fuel MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 1 of 408

HOW TO USE THIS BOOK 1-2

WHERE TOBEGIN l-2

AVOIDINGTROUBLE 1-2

MAINTENANCEORREPAIR? 1-2

AVOIDINGTHEMOSTCOMMONMISTAKES l-2

TOOLS AND EQUIPMENT 1-2

SPECIALTOOLS l-4

YOUR VEHICLE SAFELY 1-4

DON'TS l-6

FASTENERS, MEASUREMENTS AND

CONVERSIONS l-6

BOLTS,NUTSANDOTHERTHREADED

RETAINERS 1-6

TORQUE l-7

TORQUEWRENCHES l-7

TORQUEANGLEMETERS 1-9

STANDARDANDMETRIC MEASUREMENTS l-9

SERIAL NUMBER IDENTIFICATION l-10

VEHICLE IDENTIFICATION NUMBER l-10

ENGINE IDENTIFICATION NUMBER I-10

TRANSAXLEIDENTIFICATION I-10

DRlVEAXLE(AWDGALANTONLY) l-10

TRANSFERCASE(AWDGALANTONLY) l-10

ROUTINE MAINTENANCE AND TUNE-UP l-14

AIRCLEANER(ELEMENT) 1-14

REMOVAL&INSTALLATION 1-14

FUELFILTER 1-15

REMOVAL &INSTALLATION l-15

PCVVALVE l-15

REMOVAL&INSTALLATION l-15

EVAPORATIVECANISTER l-16

SERVICING 1-16

BATTERY 1-16

PRECAUTIONS I-16

GENERALMAINTENANCE 1-16

BEL BATTERYFLUID 1-16

CABLES I-17

CHARGING I-18

REPLACEMENT 1-18

TS 1-18

INSPECTiON l-18

ADJUSTMENT 1-18

REMOVAL&INSTALLATION 1-18

TIMINGBELTS l-20

INSPECTION l-20

HOSES I-20

INSPECTION l-20

REMOVAL&INSTALLATION

CV-BOOTS 1-21

INSPECTION l-21

SPARKPLUGS l-22

SPARKPLUGHEATRANGE

REMOVAL&INSTALLATION

INSPECTION &GAPPING 1.

SPARKPLUG WIRES 1-24

TESTING 1-24

REMOVAL&INSTALLATION

DISTRIBUTORCAPANDROTOR

REMOVAL&INSTALLATION

INSPECTION 1-25

IGNITIONTIMING 1-25

. GENERALINFORAMTION l-

lNSPECTlON&ADJUSTMENl

VALVE LASH l-27

ADJUSTMENT l-27

IDLESPEED 1-28 1-21

l-22

l-22

-23

1-24

l-25

l-25

.25

1-26

AIR CONDITIONING SYSTEM 1-28

SYSTEMSERVlCEiiREPAlR l-28

PREVENTIVEMAINTENANCE 1-28

SYSTEM INSPECTION l-29

WINDSHIELD WIPERS l-29

ELEMENT(REFILL)CARE&

REPLACEMENT l-29

TIRESANDWHEELS l-30

TIRE ROTATION I-30

TIRE DESIGN 1-31

TIRESTORAGE l-31

INFLATION &INSPECTION l-31

CARE OFSPECIALWHEELS l-32 OPERATION INFOREIGNCOUNTRIES l-33

ENGINE l-33

OILLEVELCHECK 1-33

OIL& FILTER CHANGE l-34

MANUALTRANSAXLE l-35

FLUIDRECOMMENDATIONS l-35

LEVELCHECK l-35

DRAIN&REFILL l-36

AUTOMATICTRANSAXLE l-36

FLUIDRECOMMENDATIONS l-36

LEVELCHECK 1-36

DRAIN&REFILL l-36

PAN & FILTERSERVICE 1-36

TRANSFERCASE(AWDGAlANT ONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

REARDRlVEAXLE(AWDGALANTONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

COOLINGSYSTEM l-39

FLUIDRECOMMENDATIONS l-39

iM-41

FLUIDS AND LUBRICANTS 1-33

FLUID DISPOSAL 1-33

FlJELANDENGlNEOILRECOMMENDATlONS

ENGINE OIL l-33

FUEL l-33

Page 2 of 408

.

1-2 GENERALINFORMATIONAND MAINTENANCE

Chitton’s Total Car Care manual for the 199M10

Mitsubishi Mirage, Galant and Diamante is intended

to help you learn more about the inner workings of

your vehicle while saving you money on its upkeep

and operation.

The beginning of the book will likely be referred to

the most, since that is where you will find information

for maintenance and tune-up. The other sections deal

with the more complex systems of your vehicle. Oper-

ating systems from engine through brakes are cov-

ered to the extent that the average do-it-yourselfer be-

comes mechanically involved. This book will not

explain such things as rebuilding a differential for the

simple reason that the expertise required and the in-

vestment in special tools make this task uneconomi-

cal. It will, however, give you detailed instructions to

help you change your own brake pads and shoes, re-

place spark plugs, and perform many more jobs that

can save you money, give you personal satisfaction

and help you avoid expensive problems.

A secondary purpose of this book is a reference for

owners who want to understand their vehicle and/or

their mechanics better. In this case, no tools at all are

required.

Before removing any bolts, read through the entire

procedure. This will give you the overall view of what

tools and supplies will be required. There is nothing

more frustrating than having to walk to the bus stop

on Monday morning because you were short one bolt

on Sunday afternoon. So read ahead and plan ahead.

Each operation should be approached logically and

all procedures thoroughly understood before attempt-

ing any work.

All sections contain adjustments, maintenance, re-

moval and installation procedures, and in some cases,

repair or overhaul procedures. When repair is not con-

sidered practical, we tell you how to remove the part

and then how to install the new or rebuilt replacement.

In this way, you at least save labor costs. “Backyard”

repair of some components is just not practical.

Many procedures in this book require you to “label

and disconnect. . ” a group of lines, hoses or wires.

Don’t be lulled into thinking you can remember where

everything goes-you won’t. If you hook up vacuum

or fuel lines incorrectly, the vehicle may run poorly, if

at all. If you hook up electrical wiring incorrectly, you

may instantly learn a very expensive lesson.

You don’t need to know the official or engineering

name for each hose or line. A piece of masking tape

on the hose and a piece on its fitting will allow you to

assign your own label such as the letter A or a short name. As long as you remember your own code, the

lines can be reconnected by matching similar letters

or names. Do remember that tape will dissolve in

gasolrne or other fluids; if a component is to be

washed or cleaned, use another method of identifica-

tion. A permanent felt-tipped marker or a metal scribe

can be very handy for marking metal parts. Remove

any tape or paper labels after assembly.

It’s necessary to mention the difference between

maintenance and repair Maintenance includes rou-

tine inspections, adjustments, and replacement of

parts which show signs of normal wear Maintenance

compensates for wear or deterioration. Repair implies

that something has broken or is not working. A need

for repair is often caused by lack of maintenance. Ex-

ample, draining and refilling the automatic transaxle

fluid is maintenance recommended by the manufac-

turer at specific mileage intervals. Failure to do this

can shorten the life of the transmission/transaxle, re-

quiring very expensive repairs. While no maintenance

program can prevent items from breaking or wearing

out, a general rule can be stated: MAINTENANCE IS

CHEAPER THAN REPAIR.

Two basic mechanrc’s rules should be mentioned

here. First, whenever the left side of the vehicle or en-

gine is referred to, it is meant to specify the drivers

side. Conversely, the right side of the vehicle means

the passengers side. Second, screws and bolts are

removed by turning counterclockwise, and tightened

by turning clockwrse unless specifically noted.

Safety is always the most important rule. Con-

stantly be aware of the dangers involved in working

on an automobile and take the proper precautions.

See the informatron in this section regarding SER-

VICING YOUR VEHICLE SAFELY and the SAFETY

NOTICE on the acknowledgment page.

Pay attention to the instructions provided. There

are 3 common mistakes in mechanical work:

1. Incorrect order of assembly, disassembly or

adjustment. When taking something apart or putting

it together, performing steps in the wrong order usu-

ally just costs you extra time; however, it CAN break

something. Read the entire procedure before begin-

ning disassembly. Perform everything in the order in

which the instructions say you should, even if you

can’t immedrately see a reason for it. When you’re

taking apart something that is very intricate, you

might want to draw a picture of how it looks when as-

sembled at one point in order to make sure you get everything back in its proper position. We will supply

exploded views whenever possible. When making

adjustments, perform them in the proper order. One

adjustment possibly will affect another.

