seat adjustment MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 2 of 408

.

1-2 GENERALINFORMATIONAND MAINTENANCE

Chitton’s Total Car Care manual for the 199M10

Mitsubishi Mirage, Galant and Diamante is intended

to help you learn more about the inner workings of

your vehicle while saving you money on its upkeep

and operation.

The beginning of the book will likely be referred to

the most, since that is where you will find information

for maintenance and tune-up. The other sections deal

with the more complex systems of your vehicle. Oper-

ating systems from engine through brakes are cov-

ered to the extent that the average do-it-yourselfer be-

comes mechanically involved. This book will not

explain such things as rebuilding a differential for the

simple reason that the expertise required and the in-

vestment in special tools make this task uneconomi-

cal. It will, however, give you detailed instructions to

help you change your own brake pads and shoes, re-

place spark plugs, and perform many more jobs that

can save you money, give you personal satisfaction

and help you avoid expensive problems.

A secondary purpose of this book is a reference for

owners who want to understand their vehicle and/or

their mechanics better. In this case, no tools at all are

required.

Before removing any bolts, read through the entire

procedure. This will give you the overall view of what

tools and supplies will be required. There is nothing

more frustrating than having to walk to the bus stop

on Monday morning because you were short one bolt

on Sunday afternoon. So read ahead and plan ahead.

Each operation should be approached logically and

all procedures thoroughly understood before attempt-

ing any work.

All sections contain adjustments, maintenance, re-

moval and installation procedures, and in some cases,

repair or overhaul procedures. When repair is not con-

sidered practical, we tell you how to remove the part

and then how to install the new or rebuilt replacement.

In this way, you at least save labor costs. “Backyard”

repair of some components is just not practical.

Many procedures in this book require you to “label

and disconnect. . ” a group of lines, hoses or wires.

Don’t be lulled into thinking you can remember where

everything goes-you won’t. If you hook up vacuum

or fuel lines incorrectly, the vehicle may run poorly, if

at all. If you hook up electrical wiring incorrectly, you

may instantly learn a very expensive lesson.

You don’t need to know the official or engineering

name for each hose or line. A piece of masking tape

on the hose and a piece on its fitting will allow you to

assign your own label such as the letter A or a short name. As long as you remember your own code, the

lines can be reconnected by matching similar letters

or names. Do remember that tape will dissolve in

gasolrne or other fluids; if a component is to be

washed or cleaned, use another method of identifica-

tion. A permanent felt-tipped marker or a metal scribe

can be very handy for marking metal parts. Remove

any tape or paper labels after assembly.

It’s necessary to mention the difference between

maintenance and repair Maintenance includes rou-

tine inspections, adjustments, and replacement of

parts which show signs of normal wear Maintenance

compensates for wear or deterioration. Repair implies

that something has broken or is not working. A need

for repair is often caused by lack of maintenance. Ex-

ample, draining and refilling the automatic transaxle

fluid is maintenance recommended by the manufac-

turer at specific mileage intervals. Failure to do this

can shorten the life of the transmission/transaxle, re-

quiring very expensive repairs. While no maintenance

program can prevent items from breaking or wearing

out, a general rule can be stated: MAINTENANCE IS

CHEAPER THAN REPAIR.

Two basic mechanrc’s rules should be mentioned

here. First, whenever the left side of the vehicle or en-

gine is referred to, it is meant to specify the drivers

side. Conversely, the right side of the vehicle means

the passengers side. Second, screws and bolts are

removed by turning counterclockwise, and tightened

by turning clockwrse unless specifically noted.

Safety is always the most important rule. Con-

stantly be aware of the dangers involved in working

on an automobile and take the proper precautions.

See the informatron in this section regarding SER-

VICING YOUR VEHICLE SAFELY and the SAFETY

NOTICE on the acknowledgment page.

Pay attention to the instructions provided. There

are 3 common mistakes in mechanical work:

1. Incorrect order of assembly, disassembly or

adjustment. When taking something apart or putting

it together, performing steps in the wrong order usu-

ally just costs you extra time; however, it CAN break

something. Read the entire procedure before begin-

ning disassembly. Perform everything in the order in

which the instructions say you should, even if you

can’t immedrately see a reason for it. When you’re

taking apart something that is very intricate, you

might want to draw a picture of how it looks when as-

sembled at one point in order to make sure you get everything back in its proper position. We will supply

exploded views whenever possible. When making

adjustments, perform them in the proper order. One

adjustment possibly will affect another.

2. Overtorquing (or undertorquing). While it is

more common for overtorquing to cause damage,

undertorquing may allow a fastener to vibrate loose

causing serious damage. Especially when dealing

with aluminum parts, pay attention to torque specifi-

cations and utilize a torque wrench in assembly. If a

torque figure is not available, remember that if you

are using the right tool to perform the job, you will

probably not have to strain yourself to get a fastener

tight enough. The pitch of most threads is so slight

that the tension you put on the wrench will be multi-

plied many times in actual force on what you are

tightening. A good example of how critical torque is

can be seen in the case of spark plug installation, es-

pecially where you are putting the plug into an alu-

minum cylinder head. Too little torque can fail to

crush the gasket, causing leakage of combustion

gases and consequent overheating of the plug and

engine parts. Too much torque can damage the

threads or distort the plug, changing the spark gap.

There are many commercial products available for

ensuring that fasteners won’t come loose, even if they

are not torqued just right (a very common brand is

Loctite? If you’re worried

about getting something

together tight enough to hold, but loose enough to

avoid mechanical damage during assembly, one of

these products might offer substantial insurance. Be-

fore choosing a threadlocking compound, read the

label on the package and make sure the product is

compatible with the materials, fluids, etc. involved.

3. Crossthreading. This occurs when a part such

as a bolt is screwed into a nut or casting at the wrong

angle and forced. Crossthreading is more likely to

occur if access is difficult. It helps to clean and lubri-

cate fasteners, then to start threading the bolt, spark

plug, etc. with your fingers If you encounter resis-

tance, unscrew the part and start over again at a dif-

ferent angle until it can be inserted and turned several

times without much effort. Keep in mind that many

parts, especially spark plugs, have tapered threads,

so that gentle turning will automatically bring the part

you’re threading to the proper angle. Don’t put a

wrench on the part until its been tightened a couple

of turns by hand. If you suddenly encounter resis-

tance, and the part has not seated fully, don’t force it.

Pull it back out to make sure it’s clean and threading

properly.

