wheel alignment MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 25 of 408

.

1-26 GENERALINFORMATIONAND MAINTENANCE

TDC of the compression stroke. If this happens, the

piston WIII be at the beginning of the power stroke

just as the compressed and ignited air/fuel mixture

forces the piston down and turns the crankshaft. Be-

cause it takes a fraction of a second for the spark

plug to ignite the mixture in the cylinder, the spark

plug must fire a little before the piston reaches TDC.

Otherwise, the mixture will not be completely ignited

as the piston passes TDC and the full power of the

explosion will not be used by the engine.

The timing measurement is given in degrees of

crankshaft rotation before the piston reaches TDC

(BTDC). If the setting for the ignition timing is 10”

BTDC, each spark plug must fire 10 degrees before

each piston reaches TDC. This only holds true, how-

ever, when the engine is at idle speed. The combus-

tion process must be complete by 23”ATDC to main-

tain proper engine performance, fuel mileage, and

low emissions.

As the engine speed increases, the pistons go

faster. The spark plugs have to ignite the fuel even

sooner if it IS to be completely ignited when the pis-

ton reaches TDC. If the ignition is set too far ad-

vanced (BTDC), the ignition and expansion of the fuel

in the cylinder wtll occur too soon and tend to force

the piston down while it is still traveling up. Thus

causes pre ignition or “knockmg and pinging”. If the

ignition spark is set too far retarded, or after TDC

(ATDC), the piston will have already started on its

way down when the fuel is ignited. The piston will be

forced down for only a portion of its travel, resulting

in poor engine performance and lack of power.

Timing marks or scales can be found on the rim of

the crankshaft pulley and the timing cover. The marks

on the pulley correspond to the posrtion of the piston

in the No. 1 cylinder. A stroboscopic (dynamic) tim-

ing light is hooked onto the No. 1 cylinder spark plug

wrre. Every time the spark plug fires, the timing light

flashes. By aiming the light at the timing marks while

the engine is running, the exact position of the piston

within the cylinder can be easily read (the flash of

light makes the mark on the pulley appear to be

standing still). Proper timing is indicated when the

mark and scale are in specified alignment.

When checking timing with the engine run-

ning, take care not to get the timing light

wires tangled in the tan blades and/or drive

belts.

INSPECTION &ADJUSTMENT

1990-96 Models

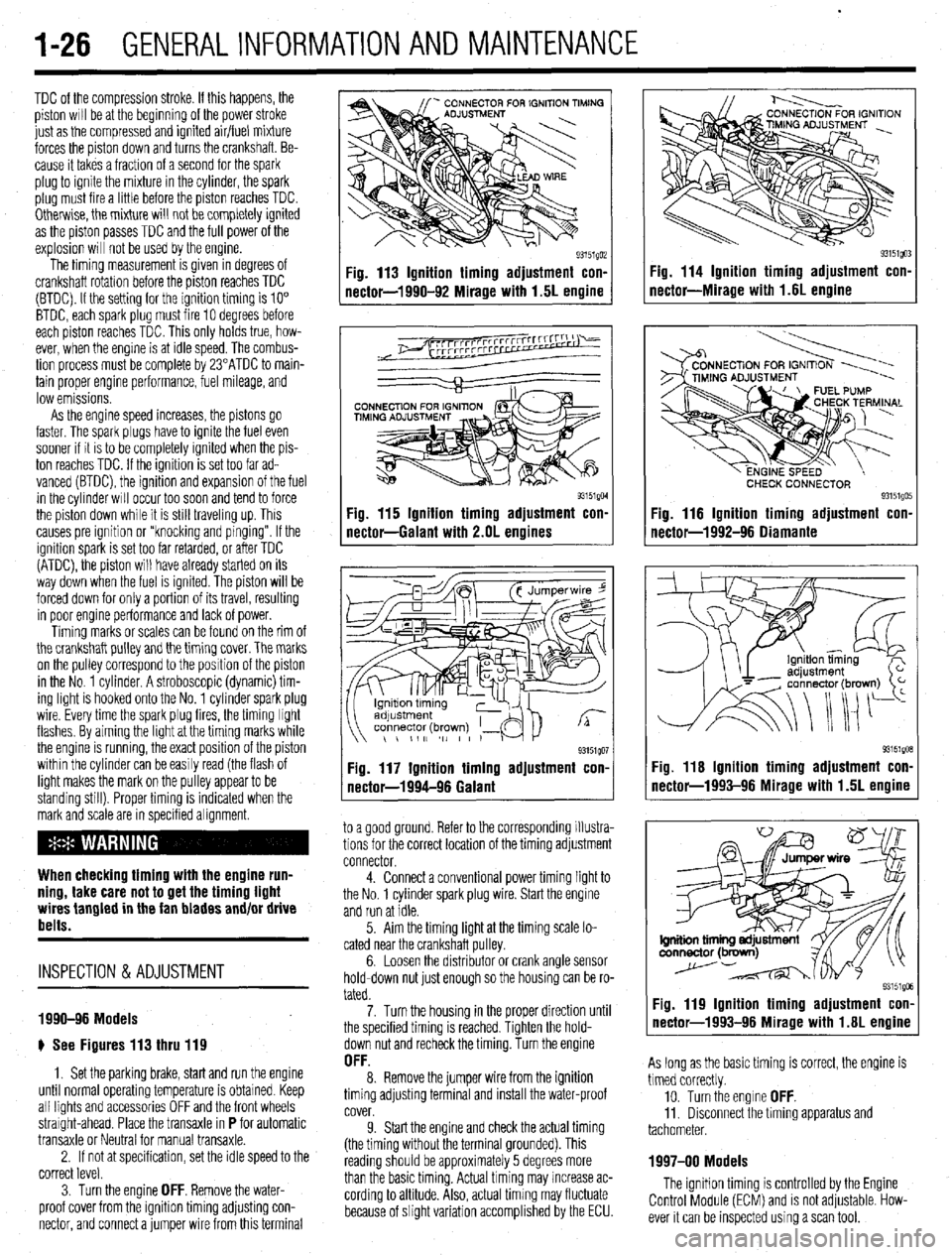

e See Figures 113 thru 119

1. Set the parking brake, start and run the engine

until normal operating temperature is obtained. Keep

all lights and accessories OFF and the front wheels

straight-ahead. Place the transaxle in

P for automatic

transaxle or Neutral for manual transaxle.

2. If not at specification, set the idle speed to the

correct level.

3. Turn the engine

OFF. Remove the water-

proof cover from the igmtion timing adjusting con-

nector, and connect a jumper wire from this terminal

Fig. 113 Ignition timing adjustment con-

nector-1990-92 Mirage with 1.5L engine

93151QM Fig. 115 Ignition timing adjustment con-

nectar-Galant with 2.OL engines

93151QO1 Fig. 117 Ignition timing adjustment con.

nectar-1994-96 Galant

to a good ground. Refer to the corresponding illustra-

tions for the correct location of the timing adjustment

connector.

4. Connect a conventional power timing light to

the No. 1 cylinder spark plug wire. Start the engine

and run at idle.

5. Aim the timing light at the timing scale lo-

cated near the crankshaft pulley.

6. Loosen the distributor or crank angle sensor

hold-down nut just enough so the housing can be ro-

tated.

7. Turn the housing in the proper direction until

the specified timing is reached. Tighten the hold-

down nut and recheck the timing. Turn the engine

OFF. 8. Remove the jumper wire from the ignition

timing adjusting terminal and install the water-proof

cover.

9. Start the engine and check the actual timing

(the timing without the terminal grounded). This

reading should be approximately 5 degrees more

than the basic timing. Actual timing may increase ac-

cording to altitude. Also, actual timing may fluctuate

because of slight variation accomplished by the ECU.

Fig. 114 Ignition timing adjustment con-

nectar-Miracle with 1.6L enaine

CHECK CONNECTOR 93151QO! Fig. 116 Ignition timing adjustment con.

nectar-1992-96 Oiamante

93151gOB Fig. 116 Ignition timing adjustment con-

nector-1993-96 Mirage with 1.5L engine

Fig. 119 Ignition timing adjustment con-

nector-1993-96 Mirage with 1.6L engine

As long as the basic timing is correct, the engine is

timed correctly.

10. Turn the engine

OFF. 11. Disconnect the timing apparatus and

tachometer.

1997-00 Models

The ignition timing is controlled by the Engine

Control Module (ECM) and is not adjustable. How-

ever it can be inspected using a scan tool.