2. Overtorquing (or undertorquing). While it is

more common for overtorquing to cause damage,

undertorquing may allow a fastener to vibrate loose

causing serious damage. Especially when dealing

with aluminum parts, pay attention to torque specifi-

cations and utilize a torque wrench in assembly. If a

torque figure is not available, remember that if you

are using the right tool to perform the job, you will

probably not have to strain yourself to get a fastener

tight enough. The pitch of most threads is so slight

that the tension you put on the wrench will be multi-

plied many times in actual force on what you are

tightening. A good example of how critical torque is

can be seen in the case of spark plug installation, es-

pecially where you are putting the plug into an alu-

minum cylinder head. Too little torque can fail to

crush the gasket, causing leakage of combustion

gases and consequent overheating of the plug and

engine parts. Too much torque can damage the

threads or distort the plug, changing the spark gap.

There are many commercial products available for

ensuring that fasteners won’t come loose, even if they

are not torqued just right (a very common brand is

Loctite? If you’re worried

about getting something

together tight enough to hold, but loose enough to

avoid mechanical damage during assembly, one of

these products might offer substantial insurance. Be-

fore choosing a threadlocking compound, read the

label on the package and make sure the product is

compatible with the materials, fluids, etc. involved.

3. Crossthreading. This occurs when a part such

as a bolt is screwed into a nut or casting at the wrong

angle and forced. Crossthreading is more likely to

occur if access is difficult. It helps to clean and lubri-

cate fasteners, then to start threading the bolt, spark

plug, etc. with your fingers If you encounter resis-

tance, unscrew the part and start over again at a dif-

ferent angle until it can be inserted and turned several

times without much effort. Keep in mind that many

parts, especially spark plugs, have tapered threads,

so that gentle turning will automatically bring the part

you’re threading to the proper angle. Don’t put a

wrench on the part until its been tightened a couple

of turns by hand. If you suddenly encounter resis-

tance, and the part has not seated fully, don’t force it.

Pull it back out to make sure it’s clean and threading

properly.

Be sure to take your time and be patient, and al-

ways plan ahead. Allow yourself ample time to per-

form repairs and maintenance You may find main-

taining your car a satisfying and enjoyable

experience.

b See Figures 1 thru 15

Naturally, without the proper tools and equipment

it is impossible to properly service your vehicle. It

would also be virtually impossible

to catalog every

tool that you would need to perform all of the opera-

tions in this book. Of course, It would be unwise for

the amateur to rush out and buy an expensive set of

tools on the theory that he/she may need one or more

of them at some time, The best approach is to proceed slowly, gathering savings will

be far outweighed by frustration and

a good quality set of those tools that are used most mangled knuckles.

frequently Don’t be misled by the low cost of bargain Begin accumulating those tools that are used most

tools. It is far better to spend a little more for better frequently: those associated with routine maintenance

quality. Forged wrenches, 6 or 12-point sockets and and tune-up. In addition to the normal assortment of

fine tooth ratchets are by far preferable to their less screwdrivers and pliers, you should have the follow-

expensive counterparts. As any good mechanic can ing tools:

tell you, there are few worse experiences than trying

l Wrenches/sockets and combination open

to work on a vehicle with bad tools. Your monetary end/box end wrenches in sizes from %-% in. or

Page 8 of 408

GENERALINFORMATIONAND MAINTENANCE l-9

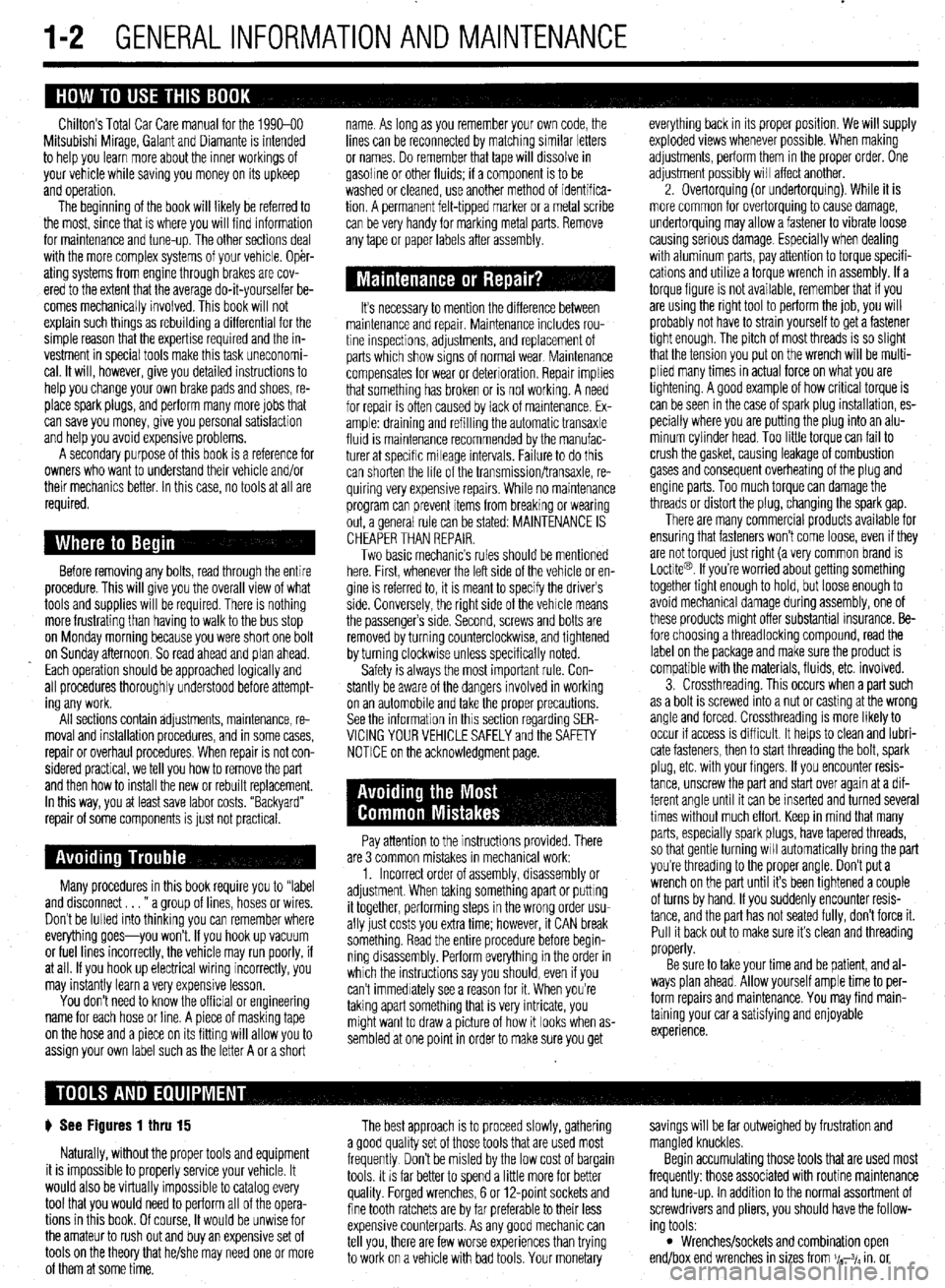

Fig. 27 A click type or breakaway torque

wrench-note that this one has a pivoting

head

v

WRONG WRONG

PIVOTED HANDLE TOR(IUE WRENCH tccS1041 Fig. 28 Torque wrenches with pivoting

heads must be grasped and used properly

to prevent an incorrect reading

Rigid Case (Direct Reading)

# See Figure 29

A rigid case or direct reading torque wrench is

equipped with a dial indicator to show torque values.

One advantage of these wrenches is that they can be

held at any position on the wrench without affecting

accuracy. These wrenches are often preferred be-

cause they tend to be compact, easy to read and have

a great degree of accuracy.

lccs1042 Fig. 29 The rigid case (direct reading)

torque wrench uses a dial indicator to show

torque

TORQUEANGLEMETERS

# See Figure 30

Because the frictional characteristics of each fas-

tener or threaded hole will vary, clamp loads which

are based strictly on torque will vary as well. In most

applications, this variance IS not significant enough

to cause worry. But, in certain applications, a manu-

facturers engineers may determine that more precise

clamp loads are necessary (such is the case with :ig. 30 Some specifications require the use

rf a torque angle meter (mechanical pro.

ractor)

many aluminum cylinder heads). In these cases, a

torque angle method of installation would be speci-

fied. When installing fasteners which are torque angle

tightened, a predetermined seating torque and stan- dard torque wrench are usually used first to remove

any compliance from the joint. The fastener is then

tightened the specified additional portion of a turn

measured in degrees. A torque angle gauge (mechan-

ical protractor) is used for these applications.

