gas tank size MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 119 of 408

3-58 ENGINEANDENGINEOVERHAUL '

*The editors at Chilton feel that most engine

machining should be performed by a profes-

sional machine shop. Don’t think of it as

wasting money, rather, as an assurance that

the job has been done right the first time.

There are many expensive and specialized

tools required to perform such tasks as bor-

ing and honing an engine block or having a

valve job done on a cylinder head. Even in-

specting the parts requires expensive mi-

crometers and gauges to properly measure

wear and clearances. Also, a machine shop

can deliver to you clean, and ready to as-

semble parts, saving you time and aggrava-

tion. Your maximum savings will come from

performing the removal, disassembly, as-

sembly and installation of the engine and

purchasing or renting only the tools required

to perform the above tasks. Depending on

the particular circumstances, you may save

40 to 60 percent of the cost doing these your-

self.

A complete rebuild or overhaul of an engine in-

volves replacing all of the moving parts (pistons,

rods, crankshaft, camshaft, etc.) with new ones and

machining the non-moving wearing surfaces of the

block and heads. Unfortunately, this may not be cost

effective. For instance, your crankshaft may have

been damaged or worn, but it can be machined un-

dersize for a minimal fee.

So, as you can see, you can replace everything in-

side the engine, but, it is wiser to replace only those

parts which are really needed, and, if possible, repair

the more expensive ones. Later in this section, we

will break the engine down into its two main compo-

nents: the cylinder head and the engine block. We

will discuss each component, and the recommended

parts to replace during a rebuild on each. spect the component, buy the necessary parts and OVERHAULTIPS

deliver these to a shop for actual machine work.

Much of the assembly work (crankshaft, bearings, Aluminum has become extremely popular for use

piston rods, and other components) is well within the in engines, due to its low weight. Observe the follow-

scope of the do-it-yourself mechanic’s tools and abil- ing precautions when handling aluminum parts:

ities. You will have to decide for yourself the depth of

l Never hot tank aluminum parts (the caustic hot

involvement you desire in an engine repair or rebuild. 6nk solution will eat the aluminum.

l Remove all aluminum parts (identification tag,

TOOLS etc.) from engine parts prior to the tanking.

l Always coat threads lightly with engine oil or

The tools required for an engine overhaul or parts

anti-seize compounds before installation, to prevent

replacement will depend on the depth of your in-

seizure.

volvement. With a few exceptions, they will be the

l Never overtighten bolts or spark plugs espe-

tools found in a mechanic’s tool kit (see Section 1 of

this manual). More in-depth work will require some cially in aluminum threads.

When assembling the engine, any parts that will

or all of the following:

be exposed to frictional contact must be prelubed to

l A dial indicator (reading in thousandths)

provide lubrication at initial start-up. Any product

mounted on a universal base

specifically formulated for this purpose can be used,

l Micrometers and telescope gauges

* Jaw and screw-type pullers but engine oil is not recommended as a prelube in

most cases.

‘ Scraper

When semi-permanent (locked, but removable) in-

l Valve spring compressor

stallation of bolts or nuts is desired, threads should l Ring groove cleaner l Piston ring expander and compressor be cleaned and coated with Loctite@ or another simi- l Ridge reamer , lar, commercial non-hardening sealant. l Cylinder hone or glaze breaker l Plastigage@ l Engine stand

The use of most of these tools is illustrated in

this section. Many can be rented for a one-time use

from a local parts jobber or tool supply house spe-

cializing in automotive work.

Occasionally, the use of special tools is called for.

