bulb MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 16 of 408

G,ENERALlNFORMATlONAND MAINTENANCE l-17

Fig. 54 On

non-maintenance-free

batteries,

the fluid level can be checked through the Fig. 55 If the fluid

level

is low, add only dis-

1 case on translucent models; the cell caps 1

must be removed on other models

1 1 tilled water through the opening until the

1 level is correct

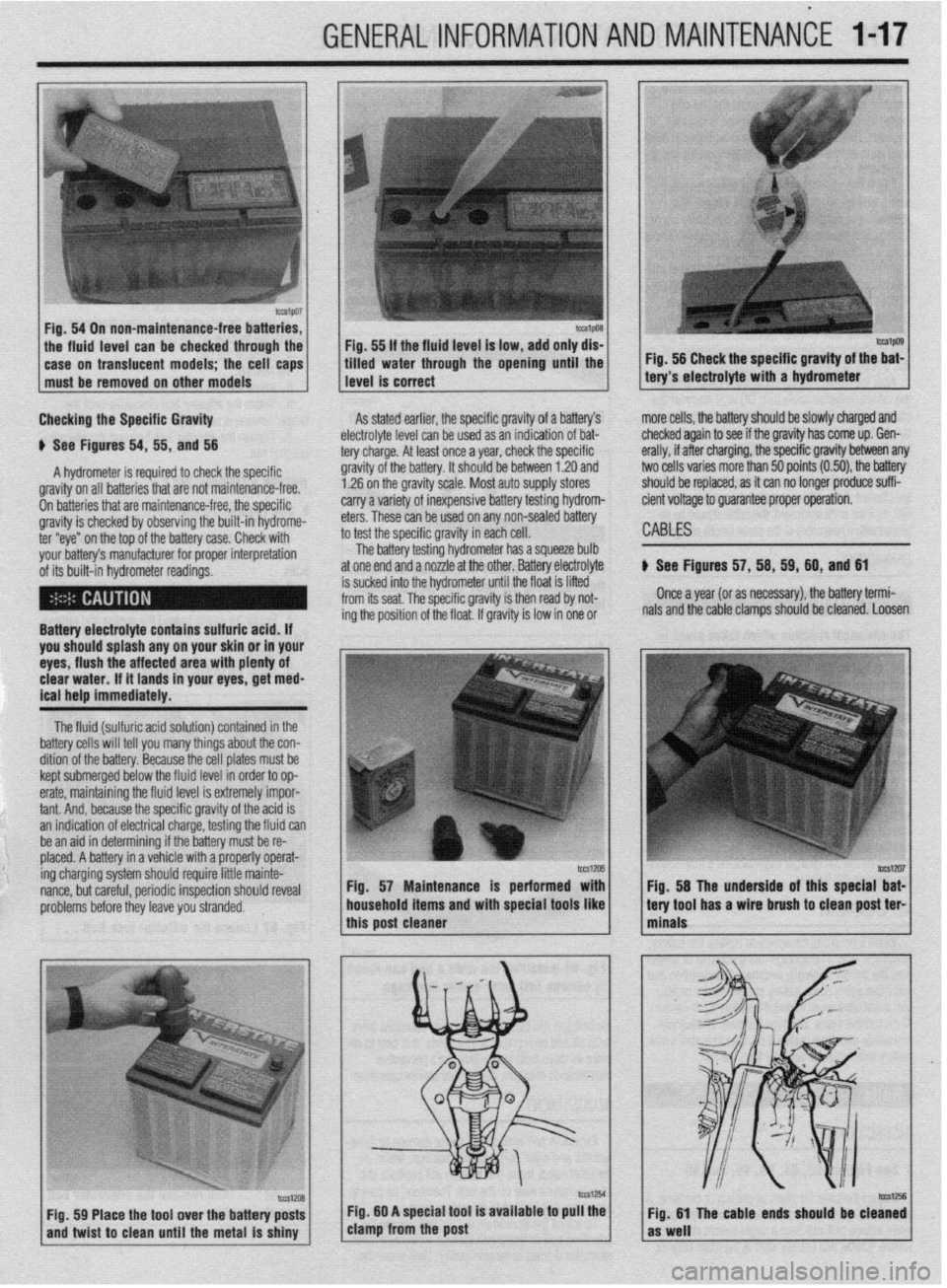

Checking the Specific Gravity

A hydrometer is required to check the specific

# See Figures 54, 55, and 56

gravity on all batteries that are not maintenance-free.

On batteries that are maintenance-free, the soecific

gravity is checked by observing the built-in hydrome-

ter “eye” on the top of the battery case. Check with

your battery’s manufacturer for proper interpretation

of its built-in hvdrometer readinas. gravity of the battery. It should be between 1.20 and As stated earlier, the specific gravity of a battery’s

electrolyte level can be u

1.26 on the gravity scale. Most auto supply stores sed as an indication of bat-

tery charge. At least once

carry a variety of inexpensive battery testing hydrom- ? a year, check the specific

eters. These can be used on any non-sealed battery

, , , ,,

.,, . .

IO rest me specmc gravny in each cell.

The battery testing hydrometer has a squeeze bulb

at one end and a nozzle at the other. Battery electrolyte

the hydrometer until the float is lifted

-he specific gravity is then read by not-

n of the float. If gravity is low in one or mg tne posrtro

Battery electrolyte contains sulfuric acid. If

you should splash any on your skin or in your

eyes, flush the affected area with plenty of

clear water. If it lands in your eyes, get med-

ical help immediately.

The fluid (sulfuric acid solution) contained in the

battery cells will tell you many things about the con-

dition of the battery. Because the cell plates must be

kept submerged below the fluid level in order to op-

erate, maintaining the fluid level is extremely impor-

tant. And. because the soecific aravitv of the acid is

an indication of electrical charge, testing the fluid can

be an aid in determining if the battery must be re-

placed. A battery in a vehicle with a properly operat-

ing charging system should require little mainte-

nance, but careful, periodic inspection should reveal

problems before they leave you stranded. Fig. 57 Maintenance is performed with

Fig. 58 The underside of this special bat-

household items and with special tools like

tery tool has a wire brush to clean post ter-

I this post cleaner

I 1 minals Fig. 56 Check the specific gravity of the bat-

tery’s electrolyte with a hydrometer

more cells, the battery should be slowly charged and

Lhecked aqain to see if the aravitv has come

UP. Gen-

erally, if affer charging, the specific gravity between any

two cells varies more than 50 points (0.50) the battery

should be replaced, as it can no longer produce suffi-

cient voltage to guarantee proper operation.

CABLES

) See Figures 57, 56, 69, 60, and 61

Once a year (or as necessary), the battery termi-

nals and the cable clamps should be cleaned. Loosen

Page 49 of 408

.~ P.X I_ - “, .- I .-., IS ” .~.I .r

2-2 ENGINE ELECTRICAL

nn

ity and trouble: shooting electrical circuits,

please refer to Section 6 of this manual.

I

The ignition system on the 1.5L, 1993-96 1.8L,

2.OL SOHC, 1994-98 2.4L SOHC, 3.OL SOHC, and

3.5L engines uses a pointless type distributor, whose

advance mechanism is controlled by the Engine Con-

trol Unit (ECU). On the 1.5L, 1.8L, 2.4L and 3.5L en-

gines, the distributor houses a built in ignition coil

and ignition power transistor. The 2.8L SOHC and

3.OL SOHC engines utilize a separate coil and tran-

sister assemblv.

When the ignition switch is turned ON, battery

voltage is applied to the ignition coil primary winding.

As the shaft of the distributor rotates, signals are

transmitted from the oowertrain control module to the

9105zp11 Fig. 1 This spark tester looks iust like a

Fiu. 2 This spark tester has an adjustable

spark plug, attach the clip to ground and air-gap for measuring spark strength and

crank the engine to check for spark testing different voltage ignition systems

.

ignition power trar rsistor. These signals activate the

power transistor to cause ignition coil primary wind-

ing current flow from the ignition coil negative termi-

nal through the power transistor to ground repeatedly.

This interruption induces high voltage in the ignition

coil secondarv windinas, which is diverted throuah

the distributor, spark plug cable and spark plug 6

ground, thus causing ignition in each cylinder.

