four wheel drive MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 29 of 408

.

l-30 GENERAL'INFORMATIONAND MAINTENANCE

n Pylon@ inserts, the clip

be removed prior to siidi then the insert can be re

After installing the replacement

strip and pull up while twisting counterclockwise.

The backing strip will snap out of the retaining tab.

Do this for the remaining tabs until the refill is free of

the blade. The length of these refills is molded into

the end and they should be replaced with identical

types. cate the front end is out of alignment or that the tires

are out of balance.

TIRE ROTATION

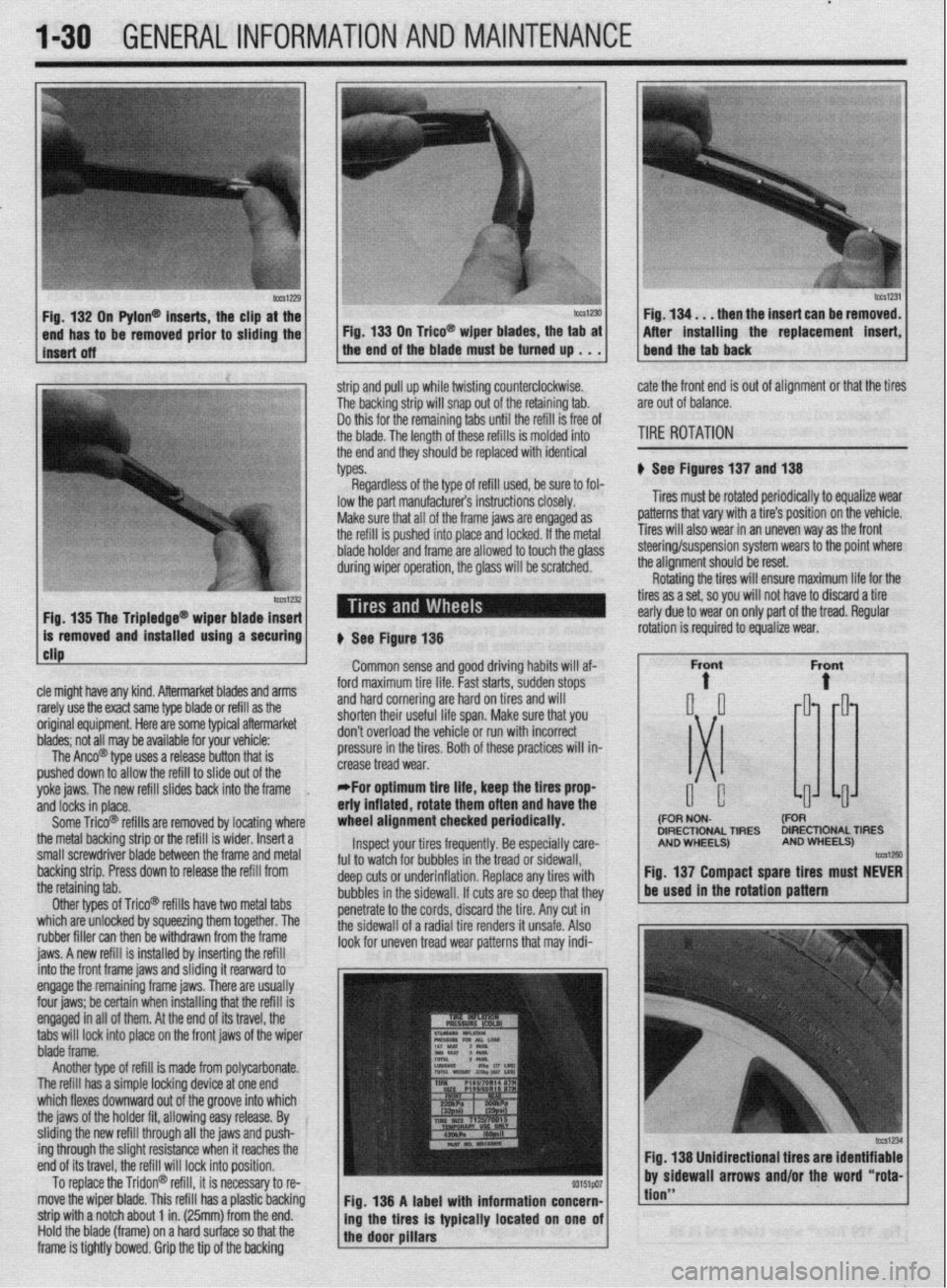

# See Figures 137 and 138

Tires must be rotated periodically to equalize wear

patterns that vary with a tire’s position on the vehicle.

Tires will also wear in an uneven way as the front

1 Fin 1% Tha Trinlarlna@

cle might have any kind. Aftermarket blades and arms

rarely use the exact same type blade or refill as the

original equipment. Here are some typiel aftermarket

blades; not all may be available for your vehicle:

The Anco@ type uses a release button that is

pushed down to allow the refill to slide out of the

yoke jaws. The new refill slides back into the frame

,

and locks in place.

Some Trico@ refills are removed by locating where

the metal backing strip or the refill is wider. Insert a

small screwdriver blade between the frame and metal

backing strip. Press down to release the refill from

the retaining tab.

Other types of Trico@’ refills have two metal tabs

which are unlocked by squeezing them together. The

rubber filler can then be withdrawn from the frame

iaws. A new refill is installed bv insertina the refill lowed to touch the olass steering/suspension system wears to the point where

the alianment should be reset.

# See Figure 138

Common sense and good driving habits will af-

ford maximum tire life. Fast starts, sudden stops

and hard cornering are hard on tires and will

shorten their useful life span. Make sure that you

don’t overload the vehicle or run with incorrect

pressure in the tires. Both of these practices will in-

crease tread wear.

