charging MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 1 of 408

HOW TO USE THIS BOOK 1-2

WHERE TOBEGIN l-2

AVOIDINGTROUBLE 1-2

MAINTENANCEORREPAIR? 1-2

AVOIDINGTHEMOSTCOMMONMISTAKES l-2

TOOLS AND EQUIPMENT 1-2

SPECIALTOOLS l-4

YOUR VEHICLE SAFELY 1-4

DON'TS l-6

FASTENERS, MEASUREMENTS AND

CONVERSIONS l-6

BOLTS,NUTSANDOTHERTHREADED

RETAINERS 1-6

TORQUE l-7

TORQUEWRENCHES l-7

TORQUEANGLEMETERS 1-9

STANDARDANDMETRIC MEASUREMENTS l-9

SERIAL NUMBER IDENTIFICATION l-10

VEHICLE IDENTIFICATION NUMBER l-10

ENGINE IDENTIFICATION NUMBER I-10

TRANSAXLEIDENTIFICATION I-10

DRlVEAXLE(AWDGALANTONLY) l-10

TRANSFERCASE(AWDGALANTONLY) l-10

ROUTINE MAINTENANCE AND TUNE-UP l-14

AIRCLEANER(ELEMENT) 1-14

REMOVAL&INSTALLATION 1-14

FUELFILTER 1-15

REMOVAL &INSTALLATION l-15

PCVVALVE l-15

REMOVAL&INSTALLATION l-15

EVAPORATIVECANISTER l-16

SERVICING 1-16

BATTERY 1-16

PRECAUTIONS I-16

GENERALMAINTENANCE 1-16

BEL BATTERYFLUID 1-16

CABLES I-17

CHARGING I-18

REPLACEMENT 1-18

TS 1-18

INSPECTiON l-18

ADJUSTMENT 1-18

REMOVAL&INSTALLATION 1-18

TIMINGBELTS l-20

INSPECTION l-20

HOSES I-20

INSPECTION l-20

REMOVAL&INSTALLATION

CV-BOOTS 1-21

INSPECTION l-21

SPARKPLUGS l-22

SPARKPLUGHEATRANGE

REMOVAL&INSTALLATION

INSPECTION &GAPPING 1.

SPARKPLUG WIRES 1-24

TESTING 1-24

REMOVAL&INSTALLATION

DISTRIBUTORCAPANDROTOR

REMOVAL&INSTALLATION

INSPECTION 1-25

IGNITIONTIMING 1-25

. GENERALINFORAMTION l-

lNSPECTlON&ADJUSTMENl

VALVE LASH l-27

ADJUSTMENT l-27

IDLESPEED 1-28 1-21

l-22

l-22

-23

1-24

l-25

l-25

.25

1-26

AIR CONDITIONING SYSTEM 1-28

SYSTEMSERVlCEiiREPAlR l-28

PREVENTIVEMAINTENANCE 1-28

SYSTEM INSPECTION l-29

WINDSHIELD WIPERS l-29

ELEMENT(REFILL)CARE&

REPLACEMENT l-29

TIRESANDWHEELS l-30

TIRE ROTATION I-30

TIRE DESIGN 1-31

TIRESTORAGE l-31

INFLATION &INSPECTION l-31

CARE OFSPECIALWHEELS l-32 OPERATION INFOREIGNCOUNTRIES l-33

ENGINE l-33

OILLEVELCHECK 1-33

OIL& FILTER CHANGE l-34

MANUALTRANSAXLE l-35

FLUIDRECOMMENDATIONS l-35

LEVELCHECK l-35

DRAIN&REFILL l-36

AUTOMATICTRANSAXLE l-36

FLUIDRECOMMENDATIONS l-36

LEVELCHECK 1-36

DRAIN&REFILL l-36

PAN & FILTERSERVICE 1-36

TRANSFERCASE(AWDGAlANT ONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

REARDRlVEAXLE(AWDGALANTONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

COOLINGSYSTEM l-39

FLUIDRECOMMENDATIONS l-39

iM-41

FLUIDS AND LUBRICANTS 1-33

FLUID DISPOSAL 1-33

FlJELANDENGlNEOILRECOMMENDATlONS

ENGINE OIL l-33

FUEL l-33

Page 15 of 408

*

l-16 GENERALINFORMATIONAND MAINTENANCE

Fig. 49 Grasp the valve and gently remove

Fig. 50 Twist and pull on the valve to re-

it from the valve cover

move it from the hose Fig. 51 Inspect the grommet and replace if

cracked or leaking oil

SERVICING

corrosive acid can also eat away at components un-

der the hood.

Always visually inspect the battery case for cracks,

leakage and corrosion. A white corrosive substance

u See Figure 52

The evaporative canister requires no periodic ser-

vicing. However, a careful inspection of the canister

and hoses should be made frequently, Replace dam- on the battery case or on nearby components would

indicate a leaking or cracked battery. If the battery is

cracked, it should be replaced immediately. GENERALMAINTENANCE '_

devices that increase parasitic load may discharge a

battery sooner. If the vehicle is to be stored for 6-B

weeks in a secure area and the alarm system, if pre-

sent, is not necessary, the negative battery cable

should be disconnected at the onset of storage to

protect the battery charge.

Remember that constantly discharging and

recharging will shorten battery life. Take rare not to

allow a battery to be needlessly discharged.

aged components as required.

The canister is typically located under one of the

front fenders, however on some later models it may

be under the rear of the vehicle, near the gas tank,

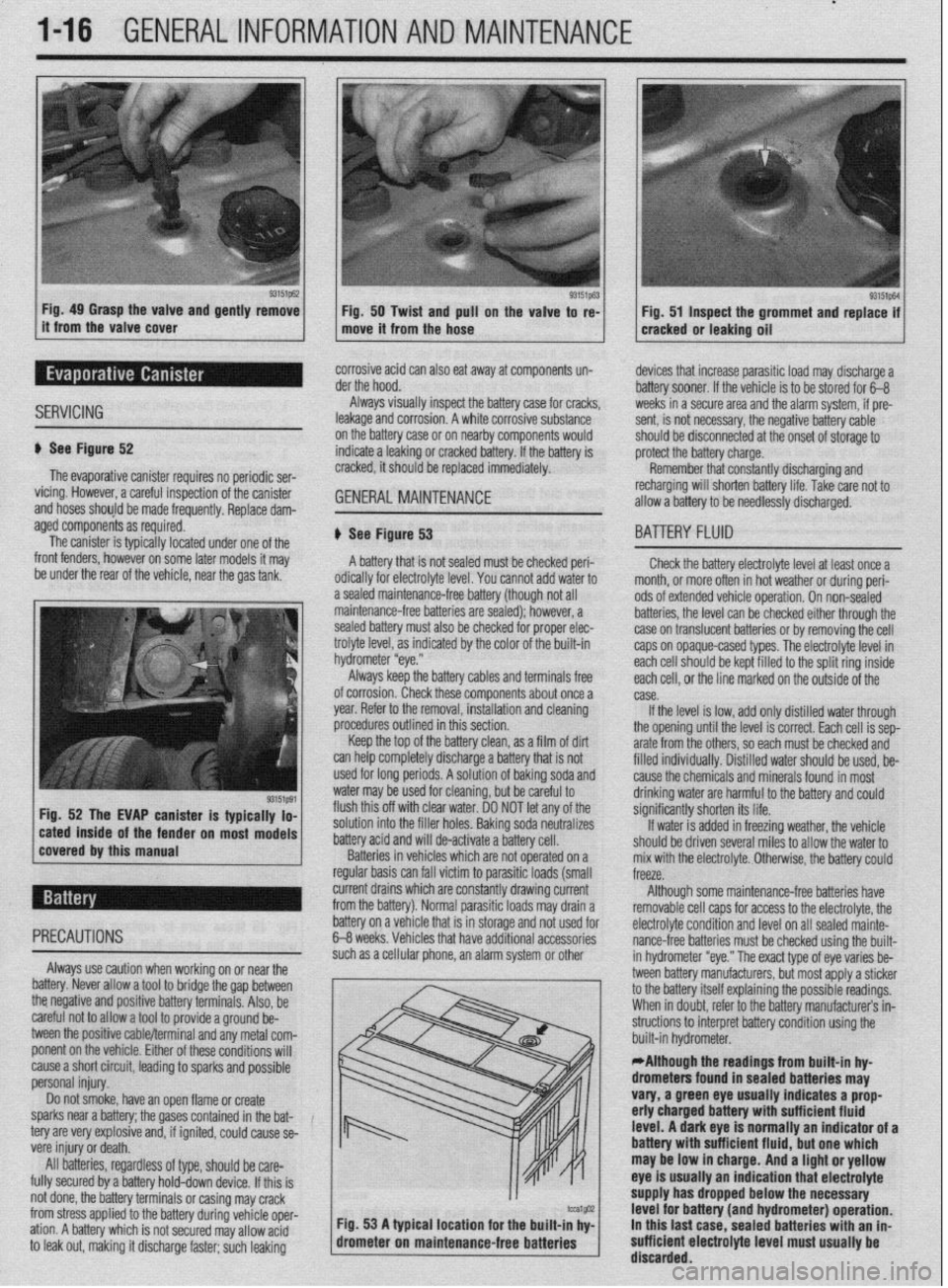

r on most models # See Figure 53

A battery that is not sealed must be checked peri-

odically for electrolyte level. You cannot add water to

a sealed maintenance-free battery (though not all

maintenance-free batteries are sealed); however, a

sealed battery must also be checked for proper elec-

trolyte level, as indicated by the color of the built-in

hydrometer “eye.”

