air filter MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 1 of 408

HOW TO USE THIS BOOK 1-2

WHERE TOBEGIN l-2

AVOIDINGTROUBLE 1-2

MAINTENANCEORREPAIR? 1-2

AVOIDINGTHEMOSTCOMMONMISTAKES l-2

TOOLS AND EQUIPMENT 1-2

SPECIALTOOLS l-4

YOUR VEHICLE SAFELY 1-4

DON'TS l-6

FASTENERS, MEASUREMENTS AND

CONVERSIONS l-6

BOLTS,NUTSANDOTHERTHREADED

RETAINERS 1-6

TORQUE l-7

TORQUEWRENCHES l-7

TORQUEANGLEMETERS 1-9

STANDARDANDMETRIC MEASUREMENTS l-9

SERIAL NUMBER IDENTIFICATION l-10

VEHICLE IDENTIFICATION NUMBER l-10

ENGINE IDENTIFICATION NUMBER I-10

TRANSAXLEIDENTIFICATION I-10

DRlVEAXLE(AWDGALANTONLY) l-10

TRANSFERCASE(AWDGALANTONLY) l-10

ROUTINE MAINTENANCE AND TUNE-UP l-14

AIRCLEANER(ELEMENT) 1-14

REMOVAL&INSTALLATION 1-14

FUELFILTER 1-15

REMOVAL &INSTALLATION l-15

PCVVALVE l-15

REMOVAL&INSTALLATION l-15

EVAPORATIVECANISTER l-16

SERVICING 1-16

BATTERY 1-16

PRECAUTIONS I-16

GENERALMAINTENANCE 1-16

BEL BATTERYFLUID 1-16

CABLES I-17

CHARGING I-18

REPLACEMENT 1-18

TS 1-18

INSPECTiON l-18

ADJUSTMENT 1-18

REMOVAL&INSTALLATION 1-18

TIMINGBELTS l-20

INSPECTION l-20

HOSES I-20

INSPECTION l-20

REMOVAL&INSTALLATION

CV-BOOTS 1-21

INSPECTION l-21

SPARKPLUGS l-22

SPARKPLUGHEATRANGE

REMOVAL&INSTALLATION

INSPECTION &GAPPING 1.