*For optimum tire life, keep the fires prop

eriy inflated, rotate them often and have the

wheel alignment checked periodically.

Inspect your tires frequently. Be especially care-

ful to watch for bubbles in the tread or sidewall,

deep cuts or underinflation. Replace any tires with

bubbles in the sidewall. If cuts are so deep that they

penetrate to the cords, discard the tire. Any cut in

the sidewall of a radial tire renders it unsafe. Also

look for uneven tread wear patterns that may indi- Rotating the tires will ensure maximum life for the

tires as a set, so you will not have to discard a tire

early due to wear on only part of the tread. Regular

DIRECTIONAL TIRES DIRECTIONAL TIRES

jnto the front frame jaws and &ding it rearward to

engage the remaining frame jaws. There are usually

four jaws; be certain when installing that the refill is

engaged in all of them. At the end of its travel, the

tabs will lock into place on the front jaws of the wiper

blade frame.

Another type of refill is made from polycarbonate.

The refill has a simple locking device at one end

which flexes downward out of the groove into which

the jaws of the holder fit, allowing easy release. By

sliding the new refill through all the jaws and push-

ing through the slight resistance when it reaches the

end of its travel, the refill will lock into position.

To replace the Tridon@ refill, it is necessary to re-

move the wiper blade. This refill has a plastic backing

strip with a notch about 1 in. (25mm) from the end.

Hold the blade (frame) on a hard surface so that the

frame is tightly bowed. Grip the tip of the backing Fig. 138 A label with information concern-

ing the tires is typically located on one of

the door pillars

tion”

Page 30 of 408

GENERALINFORMATIONAND MAlNTENANdE 1-31

When rotating “unidirectional tires,” make sure

that they always roll in the same direction. This

means that a tire used on the left side of the vehicle

must not be switched to the right side and vice-versa.

Such tires should only be rotated front-to-rear or

rear-to-front, while always remaining on the same

side of the vehicle. These tires are marked on the

sidewall as to the direction of rotation; observe the

marks when reinstalling the tire(s).

Some styled or “mag” wheels may have different

offsets front to rear. In these cases, the rear wheels

must not be used up front and vice-versa. Further-

more, if these wheels are equipped with unidirectional

tires, they cannot be rotated unless the tire is re-

mounted for the proper direction of rotation.

*The compact or space-saver spare is

strictly for emergency use. it must never be

included in the tire rotation or placed on the

vehicle for everyday use. check the installed tire for any sign of interference

with the body or suspension while the vehicle is stop-

ping, turning sharply or heavily loaded.

Snow Tires

Good radial tires can produce a big advantage in

slippery weather, but in snow, a street radial tire does

not have sufficient tread to provide traction and con-

trol. The small grooves of a street tire quickly pack

with snow and the tire behaves like a billiard ball on a

marble floor, The more open, chunky tread of a snow

tire will self-clean as the tire turns, providing much

better grip on snowy surfaces.

To satisfy municipalities requiring snow tires dur-

ing weather emergencies, most snow tires carry either

an M + S designation after the tire size stamped on

the sidewall, or the designation “all-season.” In gen-

eral, no change in tire size is necessary when buying

snow tires.

Most manufacturers stronqlv recommend the use styled wheels, see if inexpensive steel

wheels are available, Although the look of

the vehicle will change, the expensive

wheels will be protected from salt, curb hits

and pothole damage.

TIRESTORAGE

If they are mounted on wheels, store the tires at

proper inflation pressure. All tires should be kept in a

cool, dry place. If they are stored in the garage or

basement, do not let them stand on a concrete floor;

set them on strips of wood, a mat or a large stack of

newspaper. Keeping them away from direct moisture

is of paramount importance. Tires should not be

stored upright, but in a flat position.