Be sure to take your time and be patient, and al-

ways plan ahead. Allow yourself ample time to per-

form repairs and maintenance You may find main-

taining your car a satisfying and enjoyable

experience.

b See Figures 1 thru 15

Naturally, without the proper tools and equipment

it is impossible to properly service your vehicle. It

would also be virtually impossible

to catalog every

tool that you would need to perform all of the opera-

tions in this book. Of course, It would be unwise for

the amateur to rush out and buy an expensive set of

tools on the theory that he/she may need one or more

of them at some time, The best approach is to proceed slowly, gathering savings will

be far outweighed by frustration and

a good quality set of those tools that are used most mangled knuckles.

frequently Don’t be misled by the low cost of bargain Begin accumulating those tools that are used most

tools. It is far better to spend a little more for better frequently: those associated with routine maintenance

quality. Forged wrenches, 6 or 12-point sockets and and tune-up. In addition to the normal assortment of

fine tooth ratchets are by far preferable to their less screwdrivers and pliers, you should have the follow-

expensive counterparts. As any good mechanic can ing tools:

tell you, there are few worse experiences than trying

l Wrenches/sockets and combination open

to work on a vehicle with bad tools. Your monetary end/box end wrenches in sizes from %-% in. or

Page 130 of 408

ENGINEANDENGINEOVERHAUL 3-69

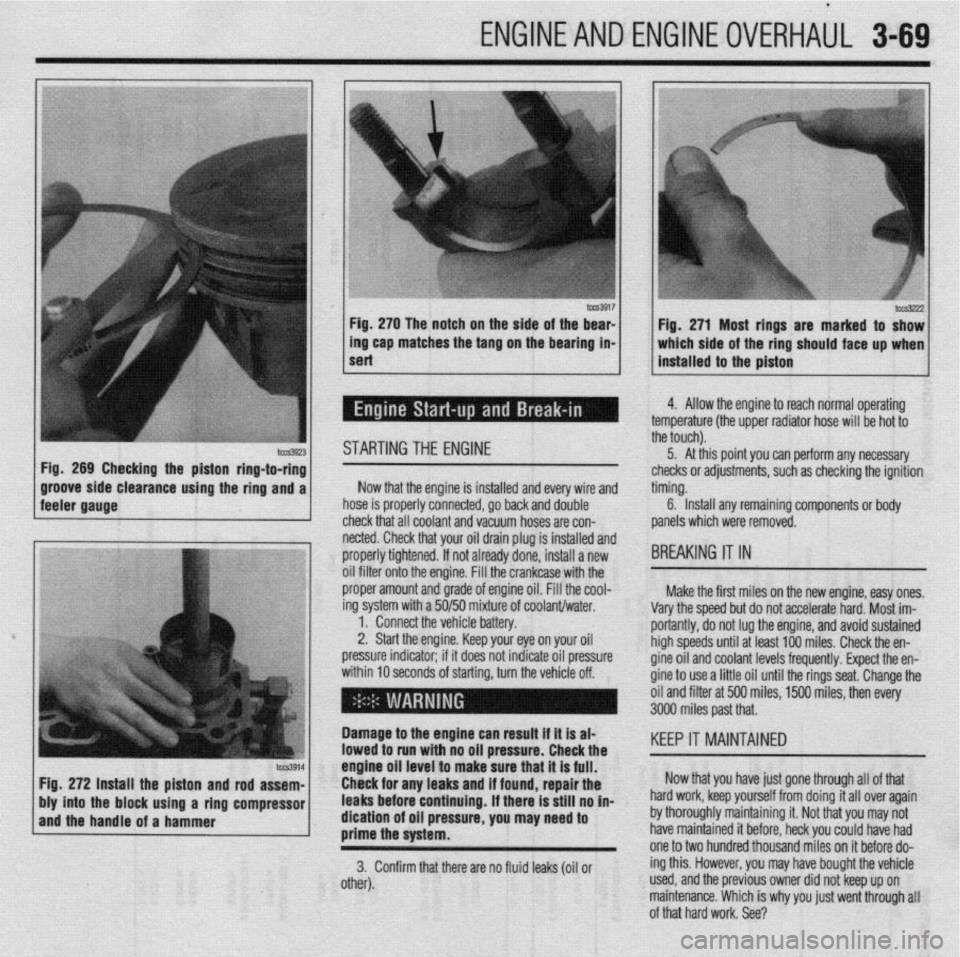

STARTING THE ENGINE

clearance using the ring and a Now that the engine is installed and every wire and

hose is properly connected, go back and double

check that all coolant and vacuum hoses are con-

, netted. Check that your oil drain plug is installed and

tt tl

C ti

hYs3222 Fig. 271 Most rings are marked to show

which side of the ring should face up when

installed to the piston

J

4. Allow the engine to reach normal operating

?mperature (the upper radiator hose will be hot to

ie touch).

5. At this point you can perform any necessary

hecks or adjustments, such as checking the ignition

ming.

6. Install any remaining components or body

anels which were removed.

IREAKING IT IN

Make the first miles on the new engine, easy ones.