I

SECONDARYSPARKTEST l;h.4-

! ,L ".~

'$ >,%

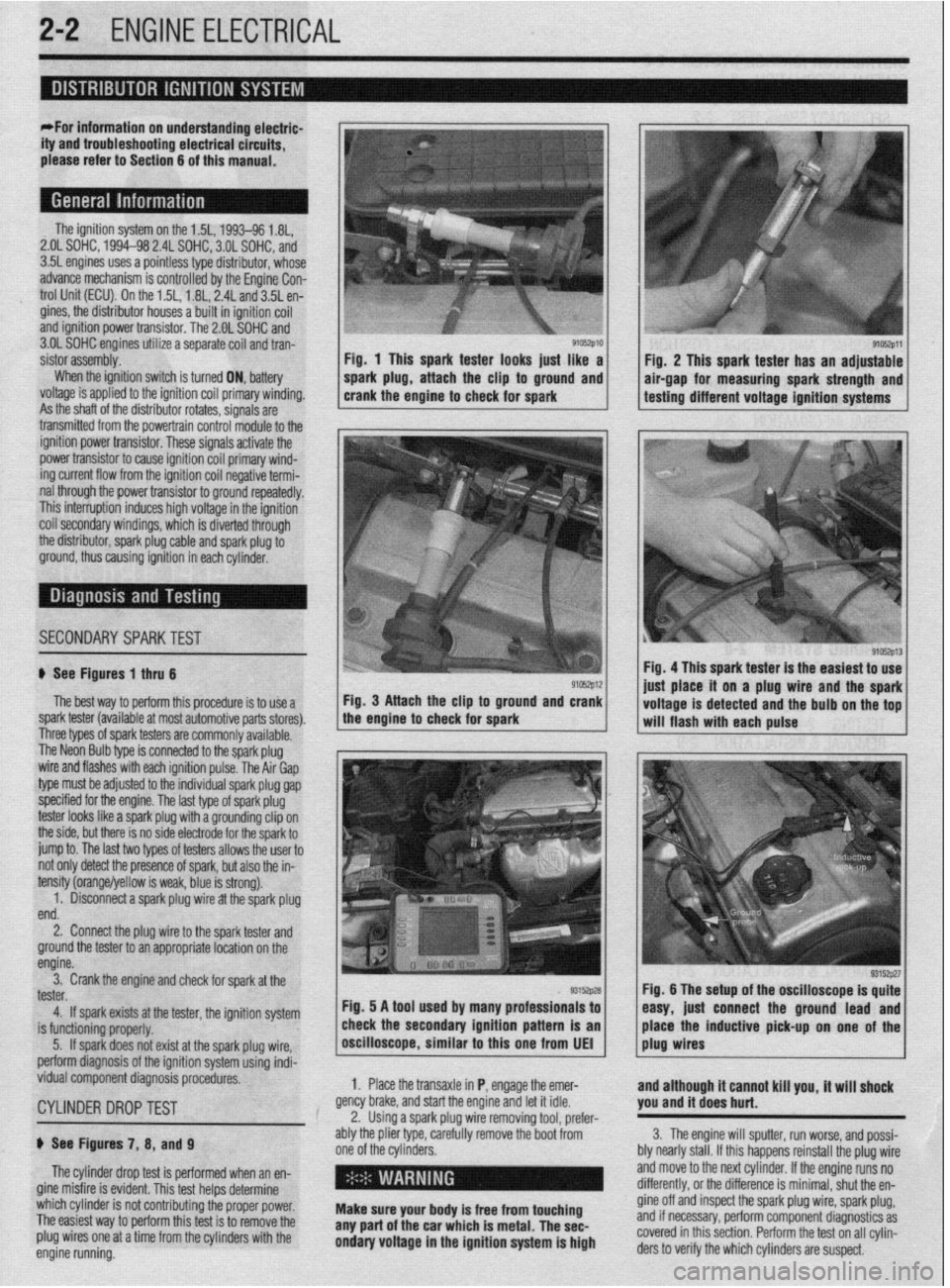

If See Figures 1 thru 6

91rJszp12 Fig. 4 This spark tester is the easiest to use

iust alace it on a plug wire and the spark

The best way to perform this procedure is to use a Fig. 3 Attach the clip to ground and crank

spark tester (available at most automotive parts stores). the engine to check for spark

I I voltage is detected and the bulb on the tof

-. will flash with each pulse

I nree types ot spark testers are commonly available.

The Neon Bulb type is connected to the spark plug

wire and flashes with each ignition pulse. The Air Gap

type must be adjusted to the individual spark plug gap

specified for the engine. The last type of spark plug

tester looks like a spark plug with a grounding clip on

the side, but there is no side electrode for the spark to

jump to. The last two types of testers allows the user to

not only detect the presence of spark, but also the in-

tensity (orange/yellow is weak, blue is strong).

1. Disconnect a spark plug wire at the spark plug

end.

2. Connect the plug wire to the spark tester and

ground the tester to an appropriate location on the

engine.

3. Crank the engine and check for spark at the

tester.

4. If spark exists at the tester, the ignition system

is functioning properly.

5. If spark does not exist at the spark plug wire,

perform diagnosis of the ignition system using indi-

vidual component diagnosis procedures,

CYLINDER DROPTEST

p See Figures 7, 8, and 9

The cylinder drop test is performed when an en-

gine misfire is evident. This test helps determine

which cylinder is not contributing the proper power.

The easiest way to perform this test is to remove the

plug wires one at a time from the cylinders with the

engine running. 1. Place the transaxle in P, engage the emer-

gency brake, and start the engine and let it idle.

2. Using a spark plug wire removing tool, prefer-

ably the plier type, carefully remove the boot from

one of the cylinders.

i ’

Make sure your body is free from touching

any part of the car which is metal. The sec-

ondary voltage in the ignition system is high and although it cannot kill you, it will shock

you and it does hurt.

3. The engine will sputter, run worse, and possi-

bly nearly stall. If this happens reinstall the plug wire

and move to the next cylinder. If the engine runs no

differently, or the difference is minimal, shut the en-

gine off and inspect the spark plug wire, spark plug,

and if necessary, perform component diagnostics as

covered in this section. Perform the test on all cylin-

ders to verify the which cylinders are suspect.

Page 61 of 408

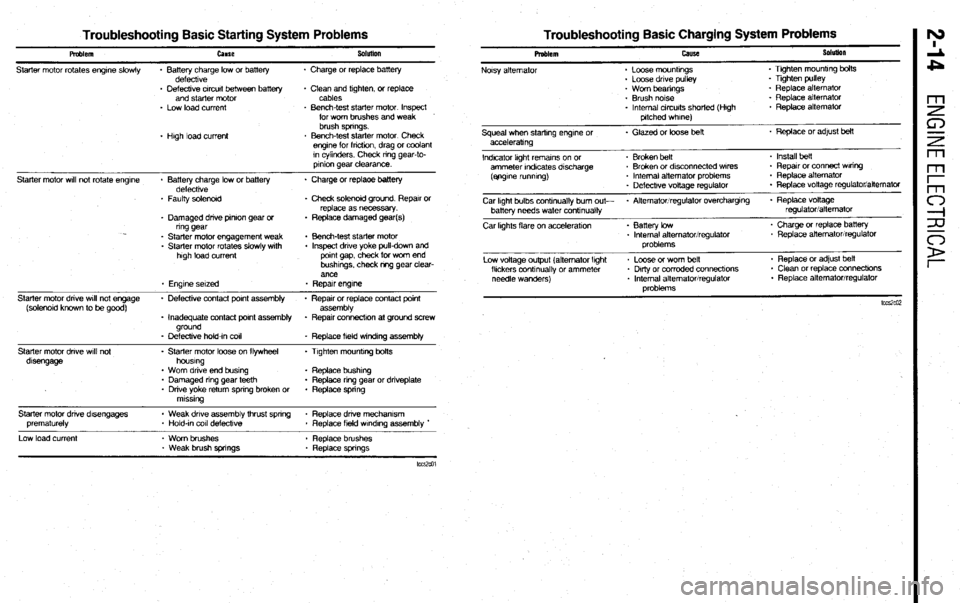

Troubleshooting Basic Starting System Problems Troubleshooting Basic Charging System Problems

Pmblem

Starter motor rotates engrne slowly cause

* Battery charge low or battery

defecttve Sobnlon

. Charge or replace battery

- Defective crrcurt between battery

and starter motor

* Low load current

* Hugh load current + Clean and ttghten, or replace

cables

* Bench-test starter motor Inspect

for wom brushes and weak

brush springs.

. Bench-test starter motor Check

engtne for fncbon, drag or coolant

rn cylinders. Check nng gear-to-

prnton gear clearance.

Starter motor wrll not rotate engrne

Starter motor dnve wrll not engage

(solenotd known to be good)

Starter motor dnve wtli not

dtsengage * Battery charge low or battery * Charge or replaoe battery

defecttve

* Faulty solenord . Check solenoid ground Reparr or

replace as necessary.

* Damaged drive pnron gear or * Replace damaged gear(s)

ring gear

* Starter motor engagement weak . Bench-test starter motor

. Starter motor rotates slowly wtth . Inspect dnve yoke pull-down and

high load current pornt gap, check for worn end

bushtngs. check m-g gear clear-

ance

. Engine setzed * Repatr engk7e

. Defecbve contact pant assembly * Reparr or replace contact pornt

assembly

. Inadequate contact pornt assembly + Repatr connectron at ground screw

ground

- Defeckve hold-In co11

* Replace field w~ndrng assembly

- Starter motor loose on flywheel . Ttghten mounttng bolts

houstng

. Worn drive end bustng . Replace bushtrg

* Damaged nng gear teeth . Replace ring gear or dnveplate

* Drive yoke return spnng broken or . Replace spnng

mtsstng

Starter motor dnve d&engages

prematurely

Low load current * Weak drive assembly thrust spnng * Replace dnve mechamsm

* Hold-tn co11 defeckve

. Replace field wtndtng assembly *

- Worn brushes . Replace brushes

* Weak brush springs * Replace spnngs Problem

Noisy alternator cause

* Loose mounbngs

. Loose drive pulley SoluIion

. Ttghten mountrng bolts

. Tighten pulley

. Worn beanngs

* Brush notse

* Internal circuits shorted (Hugh

pitched whrne) * Replace alternator

. Replace alternator

. Replace alternator

Squeal when starting engtne or . Glazed or loose belt * Replace or adfust belt

acceleratmg

Indicator light rematns on or . Broken belt . Install heft

ammeter rndrcates drscharge . Broken or dksconnected wares - Repatr or connect Waring

(ejrgrne runmng) * Internal aitemator problems * Replace alternator

. Defectrve voltage regulator . Replace vottage regulator/alternator

Car Irght bulbs contmually bum out- * Alternator/regulator overchargtng . Replace voltage

batter-v needs water conbnually regulatoriatternator

Car kghts flare on acceleratton . Battery low

. Internal alternator/regulator

problems * Charge or replace battery

. Replace alternator/regulator

Low voltage output (alternator lght

fltckers conbnually or ammeter

needle wanders) * Loose or worn belt

* Dkly or corroded connecttons

* Internal alternator/regulator

oroblems . Replace or adjust beit

. Clean or replace connecttons

* Replace alternator/regulator

Page 118 of 408

ENGINEANDENGINEOVERHAUL 3-57

Anything that generates heat and/or friction WIII

eventually burn or wear out (for example, a light bulb

generates heat, therefore its life span is limited). With

this in mind, a running engine generates tremendous

amounts of both; friction is encountered by the mov-

ing and rotating parts inside the engine and heat is

created by friction and combustion of the fuel How-

ever, the engine has systems designed to help reduce

the effects of heat and friction and provide added

longevrty. The oiling system reduces the amount of

friction encountered by the moving parts inside the

engine, while the cooling system reduces heat cre-

ated by friction and combustion If either system is

not maintained, a break-down will be inevitable.