INFLATION & INSPECTION

b See Figures 140 thru 147

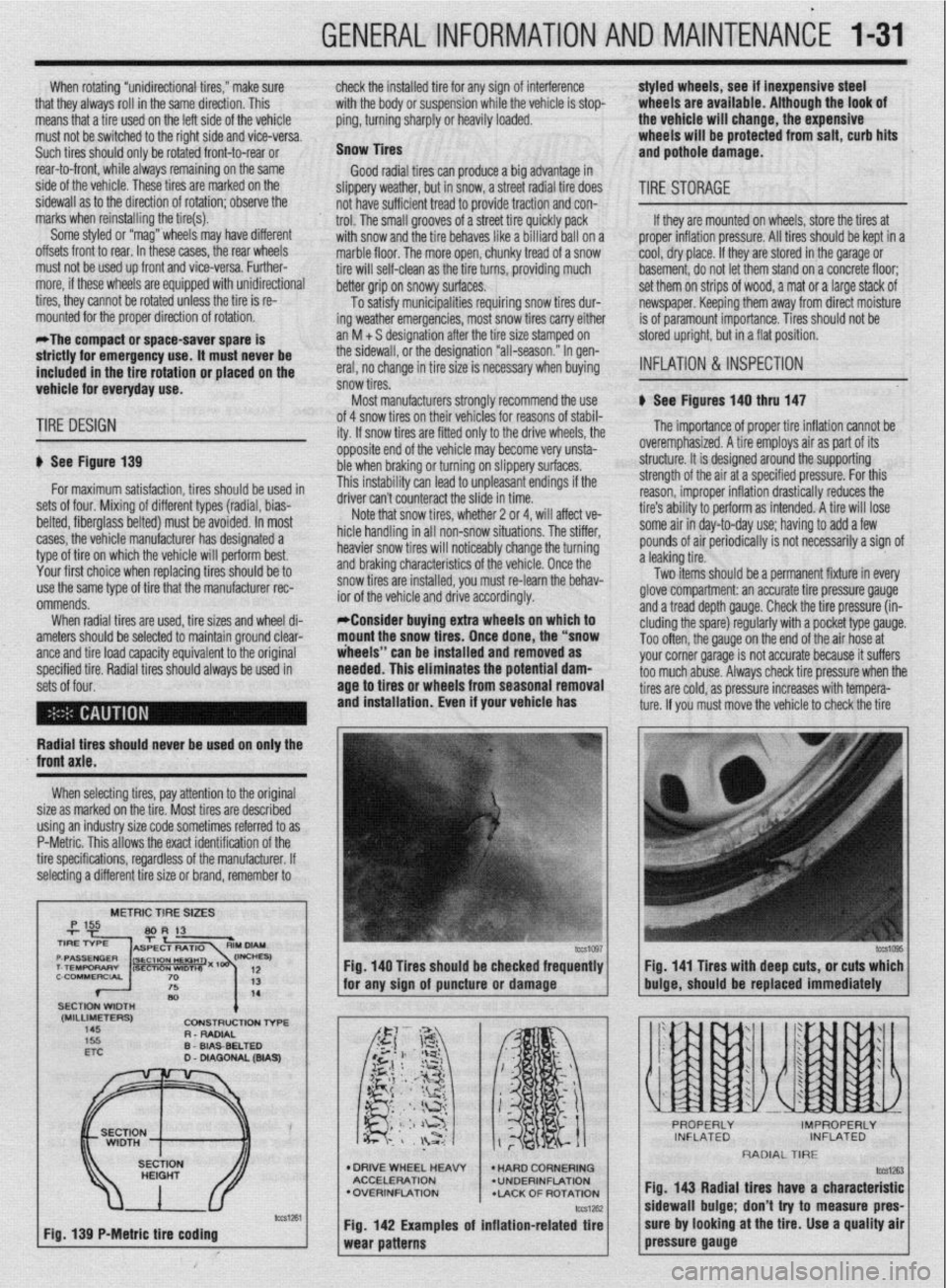

TIRE DESIGN

p See Figure 139

for maximum satisfaction, tires should be used in

sets of four. Mixing of different types (radial, bias-

belted, fiberglass belted) must be avoided. In most

cases, the vehicle manufacturer has designated a

type of tire on which the vehicle will perform best.

Your first choice when replacing tires should be to

use the same type of tire that the manufacturer rec-

ommends.

When radial tires are used, tire sizes and wheel di-

ameters should be selected to maintain ground clear-

ante and tire load caoacitv eauivalent to the oriainal

specified tire. Radial tiresshould always be used in

sets of four. of 4 snow tires on their

lehicies for reasons of stabil-

ity. If snow tires are fitter

1 only to the drive wheels, the

opposite end of the vehil cle may become very unsta-

ble when braking or turn

ring on slippery surfaces.

This instability can lead to unpleasant endings if the

A*:,,“- r-..l, ^_.. ..& ^_^^, &I.

UIIVU MII I LUUII~~MLL iue slide in time.

Note that snow tires, whether 2 or 4, will affect ve-

hicle handling in all non-snow situations. The stiffer,

heavier snow tires will noticeably change the turning

and braking characteristics of the vehicle. Once the

snow tires are installed, you must re-learn the behav-

ior of the vehicle and drive accordingly.

*Consider buying extra wheels on which to

mount the snow tires. Once done, the “snow

iheeis” can be installed and removed as

needed. This eliminates the potential

dam- age to tires or wheels from seasonal removal

and installation. Even if your vehicle has

lb The importance of proper tire inflation cannot be

overemphasized. A tire employs air as part of its

structure. It is designed around the supporting

strength of the air at a specified pressure. For this

reason, improper inflation drastically reduces the

tire’s ability to perform as intended. A tire will lose

some air in day-to-day use; having to add a few

pounds of air periodically is not necessarily a sign of

a leaking tire.

Two items should be a permanent fixture in every

glove compartment: an accurate tire pressure gauge

and a tread depth gauge. Check the tire pressure (in-

eluding the spare) regularly with a pocket type gauge.

Too often, the gauge on the end of the air hose at

vnr rr corner narane is not accurate because it suffers

~rs check tire oressure when the

Radial tires should never be used on only the

XI I._.

‘-’ --“‘“’ J s too much abuse. Alwa!

tires are cold, as pressure increases with tempera-

ture. If you must move the vehicle to check the tire

front axle.

When selecting tires, pay attention to the original

size as marked on the tire. Most tires are described

using an industry size code sometimes referred to as

P-Metric. This allows the exact identification of the

tire specifications, regardless of the manufacturer. If

selecting a different tire size or brand, remember to

METRIC TIRE SIZES

(MILLIMETERS)

