height MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 111 of 408

.

3-50 ENGINEANDENGINEOVERHALJL

F

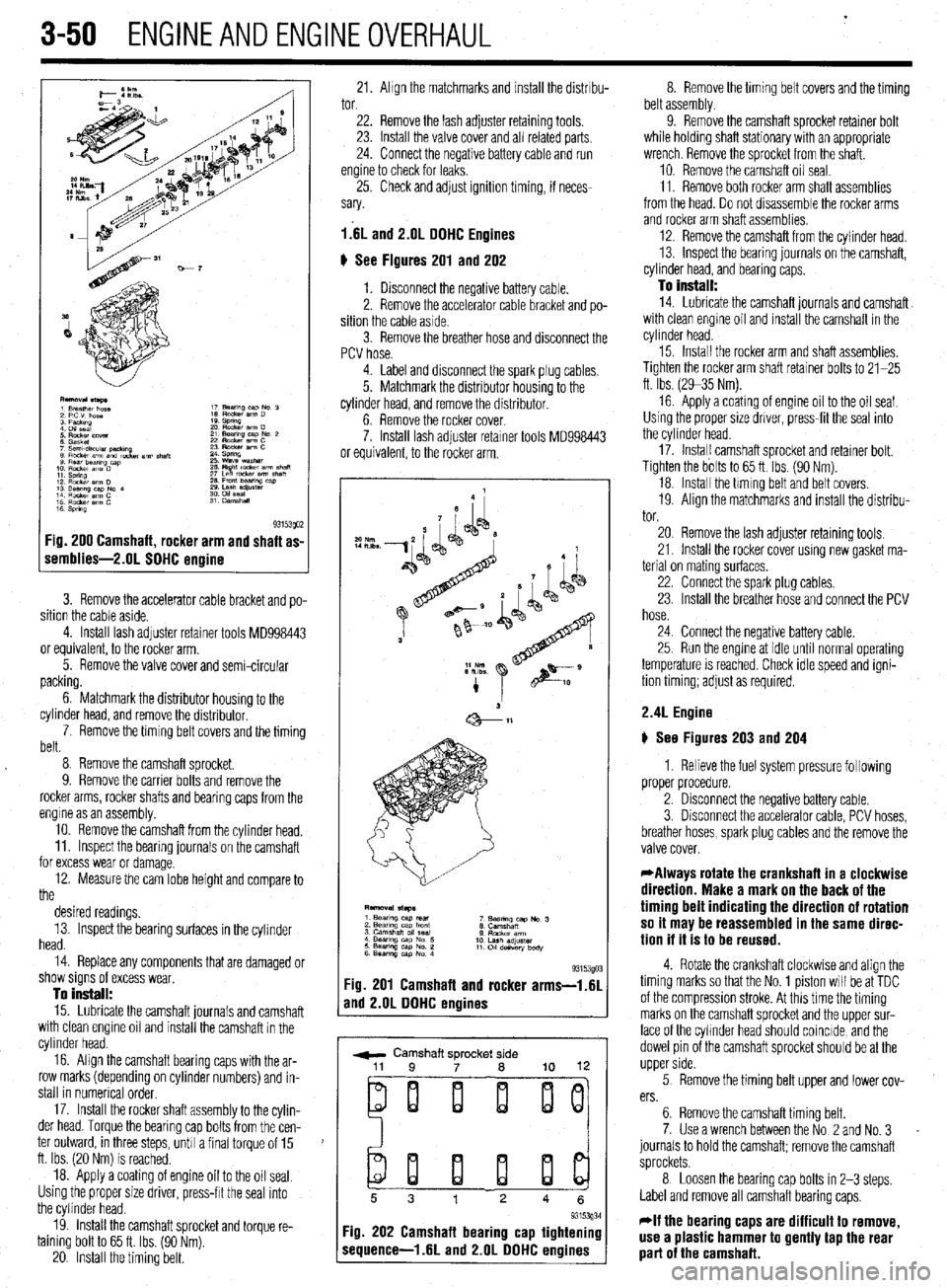

1 s 93153QO2 :ig. 200 Camshaft, rocker arm and shaft as-

iemblies-2.01 SOHC ermine

3. Remove the accelerator cable bracket and po-

sition the cable aside.

4. Install lash adjuster retainer tools MD998443

or equivalent, to the rocker arm.

5. Remove the valve cover and semi-circular

packing.

6. Matchmark the distributor housing to the

cylinder head, and remove the distributor,

7. Remove the timing belt covers and the timing

belt.

8 Remove the camshaft sprocket.

9. Remove the carrier bolts and remove the

rocker arms, rocker shafts and bearing caps from the

engine as an assembly.

10. Remove the camshaft from the cylinder head.

11. Inspect the bearing journals on the camshaft

for excess wear or damage.

12. Measure the cam lobe height and compare to

the

desired readings.

13. Inspect the bearing surfaces in the cylinder

head.

14. Replace any components that are damaged or

show signs of excess wear,

To install:

15. Lubricate the camshaft journals and camshaft

with clean engine oil and install the camshaft in the

cylinder head.

16. Align the camshaft bearing caps with the ar-

row marks (depending on cylinder numbers) and in-

stall in numerical order,

17. Install the rocker shaft assembly to the cylin-

der head. Torque the bearing cap bolts from the cen-

ter outward, in three steps, unh a final torque of 15

ft. Ibs. (20 Nm) is reached.

18. Apply a coating of engine oil to the oil seal.

Using the proper size driver, press-frt the seal into

the cylinder head.

19. install the camshaft sprocket and torque re-

taining bolt to 65 ft. Ibs. (90 Nm).

20. Install the timing belt. 21. Ahgn the matchmarks and install the distrrbu- 8. Remove the timing belt covers and the timing

tor. belt assembly.

22. Remove the lash adjuster retaining tools.

23. Install the valve cover and all related parts

24. Connect the negative battery cable and run

engine to check for leaks,

25. Check and adjust ignition timing, if neces-

sary.