Therefore, you can see how regular maintenance can

affect the service life of your vehicle, If you do not

drain, flush and refill your cooling system at the

proper intervals, deposits WIII begin to accumulate in

the radiator, thereby reducing the amount of heat it

can extract from the coolant The same applies to

your oil and filter; If it is not changed often enough it

becomes laden with contaminates and is unable to

properly lubricate the engine. This increases friction

and wear.

There are a number of methods for evaluating the

condition of your engine. A compression test can re-

veal the condition of your pistons, piston rings,

cylinder bores, head gasket(s), valves and valve

seats. An oil pressure test can warn you of possible

engine bearing, or oil pump failures. Excessrve oil

consumption, evidence of oil in the engine air intake

area and/or bluish smoke from the tailpipe may indi-

cate worn piston rings, worn valve guides and/or

valve seals. As a general rule, an engine that uses no

more than one quart of oil every 1000 miles is in

good condition. Engines that use one quart of oil or

more in less than 1000 miles should first be checked

for oil leaks. If any oil leaks are present, have them

fixed before determining how much oil is consumed

by the engine, especrally if blue smoke is not visible

at the tailpipe

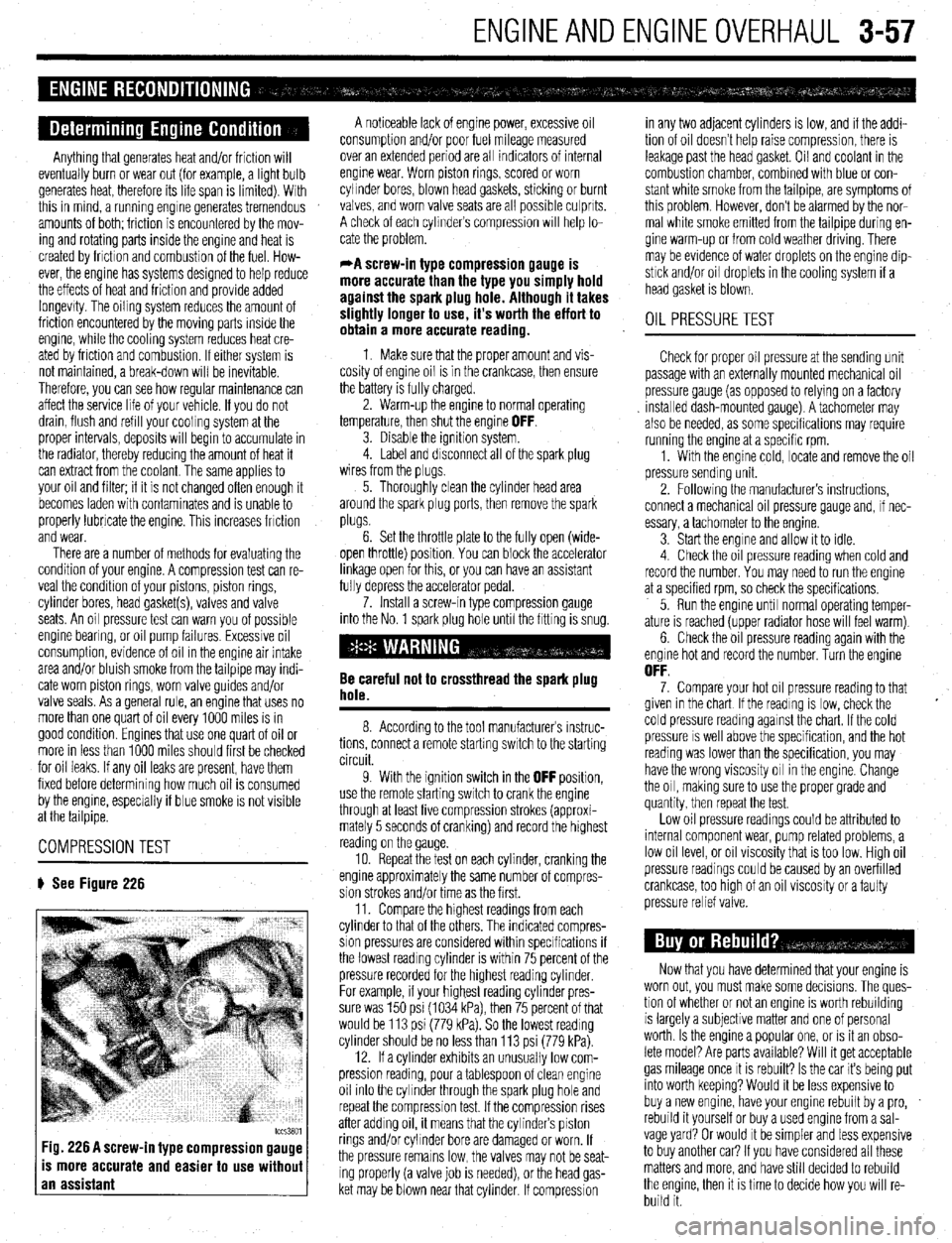

COMPRESSION TEST

# See Figure 226

tccs3801 Fig. 226 A screw-in type compression gauge

is more accurate and easier to use without

an assistant

A noticeable lack of engine power, excessive oil

consumption and/or poor fuel mileage measured

over an extended period are all indicators of internal

engine wear. Worn piston rings, scored or worn

cylinder bores, blown head gaskets, sticking or burnt

valves, and worn valve seats are all possible culprits.

A check of each cylinders compression WIII help lo-

cate the problem.

*A screw-in type compression gauge is

more accurate than the type you simply hold

against the spark plug hole. Although it takes

slightly longer to use, it’s worth the effort to

obtain a more accurate reading.

1 Make sure that the proper amount and vis-

cosity of engine oil is in the crankcase, then ensure

the battery is fully charged.

2. Warm-up the engine to normal operating

temperature, then shut the engine

OFF. 3. Disable the ignition system.

4. Label and disconnect all of the spark plug

wires from the plugs,

5. Thoroughly clean the cylinder head area

around the spark plug ports, then remove the spark

plugs.

6. Set the throttle plate to the fully open (wide-

open throttle) position You can block the accelerator

linkage open for this, or you can have an assistant

fully depress the accelerator pedal.

7. Install a screw-in type compression gauge

into the No. 1 spark plug hole until the fitting is snug.

Be careful not to crossthread the spark plug

hole.

8. According to the tool manufacturers instruc-

tions, connect a remote starting switch to the starting

circuit.

9. With the ignition switch in the

OFF position,

use the remote starting switch to crank the engine

through at least five compression strokes (approxi-

mately 5 seconds of cranking) and record the highest

reading on the gauge

10. Repeat the test on each cylinder, cranking the

engine approximately the same number of compres-

sion strokes and/or time as the first.

11. Compare the hrghest readings from each

cylinder to that of the others. The indicated compres-

sion pressures are considered within specifications if

the lowest reading cylinder is within 75 percent of the

pressure recorded for the highest reading cylinder

For example, if your highest reading cylinder pres-

sure was 150 psi (1034 kPa), then 75 percent of that

would be 113 psi (779 kPa). So the lowest reading

cylinder should be no less than 113 psi (779 kPa).

12. If a cylinder exhibits an unusually low com-

pression reading, pour a tablespoon of clean engine

oil into the cylinder through the spark plug hole and

repeat the compression test. If the compression rises

after adding oil, it means that the cylinder’s piston

rings and/or cylinder bore are damaged or worn, If

the pressure remains low, the valves may not be seat-

ing properly (a valve job is needed), or the head gas-

ket may be blown near that cylinder. If compression in any two adjacent cylinders is low, and if the addi-

tion of oil doesn’t help raise compression, there is

leakage past the head gasket. Oil and coolant in the

combustion chamber, combined with blue or con-

stant white smoke from the tailpipe, are symptoms of

this problem. However, don’t be alarmed by the nor-

mal white smoke emitted from the tailpipe during en-

gine warm-up or from cold weather driving. There

may be evidence of water droplets on the engine dip-

stick and/or oil droplets in the cooling system if a

head gasket is blown.

OIL PRESSURETEST

Check for proper oil pressure at the sending unit

passage with an externally mounted mechanical oil

pressure gauge (as opposed to relying on a factory

Installed dash-mounted gauge). A tachometer may

also be needed, as some specifications may require

running the engine at a specific rpm.

1. With the engine cold, locate and remove the oil

pressure sending unit.

2. Followrng the manufacturers instructions,

connect a mechanical oil pressure gauge and, if nec-

essary, a tachometer to the engine.

