator control cables vapors to come in contact with a spark or from the throttle body. open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect battery negative cable and drawn

the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

5. Tag and disconnect the vacuum hoses in-

cluding the brake booster hose.

6. Tag and detach the wire harness connectors,

7. Disconnect the high pressure and return fuel

hoses.

8. Disconnect EGR pipe and remove the EGR

valve and EGR temperature sensor from the intake

plenum assembly.

9. If equipped, remove the manifold pressure

sensor.

10. Remove the plenum retaining bracket.

11. Remove the plenum retaining nuts and bolts

and remove the air intake plenum from the intake

manifold. Discard the gasket.

12. Remove the upper timing belt covers.

13. Remove the water pump stay bracket.

*It is not necessav to remove the fuel ln-

jectors from the intake unless the manifold ,

assembly is being replaced.

14. Remove the fuel rail with the injectors at-

tached. 15. Disconnect the coolant hoses from the intake

manifold. Be sure to note the connections.

16. Remove the intake manifold mounting nuts

and remove the intake manifold.

17. Clean the gasket mounting surfaces.

To install: 18. Check all items for cracks, clogging and

warpage. Maximum warpage is 0.0059 inches

(0.15mm). Replace any questionable parts.

19. Thoroughly clean and dry the mating surfaces

of the heads, intake manifold and air intake plenum.

20. Install new intake manifold gaskets to the

cylinder heads with the adhesive side facing up.

21. Place the manifold on the cylinder heads.

22. Lubricate the studs lightly with oil and install

the nuts.

23. For vehicles produced up to and including

November of 1993, tighten the mounting nuts as fol-

lows:

a. Front bank nuts: 27-43 inch Ibs. (3-5 Nm)

b. Rear bank nuts: 9-11 ft. Ibs. (12-15 Nm)

c. Front bank nuts: 9-11 ft. Ibs. (12-15 Nm)

24. For vehicles produced after November of

1993, tighten the mounting nuts as follows:

a. Front bank nuts: 48-72 inch Ibs. (5-8 Nm)

b. Rear bank nuts to: 14-17 ft. Ibs. (20-23

Nm)

c. Front bank nuts to: 14-17 ft. Ibs. (20-23

NM

25. Using new clamps, connect the coolant hoses

to the intake manifold.

26. Using new O-rings, install the fuel rail as-

sembly, if removed. Tighten the mounting bolts to

7-9 ft. Ibs. (10-13 Nm).

27. Install a new intake air plenum gasket and in-

stall the plenum. Tighten the retaining nuts and bolts

evenly and gradually to 13 ft. Ibs. (18 Nm).

28. Install the retaining bracket and tighten the

retaining bolts to 13 ft. Ibs. (18 Nm).

29. If removed, install the manifold pressure sen-

sor.

30. Using a new gasket, install the EGR valve and

tighten the bolts to 16 ft. Ibs. (22 Nm).

31. Install the EGR temperature sensor and

tighten the fitting to 7-9 ft. Ibs. (10-12 Nm).

32. Connect the EGR pipe and tighten the fittings

to 43 ft. Ibs. (60 Nm).

33. Replace the O-ring and connect the high

pressure fuel hose. Tighten the retaining bolts to 48

inch Ibs. (5 Nm).

34. Using a new hose clamp, connect the fuel re-

turn hose.

35. Install the water pump stay bracket.

36. Install the upper timing belt covers.

37. Connect the harness connector and vacuum

hoses.

38. Connect and adjust the accelerator cables.

39. Install the air intake hose(s).

40. Fill the system with coolant.

41. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

completely.

42. Check and adjust the idle speed and ignition

timing.

43. Once the vehicle has cooled, recheck the

coolant level.