145 CDNStRUCtlDN l-6-E

R - RADIAL

D

WA9

Fig. 139 P-Metric tire coding Fig. 140 Tires should be checked frequently

I I Fig. 141 Tires with deep cuts, or cuts which

for any sion of auncture or damaoe

buioe, should be replaced immediately

l DRIVE WHEEL HEAW

ACCELERATION

l OVERINFLATION

*LACK OF ROTATION

Fig. 142 Examples of inflation-related tire

RADIAL TIRE

fig. 143 Radial tires have a characteristic

sidewall bulge; don’t try to measure pres-

sure by looking at the tire. Use a quality air

pressure gauge

Page 311 of 408

8116 SUSPENSION AND STEERING

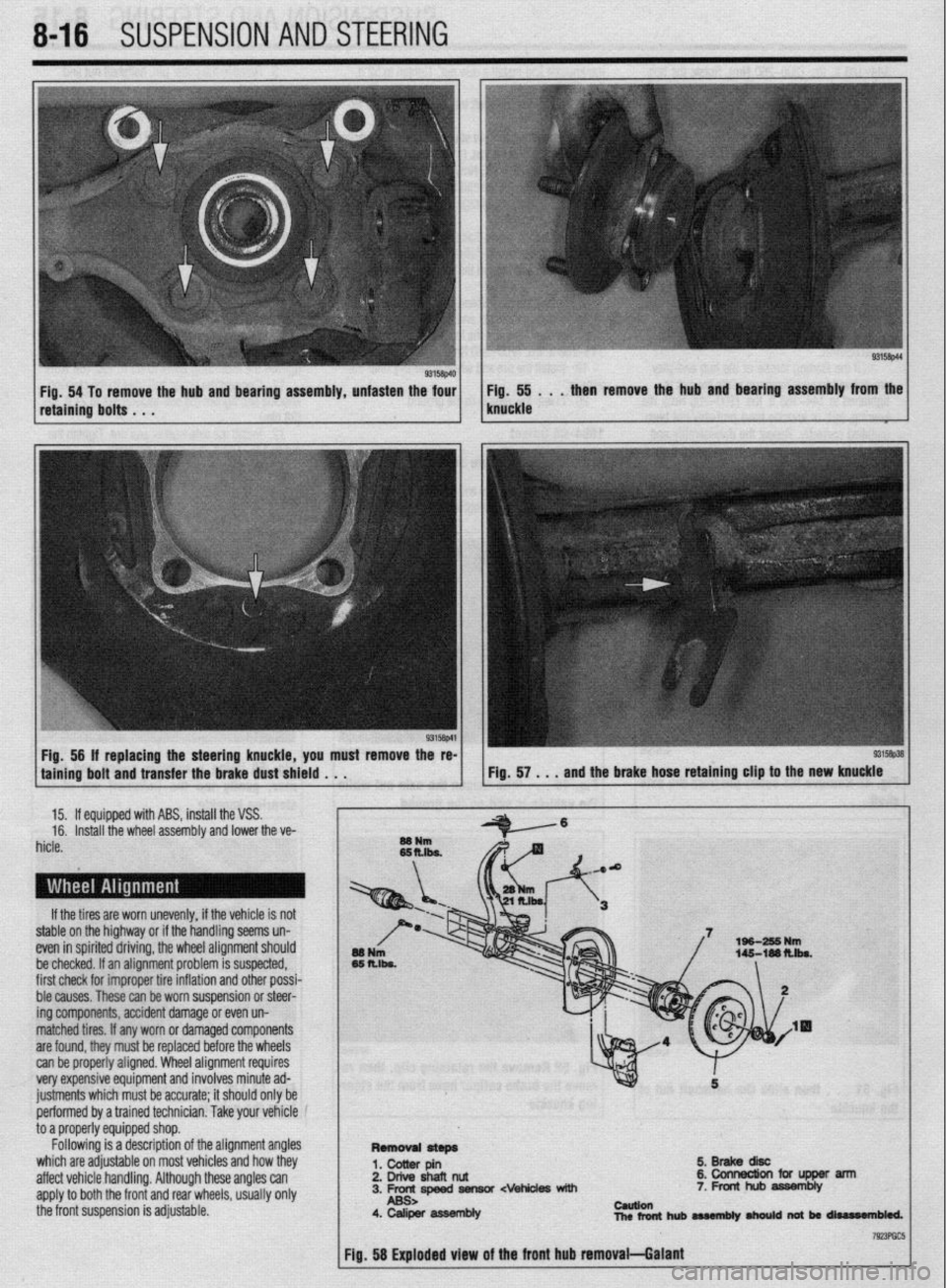

Fig. 54 To remove the hub and bearing assembly, unfasten the four Fig. 55 . . . then remove the hub and bearing assembly from the

retaining bolts . . . knuckle

Fig, 56 If replacing the steering knuckle, you must remove the re-

taining bolt and transfer the brake dust shield . . .

15. If equipped with ABS, install the VSS.

16. Install the wheel assembly and lower the ve-

hicle.

If the tires are worn unevenly, if the vehicle is not

stable on the highway or if the handling seems un-

even in spirited driving, the wheel alignment should

be checked. If an alignment problem is suspected,

first check for improper tire inflation and other possi-

ble causes. These can be worn suspension or steer-

ing components, accident damage or even un-

matched tires. If any worn or damaged components

are found, they must be replaced before the wheels

can be properly aligned. Wheel alignment requires

very expensive equipment and involves minute ad-

justments which must be accurate; it should only be

performed by a trained technician. Take your vehicle

to a properly equipped shop.

Following is a description of the alignment angles

which are adjustable on most vehicles and how they

affect vehicle handling. Although these angles can

apply to both the front and rear wheels, usually only

the front suspension is adjustable.

5.BrakediW

2. Drive shafl nut &collnectionfciflJpperarm

3. Frc-rc,speed fiensor cvehides with 7. Front hub assembly

4. Caliper asWmbly cauuen

nlcrfonthubaMmbly~natbrrliurr#n61ed.

Page 322 of 408

8-26 SUSPENSION AND STEERING

torqued to specifications. The wheel bearings are

sealed units and are not adjustable. If defective, re-

placement is the only option.

REMOVAL &INSTALLATION

Mirage

7996-92 MODELS

1. Raise the vehicle and support safely.

2. Remove the tire and wheel assembly.

3. If equipped with rear disc brakes, remove the

caliper from the disc and remove the brake disc.

4. Remove the dust cap and bearing nut. Do not

use an air gun to remove the nut.

5. Remove the outer wheel bearing.

6. Remove the drum and/or axle hub with the

inner wheel bearing and the grease seal.

7. Remove the grease seal and remove the inner

bearing.

To install: 8. Lubricate the inner bearing and install to the

drum or hub.

9. Install a new grease seal.

10. To determine if the self-locking nut is

reusable:

a. Screw in the self-locking nut until about

0.07-0.11 in. (2-3mm) of thread is visible under

the nut.

b. Measure the torque required to turn the

self-locking nut counterclockwise.

c. The lowest allowable torque is 48 inch Ibs.