See the information on Special Tools and the Safety

Notice in the front of this book before substituting

another tool. CLEANING

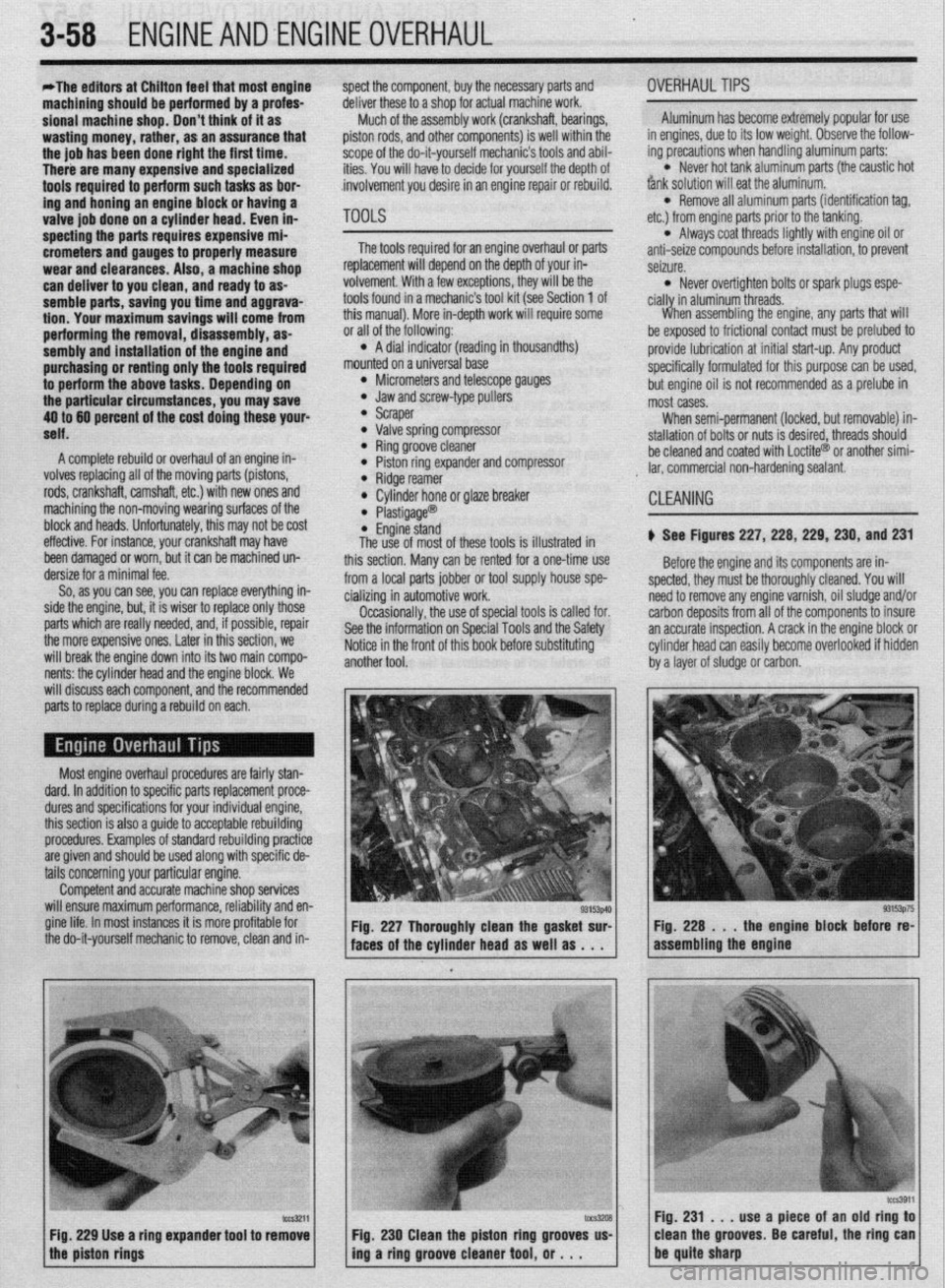

) See Figures 227, 228, 229, 230, and 231

Before the engine and its components are in-

spected, they must be thoroughly cleaned. You will

need to remove anv enaine varnish, oil sludoe and/or

c arbon deposits from ail of the componentsio insure

a In accurate inspection. A crack in the engine block or

c :ylinder head can easily become overlooked if hidden

t ry a layer of sludge or carbon.

Most engine overhaul procedures are fairly stan-

dard. In addition to specific parts replacement proce-

dures and specifications for your individual engine,

this section is also a guide to acceptable rebuilding

procedures. Examples of standard rebuilding practice

are given and should be used along with specific de-

tails concerning your particular engine.

Competent and accurate machine shop services

will ensure maximum performance, reliability and en-

gine life. In most instances it is more profitable for

the do-it-yourself mechanic to remove, clean and in- Fig. 227 Thoroughly clean the gasket sur-

faces of the cylinder head as well as . . .

Fig. 229 Use a ring expander tool to remove

the piston rings

fccs3911 ::“,z s,rpuse,a piece of fn old ring to 1

clean the grooves Be careful the ring can

230 Clean the piston ring grooves us-

ing a ring groove cleaner tool, or . . .