arv the soeed but do not accelerate hard. Most im-

oriantly, do not lug the engine, and avoid sustained

igh speeds until at least 100 miles. Check the en-

ine oil and coolant levels frequently. Expect the en-

ine to use a little oil until the rings seat. Change the

il and filter at 500 miles, 1500 miles, then every

Page 298 of 408

SUSPENSION AND STEERiNG 8-3

STUD

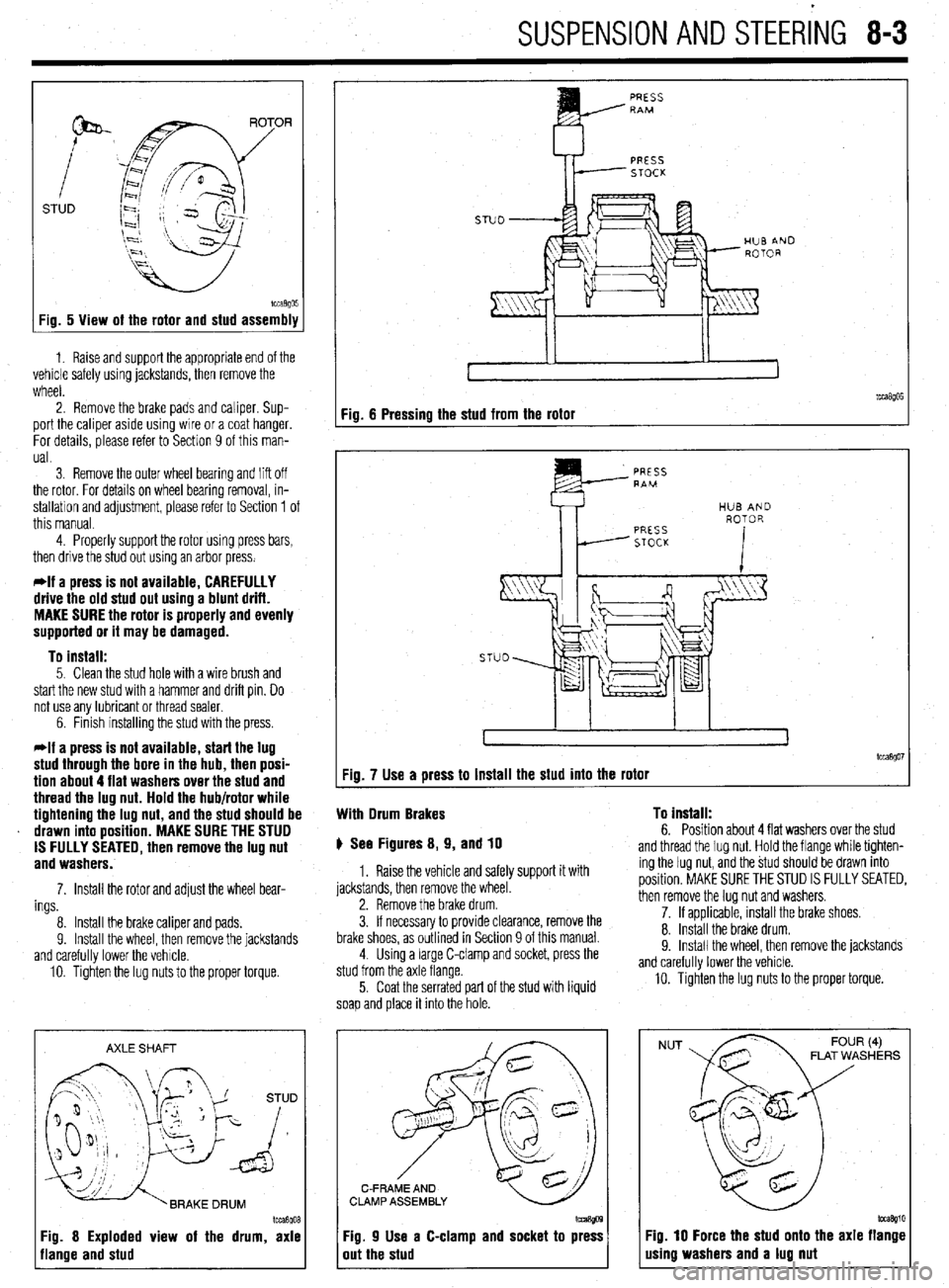

Fig. 5 View of the rotor and stud assembly

1. Raise and support the appropriate end of the

vehicle safely using jackstands, then remove the

wheel.

2. Remove the brake pads and caliper. Sup-

port the caliper aside using wire or a coat hanger.

For details, please refer to Section 9 of this man-

ual.

3 Remove the outer wheel bearing

and liff off

the rotor. For details on wheel bearing removal, in-

stallation and adjustment, please refer to Section 1 of

this manual.

4. Properly support the rotor using press bars,

then drive the stud out using an arbor press.

*If a press is not available, CAREFULLY

drive the old stud out using a blunt drift.

MAKE SURE the rotor is properly and evenly

supported or it may be damaged.

To install:

5. Clean the stud hole with a wire brush and

start the new stud with a hammer and drift pin. Do

not use any lubricant or thread sealer.

6. Finish installing the stud with the press.

*If a press is not available, start the lug

stud through the bore in the hub, then posi-

tion about 4 flat washers over the stud and

thread the lug nut. Hold the hub/rotor while

tightening the lug nut, and the stud should be

drawn into position. MAKE SURE THE STUD

IS FULLY SEATED, then remove the lug nut

and washers.

7. Install the rotor and adjust the wheel bear-

ings

8. Install the brake caliper and pads.

9. Install the wheel, then remove the jackstands

and carefully lower the vehicle.

10. Tighten the lug nuts to the proper torque.

AXLE SHAFT

Im3goa

3g. 8 Exploded view of the drum, axle

lange and stud

PRESS RAM

PRESS

STOCK

Fig. 6 Pressing the stud from the rotor

tcca$Oi Fig. 7 Use a press to install the stud into the rotor

With Drum Brakes To install:

6. Position about 4 flat washers over the stud p See Figures 8, 9, and 10

1. Raise the vehicle and safely support it with

jackstands, then remove the wheel.

2. Remove the brake drum.

3. If necessary to provide clearance, remove the

brake shoes, as outlined in Section 9 of this manual.

4. Using a large C-clamp and socket, press the

stud from the axle flange.

5. Coat the serrated part of the stud with liquid

soap and place it into the hole. and thread the lug nut. Hold the flange while tighten-

ing the lug nut, and the stud should be drawn into

position. MAKE SURE THE STUD IS FULLY SEATED,

then remove the lug nut and washers.

7. If applicable, install the brake shoes.

8. Install the brake drum.

9. Install the wheel. then remove the iackstands

and carefully lower the vehicle.