Page 29 of 408

.

l-30 GENERAL'INFORMATIONAND MAINTENANCE

n Pylon@ inserts, the clip

be removed prior to siidi then the insert can be re

After installing the replacement

strip and pull up while twisting counterclockwise.

The backing strip will snap out of the retaining tab.

Do this for the remaining tabs until the refill is free of

the blade. The length of these refills is molded into

the end and they should be replaced with identical

types. cate the front end is out of alignment or that the tires

are out of balance.

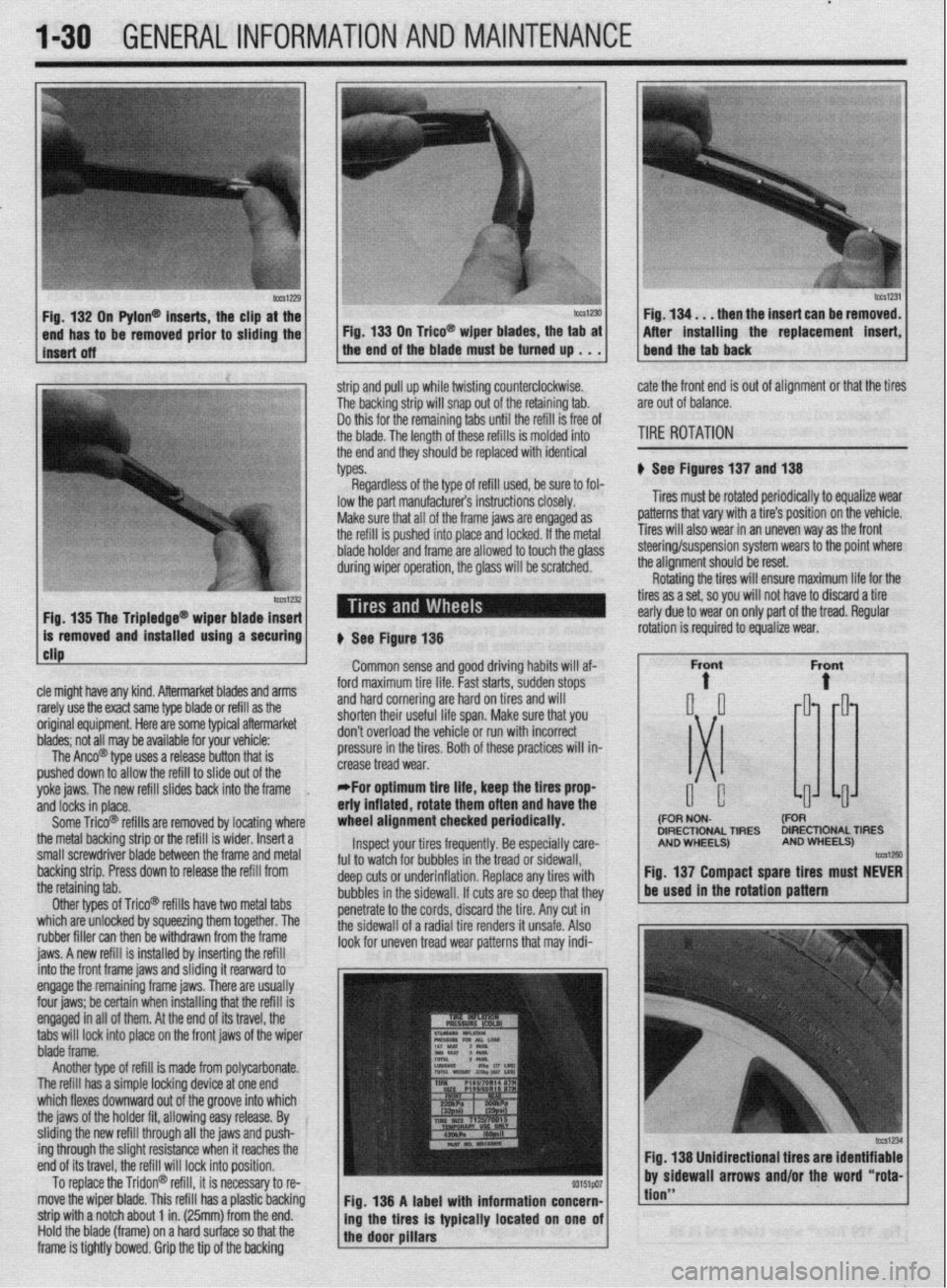

TIRE ROTATION

# See Figures 137 and 138

Tires must be rotated periodically to equalize wear

patterns that vary with a tire’s position on the vehicle.

Tires will also wear in an uneven way as the front

1 Fin 1% Tha Trinlarlna@

cle might have any kind. Aftermarket blades and arms

rarely use the exact same type blade or refill as the

original equipment. Here are some typiel aftermarket

blades; not all may be available for your vehicle:

The Anco@ type uses a release button that is

pushed down to allow the refill to slide out of the

yoke jaws. The new refill slides back into the frame

,

and locks in place.

Some Trico@ refills are removed by locating where

the metal backing strip or the refill is wider. Insert a

small screwdriver blade between the frame and metal

backing strip. Press down to release the refill from

the retaining tab.

Other types of Trico@’ refills have two metal tabs

which are unlocked by squeezing them together. The

rubber filler can then be withdrawn from the frame

iaws. A new refill is installed bv insertina the refill lowed to touch the olass steering/suspension system wears to the point where

the alianment should be reset.

# See Figure 138

Common sense and good driving habits will af-

ford maximum tire life. Fast starts, sudden stops

and hard cornering are hard on tires and will

shorten their useful life span. Make sure that you

don’t overload the vehicle or run with incorrect

pressure in the tires. Both of these practices will in-

crease tread wear.

*For optimum tire life, keep the fires prop

eriy inflated, rotate them often and have the

wheel alignment checked periodically.

Inspect your tires frequently. Be especially care-

ful to watch for bubbles in the tread or sidewall,

deep cuts or underinflation. Replace any tires with

bubbles in the sidewall. If cuts are so deep that they

penetrate to the cords, discard the tire. Any cut in

the sidewall of a radial tire renders it unsafe. Also

look for uneven tread wear patterns that may indi- Rotating the tires will ensure maximum life for the

tires as a set, so you will not have to discard a tire

early due to wear on only part of the tread. Regular

DIRECTIONAL TIRES DIRECTIONAL TIRES

jnto the front frame jaws and &ding it rearward to

engage the remaining frame jaws. There are usually

four jaws; be certain when installing that the refill is

engaged in all of them. At the end of its travel, the

tabs will lock into place on the front jaws of the wiper

blade frame.

Another type of refill is made from polycarbonate.

The refill has a simple locking device at one end

which flexes downward out of the groove into which

the jaws of the holder fit, allowing easy release. By

sliding the new refill through all the jaws and push-

ing through the slight resistance when it reaches the

end of its travel, the refill will lock into position.

To replace the Tridon@ refill, it is necessary to re-

move the wiper blade. This refill has a plastic backing

strip with a notch about 1 in. (25mm) from the end.

Hold the blade (frame) on a hard surface so that the

frame is tightly bowed. Grip the tip of the backing Fig. 138 A label with information concern-

ing the tires is typically located on one of

the door pillars

tion”

Page 31 of 408

.