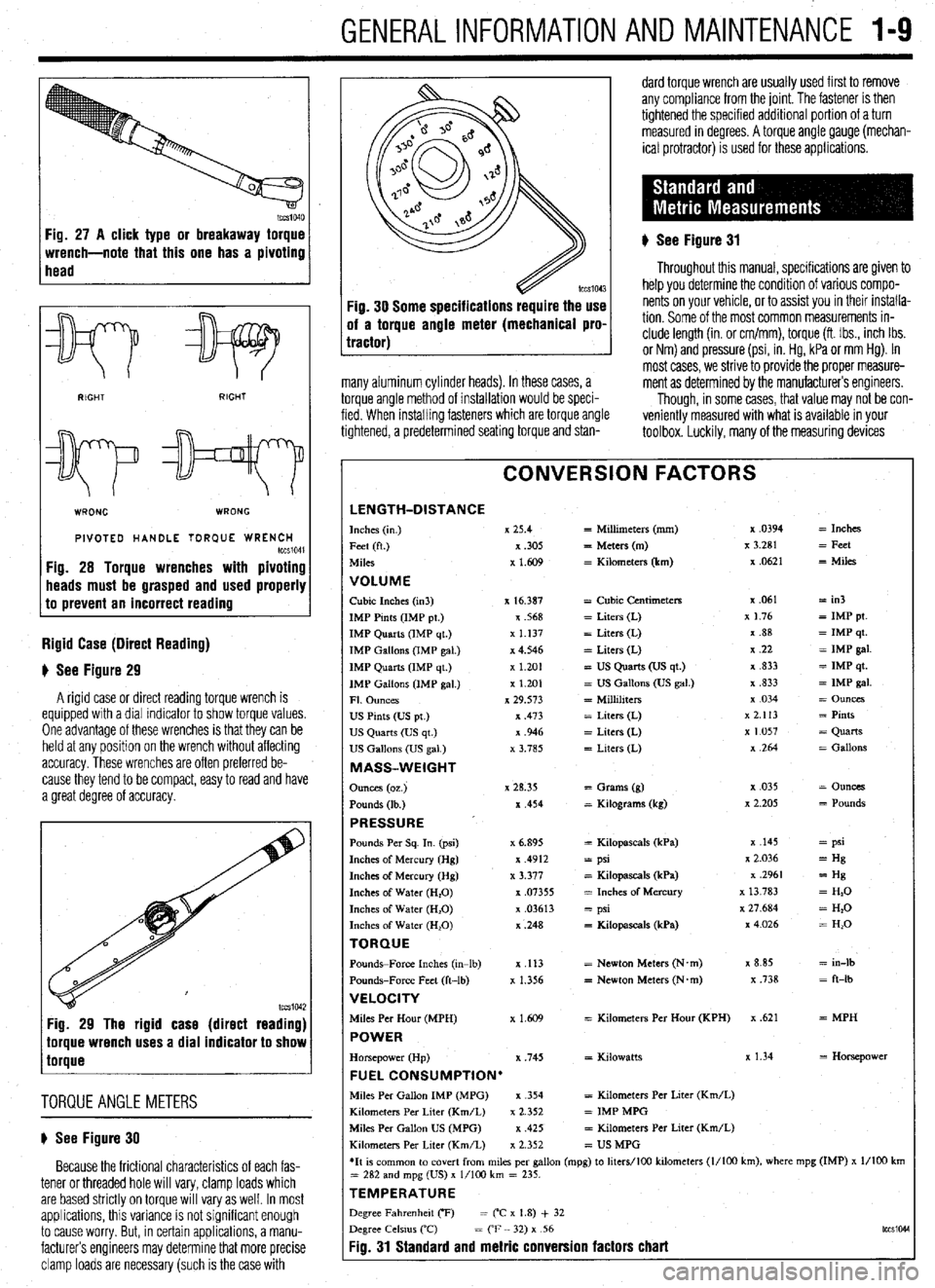

) See Figure 31

Throughout this manual, specifications are given to

help you determine the condition of various compo-

nents on your vehicle, or to assist you in their installa-

tion. Some of the most common measurements in-

clude length (in. or cm/mm), torque (ft. Ibs., inch Ibs.

or Nm) and pressure (psi, in. Hg, kPa or mm Hg). In

most cases, we strive to provide the proper measure-

ment as determined by the manufacturers engineers.

Though, in some cases, that value may not be con-

veniently measured with what is available in your

toolbox. Luckily, many of the measuring devices

CONVERSION FACTORS

LENGTH-DISTANCE Inches (I”.) x 25.4 = Millimeters (mm) x .0394 = Inches

Feet (ft.) x ,305

= Meters (m) x 3.281 = Feet

Miles x 1.609 = Kilometers (km) x .0621

= Miles

VOLUME Cubic Inches (in3) x 16.387 = Cubic Centimeters x .061 = in3

IMP Pints (IMP pt.) x .568 = Liters (L) x 1.76

= IMP pt.

IMP Quarts (IMP qt.) x 1.137 = Liters (L) x .88 = IMP qt.

IMP Gallons (IMP gal.) x 4.546 = Liters (L) 7, .22

= IMP gal.

IMP Quarts (IMP qt ) x 1.201 = US Quarts (US qt.) x ,833 = IMP qt.

IMP Gallons (IMP gal.) x 1.201

= US Gallons (US gal.) x ,833

= IMP gal.

Fl. Ounces x 29.573 = Millihters x 034

= Ounces

us Pints (Us pt.) x ,473 = Liters (L) x 2.113 = Pints

US Quarts (US qt.) x .946 = Liters (L) x 1.057

= Quarts

US Gallons (US gal.) x 3.785 = Liters (L) x ,264 = Gallons

MASS-WEIGHT

Ounces (oz.) x 28.35

= Grams (g) x ,035

= Ounces

Pounds (lb ) x ,454 = Kdograms (kg) x 2.205

= Pounds

PRESSURE ’ Pounds Per Sq. In. (psi) x 6.895 = Kilopascals (kPa) x ,145 = psi

Inches of Mercury (Hg) x .4912

= psi x 2.036 = Hg

Inches of Mercury (Hg) x 3.377 = Kilopascals (kPa) x .2961

= Hg

Inches of Water (H,O)

x .07355 = Inches of Mercury x 13 783 = H,O

Inches of Water (H,O) x .03613 = psi x 27.684

= Hz0

Inches of Water (H,O) x ,248

= Kilopascals (kPa) x4026

= H,O

TORQUE Pounds-Force Inches (in-lb)

x ,113 = Newton Meters (N.m) x 8.85 = in-lb

Pounds-Force Feet (ft-lb)

x 1.356 = Newton Meters (N*m) x ,738 = ft-lb

VELOCITY Miles Per Hour (MPH)

x 1.609 = Kilometers Per Hour (KPH) x .621 = MPH POWER Horsepower (Hp) x ,745 = Kdowatts x 1.34

= Horsepower FUEL CONSUMPTION’ Mdes Per Gallon IMP (MPG) x .354

= Kilometers Per Liter (Km/L)

Kilometers Per Liter (Km/L)

x 2.352 = IMP MPG

Miles Per Gallon US (MPG) x ,425

= Kilometers Per Liter (Km/L)

Kdometers Per Liter (Km/L) x 2.352

= US MPG

*It 1s common to covert from miles per gallon (mpg) to hters/lOO kilometers (l/100 km), where mpg (IMP) x l/ID0 km

= 282 and mpg (US) x l/lo0 km = 235.

TEMPERATURE Degree Fahrenheit CF) = (“C x 1.8) + 32

Degree Celsms (‘C)

= CF - 32) x 56

tccsio4d

Fig. 31 Standard and metric conversion factors chart

Page 9 of 408

.

l-10 GENERALINFORMATIONAND MAINTENANCE

which are available today will have two scales so the

The conversion factor chart is used by taking the

Standard or Metric measurements may easily be given specification and multiplying it by the neces-

taken. If any of the various measuring tools which are sary conversion factor. For instance, looking at the

available to you do not contain the same scale as first line, if you have a measurement in inches such

listed in the specifications, use the accompanying

as “free-play should be 2 in.” but your ruler reads

conversion factors to determine the proper value. only in millimeters, multiply 2 in. by the conversion factor of 25.4 to get the metric equivalent of 50.8mm.