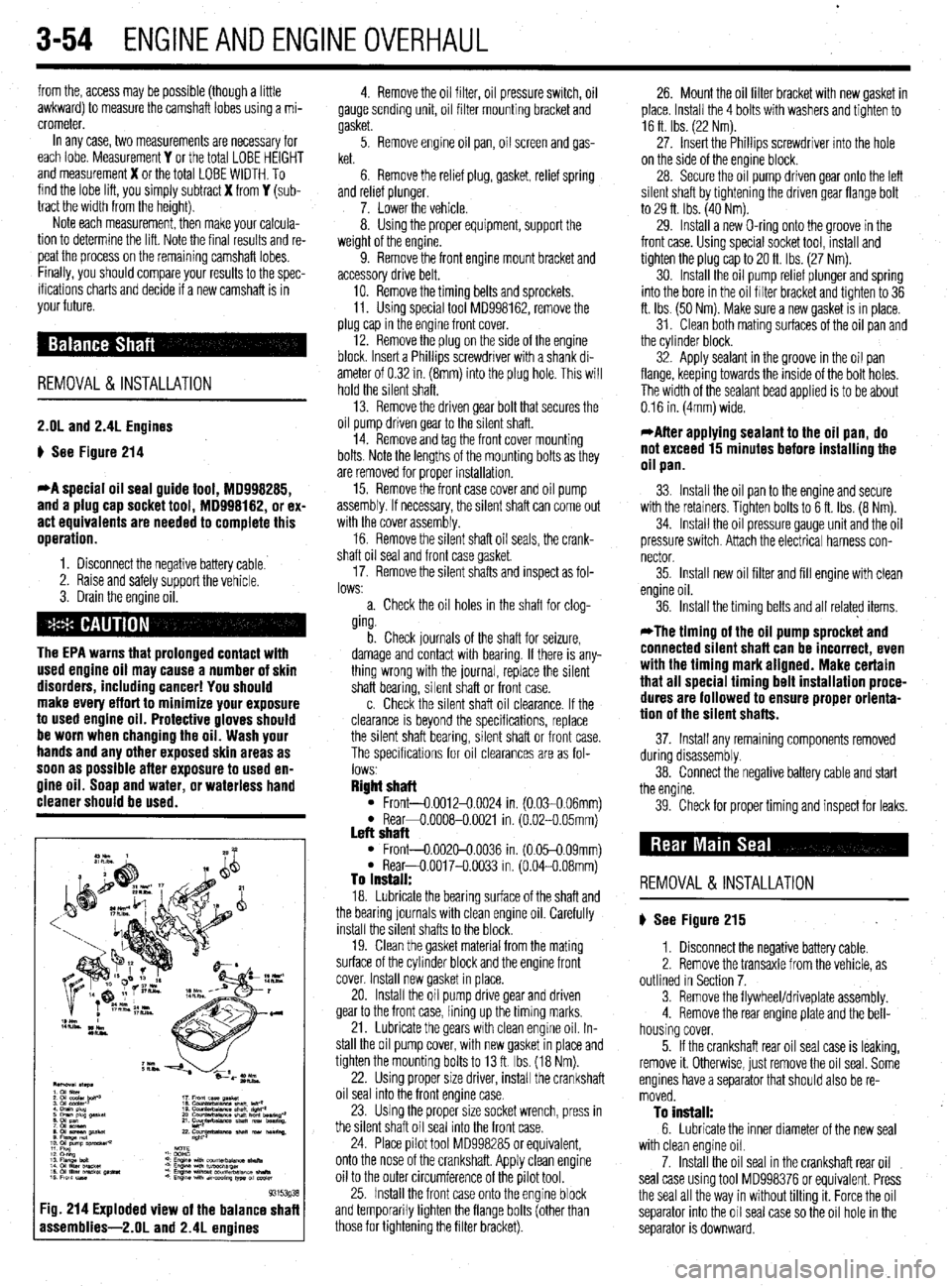

l.‘6L and 2.lJL DOHC Engines

6 See Figures 201 and 202

1. Disconnect the negative battery cable.

2. Remove the accelerator cable bracket and po-

sition the cable aside.

3. Remove the breather hose and disconnect the

PCV hose. 9. Remove the camshaft sprocket retainer bolt

while holding shaft stationary with an appropriate

wrench. Remove the sprocket from the shaft.

10. Remove the camshaft oil seal.

11. Remove both rocker arm shaft assemblies

from the head. Do not drsassemble the rocker arms

and rocker arm shaft assemblies.

12. Remove the camshaft from the cylinder head.

13. inspect the bearing journals on the camshaft,

cylinder head, and bearing caps.

To install:

14. Lubricate the camshaft journals and camshaft

with clean engine oil and install the camshaft in the

cylinder head.

4. Label and disconnect the spark plug cables.

5. Matchmark the distributor housing to the

cylinder head, and remove the distributor.

6. Remove the rocker cover.

7. Install lash adjuster retarner tools MD998443

or equivalent, to the rocker arm. 15. Install the rocker arm and shaft assemblies.

Tighten the rocker arm shaft retainer bolts to 21-25

ft. Ibs. (2935 Nm).

16 Apply a coating of engine oil to the oil seal.

Using the proper size driver, press-fit the seal into

the cylinder head.

17. Instal! camshaft sprocket and retainer bolt.

Tighten the bolts to 65 ft. Ibs. (90 Nm).

18. Install the hming belt and belt covers.

19. Align the matchmarks and install the distribu-

tor.

93153gO: :ig. 201 Camshaft and rocker arms-i.61

rnd 2.OL DOHC engines

r ,

w Camshaft sprocket side

ei i i ij

20. Remove the lash adjuster retaining tools,

21. Install the rocker cover using new gasket ma-

terial on mating surfaces,

22. Connect the spark plug cables.

23. Install the breather hose and connect the PCV

hose.

24. Connect the negative battery cable.

25. Run the engme at idle until normal operating

temperature is reached. Check idle speed and igni-

tion timing; adjust as required.

2.4L Engine

) See Figures 203 and 204

1. Relieve the fuel system pressure following

proper procedure.

2. Disconnect the negative battery cable.

3. Disconnect the accelerator cable, PCV hoses,

breather hoses, spark plug cables and the remove the

valve cover.

*Always rotate the crankshaft in a clockwise

direction. Make a mark on the back of the

timing belt indicating the direction of rotation

so it may be reassembled in the same direc-

tion if it is to be reused.

4. Rotate the crankshaft clockwise and align the

timing marks so that the No. 1 piston will be at TDC

of the compression stroke. At this time the timing

marks on the camshaft sprocket and the upper sur-

face of the cyhnder head should coincide, and the

dowel pin of the camshaft sprocket should be at the

upper side.

5 Remove the timing belt upper and lower cov-

ers.

6. Remove the camshaft timing belt.

7. Use a wrench between the No 2 and No. 3

journals to hold the camshaft; remove the camshaft

sprockets.

8 Loosen the bearing cap bolts in 2-3 steps.

Label and remove all camshaft bearing caps,

*If the bearing caps are difficult to remove,

use a plastic hammer to gently tap the rear

part of the camshaft.

Page 115 of 408

3-54 ENGINEANDENGINEOVERHALJL

from the, access may be possible (though a little

awkward) to measure the camshaft lobes using a mi-

crometer

In any case, two measurements are necessary for

each lobe. Measurement Y or the total LOBE HEIGHT

and measurement X or the total LOBE WIDTH. To

find the lobe lift, you simply subtract X from Y (sub-

tract the width from the height).

Note each measurement, then make your calcula-

tion to determine the lift. Note the final results and re-

peat the process on the remaining camshaft lobes.

Finally, you should compare your results to the spec-

ifications charts and decide if a new camshaft is in

your future.