1-32 GENERALINFORMATIONAND MAINTENANCE

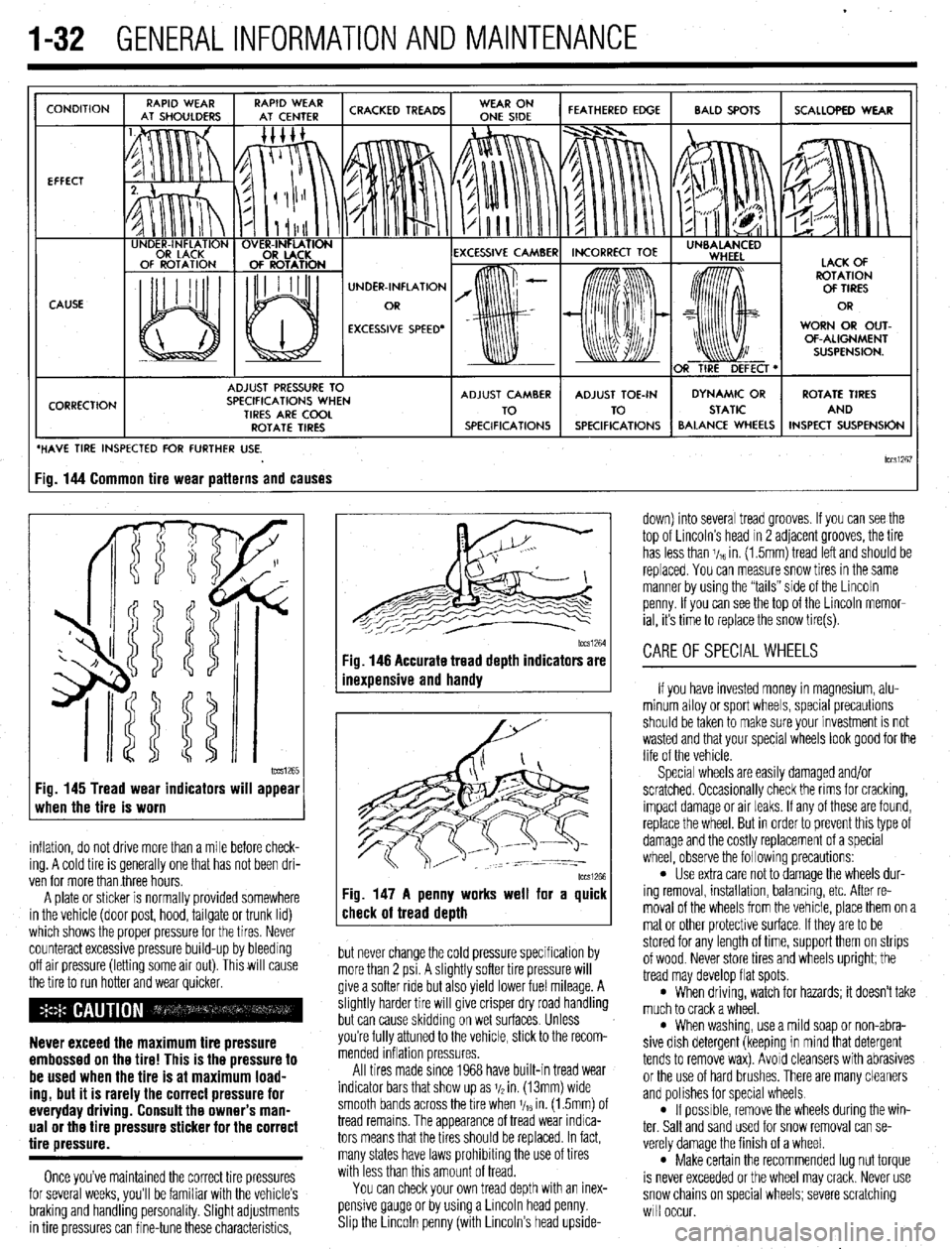

CONDITION

EFFECT

CAUSE

CORRECTION UNDER-INFLATION

EXCESSIVE SPEED’ WORN OR OUT-

OF-ALIGNMENT

ADJUST PRESSURE TO

SPECIFICATIONS WHEN

TIRES ARE COOL

ROTATE TIRES

/ BALANCE WHEELS INSPECT SUSPENSION

HAVE TIRE INSPECTED FOR FURTHER USE.

lCCSi267 ig. 144 Common tire wear patterns and causes

1~~~1265 Fig. 145 Tread wear indicators will appear

when the tire is worn

inflation, do not drive more than a mile before check-

ing. A cold tire is generally one that has not been dri-

ven for more than three hours.

A plate or sticker is normally provided somewhere

in the vehicle (door post, hood, tailgate or trunk lid)

which shows the proper pressure for the tires. Never

counteract excessive pressure build-up by bleeding

off air pressure (letting some air out). This will cause

the tire to run hotter and wear quicker.

Never exceed the maximum tire pressure

embossed on the tire! This is the pressure to

be used when the tire is at maximum load-

ing, but it is rarely the correct pressure for

everyday driving. Consult the owner’s man-

ual or the tire pressure sticker for the correct

tire pressure.

Once you’ve maintained the correct tire pressures

for several weeks, you’ll be familiar with the vehicle’s

braking and handling personality. Slight adjustments

in tire pressures can fine-tune these characteristics,

1~~~1264 Fig. 146 Accurate tread depth indicators are

inexuensive and handv

Fig. 147 A penny works well for a quick

check of tread death

but never change the cold pressure specification by

more than 2 psi. A slightly softer tire pressure will

give a softer ride but also yield lower fuel mileage. A

slightly harder tire will give crisper dry road handling

but can cause skidding on wet surfaces. Unless

you’re fully attuned to the vehicle, stick to the recom-

mended inflation pressures.

All tires made since 1968 have built-in tread wear

indicator bars that show up as j/2 in. (13mm) wide

smooth bands across the bre when V,~ in. (1.5mm) of

tread remains. The appearance of tread wear indica-

tors means that the tires should be replaced. In fact,

many states have laws prohibiting the use of tires

with less than this amount of tread.

You can check your own tread depth with an inex-

pensive gauge or by using a Lincoln head penny.

Shp the Lrncoln penny (with Lincoln’s head upside- down) into several tread grooves. If you can see the

top of Lincoln’s head in 2 adjacent grooves, the tire

has less than V,~ in. (1.5mm) tread left and should be

replaced. You can measure snow tires in the same

manner by using the “tails” side of the Lincoln

penny. If you can see the top of the Lincoln memor-

ial, its time to replace the snow tire(s).

CAREOFSPECIALWHEELS

If you have invested money in magnesium, alu-

minum alloy or sport wheels, special precautions

should be taken to make sure your investment is not

wasted and that your special wheels look good for the

life of the vehicle.

Special wheels are easily damaged and/or

scratched. Occasionally check the rims for cracking,

impact damage or air leaks. If any of these are found,

replace the wheel. But in order to prevent this type of

damage and the costly replacement of a special

wheel, observe the following precautions:

l Use extra care not to damage the wheels dur-

ing removal, installation, balancing, etc. After re-

moval of the wheels from the vehicle, place them on a

mat or other protective surface. If they are to be

stored for any length of time, support them on strips

of wood. Never store tires and wheels upright; the

tread may develop flat spots.

l When driving, watch for hazards; it doesn’t take

much to crack a wheel.

l When washing, use a mild soap or non-abra-

sive dish detergent (keeping in mind that detergent

tends to remove wax). Avoid cleansers with abrasives

or the use of hard brushes. There are many cleaners

and polishes for special wheels.

l If possrble, remove the wheels during the win-

ter. Salt and sand used for snow removal can se-

verely damage the finish of a wheel.

l Make certain the recommended lug nut torque

is never exceeded or the wheel may crack. Never use

snow chains on special wheels; severe scratching

will occur.

Page 126 of 408

I)

ENGINEANDENGINEOVERHAUL 3-65

10. Install the camshaft(s), rockers, shafts and

any other components that were removed for disas-

sembly.

GENERAL INFORMATION ways number 1. However, depending on the engine

placement, the front of the engine could either be the

flywheel or damper/pulley end. Generally the front of

the engine faces the front of the vehicle. Use a num-

ber punch or scribe and also mark the main bearing

caps from front to rear with the front most cap being

number 1 (if there are five caps, mark them 1 through

5, front to rear).