Page 85 of 408

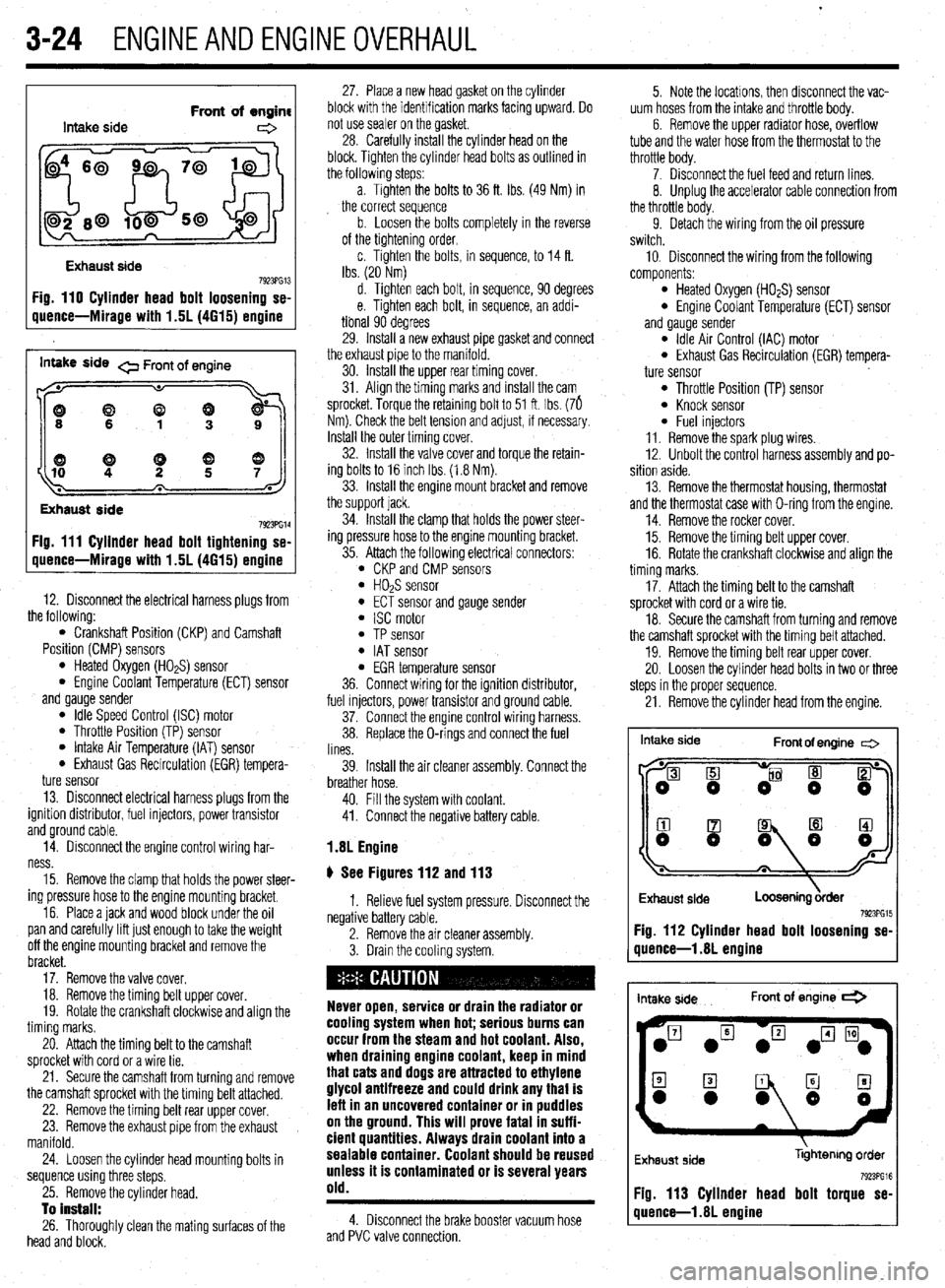

3-24 ENGINEANDENGINEOVERHAUL

Intake side Front of engine

e

Exhaust side

7923PG13 Fig. 110 Cylinder head bolt loosening se-

uuence-Mirage with 1.5L (4615) ermine

inwe side 0 Front of engine

((9

Exhaust side

7923PG14 Fig. 111 Cyllnder head bolt tightening se-

quence-Mirage with 1.5L (4615) engine

12. Disconnect the electrical harness plugs from

the following:

l Crankshaft Position (CKP) and Camshaft

Position (CMP) sensors

l Heated Oxygen (HO*S) sensor l Engine Coolant Temperature (ECT) sensor

and gauge sender

l Idle Speed Control (ISC) motor l Throttle Position (TP) sensor l Intake Air Temperature (IAT) sensor l Exhaust Gas Recirculation (EGR) tempera-

ture sensor

13. Disconnect electrical harness plugs from the

ignition distributor, fuel injectors, power transistor

and ground cable.