Always keep the battery cables and terminals free

of corrosion. Check these components about once a

year. Refer to the removal, installation and cleaning

procedures outlined in this section,

Keep the top of the battery clean, as a film of dirt

can help completely discharge a battery that is not

used for long periods. A solution of baking soda and

water may be used for cleaning, but be careful to

flush this off with clear water. DO NOT let any of the

solution into the filler holes. Baking soda neutralizes

battery acid and will de-activate a battery cell.

Batteries in vehicles which are not operated on a

regular basis can fall victim to parasitic loads (small

BA-ITERY FLUID

Check the battery electrolyte level at least once a

month. or more often in hot weather or during peri-

ods of extended vehicle operation. On non-sealed

batteries, the level can be checked either through the

case on translucent batteries or by removing the cell

caps on opaque-cased types. The electrolyte level in

each cell should be kept filled to the split ring inside

each ceil, or the line marked on the outside of the

case.

If the level is low, add only distilled water through

the opening until the level is correct. Each cell is sep-

arate from the others, so each must be checked and

filled individuallv. Distilled water should be used, be-

cause the chemicals and minerals found in most

drinking water are harmful to the battery and could

significantly shorten its life.

If water is added in freezing weather, the vehicle

should be driven several miles to allow the water to

mix with the electrolyte. Otherwise, the battery could

freeze.

current drains which are constantly drawing current

from the battery). Normal parasitic loads may drain a Although some maintenance-free batteries have

removable cell caos for access to the electrolyte, the

cause a short circuit, leading to sparks and possible

personal injury.

Do not smoke, have an open flame or create

sparks near a battery; the gases contained in the bat-

tery are very explosive and, if ignited, could cause se-

vere injury or death.

All batteries, regardless of type, should be care-

fully secured by a battery hold-down device. If this is

not done, the battery terminals or casing may crack

from stress applied to the battery during vehicle oper-

ation. A battery which is not secured may allow acid

to leak out, making it discharge faster; such leaking m / built-in hydrometer. .

*Although the readings from built-in hy-

drometers found in sealed batteries may

vary, a green eye usually indicates a prop

erly charged battery with sufficient fluid

level. A dark eye is normally an indicator of a

battery wlth sufficient fluid, but one which

may be low in charge. And a light or yellow

eye is usually an indication that electrolyte

supply has dropped below the necessary

tcu1@32 Fig. 53 A typical location for the built-in hv- level for battery (and hydrometer) operation.

drometer on maintenan

ce-free batteries ’ I In this last case. sealed batteries with an in-

sufficient electrolyte level must usually be

’ discarded.

Page 16 of 408

G,ENERALlNFORMATlONAND MAINTENANCE l-17

Fig. 54 On

non-maintenance-free

batteries,

the fluid level can be checked through the Fig. 55 If the fluid

level

is low, add only dis-

1 case on translucent models; the cell caps 1

must be removed on other models

1 1 tilled water through the opening until the

1 level is correct

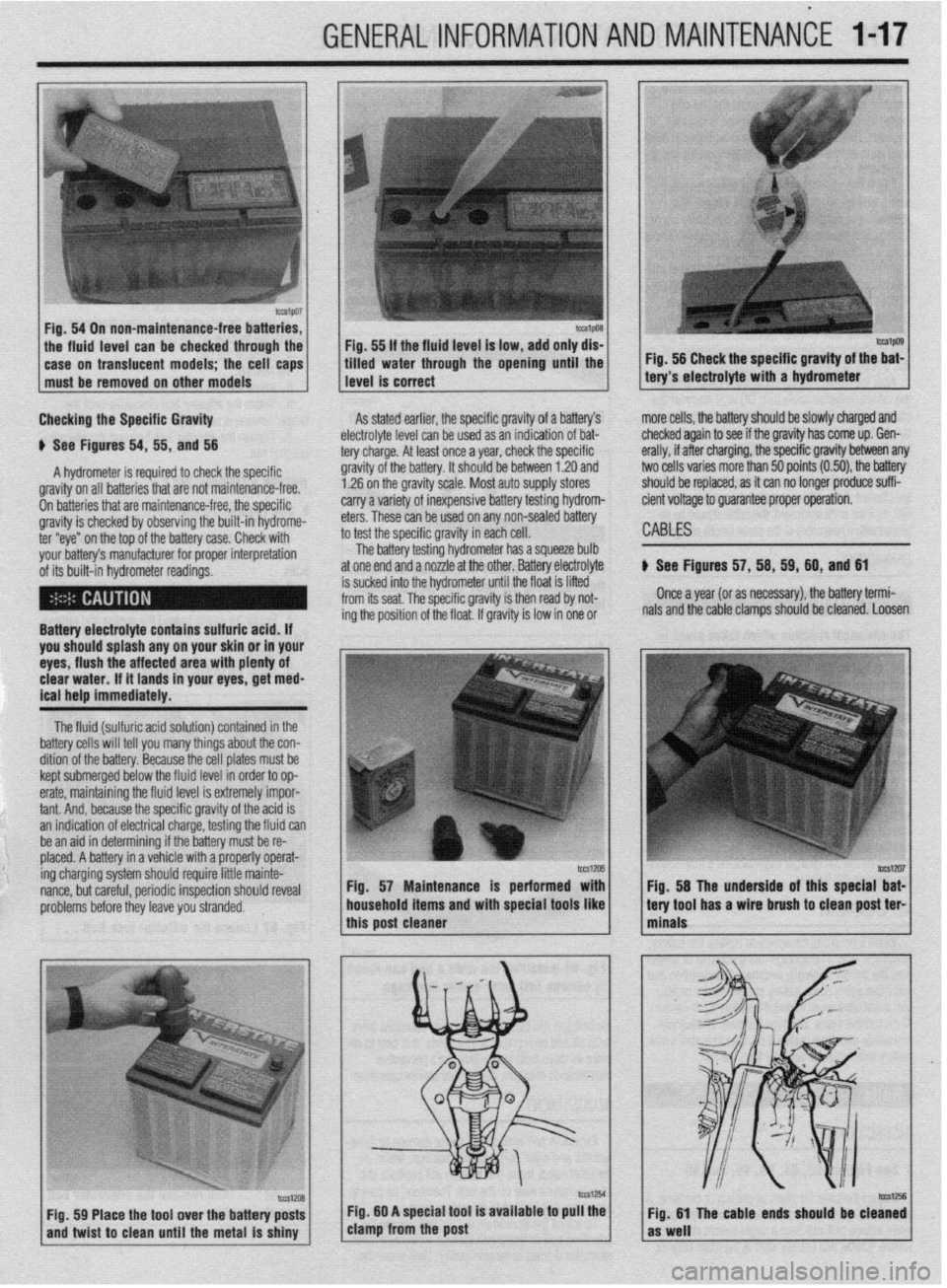

Checking the Specific Gravity

A hydrometer is required to check the specific

# See Figures 54, 55, and 56

gravity on all batteries that are not maintenance-free.

On batteries that are maintenance-free, the soecific

gravity is checked by observing the built-in hydrome-

ter “eye” on the top of the battery case. Check with

your battery’s manufacturer for proper interpretation

of its built-in hvdrometer readinas. gravity of the battery. It should be between 1.20 and As stated earlier, the specific gravity of a battery’s

electrolyte level can be u

1.26 on the gravity scale. Most auto supply stores sed as an indication of bat-

tery charge. At least once

carry a variety of inexpensive battery testing hydrom- ? a year, check the specific

eters. These can be used on any non-sealed battery

, , , ,,

.,, . .

IO rest me specmc gravny in each cell.

The battery testing hydrometer has a squeeze bulb

at one end and a nozzle at the other. Battery electrolyte

the hydrometer until the float is lifted

-he specific gravity is then read by not-

n of the float. If gravity is low in one or mg tne posrtro

Battery electrolyte contains sulfuric acid. If

you should splash any on your skin or in your

eyes, flush the affected area with plenty of

clear water. If it lands in your eyes, get med-

ical help immediately.