(6 Nm). If the measured torque is less than the

specification, replace the nut.

11. Install the drum and/or hub to the vehicle.

12. Lubricate and install the outer wheel bearing

to the spindle.

13. Tighten the self-locking nut to 108-145 ft.

Ibs. (150-200 Nm).

14. Set up a dial indicator and measure the end-

play while moving the hub or drum in and out. If the

endplay exceeds 0.008 in. (0.002mm) retorque the

nut. If still beyond the limit, replace the bearings.

15. Install the grease cap and wheel assembly.

7993-60 MODELS

*Never disassemble the rear hub bearing.

The wheel bearing is serviced by replace-

ment of the hub.

1. If equipped with ABS, remove the wheel

speed sensor.

2. Raise and safely support the vehicle.

3. Remove the rear wheel.

4. Remove the caliper and brake disc or brake

drum.

5. Remove the dust cap and flange nut.

6. Remove the rear hub assembly.

To install: 7. Install the rear hub assembly using a new

flange nut. Tighten the flange nut to 130 ft. Ibs. (180

Nm).

8. install the dust cap.

9. Install the wheel speed sensor if removed.

The air gap should be 0.012-0.035 in. (0.3-0.9mm).

10. Install the brake disc and caliper, or brake

drum.

11. Install the rear wheel assembly and lower the

vehicle to the floor.

1990-93 Galant

DRUM BRAKE VEHICLES

1. Raise the vehicle and support it safely.

2. Remove the wheel and tire assemblies.

3. Remove the grease cap and the hub nut.

4. Remove the brake drum. The outer bearing

will fall out while the drum is coming off. Do not drop

it. Remove the hub and rotor assembly.

5. Pry out and discard the oil seal.

6. Remove the inner bearing.

*Check the bearing races. If any scoring,

heat checking or damage is noted, they

should be replaced. When bearing or races

need replacement, replace them as a set.

7. If the bearings and races are to be replaced,

drive out the race with a brass drift.

To install: 8. Before installing new races, coat them with

wheel bearing grease. Drive into place with proper

size driver. Make sure they are fully seated.

9. Thoroughly pack the bearings and lubricate

the hubs with wheel bearing grease. Install the inner

bearing and coat the lip and rim of the grease seal

with grease. Drive the seal into place with a seal dri-

ver.

10. Install the drum assembly on the axle.

11, Lubricate and install the outer wheel bearing,

washer and nut. To properly adjust the wheel bearing

preload:

a. Tighten the wheel bearing nut to 20 ft. Ibs.

(27 Nm) while rotating the drum.

b. Back off the adjusting nut to remove the

preload, then tighten it to 7 ft. Ibs. (10 Nm).

c. Install the nut lock and a new cotter pin.

12. Install the wheel and lower the vehicle.

O/SC BRAKE VEHICLES

1. Raise the vehicle and support safely.

2. Remove the tire and wheel assembly.

3. Remove the bolt(s) holding the speed sensor

bracket to the knuckle and remove the assembly from

the vehicle.

The speed sensor has a pole piece projecting

from it. This exposed tip must be protected

from impact or scratches. Do not allow the

oole oiece to contact the toothed wheel dur-

in0 removal or installation.

4. Remove the caliper from the brake disc and

suspend with a wire.

5. Remove the brake rotor.

6. Remove the grease cap, locking nut and

tongued washer.

7. Remove the rear hub and bearing assembly.

*The rear hub assembly can not be disas-

sembled. If bearing replacement is required,

replace the assembly as a unit.

8. If replacing the hub assembly, remove the

two bolts securing the speed sensor ring to the hub.

To install: 9. Install the speed sensor to the hub and bear-

ing assembly. Tighten the mounting bolts to 8 ft. Ibs.

(11 Nm). 10. Install the hub and bearing assembly to the

axle shaft.

11, Install the tongued washer and a new locking

nut. Tighten the locknut to 144-188 ft. Ibs. (200-260

Nm). Once the locknut has been properly torqued,

crimp the nut flange over the slot in the spindle, and

install the grease cap.

12. Install the brake caliper and rotor.

13. Install the speed sensor and tighten the

mounting bolt to 8 ft. Ibs. (11 Nm).

14. Install the tire and wheel assembly.

Be sure to pump the brake pedal until it’s

firm, before moving vehicle.