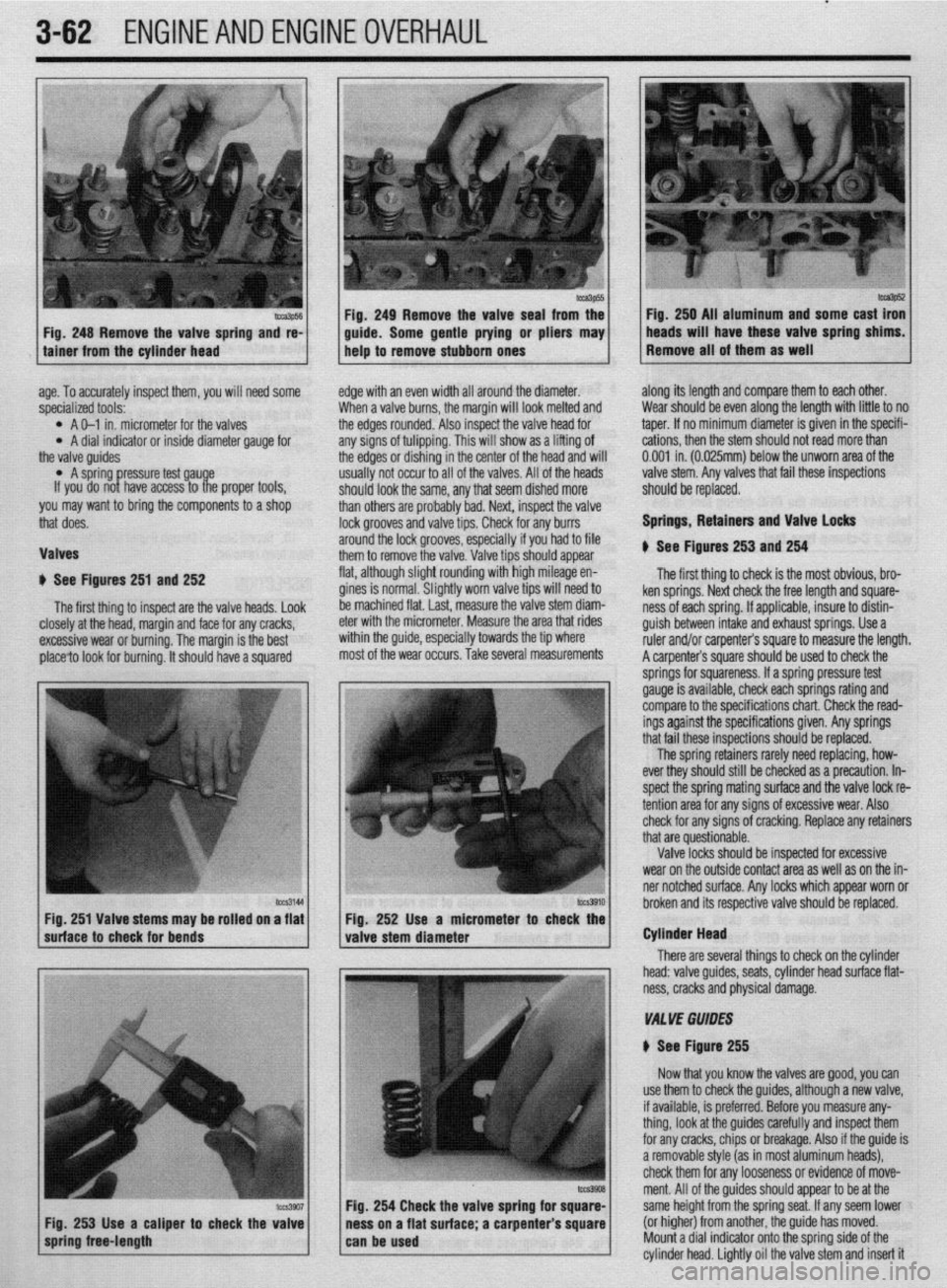

REMOVAL &INSTALLATION

2.OL and 2.4L Engines

p See Figure 214

*A special oil seal guide tool, 18998285,

and a plug cap socket tool, MD998182, or ex-

act equivalents are needed to complete this

operation.

1. Disconnect the negative battery cable.

2. Raise and safely support the vehicle.

3. Drain the engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

93153g3

:ig. 214 Exploded view of the balance shaf

assemblies-2.01 and 2.4L enoines

4. Remove the oil filter, oil pressure switch, oil

gauge sending unit, oil filter mounting bracket and

gasket.

5. Remove engine oil pan, oil screen and gas-

ket.

6. Remove the relief plug, gasket, relief spring

and relref plunger.

7. Lower the vehicle.

8. Using the proper equipment, support the

weight of the engine.

9. Remove the front engine mount bracket and

accessory drive belt,

10. Remove the timing belts and sprockets.

11. Using special tool MD998162, remove the

plug cap in the engine front cover.

12. Remove the plug on the side of the engine

block. Insert a Phillips screwdriver with a shank di-

ameter of 0.32 in. (8mm) into the plug hole. This will

hold the silent shaft.

13. Remove the driven gear bolt that secures the

oil pump driven gear to the silent shaft.

14. Remove and tag the front cover mounting

bolts. Note the lengths of the mounting bolts as they

are removed for proper installation.

15. Remove the front case cover and oil pump

assembly. If necessary, the silent shaft can come out

with the cover assembly.

16. Remove the silent shaft oil seals, the crank-

shaft oil seal and front case gasket

17. Remove the silent shafts and inspect as fol-

lows:

a. Check the oil holes in the shaft for clog-

ging.

b. Check journals of the shaft for seizure,

damage and contact with bearing. If there is any-

thing wrong with the journal, replace the silent

shaft bearing, silent shaft or front case.

c. Check the silent shaft oil clearance. If the

clearance is beyond the specifications, replace

the silent shaft bearing, silent shaft or front case.

The specifications for oil clearances are as fol-

lows

Right shaft l Front-0.0012-0.0024 in. (0.030.06mml l Rear+0.0008-0.0021 in. (6.02-O 05mm) Left shaft l Front-0.002&0.0036 in. (0.05-0.09mm) l Rear-O.0017-O.0033 in. (0.04-0.08mm) To install: 18. Lubricate the bearing surface of the shaft and

the bearing journals with clean engine oil. Carefully

install the silent shafts to the block.

19. Clean the gasket material from the mating

surface of the cylinder block and the engine front

cover. Install new gasket in place.

20. Install the oil pump drive gear and driven

gear to the front case, lining up the timing marks.

21. Lubricate the gears with clean engine oil. In-

stall the oil pump cover, with new gasket in place and

tighten the mounting bolts to 13 ft. Ibs. (18 Nm).

22. Using proper size driver, install the crankshaft

oil seal into the front engine case.

23. Using the proper size socket wrench, press in

the silent shaft oil seal into the front case.

24. Place pilot tool MD998285 or equivalent,

onto the nose of the crankshaft. Apply clean engine

oil to the outer circumference of the pilot tool.

25. Install the front case onto the engine block

and temporarily tighten the flange bolts (other than

those for tightening the filter bracket). 26. Mount the oil filter bracket with new gasket in

place. Install the 4 bolts with washers and tighten to

16 ft Ibs. (22 Nm).

27. Insert the Phillips screwdriver into the hole

on the side of the engine block.

28. Secure the oil pump driven gear onto the left

silent shaft by tightening the driven gear flange bolt

to 29 ft. Ibs. (40 Nm).

29. Install a new O-ring onto the groove in the

front case. Using special socket tool, install and

tighten the plug cap to 20 ft. Ibs (27 Nm).

30. Install the oil pump relief plunger and spring

into the bore in the oil filter bracket and tighten to 36

ft. Ibs. (50 Nm). Make sure a new gasket is in place.

31. Clean both mating surfaces of the oil pan and

the cylinder block.

32. Apply sealant in the groove in the oil pan

flange, keeping towards the inside of the bolt holes.

The width of the sealant bead applied is to be about

0.16 in. (4mm) wide.

*After applying sealant to the oil pan, do

not exceed 15 minutes before installing the

oil pan.

33. Install the oil pan to the engine and secure

with the retainers. Tighten bolts to 6 ft. Ibs. (8 Nm).

34. Install the oil pressure gauge unit and the oil

pressure switch. Attach the electrical harness con-

nector

35. Install new oil filter and fill engine with clean

engine oil.

36. Install the timing belts and all related items,

*The timing of the oil pump sprocket and

connected silent shaft can be incorrect, even

with the timing mark aligned. Make certain

that all special timing belt installation proce-

dures are followed to ensure proper orienta-

tion of the silent shafts.

37. Install any remaining components removed

during disassembly.

38. Connect the negative battery cable and start

the engine.

39. Check for proper timing and inspect for leaks.

REMOVAL &INSTALLATION

p See Figure 215

1. Disconnect the negative battery cable.

2. Remove the transaxle from the vehicle, as

outlined in Section 7.

3. Remove the flywheel/driveplate assembly.

4. Remove the rear engine plate and the bell-

housing cover.

5. If the crankshaft rear oil seal case is leaking,

remove it. Otherwise, just remove the oil seal. Some

engines have a separator that should also be re-

moved.

To install: 6. Lubricate the inner diameter of the new seal

with clean engine oil.

7. Install the oil seal in the crankshaft rear oil

seal case using tool MD998376 or equivalent. Press

the seal all the way in without tilting it. Force the oil

separator into the oil seal case so the oil hole in the

separator is downward.