Likewise, if the specification was given only in a Met-

ric measurement, for example in Newton Meters

(Nm), then look at the center column first. If the mea-

surement is 100 Nm, multiply it by the conversion

factor of 0.738 to get 73.8 ft. Ibs.

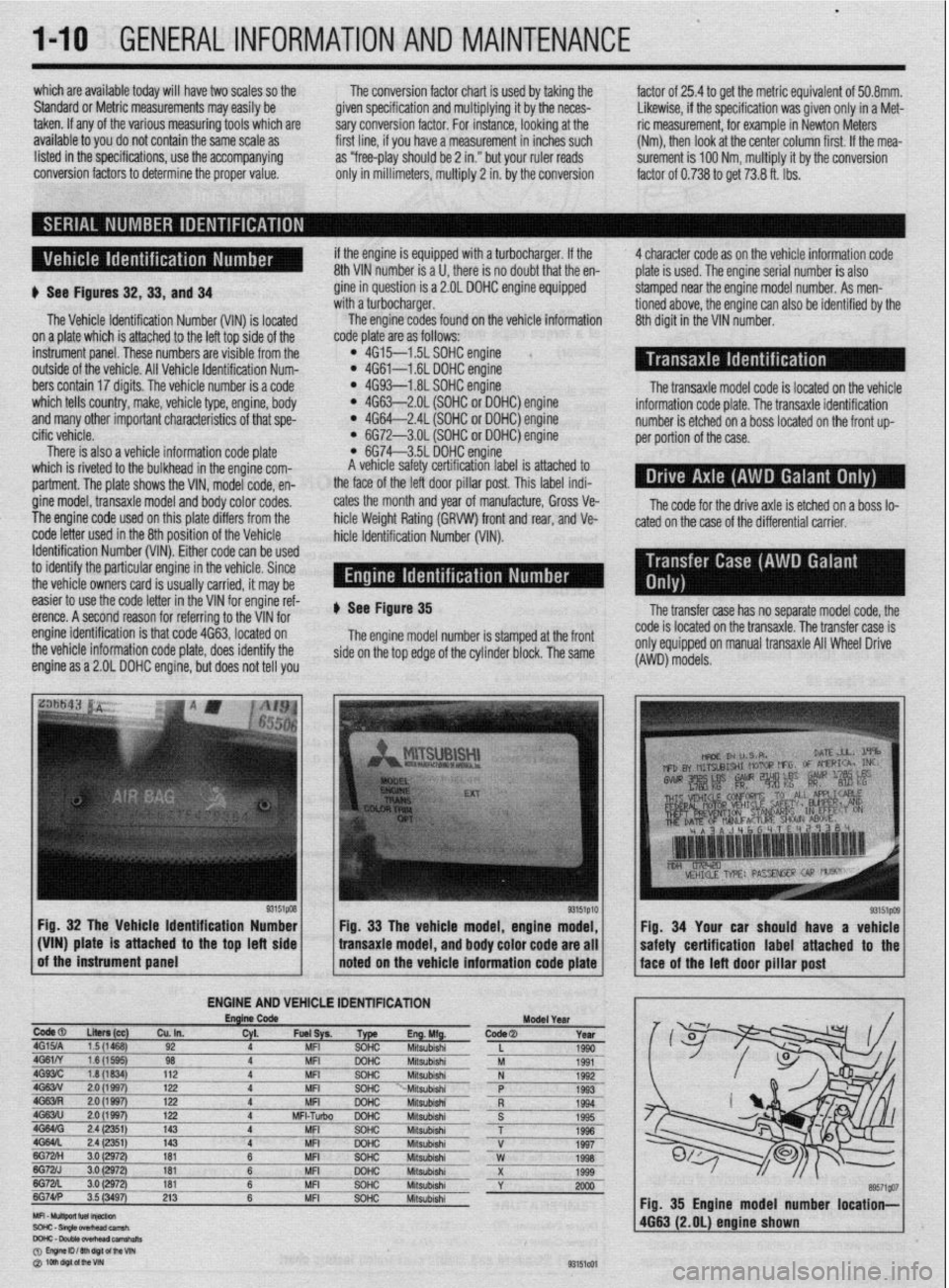

b See Figures 32,33, and 34

The Vehicle Identification Number (VIN) is located

on a plate which is attached to the left top side of the

instrument panel. These numbers are visible from the

outside of the vehicle. All Vehicle Identification Num-

bers contain 17 digits. The vehicle number is a code

which tells country, make, vehicle type, engine, body

and many other important characteristics of that spe-

cific vehicle.

There is also a vehicle information code plate

which is riveted to the bulkhead in the engine com-

partment. The plate shows the VIN, model code, en-

gine model, transaxle model and body color codes.

The engine code used on this plate differs from the

code letter used in the 8th position of the Vehicle

Identification Number (VIN). Either code can be used

to identify the particular engine in the vehicle. Since

the vehicle owners card is usually carried, it may be if the engine is equipped with a turbocharger. If the

8th VIN number is a U, there is no doubt that the en-

gine in question is a 2.OL DOHC engine equipped

with a turbocharger.

The engine codes found on the vehicle information

code plate are as follows:

l 4G15--1.5L SOHC engine l 4G61-1.6L DOHC engine l 4G93-1.8L SOHC engine l 4G63-2.OL (SOHC or DOHC) engine l 4G64-2.4L (SOHC or DOHC) engine l 6G72-3.OL (SOHC or DOHC) engine l 6G74-3.5L DOHC engine

A vehicle safety certification label is attached to

the face of the left door pillar post. This label indi-

cates the month and year of manufacture, Gross Ve-

hicle Weight Rating (GRVW) front and rear, and Ve-

hicle Identification Number (VIM). 4 character code as on the vehicle information code

plate is used. The engine serial number is also

stamped near the engine model number. As men-

tioned above, the engine can also be identified by the

8th digit in the VIN number.

The transaxle model code is located on the vehicle

information code plate. The transaxle identification

number is etched on a boss located on the front up-

per portion of the case.

The code for the drive axle is etched on a boss lo-

cated on the case of the differential carrier.

easier to use the code letter in the VIN for engine ref-

erence. A second reason for referring to the VIN for

engine identification is that code 4663, located on

the vehicle information code plate, does identify the

engine as a 2.OL DOHC engine, but does not tell you ) See Figure 35

The engine model number is stamped at the front

side on the top edge of the cylinder block. The same

Fig. 32 The Vehicle Identification Number

g3’51p’o of the instrument panel _I:^1 / Fig. 33 The vehicle model, engine model,

(VIN) plate is attached to the top left side

bansaxle model, and body color code are all

noted on the vehicle information code plate

ENGINE AND VEHiCLE IDENTlFlCATlON

EnglnCode

ModelYerr

todeal

LIten (cc)

Cu. In. W. Fuel+ Type m.hWg. Code@ Year ,G15JA 1.5 (1468) 92 4 MFI SOHC Mitsubishi

L 1990

IG61N 1.6(15QQ) 98 4 MFI DOHC

Mitsubishi M 1991

1G93lC 1.8 (1834) 112 4 MFI SOHC Mitsubishi N 1992

IG63N 2.0 (1997) 122 4 MFI SOHC “-Mitsubishi P

1993

!G63Fi 2.0 (1997) 122 4 MFI DOHC Mitsubishi

R 1994

,G63iU 2.0 (1997) 122 4 MFI-Tuibo DOHC Mitsubishi

S 1995

.GMffi 2.4 (2351) 143 4 MFI SOHC

Mitsubishi T 1996

iG64L 2.4 (2351) 143 4 MFI DOHC Mitsubishi V

lEzH 3.0 1997

(2972) 161 6 MFI SOHC Mitsubishi W 1998

;G7ZJ 3.0 (2Q72) 161 6 MFI GQHC Mitsubishi

~.. X 1999

iG7zL 3.0 (2972) 181

~ 6 MFI SOHC ___-___ Miisubishi

Y 2000

iG74lP 3.5 (3497) 213 6 MFI SOHC Miisubishi

The transfer case has no separate model code, the

code is located on the transaxle. The transfer case is

onlv eoUiODed on manual transaxle All Wheel Drive

(AWD)‘mbdels.