Page 389 of 408

TROUBLESHOOiNG 11-7

4. Starter motor spins, but does not engage

a. Check the starter motor for a seized or binding pinion gear.

b. Remove the flywheel inspection plate and check for a damaged ring gear.

Gasoline Engines

1. Engine runs poor/y, hesiiates

a. Check the engine ignition system operation and adjust if possible, or replace defective

parts.

b. Check for restricted fuel injectors and replace as necessary.

c. Check the fuel pump output and delivery. Inspect fuel lines for restrictions. If the fuel

pump pressure is below specification, replace the fuel pump.

d. Check the operation of the engine management system and repair as necessary.

2. Enfline lacks power

a. Check the engine’s tune-up status. Note the tune-up specifications and check for items

such as severely worn spark plugs; adjust or replace as needed. On vehicles with

manually adjusted valve clearances, check for tight valves and adjust to specification.

b. Check the air filter and air intake system. Replace the air filter if it is dirty or contami-

nated. Check the fresh air intake system for restrictions or blockage.

c. Check the operation of the engine fuel and ignition management systems. Check the

sensor operation and wiring. Check for low fuel pump pressure and repair or replace

components as necessary.

d. Check the throttle linkage adjustments. Check to make sure the linkage is fully open-

ing the throttle. Replace any worn or defective bushings or linkages.

e. Check for a restricted exhaust system. Check for bent or crimped exhaust pipes, or in-

ternally restricted mufflers or catalytic converters. Compare inlet and outlet tempera-

tures for the converter or muffler. If the inlet is hot, but outlet cold, the component is

restricted.

f. Check for a loose or defective knock sensor. A loose, improperly torqued or defective

knock sensor will decrease spark advance and reduce power. Replace defective knock

sensors and install using the recommended torque specification.

g. Check for engine mechanical conditions such as low compression, worn piston rings,

worn valves, worn camshafts and related parts. An engine which has severe mechani-

cal wear, or has suffered internal mechanical damage must be rebuilt or replaced to re-

store lost power.

h. Check the engine oil level for being overfilled. Adjust the engine’s oil level, or change

the engine oil and filter, and top off to the correct level.

i. Check for an intake manifold or vacuum hose leak. Replace leaking gaskets or worn

vacuum hoses.

j. Check for dragging brakes and replace or repair as necessary.

k. Check tire air pressure and tire wear. Adjust the pressure to the recommended set-

tings. Check the tire wear for possible alignment problems causing increased rolling

resistance, decreased acceleration and increased fuel usage.

I. Check the octane rating of the fuel used during refilling, and use a higher octane rated

fuel.

3. Poor fuel economy

a. Inspect the air filter and check for any air restrictions going into the air filter housing.

Replace the air filter if it is dirty or contaminated.

b. Check the engine for tune-up and related adjustments. Replace worn ignition parts,

check the engine ignition timing and fuel mixture, and set to specifications if possible.

c. Check the tire size, tire wear, alignment and tire pressure. Large tires create more

rolling resistance, smaller tires require more engine speed to maintain a vehicle’s road

speed. Excessive tire wear can be caused by incorrect tire pressure, incorrect wheel

alignment or a suspension problem. All of these conditions create increased rolling

resistance, causing the engine to work harder to accelerate and maintain a vehicle’s

speed.

d. Inspect the brakes for binding or excessive drag. A sticking brake caliper, overly ad-

justed brake shoe, broken brake shoe return spring, or binding parking brake cable or

linkage can create a significant drag, brake wear and loss of fuel economy. Check the

brake system operation and repair as necessary.

4. Engine runs on (diesels) when turned off

a. Check for idle speed set too high and readjust to specification.

b. Check the operation of the idle control valve, and replace if defective.

c. Check the ignition timing and adjust to recommended settings.