3 Start the engine and allow it to idle.

4 Check the oil pressure reading when cold and

record the number. You may need to run the engine

at a specified rpm, so check the specifications,

5. Run the engine until normal operating temper-

ature is reached (upper radiator hose will feel warm)

6. Check the oil pressure reading again with the

engine hot and record the number. Turn the engine

OFF. 7. Compare your hot oil pressure reading to that

given in the chart If the reading is low, check the

cold pressure reading against the chart. If the cold

pressure IS well above the specification, and the hot

reading was lower than the specification, you may

have the wrong viscosity oil in the engine. Change

the oil, making sure to use the proper grade and

quantity, then repeat the test.

Low oil pressure readings could be attributed to

internal component wear, pump related problems, a

low oil level, or oil viscosity that is too low. High oil

pressure readings could be caused by an overfilled

crankcase, too htgh of an oil viscosity or a faulty

pressure relief valve.

Now that you have determined that your engine is

worn out, you must make some decisions. The ques-

tion of whether or not an engine IS worth rebuilding

is largely a subjective matter and one of personal

worth. Is the engine a popular one, or IS it an obso-

lete model? Are parts available? Will it get acceptable

gas mileage once It is rebuilt? Is the car its being put

into worth keeping? Would it be less expensive to

buy a new engine, have your engine rebuilt by a pro,

rebuild it yourself or buy a used engine from a sal-

vage yard? Or would It be simpler and less expensive

to buy another car? If you have considered all these

matters and more, and have still decided to rebuild

the engine, then it is time to decide how you will re-

build it.

Page 169 of 408

4-26 DRIVEABILITYAND EMISSIONS CONTROLS

The Powertrain Control Module (PCM) monitors

the signals of input and output sensors, some all the

time and others at certain times and processes each

signal. When the PCM notices that an irregularity has

continued for a specified time or longer from when

the irregular signal was initially monitored, the PCM

judges that a malfunction has occurred and will

memorize the malfunction code. The code is then

stored in the memory of the PCM and is accessible

through the data link (diagnostic connector) with the

use of an electronic scan tool or a voltmeter.

CHECK ENGINE/MALFUNCTION

INDICATOR LIGHT

Among the on-board diagnostic items, a check

engine/malfunction indicator light comes on to notify

the driver of a emission control component irregular-

ity. If the irregularity detected returns to normal or the

PCM judges that the component has returned to nor-

mal, the check engine/malfunction indicator light will

be turned off Moreover, if the ignition is turned OFF

and then the engine is restarted, the check

engine/malfunction indicator light will not be turned

on unttl a malfunction is detected.

The check engine/malfunction indicator light will

come on immediately after the ignition switch is

turned ON. The light should stay lit for 5 seconds

and then will go off. This Indicates that the check en-

gine/malfunction indicator lamp is operating nor-

mally. This does not signify a problem with the sys-

tem.

*The check engine/malfunction indicator

lamp will come on when the terminal for the

ignition timing adjustment is shorted to

ground. Therefore, it is not abnormal that the

light comes on even when the terminal for ig-

nition timing is shorted at time of ignition

timing adjustment.

To test the light, perform the following:

1. Turn the ignition switch ON. Inspect the check

engine/malfunction indicator lamp for Illumination.

2. The light should be lit for 5 seconds and then

should go out.

3. If the lamp does not illuminate, check for open

circuit In the harness, blown fuse or blown bulb.

SERVICE PRECAUTIONS

l Before attachrng or detaching the PCM harness

connectors, make sure the ignition switch is OFF and

the negative battery cable is disconnected to avoid

the possibility of damage to the PCM.

l When performing PCM input/output signal di-

agnosis, remove the pin terminal retainer from the

connectors to make it easier to insert tester probes

into the connector.

l When attaching or detaching pin connectors ,

from the PCM, take care not to bend or break any pin

terminals. Check that there are no bends or breaks on

PCM pin terminals before attempting any connec-

tions.

l Before replacing any PCM, perform the PCM

input/output signal diagnosis to make sure the PCM

is functioning properly.

l When measuring supply voltage of PCM-con-

trolled components with a circuit tester, separate 1

tester probe from another. If the 2 tester probes acci-

dentally make contact with each other during mea-

surement, a short circuit WIII result and damage the

PCM.

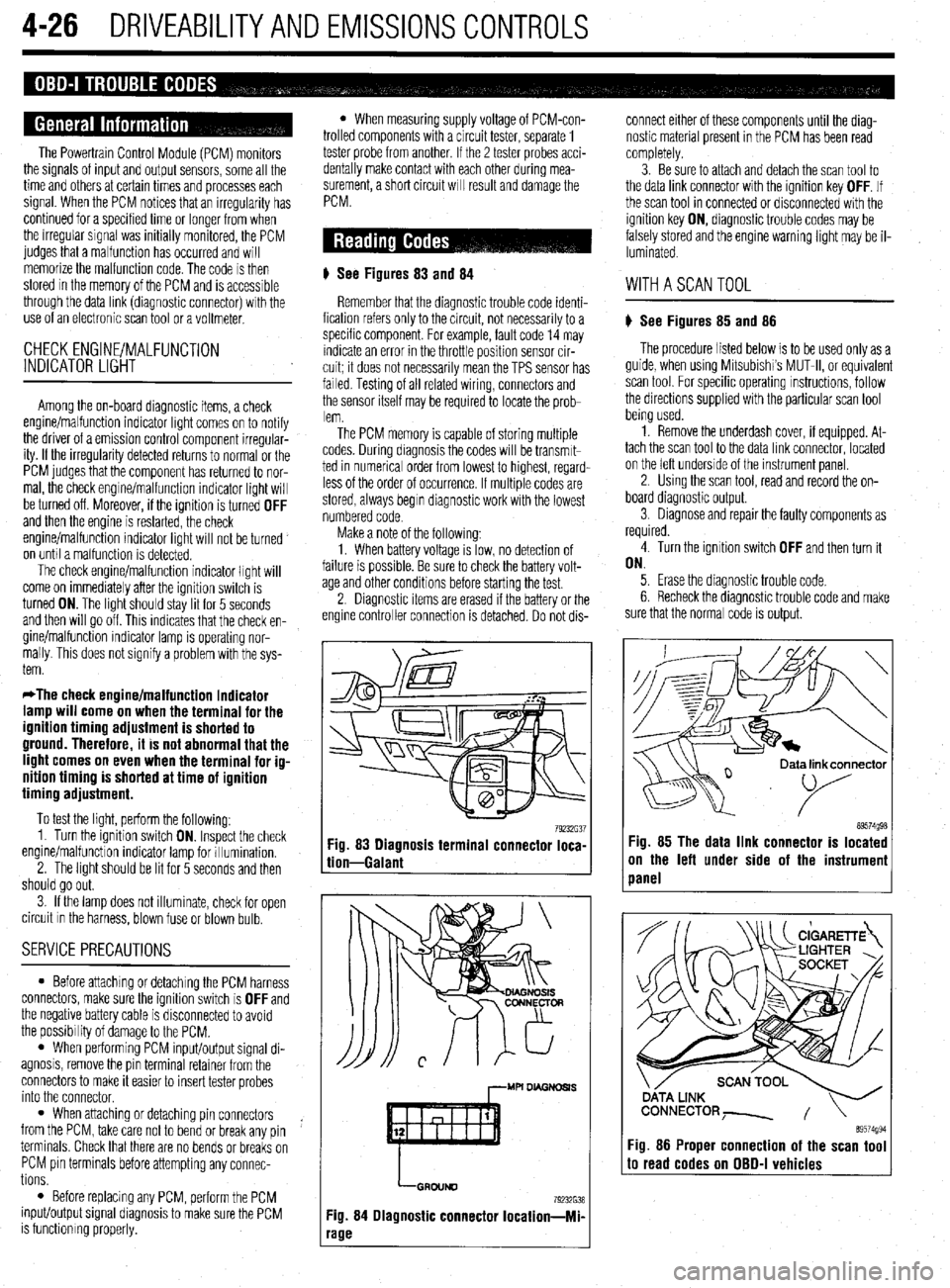

# See Figures 83

and 84

Remember that the diagnostic trouble code identi-

fication refers only to the circuit, not necessarily to a

specific component. For example, fault code 14 may

indicate an error in the throttle position sensor cir-

cuit; it does not necessarily mean the TPS sensor has

failed Testing of all related wiring, connectors and

the sensor itself may be required to locate the prob-

lem.

The PCM memory is capable of storing multiple

codes. During diagnosis the codes will be transmlt-

ted in numerical order from lowest to highest, regard-

less of the order of occurrence. If multiple codes are

stored, always begin diagnostic work with the lowest

numbered code

Make a note of the following:

1. When battery voltage IS low, no detection of

failure is possible. Be sure to check the battery volt-

age and other conditions before starting the test.

2. Diagnostic items are erased if the battery or the

engine controller connection is detached. Do not dis- connect either of these components until the diag-

nostic material present in the PCM has been read

completely.

3. Be sure to attach and detach the scan tool to

the data link connector with the ignition key OFF. If

the scan tool in connected or disconnected with the

ignition key ON, diagnostic trouble codes may be

falsely stored and the engine warning light may be il-

luminated. WITHASCANTOOL

) See Figures 85 and 86

The procedure listed below is to be used only as a

guide, when using Mitsubishi’s MUT-II, or equivalent

scan tool. For specific operating instructions, follow

the directions supplied with the particular scan tool

bemg used.

1. Remove the underdash cover, if equipped. At-

tach the scan tool to the data link connector, located

on the left underside of the instrument panel.

2. Using the scan tool, read and record the on-

board diagnostic output.

3. Diagnose and repair the faulty components as

required

4. Turn the ignition switch OFF and then turn it

ON.