Fig. 34 Your car should have a vehicle

Fig. 35 Engine model number location-

4663 (2.OL) engine shown

Page 10 of 408

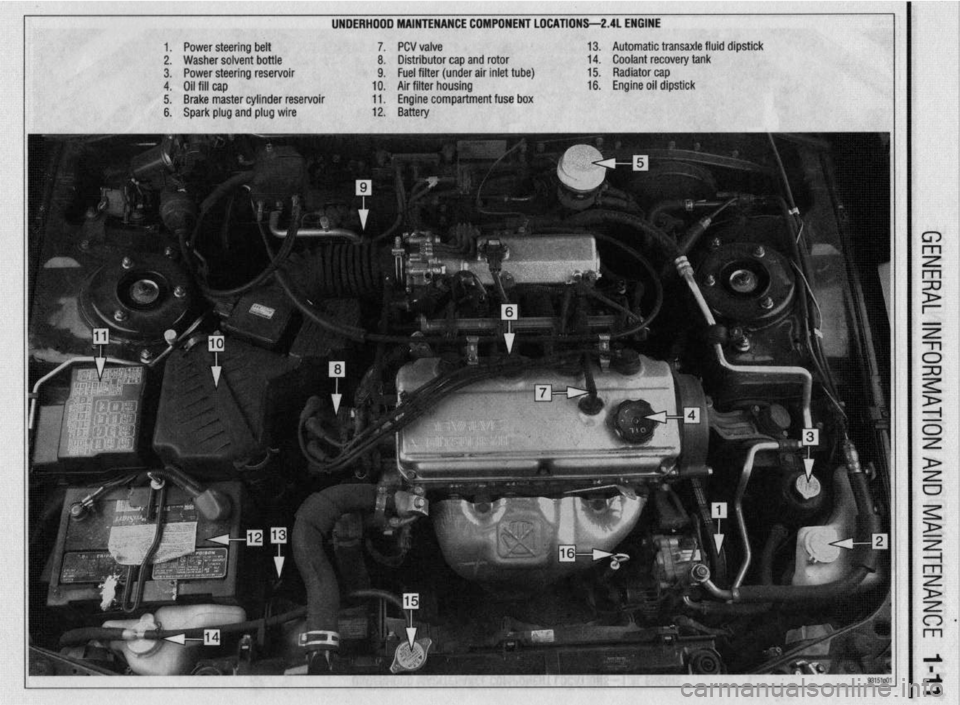

UNDERHDDD MAINTENANCE COMPONENT LOCATIONS-2AL ENGINE

II

1. Power steering belt 7. PCV valve

2. Washer solvent bottle 8. Distributor cap and rotor

3. Power steering reservoir 9. Fuel filter (under air inlet tube)

4. Oil fill cap 10. Air filter housing

5. Brake master cylinder reservoir 11. Engine compartment fuse box

6. Spark plug and plug wire 12. Battery 13. Automatic transaxle fluid dipstick

14. Coolant recovery tank

15. Radiator cap

16. Engine oil dipstick

Page 11 of 408

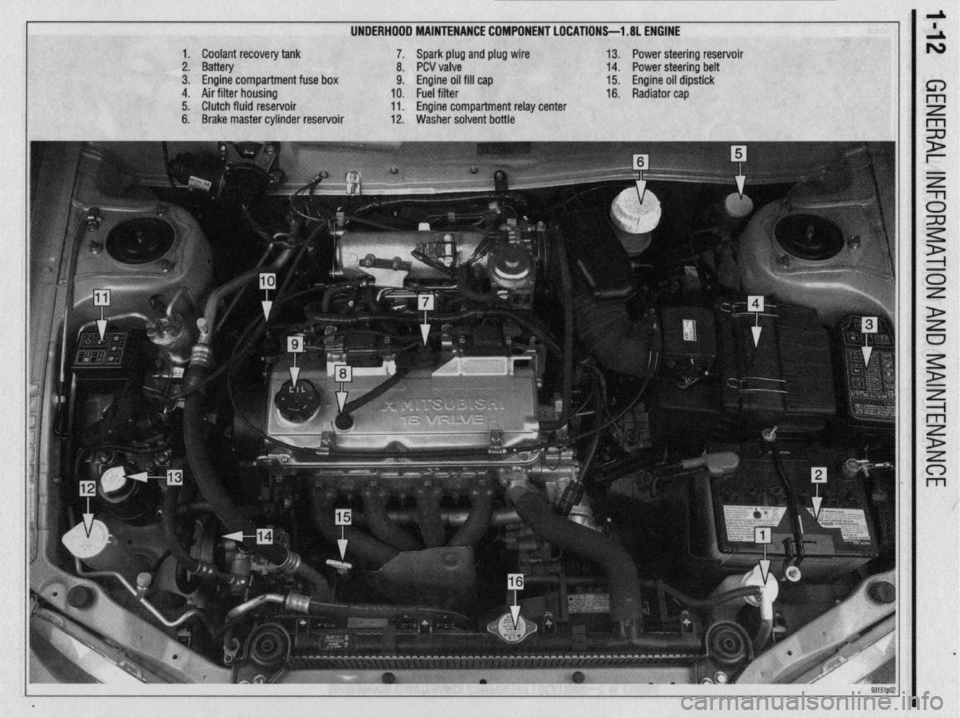

UNDERHOOD MAINTENANCE COMPONENT LOCATIONS-l .8L ENGINE

1. Coolant recovery tank

2. Battery

3. Engine compartment fuse box

4. Air filter housing

5. Clutch fluid reservoir

6. Brake master cylinder reservoir 7. Spark plug and plug wire

8. PCV valve

9. Engine oil fill cap

10. Fuel filter

11. Engine compartment relay center

12. Washer solvent bottle 13. Power steering reservoir

14. Power steering belt

15. Engine oil dipstick

16. Radiator cap

Page 12 of 408

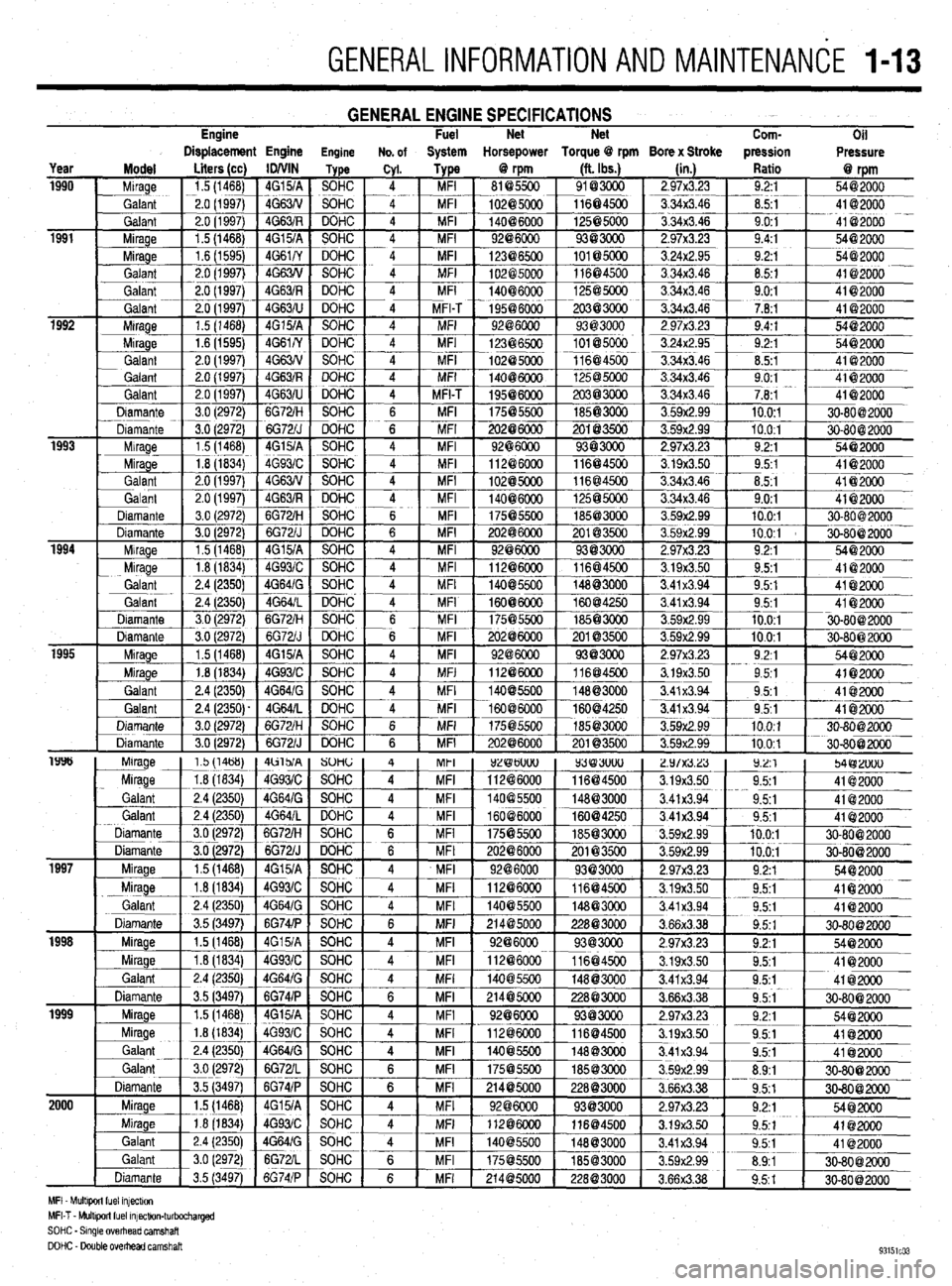

GENERALINFORMATIONAND MAlNTENANdE 1-13

Engine GENERAL ENGINE SPECIFICATIONS Fuel Net Net

Com-

Oil

Displacement Engine Engine No. of System Horsepower Torque @ rpm Bore x Stroke pression