A thorough overhaul or rebuild of an engine block

would include replacing the pistons, rings, bearings,

timing belt/chain assembly and oil pump. For OHV

engines also include a new camshaft and lifters. The

block would then have the cylinders bored and honed

oversize (or if using removable cylinder sleeves, new

sleeves installed) and the crankshaft would be cut

undersize to provide new wearing surfaces and per-

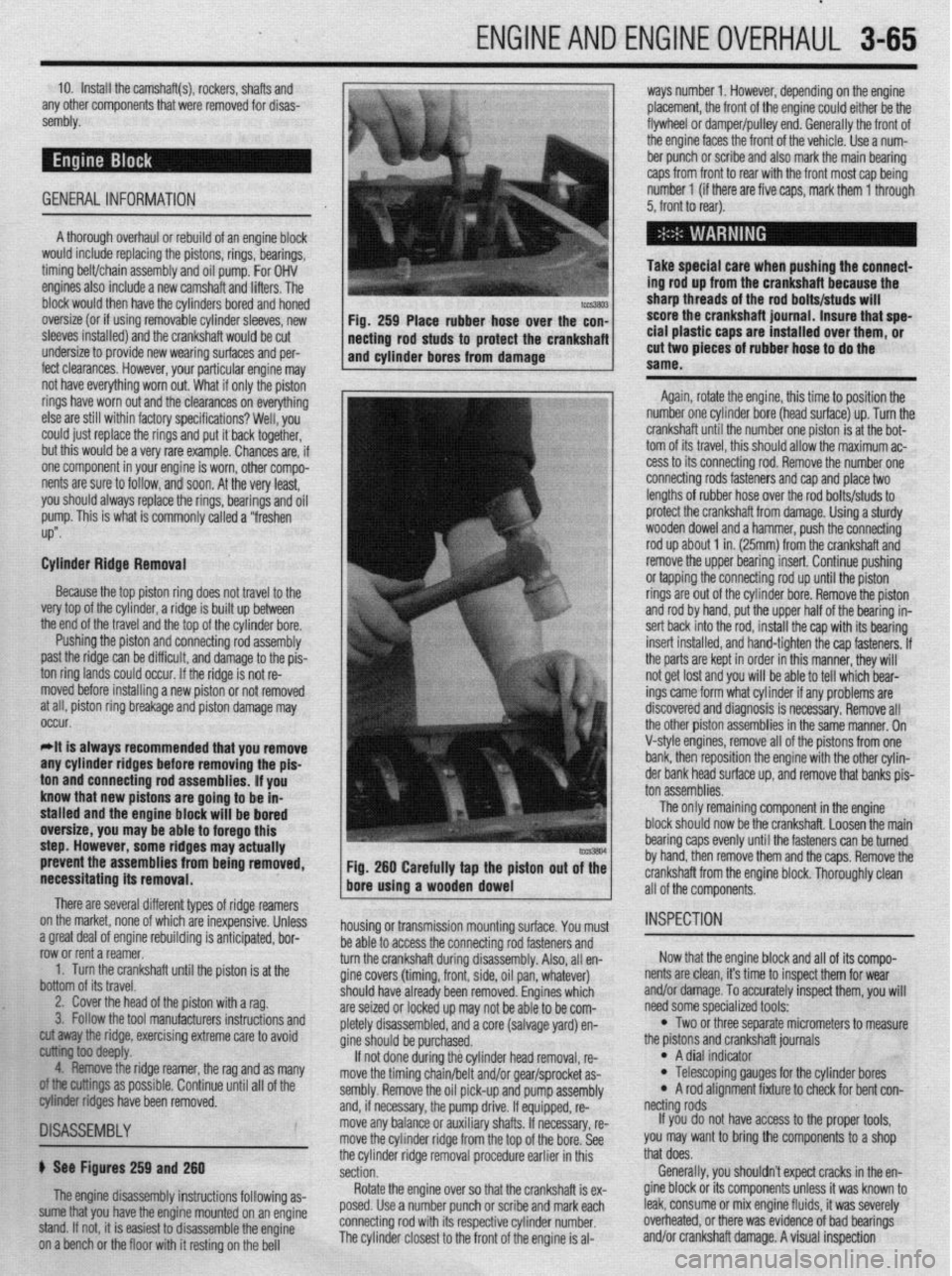

feet clearances. However, your particular engine may Take special care when pushing the connect-

ing rod up from the crankshaft because the

sharp threads of the rod bolts/studs will

score the crankshaft journal. Insure that spe-

cial plastic caps are installed over them, or

cut two pieces of rubber hose to do the

same.

Again, rotate the engine, this time to position the

number one cylinder bore (head surface) up. Turn the

crankshaft until the number one piston is at the bot-

tom of its travel, this should allow the maximum ac-

cess to its connecting rod. Remove the number one

connecting rods fasteners and cap and place two

lengths of rubber hose over the rod bolts/studs to

protect the crankshaft from damage. Using a sturdy

wooden dowel and a hammer, push the connecting

rod up about 1 in. (25mm) from the crankshaft and

remove the upper bearing insert. Continue pushing

or tapping the connecting rod up until the piston

rings are out of the cylinder bore. Remove the piston

and rod by hand, put the upper half of the bearing in-

sert back into the rod, install the cap with its bearing

insert installed, and hand-tighten the cap fasteners. If

the parts are kept in order in this manner, they will

not get lost and you will be able to tell which bear-

ings came form what cylinder if any problems are

discovered and diagnosis is necessary. Remove all

the other piston assemblies in the same manner. On

V-style engines, remove all of the pistons from one

bank, then reposition the engine with the other cylin-

der bank head surface up, and remove that banks nis-

prevent the assemblies from being removed,

necessitating its removal. Fig. 260 Carefully tap the piston out of the

bore using a wooden dowel

There are several different types of ridge reamers

on the market, none of which are inexpensive, Unless

.3 “me.+ ,-ins, rdnnn;nn mh~lil.-linn ;I nn+:n:nnL.* l.^W

a ylwx “Gal “I cllylllc Ir;““ll”llly 13 dllLILlpxC”, ““I- row or rent a reamer.

1. Turn the crankshaft until the piston is at the

bottom of its travel.

2. Cover the head of the piston with a rag.

3. Follow the tool manufacturers instructions and housing or transmission mounting surface. You must

1 as many

II of the

~1SA~E~BLY

b See Figures 259 and 260

The engine disassembly instructions following as-

sume that you have the engine mounted on an engine

stand. If not, it is easiest to disassemble the engine

on a bench or the floor with it resting on the bell be able to access the connecting rod fasteners and

turn the crankshaft during disassembly. Also, all en-

gine covers (timing, front, side, oil pan, whatever)

should

are sei2

nletelv have already been removed. Engines which

,ed or locked up may not be able to be com-

r’-‘-‘, disassembled, and a core (salvage yard) en-

gine sh ould be purchased.

If no

t done during the cylinder head removal, re-

move the timing chain/belt and/or gear/sprocket as-

sembly. Remove the oil pick-up and pump assembly

and, if necessary, the pump drive. If equipped, re-

move any balance or auxiliary shafts. If necessary, re-

move the cylinder ridge from the top of the bore. See

the cylinder ridge removal procedure earlier in this

section.

Rotate the engine over so that the crankshaft is ex-

posed. Use a number punch or scribe and mark each

connecting rod with its respective cylinder number.

The cylinder closest to the front of the engine is al- cut away the ridge, exercising extreme care to avoid

~ ioo deepfy.

4. Remove the ridge reamer, the rag and

armings as possible. Continue until a

biter ridges have been removed. ton assemblies.

The only remaining component in the engine

block should now be the crankshaft. Loosen the main

bearing caps evenly until the fasteners can be turned

by hand, then remove them and the caps. Remove the

crankshaft from the engine block. Thoroughly clean

all of the components.

INSPECTION

Now that the engine block and all of its compo-

nents are clean, it’s time to inspect them for wear

and/or damage. To accurately inspect them, you will

need some specialized tools:

l Two or three separate micrometers to measure

the prstons and crankshaft journals

l A dial indicator l Telescoping gauges for the cylinder bores l A rod alignment fixture to check for bent con-

netting rods

If you do not have access to the proper tools,

you may want to bring the components to a shop

that does.