10. Tighten the lug nuts to the proper torque.

C-FRAME AND

CLAMP ASSEMBLY

Fig. 9 Use a C-clamp and socket to press

out the stud

NUT FLAT WASHERS

Fig. 10 Force the stud onto the axle flange

using washers and a lug nut

Page 356 of 408

‘I

9-20 ,BRAKES

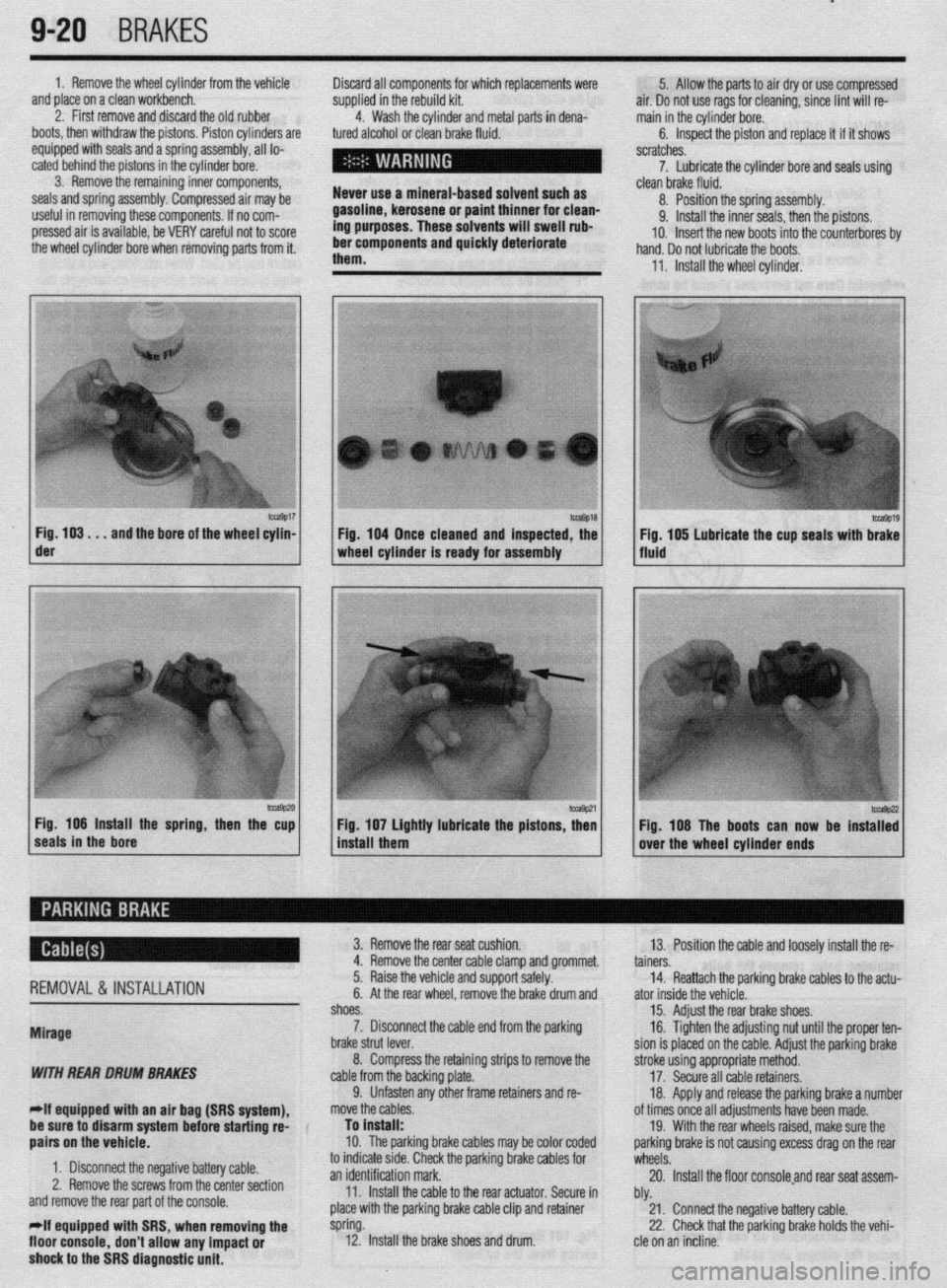

1. Remove the wheel cylinder from the vehicle

and place on a clean workbench.

2. First remove and discard the old rubber

boots, then withdraw the pistons. Piston cylinders are

equipped with seals and a spring assembly, all lo-

cated behind the pistons in the cylinder bore.

3. Remove the remaining inner components,

seals and spring assembly. Compressed air may be

useful in removing these components. If no com-

pressed air is available, be VERY careful not to score

the wheel cylinder bore when removing parts from it. Discard all components for which replacements were

supplied in the rebuild kit.

4. Wash the cylinder and metal parts in dena-

tured alcohol or clean brake fluid.

Never use a mineral-based solvent such as

gasoline, kerosene or paint thinner for clean-

ing purposes. These solvents will swell rub-

ber components and quickly deteriorate

them. 5. Allow the parts to air dry or use compressed

air. Do not use rags for cleaning, since lint will re-

main in the cylinder bore.

6. Inspect the piston and replace it if it shows

scratches.

7. Lubricate the cylinder bore and seals using

- clean brake fluid.

8. Position the spring assembly.

9. Install the inner seals, then the pistons.

IO. Insert the new boots into the counterbores bv

hand. Do not lubricate the boots,

11, Install the wheel cylinder,

m9017 Fig. 103. . .

and the bore of the wheel cylin- der

-9P20 Fig. 106 Install the spring, then the cup

seals in the bore 1 Fig. 104 Once cleaned and inspected, the

1 wheel cylinder Is ready for assembly

1 install them Fig 107 Lightly lubricate the pistons z

’ Fig. 108 The boots can now be instaT:

over the wheel cylinder ends

REMOVAL& INSTALLATION

Mirage

WITH REAR DRUM BRAKES

-If equipped witti an air bag (SRS system), 3. Remove the rear seat cushion.

13. Position the cable and loosely install the re-

4. Remove the center cable clamp and grommet.

tainers.

5. Raise the vehicle and support safely.

14. Reattach the parking brake cables to the actu-

6. At the rear wheel, remove the brake drum and

ator inside the vehicle.

shoes.

15. Adjust the rear brake shoes.

7. Disconnect the cable end from the parking

16. Tighten the adjusting nut until the proper ten-

brake strut lever.

sion is placed on the cable. Adjust the parking brake

8. Compress the retaining strips to remove the

stroke using appropriate method.

cable from the backing plate.

17. Secure all cable retainers,

9. Unfasten any other frame retainers and re-

18. Apply and release the parking brake a number

move the cables.

of times once all adjustments have been made.

be sure to disarm system

befok starting rd-

aairs on the vehicle. To install:

10. The parkinq brake cables mav be color coded 19. With the rear wheels raised, make sure the

oarkino brake is not causina excess draa on the rear

1. Disconnect the negative battery cable.

2. Remove the screws from the center section

and remove the rear part of the console.

*If equipped with SRS, when removing the

floor console,

don’t allow any impact or

shock to the SRS diagnostic unit. to indicate stde. Check the parking brake cables for

wheels: .A

an identification mark.

20. Install the floor consoleand rear seat assem-

11. Install the cable to the rear actuator. Secure in

bly.

place with the parking brake cable clip and retainer

21. Connect the negative battery cable.

spring.

22. Check that the parking brake holds the vehi-

12. Install the brake shoes and drum.

cle on an incline.

Page 357 of 408

BRAKES 9-21

WITH REAR DISC BRAKES

*If equipped with an air bag (SRS system),

be sure to disarm the system before starting

repairs on the vehicle.

1. Disconnect the negative battery cable.

2. Remove the screws from the center section

and remove the rear part of the console.

*If equipped with SRS, when removing the

floor console, don’t allow any impact or

shock to the SRS diagnostic unit.