14. Disconnect the engine control wiring har-

ness.

15. Remove the clamp that holds the power steer-

ing pressure hose to the engine mounting bracket.

16. Place a jack and wood block under the oil

pan and carefully lift just enough to take the weight

off the engine mounting bracket and remove the

bracket.

17. Remove the valve cover.

18. Remove the timing belt upper cover.

19. Rotate the crankshaft clockwise and align the

timing marks.

20. Attach the timing belt to the camshaft

sprocket with cord or a wire tie.

21. Secure the camshaft from turning and remove

the camshaft sprocket with the timing belt attached.

22. Remove the timing belt rear upper cover.

23. Remove the exhaust pipe from the exhaust

manifold.

24. Loosen the cylinder head mounting bolts in

sequence using three steps.

25. Remove the cylinder head.

To install:

26. Thoroughly clean the mating surfaces of the

head and block. 27. Place a new head gasket on the cylinder

block with the identification marks facing upward. Do

not use sealer on the gasket.

28. Carefully install the cylinder head on the

block. Tighten the cylinder head bolts as outlined in

the followlng steps:

a. Tighten the bolts to 36 ft. Ibs. (49 Nm) in

the correct sequence

b. Loosen the bolts completely in the reverse

of the tightening order,

c. Tighten the bolts, in sequence, to 14 ft.

Ibs. (20 Nm)

d. Tighten each bolt, in sequence, 90 degrees

e. Tighten each bolt, in sequence, an addi-

tional 90 degrees

29. Install a new exhaust pipe gasket and connect

the exhaust pipe to the manifold.

30. Install the upper rear timing cover.

31. Align the timing marks and install the cam

sprocket. Torque the retaining bolt to 51 ft. Ibs. (76

Nm). Check the belt tension and adjust, if necessary.

Install the outer timing cover.

32. Install the valve cover and torque the retain-

ing bolts to 16 inch Ibs. (1.8 Nm).

33. Install the engine mount bracket and remove

the support jack.

34. Install the clamp that holds the power steer-

ing pressure hose to the engine mounting bracket.

35. Attach the following electrical connectors:

l CKP and CMP sensors l HOPS sensor l ECT sensor and gauge sender l ISC motor l TP sensor l IAT sensor l EGR temperature sensor

36. Connect wiring for the ignition distributor,

fuel injectors, power transistor and ground cable.

37. Connect the engine control wiring harness.

38. Replace the O-rings and connect the fuel

lines.

39. Install the air cleaner assembly. Connect the

breather hose.

40. Fill the system with coolant.

41. Connect the negative battery cable.

1.8L Engine

# See Figures 112 and 113

1. Relieve fuel system pressure. Disconnect the

negative battery cable.

2. Remove the air cleaner assembly.

3. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

lefl in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

4. Disconnect the brake booster vacuum hose

and PVC valve connection. 5. Note the locations, then disconnect the vac-

uum hoses from the intake and throttle body.

6. Remove the upper radiator hose, overflow

tube and the water hose from the thermostat to the

throttle body.

7. Disconnect the fuel feed and return lines.

8. Unplug the accelerator cable connection from

the throttle body.

9. Detach the wiring from the oil pressure

switch.

10, Disconnect the wiring from the following

components:

l Heated Oxygen (HO*S) sensor l Engine Coolant Temperature (ECT) sensor

and gauge sender

l Idle Air Control (IAC) motor l Exhaust Gas Recirculation (EGR) tempera-

ture sensor

l Throttle Position (TP) sensor l Knock sensor l Fuel injectors

11. Remove the spark plug wires.

12. Unbolt the control harness assembly and po-

sition aside.