Generally, you shouldn’t expect cracks in the en-

gine block or its components unless it was known to

leak, consume or mix engine fluids, it was severely

overheated, or there was evidence of bad bearings

and/or crankshaft damage. A visual inspection

Page 287 of 408

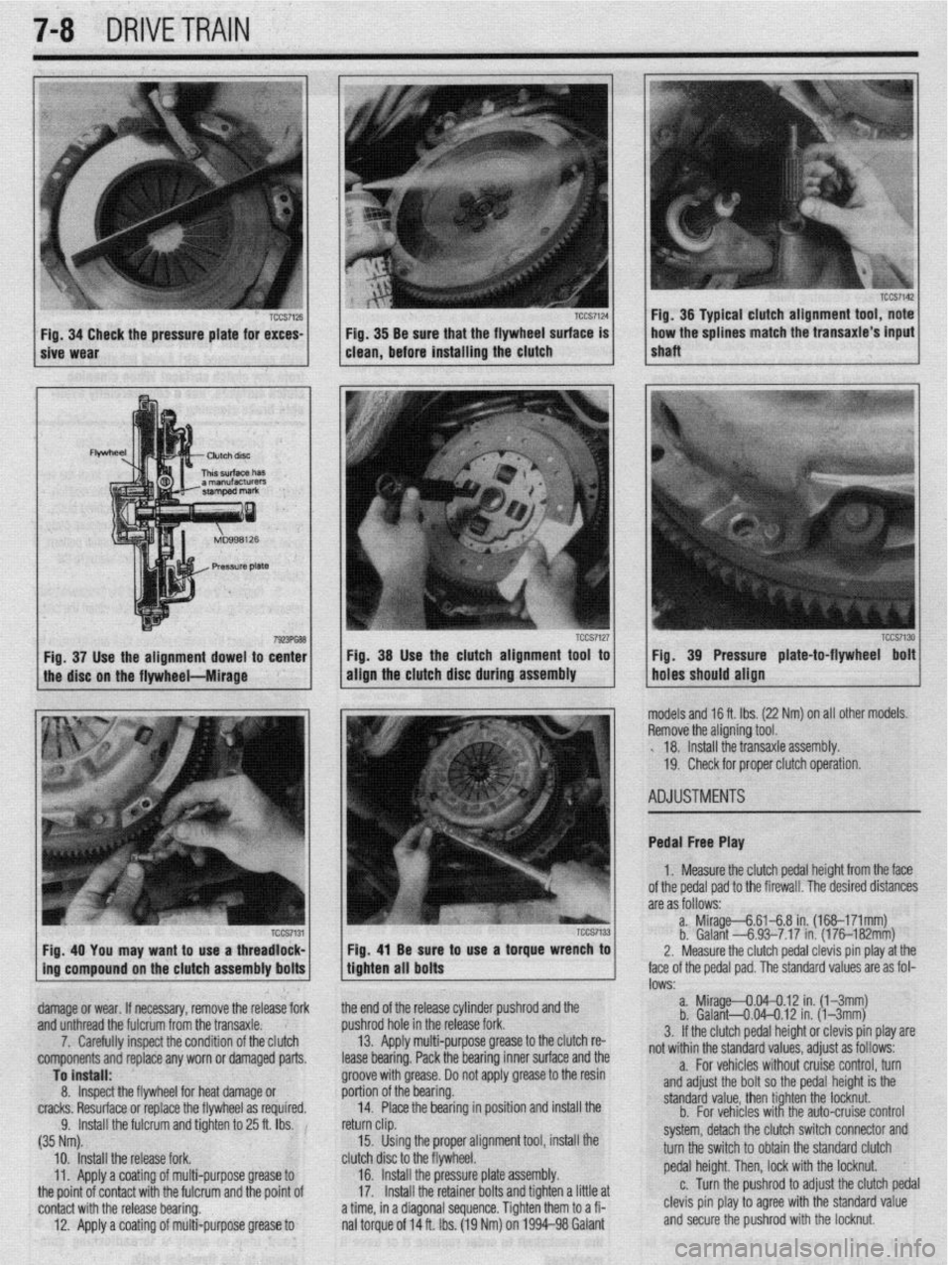

7-8 DRIVETRAIN

/ sive Wear TCCS7124 1 Fig 34 Check the pressure plate for exces- TCCS7126 j / . Fig 38 Be sure that the flywheel surface is

clean, before installing the clutch

Fig. 38 Use the clutch alignment tool to

align the

clutch disc during assembly

Fig. 40 You may want to use a threadlock- Fig, 41 Be sure to use a torque wrench to

ing compound on the clutch assembly bolts

tighten all bolts

damage or wear. If necessary, remove the release fork the end of the release cylinder pushrod and the

and unthread the fulcrum from the transaxle. pushrod hole in the release fork.

7. Carefully inspect the condition of the clutch 13. Apply multi-purpose grease to the clutch re-

components and replace any worn or damaged parts.

lease bearing. Pack the bearing inner surface and the r Fig. 36 Typical clutch alignment tool, note

shaft ,,, 1 how the splines match the transaxle’s input

TCCS7130 Fig. 39 Pressure plate-to-flywheel bolt

holes should align

nodels and 16 ft. Ibs. (22 Nm) on all other models.

3emove the aligning tool.

. 18. Install the transaxle assembly.

19. Check for proper clutch operation.

4DJUSTMENTS

Pedal Free Play

1. Measure the clutch pedal height from the face

of the pedal pad to the firewall. The desired distances

are as follows:

a. Mirage--&6148 in. (168-171mm)

b. Galant -6.93-7.17 in. (176182mm)

2. Measure the clutch pedal clevis pin play at the

ace of the pedal pad. The standard values are as fol-

DWS: a. Mirage--0.04--0.12 in. (l-3mm)

b. Galant4.04-0.12 in. (l-3mm)

3. If the clutch pedal height or clevis pin play are

rot within the standard values, adjust as follows:

Page 292 of 408

DRIVETRAIN 7-13

27. Shde the transaxle rearward and carefully

lower it from the vehicle.

To install: 28. After the torque converter has been mounted

on the transaxle, install the transaxle assembly to the

engine. Install the mounting bolts and tighten to 35

ft. Ibs. (48 Nm).

29. Install the transaxle lower coupling bolt and

tighten to 21-25 ft Ibs. (29-34 Nm).

30. Connect the torque converter to the flexplate

and tighten the bolts to 33-38 ft. Ibs. (45-52 Nm).

31. Install the cover to the transaxle bellhous-

ing and tighten the mounting bolts to 7 ft. Ibs. (9

Nm).

32 Install the crossmember and tighten the front

mounting bolts to 65 ft. Ibs (88 Nm) and the rear

bolt to 54 ft. Ibs. (73 Nm) Install the front engine roll

stopper through-bolt and lightly tighten. Once the full

weight of the engine is on the mounts, tighten the ’

bolt to 42 ft. Ibs. (57 Nm),

33. Install the triangular stay bracket and tighten

the mounting bolts to 65 ft. Ibs. (88 Nm).

34. Install the halfshafts, using new circlips on

the axle ends.

When installing the axleshaft, keep the in-

board joint straight in relation to the axle, so

as not to damage the oil seal lip of the

transaxle with the serrated part of the half-

shaft.

35. Connect the tie rod and ball joints to the

steering knuckle. Tighten the ball joint self-locking

nuts to 48 ft. Ibs. (65 Nm). Tighten the tie rod end nut

to 21 ft. Ibs. (28 Nm) and secure with a new cotter

pin.

36. Connect the damper fork to the lower control

arm and tighten the through-bolt to 65 ft Ibs. (88

Nm).

37. Connect the stabilizer link to the damper fork,

and tighten the self-locking nut to 29 ft. Ibs. (39 Nm).

38. Install the undercover.

39. Install the wheels and carefully lower the ve-

hicle

40. Install the transaxle mount bracket to the

transaxle, and tighten the mounting nuts to 32 ft. Ibs.

(43 Nm).

41. Install the rear roll stopper mounting bracket.

42. Remove the engine support. Tighten the

transaxle mount through-bolt to 51 ft. Ibs. (69 Nm)

and tighten the front engine roll stopper through-bolt.

43. Install the upper transaxle mounting bolts

and tighten to 35 fl. Ibs. (48 Nm).

44. Install the starter motor.

45. Install the dipstick tube and the dipstick

46. Install the shifter cable mounting bracket.

47. Connect the shifter lever and tighten the re-

taining nut to 14 ft. Ibs. (19 Nm).

48. Connect the oil cooler lines and secure with

clamps.

49. Attach the electrical connectors for the

speedometer, solenoid, neutral safety switch (in-,

hibitor switch), the pulse generator, kickdown servo

switch and oil temperature sensor.

50. Install the air cleaner and the air intake hose.

51. Connect the negative battery cable.

52. Make sure the vehicle is level, and refill the

transaxle. Start the engine and allow to idle for 2 minutes. Apply parking brake and move selector

through each gear position, ending in N. Recheck

fluid level and add if necessary. Fluid level should be

between the marks in the HOT range.

53. Check the transaxle for proper operation.

Make sure the reverse lights come on when in re-

verse and the engine starts only in

P or N.

Mirage

*If the vehicle is going to be rolled on its

wheels while the halfshafts are out of the ve-

hicle, obtain two outer CV-joints or proper

equivalent tools and install to the hubs. If the

vehicle is rolled without the proper torque

applied to the front wheel bearings, the bear-

ings will no longer be usable.

1. Disconnect the negative battery cable then

the positive battery cable.

2. Remove the battery and battery tray.

3. Remove the air hose and air cleaner assem-

bly.

4. Raise the vehicle and support safely.

5. Remove the under guard pan.

6. Drain the transaxle oil into a suitable con-

tainer.

7. If equipped with 1.6L engine, remove the ten-

sion rod.

8. Disconnect the control cable and cooler

lines.

9. On 3-speed transaxles, disconnect the throt-

tle control cable.

10. On 4-speed transaxles, perform the following:

a. Detach the shift control solenoid valve

connector.

b. Disconnect the inhibitor switch and kick-

down servo switch.

c. Disconnect the pulse generator and oil

temperature sensor.

11. Disconnect the speedometer cable and re-

move the starter.

12. Remove the transaxle mounting bolts and

bracket.