3. Remove the rear seat cushion.

4. Loosen the cable adjusting nut and discon-

nect the rear brake cables from the actuator.

5. Remove the center cable clamp and grommet.

6. Raise the vehicle and support safely.

7. Remove the parking brake cable clip and re-

tainer spring.

8. Disconnect the cable end from the parking

brake assembly.

9. Unfasten any remaining frame retainers and

remove the cables from the vehicle.

To install: IO. The parking brake cables may be color coded

to indicate side. Check the parking brake cables for

an identification mark.

11. Install the cable to the rear actuator. Secure in

place with the parking brake cable clip and retainer

spring.

12. Position the cable and loosely install the re-

tainers.

13. Reattach the parking brake cables to the actu-

ator inside the vehicle.

14. Tighten the adjusting nut until the proper ten-

sion is placed on the cable. Adjust the parking brake

. stroke using appropriate method.

15. Secure all cable retainers.

16. Apply and release the parking brake a number

of times once all adjustments have been made.

17. With the rear wheels raised, make sure the

parking brake is not causing excess drag on the rear

wheels.

18. Install the floor console and rear seat assem-

bly.

19. Connect the negative battery cable.

20. Check console electrical components for

proper operation.

21. Road test the vehicle and check for proper

brake operation.

22. Check that the parking brake holds the vehi-

cle on an incline.

1990-93 Galant

WITH REAR DRUM BRAKES

1. Disconnect the negative battery cable.

2. Remove the center console as follows:

a. Remove both side cover panels.

b. Remove the shifter knob on manual

transaxle models. Remove the spacer trim piece

on automatic transaxle models.

c. Remove the switch panel/box and remove

the two screws beneath the panel/box.

d. Remove the radio trim panel.

e. Remove the radio and tape player.

f. Remove the console inner panel and re-

move the two screws for beneath the panel.

g. Remove the remaining screws from the

sides of the console. h. Remove the console assembly from the ve-

hicle.

3. While pressing downward on the front of the

rear seat cushion, release the locking levers and re-

move the seat cushion.

4. Loosen the cable adjustment at the cable

equalizer.

5. Remove the center cable clamp and grommet.

6. Raise the vehicle and support safely.

7. At the rear wheel, remove the brake drum and

shoes.

8. Disconnect the cable end from the parking

brake strut lever.

9. Remove the snapring securing the cable to

the backing plate.

IO. Unfasten any other frame retainers and re-

move the cables.

To install:

*The parking brake cables may be color

coded to indicate side. Check the parking

brake cables for an identification mark.

11. Install the cable to the rear actuator. Secure in

place with the parking brake cable clip and snapring.

12. Install the brake shoes and drum.

13. Position the cable and loosely install the re-

tainers

14. Reattach the parking brake cables to the actu-

ator inside the vehicle. Tighten the adjusting nut until

the proper tension is placed on the cable. Adjust the

parking brake stroke using appropriate method.

15. Secure all cable retainers.

16. Apply and release the parking brake a number

of times once all adjustments have been made.

17. Adjust the rear brakes and parking brake ca-

bles.

18. Check the rear wheels to confirm that the rear

brakes are not dragging.

19. Install the center console and rear seat cush-

ion.

20. Connect the negative battery cable.

21. Check console electrical components for

proper operation.

22. Check that the parking brake holds the vehi-

cle on an incline.

WITH REAR DISC BRAKES

1. Disconnect the negative battery cable.

2. Remove the center console as follows:

a. Remove both side cover panels.

b. Remove the shifter knob on manual

transaxle models. Remove the spacer trim piece

on automatic transaxle models.

c. Remove the switch panel/box and remove

the two screws beneath the panel/box.

d. Remove the radio trim panel.

e. Remove the radio and tape player.

f. Remove the console inner panel and re-

move the two screws from beneath the panel.

g. Remove the remaining screws from the

sides of the console.

h. Remove the console assembly from the ve-

hicle.

3. While pressing downward on the front of the

rear seat cushion, release the locking levers and re-

move the seat cushion.

4. Loosen the cable adjusting nut and discon-

nect the rear brake cables from the actuator.

5. Remove the center cable clamp and grommet.

6. Raise the vehicle and support it safely. 7. At the rear caliper assembly, remove the

parking brake cable clip and retainer spring.

8. Disconnect the cable end from the caliper.

9. Unfasten any remaining frame retainers and

remove the cables from the vehicle.

To install:

*The parking brake cables may be color

coded to indicate side. Check the parking

brake cables for an identification mark.

IO. Connect the cable to the actuator at the brake

caliper. Secure in place with the parking brake cable

clip and retainer spring.

11. Position the cable and loosely install the re-

tainers.

12. Reattach the parking brake cables to the actu-

ator inside the vehicle. Tighten the adjusting nut until

the proper tension is placed on the cable.

13. Adjust the parking brake stroke using appro-

priate method.

14. Secure all cable retainers.

15. Apply and release the parking brake a number

of times once all adjustments have been made.

16. With the rear wheels raised, make sure the

parking brake is not causing excess drag on the rear

wheels.

17. Install the floor console assembly and rear

seat cushion.

18. Connect the negative battery cable.

19. Check console electrical components for

proper operation.

20. Road test the vehicle and check for proper

brake operation.

21. Check that the parking brake holds the vehi-

cle on an incline.

1994-00 Galant

WITH REAR DRUM BRAKES

1. Disconnect the negative battery cable.

The SRS control unit is mounted beneath the

center console. Use care when working with

the center console assembly not to impact or

shock the control unit.

2. Remove the center floor console assembly as

follows:

a. Remove the shifter knob on models

equipped with a manual transaxle.

b. Remove the shifter trim panel.

c. Remove the center instrument panel.

d. Remove the panel box from the console

assembly.

e. Remove the two screws from the center of

the console.

f. Remove the four side panel screws and re-

move the console from the vehicle.

3. Loosen the cable adjuster nut, then remove

the parking brake cable by pulling it from the passen-

ger compartment.

4. Raise the vehicle and support safely.

5. At the rear wheel, remove the brake drum and

shoes.

6. Disconnect the cable end from the parking

brake strut lever. Compress the retaining strips to re-

move the cable from the backing plate.