SPARKPLUG WIRES 1-24

TESTING 1-24

REMOVAL&INSTALLATION

DISTRIBUTORCAPANDROTOR

REMOVAL&INSTALLATION

INSPECTION 1-25

IGNITIONTIMING 1-25

. GENERALINFORAMTION l-

lNSPECTlON&ADJUSTMENl

VALVE LASH l-27

ADJUSTMENT l-27

IDLESPEED 1-28 1-21

l-22

l-22

-23

1-24

l-25

l-25

.25

1-26

AIR CONDITIONING SYSTEM 1-28

SYSTEMSERVlCEiiREPAlR l-28

PREVENTIVEMAINTENANCE 1-28

SYSTEM INSPECTION l-29

WINDSHIELD WIPERS l-29

ELEMENT(REFILL)CARE&

REPLACEMENT l-29

TIRESANDWHEELS l-30

TIRE ROTATION I-30

TIRE DESIGN 1-31

TIRESTORAGE l-31

INFLATION &INSPECTION l-31

CARE OFSPECIALWHEELS l-32 OPERATION INFOREIGNCOUNTRIES l-33

ENGINE l-33

OILLEVELCHECK 1-33

OIL& FILTER CHANGE l-34

MANUALTRANSAXLE l-35

FLUIDRECOMMENDATIONS l-35

LEVELCHECK l-35

DRAIN&REFILL l-36

AUTOMATICTRANSAXLE l-36

FLUIDRECOMMENDATIONS l-36

LEVELCHECK 1-36

DRAIN&REFILL l-36

PAN & FILTERSERVICE 1-36

TRANSFERCASE(AWDGAlANT ONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

REARDRlVEAXLE(AWDGALANTONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

COOLINGSYSTEM l-39

FLUIDRECOMMENDATIONS l-39

iM-41

FLUIDS AND LUBRICANTS 1-33

FLUID DISPOSAL 1-33

FlJELANDENGlNEOILRECOMMENDATlONS

ENGINE OIL l-33

FUEL l-33

Page 10 of 408

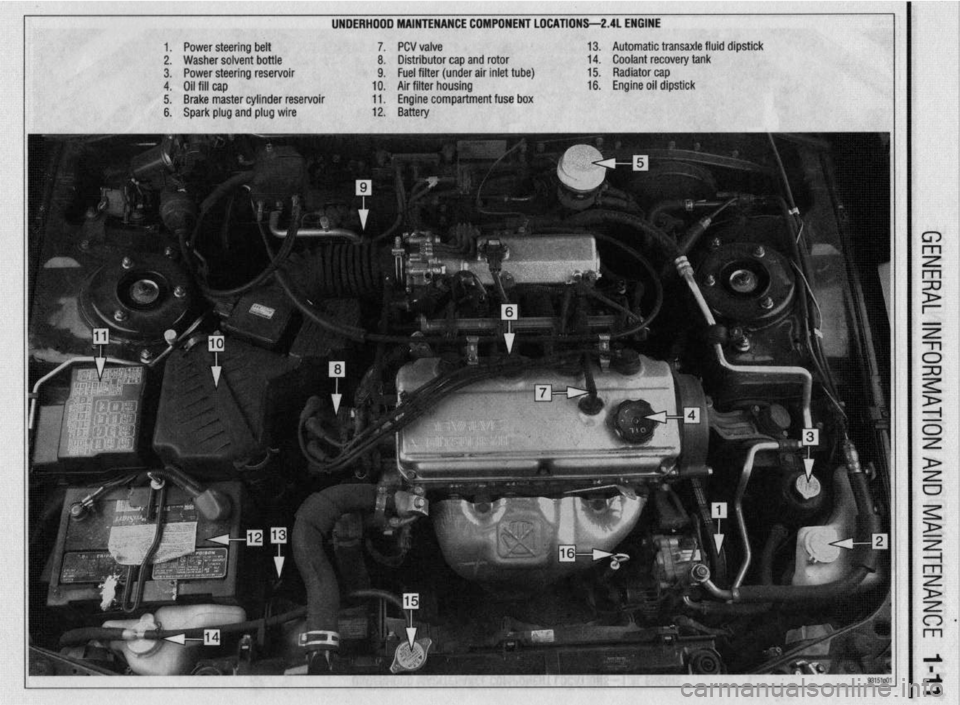

UNDERHDDD MAINTENANCE COMPONENT LOCATIONS-2AL ENGINE

II

1. Power steering belt 7. PCV valve

2. Washer solvent bottle 8. Distributor cap and rotor

3. Power steering reservoir 9. Fuel filter (under air inlet tube)

4. Oil fill cap 10. Air filter housing

5. Brake master cylinder reservoir 11. Engine compartment fuse box

6. Spark plug and plug wire 12. Battery 13. Automatic transaxle fluid dipstick

14. Coolant recovery tank

15. Radiator cap

16. Engine oil dipstick

Page 11 of 408

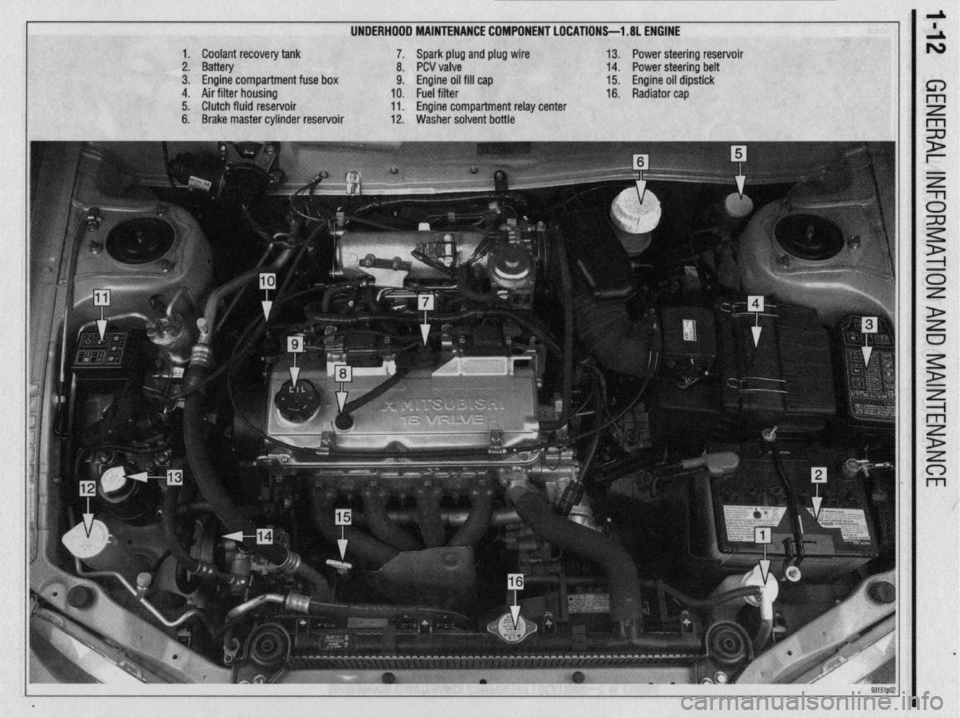

UNDERHOOD MAINTENANCE COMPONENT LOCATIONS-l .8L ENGINE

1. Coolant recovery tank

2. Battery

3. Engine compartment fuse box

4. Air filter housing

5. Clutch fluid reservoir

6. Brake master cylinder reservoir 7. Spark plug and plug wire

8. PCV valve

9. Engine oil fill cap

10. Fuel filter

11. Engine compartment relay center

12. Washer solvent bottle 13. Power steering reservoir

14. Power steering belt

15. Engine oil dipstick

16. Radiator cap

Page 13 of 408

l

l-14 GENERALINFORMATIONAND MAINTENANCE

Proper maintenance and tune-up is the key to long

and trouble-free vehicle life, and the work can yield

its own rewards. Studies have shown that a properly

tuned and maintained vehicle can achieve better gas

mileage than an out-of-tune vehicle. As a conscien-

tious owner and driver, set aside a Saturday morning,

say once a month, to check or replace items which

could cause major problems later. Keep your own

personal log to jot down which services you per-

formed, how much the parts cost you, the date, and

the exact odometer reading at the time. Keep all re-

selfer, these receipts are the only proof you have that ceipts for such items as engine oil and filters, so that

they may be referred tp in case of related problems or

to determine operating expenses. As a do-it-your- the required maintenance was performed. In the event

of a warranty problem, these receipts will be invalu-

able.

The literature provided with your vehicle when it

was originally delivered includes the factory recom-

mended maintenance schedule. If you no longer have

this literature, replacement copies are usually avail-

able from the dealer. A maintenance schedule is pro-

vided later in this section, in case you do not have

the factory literature. *

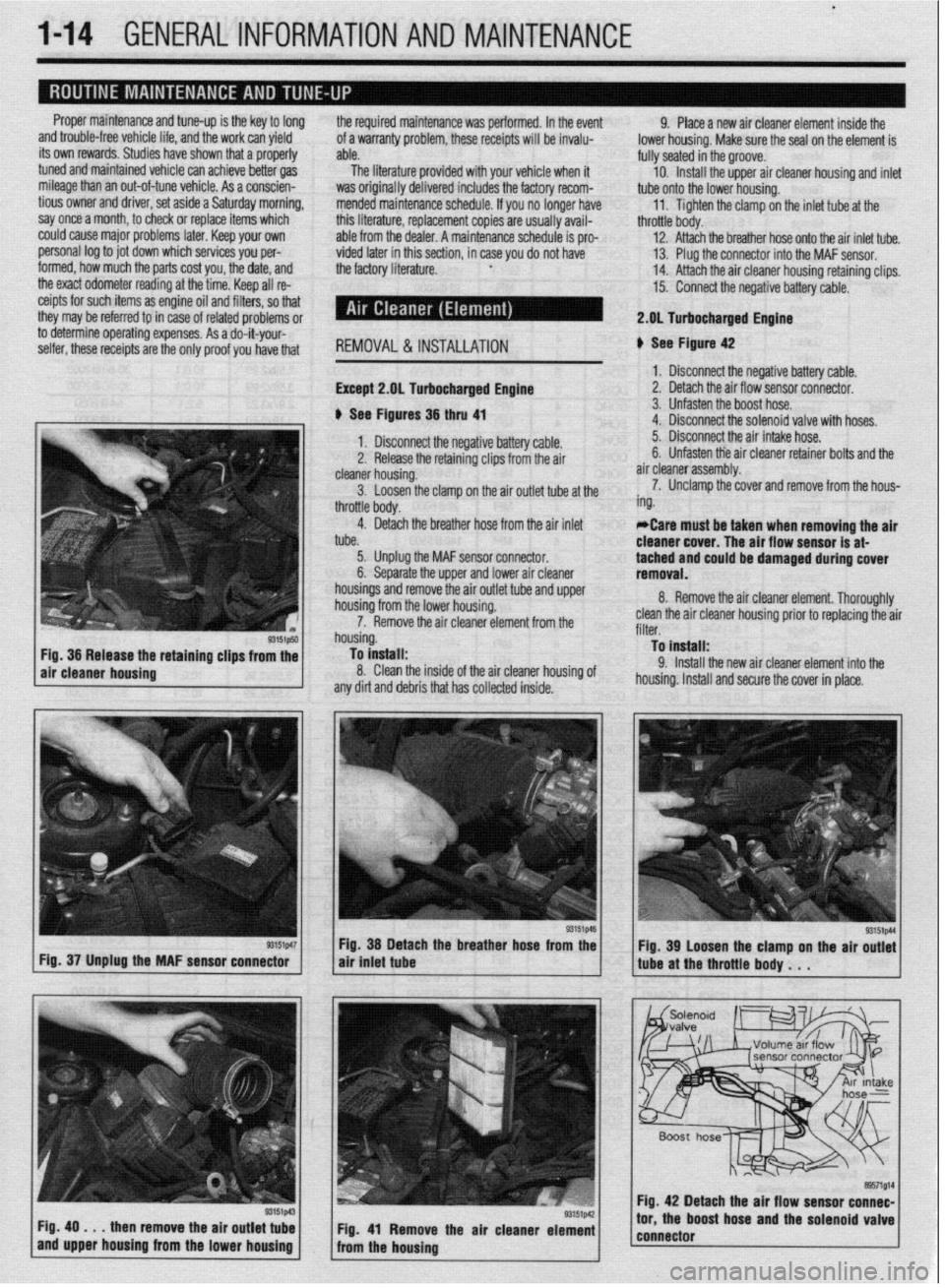

REMOVAL &INSTALLATION

Except 2.gL Turbocharged Engine

b See Figures 36 thru 41 9. Place a new air cleaner element inside the

lower housing. Make sure the seal on the element is

fully seated in the groove.

10. Install the upper air cleaner housing and inlet

tube onto the lower housing.

11. Tighten the clamp on the inlet tube at the

throttle body.

12. Attach the breather hose onto the air inlet tube.

13. Plug the connector into the MAF sensor.

14. Attach the air cleaner housing retaining clips.

15. Connect the negative battery cable.

2.DL Turbocharged Engine

b See Figure 42

1. Disconnect the negative battery cable.

2. Detach the air flow sensor connector.

3. Unfasten the boost hose.

4. Disconnect the solenoid valve with hoses.

93151p50 Fig. 36 Release the retaining clips from the

air cleaner housing

r3151p47 Fig. 37 Unplug the MAF sensor connector

Fig. 49

. . . then remove the air outlet tube

and upper housing from the lower housing 1. Disconnect the negative battery cable. 5. Disconnect the air intake hose.

2. Release the retaining clips from the air 6. Unfasten tie air cleaner retainer bolts and the

cleaner housing. air cleaner assembly.