5. Erase the diagnostic trouble code.

6 Recheck the diaanostic trouble code and make

sure that the normal &de is output.

79232G37 89574g98 Fig. 83 Diagnosis terminal connector loca-

tion-Galant Fig. 85 The data link connector is located

on the left under side of the instrumeni

panel

,--MU DL4GNDSl.S

LGRDIJND

79232638

Fig. 84 Diagnostic connector Iocation-Mi-

‘age

ata link connector

89574994 Fig. 86 Proper connection of the scan tool to read codes on OBD-I vehicles

Page 205 of 408

6-2 CHASSIS ELECTRICAL

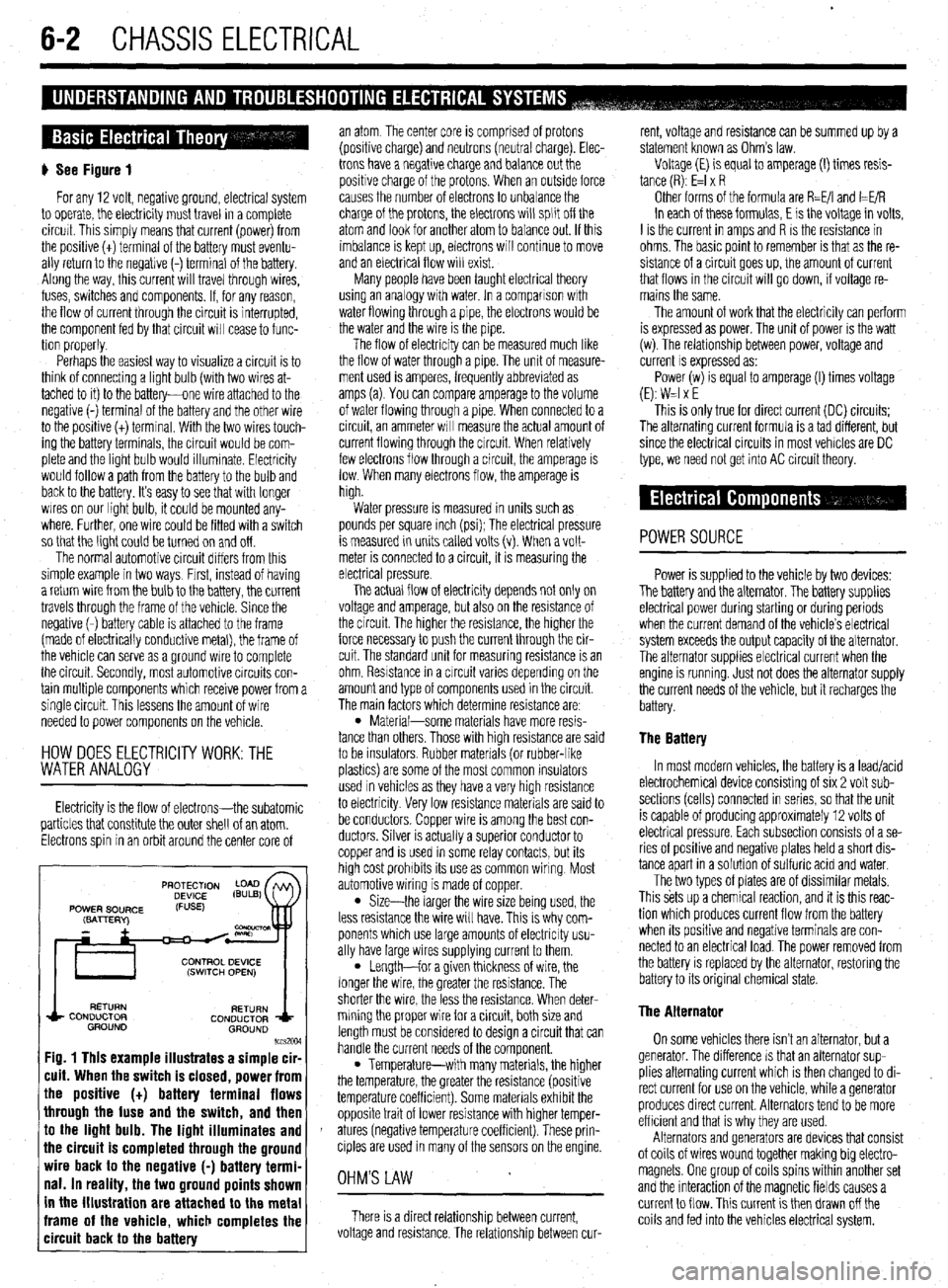

) See Figure 1

For any 12 volt, negative ground, electrical system

to operate, the electricity must travel in a complete

circurt. This simply means that current (power) from

the posibve (t) terminal of the battery must eventu-

ally return to the negative (-) terminal of the battery.

Along the way, this current will travel through wires,

fuses, switches and components. If, for any reason,

the flow of current through the circuit is interrupted,

the component fed by that circuit will cease to func-

tion properly.

Perhaps the easiest way to visualize a circuit is to

think of connecting a light bulb (with two wires at-

tached to it) to the battery-one wire attached to the

negative (-) terminal of the battery and the other wire

to the positive (t) terminal. With the two wires touch-

ing the battery terminals, the circuit would be com-

plete and the light bulb would illummate. Electricity

would follow a path from the battery to the bulb and

back to the battery. It’s easy to see that wrth longer

wires on our light bulb, it could be mounted any-

where. Further, one wire could be fitted with a switch

so that the light could be turned on and off.

The normal automotive circuit differs from this

simple example in two ways, Frrst, instead of having

a return wire from the bulb to the battery, the current

travels through the frame of the vehicle. Since the

negative (-) battery cable is attached to the frame

(made of electrically conductive metal), the frame of

the vehicle can serve as a ground wire to complete

the circuit. Secondly, most automotive circuits con-

tain multiple components which receive power from a

single circuit. This lessens the amount of wire

needed to power components on the vehicle.

HOW DOES ELECTRlClTYWORK:THE

WATER ANALOGY

Electricity is the flow of electrons-the subatomic

particles that constitute the outer shell of an atom.

Electrons spin in an orbit around the center core of

RETURN

RETURN

CONDUCTOR

CONDUCTOR

GROUND

GROUND

lccs2w

Fig. 1 This example illustrates a simple cir-

cuit. When the switch is closed, power from

the positive (t) battery terminal flows

through the fuse and the switch, and then

to the light bulb. The light illuminates and

the circuit is completed through the ground

wire back to the negative (-) battery termi-

nal. In reality, the two ground points shown

in the illustration are attached to the metal

frame of the vehicle, which completes the

circuit back to the battery

an atom The center core is comprised of protons

(positive charge) and neutrons (neutral charge). Elec-

trons have a negative charge and balance

out the

positive charge of the protons. When an outside force

causes the number of electrons to unbalance the

charge of the protons, the electrons will split off the

atom and look for another atom to balance out. If this

imbalance is kept up, electrons will continue to move

and an electrical flow will exist.

Many people have been taught electrical theory

using an analogy with water. In a comparison wrth

water flowing through a pipe, the electrons would be

the water and the wire is the pipe.

The flow of electricity can be measured much like

the flow of water through a pipe. The unit of measure-

ment used is amperes, frequently abbreviated as

amps (a). You can compare amperage to the volume

of water flowing through a pipe. When connected to a

circuit, an ammeter WIII measure the actual amount of

current flowing through the circuit. When relatively

few electrons flow through a circuit, the amperage is

low. When many electrons flow, the amperage is

high.

Water pressure is measured in units such as

pounds per square inch (psi); The electrical pressure

is measured in unrts called volts (v). When a volt-

meter is connected to a circuit, it is measuring the

electrical pressure.

The actual flow of electricity depends not only on

voltage and amperage, but also on the resistance of

the circuit The higher the resistance, the higher the

force necessary to push the current through the cir-

cuit. The standard unit for measuring resistance is an

ohm. Resistance in a crrcuit varies dependmg on the

amount and type of components used in the circuit.

The main factors which determine resistance are:

l Material-some materials have more resis-

tance than others Those with high resistance are said

to be insulators Rubber materials (or rubber-like

plashcs) are some of the most common insulators

used in vehicles as they have a very high resistance

to electricity Very low resistance materials are said to

be conductors. Copper wire is among the best con-

ductors. Silver is actually a superior conductor to

copper and is used in some relay contacts, but its

high cost prohibits its use as common wiring Most

automotive wiring is made of copper.

l Size-the larger the wire size being used, the

less resistance the wire will have. This IS why com-

ponents which use large amounts of electricity usu-

ally have large wires supplying current to them.

l Length-for a given thickness of wire, the

longer the wire, the greater the resistance. The

shorter the wire, the less the resistance. When deter-

mining the proper wire for a circuit, both size and

length must be considered to design a circuit that can

handle the current needs of the component.

l Temperature-with many materials, the higher

the temperature, the greater the resistance (positive

temperature coefficient). Some materials exhibit the

opposite trait of lower resistance with higher temper-

atures (negative temperature coefficient). These prin-

ciples are used in many of the sensors on the engine

OHM'S LAW

There is a direct relationship between current,

voltage and resistance. The relationship between cur- rent, voltage and resistance can be summed up by a

statement known as Ohm’s law.

Voltage (E) is equal to amperage (I) times resis-

tance (R): E=l x R

Other forms of the formula are R=E/I and I=E/R

In each of these formulas, E is the voltage in volts,

I is the current in amps and R IS the resistance in

ohms. The basic point to remember is that as the re-

sistance of a circuit goes up, the amount of current

that flows in the circuit will go down, if voltage re-

mains the same.