Check for defective

sensors or related components and replace if defective.

d. Check for a vacuum leak at the intake manifold or vacuum hose

and replace defective

gaskets or hoses.

e. Check the engine for excessive carbon build-up in the combustion chamber. Use a

recommended decarbonizing fuel additive or disassemble the cylinder head to remove

the carbon.

f. Check the operation of the engine fuel management system and replace defective sen-

sors or control units.

g. Check the engine operating temperature for overheating and repair as necessary. 5. Engine knocks and pinfls during heavy accele/ation, and on steep hills

a. Check the octane rating of the fuel used during refilling, and use a higher octane rated

fuel.

b. Check the ignition timing and adjust to recommended settings. Check for defective

sensors or related components and replace if defective.

c. Check the engine for excessive carbon build-up in the combustion chamber. Use a

recommended decarbonizing fuel additive or disassemble the cylinder head to remove

the carbon.

d. Check the spark plugs for the correct type, electrode gap and heat range. Replace worn

or damaged spark plugs. For severe or continuous high speed use, install a spark plug

that is one heat range colder.

e. Check the operation of the engine fuel management system and replace defective sen-

sors or control units.

f. Check for a restricted exhaust system. Check for bent or crimped exhaust pipes, or in-

ternally restricted mufflers or catalytic converters. Compare inlet and outlet tempera-

tures for the converter or muffler. If the inlet is hot, but outlet cold, the component is

restricted.

6. Engine atxelerates, but vehicle does not gain speed

a. On manual transmission vehicles, check for causes of a slipping clutch. Refer to the

clutch troubleshooting section for additional information.

b. On automatic transmission vehicles, check for a slipping transmission” Check the

transmission fluid level and condition. If the fluid level is too high, adjust to the cor-

rect level. If the fluid level is low, top off using the recommended fluid type. If the fluid

exhibits a burning odor, the transmission has been slipping internally. Changing the

fluid and filter may help temporarily, however in this situation a transmission may re-

quire overhauling to ensure long-term reliability.

Diesel Engines

1. Engine runs pOOr!y a. Check the injection pump timing and adjust to specification.

b. Check for air in the fuel lines or leaks, and bleed the air from the fuel system.

c. Check the fuel filter, fuel feed and return lines for a restriction and repair as necessary.

d. Check the fuel for contamination, drain and flush the fuel tank and replenish with fresh

fuel.

2. Enfline lacks power

a. Inspect the air intake system and air filter for restrictions and, if necessary, replace the

air filter.

b. Verify the injection pump timing and reset if out of specification.

c. Check the exhaust for an internal restriction and replace failed parts.

d. Check for a restricted fuel filter and, if restricted, replace the filter.

e. Inspect the fuel filler cap vent. When removing the filler cap, listen for excessive hiss-

ing noises indicating a blockage in the fuel filler cap vents, If the filler cap vents are

blocked, replace the cap.

f. Check the fuel system for restrictions and repair as necessary.

g. Check for low engine compression and inspect for external leakage at the glow plugs

or nozzles. If no external leakage is noted, repair or replace the engine.

ENGINE PERFORMANCE TROUBLESHOOTING HINTS When troubleshooting an engine running or performance condition, the mechanical

condition of the engine should be determined before lengthy troubleshooting procedures

are performed.

The engine fuel management systems in fuel injected vehicles rely on electronic sen-

sors to provide information to the engine control unit for precise fuel metering. Unlike

carburetors, which use the incoming air speed to draw fuel through the fuel metering jets

in order to provide a proper fuel-to-air ratio, a fuel injection system provides a specific

amount of fuel which is introduced by the fuel injectors into the intake manifold or intake

port, based on the information provided by electronic sensors.

The sensors monitor the engine’s operating temperature, ambient temperature and the

amount of air entering the engine, engine speed and throttle position to provide informa-

tion to the engine control unit, which, in turn, operates the fuel injectors by electrical

pulses. The sensors provide information to the engine control unit using low voltage

electrical signals. As a result, an unplugged sensor or a poor electrical contact could

cause a poor running condition similar to a failed sensor.

When troubleshooting a fuel related engine condition on fuel injected vehicles, care-

fully inspect the wiring and electrical connectors to the related components. Make sure

the electrical connectors are fully connected, clean and not physically damaged. If neces-

sary, clean the electrical contacts using electrical contact cleaner. The use of cleaning

agents not specifically designed for electrical contacts should not be used, as they could

leave a surface film or damage the insulation of the wiring.

The engine electrical system provides the necessary electrical power to operate the ve-

hicle’s electrical accessories, electronic control units and sensors. Because engine man-

agement systems are sensitive to voltage changes, an alternator which over or under-

charges could cause engine running problems or component failure. Most alternators

utilize internal voltage regulators which cannot be adjusted and must be replaced indi-

vidually or as a unit with the alternator.