3. Loosen the clamp on the air outlet tube at the 7. Unclamp the cover and remove from the hous-

throttle body. ing.

4. Detach the breather hose from the air inlet

tube. *Care must be taken when removing the air

cleaner cover. The air flow sensor is at-

5. Unplug the MAF sensor connector.

6. Separate the upper and lower air cleaner tached and could be damaged during cover

removal.

housings and remove the air outlet tube and upper

housing from the lower housing.

7. Remove the air cleaner element from the

housing.

To install:

8. Clean the inside of the air cleaner housing of

any dirt and debris that has collected inside. 8. Remove the air cleaner element. Thoroughly

clean the air cleaner housing prior to replacing the air

filter.

To install:

9. Install the new air cleaner element into the

housing. Install and secure the cover in place.

Fig. 38 Detach the breather hose from the

air tniet tube

Fig. 41 Remove the air cleaner element

from the housing Fig. 39 Loosen the clamp on the air outlet

tube at the throttle body . . .

Fig. 42 Detach the air flow sensor connec-

tor, the boost hose and the solenoid valve

connector

Page 14 of 408

GENERALINFORMATIONAND MAINTENANCE l-15

10. install the air cleaner assembly and the re- *Wrap shop towels around the fitting that is

tainer bolts. being dtsconnected to absorb residual fuel in

11. Connect the air intake hose. the lines. 9. While holding the fuel filter nut with aback-

up wrench, tighten the banjo bolt to 22 ft. Ibs. (30

Nm). Tighten the flare nut to 25 ft. Ibs. (35 Nm), with

12. Attach the solenoid valve.

4. Cover the hose connection with shop towels to a back-up wrench on the nut.

13. Connect the boost hose.

14. Attach the air flow sensor connector. prevent any splash of fuel that could be caused by 10. Tighten the filter mounting bolts to 10 ft. Ibs.

residual pressure in the fuel pipe line. Hold the fuel (14 Nm).

15. Connect the negative battery cable. 11.

filter nut securely with a backup wrench, then remove Connect the negative battery cable. Turn the

REMOVAL &INSTALLATION the banjo bolt on the engine feed line. Disconnect the

high-pressure fuel line from the filter. Remove and

discard the gaskets.

5. While holding the fuel filter nut securely with a

back-up wrench, loosen the filter feed pipe flare nut key to the ON position to pressurize the fuel system

and check for leaks.

12. If repairs of a leak are required, remember to

release the fuel pressure before opening the fuel sys-

tern.

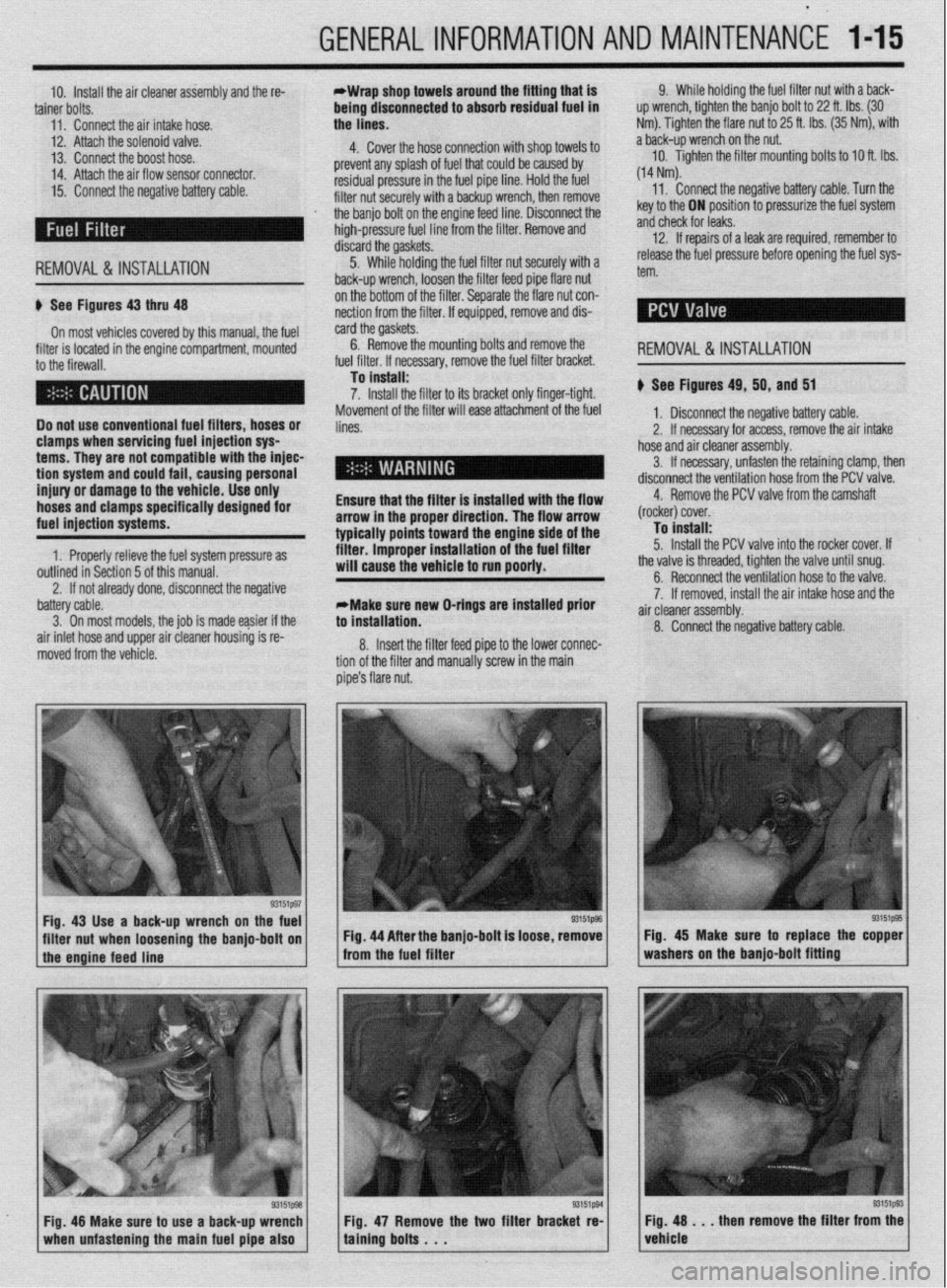

u See Figures 43 thru 48

On most vehicles covered by this manual, the fuel

filter is located in the engine compartment, mounted

to the firewall.

Do not use conventional fuel filters, hoses or

clamps when servicing fuel injection sys

terns. They are not compatible with the injec-

tion

system and could fail, causing personal

injury or damage to the vehicle. Use only

hoses and clamps specifically designed for

fuel injection systems.

1. Properly relieve the fuel system pressure as

outlined in Section 5 of this manual. on the bottom of the filter. Separate the flare nut con-

nection from the filter. If equipped, remove and dis-

card the gaskets.

6. Remove the mounting bolts and remove

. ,,,. ,.

.a r I,.,< I the

ruer rrrter. II necessary, remove me ruer rrrrer oracket.

To install:

7. Install the filter to its bracket only finger-tight.

Movement of the filter will ease attachment of the fuel

lines.

Ensure that the filter is installed with the flow

arrow in the proper direction. The flow arrow

typically points toward the engine side of the

filter. improper installation of the fuel filter

will cause the vehicle to run poorly.

2. If not already done, disconnect the negative REMOVAL&INSTALLATION

u See Figures 49, 50, and 51

1, Disconnect the negative battery cable.

2. If necessary for access, remove the air intake

hose and air cleaner assembly.

3. If necessary, unfasten the retaining clamp, then

disconnect the ventilation hose from the PCV valve.

4. Remove the PCV valve from the camshaft

(rocker) cover.

To install:

5. Install the PCV valve into the rocker cover. If

the valve is threaded, tighten the valve until snug.

battery cable.