Page 123 of 408

.

3-62 ENGINEANDENGINEOVERHAUL

lge. To accurately inspect them, you will need some

,pecialized tools:

l A O-l in. micrometer for the valves l A dial indicator or inside diameter gauge for

he valve guides

l A spring ressure test gau e

If you do no P Yl have access to t e proper tools,

‘ou may want to bring the components to a shop

hat does.

lalves

1 See Figures 251 and 252

The first thing to inspect are the valve heads. Look

E :losely at the head, margin and face for any cracks,

rxcessive wear or burning. The margin is the best

)lace?o look for burning. It should have a squared E

c

edge with an even width all around the diameter.

When a valve burns, the margin will look melted and

the edges rounded. Also inspect the valve head for

any signs of tulipping. This will show as a lifting of

the edges or dishing in the center of the head and will

usually not occur to all of the valves. All of the heads

should look the same, any that seem dished more

than others are probably bad. Next, inspect the valve

lock grooves and valve tips. Check for any burrs

around the lock grooves, especially if you had to file

them to remove the valve. Valve tips should appear

flat, although slight rounding with high mileage en-

gines is normal. Slightly worn valve tips will need to

be machined flat. last, measure the valve stem diam-

eter with the micrometer. Measure the area that rides

within the guide, especially towards the tip where

most of the wear occurs. Take several measurements along its length and compare them to each other.

Wear should be even along the length with little to no

taper. If no minimum diameter is given in the specifi-

cations, then the stem should not read more than

0.001 in. (0.025mm) below the unworn area of the

valve stem. Any valves that fail these inspections

should be replaced.

Springs, Retainers and Valve Locks

$ See Figures 253 and 254

The first thing to check is the most obvious, bro-

ken springs. Next check the free length and square-

ness of each spring. If applicable, insure to distin-

guish between intake and exhaust springs. Use a

ruler and/or carpenter’s square to measure the length.

A carpenter’s square should be used to check the

lCZS3144

I I hrnknn itc Fig. 251 Valve stems may be rolled on a flat Fio. 252 Use a micrometer

suhace to check for bends

valve stem diameter r to check the

I

There are seve Cylinder Head

ral things to check on the cylinder

head: valve guides, seats, cylinder head surface flat-

ness, cracks and physical damage.

VA1 YE GUIDES

N See Figure 255

Now that you know the valves are good, you can

254 Check the valve spring fo

s on a flat surface; a carpenter use them to check the guides, although a new valve,

if available, is preferred. Before you measure any-

thing, look at the guides carefully and inspect them

for any cracks, chips or breakage. Also if the guide is

a removable style (as in most aluminum heads),

check them for any looseness or evidence of move-

ment. All of the guides should appear to be at the

same height from the spring seat. If any seem lower

(or higher) from another, the guide has moved.

Mount a dial indicator onto the sorina side of the

cylinder head. Lightly oil the valve stem and insert it

Page 131 of 408

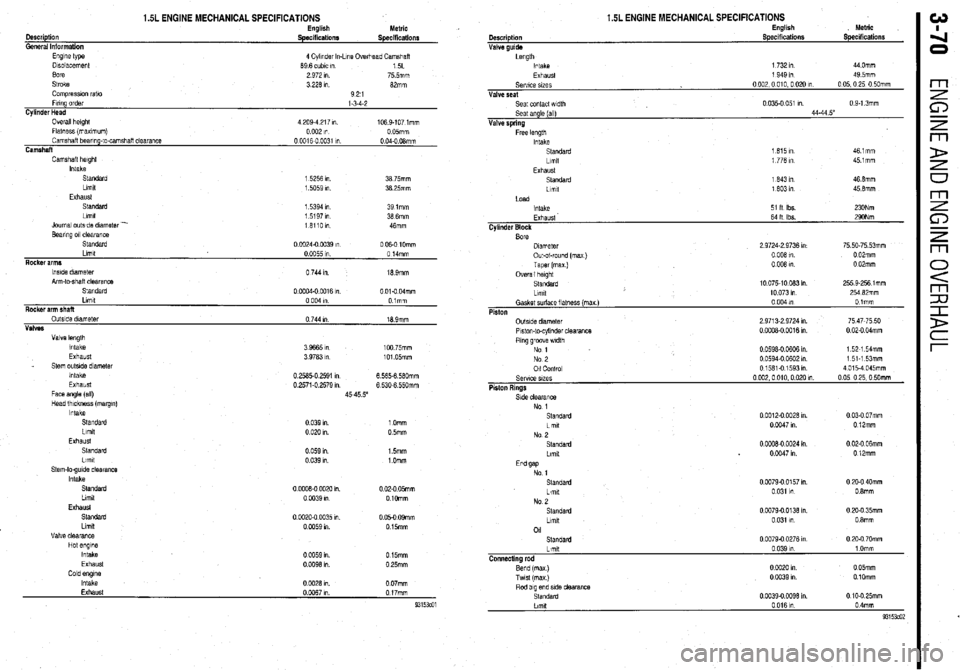

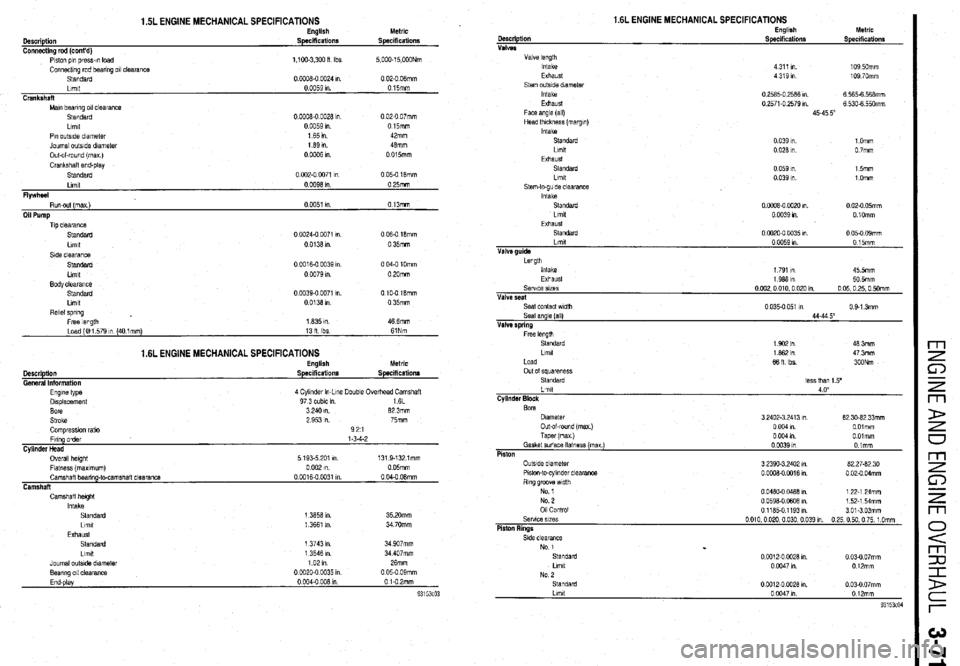

1.5L ENGINE MECHANICAL SPECIFICATIONS English

Metric

Description

Specificationr

Specifications

General Information

Engine type

4 Cylinder In-Line Ovethead Camshaft

Displacement 69 6 cubic I” 15L

sore 2 972 I” 75 5mm

Stroke 3 226 I” 82mm

Compression rat10 921

Firing order

l-3-4-2

Cylinder Head

Overall height 4 209.4 217 I” 1059-107 lmm

Flatness (maximum) 0 002 I” 0 05mm

Camshaft bearing-to-camshaft clearance 0 0016-O 0031 I” 0 04-O OBmm

Camshaft

Camshaft height

Intake

Standard 1 5256 I”. 39 75mm

Limit

1.5059 In 38.25mm

Exhaust

Standard 1 5394 I” 391mm

Llmlt 1 5197 In 38 6mm

Journal outside diameter -

161101”