13. Remove the thermostat housing, thermostat

and the thermostat case with O-ring from the engine.

14. Remove the rocker cover.

15. Remove the timing belt upper cover.

16. Rotate the crankshaft clockwise and align the

timing marks.

17. Attach the timing belt to the camshaft

sprocket with cord or a wire tie.

18. Secure the camshaft from turning and remove

the camshaft sprocket with the timing belt attached.

19. Remove the timing belt rear upper cover.

20. Loosen the cylinder head bolts in two or three

steps in the proper sequence.

21. Remove the cylinder head from the engine.

Intake side

Front of engine c=>

I

Exhaust side

Loosening &der 7923PG15 Fig. 112 Cylinder head bolt loosening se-

quence-l .8L engine

intake side Front of engine *

Exhaust side libhtenng order

Fig. 113 Cylinder head bolt torque se-

quence-l .8L engine

Page 86 of 408

ENGINEANDENGINEOVERHAUL 3-25

When removina the cvlinder head. take care

not to bend or iamag;! the plug guide. The

plug guide can not be replaced.

To install:

22. Thoroughly clean the mating surfaces of the

head and block.

23. Place a new head gasket on the cylinder

block with the identification marks facing upward. Do

not use sealer on the gasket.

24. Carefully install the cylinder head on the

block.

25. Measure the cylinder head bolts prior to in-

stallation Replace any that exceed 3.795 in.

(96.4mm)

26. Apply a small amount of engine oil to the

thread section of the bolt and install so the chamfer

of the washer faces upward.

27. Tighten the cylinder head bolts as follows:

a. In the proper tightening sequence, torque

bolts to 54 ft. Ibs. (75 Nm).

b. In the reverse order of the tightening se-

quence, fully loosen all bolts.

c In the proper trghtening sequence, torque

bolts to 14 ft. Ibs. (20 Nm).

d. In the proper tightening sequence, tighten

bolts 1/4 turn (90 degrees).

e. In the proper tightening sequence, tighten

bolts an additional 1/4 turn (90 degrees).

28. Install the camshaft sprocket and tighten the

bolt to 65 ft. Ibs (90 Nm), while holding the sprocket

in place using the appropriate wrench. Confirm

proper timing mark alignment.

29. Install the upper timing belt cover and rocker

cover. Torque the rocker cover bolts to 29 inch Ibs.

(3 Nm).

30. Loosen the water pipe mounting bolt for ease

of thermostat housing installation.

31. Apply a thin bead of sealant MD970389 or

equivalent, to the water tube connection on the ther-

mostat case.

32. Apply a small amount of water to the O-ring

of the water inlet pipe and press the thermostat case

assembly onto the water inlet pipe. Install the ther-

mostat case assembly mounting bolt tightening to 16

ff. Ibs. (22 Nm).

l ECT sensor and gauge sender l IAC motor 33. Tighten the water pipe mounting bolt.

34. Install the thermostat into the housing so the

jiggle valve is located at the top. Tighten the housing

bolts to 10 ft. Ibs (14 Nm).

35. Attach the wiring to the following compo-

nents:

l HO& sensor

l EGR temperature sensor l TP sensor l Knock sensor l Fuel injectors

36. Connect the upper radiator hose to the ther-

mostat housing.

37. Connect the accelerator cable connection to

the throttle body.

38. Connect the oil pressure switch.

39. Install the spark plug wires,

40. Connect the control harness assembly.

41. Replace the O-ring for the high pressure hose

and install a new clamp on the return hose and re-

connect the fuel lines. 42. Install the air intake hose. Connect the

breather hose and air cleaner case cover

43. Reconnect the brake booster and the PCV

vacuum hoses.