3. On most models. the iob is made easier if the

air inlet hose and upper air cleaner housing is re-

moved from the vehicle. *Make sure new O-rings are installed prior

to installation.

8. Insert the filter feed pipe to the lower connec-

tion of the filter and manually screw in the main

pipe’s flare nut. 6. Reconnect the ventilation hose to the valve.

7. If removed, install the air intake hose and the

a .ir cleaner assembly.

8. Connect the negative battery cable.

Fig. 43 Use a back-up wrench on the fuel

I I

93151@3

filter nut when loosening the banjo-bolt on Fig. 44 After the banjo-bolt is loose, remove

I

1 the engine feed line - from the fuel filter

93151p93 Fig. 48 Make sure to use a back-up wrench

1 when unfastening the main fuel pipe also 1 Fig. 47 Remove the two filter bracket re-

taining bolts . . . Fig. 45 Make sure to replace the copper

washers on the banjo-bolt fitting

Fig. 48 . . . then remove the filter from the

vehicle

Page 35 of 408

.

l-36 GENERALINFORMATIONAND MAINTENANCE

Install the drain plug and tighten to 22 ft. Ibs.

(304Nm)

5. Refill the transaxle to the proper level, as

shown in the Capacities chart, with the appropriate

fluid. The oil level should be at the bottom of the oil

filler hole. I

6. When the oil reaches the orooer level, install

the filler plug and tighten to 22 ft. Ibs. (30 Nm).

FLUID RECOMMENDATIONS

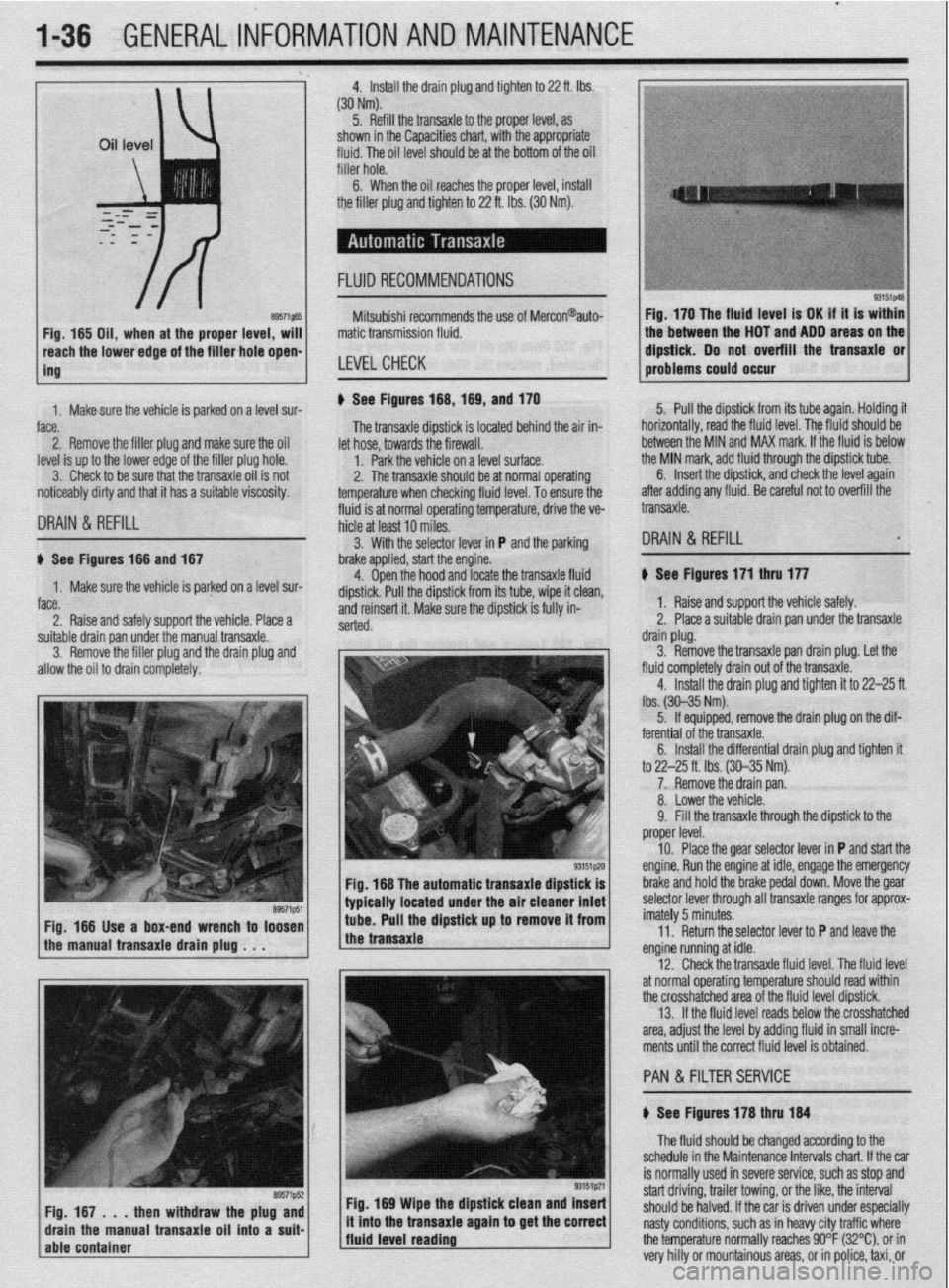

8957i565 Fig, 165 Oil, when at the proper level, will

reach the lower edge of tC=+ frfr*r u*rn -non-

ing Mitsubishi recommends the use of Mercon@auto-

matic transmission fluid.

LEVELCHECK

Fig. 170 The fluid level is OK if it is within

the between the HOT and ADD areas on the

&&i& Do not overfill the transaxle or

-.*".."... -- .*"- problems could o ccur

1. Makesure the vehicle is oarked on a level sur-

face.

2. Remove the filler plug and make sure the oil

level is up to the lower edge of the filler plug hole.

3. Check to be sure that the transaxle oil is not

noticeably dirty and that it has a suitable viscosity. u See Figures 168,169, and 170

fluid is at normal operating temperature, drive the ve- The transaxle dipstick is located behind the air in-

hicle at least 10 miles. let hose, towards the firewall.

1. Park the vehicle on a level surface.

2. The transaxle should be at normal operating

temperature when checking fluid level. To ensure the 5. Pull the dipstick from its tube again. Holding it

horizontally, road the fluid level. The fkrid should be

between the MIN and MAX mark. If the fluid is below

the MIN mark, add fluid through the dipstick tube.

DRAIN & REFILL

6. Insert the dipstick, and check the level again

after adding any fluid. Be careful not to overfill the

transaxle.

3. With the selector lever in P and the parking

DRAIN & REFILL u See Figures 166 and 167

1. Make sure the vehicle is parked on a level sur-

face.

2. Raise and safely support the vehicle. Place a brake applied, start the engine.

4. Open the hood and locate the transaxle fluid

dipstick. Pull the dipstick from its tube, wipe it clean,

and reinsert it. Make sure the dipstick is fully in-

serted.

suitable drain pan under the manual transaxle.

3. Remove the filler plug and the drain plug and

allow the oil to drain completely.

Fig. 166 The automatic transaxle dipstick is

typically located under the air cleaner inlet

Fig. 166 Use a box-end wrench to loosen

the manual transaxle drain plug . . . tube. Pull the dipstick up to remove it from

the transaxle

Fig. 169 Wipe the dipstick clean and Insert

/fluid level reading ., it mto the transaxle agam to get the correct

j The fluid should be changed according to the

schedule in the Maintenance Intervals chart. If the car

is normally used in severe service, such as stop and

start driving, trailer towing, or the like, the interval

should be halved. If the car is driven under especially

nasty conditions, such as in heavy city traffic where

the temperature normally reaches 90°F (32%), or in

very hilly or mountainous areas, or in police, taxi, or b See Figures 171 thru 177

1. Raise and support the vehicle safely.

2. Place a suitable drain pan under the transaxle

drain plug.