46mm

Bearing 011 clearance

Standard

0 1X324.0 a)39 I” 0 06-O 10mm

Rocker arms Limit

0 0055 I” 0 14mm

lwde diameter

Arm-to-shalt clearance

Standard 0 744 I”. 18 Smm

0 OCQ4-0 0016 I”. 0 Old 04mm

Llmlt 0 004 I” Olmm

Rocker arm shaft

OutsIde diameter 0 744 I” 16 9mm

Valves

Valve length

Intake 3 9665 I” 100 75mm

Exhaust 3 9763 I” 101.05mm

_ Stem outslde diameter

Intake 0 2585.0 2591 I” 6.565-6 5tlOmm

Exhaust 0 2571-o 2579 I” 6 530-6 55Omm

Face angle (ail)

45-45 5”

Head thickness (margm)

Intake

Standard 0 039 I”. 1 Omm

Llmlt

0 02u In. 05mm

Exhaust

0 059 I”

0 039 I”. 1.5mm

1 .Omm

0 02-O 05mm

0 1Omm

0 05-O OSmm

0 15mm

0 15mm

0 25mm

0 07mm Cescriptlon

Valve guide 1.5L ENGINE MECHANICAL SPECIFICATIONS English

Specifications Metric

Specifications

Length

Intake 1 732 I” 44 Omm

Exhaust

Selwe wes

Valve seat

Seat contact width

Seat angle (all)

Valve spring

Free length

Intake

Standard

Llmlt

Exhaust

Standard

Llmlt 1 949 I” 49 5mm

0002,0010.002cIn 0 05,O 25,O 50mm

0 035-o 051 I” 0 S-1 3mm

44.44 5”

1 615 I” 461mm

1 776 I” 451mm

1 643 I” 46 8mm

1 603 I” 45 6mm

Load

Intake

Exhaust 64 It Ibs. 290Nm

Cylinder Block

Bore

Dnmeter

Out-of-round (ma)

Taper (max.) 2 9724-Z 9736 I” 75 50.75 53mm

0 006 I” 0 02mm

0 006 I” 0 02mm

Overall height

Standard

Llrnbt 10075-10083In 255 9.256 1 mm

10 073 I” 254 62mm

No 1

Standard 0 0012-o 0028 I”. 0 03-O 07mm

Llmlt 0 0047 I” 0 12mm

No 2

Standard 0 OCOE-0 0024 I” 0 02-O 06mm

Llmlt 0 0047 I” 0 l2mm

End gap

No 1

Standard

Limit

No 2

Standard

Ltmlt

01

Standard 0 0079-o 0157 I”.

0 I” 031

0 0079.0.0136 I”

0.031 I”

0 0079.0 0276 I” 0 20-O 40mm

0 8mm

0 20-O 35mm

0.8mm

0 20-O 70mm

Limit

Connecting rod

Bend (mex)

Twst (max) 0 039 I” 1 Omm

0 CO20 I” 0 05mm

0 0039 In 0 10mm

Page 132 of 408

1.5L ENGINE MECHANICAL SPECIFICATIONS English

Description Specifications

Connecting rod (cont’d)

Piston p,n press-m load

1,100.3,300 II Ibs

Connecting rod bearing 011 clearance

Standard 0 0006-O CO24 I”

Limit

0 0059 I”.

Crankshaft

Main bearing 011 clearanc8

Standard

0 0006.0 0026 I”

Ltmit

0 0059 I”

Pin outslde diameter 165111

Journal outside dlametei

1 89 I”.

Out-al-round imax I 0oLx%l” Metric

Specifications

5,000.15,OWNm

0 02-O 06mm

015mm

0 02-O 07mm

0 15mm

42mm

46mm

0 015mm

SI& clearance

Standard

0 0016-O 0039 I” 0 04-O 1Omm

Llmtt

0 0079 I” 0 20mm

Body clearance

Standard

0 0039-o 0071 I”. 0 10-O 16mm

Llmlt 0013am 0 35mm

AelM

spring . Free length

1635 I” 46 6mm

Load (@ 1 579 tn (40 1 mm)

13H Ibs 61Nm

Description

General Information

1.6L ENGINE MECHANICAL SPECIFICATIONS English

Specifications Metric

Specifications

Camshaft height

Intake

Standard

Llmlt

Exhaust

Standard

Llmlt 1 3556 I” 35 2Omm

1 3661 I” 34 70mm

1 3743 I” 34 W7mm

1 3546 I”. 34 407mm

Journal outslde diameter 1021n 26mm

Bearing 011 clearance

0 0020-0 w35 I” 0 05-0 09mm

End-play

0 004.0 oQ6 In 0 i-02mm

1.6L ENGINE MECHANICAL SPECIFICATIONS

Page 135 of 408

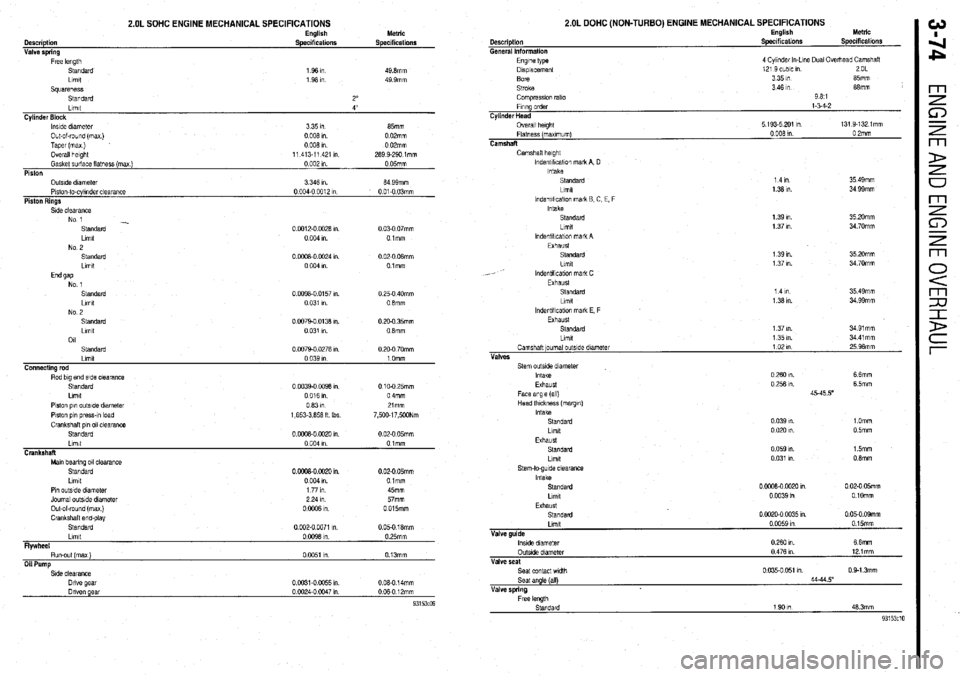

2.OL SOHC ENGINE MECHANICAL SPECIFICATIONS

Description

General Information

2.OL DOHC (NON-TURBO) ENGINE MECHANICAL SPECIFICATIONS English

Specifications Metric

Speciticatlonr Description

Valve sorino Engbsh

Specifications Metric

Specifications

Engine type

Dlsplacemenl

Bore

Stroke

Comprwon rat10

Flung order

Cylinder Head

Overall height

Flatness (maximum)