44. Fill the system with coolant.

45. Connect the negative battery cable

2.01 SOHC Engine

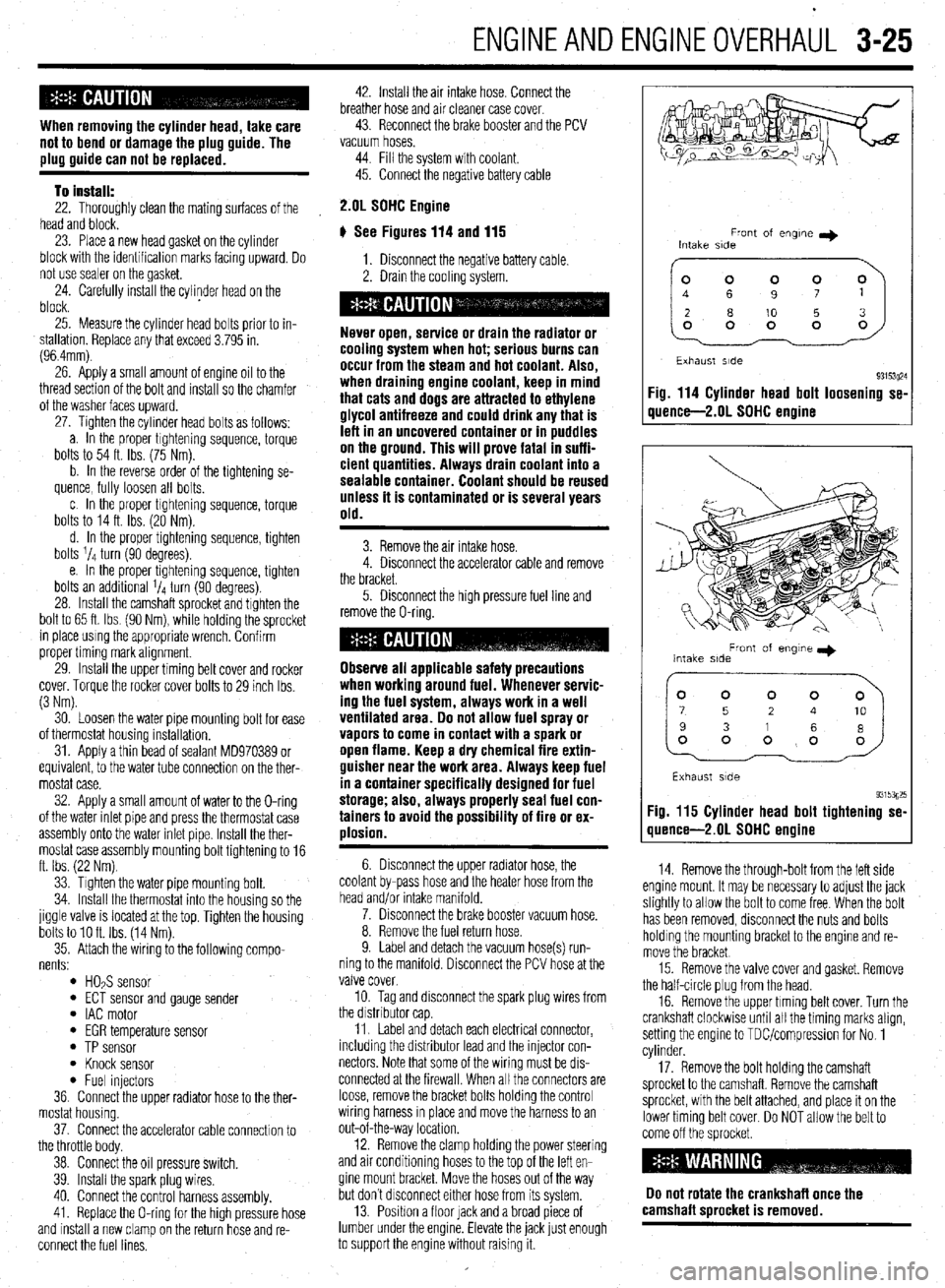

# See Figures 114 and 115

1. Disconnect the negative battery cable.

2. Drain the coolrng system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the air intake hose.

4. Disconnect the accelerator cable and remove

the bracket.