The fluid (sulfuric acid solution) contained in the

battery cells will tell you many things about the con-

dition of the battery. Because the cell plates must be

kept submerged below the fluid level in order to op-

erate, maintaining the fluid level is extremely impor-

tant. And. because the soecific aravitv of the acid is

an indication of electrical charge, testing the fluid can

be an aid in determining if the battery must be re-

placed. A battery in a vehicle with a properly operat-

ing charging system should require little mainte-

nance, but careful, periodic inspection should reveal

problems before they leave you stranded. Fig. 57 Maintenance is performed with

Fig. 58 The underside of this special bat-

household items and with special tools like

tery tool has a wire brush to clean post ter-

I this post cleaner

I 1 minals Fig. 56 Check the specific gravity of the bat-

tery’s electrolyte with a hydrometer

more cells, the battery should be slowly charged and

Lhecked aqain to see if the aravitv has come

UP. Gen-

erally, if affer charging, the specific gravity between any

two cells varies more than 50 points (0.50) the battery

should be replaced, as it can no longer produce suffi-

cient voltage to guarantee proper operation.

CABLES

) See Figures 57, 56, 69, 60, and 61

Once a year (or as necessary), the battery termi-

nals and the cable clamps should be cleaned. Loosen

Page 17 of 408

l

1-18 GENERALINFORMATIONAND MAINTENANCE

the clamps and remove the cables, negative cable

first. On batteries with posts on top, the use of a

puller specially made for this purpose is recom-

mended. These are inexoensive and available in most alternator or turn the adjusting bolt to adjust belt ten-

sion. Once the desired value is reached, secure the

bolt or locknut and recheck tension.

d”t” lJdlL> X”lt;>. 31°C LtXlllllldl lJdllt2)’ MLJIC, dlt’ X- cured with a small bolt. ST& I REMOVAL &INSTALLATION

Clean the cable clamps and the battery terminal I

with a wire brush, until all corrosion, grease, etc., is

removed and the metal is shinv. It is esneciallv imnnr-

tant to c

knife is useful nere), since a smart

material or oxidation there will pre Clean the cable clamps and the battery terminal

with a wire brush, until all corrosion, grease, etc., is

removed and the metal is shiny. It is especially impor-

tant to clean the inside of the clamp thoroughly (an old

knife is useful here), since a small deposit of foreign

material or oxidation there will prevent a sound electri-

cal connection and inhibit either starting or charging.

Special tools are available for cleaning these parts,

one type for conventional top post batteries and an-

other type for side terminal batteries. It is also a good

idea to apply some dielectric grease to the terminal, as

this will aid in the prevention of corrosion,

After the clamps and terminals are clean, reinstall

the cables, negative cable last; DO NOT hammer the

clamps onto battery posts. Tighten the clamps se-

curely, but do not distort them. Give the clamps and

terminals a thin external coating of grease after in-

stallation, to retard corrosion.

Check the cables at the same time that the terminals

are cleaned. If the cable insulation is cracked or bro-

ken, or if the ends are frayed, the cable should be re-

placed with a new cable of the same length and gauge.

CHARGING

the cables, negative cable last; DO NOT hammer the

curely, but do not distort them. Give the clamps and

terminals a thin external coating of grease after in-

stallation, to retard corrosion.

Check the cables at the same time that the terminals

are cleaned. If the cable insulation is cracked or bro-

ken, or if the ends are frayed, the cable should be re-

placed with a new cable of the same length and aauae.

CHARGING

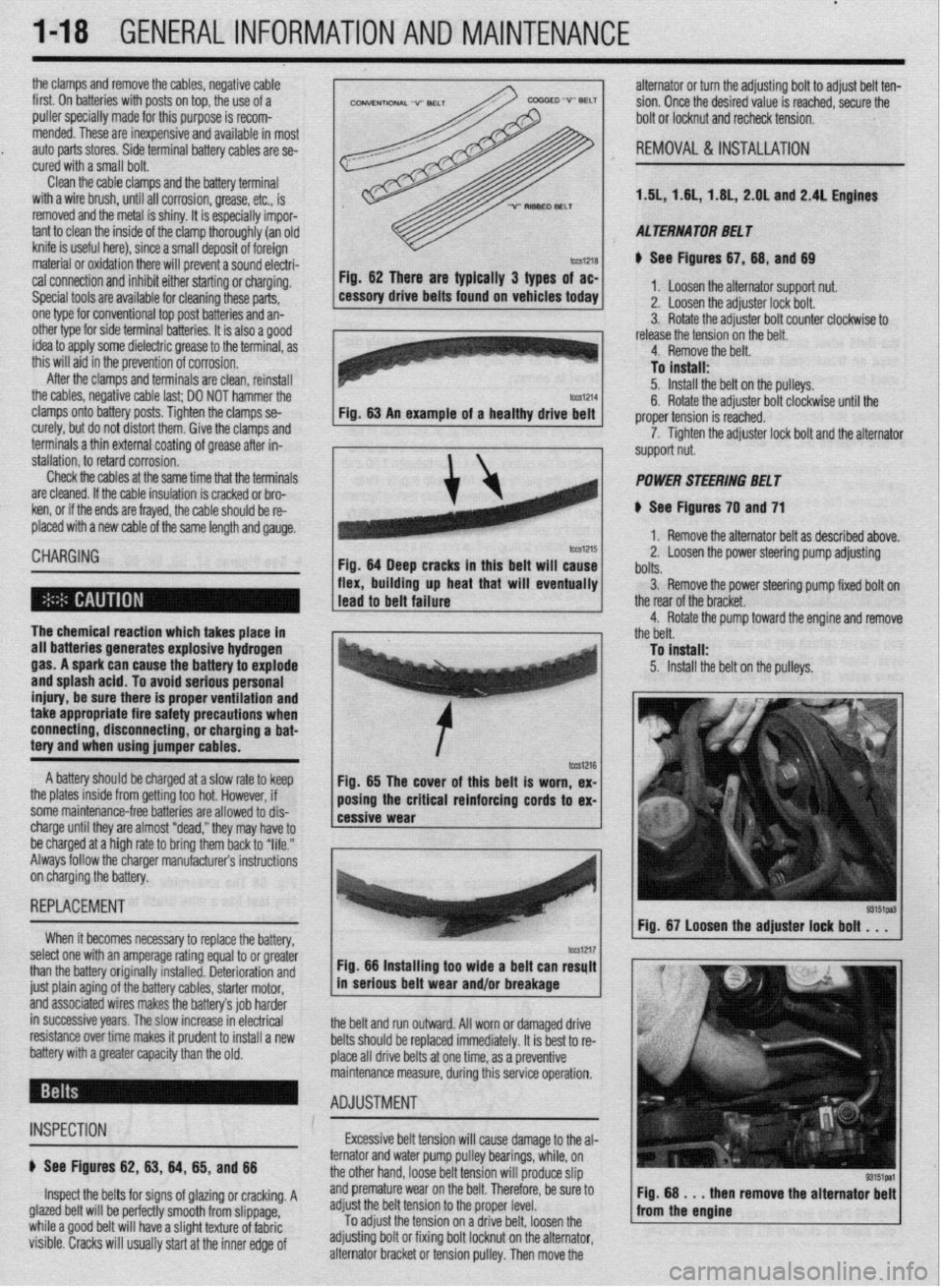

Fig. 62 mere are typically 3 types of ac-

cessory drive belts found on vehicles today 1. Loosen the alternator support nut.

2. Loosen the adjuster lock bolt.

3. Rotate the adjuster bolt counter clockwise to

I .I , . . . * . .

I Tn i”et*ll* Fig. 62 There are typically 3 types of ac-

Fig. 64 Deep cracks in this belt will cause

flex, building up heat that will eventually 11, 1.8L, 2.OL and 2.4L Engines

cal connection and inhibit either starting or charging.

Special tools are available for cleaning these parts,

one type for conventional top post batteries and an-

other type for side terminal batterin, I+ if QI@* 3 nnnd

idea to apply some dielectric grr

this will aid in the prevention of ,,vIIuaIUII.

After the clamps and terminals are clean, reinstall 1.5L, 1.6

AL TERNA TOR BE1 T

e See Figures 67,68, and 69

1. Loosen the alternator support nut.

2. Loosen the adjuster lock bolt.

3. Rotate the adjuster bolt counter clockwise to

release the tension on the belt.

4. Remove the belt.

To install:

5. Install the belt on the pulleys.

6. Rotate the adjuster bolt clockwise until the

proper tension is reached.

7. Tighten the adjuster lock bolt and the alternator

support nut.

POWER STEERING BELT

8 See Figures 70 and 71

1. Remove the alternator belt as described above.

2. Loosen the power steering pump adjusting

bolts.

3. Remove the power steering oumo fixed bolt on

R Rntatn the cxiillrtm hnit A&+,& until the r -r- .- .- ._.. ._ .______

7. Tighten the adjuster lock bolt and the alternator

support nut.