Page 406 of 408

l

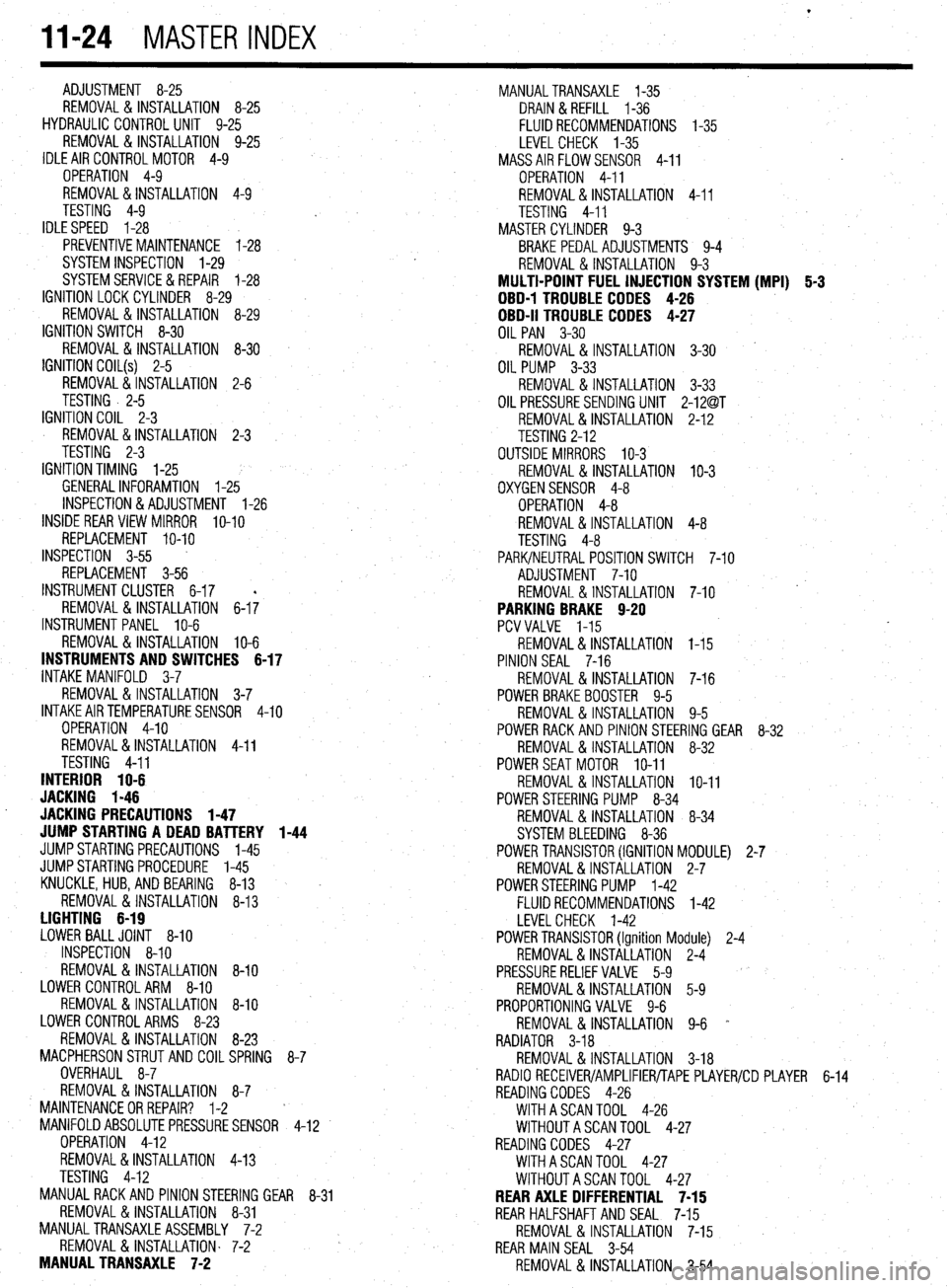

II-24 MASTER INDEX

ADJUSTMENT 8-25

REMOVAL &INSTALLATION 8-25

HYDRAULIC CONTROL UNIT 9-25

REMOVAL & INSTALLATION 9-25

IDLE AIR CONTROLMOTOR 4-9

OPERATION 4-9

REMOVAL&INSTALLATION 4-9

TESTING 4-9

IDLESPEED 1-28

PREVENTIVEMAINTENANCE 1-28

SYSTEM INSPECTION 1-29

SYSTEMSERVlCE&REPAlR 1-28

IGNITION LOCK CYLINDER 8-29

REMOVAL & INSTALLATION 8-29

IGNITION SWITCH 8-30

REMOVAL & INSTALLATION 8-30

IGNITION COIL(s) 2-5

REMOVAL&INSTALLATION 2-6

TESTING . 2-5

IGNITION COIL 2-3

REMOVAL&INSTALLATION 2-3

TESTING 2-3

IGNITION TIMING l-25

GENERALINFORAMTION l-25

INSPECTION&ADJUSTMENT l-26

INSIDE REAR VIEW MIRROR

IO-IO

REPLACEMENT IO-IO

INSPECTION 3-55

REPLACEMENT 3-56

INSTRUMENT CLUSTER 6-17

REMOVAL&INSTALLATION 6-I;