3. Remove the transaxle pan drain plug. Let the

fluid completely drain out of the transaxle.

4. Install the drain plug and tighten it to 22-25 ft.

lbs. (30-35 Nm).

5. If equipped, remove the drain plug on the dif-

ferential of the transaxle.

6. Install the differential drain plug and tighten ft

to 22-25 ft. Ibs. (30-35 Nm).

7. Remove the drain pan.

8. Lower the vehicle.

9. Fill the transaxle through the dipstick to the

proper level.

10. Place the gear selector lever in P and start the

engine. Run the engine at idle, engage the emergency

brake and hold the brake pedal down. Move the gear

selector lever through all transaxle ranges for approx-

imately 5 minutes.

11. Return the selector lever to P and leave the

engine running at idle.

12. Check the transaxle fluid level. The fluid level

at normal operating temperature should read within

the crosshatched area of the fluid level dipstick.

13. If the fluid level reads below the crosshatched

area, adjust the level by adding fluid in small incre-

ments until the correct fluid level is obtained.

PAN &FILTER SERVICE

b See Figures 178 thru 184

Page 37 of 408

t

1-38 GENERALINFORMATIONAND MAINTENANCE

11 I Add the recommended automatic transaxle

fluid to the transaxle through the dipstick tube. You

will need a long necked funnel, or a funnel and tube

to do this. A quick check of the capacities chart later

in this Section will reveal the capacity of the transaxle

in your vehicle. On a first fill after removing the pan

and filter, this number should be cut into a ‘hand

checked on the dipstick before refilling.

12. With the transaxle in P, put on the parking

brake, block the front wheels, start the engine and let

it idle. DO NOT RACE THE ENGINE. DO NOT MOVE

THE LEVER THROUGH ITS RANGES.

13. With the lever in Park, check the fluid level. If

it’s OK, take the car out for a short drive, park on a

level surface, and check the level again, as outlined

earlier in this section. Add more fluid if necessary. Be

careful not to overfill, which will cause foaming and

w fluid loss. n of the transfer case filler

3. Remove the filler and the drain plug and allow

the oil to drain into the drain pan.

4. After the fluid has drained completely, install

the drain plug and tighten to 24 ft. Ibs. (32 Nm).

5. Refill the transfer case to the proper level with

Fig. 184 . . .

the transaxle case before in-

stalling the gasket

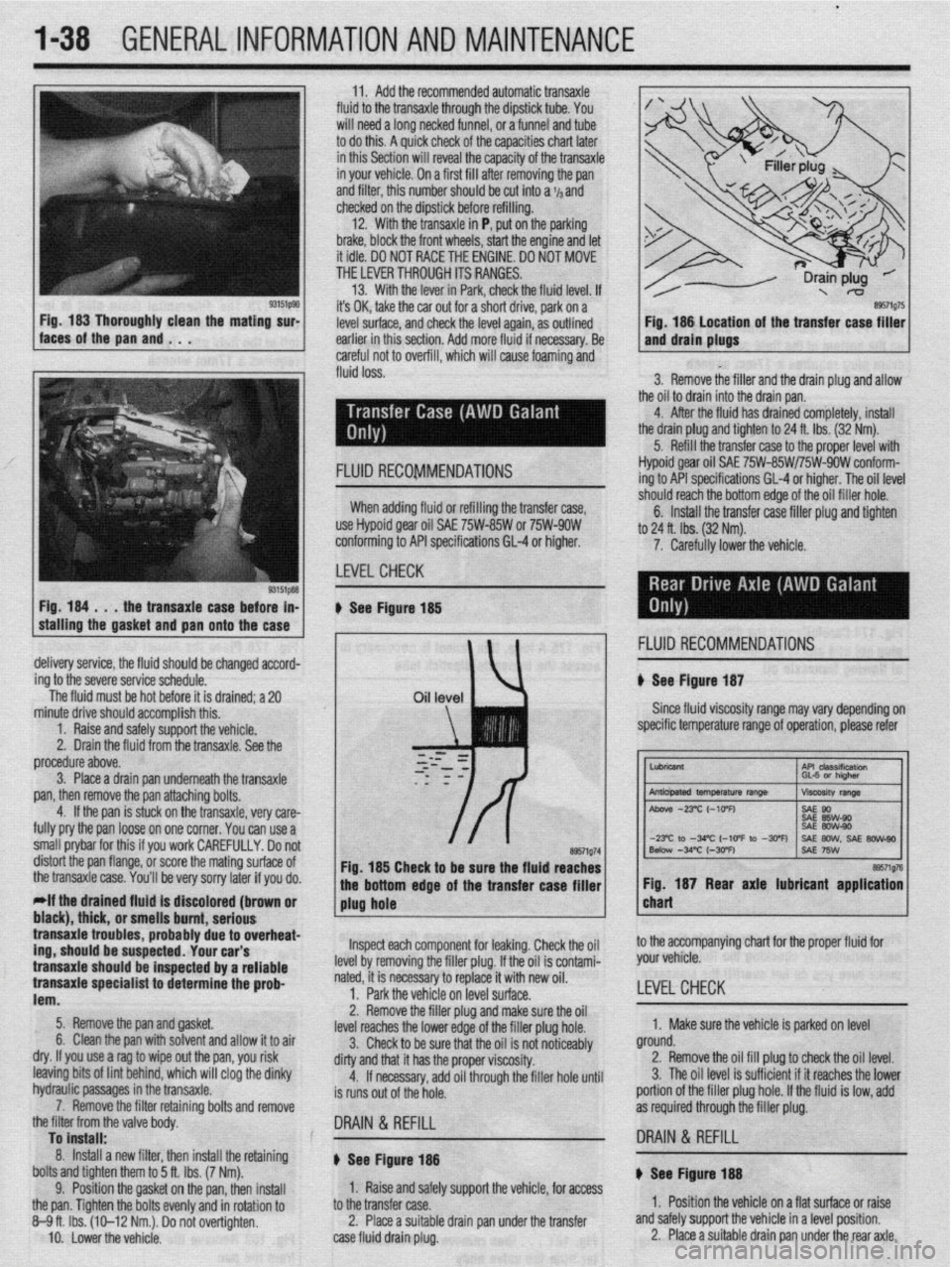

and pan onto the case FLUID RECOMMENDATIONS Hypoid gear oil SAE 75W-85W/75W-9OW conform-

ing to API specifications GL-4 or higher. The oil level

-‘-,*I’ -nnnh +‘* “%om edge of the oil filler hole.

nxfer raw filler nlm and tinhtm When adding fluid or refilling the transfer case,

use Hypoid gear oil SAE 75W-85W or 75W-9OW

conforming to API specifications 61-4 or higher.

LEVELCHECK 6. Install the tra .._._. ____ .._. T.-J _.._ .lJ . .._..

to 24 ft. lbs. (32 Nm).

7. Carefully lower the vehicle.

u See Figure 185

, 1 FLUID RECOMMENDATIONS

delivery service, the fluid should be changed accord-

ing to the severe service schedule.

The fluid must be hot before it is drained; a 20 u See Figure 187

Since fluid viscosity range may

vary depending on

specific temperature range of operation, please refer

~~

tne transaxle case.

You’ll be very sorry later if you do. bottom edge of the transfer case filler 1 1 Fig. 187 Rear axle lubricant application I

*If the drained fluld is discolored (brown or

1 plug hole chart black), thick, or pmmll~ hmmt nnrinmm I transaxle trouble .llln3llU ““III., url,““P s, probably due to overheat-

,r..rr,rA “#.a.- rrdr

trig, should be susp~~lr;u. lvUl vLlr J

transaxle should be inspected by a reliable

transaxle specialist to determine the prob-

lem.

5. Remove the pan and gasket.

6. Clean the pan with solvent and allow it to air

dry. If you use a rag to wipe out the pan, you risk

leaving bits of lint behind, which will clog the dinky

hydraulic passages in the bansaxle.