POWER STEERING BELT

1 ..“‘.I ““..Y...Y up II”“. ..IU. ..m.*

1 lead to belt failure V.

I

I

The chemical reaction which takes place in - 1 the rear of the bracket.

4. Rotate the pump toward the engine and remove

the belt.

all batteries generates explosive hydrogen

gas. A spark can cause the battery to explode

and splash acid. To avoid serious personal

injury, be sure there is proper ventilation and

take appropriate fire safety precautions when

connecting, disconnecting, or charging a bat-

tery and when using jumper cables. To fnstall:

5. Install the belt on the pulleys.

A battery should be charged at a slow rate to keep

the plates inside from getting too hot. However, if

some maintenance-free batteries are allowed to dis-

charge until they are almost “dead,” they may have to

be charged at a high rate to bring them back to “life.”

Always follow the charger manufacturers instructions

on charging the battery. 85 The cover of this belt ex-

Fig. is worn,

REPLACEMENT

When it becomes necessary to reolace thn haeoN

‘” yyL’“‘J’ I or oreMer

select one with an amperage rating equal tc .

a ----

than the battery originally installed. Deterioration and

just plain aging of the battery cables, starter motor,

and associated wires makes the battery’s job harder

in successive years. The slow increase in electrical

resistance over time makes it prudent to install a new

battery with a greater capacity than the old. 1 Fig. 67 Loosen the adjuster lock bolt . . .

I ‘-

I -. -_ tm1217 Fig. 66 Installing too wide a belt can resylt

in serious belt wear and/or breakage

the belt and run outward. All worn or damaged drive

belts should be replaced immediately. It is best to re-

place all drive belts at one time, as a preventive

uring this service operation. maintenance measure, d

- ADJUSTMENT : *

INSPECTION Excessive belt tension will cause damage to the al-

e See Figures 62, 83, 64, 65, and 88

Inspect the belts for signs of glazing or cracking. A

glazed belt will be perfectly smooth from slippage,

while a good belt will have a slight texture of fabric

visible. Cracks will usually start at the inner edge of pulley bearings, while, on

It tension will

Droduce slin ternator and water pump

the other hand, loose be

r ------ r

and premature wear on the belt. Therefore, be sure to

adjust the belt tension to the proper level.

To

adjust the tension ’ ’ ’ ” ’ ‘* adjusting bolt or fixing b

alternator bracket or tens on a onve Den. loosen me I Fig. 68 . . . then

from the engine remove the alternator

bolt locknut on the alternator,

iion pulley. Then move the

Page 44 of 408

GENERALINFORMATIONAND MAINTENANCE 1-45

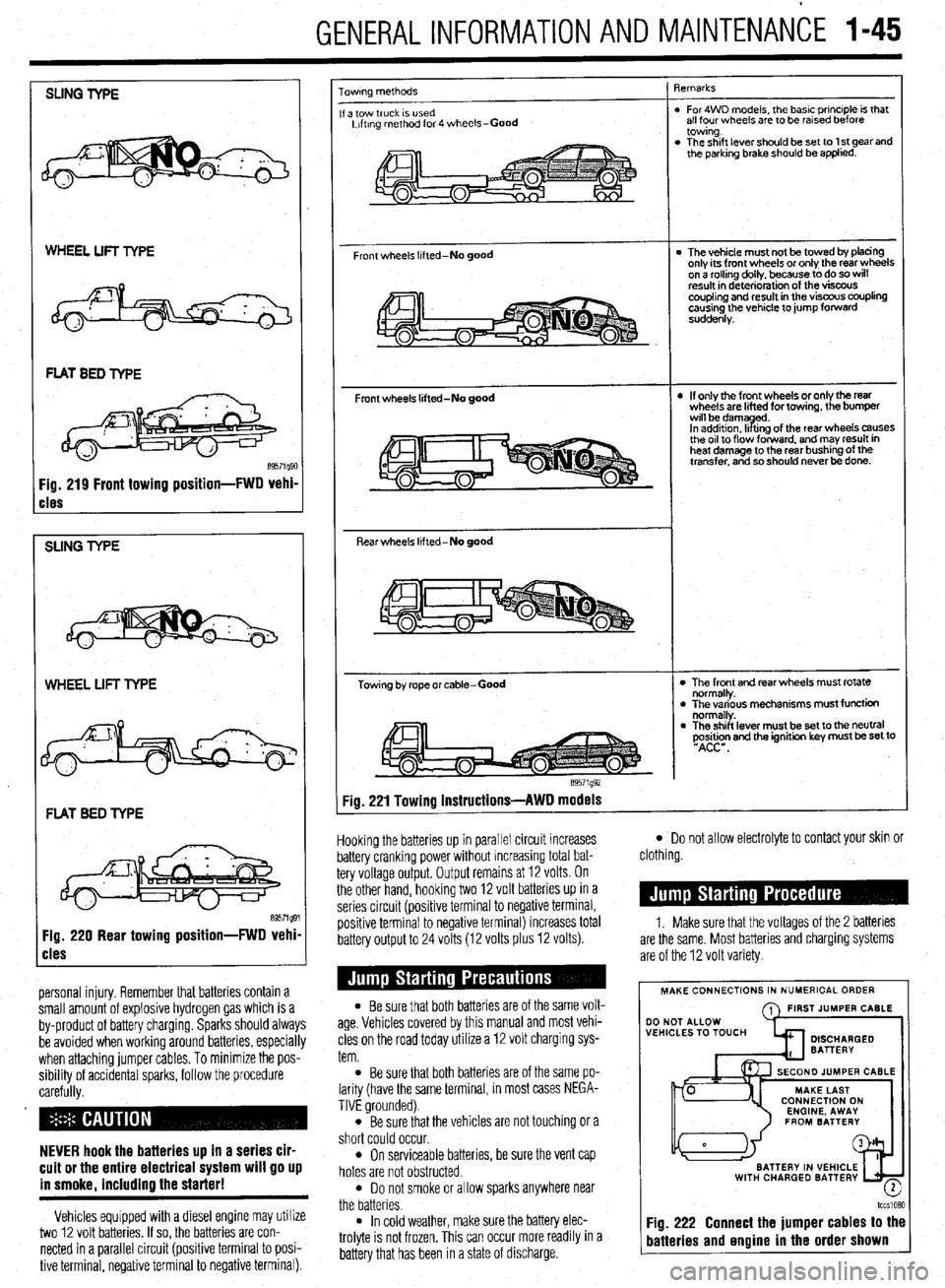

SLING TYPE

WHEEL LIFT TYPE

cles

SUNG TYPE

WHEEL LIFT TYPE

FLAT BED TYPE

Fig. 220 Rear towing position-FWD vehi

cles

personal injury. Remember that batteries contain a

small amount of explosive hydrogen gas which is a

by-product of battery charging. Sparks should always

be avoided when working around batteries, especially

when attaching jumper cables. To minimize the pos-

sibility of accidental sparks, follow the procedure

carefully.

NEVER hook the batteries up in a series cir-

cuit or the entire electrical system will go up

in smoke. includino the starter!

Vehicles equipped with a diesel engine may utilize

two 12 volt batteries. If so, the batteries are con-

nected in a parallel circuit (positive terminal to posi-

tive terminal, negative terminal to negative terminal).

owrng methods

a tow truck IS used

Lrftrng method for 4 wheels-Good

Front wheels lifted-No good

Front wheels lifted-No good

Rear wheels lifted-No good

Towing by rope or cable-Good

e9571g92 qemarks

. For4WD models, the basic principle is that

all four wheels are to be rarsed before

towing.

. The shift lever should be set to 1 st gear and

the parking brake should be applied.

l The vehicle must not be towed by tofacing

only its front wheels or only the rear wheels

on a rollino dollv, because to do so will

result in d&e&ration of the visfx~s

coupling and result in the viscous coupling

causing the vehicle to jump forward

suddenly.

l If only the front wheels or only the rear

wheels are lifted for towing, the bumper

wrll bedamyd.

In addrtron. II trng of the rear wheels causes

the or1 to flow forward. and may result in

heat damage to the rear bushing of the

transfer, and so should never be done.

l The front and rear wheels must rotate

normally.

l The various mechanisms must function

normally.

l The shift lever must be set to the neutral

~Asi&n and the ignition key must be set to

Fig. 221 Towing instructions-AWD models

Hooking the batteries up in parallel circuit increases

battery cranking power without increasing total bat-

tery voltage output. Output remains at 12 volts. On

the other hand, hooking two 12 volt batteries up in a

series circuit (positive terminal to negative terminal,

positive terminal to negative terminal) increases total

battery output to 24 volts (12 volts plus 12 volts).

l Be sure that both batteries are of the same volt-

age. Vehicles covered by this manual and most vehi-

cles on the road today utilize a 12 volt charging sys-

tem.

l Be sure that both batteries are of the same po-

larity (have the same terminal, in most cases NEGA-

TIVE grounded).

l Be sure that the vehicles are not touching or a

short could occur.

l On serviceable batteries, be sure the vent cap

holes are not obstructed.

l Do not smoke or allow sparks anywhere near

the batteries.

l In cold weather, make sure the battery elec-

trolyte is not frozen, This can occur more readily in a

battery that has been in a state of discharge.

l Do not allow electrolyte to contact your skin or

clothing.