The amount of work that the electricity can perform

is expressed as power. The unit of power is the watt

(w). The relationship between power, voltage and

current

IS expressed as:

Power(w) is equal to amperage (I) times voltage

(E): W=l x E

This is only true for direct current (DC) circuits:

The alternating current formula is a tad different, but

since the electrical circuits in most vehicles are DC

type, we need not get into AC circuit theory.

POWERSOURCE

Power is supplied to the vehicle by two devices:

The battery and the alternator. The battery supplies

electrical power during starting or during periods

when the current demand of the vehicle’s electrical

system exceeds the output capacity of the alternator.

The alternator supplies electrical current when the

engine is running

Just not does the alternator supply

the current needs of the vehicle, but it recharges the

battery.

The Battery

In most modern vehicles, the battery is a lead/acid

electrochemical device consisting of six 2 volt sub-

sections (cells) connected in series, so that the unit

is capable of producing approximately 12 volts of

electrical pressure. Each subsection consists of a se-

ries of positive and negative plates held a short dis-

tance apart in a solutron of sulfuric acid and water.

The two types of plates are of dissimilar metals,

This sets up a chemrcal reaction, and it is this reac-

tion which produces current flow from the battery

when Its positive and negattve terminals are con-

nected to an electrical load. The power removed from

the battery is replaced by the alternator, restoring the

battery to its original chemical state.

The Alternator

On some vehicles there isn’t an alternator, but a

generator. The difference IS that an alternator sup-

plies alternating current which is then changed to di-

rect current for

use on the vehicle, while a generator

produces direct current. Alternators tend to be more

efficient and that is why they are used.

Alternators and generators are devices that consist

of coils of wires wound together making big electro-

magnets. One group of coils spins within another set

and the interaction of the magnetic fields causes a

current to flow. This current is then drawn off the

coils and fed into the vehicles electrical system.

Page 222 of 408

CHASSIS ELECTRICAL 6-19

1. Disconnect the negative battery cable.

are all built into 1 multi-function combination

2. Remove the instrument cluster, as outlined 1. Disconnect the negative battery cable.

earlier in this section. switch that is mounted on the steering col-

2. Using a small screwdriver or other suitable

umn. Refer to Section 8 for procedures re-

3. Remove the retaining screws for the instrument tool, carefully pry the retaining clips from either side

garding the combination switch.

cluster lens and cover assembly. Remove the cover of the switch trim plate.

3.

and lens. Carefully pull the switch and trim plate out of

,

4. Remove the retaining screws for the gauge or the instrument panel.

4. Detach the electrical connectors and remove

warning lamp to be replaced, then remove the gauge

the switch.

or warning lamp.

REMOVAL&INSTALLATION : 5. The installation is the reverse of removal.

To install:

5. Place the gauge or warning lamp into place

and tighten the retaining screws. 1. Disconnect the negative battery cable.

6. Install the instrument cluster lens and cover 2. Using a suitable prytool, disengage the switch

assembly. retaining tabs.

REMOVAL &INSTALLATION 7. Install the instrument cluster. 3. Gently pull the switch from the instrument

8. Connect the negative battery cable. panel.

4. Detach the electrical connector and remove the *On all models the headlights, turn signals,

switch. and on some models, the cruise control func-

5. The installation is the reverse of removal. tion are all built into 1 multi-function combi-

nation switch that is mounted on the steerinq

REMOVAL &INSTALLATION column. Refer to Section 8 for procedures 6

garding the combination switch.

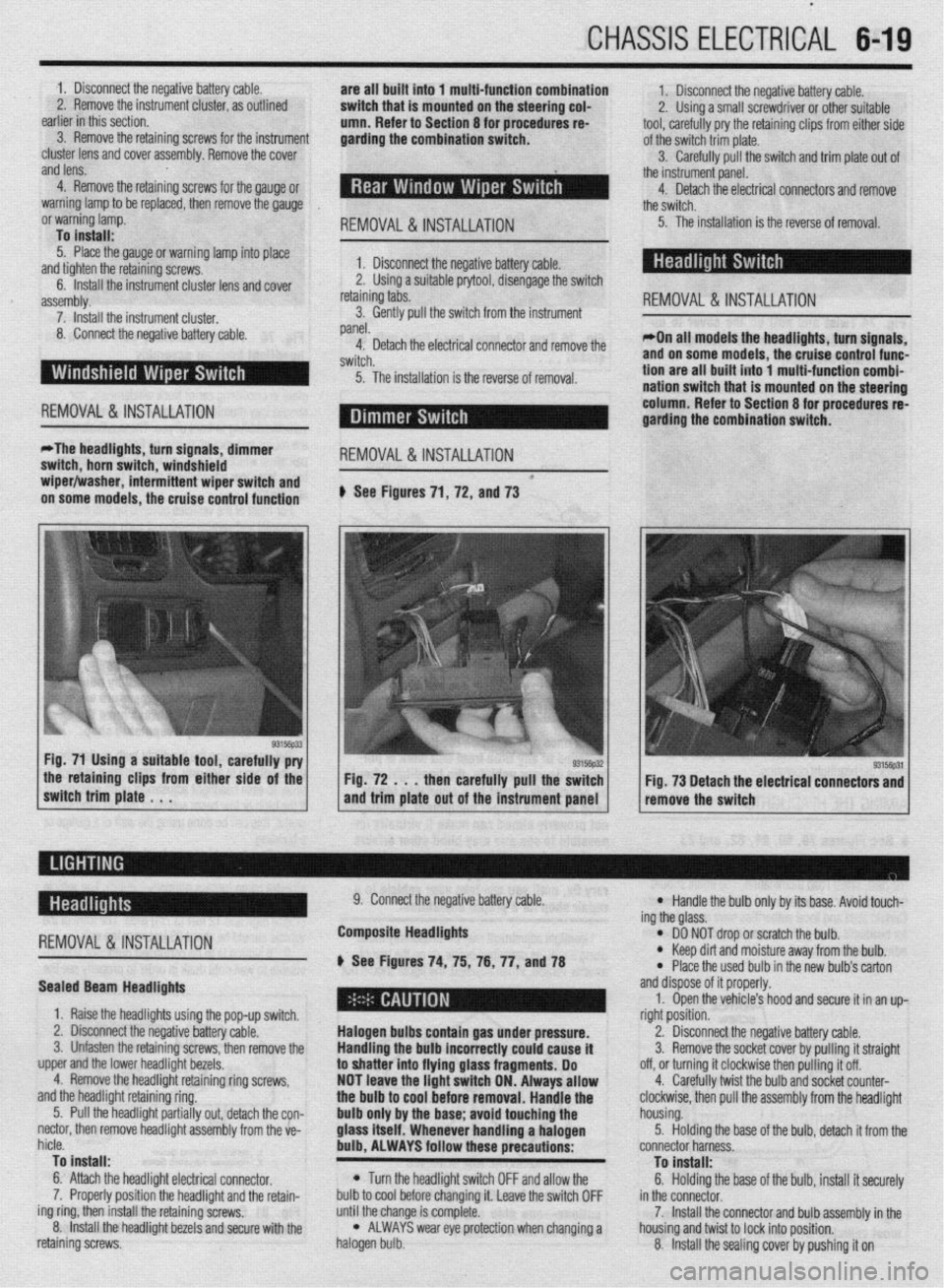

*The headlights, turn signals, dimmer

switch, horn switch, windshield

REMOVAL &INSTALLATION

wiper/washer, intermittent wiper switch and *

on some models, the cruise control function # See Figures 71, 72, and 73

the retaining clips from either side of the

switch trim plate . . . Fig. 72 . . . then carefully pull the switch

and trim plate out of the instrument panel Fig. 73 Detach the electrical connectors and

remove the switch

-

REMOVAL &INSTALLATION

Sealed Beam Headlights

1. Raise the headlights using the pop-up switch.

2. Disconnect the negative battery cable.

3. Unfasten the retaining screws, then remove the

upper and the lower headlight bezels.

4. Remove the headlight retaining ring screws,

and the headlight retaining ring.

5. Pull the headlight partially out, detach the con-

nectar, then remove headlight assembly from the ve-

hicle.

To install:

6. Attach the headlight electrical connector.

7. Properly position the headlight and the retain-

ing ring, then install the retaining screws.

8. Install the headlight bezels and secure with the

retaining screws. 9. Connect the negative battery cable.