5. Disconnect the high pressure fuel line and

remove the O-ring.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

6. Disconnect the upper radiator hose, the

coolant by-pass hose and the heater hose from the

head and/or intake manifold.

7. Disconnect the brake booster vacuum hose.

8. Remove the fuel return hose.

9. Label and detach the vacuum hose(s) run-

ning to the manifold. Disconnect the PCV hose at the

valve cover.

10. Tag and disconnect the spark plug wires from

the drstnbutor cap

11. Label and detach each electrical connector,

including the distributor lead and the injector con-

nectors Note that some of the wiring must be drs-

connected at the firewall. When all the connectors are

loose, remove the bracket bolts holding the control

wiring harness rn place and move the harness to an

out-of-the-way location.

12. Remove the clamp holding the power steering

and air conditioning hoses to the top of the left en-

gine mount bracket. Move the hoses out of the way

but don’t drsconnect either hose from its system.

13. Position a floor lack and a broad piece of

lumber under the engine. Elevate the jack lust enough

to support the engine without raising it.

Front of engne I)

Intake side

~~

Exhaust side

93153~24 Fig. 114 Cylinder head bolt loosening se-

quence-2.01 SOHC engine

Front of engme I)

Intake side

Exhaust side

93153g25 Fig. 115 Cylinder head bolt tightening se-

quence-2.01 SDHC engine

14. Remove the through-bolt from the left side

engine mount. It may be necessary to adjust the jack

slightly to allow the bolt to come free When the bolt

has been removed, disconnect the nuts and bolts

holding the mounting bracket to the engine and re-

move the bracket

15. Remove the valve cover and gasket. Remove

the half-circle plug from the head.

16. Remove the upper timing belt cover. Turn the

crankshaft clockwise until all the timing marks align,

setting the engine to TDUcompression for No. 1

cylinder.

17. Remove the bolt holding the camshaft

sprocket to the camshaft. Remove the camshaft

sprocket, with the belt attached, and place it on the

lower timing belt cover. Do NOT allow the belt to

come off the sprocket

Do not rotate the crankshaft once the

camshaft sorocket is removed.

Page 87 of 408

3-26 ENGINEANDENGINEOVERHAUL

18. Remove the self-locking nuts and the small

retaining bolt holding the exhaust pipe to the bottom

of the exhaust manifold. Separate the pipe from the

manifold and remove the gasket.

19. Remove the bolts holding the support brace

to the bottom of the intake manifold.

20. Use the special hex wrench (MB 998051-01)

and loosen the head bolts in the order shown in 2 or

3 passes. When all are finger loose, remove the bolts.

21. Rock the head gently to break it loose; if tap-

ping is necessary, do so with a rubber or wooden

mallet at the corners of the head. DO NOT pry the

head up by wedging tools between the head and the

block.

22. Lift the head free of the engine. It is coming

off with both manifolds and the intake plenum at-

tached; the help of an assistant is recommended for

lifting. Support the head assembly on wooden blocks

on a suitable workbench. Refer to Cleaning and In-

spection in this section for work to be done before in-

stalling the head. If the head has been removed for

work other than gasket replacement, the rocker as-

sembly and camshaft or other components may be

removed.

Before reinstallation, the head should be com-

pletely assembled on the bench. This allows proper

location and tightening of all the external items.

To install: 23. Place a new gasket on the engine so that the

identifying mark faces up (towards the head) and is at

the timing belt end of the block. Install a new gasket

on the exhaust pipe.

Do not apply sealant to the head gasket or

mating surfaces.

24. Install the head straight down onto the block.

Try to eliminate most of the side-to-side adjust-

ments as this may move the gasket out of position.

Install the bolts by hand and just start each bolt 1 or

2 turns on the threads.

25. The head bolt torque specification is 68 ft.

Ibs. (92 Nm) for a cold engine. The bolts must be

tightened in the order shown in 3 steps. On the first

pass, tighten all the bolts to about 22 ft. Ibs. (30 Nm),

then proceed through the order tightening each bolt

to about 45 ft. Ibs. (61 Nm). The final torque is

achieved on the third pass.