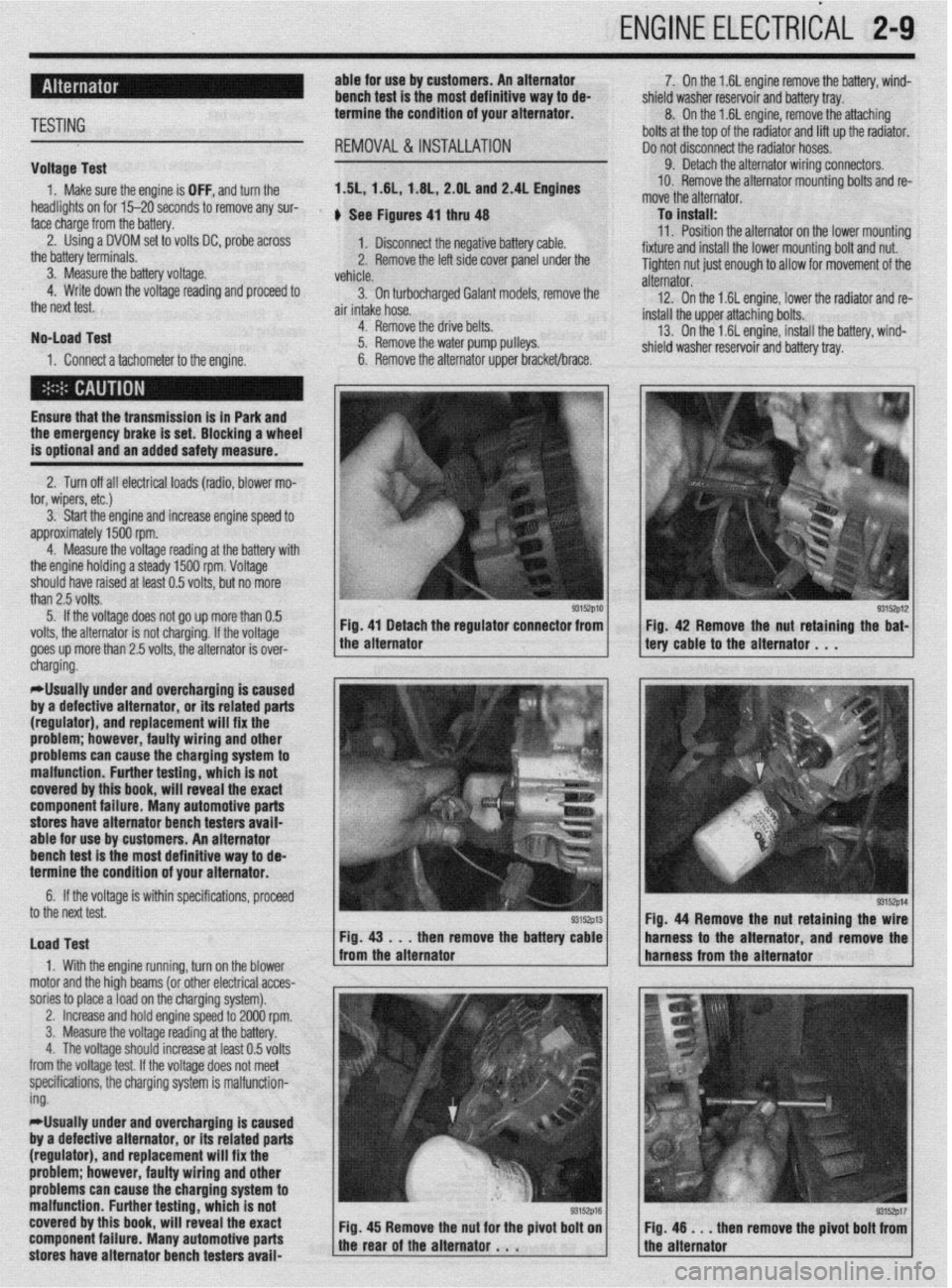

1. Make sure that the voltages of the 2 batteries

are the same. Most batteries and charging systems

are of the 12 volt variety.

MAKE CONNECTIONS IN NUMERICAL ORDER

A FIRST JUMPER CABLE

WITH CHARGED BATTERY

-

lccslQ?,Q

Fig. 222 Connect the jumper cables to the

batteries and engine in the order shown

Page 48 of 408

DISTRIBUTOR IGNITION SYSTEM

GENERALINFORMATION 2-2

DIAGNOSISANDTESTING 2-2

SECONDARYSPARKTEST 2-2

CYLINDERDROPTEST 2-2

ADJUSTMENTS 2-3

IGNITION COIL 2-3

TESTING 2-3

REMOVAL&INSTALLATION 2-3

POWERTRANSISTOR

(Ignition Module) 2-4

REMOVAL&INSTALLATION 2-4

DISTRIBUTOR 2-4

REMOVAL&INSTALLATION 2-4 2-2

INSTALLATION 2-4

CRANKSHAFTANDCAMSHAFTPOSITION

SENSORS 2-5

DISTRIBUTORLESS IGNITION

SYSTEM 2-5

GENERALINFORMATION 2-5

DIAGNOSISANDTESTING 2-5

ADJUSTMENTS 2-5

IGNITION COIL(s) 2-5

TESTING 2-5

REMOVAL&INSTALLATION 2-6

POWERTRANSISTOR

(IGNITION MODULE) 2-7

REMOVAL&INSTALLATION 2-7

CRANKSHAFTANDCAMSHAFTPOSITION

SENSORS 2-7

FIRING ORDERS 2-7

CHARGING SYSTEM 2-8

GENERALINFORMATION 2-8

ALTERNATORPRECAUTIONS 2-8

ALTERNATOR 2-8

TESTING 2-8 I

REMOVAL&INSTALLATION 2-9

REGULATOR 2-10

REMOVAL&INSTALLATION 2-10

STARTING SYSTEM 2-10

GENERALINFORMATION 2-10

STARTER 2-10

TESTING 2-10

REMOVAL&INSTALLATION 2-11

SENDING UNITS 2-11

ENGINECOOLANTTEMPERATURE

SENDING UNIT 2-11

TESTING 2-11

REMOVAL&INSTALLATION 2-11

OIL PRESSURESENDING UNIT 2-12

TESTING 2-12

REMOVAL&INSTALLATION 2-12

Page 55 of 408

.