13. Disconnect the stabilizer bar from the lower

control arm.

14. Disconnect the steering tie rod end and the

ball joint from the steering arm.

15. Remove the halfshafts at the inboard side

from the transaxle. Tie the joint assembly aside.

*It is not necessary to disconnect the half-

shafts from the wheel hubs.

16. Support the engine and remove the center

member.

17. Remove the bellhousing cover and remove

the driveplate bolts.

18 Remove the transaxle assembly lower con-

necting bolt, located just over the halfshaft opening.

19. Properly support the transaxle assembly, then

lower it, moving it to the right for clearance.

To install: 20. After the torque converter has been mounted

on the transaxle, install the transaxle assembly on the

engine. Install the mounting bolts and tighten to

31-40 ft. Ibs. (43-55 Nm) on 1990-92 models and

35 ft. Ibs. (48 Nm) on 1993-00 models.

21. Tighten the driveplate bolts to 33-38 ft. Ibs.

(46-53 Nm). Install the bellhousing cover.

22. Install the center member. 23. Replace the circlips and install the halfshafts

to the transaxle.

24. Install the tie rods, ball joints and stabilizer

links to the steering arm

25. Install the transaxle mounting bracket and

bolts.

26. Install the starter.

27. Connect the speedometer cable.

28. Connect the inhibitor switch, kickdown servo

switch, the pulse generator and oil temperature sen-

sor, if disconnected.

29. Connect the shift control solenoid valve con-

nector.

30. Connect the control cables and oil cooler

lines.

31. Install the tension rod, if removed.

32. Install the air cleaner assembly.

33. Install the battery tray and battery.

34. Connect the positive then the negative termi-

nal.

35. Refill with Dexron@ II, Mopar ATF Plus type

7176 or equivalent, automatic transaxle fluid.

36. Start the engine and allow to idle for two min-

utes. Apply parking brake and move selector through

each gear position, ending in N. Recheck fluid level

and add if necessary. Fluid level should be between

the marks in the HOT range.

ADJUSTMENTS

Shifter Control Cable Adjustment

1. The shifter cable adjustment is done at the

neutral safety switch (inhibitor switch). Locate the

switch on the transaxle and note the alignment holes

in the arm and the body of the switch. Place the se-

lector lever in N. Place the manual lever of the

transaxle in the neutral position.

2. Check alignment of the hole in the manual

control lever to the hole in the inhibitor switch body.

If the holes do not align, adjustment is required.

3. To adjust, loosen the nut on the cable end and

pull the cable end by hand until the alignment holes

match. Tighten the nut. Check that the transaxle

shifts and conforms to the positions of the selector

lever.

Throttle Valve Cable

The throttle valve adjustment applies only to the

1990-96 Mirage.

1. Place selector lever and manual control lever

in N position.

2. Loosen adjusting nut. While lightly pulling on

control cable tighten mounting nut to 7-10 ft. Ibs.

(X-14 Nm).

3. When adjustment is complete, be sure selector

lever is still in the N position. Verify all functions

correspond to the position indicated on the selector

lever.

The halfshaft removal and installation and over-

haul are the same as a manual transaxle Please refer

to Manual Transaxle in this Section

Page 296 of 408

WHEELS 8-2

WHEEL ASSEMBLY 8-2

REMOVAL & INSTALLATION 8-2

INSPECTION 8-2

WHEELLUG STUDS 8-2

REMOVAL & INSTALLATION 8-2

FRONT SUSPENSION 8-4

MACPHERSONSTRUTAND COIL

SPRING 8-7

REMOVAL & INSTALLATION 8-7

OVERHAUL 8-7

SHOCKABSORBERAND COIL

SPRING 8-8

REMOVAL &INSTALLATION 8-8

OVERHAUL 8-9

UPPER BALLJOINT 8-9

REMOVAL & INSTALLATION 8-9

INSPECTION 8-9

UPPER CONTROLARM 8-10

REMOVAL &INSTALLATION 8-10

LOWER BALLJOINT 8-10

REMOVAL &INSTALLATION 8-10

INSPECTION 8-10

LOWER CONTROL ARM 8-10

REMOVAL&INSTALLATION 8-10

SWAY BAR 8-12

REMOVAL & INSTALLATION 8-12

KNUCKLE, HUB, AND BEARING 8-13

REMOVAL & INSTALLATION 8-13

WHEEL ALIGNMENT 8-16

CASTER 8-16

CAMBER 8-17

TOE 8-17

REAR SUSPENSION 8-18

STRUT AND COIL SPRING 8-21

REMOVAL & INSTALLATION 8-21

OVERHAUL 8-22

UPPER CONTROLARMS 8-22

REMOVAL & INSTALLATION 8-22

LOWER CONTROL ARMS 8-23

REMOVAL &INSTALLATION 8-23

TRAINING ARM 8-24

REMOVAL & INSTALLATION 8-24

SWAY BAR 8-25

REMOVAL &INSTALLATION 8-25

HUB & BEARINGS 8-25

ADJUSTMENT 8-25

REMOVAL & INSTALLATION 8-25

STEERING 8-27

STEERING WHEEL 8-27

REMOVAL &INSTALLATION 8-27

COMBINATION SWITCH 8-29

REMOVAL &INSTALLATION 8-29

WINDSHIELD WIPER SWITCH 8-29

REMOVAL&INSTALLATION 8-29

IGNITION LOCK CYLINDER 8-29 '

REMOVAL &INSTALLATION 8-29

IGNITION SWITCH 8-30

REMOVAL &INSTALLATION 8-30

STEERING LINKAGE 8-30

REMOVAL&INSTALLATION 8-30

MANUAL RACK AND PINION STEERING

GEAR 8-31 REMOVAL & INSTALLATION 8-31

POWER RACK AND PINION STEERING

GEAR 8-32

REMOVAL &INSTALLATION 8-32

POWERSTEERING PUMP 8-34

REMOVAL &INSTALLATION 8-34

SYSTEM BLEEDING 8-36

COMPONENT LOCATIONS

FRONTSUSPENSION COMPONENT

LOCATIONS 8-4

REARSUSPENSION COMPONENT

LOCATIONS 8-18

SPECIFICATIONS CHARTS ’