7. Remove the filter retaining bolts and remove

the filter from the valve bodv. lnsoect each component for leaking. Check the oil

he filler plug. If the oil is contami-

ry to replace it with new oil.

if% nn IPVPI z11rf2r~

level by removing t

nated, it is necessa

1. Park the vehi,., -.. ,-.“, __. ,“-_.

2. Remove the filler plug and make sure the oil

level reaches the lower edge of the filler plug hole.

3. Check to be sure that the oil is not noticeably

dirty and that it has the proper viscosity.

4. If necessary, add oil through the filler hole until

is runs out of the hole. to the accompanying chart for the proper fluid for

your vehicle.

LEVEL CHECK

1. Make sure the vehicle is parked on level

ground.

2. Remove the oil fill plug to check the oil level.

3. The oil level is sufficient if it reaches the lower

portion of the filler plug hole. If the fluid is low, add

as required through the filler plug.

To install: .

8. Install a new filter, then install the retaining

bolts and tighten them to 5 ft. Ibs. (7 Nm).

9. Position the gasket on the pan, then install

the pan. Tighten the bolts evenly and in rotation to

8-9ft. Ibs. (10-12 Nm.). Do not overtighten.

IO. Lower the vehicle. DRAIN & REFILL

I8 DRAIN & REFILL

u See Figure 188 ) See Figure- 14

1. Raise and safely support the vehicle, for access

to the transfer case.

2. Place a suitable drain pan under the transfer

case fluid drain plug. 1. Position the vehicle on a flat surface or raise

and safely support the vehicle in a level position.

2. Place a suitable drain pan under the rear axle.

Page 46 of 408

GENERAL INFORMATION AND MAINTENANCE 1-47

ramps are also a handy and safe way to both raise l When the drive wheels are to remain on the

and support the vehicle. Be careful though, some ground, leave the vehicle in gear to help prevent it

ramps may be too steep to drive your vehicle onto

The following safety points cannot be overempha- from rolling.

without scraping the front bottom panels. Never sup-

sized:

l Always use jackstands to support the vehicle

port the vehicle on any suspension member (unless l Always block the opposite wheel or wheels to when you are working underneath. Place the stands

specifically instructed to do so by a repair manual) or

keep the vehicle from rolling off the jack. beneath the vehrcle’s jacking brackets Before climb-

by an underbody panel.

l When raising the front of the vehicle, firmly ap- ing underneath, rock the vehicle a bit to make sure it

ply the parking brake. is firmly supported.

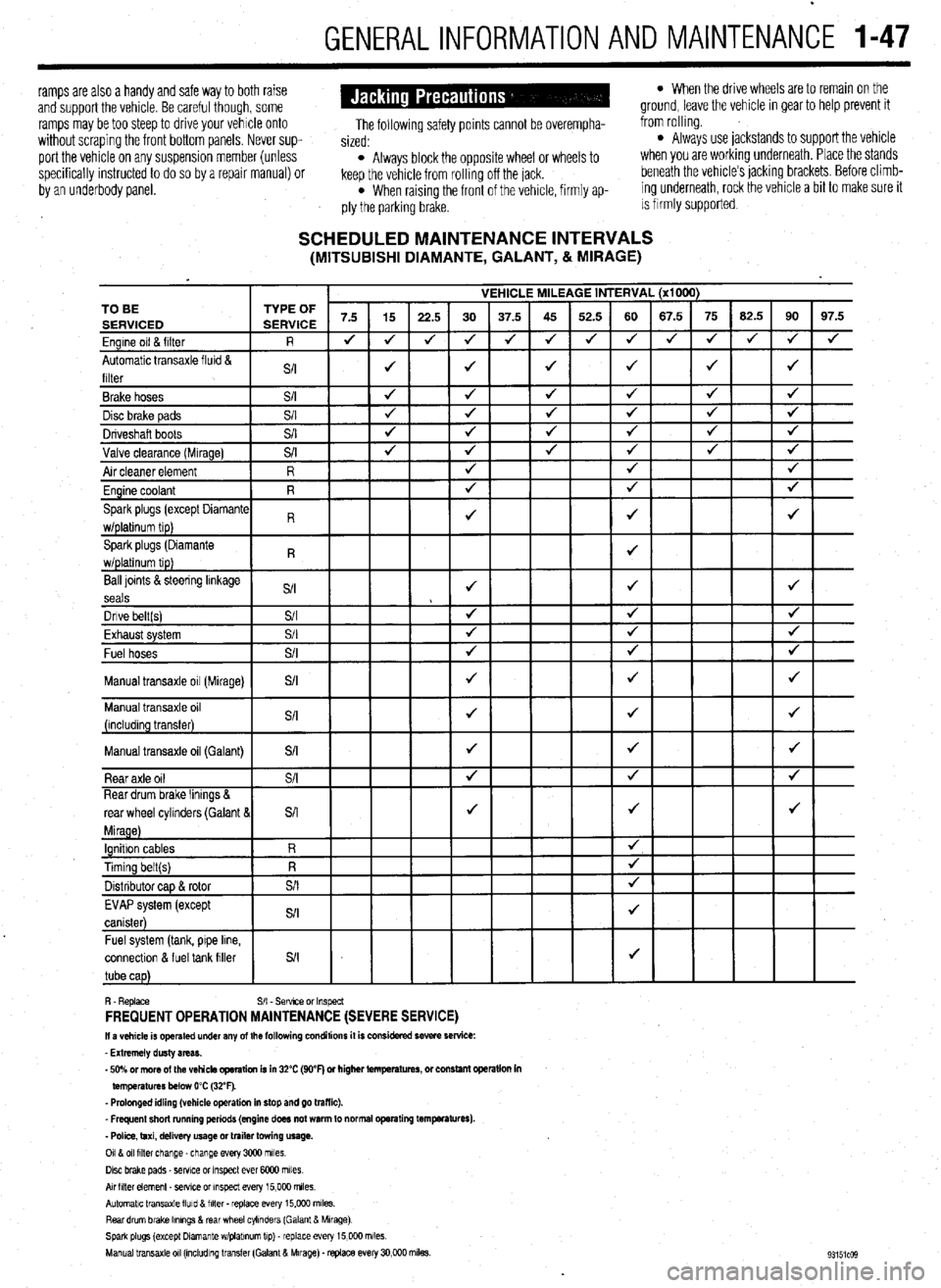

SCHEDULED MAINTENANCE INTERVALS (MITSUBISHI DIAMANTE, GALANT, & MIRAGE)

VEHICLE MILEAGE INTERVAL (x1000)

7.5 15

22.5 30 37.5 45 52.5 60 67.5 75 62.5 90 97.5

J J

J 4 J J 4 4 4 J J

J 4

4

J J J J 4 TO BE

Ball loints &steering linkage

S/I J J J

seals

Dnve belt(s) S/I 4 4 J

Fvha,,rt cvctom $/I

J J J LmI,..“w. “,YL”,‘. Fuel hoses

+

Manual transaxle oil (Galant)

connectlon & fuel tank filler

R. Replace S/I - Sefwce or Inspect FREQUENT OPERATION MAINTENANCE (SEVERE SERVICE) II a vehicle is operated under any of the following conditions it is considered severe service:

- Extremely dusty areas.

- 50% or more of the vehicle operation is in 32% (WF) or higher temperatures, or constant opsralion in

temperatures below 0% (32°F).

- Prolonged idling (vehicle operation in stop and go traffic).

_ Frequent short running periods (engine does not warm to normal operating temfwatures).

- Police, taxi, delivery usage or trailer towing usage.

0118 011 filter change-change every 3CQO miles.

Disc brake pads - sewce or Inspect ever 6COO miles

AN hlter element _ setwe or inspect every 15,000 miles.

Automatic transaxle lluld 8 filter . replace every 15,COO m&s.

Rear drum brake Ikmngs & rear wheel cylinders (Galant & Mirage)

Spark plugs (except Dlamante wlplabnum tip) - replace every 15,COO miles.

Manual transaxle 011 (mcludlng transfer (Galant & Mirage). replace every 30,000 miles.