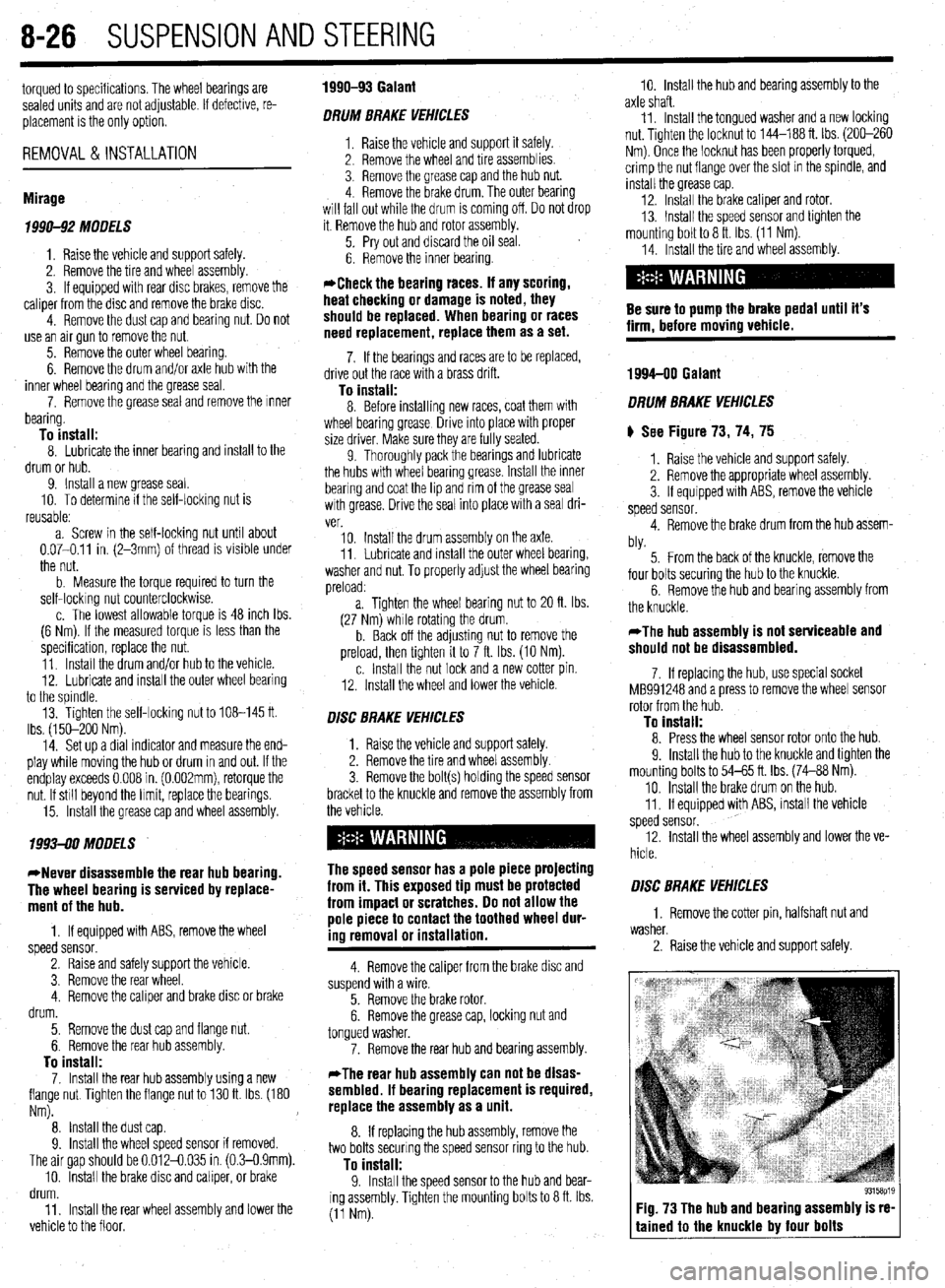

1994-00 Galant

DRUM BRAKE VEHICLES

) See Figure 73, 74, 75

1. Raise the vehicle and support safely.

2. Remove the appropriate wheel assembly.

3. If equipped with ABS, remove the vehicle

speed sensor.

4. Remove the brake drum from the hub assem-

bly.

5. From the back of the knuckle, remove the

four bolts securing the hub to the knuckle.

6. Remove the hub and bearing assembly from

the knuckle.

*The hub assembly is not serviceable and

should not be disassembled.

7. If replacing the hub, use special socket

MB991248 and a press to remove the wheel sensor

rotor from the hub.

To install: 8. Press the wheel sensor rotor onto the hub.

9. Install the hub to the knuckle and tighten the

mounting bolts to 54-65 ft. Ibs. (74-88 Nm).

10. Install the brake drum on the hub.

11. If equipped with ABS, install the vehicle

speed sensor.

12. Install the wheel assembly and lower the ve-

hicle.

O/SC BRAKE VEHICLES

1. Remove the cotter pin, halfshaft nut and

washer.

2. Raise the vehicle and support safely.

Fig. 73 The hub and bearing assembly is re-

tained to the knuckle by four bolts

Page 331 of 408

SUSPENSION AND STEERING 8-35

1. Steering shaft assembly and gear

box connecting bolt

2. Band

3. Cotter pin

4. Tie-rod end and knuckle connection

5. Return tube connection 6. Pressure tube connection

7. Cylinder clamp

8. Gear housing clamp

9. Gear box assembly 10. Steering cover assembly

7923PGAl FiD= 97 Exploded view of the power steering gear assembly-Mirage

1993-90 MODELS To install:

) See Figure 97

*Prior to removal of the steering gear box,

center the front wheels and remove the igni-

tion key. Failure to do so may damage the

SRS clockspring and render SRS system in-

operative.

,mr;iin thepower steering system.

2. Disconnect the battery negative cable. Raise

the vehicle and support safely.

3. Disconnect the Heated Oxygen (HOPS) sen-

sor and remove the front exhaust pipe.

4. Properly support the engine.

5. Remove both roll stopper mounting bolts and

the four center member installation bolts. Remove the

center member.

6. Remove the center member. 11. Align the matchmarks of the input shaft and

install the rack to the vehicle.

12. Secure the rack using the retainer clamps and

bolts. Tighten the bolts to 51 ft. Ibs. (70 Nm).

13. Tighten the steering column pinch bolt to 13

ft. Ibs. (18 Nm).

14. Using new O-rings, connect the power steer-

ing fluid lines to the rack fittings.

15. Install the center member.

16. Install the front exhaust pipe.

17. Connect the H02S sensor.

18. Connect the tie rod ends to the steering

knuckles and tighten the castle nuts to 25 ft. Ibs. (34

Nm). Install new cotter pins.

19. Install the wheels and connect the negative

battery cable.

20. Refill ‘the reservoir and bleed the system.

21. Have a front end alignment performed.

stallation purposes. -

7. Remove the pinch bolt holding the lower REMOVALANDINSTALLATION

steering column joint to the rack and pinion input

shaft.

8. Remove the cotter pins and disconnect the tie

rod ends from the steering knuckle.