Pressure

MFI Mult+wt fuel mfectw,

MFI-T - Multlporl fuel mfectlon-turbocharged

SOHC - Smgle overhead camshaft

DOHC - Double OvedEad camshaft

Page 14 of 408

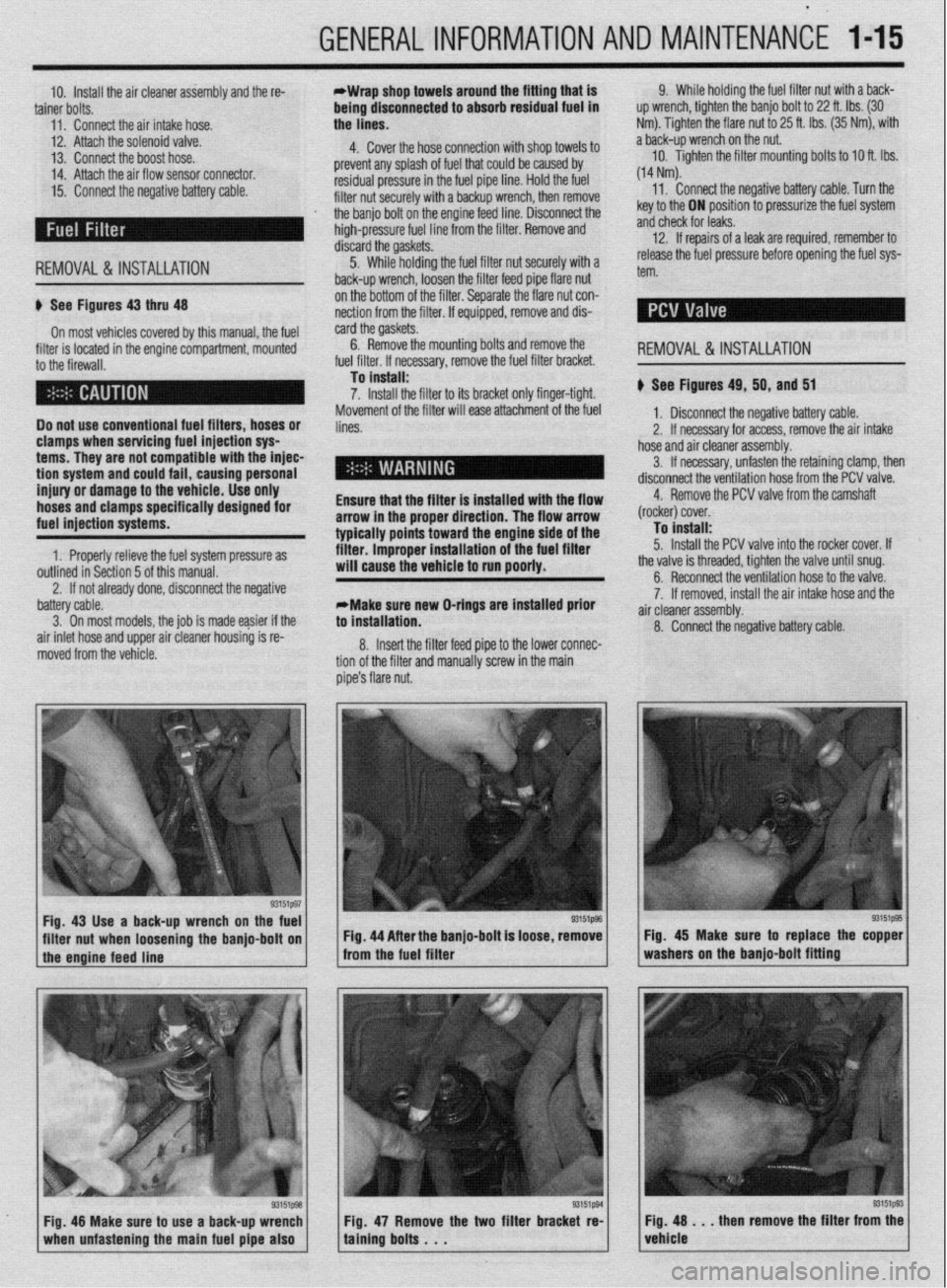

GENERALINFORMATIONAND MAINTENANCE l-15

10. install the air cleaner assembly and the re- *Wrap shop towels around the fitting that is

tainer bolts. being dtsconnected to absorb residual fuel in

11. Connect the air intake hose. the lines. 9. While holding the fuel filter nut with aback-

up wrench, tighten the banjo bolt to 22 ft. Ibs. (30

Nm). Tighten the flare nut to 25 ft. Ibs. (35 Nm), with

12. Attach the solenoid valve.

4. Cover the hose connection with shop towels to a back-up wrench on the nut.

13. Connect the boost hose.

14. Attach the air flow sensor connector. prevent any splash of fuel that could be caused by 10. Tighten the filter mounting bolts to 10 ft. Ibs.

residual pressure in the fuel pipe line. Hold the fuel (14 Nm).

15. Connect the negative battery cable. 11.

filter nut securely with a backup wrench, then remove Connect the negative battery cable. Turn the

REMOVAL &INSTALLATION the banjo bolt on the engine feed line. Disconnect the

high-pressure fuel line from the filter. Remove and

discard the gaskets.

5. While holding the fuel filter nut securely with a

back-up wrench, loosen the filter feed pipe flare nut key to the ON position to pressurize the fuel system

and check for leaks.

12. If repairs of a leak are required, remember to

release the fuel pressure before opening the fuel sys-

tern.

u See Figures 43 thru 48

On most vehicles covered by this manual, the fuel

filter is located in the engine compartment, mounted

to the firewall.

Do not use conventional fuel filters, hoses or

clamps when servicing fuel injection sys

terns. They are not compatible with the injec-

tion

system and could fail, causing personal

injury or damage to the vehicle. Use only

hoses and clamps specifically designed for

fuel injection systems.

1. Properly relieve the fuel system pressure as

outlined in Section 5 of this manual. on the bottom of the filter. Separate the flare nut con-

nection from the filter. If equipped, remove and dis-

card the gaskets.

6. Remove the mounting bolts and remove

. ,,,. ,.

.a r I,.,< I the

ruer rrrter. II necessary, remove me ruer rrrrer oracket.

To install:

7. Install the filter to its bracket only finger-tight.

Movement of the filter will ease attachment of the fuel

lines.

Ensure that the filter is installed with the flow

arrow in the proper direction. The flow arrow

typically points toward the engine side of the

filter. improper installation of the fuel filter

will cause the vehicle to run poorly.

2. If not already done, disconnect the negative REMOVAL&INSTALLATION

u See Figures 49, 50, and 51

1, Disconnect the negative battery cable.

2. If necessary for access, remove the air intake

hose and air cleaner assembly.

3. If necessary, unfasten the retaining clamp, then

disconnect the ventilation hose from the PCV valve.

4. Remove the PCV valve from the camshaft

(rocker) cover.

To install:

5. Install the PCV valve into the rocker cover. If

the valve is threaded, tighten the valve until snug.

battery cable.

3. On most models. the iob is made easier if the

air inlet hose and upper air cleaner housing is re-

moved from the vehicle. *Make sure new O-rings are installed prior

to installation.

8. Insert the filter feed pipe to the lower connec-

tion of the filter and manually screw in the main

pipe’s flare nut. 6. Reconnect the ventilation hose to the valve.

7. If removed, install the air intake hose and the

a .ir cleaner assembly.