26. Install the intake manifold support brace to

the manifold and tighten the bolts to 16 ft. Ibs. (22

Nm). 27. Making sure the gasket is still in place, con-

nect the exhaust pipe to the base of the exhaust man-

ifold. Use new self-locking nuts; tighten the nuts and

the small bracket bolt to 26 ft. Ibs. (35 Nm).

28. Make sure the camshaft has not changed po-

sition during repalrs. Carefully install the camshaft

sprocket and belt onto the camshaft. Tighten the re-

taining bolt to 66 ft. Ibs. (91 Nm).

29. Install the upper timing belt cover, then

tighten the bolts to 8 ft. Ibs. (11 Nm).

30. Apply sealant to the contact surfaces of the

half-circle plug and install the plug in the head In-

stall the valve cover and gasket.

31. Install the engine mount bracket to the en-

gine. Tighten the mounting nuts and bolts to 42 ft.

Ibs. (57 Nm).

32. Adjust the jack (if necessary) so that the en-

gine mount bushing aligns with the bodywork

bracket. Install the through-bolt and tighten the nuts

snug.

33. Slowly release tension on the floor jack so

that the weight of the engine bears fully on the

mount. Tighten the through-bolt to 52 ft. Ibs. (71

Nm) and the small safety nut to 26 ft. tbs. (36 Nm).

34. Install the bracket holding the power steering

hose and air conditioning hose to the top of the en-

gine mount.

35. Position the control wiring harness and in-

stall the retaining bolts. Attach each electrical con-

nector to its proper location, making sure the wires

are properly routed and firmly connected.

36. Install the spark plug wires in the distributor

cap.

37. Connect the PCV hose and the vacuum

hose(s).

38. Connect the fuel return line. Connect the

brake booster vacuum hose.

39. Install the heater hose, the coolant by-pass

hose and.the upper radiator hose. Pay close attention

to the position and routing of these hoses and insure

that they are not crimped or constricted. Install the

clamps in the same location as before removal.

40. Install a new O-ring on the high pressure fuel

line and lubricate it with a coating of gasoline. Care-

fully connect the high pressure fuel line to the fuel

rail, taking care not to damage the O-ring. Tighten the

bolts only to 4 ft. Ibs. (6 Nm).

41. Connect the accelerator cable and adjust it as

necessary.

42. Install the air intake hose.

43. Fill the cooling system with coolant.

44. Changing the oil and filter is recommended

to eliminate pollutants in the oil.