TORQUE SPECIFICATIONS 8-39

Page 302 of 408

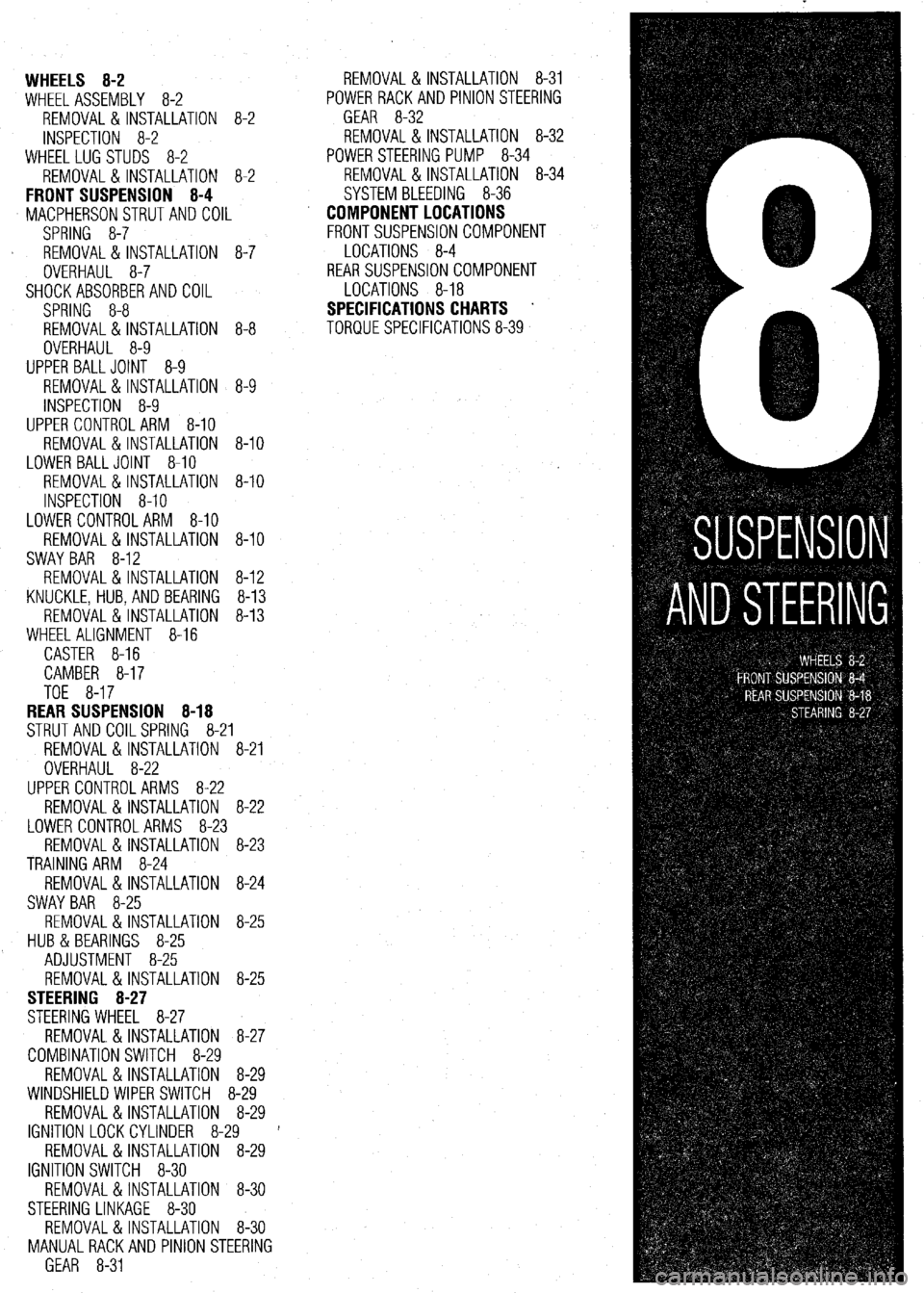

SUSPENSION AND STEERING 8-7

1 Cotter p,n

2 Drive shaft

3 Washer

4 Caliper assembly connecf~on

5 Self-IockIng ““f

6 Lower arm ball ,Ol”f Connectlo”

7 cotter PI”

8 T,e rod end connectton

9 Drive Shaft

10 Strut assembly connection

11 Hub and knuckle

1990-92 Mirage front suspension components

-

1 Cutter PI”

2 Drtve shaft

3 Washer

4 Ca,,perassembly connect~o”

5 Self-locking nut

6 Lower arm ball ,o,nt connection

7 cotter PI”

8 Tie rod end connection

9 Dwe shaft

10 Strut assembly connection

11 Hub and knuckie

Diamante front suspension components

1

to knuckle bolts Use a piece of wire to suspend the

knuckle to keep the weight off the brake hose.

6. If equipped with Active Electronrc Control

Suspension (Active-ECS) perform the followrng:

REMOVAL &INSTALLATION a. Loosen the nut that secures the an line to

the to the too of the strut and discard the O-ring.

Diamante, 1990-93 Galant, and 1999-00

Galant

1. Disconnect the negative battery cable.

2. Raise and safely support the vehicle.

3. Remove the brake hose and the tube bracket.

40 not pry the brake hose and tube clamp

awav when removino it.

b. Remove the bolts that secure the actuator

to the top of the strut and remove the compo-

nent. Disconnect the wiring harness.

*Before removing the top bolts, make

matchmarks on the body and the strut insula-

tor for proper reassembly.

7. Remove the strut upper nuts and remove the

strut assemblv from the vehicle.

4. If equipped with ABS, disconnect the front

speed sensor mounting clamp from the strut.

5. Support the lower arm and remove the strut

To instalf: 8. Install the strut to the vehicle and tighten the

upper mounting nuts to 33 ft. Ibs. (45 Nm)

9 Align the strut to the knuckle and connect with the mounting bolts. Tighten the mounting bolts

to 70-76 ft. Ibs. (90-105 Nm).

10. If equipped with Active-ECS, perform the fol-

lowing,

a. Install the air line with a new O-ring.

b Install the actuator to the top of the strut

Connect the wiring harness.

11. Install the brake hose bracket and the ABS

clamp, if equipped.

12. Install the wheel and tire assembly.

13. Have a front end alignment performed.

Mirage

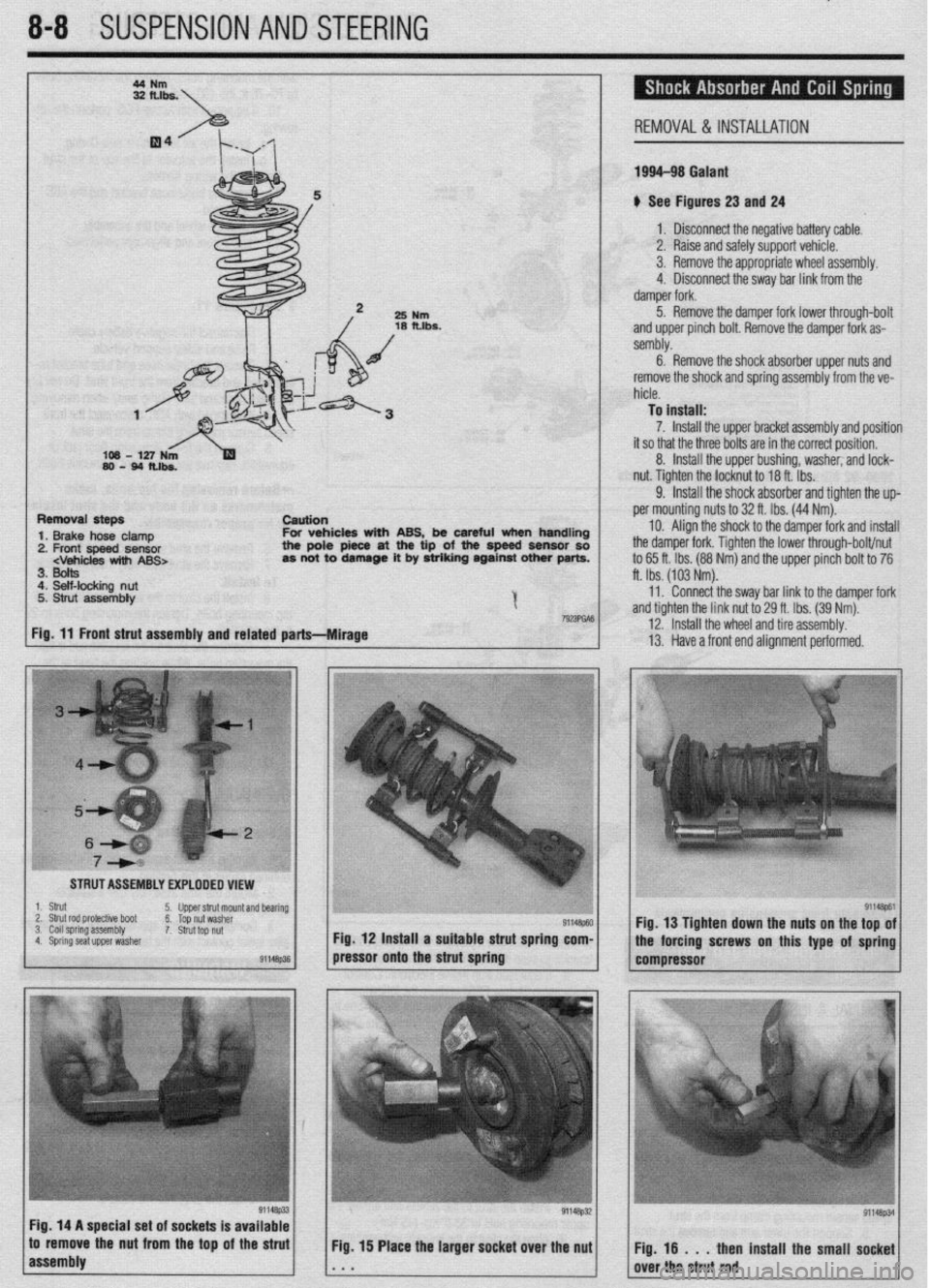

# See Figure 11

1, Disconnect the negative battery cable.

2. Raise and safely support vehicle.

3. Remove the brake hose and tube bracket re-

tainer bolt and bracket from the front strut. Do not pry

the brake hose and tube clamp away when removrng.

4. If equipped with ABS, disconnect the front

speed sensor mounting clamp from the strut.

5. Support the lower arm usmg floor jack or

equivalent Remove the lower strut to knuckle bolts.

*Before removing the top bolts, make

matchmarks on the body and the strut insula-

tor for proper reassembly.

6. Remove the strut upper mounting bolts.

7. Remove the strut assembly from the vehicle.

To install: 8. Install the strut to the vehicle and install the

top mounting bolts, Tighten the mountrng bolts to 29

ft. Ibs. (40 Nm)

9. Position the strut on the knuckle and mstall

the mounting bolts, While holdrng the head of the

lower mounting bolt, tighten the nuts to 80-94 ft. Ibs.