8. Connect the negative battery cable.

Fig. 43 Use a back-up wrench on the fuel

I I

93151@3

filter nut when loosening the banjo-bolt on Fig. 44 After the banjo-bolt is loose, remove

I

1 the engine feed line - from the fuel filter

93151p93 Fig. 48 Make sure to use a back-up wrench

1 when unfastening the main fuel pipe also 1 Fig. 47 Remove the two filter bracket re-

taining bolts . . . Fig. 45 Make sure to replace the copper

washers on the banjo-bolt fitting

Fig. 48 . . . then remove the filter from the

vehicle

Page 21 of 408

l-22 GENERALINFORMATIONAND MAINTENANCE

tears. If the boot is damaged, it should be replaced

trode is to the block’s cooling passages) the cooler it

your driving is long distance, high speed travel, use a

immediately. Please refer to Section 7 for procedures.

will operate. A plug that absorbs little heat and re-

colder plug; if most of your driving is stop and go,

mains too cool will quickly accumulate deposits of

use a hotter plug. Original equipment plugs are gen-

oil and carbon since it is not hot enough to burn

erally a good compromise between the 2 styles and

them off. This leads to plug fouling and consequently

most people never have the need to change their

to misfiring. A plug that absorbs too much heat will

plugs from the factory-recommended heat range.

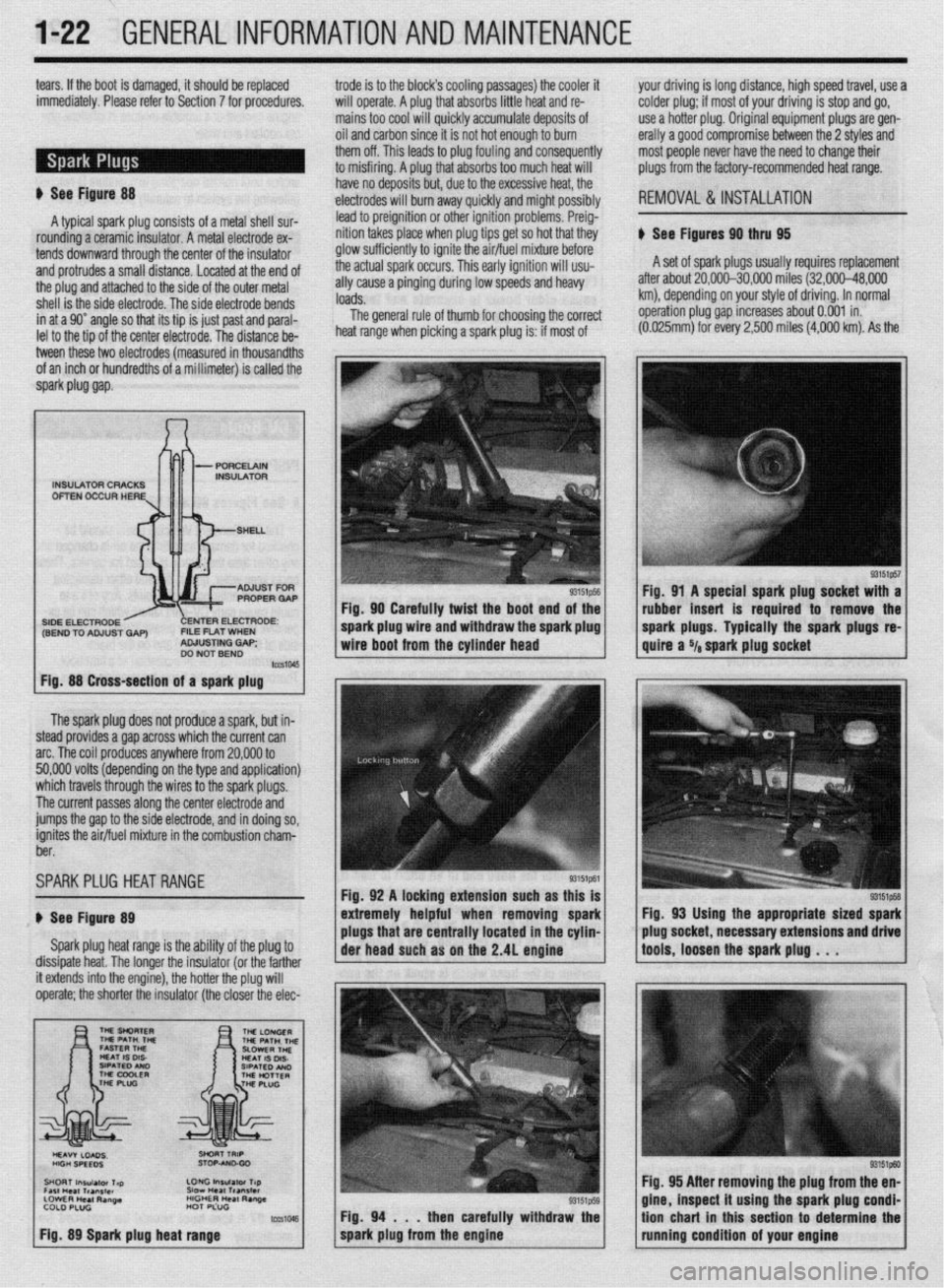

ti See Figure 88 have no deposits but, due to the excessive heat, the

,electrodes will burn away quickly and might possibly

REMOVAL &INSTALLATION

A typical spark plug consists of a metal shell sur- lead to preignition or other ignition problems. Preig-

rounding a ceramic insulator. A metal electrode ex- nition takes place when plug tips get so hot that they

ti See Figures 90 thru 95

tends downward through the center of the insulator glow sufficiently to ignite the air/fuel mixture before

and protrudes a small distance. Located at the end of the actual spark occurs. This early ignition will usu- A set of spark plugs usually requires replacement

the plug and attached to the side of the outer metal ally cause a pinging during low speeds and heavy after about 20,000-30,000 miles (32,000-48,000

shell is the side electrode. The side electrode bends loads. km), depending on your style of driving. In normal

in at a 90” angle so that its tip is just past and paral- The general rule of thumb for choosing the correct operation plug gap increases about 0.001 in.

lel to the tio of the center electrode. The distance be- heat range when picking a spark plug is: if most of (0.025mrn) for every 2,500 miles

(4,000 km). As the

tween these two electrodes (measured in thousandths

of an inch or hundredths of a millimeter) is called the

spark piug gap.

The spark plug does not produce a spark, but in-

steed provides a gap across which the current can

arc. The coil produces anywhere from 20,000 to

50,000 volts (depending on the type and application)

which travels through the wires to the spark plugs.

The current passes along the center electrode and

jumps the gap to the side electrode, and in doing so,

ignites the air/fuel mixture in the combustion charn-

ber.

SPARKPLUG HEATRANGE

ti See Figure 89

Spark plug heat range is the ability of the plug to

dissipate heat. The longer the insulator (or the farther

INSULATOR CRACKS

OFTEN OCCUR HERE

SIDE ELECTRODE ENTER ELECTRODE:

(SEND TO ADJUST GAP) FILE FLAT WHEN

ADJUSTING GAP;

DO NOT BEND

Fig. 88 Cross-section of a spark plug

it extends into the engine), the hotter the plug will

operate; the shorter the insulator (the closer the elec- Fig. 90 Carefully twist the boot end of the

I

spark plug wire and withdraw the spark plug

wire boot from the cylinder head

Fig. 92 A locking extension such as this is

extremely helpful when removing spark

plugs that are centrally located in the cyhn-

Fig. 94 . . .

then carefully withdraw the

spark plug from the engine Fig. 91 A special spark plug socket with a

rubber insert is required to remove the

spark plugs. Typically the spark plugs

re-

quire a Ya spark plug socket

Fig, 93 Using the appropriate sized spark

plug socket, necessary extensions and drive

tools, loosen the spark plug . . .

93151ptxl Fig. 95 After removing the plug from the en-

gine, inspect it using the spark plug condi-

tion chart in this section to determine the

running condition of your engine

Page 22 of 408

t

GENERALINFORMATIONAND MAINTENANCE l-23

gap increases, the plug’s voltage requirement also in-

creases. It requires a greater voltage to jump the the spark plug counterclockwise to loosen and re-

move the spark plug from the bore.

wider gap and about &o to three times as much volt-

age to fire the plug at high speeds than at idle. The

improved air/fuel ratio control of modern fuel injec-

tion combined with the higher voltage output of mod- Be sure not to use a flexible extension on the place. The click may be felt or heard, then gently pull

ern ignition systems will often allow an engine to run socket. Use of a flexible extension may allow back on the boot to assure proper contact.