9. Disconnect the power steering fluid pressure

pipe and return hose from the rack fittings.

IO. Remove the rack and pinion steering assem-

bly and its rubber mounts from the right side of the

vehicle. Mirage

1, Drain the power steering system as follows:

a. Disconnect the return hose at the reservoir

and place into a suitable container.

b. Disable the ignition system. While crank-

ing the engine, turn the wheels several times, un-

til system has been drained. 2. Disconnect the battery negative cable.

3. Remove the pressure switch connector from

the side of the pump.

4. If the alternator is located under the oil pump,

cover it with a shop towel to protect it from oil.

5. Disconnect the pressure line.

6. Remove the steering pump drive belt and the

water pump pulley drive belt.

7. Remove the water pump pulley.

8. Remove the bolts that secure the oil pump,

then remove the pump from its bracket.

To install: 9. Install the power steering pump and tighten

the mounting bolts to specifications.

IO. Install the water pump pulley and tighten the

mounting bolts 14 ft. Ibs. (19 Nm).

11. Install and adjust the drive belts.

12. Replace the O-rings and connect the pressure

line. Connect the pressure line so the notch in the fit-

ting aligns and contacts the pump’s guide bracket.

Tighten the nut that secures the pressure line to 13 ft.

Ibs. (18 Nm).

13. Connect the return line.

14. Attach the pressure switch connector.

15. Refill the reservoir and bleed the system.

1990-93 Galant

FRONT

1. Disconnect the battery negative cable.

2. Remove the pressure switch connector from

the side of the pump.

Page 385 of 408

I TROUBLESHOOTING II-3

Condition Section/hem Number

2-A, 1

2-A, 2

2-A, 3 Transmission shifts erratically

Transmission will not engage

Transmission will not downshift during heavy acceleration

Transmission grinds going into forward gears while driving

Transmission jumps out of gear

Transmission difficult to shift

Transmission leaks fluid 2-B, 1 2-C, 2

2-B, 2

2-B, 3 2-C, 2

2-B, 4

2-C,l

2-c,2

2-c,3

2-c,4

2-c,5

2-C,6 Clutch slips on hills or during sudden acceleration

Clutch will not disengage, difficult to shift

Clutch is noisy when the clutch pedal is pressed

Clutch pedal extremely difficult to press

Clutch pedal remains down when pressed

Clutch chatters when engaging

2-D, 1

2-D, 2 Differential makes a low pitched rumbling noise

Differential makes a howling noise

All Wheel and Four Wheel Drive Vehicles Leaks fluid from seals or vent after being driven

Makes excessive noise while driving

Jumps out of gear 2-E, 1

2-E, 2

2-E, 3

Rear Wheel, All Wheel and Four Wheel Drive Vehicles Clunking noise from center of vehicle shifting from forward to reverse

,Excessive vibration from center of vehicle when accelerating 2-F, l

2-F,2

All Wheel and Four Wheel Drive Vehicles , Front or rear wheel makes a clicking noise

Front or Rear wheel vibrates with increased speed 2-G,l

2-G,2

Front Wheel Drive Vehicles Front wheel makes a clicking noise

Rear wheel makes a clicking noise 2-G,3

2-G,4

Rear Wheel Drive Vehicles Front or rear wheel makes a clicking

Rear wheel shudders or vibrates noise 2-G,5

2-G,6

2-H, 1; 2-C, 1; 3-A, 9

2-H, 2; 2-C, 1; 3-A, 9 Burning odor from center of vehicle when accelerating

Engine accelerates, but vehicle does not gain speed

Brakes pedal pulsates or shimmies when pressed 3-A-l

Brakes make a squealing noise CI

3-A, 2

Brakes make a grinding noise

Vehicle pulls to one side during.braking

Brake pedal feels spongy or has excessive brake pedal travel

Brake pedal feel is firm, but brakes lack sufficient stopping power or fade 3-A, 3

3-A, 4

3-A, 5

3-A, 6

Page 386 of 408

11-4 TROUBLESHOOTING

Condition

2 Section/Item Number ^i Vehicle has excessive front end dive or locks rear brakes too easily

3-A, 7

Brake pedal goes to floor when pressed and will not pump up

3-A, 8

Brakes make a burning odor

3-A, 9

All Wheel and Four Wheel Drive Vehicles Front wheel or wheel bearing loose

Rear wheel or wheel bearingloose

Front Wheel Drive Vehicles Front wheel or wheel bearing loose

Rear wheel or wheel bearing loose 4-A. 1

4-A: 1

4-A, 1

4-A, 2

Rear Wheel Drive Vehicles Front wheel or wheel bearing loose

Rear wheel or wheel bearing loose 4-A, 2

4-A, 1

Tires worn on inside tread

Tires worn on outside tread

s Tires worn unevenly 4-B, 1

4-B, 2

4-B, 3

Excessive play in steering wheel

Steering wheel shakes at cruising speeds

Steering wheel shakes when braking

Steering wheel becomes stiff when turned 4-c, 1

4-c, 2

3-A, 1

4-c, 4

Vehicle pulls to one side

Vehicle is very bouncy over bumps

Vehicle seems to lean excessively in turns

Vehicle ride quality seems excessively harsh

Vehicle seems low or leans to one side 4-D 1

4-D, 2

4-D, 3

4-D, 4

4-D, 5

Noises Vehicle makes a clicking noise when driven

Vehicle makes a clunking or knocking noise over bumps

Vehicle makes a low pitched rumbling noise when driven

Vehicle makes a squeaking noise over bumps

Vibrations Vehicle vibrates when driven 4-E, 1

4-E, 2

4-E, 3

4-E, 4

4-E, 5

One headlight only works on high or low beam

Headlight does not work on high or low beam

Headlight(s) very dim

Tail light, running light or side marker light inoperative

Tail light, running light or side marker light works intermittently

Tail light, running light or side marker light very dim 5-A, 1

5-A, 2

5-A, 3

/ .