Composite Headlights

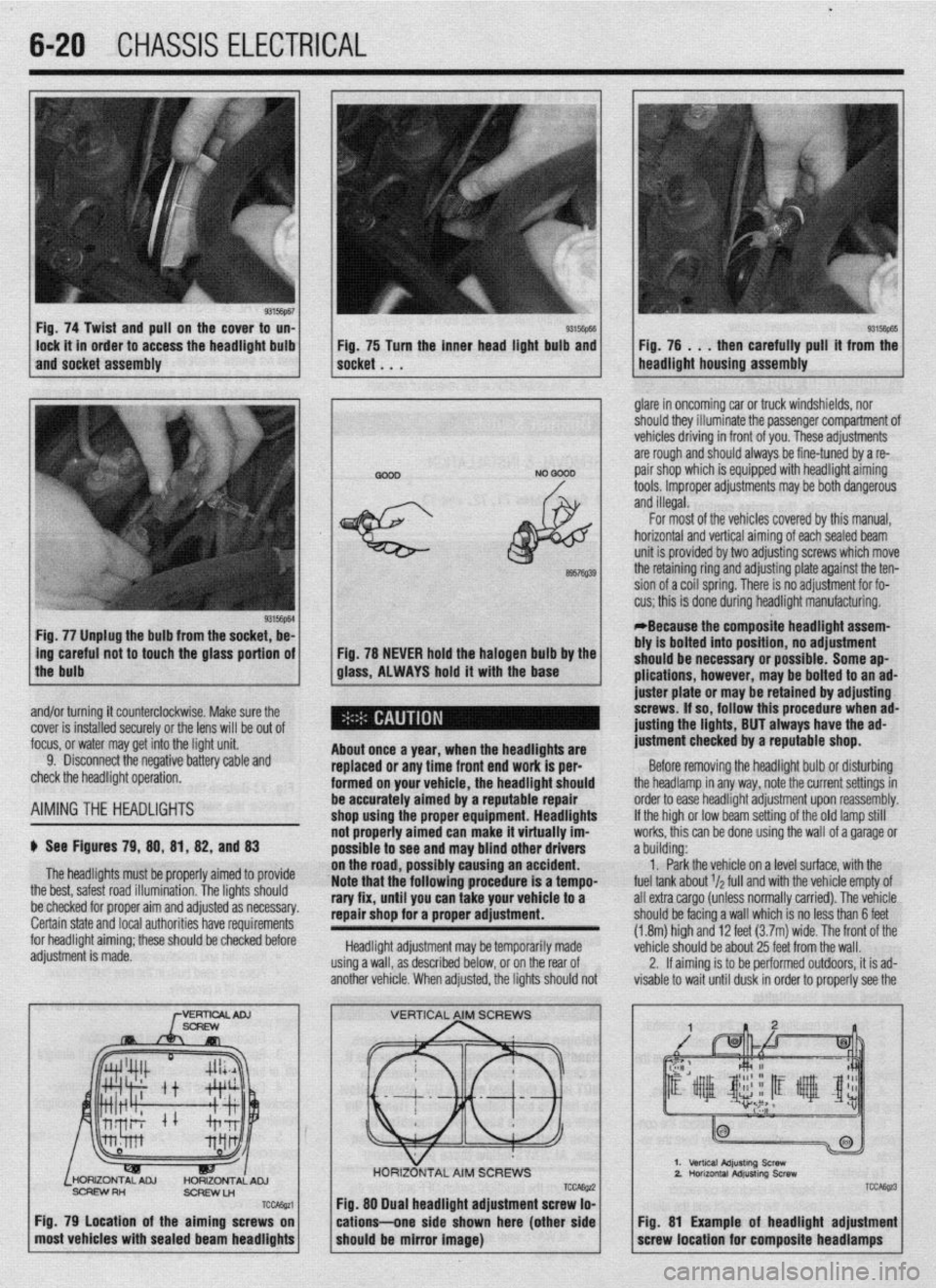

6 See Figures 74, 75, 76, 77, anU78

Halogen bulbs contain gas under pressure.

Handling the

bulb incorrectly could cause it

to shatter into flying glass fragments. Do

NOT leave the light switch ON. Always allow

the bulb to cool before removal. Handle the

bulb only by the base; avoid touching the

glass itself. Whenever handling a halogen

bulb, ALWAYS follow these precautions:

l Turn the headlight switch OFF and allow the

bulb to cool before changing it. Leave the switch OFF

until the change is complete.

l ALWAYS wear eye protection when changing a

halogen bulb.

l Handle the bulb only by its base. Avoid touch-

ing the glass.

l DO NOT drop or scratch the bulb. l Keep dirt and moisture away from the bulb.

* Place the used bulb in the new bulb’s carton

and dispose of it properly.

1. Open the vehicle’s hood and secure it in an up-

right position.

2. Disconnect the negative battery cable.

3. Remove the socket cover by pulling it straight

off, or turning it clockwise then pulling it off.

4. Carefully twist the bulb and socket counter-

clockwise, then pull the assembly from the headlight

housing.

5. Holding the base of the bulb, detach it from the

connector harness.

To install:

6. Holding the base of the bulb, install it securely

in the connector.

7. Install the connector and bulb assembly in the

housing and twist to lock into position.

8. Install the sealing cover by pushing it on

Page 223 of 408

.

6-20 CHASSIS ELECTRICAL

Fig. 74 Twist and pull on the cover to un-

lock it in order to access the headlight bulb

and socket assembly 93Mm Fig, 75 Turn the inner head light bulb and then carefully pull’ it from the

NO 0000 . glare in oncoming car or truck windshields, nor

should they illuminate the passenger compartment of

vehicles driving in front of you. These adjustments

are rough and should always be fine-tuned by a re-

pair shop which is equipped with headlight aiming

tools. Improper adjustments may be both dangerous

and illegal.

Fig. 77 Unplug the bulb from the socket, be-

L

ing careful not to touch the glass portion of

the bulb

I

6957Q39

Fig. 78 NEVER hold the halogen bulb by the

glass, ALWAYS hold it with the base

,

About once a year, when the headllgftts are

replaced or any time front end work is per-

formed on your vehicle, the headlight should

be accurately aimed by a reputable repair

shop uslng the proper equipment. Headlights

not properly aimed can make it virtually im-

possible to see ar Id may blind other drivers

ibly causing an accident.

Note that the’following procedure is a tempo-

rary fix, until you can take your vehicle to a

repair shop for a proper adjustment.

Headlight adjustment may be temporarily made

using a wall, as described below, or on the rear of

another vehicle. When adjusted, the lights should not For most of the vehicles covered by this manual,

horizontal and vertical aiming of eachsealed beam

unit is provided by two adjusting screws which move

the retaining ring and adjusting plate against the ten-

sion of a coil spring. There is no adjustment for fo-

cus; this is done during headlight manufacturing.

*Because the composite headlight assem-

bly is bolted into position, no adjustment

should be necessary or possible. Some ap-

plications, however, may be bolted to an ad-

juster plate or may be retained by adjusting

screws. If so, follow this procedure when ad-

@sting the lights, BUT always have the ad-

justment checked by a reputable shop.

Before removing the headlight bulb or disturbing

the headlamp in any way, note the current settings in

order to ease headlight adjustment upon reassembly.

If the high or low beam setting of the old lamp still

works, this can be done using the wall of a garage or

a building:

1. Park the vehicle on a level surface, with the

fuel tank about r/a full and with the vehicle empty of

all extra cargo (unless normally carried). The vehicle

should be facing a wall which is no less than 6 feet

(1.8m) high and 12 feet (3.7m) wide. The front of the

vehicle should be about 25 feet from the wall.

2. If aiming is to be performed outdoors, it is ad-

visable to wait until dusk in order to properly see the

% and/or turning it counterclockwise. Make sure the

cover is installed securely or the lens will be out of

focus, or water may get into the light unit.

9. Disconnect the negative battery cable and

check the headlight operation.

AIMINGTHE HEADLIGHTS

$ See Figures 79, 88, 81, 82, and 83

The headlights must be proper’ ’ ’ ’

the best, safest road illumination. ’ ’

ly armea IO provrae

The lights should

:.__1__1 __ - -___-_-. on the road, POSSI

be checked for proper aim and adfusreu as IlweSYdly. Certain state and local authorities have requirements

for headlight aiming; these should be checked before

adjustment is made.

SCFEWRH

ScFlEwLn

TCcAssa

Fig. 79 Location of the aiming screws on

most vehicles with sealed beam headlights

TCCAE@ Fig. 88 Dual headlight adjustment screw lo-

cations--one side shown here (other side

should be mirror image)

2.