.___. . _

significantly longer on a set of standard spark plugs, a shear force to be agptf’ ea to me plug.

A 12. On the 3.OL fSOHC and DOHC) and 3.5L en-

LL_ _I___ -u I_ IL-

but keep in mind that efficiency will drop as the gap shear force could break tne pug on III me

tion 3 for the installation procedure.

widens (along with fuel economy and power). cylinder head, leading to costly and frustrat-

13. If equipped, install the center cover.

When you’re removing spark plugs, work on one ing repairs.

at a time. Don’t start by removing the plug wires all at

once, because, unless you number them, they may To install:

INSPECTION & GAPPING

11. Apply a small amount of silicone dielectric

compound to the end of the spark plug lead or inside

the spark plug boot to prevent sticking, then install

the boot to the spark plug and push until it clicks into

gines, install the upper intake manifold. Refer to Sec-

,,Y” ..1111 uy”’ 1 the neaative bat&v cable and if become mixed up. Take a minute before you begin

and number the wrrpc with +sne

1. Disconnect. ~~.~

--..-., -..-.-, -..-

thevehicle has been run recently, allow the engine to

thoroughly cool.

2. If equipped, remove the center cover.

3. On the 3.OL (SOHC and DOHC) and 3.5L en-

gines, the upper intake manifold must be removed to

access the rear spark plugs. Refer to Section 3 for the

removal procedure.

4. Carefully twist the spark plug wire boot to

loosen it, then pull upward and remove the boot from

the plug. Be sure to pull on the boot and not on the

wire, otherwise the connector located inside the boot

may become separated.

5. Using compressed air, blow any water or de-

bris from the spark plug well to assure that no harm-

ful contaminants are allowed to enter the combustion

chamber when the spark plug is removed. If com-

pressed air is not available, use a raa or a brush to must be replaced.

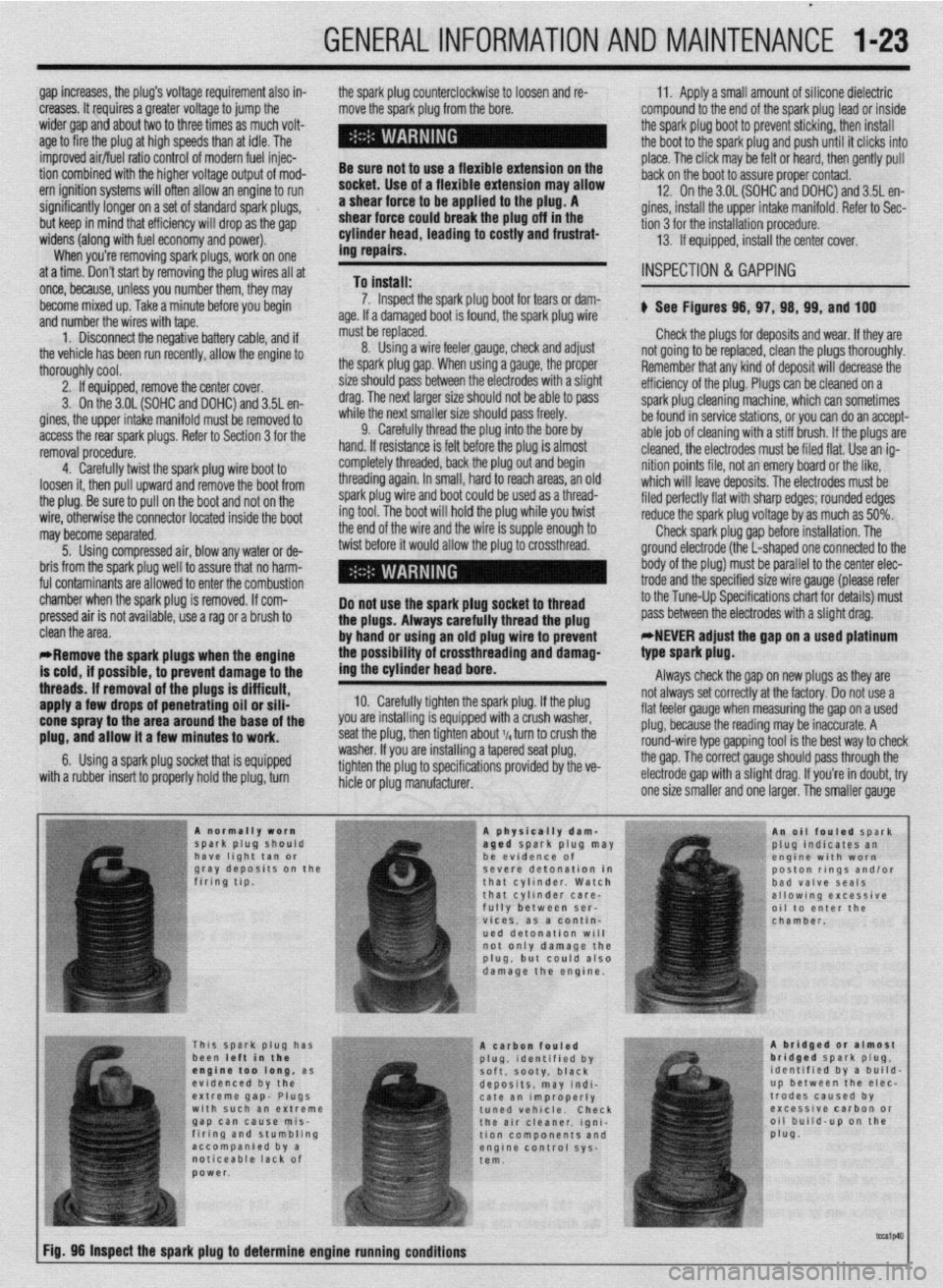

Check the plugs for deposits and wear, If they are 7. Inspect the spark plug boot for tears or dam-

age. If.a damaged boot is found, the spark plug wire

8. Using a wire feelergauge, check and adjust

the spark plug gap. When using a gauge, the proper

size should pass between the electrodes with a slight

drag. The next larger size should not be able to pass

while the next smaller size should pass freely.

9. Carefully thread the plug into the bore by

hand. If resistance is felt before the plug is almost

completely threaded, back the plug out and begin

threading again. In small, hard to reach areas, an old

spark plug wire and boot could be used as a thread-

ing tool. The boot will hold the plug while you twist

the end of the wire and the wire is supple enough to

twist before it would allow the plug to crossthread.

Do not use the spark plug sock?

l -- K-rrA tha nhme Alwmm rarntdlv thw GL I” IlllGa”

the possibility of crossthreading and damag- lad the plug

. ..Y f..“YY. rn”Y,‘““mY*“.‘, .I**” by hand or using an old plug wire to prevent

ing the cylinder head bore.

10. Carefully tighten the spark plug. If the plug

you are installing is equipped with a crush washer,

seat the plug, then tighten about I/, turn to crush the

washer. If you are installing a tapered seat plug,

tighten the plug to specifications provided by the ve-

hicle or plug manufacturer. b See Figures 98, 97, 98, 99, and 100

not going to be replaced, clean the plugs thoroughly.

Remember that any kind of deposit will decrease the

efficiency of the plug. Plugs can be cleaned on a

spark plug cleaning machine, which can sometimes

be found in service stations, or you can do an accept-

able job of cleaning with a stiff brush. If the plugs are’

cleaned, the electrodes must be filed flat. Use an ig-

nition points file, not an emery board or the like,

which will leave deposits. The electrodes must be

filed perfectly flat with sharp edges; rounded edges

reduce the spark plug voltage by as much as 50%.

Check spark plug gap before installation. The

ground electrode (the L-shaped one connected to the

body of the plug) must be parallel to the center elec-

trode and the specified size wire gauge (please refer

to the Tune-Up Specifications chart for details) must

pass between the electrodes with a slight drag:

*,NEVER adjust the gap on a used platinum

. clean the area.

*Remove the spark plugs when the engine

is cold, if possible, to prevent damage to the

threads. If removal of the plugs is difficult,

apply a few drops of penetrating oil or sili-

cone spray to the area around the base of the

plug, and allow it a few minutes to work.

6. Using a spark plug socket that is equipped

with a rubber insert to properly hold the plug, turn type spark plug.

Always check the gap on new plugs as they are

not always set correctly at the factory. Do not use a

flat feeler gauge when measuring the gap on a used

plug, because the reading may be inaccurate. A

round-wire type gapping tool is the best way to check

the gap. The correct gauge should pass through the

electrode gap with a slight drag. If you’re in doubt, try

one size smaller and one laraer. The smaller aauqe