Camshaft 4 Cylmdet In-Lone Dual Overixad Camshaft

12’ 3 cubic m 2OL

3351n 85mm

3 46 I” 68mm

981

l-54-2

5 193.5 201 Ill 131 9.1321mm

0 008 1” 0 2mm S&dard

Llmlt

Squareness

Standard

Gasket surface flatness (mex Llmll

) Cylinder Block

Piston lnslde diameter

Outside dlameler O&of-round (max)

Piston-lo-cylinder clearance Taper (max)

Piston Rings Overall height 1 36 I”

1 96 I”

2”

0 002 I”. 4”

0 05mm 335m

3 346 I”. 65mm

64 99mm 0 008

0 I”.

004-o 04312 0 02mm

I” 0 008

0 I”

01-O 03mm 0 02mm

11 413.11 421 I” 263 Q-290 lmm m

Camshaft height

lndentlficaiw mark A, D

Intake

Standard

Llmlt

lndentll!cat!on mark B C, E, F

Intake

Standard

Llmlt

lndentlllcallon mark A

Exhaust

Standard

Lrmt

lndenbllcabon mah C

Exhaust

Standard

Limit 35 49mm

34 99mm 14m

1 36 I”.

0.0012-0 0026 I”.

0 004 I” 0 03-O 07mm

01mm 35 20mm

34 70mm 1 39 I”.

1 37 I”.

7 m 1 39 I”.

1 37 I”. 35 20mm

34 70mm 0 0008-O 0024 I”

0 004 I” 0 02-O 06mm

Olmm

14m

1 38 I”. 35 49mm

34 QQmm 0 0098-0 0157 I”.

0 031 I” 0 25.0 40mm

0 6mm

0.0079-O 0136 I”.

0 031 I” 0 20-O 35mm

08mm

0 0079-O 0276 I”.

Stem outside diameter

Intake

Exhaust

Face angle (all)

Head lhlckness (margm)

Intake

Standard

Llmlt 0 260 I”. 6 6mm

0 256 I”. 6 5mm

45-45 50

0 039 WI. 1 Omm

0 020 I”. 0 5mm Piston pm outside diameter

Piston p,” press-!” load

Crankshaft PI” 011 clearance

Standard 0631ll

1,653.3,656 ft Ibs 21mm

7,500.17,5WNm

0 oooa-o 0020 In. 0 02-O 05mm

Exhaust

Standard

Limit 0 059 I”.

0 031 I”. 15mm

0 6mm Limit

0 004 I” Olmm

Crankshaft

Man bearing 011 clearance

Standard

Llmlt

Pm outside dwneler

Journal outslde diameter

Out-of-round (max)

CrankshaH end-play

Standard

Limtt

Flywheel

Run-out (max)

Oil Pump 0 ciw0 0020 I”. 0 02-O 05mm

0 004 I”. Olmm

1771n 45mm

2 24 I” 57mm

0 0006 I” 0 015mm

0 002-O 0071 I” 0 05-O 16mm

0 0098 I” 0 25mm

0 0051 I” 0.13mm Stem-to-gude clearance

Intake

Standard

Llmlt 0 oooa-o 0020 I” 0 02-O 05mm

0 0039 in 0 1Omm

Exhaust

Standard 0 0020-O 0035 I” 0 05-O 09mm

Llmlt

Valve guide

lnstde diameter

OutsIde diameter

Valve seat

Seal contact wldlh

Seat angle (all)

Valve spring 0 W59 m 0 15mm

026Om 66mm

0 476 I” 121mm

0 035-o 051 I”. 0 Q-1 3mm

44-44.5

Page 136 of 408

2.OL DOHC (NON-TURBO) ENGINE MECHANICAL SPECIFICATIONS

Cyltnder Block

lnslde dnnetet

335m 65mm

Out&round (ma)

0 006 I” 0 02mm

Taper (ma)

oooh

0 OPmm

Overall haght

11 413-l 1 421 I”. 269 9-290 lmm

Gasket surface flatness (ma )

0 002 I” 0 05mm

Piston

Side clearance

No 1

Standard

Llmlt

No 2

Standard

Llmlt 0 0012-O 0028 I”. 0 03-O 07mm

0 004 I” Olmm

0 0012-O W26 I”

0 03-O 07mm

0 004 I” Olmm

Standard

00096-0 0157 I” 0 25-O 40mm

Limit

0 031 I” 0 8mm

No 2

Standard

0 0177-O 0236 I” 0 45-O 6Omm

Llmlt 0 031 I”. 0 6mm

011

Standard

0 0079.0 0276 I” 0 20-O 70mm

Piston pin outslde diameter

Ot331n

Piston own oress-m load

1.653-3.856 n Ibs Zlmm

7 500-l 7 500Nm

Mm bearing 011 clearance

Standard

Llmlt

Pin outsIde diameter

Journal outslde diameter

Out-of-round (max )

Crankshall end&v 0 OOOB-0 0020 1” 0 02-O 05mm

0 004 I” Olmm

1 77 I”. 45mm

2 24 I”. 57mm

0 0006 I” 0 015mm

Standard’ ‘

0 002-O 0071 I” 0 05-O 16mm

Llmlt

0 0096 I”. 0 25mm

FlVWheel

Run-out (max)

0 BO51 I” 0 13mm

Oil Pump Description

General Information

2.OL DOHC (TURBO) ENGINE MECHANICAL SPECIFICATIONS English

Specifications Metric

Specifications

Camshafl height

lndentlkcatlon mark A. D

Intake

Standard

1 4 In 35 49mm

Llmlt

1 36 I” 34 99mm

lndentlflcatlon mark E C. E, F

Intake

Standard 1 39 I”. 35 20mm

Llmlt 1 37 I”. 34 70mm

lndentlflcal!on mark A

Exhaust

Standard

1 39 I”. 35 20mm

Llmlt

1 37 I”. 34 70mm

lndentlflcatlon mark C

Exhaust

Standard

1 4 I” 35 49mm

Llmlt

1 36 I” 34 99mm

lndentlflcatlon mark E, F

Exhaust

Standard

1 37 I”. 34 91mm

Llmlt

1351n 34 41 mm

Camshaft journal outslde dlametar

1021n

25 96mm

Vhf&S

Standard

LilTlIt

Exhaust 0 039 I”. 1 Omm

0 020 I”. 0 5mm

Standard

Llmlt

Stem-to-guide clearance

Intake

Standard

Llmtt

Exhaust

Standatd

Limit

Valve guide

lnslde diameter

OutsIde dlametat

Valve peat

Seat contact wdth

Seat angle (all) 0 059 I”. 15mm

0 031 I”. 0 6mm

0 0008-0 0020 I” 0 02-O 05mm

0 0039 I” OlOmm

0 0020-0 0035 I”. 0 05.0 09mm

0 0059 I”. 015mm

0260 In.

66mm

0 476 I” 12 lmm

0 035-o 051 m 0 9.1 3mm

44.44 5”