2-8 ENGINEELECTRICAL

Front

of the

Vehicle

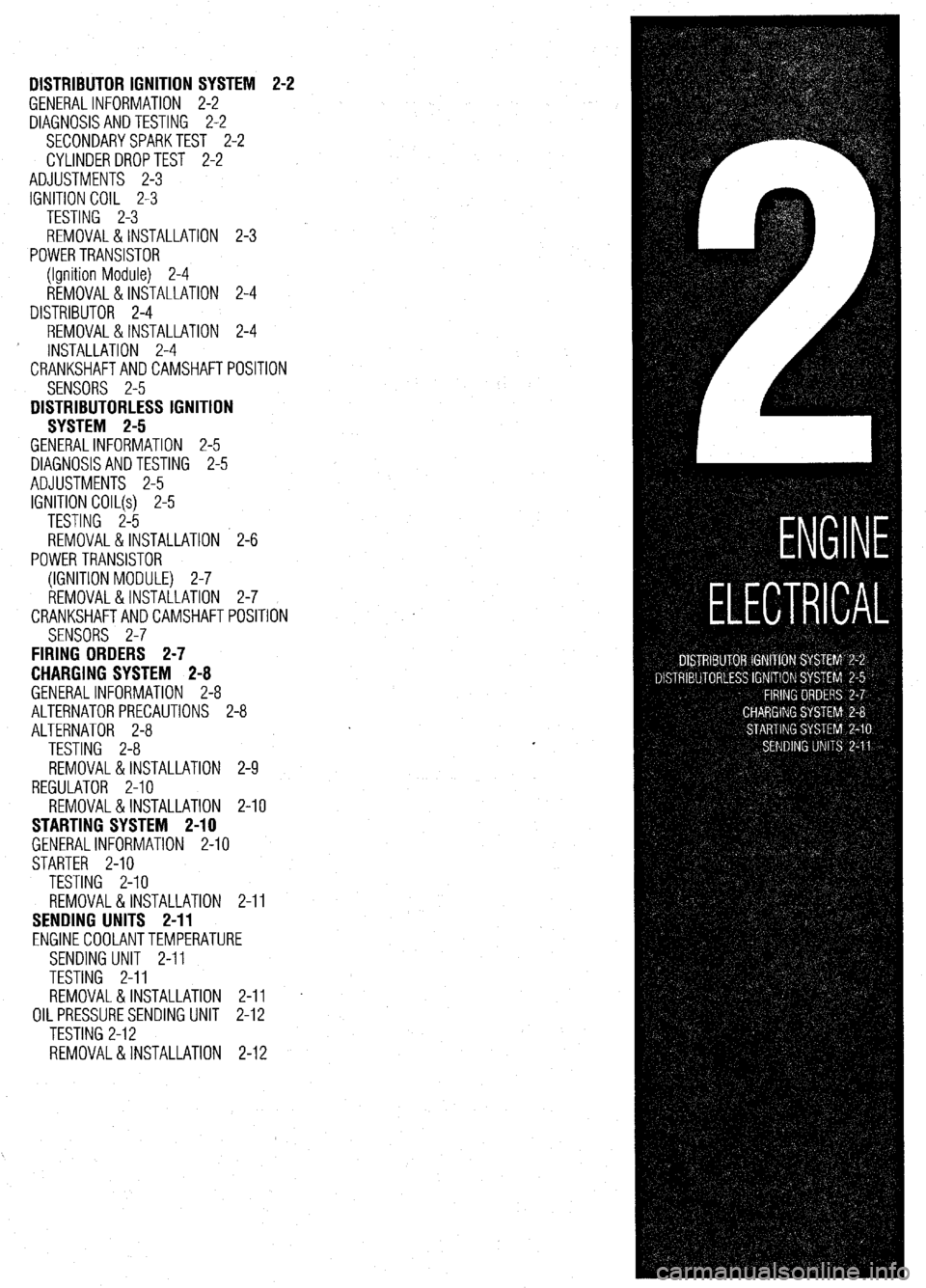

Fig. 35 1.61(4661) and 2.OL (4663) DDHC

engines

Firing order: l-3-4-2

Distributorless ignition system

Fig. 36 2.4L (4664) DDHC engine with dis-

lributorless ignition

Firing order: l-3-4-2

gistributorless ignition system

Front

of the

Vehicle

+

Fig. 36 1997-00 1.6L (4693) and 1999-00

2.41(4664) Engines with distributorless ig-

nition

Firing order: l-3-4-2

Distributorless ignition system

792!33g26 Fig. 39 3.OL (6672) SDHC and 3.5L (6674)

engines

Firing order: l-2-3-65-6

Distributor rotation: Counterclockwise Fig. 37 2.4L (4664) engine with distributor

ignition

Firing order: l-3-4-2

Distributor rotation: Counterclockwise

:ig. 40 3.OL (6672) DDHC engine

Yring order: l-2-3-4-5-6

Iistributorless ignition system

The automobile charging system provides electri-

cal power for operation of the vehicle’s ignition and

starting systems and all the electrical accessories.

The battery serves as an electrical surge or storage

tank, storing (in chemical form) the energy originally

produced by the engine driven alternator. The system

also provides a means of regulating generator output

to protect the battery from being overcharged and to

avoid excessive voltage to the accessories.

The storage battery IS a chemical device incorpo-

rating parallel lead plates in a tank containing a sul-

furic acid/water solution. Adjacent plates are slightly

dissimilar, and the chemical reaction of the 2 dissim-

ilar plates produces electrical energy when the battery

is connected to a load such as the starter motor. The

chemical reaction is reversible, so that when the gen-

erator IS producing a voltage (electrical pressure)

greater than that produced by the battery, electricity is

forced into the battery, and the battery is returned to

its fully charged state.

The vehicle’s alternator is driven mechanically, by

a belt(s) that is driven by the engine crankshaft. In an alternator, the field rotates while all the current pro-

duced passes only through the stator winding. The

brushes bear against continuous slip rings rather

than a commutator. This causes the current produced

to periodically reverse the direction of its flow creat-

ing alternating current (A/C). Diodes (electrical one-

way switches) block the flow of current from traveling

in the wrong direction. A series of diodes is wired to-

gether to permit the alternating flow of the stator to be

converted to a pulsating, but unidirectional flow at

the alternator output, The alternators field is wired in

series with the voltage regulator.

The regulator consists of several circuits. Each cir-

cuit has a core, or magnetic coil of wire, which oper-

ates a switch. Each switch is connected to ground

through one or more resistors. The coil of wire re-

sponds directly to system voltage. When the voltage

reaches the required level, the magnetic field created

by the winding of wire closes the switch and inserts a

resistance into the generator field circuit, thus reduc-

ing the output. The contacts of the switch cycle open

and close many times each second to precisely con-

trol voltage. Several precautions must be observed when per-

forming work on alternator equipment.

l If the battery is removed for any reason, make

sure that it is reconnected with the correct polarity.

Reversing the battery connections may result In dam-

age to the one-way rectifiers.

l Never operate the alternator with the main cir-

cuit broken. Make sure that the battery, alternator,

and regulator leads are not disconnected while the

engine is running.

l Never attempt to polarize an alternator. l When charging a battery that is installed in the

vehicle, disconnect the negative battery cable.

l When utilizing a booster battery as a starting

aid, always connect it in parallel; negatrve to nega-

tive, and positive to positrve.

l When arc (electric) welding is to be performed

on any part of the vehicle, disconnect the negative

battery cable and alternator leads.

l Never unplug the PCM while the engine is run-

ning or with the ignition in the ON position. Severe

and expensive damage may result within the solid

state equipment.

Page 56 of 408

ENGlNEELECTRldAL 2-9

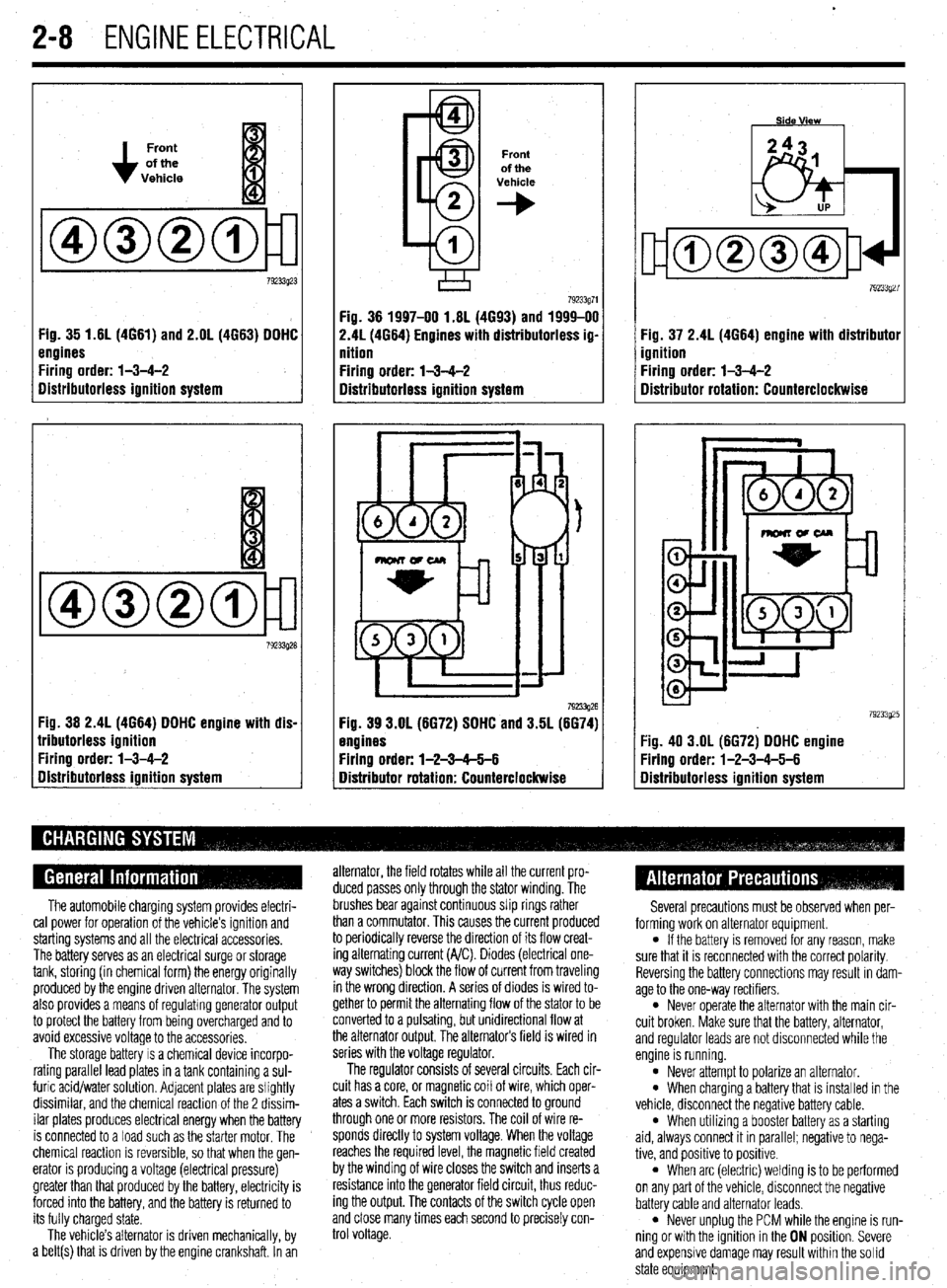

TESTING

Voltage Test able for use by customers. An alternator

bench test is the most definitive way to de-

termine the condition of your alternator.