INSTRUMENTPANEL IO-6

REMOVAL &INSTALLATION IO-6

INSTRUMENTS AND SWITCHES 6-17

INTAKE MANIFOLD 3-7

REMOVAL &INSTALLATION 3-7

INTAKEAIRTEMPERATURESENSOR 4-10

OPERATION 4-10

REMOVAL&INSTALLATION 4-11

TESTING 4-11

INTERIOR 1 O-6

JACKING I-46

. JACKING PRECAUTIONS 1-47

JUMP STARTING A DEAD BATTERY 1-44

JUMPSTARTING PRECAUTIONS l-45

JUMPSTARTING PROCEDURE l-45

KNUCKLE,HUB, AND BEARING 8-13

REMOVAL &INSTALLATION 8-13

LIGHTING 6-19

LOWER BALLJOINT 8-10

INSPECTION 8-10

REMOVAL & INSTALLATION 8-10

LOWER CONTROLARM 8-10

REMOVAL&INSTALLATION 8-10

LOWER CONTROL ARMS 8-23

REMOVAL & INSTALLATION 8-23

MACPHERSONSTRUTAND COILSPRING

8-7

OVERHAUL 8-7

REMOVAL & INSTALLATION 8-7

MAINTENANCEORREPAIR? l-2

MANIFOLDABSOLUTEPRESSURESENSOR

4-12

OPERATION 4-12

REMOVAL&INSTALLATION 4-13

TESTING 4-12

MANUAL RACK AND PINION STEERING GEAR

8-31

REMOVAL & INSTALLATION 8-31

MANUALTRANSAXLEASSEMBLY 7-2

REMOVAL & INSTALLATION. 7-2

MANUAL TRANSAXLE 7-2 MANUALTRANSAXLE l-35

DRAIN &REFILL l-36

FLUID RECOMMENDATIONS l-35

LEVEL CHECK l-35

MASSAIRFLOWSENSOR 4-11

OPERATION 4-11

REMOVAL&INSTALLATION 4-11

TESTING 4-11

MASTER CYLINDER 9-3

BRAKE PEDALADJUSTMENTS 9-4

REMOVAL & INSTALLATION 9-3

MULTI-POINT FUEL INJECTION SYSTEM (MPI) 5-3

DBD-1 TROUBLE CODES 4-26

OBD-II TROUBLE CODES 4-27

OIL PAN 3-30

REMOVAL & INSTALLATION 3-30

OIL PUMP 3-33

REMOVAL & INSTALLATION 3-33

OIL PRESSURESENDING UNIT 2-12@T

REMOVAL&INSTALLATION 2-1.2

TESTING 2-12

OUTSIDE MIRRORS IO-3

REMOVAL&INSTALLATION IO-3

OXYGENSENSOR 4-8

OPERATION 4-8

REMOVAL&INSTALLATION 4-8

TESTING 4-8

PARK/NEUTRAL POSITIONSWITCH 7-10

ADJUSTMENT 7-10

REMOVAL & INSTALLATION 7-10

PARKING BRAKE 9-20

PCVVALVE l-15

REMOVAL&INSTALLATION I-15

PINION SEAL 7-16

REMOVAL &INSTALLATION 7-16

POWER BRAKEBOOSTER 9-5

REMOVAL &INSTALLATION 9-5

POWER RACK AND PINION STEERING GEAR 8-32

REMOVAL &INSTALLATION 8-32

POWERSEATMOTOR IO-11

REMOVAL & INSTALLATION IO-11

POWER STEERING PUMP 8-34

REMOVAL & INSTALLATION 8-34

SYSTEM BLEEDING 8-36

POWER TRANSlSTOR(IGNITION MODULE) 2-7

REMOVAL&INSTALLATION 2-7

POWERSTEERING PUMP l-42

FLUID RECOMMENDATIONS l-42

LEVELCHECK l-42

POWER TRANSlSTOR(Ignition Module) 2-4

REMOVAL&INSTALLATION 2-4

PRESSURERELIEFVALVE 5-9

REMOVAL&INSTALLATION 5-9

PROPORTIONING VALVE 9-6

REMOVAL & INSTALLATION 9-6 *

RADIATOR 3-18

REMOVAL &INSTALLATION 3-18

RADIO RECEIVER/AMPLIFIER/TAPE PLAYER/CD PLAYER 6-14

READING CODES 4-26

WITHASCANTOOL 4-26

WITHOUTASCANTOOL 4-27

READING CODES 4-27

WITHASCANTOOL 4-27

WITHOUTASCANTOOL 4-27

REAR AXLE DIFFERENTIAL 7-15

REAR HALFSHAFTAND SEAL 7-15

REMOVAL&INSTALLATION 7-15

REAR MAIN SEAL 3-54

REMOVAL & INSTALLATION 3-54

Page 407 of 408

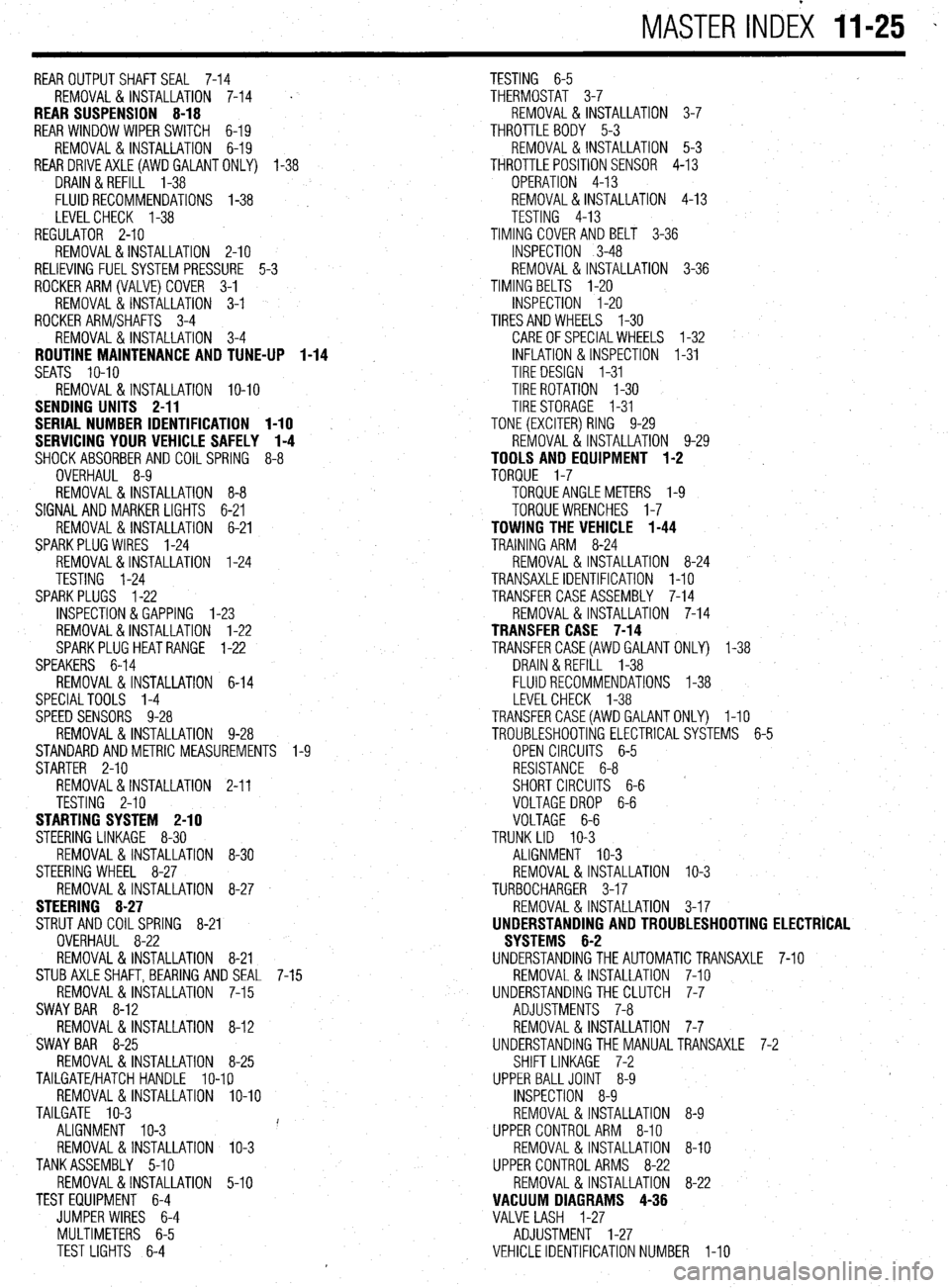

MASTER INDEX 11-25 -

REAROUTPUTSHAFTSEAL 7-14

TESTING 6-5

REMOVAL & INSTALLATION 7-14

' THERMOSTAT 3-7

REAR SUSPENSION 8-18 REMOVAL & INSTALLATION 3-7

REAR WINDOW WIPER SWITCH 6-19 THROTTLE BODY 5-3

REMOVAL&INSTALLATION 6-19 REMOVAL & INSTALLATION 5-3

REARDRlVEAXLE(AWDGALANTONLY) l-38