(110-130 Nm).

10. Install the brake hose bracket and the ABS

clamp, if equipped

11 Install the wheel and tire assembly

12. Have a front end alignment performed.

OVERHAUL

) See Figures 12 thru 22

1. Remove the strut assembly from the vehicle, as

outlined earlier in this Section.

2. Mount the strut assembly into a suitable

spring compressor.

3. Compress the strut approximately r/a its height

after initial contact with the top cap.

Never bottom the spring or dampener rod!

4. Remove the center nut from the strut and re-

move the upper mounting bracket and bushings.

5. Remove the coil spring.

To install: 6. Install the compressed spring on the strut as-

sembly.

7. Install the upper bushings and the mounting

bracket Install the nut and tighten it to 43 ft. Ibs. (59

Nm).

8. Remove the strut from the spring compressor.

9. Install the strut into the vehrcle

Page 303 of 408

8-8 SUSPENSION AND STEERING

REMOVAL &INSTALLATION

199443 Galant

u See Figures 23 and 24

1 a Disconnect the neaative batterv cable.

I 3. Remove the appronnate wheel assembly.

25

Nm

18 fths.

I 2. Raise and safelv su~oort vehicle.

I I ,I 4. Disconnect the sway bar link from the

oamper rork.

5. Remove the damper fork lower through-bolt

and upper pinch bolt. Remove the damper fork as-

sembly.

6. Remove the shock absorber upper nuts and

remove the shock and spring assembly from the ve-

hicle.

To install:

7. Install the upper bracket assembly and position

it so that the three bolts are in the correct position.

8. Install the upper bushing, washer, and lock-

nut. Tighten the locknut to 18 ft.-lbs.

9. Install the shock absorber and tighten the up-

Removal steps

csution

1. Brake hose clamp For vehicles with ABS, be careful when handling

2. Front speed sensor the pole piece at the tip of the spaed sensor so

3. Bolts

4. Self-locking nut

5. Strut assembly

I

7wmA6

Fig. 11 Front strut assembly and related parts---Mirage ft. Ibs. (103 Nm).

11. Connect the sway bar link to the damoer fork per mounting nuts to 32 ft. Ibs. (44 Nm).

IO. Align the shock to the damper fork and install

the damper fork. Tighten the lower through-bolt/nut

to 65 ft. Ibs. (88 Nm) and the upper pinch bolt to 76

and tighten the link nut tb 29 ft. Ibs. (39 Nm):

12. Install the wheel and tire assembly.

13. Have a front end alignment performed.

I STRUT ASSEMBLY EXPLODED VIEW

I ,-

:-, : ;i

,\,.^ -_ I~.’ :“:;rL~~<

-_ cy -.:;;yp;:,

91146p?Jl Fig. 12 Install a suitable strut spring com-

91146p61 Fig. 13 Tighten down the nuts on the top of

the forcing screws on this type of spring

pressor onto the strut spring

compressor

Fig. 14 A special set of sockets Is available

to remove the nut from the top of the strut

Fig. 15 Place the larger socket over the nut

1 ;ir ;;ostrut;;; install the small soi8oet

Page 306 of 408

SUSPENSION AND STEERING 8-11

-*i-

7928685

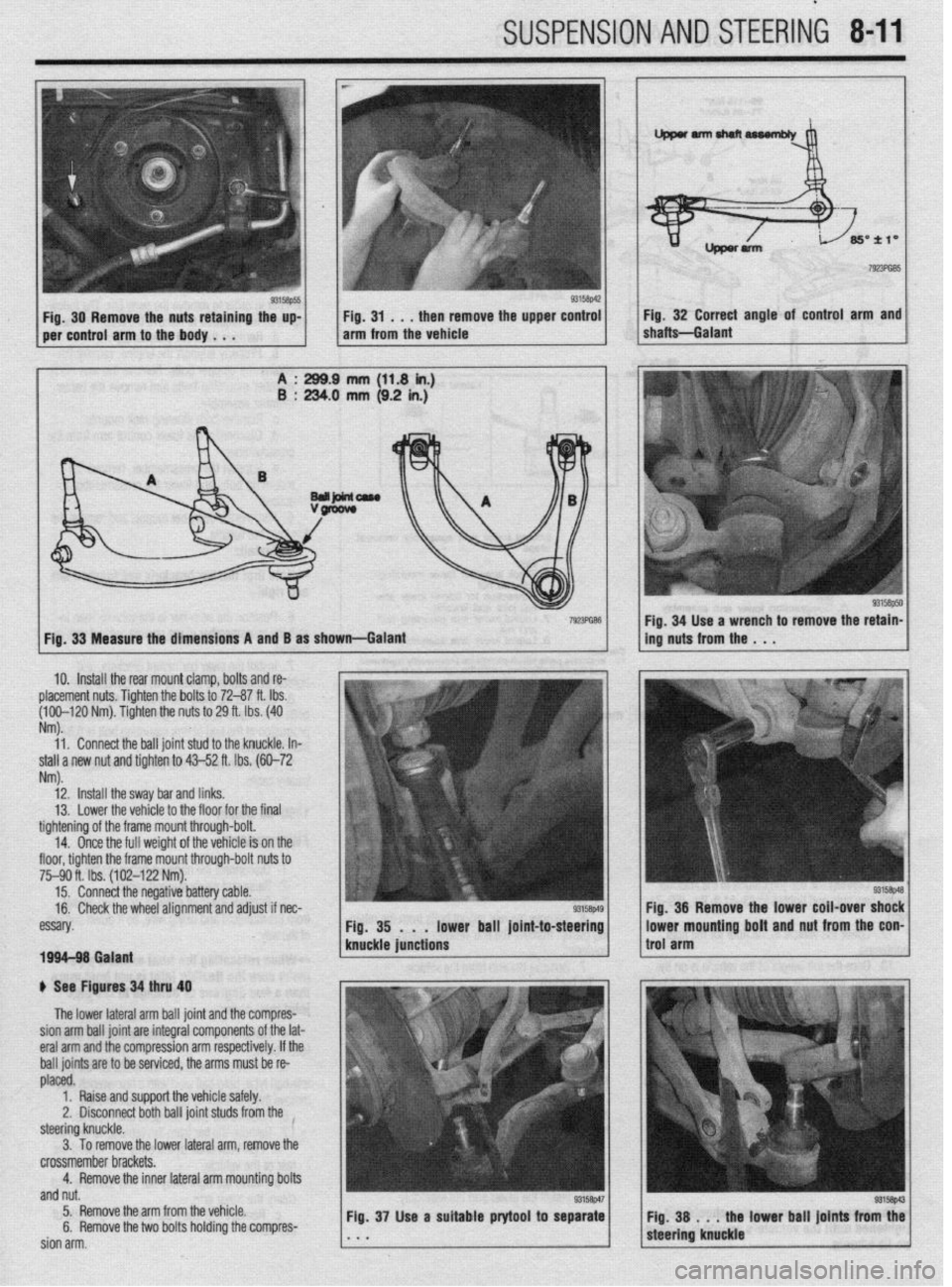

g3’w5 Fig, 30 Remove the nuts retaining the up-

per control arm to the body . . . I$ ;A, -;h$re~ove the upper co;:; 1 Fig 32 Correct angle of control arm and

shaftsGa,ant

ench to remove the

retain-

1. Connect the ball joint stud to the knuckle.

In-

Nm).

12. Install the sway bar and links.

13.

Lower the vehicle to the floor for the final

tightening of the frame mount through-bolt.

14.

Once the full weight of the vehicle is on the

floor, tighten the frame mount through-bolt nuts to

75-90 ft. Ibs. (102-122 Nm).

15. Connect the negative battery cable.

16. Check the wheel alignment and adjust if nec-

essary

1994-98 Galant

) See Figures 34 thru 40

The lower lateral arm ball joint and the compres-

sion arm ball joint are integral components of the lat-

eral arm and the compression arm respectively. If the

ball joints are to be serviced, the arms must be re-

placed.

1.

Raise and support the vehicle safely.

2, Disconnect both ball joint studs from the

steering knuckle.

3. To remove the lower lateral arm, remove the

crossmember brackets.

4. Remove the inner lateral arm mounting bolts

and nut.

5.

Remove the arm from the vehicle.

6. Remove the two bolts holding the compres-

sion arm. Fig. 37 Use

a suitable prytool to separate

the lower ball

joints from the