Intake side

I Front of

engine

Exhaust side

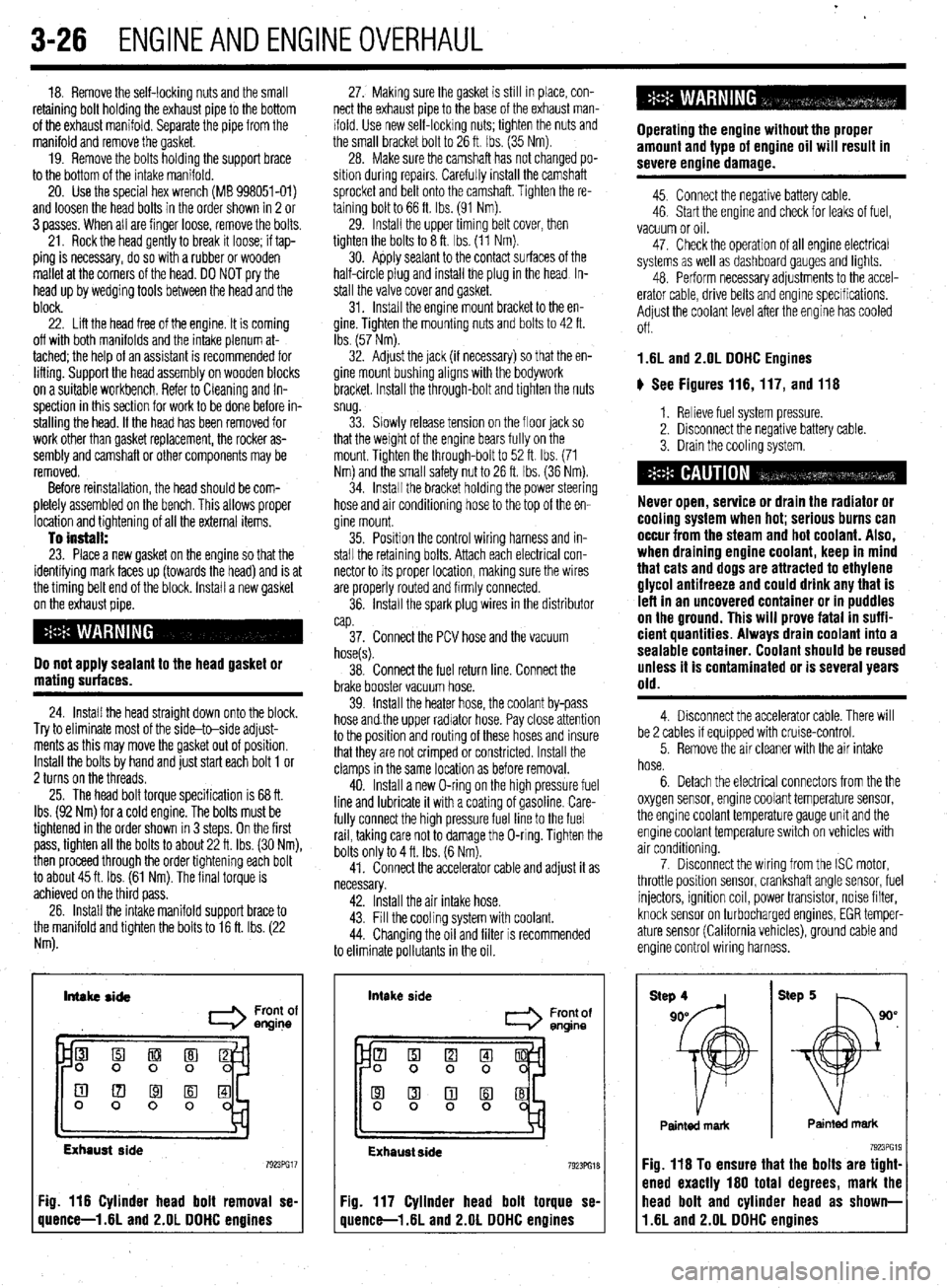

Fig. 116 Cylinder head bolt removal se-

quence-l .6L and 2.OL DDHC engines intake

side

Front of

entine

Exhaust side 7923PG18

Fig. 117 Cylinder head bolt torque se-

quence-l .6L and 2.OL DDHC engines Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

45. Connect the negative battery cable.

46. Start the engine and check for leaks of fuel,

vacuum or oil.

47. Check the operation of all engine electrical

systems as well as dashboard gauges and lights.

48. Perform necessary adjustments to the accel-

erator cable, drive belts and engine specifications.

Adjust the coolant level after the engine has cooled

Off.

1.6L and 2.OL DDHC Engines

ti See Figures 116,117, and 116

1. Relieve fuel system pressure.

2. Disconnect the negative battery cable.

3. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

4. Disconnect the accelerator cable. There will

be 2 cables if equipped with cruise-control.

5. Remove the air cleaner with the air intake

hose.

6. Detach the electrical connectors from the the

oxygen sensor, engine coolant temperature sensor,

the engine coolant temperature gauge unit and the

engine coolant temperature switch on vehicles with

air conditioning.

7. Disconnect the wiring from the ISC motor,

throttle position sensor, crankshaft angle sensor, fuel

injectors, ignition coil, power transistor, noise filter,

knock sensor on turbocharged engines, EGR temper-

ature sensor (California vehicles), ground cable and

engine control wiring harness.

Painted mark Painted mark

Fig. 116 To ensure that the bolts are tight-

ened exactly 160 total degrees, mark the

11.6L and 2.OL DDHC engines head bolt and cylinder head as shown-