THROTTLEPOSITIONSENSOR 4-13

DRAIN &REFILL 1-38

OPERATION 4-13

FLUIDRECOMMENDATIONS 1-38 , REMOVAL&INSTALLATION 4-13

LEVELCHECK l-38

TESTING 4-13

REGULATOR 2-10 TIMING COVERAND BELT 3-36

REMOVAL&INSTALLATION 2-10

INSPECTION 3-48

RELIEVING FUELSYSTEM PRESSURE 5-3 REMOVAL & INSTALLATION 3-36

ROCKERARM(VALVE)COVER 3-1

TIMING BELTS l-20

REMOVAL & INSTALLATION 3-1

INSPECTION I-20

ROCKER ARM/SHAFTS 3-4

TIRESANDWHEELS I-30

REMOVAL & INSTALLATION 3-4

CAREOFSPECIALWHEELS l-32

ROUTINE MAINTENANCE AND TUNE-UP 1-14 INFLATION & INSPECTION I-31

SEATS IO-IO

TIRE DESIGN I-31

REMOVAL&INSTALLATION IO-IO TIRE ROTATION I-30

SENDING UNITS 2-11

TIRESTORAGE I-31

SERIAL NUMBER IDENTIFICATION l-10

TONE (EXCITER) RING 9-29

SERVICING YOUR VEHICLE SAFELY I-4

REMOVAL & INSTALLATION 9-29

SHOCKABSORBERAND COILSPRING 8-8

TOOLS AND EQUIPMENT 1-2

OVERHAUL 8-9

TORQUE 1-7

REMOVAL&INSTALLATION 8-8 TORQUEANGLEMETERS l-9

SIGNAL AND MARKER LIGHTS 6-21

TORQUEWRENCHES l-7

REMOVAL & INSTALLATION 6-21

TOWING THE VEHICLE 1-44

SPARKPLUG WIRES 1-24

TRAINING ARM 8-24

REMOVAL&INSTALLATION 1-24

REMOVAL & INSTALLATION 8-24

TESTING 1-24

TRANSAXLEIDENTIFICATION I-10

SPARKPLUGS l-22

TRANSFER CASE ASSEMBLY 7-14

INSPECTION &GAPPING l-23

REMOVAL & INSTALLATION 7-14

REMOVAL&INSTALLATION 1-22

TRANSFER CASE 7-14

SPARKPLUGHEATRANGE 1-22

TRANSFERCASE(AWD GALANT ONLY) 1-38

SPEAKERS 6-14

DRAIN &REFILL 1-38

REMOVAL & INSTALLATION 6-14

FLUIDRECOMMENDATIONS 1-38

SPECIALTOOLS 1-4

LEVELCHECK 1-38

SPEED SENSORS 9-28

TRANSFERCASE(AWDGALANTONLY) I-10

REMOVAL & INSTALLATION 9-28

TROUBLESHOOTING ELECTRICALSYSTEMS 6-5

STANDARDANDMETRIC MEASUREMENTS l-9

OPEN CIRCUITS 6-5

STARTER 2-10

RESISTANCE 6-8

REMOVAL&INSTALLATION 2-11

SHORT CIRCUITS 6-6

TESTING 2-10

VOLTAGEDROP 6-6

STARTING SYSTEM 2-10

VOLTAGE 6-6

STEERING LINKAGE 8-30

TRUNK LID IO-3

REMOVAL &INSTALLATION 8-30

ALIGNMENT IO-3

STEERING WHEEL 8-27

REMOVAL & INSTALLATION IO-3

REMOVAL &INSTALLATION 8-27

TURBOCHARGER 3-17

STEERING 8-27

REMOVAL & INSTALLATION 3-17

STRUT AND COIL SPRING

8-21

UNDERSTANDING AND TROUBLESHOOTING ELECTRICAL

OVERHAUL 8-22

SYSTEMS 6-2

REMOVAL & INSTALLATION 8-21

UNDERSTANDINGTHEAUTOMATICTRANSAXLE 7-10

STUBAXLESHAFT,BEARlNG AND SEAL 7-15

REMOVAL & INSTALLATION 7-10

REMOVAL&INSTALLATION 7-15

UNDERSTANDINGTHECLUTCH 7-7

SWAY BAR 8-12

ADJUSTMENTS 7-8

REMOVAL 8, INSTALLATION 8-12

REMOVAL&INSTALLATION 7-7

SWAY BAR 8-25

UNDERSTANDINGTHE MANUALTRANSAXLE 7-2

REMOVAL&INSTALLATION 8-25

SHIFT LINKAGE 7-2

TAILGATE/HATCH HANDLE lo-19

UPPER BALLJOINT 8-9

REMOVAL &INSTALLATION lo-10

INSPECTION 8-9

TAILGATE IO-3

REMOVAL &INSTALLATION 8-9

ALIGNMENT IO-3 i'

UPPER CONTROLARM 8-10

REMOVAL & INSTALLATION IO-3

REMOVAL & INSTALLATION 8-10

TANKASSEMBLY 5-10

UPPER CONTROL ARMS 8-22

REMOVAL&INSTALLATION 5-10

REMOVAL & INSTALLATION 8-22

TEST EQUIPMENT 6-4

VACUUM DIAGRAMS 4-36

JUMPER WIRES 6-4

VALVE LASH 1-27

MULTIMETERS 6-5

ADJUSTMENT 1-27

TEST LIGHTS 6-4

VEHICLE IDENTIFICATION NUMBER I-10