Page 60 of 408

ENGINE ELECTRlCiL 2-13

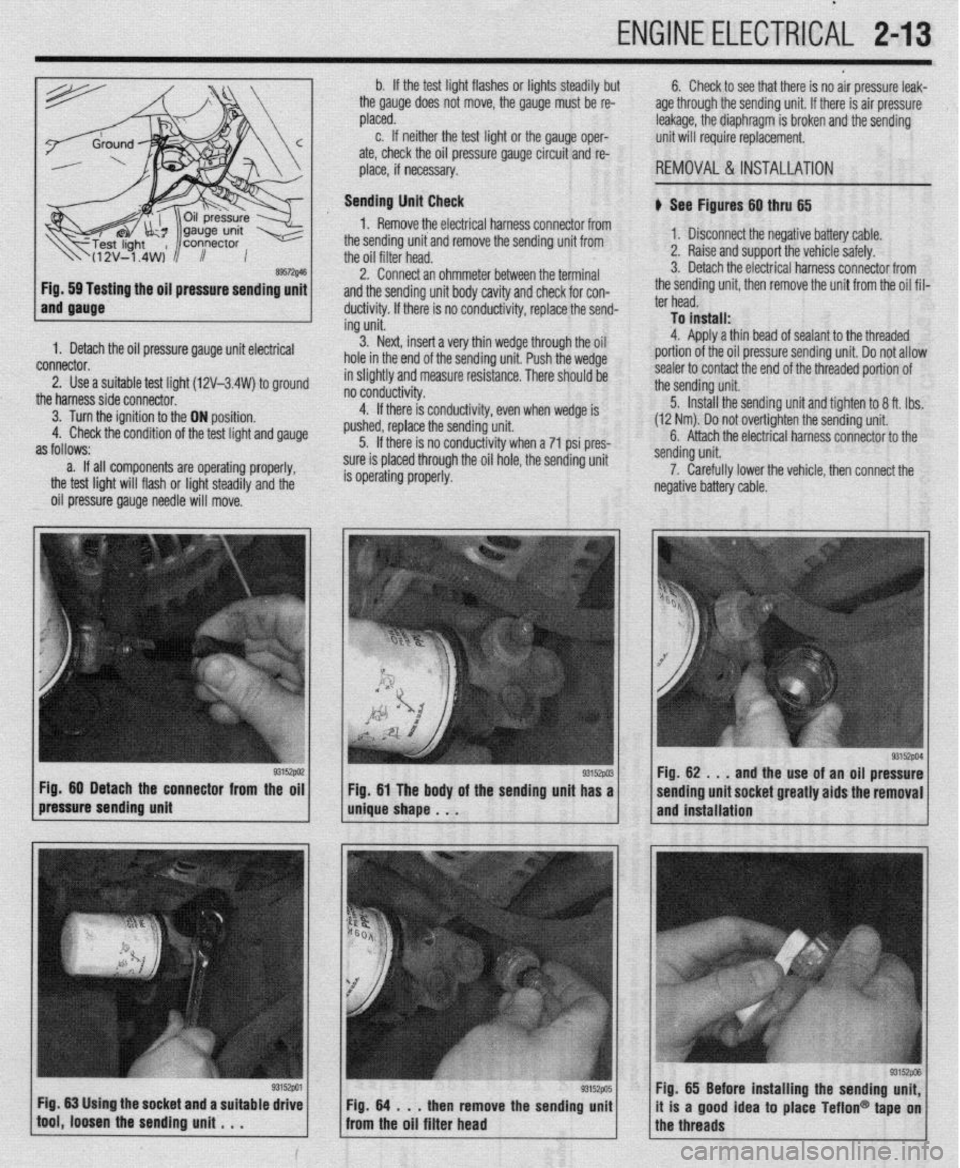

ing the oil pressure sending unit

1. Detach the oil pressure gauge unit electrical

connector.

2. Use a suitable test lioht (12V-3.4W) to around

the harnesssideconnecto~ ’ ’ -

3. Turn the ignition to the ON position.

4. Check the condition of the test light and gauge

as follows:

a. If all components are operating properly,

the test light will flash or light steadily and the

oil pressure gauge needle will move. b. If the test light flashes or lights steadily but

the gauge does not move, the gauge must be re-

placed.

c. If neither the test light or the gauge oper-

ate, check the oil pressure gauge circuit and re-

place, if necessary.

Sending Unit Check

1. Remove the electrical harness connector from

the sending unit and remove the sending unit from

the oil filter head.

2. Connect an ohmmeter between the terminal

and the sending unit body cavity and check for con-

ductivity. If there is no conductivity, replace the send-

ing unit.

3. Next, insert a very thin wedge through the oil

hole in the end of the sending unit. Push the wedge

in slightly and measure resistance. There should be

- - -- d . . . .

no conoucovey.

4. If there is conductivity, even when wedge is

pushed, replace the sending unit.

5. If there is no conductivity when a 71 psi pres-

sure is placed through the oil hole, the sending unit

is operating properly. 6. Check to see that there is no air pressure leak-

age through the sending unit. If there is air pressure

leakage, the diaphragm is broken and the sending

unit will require replacement.

REMOVAL &INSTALLATION

b See Figures 60 thru 65

1. Disconnect the negative battery cable.

2. Raise and support the vehicle safely.

3. Detach the electrical harness connector from

the sending unit, then remove the unit from the oil fil-

ter head.

To install:

4. Aoolv a thin bead of sealant to the threaded

portion of the oil pressure sending unit. Do not allow

sealer to contact the end of the threaded portion of

the sending unit.

5. Install the sending unit and tighten to 8 ft. tbs.

(12 Nm). Do not over-tighten the sending unit.

6. Attach the electrical harness connector to the

/pressure sending unit g3’9wi / m&e shape . . . Fig 60 Detach the connector from the oil

g3152w Fig 61 The body of the sending unit has a sending unit.

7. Carefully lower the vehicle, then connect the

negative battery cable.

93152PM Fig. 62 . , .