REMOVAL&INSTALLATION

1. Make sure the engine is OFF, and turn the 1.51,1.61, 1.6L, 2.OL and 2.4L Engines

headlights on for 15-20 seconds to remove any sur-

face charge from the battery. , See Figures 4, thru 48

2. Using a DVOM set to volts DC, probe across

1. Disconnect the negative battery cable.

the battery terminals.

3. Measure the battery voltage. 2. Remove the left side cover panel under the

vehicle.

4. Write down the voltage reading and proceed to

3. On turbocharaed Galant models, remove the

the next test.

air intake hose. -

No-load Test

1. Connect a tachometer to the engine. 4. Remove the drive belts.

5. Remove the water pump pulleys.

6. Remove the alternator upper bracket/brace.

Ensure that the transmission

is in Park and the emergency brake is set. Blocking a wheel

is optional and an added safety measure.

2. Turn off all electrical loads (radio, blower mo-

tor, wipers, etc.)

3. Start the engine and increase engine speed to

approximately 1500 rpm.

4. Measure the voltage reading at the battery with

the engine holding a steady 1500 rpm. Voltage

should have raised at least 0.5 volts, but no more

than 2.5 volts.

5. If the voltage does not go up more than 0.5

volts, the alternator is not charging. If the voltage

goes up more than 2.5 volts, the alternator is over-

* 7. On the 1.6L engine remove the battery, wind-

shield washer reservoir and battery tray.

8. On the 1.6L engine, remove the attaching

bolts at the top of the radiator and lift up the radiator.

Do not disconnect the radiator hoses.

9. Detach the alternator wiring connectors.

10. Remove the alternator mounting bolts and re-

move the alternator.

To install:

11. Position the alternator on the lower mountina

fixture and install the lower mounting bolt and nut. U

Tighten nut just enough to allow for movement of the

alternator.

12. On the 1.6L engine, lower the radiator and re-

install the upper attaching bolts.

13. On the 1.6L engine, install the battery, wind-

shield washer reservoir and battery tray.

/ tery cable to the alternator . , . 93152p12 Fig 42 Remove the nut retaining the bat-

cnargmg.

*Usually under and overcharging is‘caused

by a defective alternator, or its related parts

(regulator), and replacement will fix the

problem; however, faulty wiring and other

problems can

cause the charging system to

malfunction. Further testing, which is not

covered by this book, will reveal the exact

component failure. Many automotive parts

stores have alternator bench testers avaii-

able for use by customers. An alternator

bench test is the most definitive way to de-

termine the condition of your alternator.

6. If the voltage is within specifications, proceeU

to the next test.

Load Test

1. With the engine running, turn on the blower

motor and the hioh beams (or other electrical acces-

sories to place aioad on the charging system). Fig. 44 Remove the nut retaining the

then remove the batte harness to the alternator and remov

,

2. Increase and hold engine speed to 2000 rpm.

3. Measure the voltage reading at the battery.

4. The voltage should increase at least 0.5 volts

from the voltage test. If the voltage does not meet

specifications, the charging system is malfunction-

ing.

*Usually under and overcharging is caused

by a defective alternator, or its related parts

(regulator), and replacement will fix the

problem; however, faulty wiring and other

problems can cause the charging system to

malfunction. Further testing, which is not

covered by this book, will reveal the exact

component failure. Many automotive parts

stores have alternator bench testers avaii-

93152p17 en remove the pivot bolt from

Page 57 of 408

.

2-10 ENGINEELECTRICAL 1

2. Disconnect and remove the air intake hose.

3. Loosen the tensioner pulley and remove the

alternator drive belt.

4. On California models, remove the rear bank

converter assembly.

5. Remove the engine roll stopper stay bracket

assembly.

6. On the 3.OL SDHC engine, disconneCt the

EGR temperature sensor wire and remove the EGR

pipe assembly.

7. On the 3.OL SOHC engine, remove the intake

plenum stay bracket assembly.

8. Detach the alternator wiring harness connec-

tors.

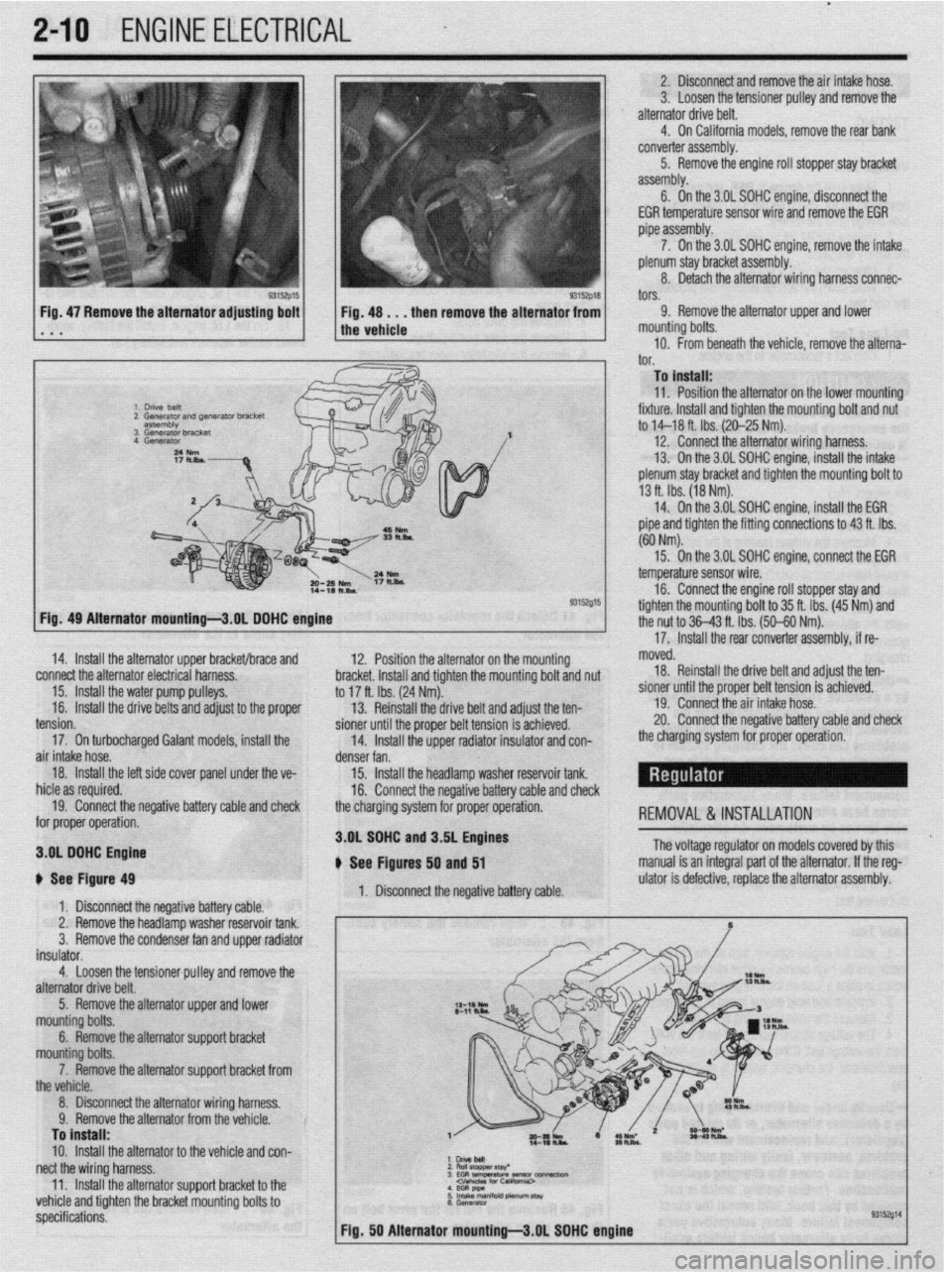

Fig, 47 Remove the alternator adjusting bolt

. a a 9. Remove the alternator upper and lower

mounting bolts.