93153c12

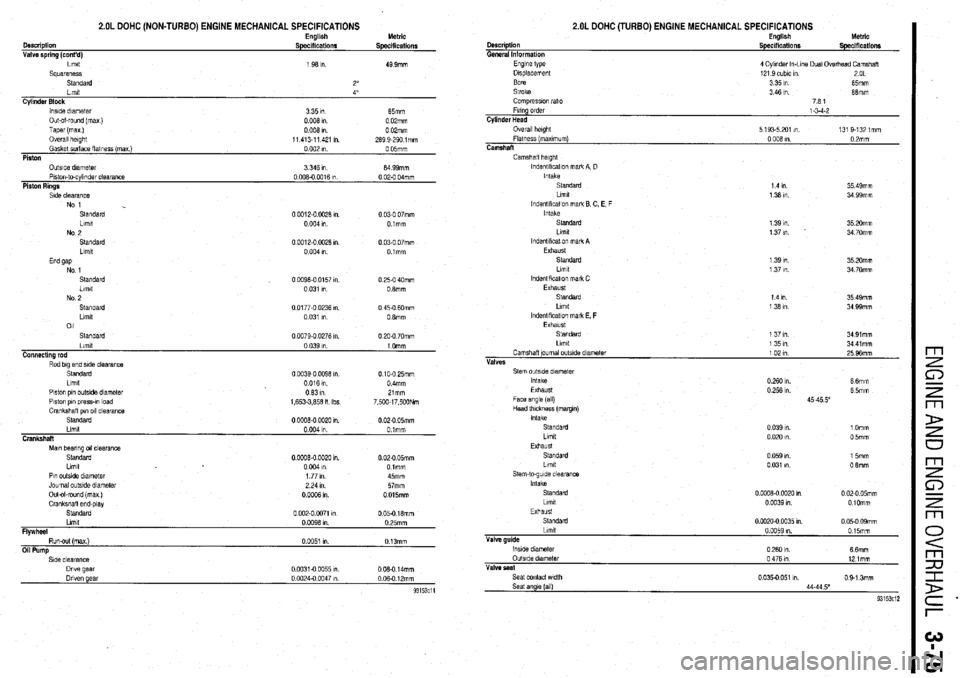

Page 137 of 408

Description

Valve spring

Free length

Standard

Llmlt

Squareness

Standard

Llmlt

2.OL DOHC (TURBO) ENGINE MECHANICAL SPECIFICATIONS English Metric

Specifications Specifications

1 90 I”. 46 3mm

1 98 I” 49 9mm

2’

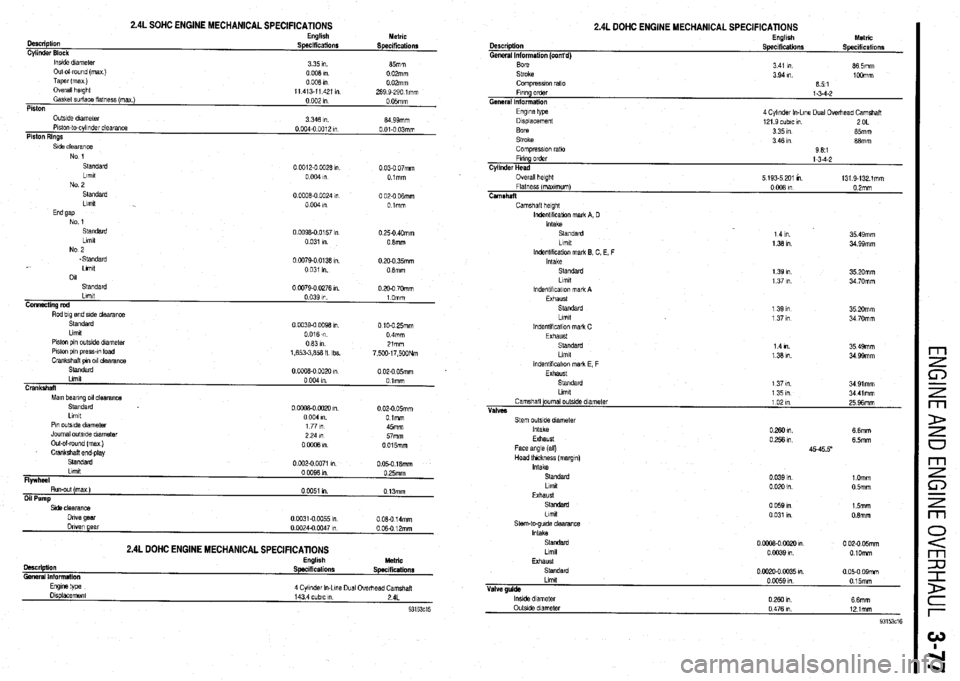

4’ 2.4L SOHC ENGINE MECHANICAL SPECIFICATIONS

Description

General Information

Engine type

Displacement

Bore

Stroke

Compression rat10

Frrlng order

Cylinder Head

Overall height

Flatness (maxlmum)

Camshaft

Camshaft height

lndenbflcatlon mark D

Intake

Standard

Llrnd

Exhaust

Standard

Limit

lndenbflcabon mark AR

Intake

Standard

Llmlt

Exhaust

Standard

Llmlt

Camshalt journal outside dnmeter

Valves

Stem outside diameter

Intake

Exhaust

Face angle (all)

Head thickness (margm)

intake

Standard

Llmlt

Exhaust

Standard

Llmlt

Stem-to-guide clearance

Intake

Standard

Llmlt

Exhaust

Standard

Llmlt

Valve guide

lwde diameter

OutsIde diameter

Valve seal

Seat contact wdlh

Seat angle (all)

Valve spring

Free length

Standard

Llmlt

Squareness

Standard

Llmlt English MlxdC

Specifications Specifications

4 Cylinder In-Lme Overhead Camshaft

143 4 cLblc I” 24L

341 I” 86 5mm

3941n 1OOmm

651

l-3-4-2

3 539-3 547 I” 89 9-90 1 mm

0 008 1” 02mm

167Ill 42 4mm

165vl 419mm

167m 42 4mm

165In 419mm

1751n 44 53mm

1.73 I” 44 03mm

175m 44 53mm

I 73 I” 44 03mm

1 34 I” 33 95mm

0315m 8 Omm

0311 I” 7 9mm

45.45 5

0047m 1 2mm

0.020 I” 0 5mm

0 079 I” 2 Omm

0 031 ,” 0 8mm

0 0008-O 0024 I” 0 03-O &mm

0 0039 I” 0 1Omm

0 oQ20-0 0035 I” 0 05-O 09mm

0 0059 In 0 15mm

0 315 tn. 8 Omm

0 516 I” 131mm

0 035.0 051 I” 0 9-l 3mm

44-44 5”

1961n 49 6mm

I 98 I” 49 9mm

2”

4”

93153ci4

Page 138 of 408

2.4L SOHC ENGINE MECHANICAL SPECIFICATIONS English

Description

Specifications

Cylinder Block

lnstde dnmeter

3 35 I”.

Out-o-round (max )

0008ln

Taper(max)

0008ln

Overall hwght

11 413-11 421 I”

Gasket &ace flatness (max )

0 002 I”

Piston Metric

Specifications

85mm

0 02mm

0 02mm

289 9-290 lmm

0 05mm

OutsIde dlameler

Plslon-to-cylinder clearance

Piston Rings 3 346 I” 04 99mm

0 004-o 0012 I” 0 01-O 03mm

Standard

0 0012-O 0928 I” 0 03-O 07mm

Lfmlt

0 004 I” Olmm

No 2

Standard 00008-O

0024 I” 0 02-O ffimm

Llmlt

0004," Olmm

End gap

No 1

Standard 0

0098-O 0157 In 0 25-O 40mm

Llmlt

0 031 I”. 0 Smm

No 2

.Standard

Llmlt

011

Standard 0 0079-o 0138 I”

0 031 I”.

00079-002761". 0 20-O 35mm

0 8mm

0 20-O 70mm

Standard

Llmlt

Piston pin outside dlametar

Piston pin press-m load

Crankshaft om 011 clearance 0 0039-o 0098 I” 0 10.0 25mm

0 016 m 0 4mm

0631n 21mm

1,653-3,&a fl Ibs.

7,500~17,500Nm

Standard

0 02-O 05mm

Mam beanna 011 clearance

Standard

0 OuoE-0 0020 I”. 0.024 05mm

Limit

0004 I”. 0 lmm

Pm outslde diameter

1 77 I” 45mm

Journal outside diameter 2P4m wmm

Out-al-round (max )

Crankshaft end-play

o-i& I”. _

0015mm

Flywheel Standard

Ltmit 0002-00071 I”.