and the use of an oil pressure

sending unit socket greatly aids the removal

and installation

Fig. 65 Before installing the sending unit,

it is a good idea to place Teflon@ tape on

the threads

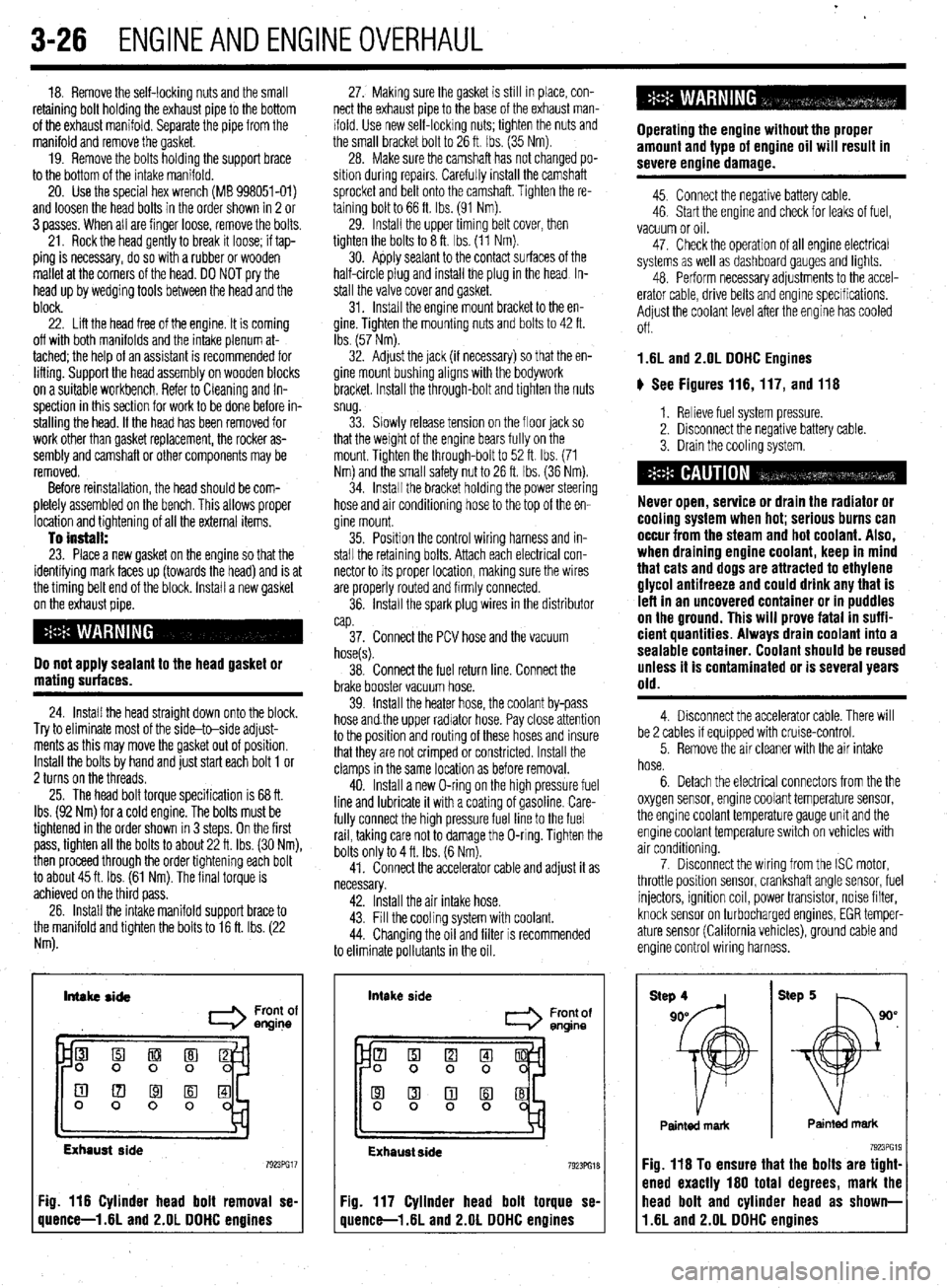

Page 87 of 408

3-26 ENGINEANDENGINEOVERHAUL

18. Remove the self-locking nuts and the small

retaining bolt holding the exhaust pipe to the bottom

of the exhaust manifold. Separate the pipe from the

manifold and remove the gasket.

19. Remove the bolts holding the support brace

to the bottom of the intake manifold.

20. Use the special hex wrench (MB 998051-01)

and loosen the head bolts in the order shown in 2 or

3 passes. When all are finger loose, remove the bolts.

21. Rock the head gently to break it loose; if tap-

ping is necessary, do so with a rubber or wooden

mallet at the corners of the head. DO NOT pry the

head up by wedging tools between the head and the

block.

22. Lift the head free of the engine. It is coming

off with both manifolds and the intake plenum at-

tached; the help of an assistant is recommended for

lifting. Support the head assembly on wooden blocks

on a suitable workbench. Refer to Cleaning and In-

spection in this section for work to be done before in-

stalling the head. If the head has been removed for

work other than gasket replacement, the rocker as-

sembly and camshaft or other components may be

removed.

Before reinstallation, the head should be com-

pletely assembled on the bench. This allows proper

location and tightening of all the external items.

To install: 23. Place a new gasket on the engine so that the

identifying mark faces up (towards the head) and is at

the timing belt end of the block. Install a new gasket

on the exhaust pipe.

Do not apply sealant to the head gasket or

mating surfaces.

24. Install the head straight down onto the block.

Try to eliminate most of the side-to-side adjust-

ments as this may move the gasket out of position.

Install the bolts by hand and just start each bolt 1 or

2 turns on the threads.

25. The head bolt torque specification is 68 ft.

Ibs. (92 Nm) for a cold engine. The bolts must be

tightened in the order shown in 3 steps. On the first

pass, tighten all the bolts to about 22 ft. Ibs. (30 Nm),

then proceed through the order tightening each bolt

to about 45 ft. Ibs. (61 Nm). The final torque is

achieved on the third pass.

26. Install the intake manifold support brace to

the manifold and tighten the bolts to 16 ft. Ibs. (22

Nm). 27. Making sure the gasket is still in place, con-

nect the exhaust pipe to the base of the exhaust man-

ifold. Use new self-locking nuts; tighten the nuts and

the small bracket bolt to 26 ft. Ibs. (35 Nm).

28. Make sure the camshaft has not changed po-

sition during repalrs. Carefully install the camshaft

sprocket and belt onto the camshaft. Tighten the re-

taining bolt to 66 ft. Ibs. (91 Nm).

29. Install the upper timing belt cover, then

tighten the bolts to 8 ft. Ibs. (11 Nm).

30. Apply sealant to the contact surfaces of the

half-circle plug and install the plug in the head In-

stall the valve cover and gasket.

31. Install the engine mount bracket to the en-

gine. Tighten the mounting nuts and bolts to 42 ft.

Ibs. (57 Nm).

32. Adjust the jack (if necessary) so that the en-

gine mount bushing aligns with the bodywork

bracket. Install the through-bolt and tighten the nuts

snug.

33. Slowly release tension on the floor jack so

that the weight of the engine bears fully on the

mount. Tighten the through-bolt to 52 ft. Ibs. (71

Nm) and the small safety nut to 26 ft. tbs. (36 Nm).

34. Install the bracket holding the power steering

hose and air conditioning hose to the top of the en-

gine mount.

35. Position the control wiring harness and in-

stall the retaining bolts. Attach each electrical con-

nector to its proper location, making sure the wires

are properly routed and firmly connected.

36. Install the spark plug wires in the distributor

cap.

37. Connect the PCV hose and the vacuum

hose(s).

38. Connect the fuel return line. Connect the

brake booster vacuum hose.

39. Install the heater hose, the coolant by-pass

hose and.the upper radiator hose. Pay close attention

to the position and routing of these hoses and insure

that they are not crimped or constricted. Install the

clamps in the same location as before removal.

40. Install a new O-ring on the high pressure fuel

line and lubricate it with a coating of gasoline. Care-

fully connect the high pressure fuel line to the fuel

rail, taking care not to damage the O-ring. Tighten the

bolts only to 4 ft. Ibs. (6 Nm).

41. Connect the accelerator cable and adjust it as

necessary.

42. Install the air intake hose.

43. Fill the cooling system with coolant.

44. Changing the oil and filter is recommended

to eliminate pollutants in the oil.

Intake side

I Front of

engine

Exhaust side

Fig. 116 Cylinder head bolt removal se-

quence-l .6L and 2.OL DDHC engines intake

side

Front of

entine

Exhaust side 7923PG18

Fig. 117 Cylinder head bolt torque se-

quence-l .6L and 2.OL DDHC engines Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

45. Connect the negative battery cable.

46. Start the engine and check for leaks of fuel,

vacuum or oil.

47. Check the operation of all engine electrical

systems as well as dashboard gauges and lights.

48. Perform necessary adjustments to the accel-

erator cable, drive belts and engine specifications.

Adjust the coolant level after the engine has cooled

Off.

1.6L and 2.OL DDHC Engines

ti See Figures 116,117, and 116

1. Relieve fuel system pressure.

2. Disconnect the negative battery cable.

3. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

4. Disconnect the accelerator cable. There will

be 2 cables if equipped with cruise-control.

5. Remove the air cleaner with the air intake

hose.

6. Detach the electrical connectors from the the

oxygen sensor, engine coolant temperature sensor,

the engine coolant temperature gauge unit and the

engine coolant temperature switch on vehicles with

air conditioning.

7. Disconnect the wiring from the ISC motor,

throttle position sensor, crankshaft angle sensor, fuel

injectors, ignition coil, power transistor, noise filter,

knock sensor on turbocharged engines, EGR temper-

ature sensor (California vehicles), ground cable and

engine control wiring harness.

Painted mark Painted mark

Fig. 116 To ensure that the bolts are tight-

ened exactly 160 total degrees, mark the

11.6L and 2.OL DDHC engines head bolt and cylinder head as shown-