10. From beneath the vehicle, remove the alterna-‘

I^”

._. To install:

11. Position the alternator on the lower mountino

fixture. Install and tighten the mounting bolt and nu<

to M-18 ft. Ibs. (20-25 Nm).

12. Connect the alternator wiring harness.

13. On the 3.OL SOHC engine, install the intake

plenum stay bracket and tighten the mounting bolt to

13 ft. Ibs. (18 Nm).

14. On the 3.OL SOHC engine, install the EGR

pipe and tighten the fitting connections to 43 ft. Ibs.

(60 Nm).

93152015

12. Position the alternator on the mour

sting hmrkd lnrtnll rmr( tinhtnn thn mm dim L VIUVI,VL. lllcllUll Ully llylllvll LltU ,,tvuln,,ly volt and nut

to 17 ft. Ibs. (24 Nm).

13. Reinstall the drive belt and adjust the ten-

pinnor fmtil the nmnor hdt toncinn ic art-:--~

15. On the 3.OL SOHC enoine. connect the EGR

- temperature sensor wire.

16. Connect the engine roll stopper stay and

tighten the mountina bolt to 35 ft. Ibs. (45 Nm) and

the nut to 36-43 ft. Tbs. (50-60 Nm).

’

17. Install the rear converter assembly, if re- Fia. 49 Alternator mountinu-3.0L DOHC enoine

14. Install the alternator upper bracket/brace and

connect the alternator electrical harness.

15. Install the water pump pulleys.

16.

Install the drive belts and adjust to the proper moved.

18. Reinstall the drive belt and adjust the ten-

sioner until the proper belt tension is achieved.

19. Connect the air intake hose.

20. Connect the neoativa hatterv rzahle and check -_. -_. __. _. _=-__

_ _-.._. , ___ _ _. _ _ _ _

the charoina system for orooer ooeration. - - _ -rr- -- - I Ull” Yvll air intake hose.

denser fan.

18.

Install the left side cover panel unde

r the ve-

15. Install the headlamp washer reservoir tank.

hid@ zx ran~kwl 1IIVI” YY ‘“~“““Y.

16. Connect the negative battery cable and check

19. Connect the negative battery cable and check

the charging svstem for proper operation.

-,-.- for proper operation. REMOVAL &INSTALLATION

3.OL SOHC n C, n---I_--

3.OL DOHC Engine

i fhs Itin** tension.

17. On turbocharged Galant models, install the

b See Figure 49

1. Disconnect the negative battery cable.

2. Remove the headlamp washer reservoir tank.

3.

Remove the condenser fan and upper radiator

insulator.

4.

Loosen the tensioner pulley and remove the

alternator drive belt. and J.DL engines

, - , lyures 50 and 51

1. Disconnect the negative battery cable. The voltage regulator on models covered by this

manual is an integral part of the alternator. If the reg-

ulator is defective, replace the alternator assembly.

5. Remove the alternator upper and lower

mounting bolts.

6. Remove the alternator support bracket

mn~lntinn h&c

_ _ _ _ -. ._ ,_._

--TT-.. -.--..-. ..-...

the vehicle.

8. Disconnect the alternator wiring harness.

Q Romnm thn slternatnr frnm thn mhirln V. llYlll”“Y LI1”“I~Y1IIU,“I II”,,, Lll” ,“,,,“,“. To install:

10.

Install the alternator to the vehicle and con-

nect the wiring harness. :z

E$llaf 3EG RtEWtiW~-~ 11

Install the alternatnr wnnnrt hrxket tn thp .._. -.. .._ - .._..._._.

--rT-.. -.--..-. .- I.._ .P _ vehicle and tighten the bracket mounting bolts to

specifications.

Page 61 of 408

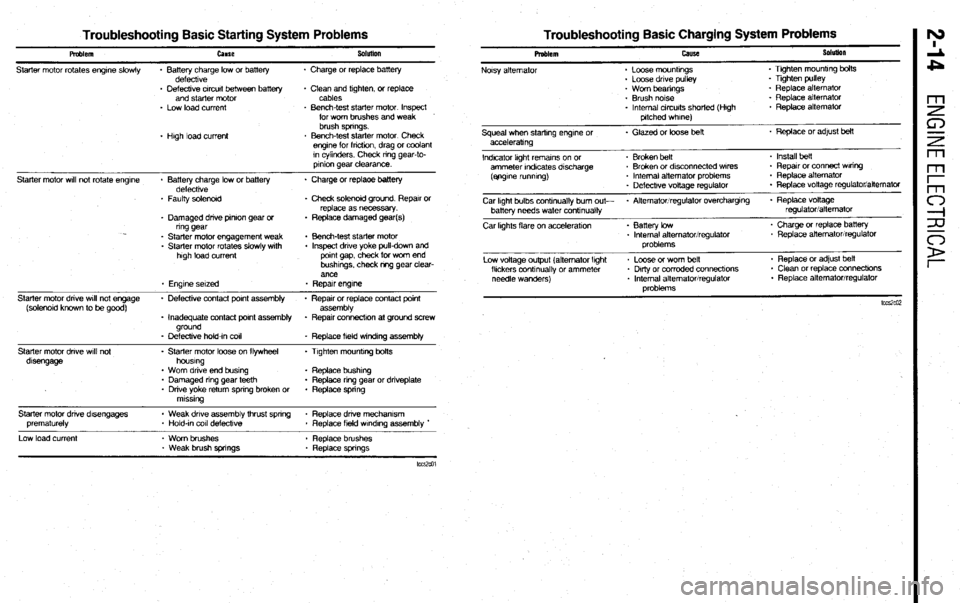

Troubleshooting Basic Starting System Problems Troubleshooting Basic Charging System Problems

Pmblem

Starter motor rotates engrne slowly cause

* Battery charge low or battery

defecttve Sobnlon

. Charge or replace battery

- Defective crrcurt between battery

and starter motor

* Low load current

* Hugh load current + Clean and ttghten, or replace

cables

* Bench-test starter motor Inspect

for wom brushes and weak

brush springs.

. Bench-test starter motor Check

engtne for fncbon, drag or coolant

rn cylinders. Check nng gear-to-

prnton gear clearance.

Starter motor wrll not rotate engrne

Starter motor dnve wrll not engage

(solenotd known to be good)

Starter motor dnve wtli not

dtsengage * Battery charge low or battery * Charge or replaoe battery

defecttve

* Faulty solenord . Check solenoid ground Reparr or

replace as necessary.

* Damaged drive pnron gear or * Replace damaged gear(s)

ring gear

* Starter motor engagement weak . Bench-test starter motor

. Starter motor rotates slowly wtth . Inspect dnve yoke pull-down and

high load current pornt gap, check for worn end

bushtngs. check m-g gear clear-

ance

. Engine setzed * Repatr engk7e

. Defecbve contact pant assembly * Reparr or replace contact pornt

assembly

. Inadequate contact pornt assembly + Repatr connectron at ground screw

ground

- Defeckve hold-In co11

* Replace field w~ndrng assembly

- Starter motor loose on flywheel . Ttghten mounttng bolts

houstng

. Worn drive end bustng . Replace bushtrg

* Damaged nng gear teeth . Replace ring gear or dnveplate

* Drive yoke return spnng broken or . Replace spnng

mtsstng

Starter motor dnve d&engages

prematurely

Low load current * Weak drive assembly thrust spnng * Replace dnve mechamsm

* Hold-tn co11 defeckve

. Replace field wtndtng assembly *

- Worn brushes . Replace brushes

* Weak brush springs * Replace spnngs Problem

Noisy alternator cause

* Loose mounbngs

. Loose drive pulley SoluIion

. Ttghten mountrng bolts

. Tighten pulley

. Worn beanngs

* Brush notse

* Internal circuits shorted (Hugh

pitched whrne) * Replace alternator

. Replace alternator

. Replace alternator

Squeal when starting engtne or . Glazed or loose belt * Replace or adfust belt

acceleratmg

Indicator light rematns on or . Broken belt . Install heft

ammeter rndrcates drscharge . Broken or dksconnected wares - Repatr or connect Waring

(ejrgrne runmng) * Internal aitemator problems * Replace alternator

. Defectrve voltage regulator . Replace vottage regulator/alternator

Car Irght bulbs contmually bum out- * Alternator/regulator overchargtng . Replace voltage

batter-v needs water conbnually regulatoriatternator

Car kghts flare on acceleratton . Battery low

. Internal alternator/regulator

problems * Charge or replace battery

. Replace alternator/regulator

Low voltage output (alternator lght

fltckers conbnually or ammeter

needle wanders) * Loose or worn belt

* Dkly or corroded connecttons

* Internal alternator/regulator

oroblems . Replace or adjust beit

. Clean or replace connecttons

* Replace alternator/regulator