TCC&z3

Fig. 81 Example of headlight adjustment

screw location for composite headlamps

Page 224 of 408

CHASSIS ELECTRICAL 6-21

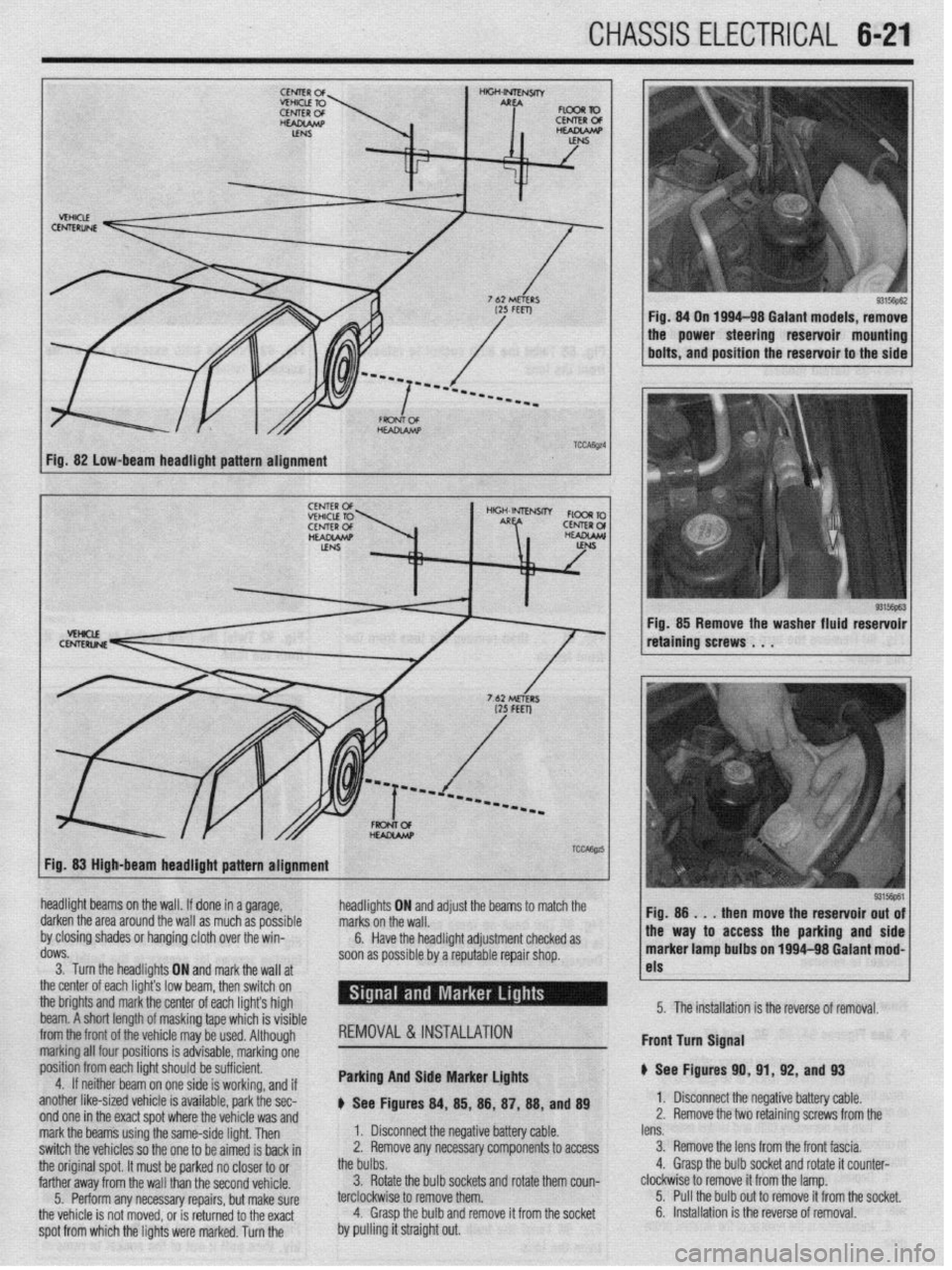

Fig. 82 low-beam headlight pattern alignment

93156pE.3 Fig. 85 Remove the washer fluid reservoir

retaining screws . . .

Fig. 83 High-beam headlight pattern alignment

headlight beams on the wall. If done in a garage,

darken the area around the wall as much as possible

by closing shades or hanging cloth over the win-

dows.

3. Turn the headlights ON and markthe wall at

the center of each light’s low br ram, then switch on

the brights and mark the center of each lights high

beam. A short length of maskin g tape which is visible

from the front of the

whir+ ma . ._..._._ . .._ y be used. Although

marking all four po:

sitions is advisable, marking one

position from each

light should be sufficient.

4. If neithar he; ~. __

Irn on one side is working, and if

another like-sized vehicle is available, park the sec-

nnri nm in the wart cnnt whrw the whirlo um md

headli! jhts ON and adjust the beams to marcn me

I. Disconnect the negative battery cable. marks on the wall.

2. Remove any necessary components to access 6.

the bulbs. Have the headlight adjustment checked as

soon as possible by a reputable repair shop.

3. Rotate the bulb sockets and rotate them coun-

terclockwise to remove them.

4. Grasp the bulb and remove it from the socket REMOVAL&INSTALLATION

Parking And Side Marker Lights

p See Figures 84, 85, 88, 87, 88, and 89 !ss the parking and side

1~ nn loo4-98 Galant mod-

I

1 I-

5315@61

lens. 1 Fio. 8

then move the reservoir out of

3. Remove the lens from the front fascia.

4. Grasp the bulb socket and rotate it counter- marker lamp bult, _.. ._“~-

clockwise to remove it from the lamp.

5. Pull the bulb out to remove it from the socket. 5. The installation is the reverse of removal.

6. Installation is the reverse of removal. Front turn Signal

p See Figures 91

1. Disconnect tl

2. Remove the t 0, 91, 92, and 93

I(? n,-.nn+:.m b.Hnn, nnL.L

z Ill7yau”e “allcly ul”IC. 10 retainino screws from the

spot from which the lights were marked. Turn the . ..I_ WIIY I.8 %,I” V”UVL”fdYI T.II”IU Lll” “VlllUlY ,.UU U,,” mark the beams using the same-side light. Then

switch the vehicles so the one to be aimed is back in

the original spot. It must be parked no closer to or

farther away from the wall than the second vehicle.

5. Perform any necessary repairs, but make sure

the vehicle is not moved, or is returned to the exact

by pulling it straight out.

Page 225 of 408

6-22 CHASSIS ELECTRICAL

b

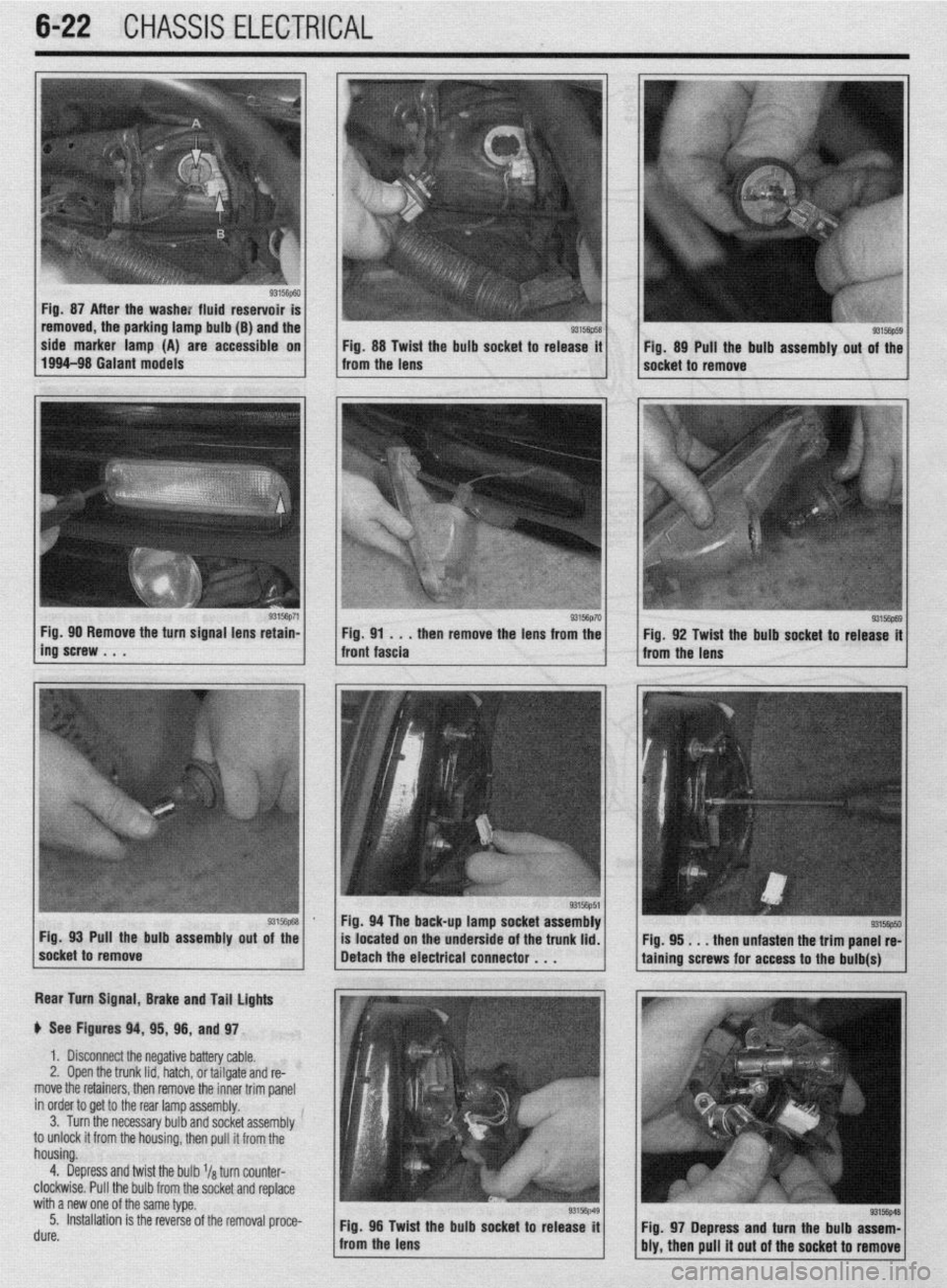

Fig. 87 After the washe: fluid reservoir

removed, the parking lamp bulb (B) and the

side marker lamp (A) are accessible on

Fig. 88 Twist the bulb socket to release it

1994-98 Galant models

from the lens Fig. 89 Pull the bulb assembly out of the

socket to remove

g3156p71 / Fig 90 Remove the turn signal lens retain-

ing’screw . . . . then remove the lens from the

Rear Turn Signal, Brake and Tail lights

p See Figures 94, 95, 96, and 97.

1. Disconnect the negative battery cable.

2, Open the trunk lid, hatch, or tailgate and re-

move the retainers, then remove the inner trim panel

in order to get to the rear lamp assembly.

3. Turn the necessary bulb and socket assembly

to unlock it from the housing, then pull it from the

housing.

4. Depress and twist the bulb l/a turn counter-

clockwise. Pull the bulb from the socket and replace

with a new one of the same type.

5. Installation is the reverse of the removal proce-

rl. ._^

UUIt?. Fig. 96 Twid

: the bulb socket to release it

from the lens

93156p69 Fig. 92 Twist the bulb socket to release it

from the lens

I

Fig. 94 The back-up lamp socket assembly

Pull the bulb assembly

out of the

located on the underside of the trunk lid.

. . . then unfasten the trim panel re-

Fig. 97 Depress and turn the bulb assem-

bly, then pull it out of the socket to remove