0 050 18mm

000981n 0 25mm

Side clearance

Dnve gear

Driven gear

lMCriptlOfl

General Information OOm-00055,"

0 0024-O 0047 I”

2.4L DOHC ENGINE MECHANICAL SPECIFICATIONS English

Specifications 0 08.0 14mm

006012mm

Metric

Specifications

4 Cyi~nder In-Lme Dual Overhead Camshaft

143 4 cubtc I”. 24L

2.4L DOHC ENGINE MECHANICAL SPEClFlCATlONS

Description

General Information (cont’d) English

Specifications Metric

Specifications

Fmng order

Cylinder Head

Overall height

Flatness (maxtmum)

Camshaft l-3-4-2

5 193.5 201 K1 131 9-132 lmm

0 008 I” 0.2mm

Camshaft height

lndentlhcabon malk A, D

Intake

Standard

Limit

lndentlkcatlon mark 8, C, E. F 1 4 I”. 35 49mm

1331n 34 99mm

Head thickness (margtn)

Intake

StaMkrd

hrnft

Exhaust

Standard

Llmlt

Stem-to-gulda clearance

Intake

Standard

Llmlt

Exhaust

Standard

Limit

Valve guide

lnslde diameter

Outside diameter 0 039 I”. 1 Omm

0 020 I”. 05mm

0 059 I” 15mm

0 031 I” 0.8mm

0 cooa- NJ20 I”. 0 02-O 05mm

0 0039 I”. O.lOmm

0002+0M)35m 005.009mm

0 0059 I”. 015mm

02mm 6 6mm

0 476 I”. 121mm

Page 139 of 408

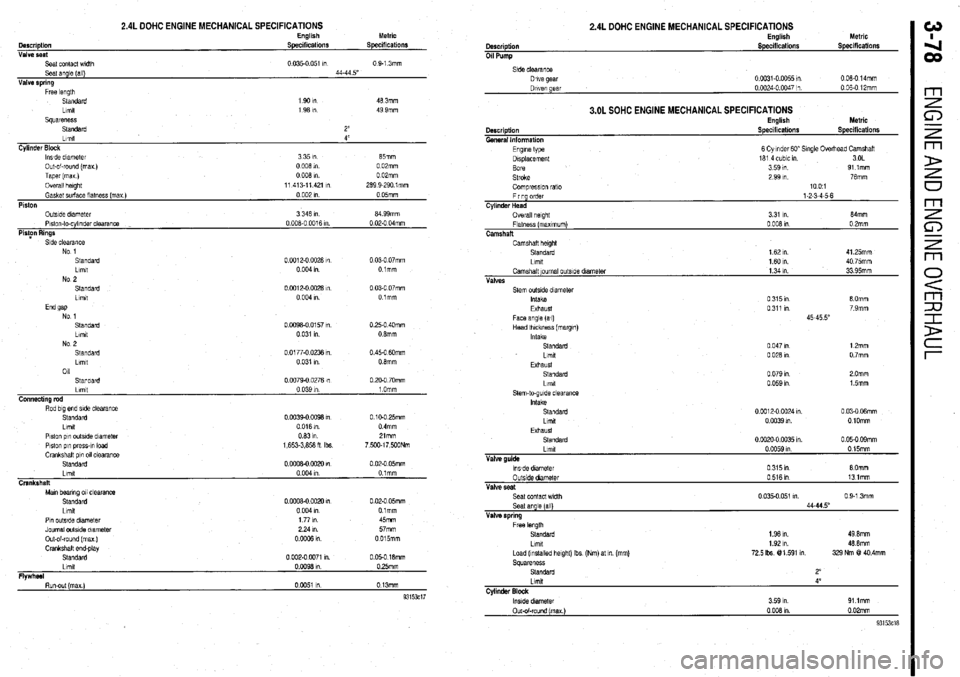

2.4L DOHC ENGINE MECHANICAL SPECIFICATIONS English Metric

Description Specifications Specdications

Valve seat

Seat contact wldlh 0.035-o 051 I”

0 9-l 3mm

Seat angle (all) 44-44 5”

Valve spring

Free length

Standard 1901n 46 3mm

Llmlt

1 96 I” 49 9mm

squareness

Standard 2”

Llmlt 4”

Cylinder Block

lwde diameter 3351n 65mm

Out-of-round (max)

0 006 in 0 02mm

Taper (mu)

0 006 I” 0 02mm

Overall height

11 413-11421 I” 269 9-290 lmm

Gasket surface llatnass (max )

0 002 In 0 05mm

Piston

OutsIde diameter

3 346 In 64 99mm

Plslon-lo-cylinder clearance

0 006.0 0016 m 0 02.0 04mm

PioFn Rings

Side clearance

No 1

Standard

0 0012-O 0026 I”

0 03-O 07mm

Limit

0 004 I”. Olmm

No 2

Standard

0 Cot 2-o 0028 I”

0 03-O 07mm

Llmlt

0 004 I” Olmm

End 9ap

No 1

Standard O.W96-0 0157 I”

0.25-O 40mm

Llmtt

0 031 I”. 0 6mm

NO 9

.__

Standard

Lrmt

011 0 0177-O 0236 I”

0 031 I” 0.45-O 6Omm

0 6mm

Standard

Llmll

Connecting rod

Rod big end side clearance

Standard

Llmlt

Plston pin outsIde dlametar

Piston p,” press-,” load

Crankshatl pin 011 clearance

Standard

Llmlt

Crankshaft

Man bearing 011 clearance

Standard

Llmlt 0

0979.0 0276 I”

0 039 I”

0 0039-o co96 I”

0 016 m.

0631n

1,653.3,656 H Ibs

0

0006-0 0020 I”

0004m

0

0006-0 0020 1”

0 004 I” 0 PO-O 70mm

1 Omm

0 10-O 25mm

0 4mm

Zlmm

7,5Wl7,500Nm

0 02-O 05mm

0 tmm

0 02-O 05mm

Olmm

Pin outstde dlameler

Journal outside diameter

Out-of-round (max )

Crankshalt and-play

Standard

Llmll

Flwhd 177m 45mm

224111 57mm

ooGQ6m 0015mm

0 002-o 0071 I”. 0 05-O 16mm

OW96Ul 0 25mm

I -. Run-out (max)

0 0051 I” 0 13mm

93153ci7

2.4L DOHC ENGINE MECHANICAL SPECIFICATIONS

0 06-O 14mm

3.OL SOHC ENGINE MECHANICAL SPECIFICATIONS

Description

General Information

Engme type

Displacement

Bore

Stroke English

Specifications Metric

Specifications

6 Cylmder GO” Single Overhead Camshatl

161 4 cubic I” 3OL

3 59 I”. 91 lmm

2 99 In. 76mm

Compreswn rat0

Firing order

Cylinder Head

Overall helghl

Flatness (maxImum)

Camshaft 1001

1-2-3-4-5-6

3 31 I” 64mrn

0 006 I” 0 2mm

Camshaft helgM

Standard

1 62 ,n 41 25mm

Llmlt

1601n 40 75mm

Camshaft ~oumal outslde diameter

1 34 I” 33 95mm

Valves

Seat contact width 0 9-1 3mm

Seat angle [all)

Valve spring

Free length

Standard

1.96 I”. 49 0mm

Llmlt

Load (Installed height) Ibs (Nm) at m (mm)

72.5 Ibs @l 591 I”.

Squareness

Standard 46 6mm

329 Nm @! 40.4mm

Lmxt 4’

Cylinder Block m