5-B, 1

5-B, 2

5-B, 3

Interior light inoperative

Interior light works intermittently

Interior light very dim 5-c, 1

5-c, 2

5-c, 3

Page 392 of 408

II-10 TROUBLESHOOTING

1. Transmission grinds going into forward gears while driving

a. Check the clutch release system. On clutches with a mechanical or cable linkage,

check the adjustment. Adjust the clutch pedal to have 1 inch (25mm) of free-play at

the pedal.

b. If the clutch release system is hydraulically operated, check the fluid level and, if low,

top off using the recommended type and amount of fluid. ,

c. Synchronizers worn. Remove transmission and replace synchronizers.

d. Synchronizer sliding sleeve worn. Remove transmission and replace sliding sleeve.

e. Gear engagement dogs worn or damaged. Remove transmission and replace gear.

2. Transmission jumps out of gear

a. Shift shaft detent springs worn. Replace shift detent springs.

b. Synchronizer sliding sleeve worn. Remove transmission and replace sliding sleeve.

c. Gear engagement dogs worn or damaged. Remove transmission and replace gear.

d. Crankshaft thrust bearings worn. Remove engine and crankshaft, and repair as neces-

sary.

3. Transmission difficult to shift

a. Verify the clutch adjustment and, if not properly adjusted, adjust to specification.

b. Synchronizers worn. Remove transmission and replace synchronizers.

c. Pilot bearing seized. Remove transmission and replace pilot bearing.

d. Shift linkage or bushing seized. Disassemble the shift linkage, replace worn or dam-

aged bushings, lubricate and reinstall.

4. Transmission leaks fluid

a. Check the fluid level for an overfilled condition. Adjust the fluid level to specification.

b. Check for a restricted transmission vent or breather tube. Clear the blockage as neces-

sary and check the fluid level. If necessary, top off with the recommended lubricant.

c. Check for a porous casting, leaking seal or gasket. Replace defective parts and top off

the fluid level with the recommended lubricant.

1. Clutch slips on hills or during sudden acceleration

a. Check for insufficient clutch pedal free-play. Adjust clutch linkage or cable to allow

about 1 inch (25mm) of pedal free-play.

b. Clutch disc worn or severely damaged. Remove engine or transmission and replace

clutch disc.

c. Clutch pressure plate is weak. Remove engine or transmission and replace the clutch

pressure plate and clutch disc.

d. Clutch pressure plate and/or flywheel incorrectly machined. If the clutch system has

been recently replaced and rebuilt, or refurbished parts have been used, it is possible

that the machined surfaces decreased the clutch clamping force. Replace defective

parts with new replacement parts.

2. Clutch will not disengage, difficult to shift

a. Check the clutch release mechanism. Check for stretched cables, worn linkages or

failed clutch hydraulics and replace defective parts. On hydraulically operated clutch

release mechanisms, check for air in the hydraulic system and bleed as necessary.

b. Check for a broken, cracked or fatigued clutch release arm or release arm pivot. Re-

place defective parts and properly lubricate upon assembly.

c. Check for a damaged clutch hub damper or damper spring. The broken parts tend to

become lodged between the clutch disc and the pressure plate. Disassemble clutch

system and replace failed parts.

d. Check for a seized clutch pilot bearing. Disassemble the clutch assembly and replace

the defective parts.

e. Check for a defective clutch disc. Check for warpage or liningthicknesses larger than

original equipment.

3. Clutch is noisy when the clutch pedal is pressed

a. Check the clutch pedal stop and pedal free-play adjustment for excessive movement

and adjust as necessary.

b. Check for a worn or damaged release bearing. If the noise ceases when the pedal is re-

leased, the release bearing should be replaced.

c. Check the engine crankshaft axial play. If the crankshaft thrust bearings are worn or

damaged, the crankshaft will move when pressing the clutch pedal. The engine must

be disassembled to replace the crankshaft thrust bearings.

4. Clutch pedal extremely difficult to press

a. Check the clutch pedal pivots and linkages for binding. Clean and lubricate linkages.

b. On cable actuated clutch systems, check the cable routing and condition. Replace

kinked, frayed, damaged or corroded cables and check cable routing to avoid sharp

bends. Check the engine ground strap for poor conductivity. If the ground strap is

marginal, the engine could try to ground itself via the clutch cable, causing premature

failure. c. On mechanical linkage clutches, check the linkage for binding or misalignment. Lubri-

cate pivots or linkages and repair as necessary.

d. Check the release bearing guide tube and release fork for a lack of lubrication. Install a

smooth coating of high temperature grease to allow smooth movement of the release

bearing over the guide tube.

5. Clutch pedal remains down when pressed

a, On mechanical linkage or cable actuated clutches, check for a loose or disconnected

link.

b. On hydraulically actuated clutches, check the fluid level and check for a hydraulic leak

at the clutch slave or master cylinder, or hydraulic line. Replace failed parts and bleed

clutch hydraulic system. If no leakage is noted, the clutch master cylinder may have

failed internally. Replace the clutch master cylinder and bleed the clutch hydraulic sys-

tem.

6. clutch chatters when engaging

a. Check the engine flywheel for warpage or surface variations and replace or repair as

necessary.

b. Check for a warped clutch disc or damaged clutch damper hub. Remove the clutch

disc and replace.

c. Check for a loose or damaged clutch pressure plate and replace defective components.

NOTE: The clutch is actuated either by a mechanical linkage, cable or a

clutch hydraulic system. The mechanical linkage and cable systems may

require the clutch pedal free-play to be adjusted as the clutch disc wears. A

hydraulic clutch system automatically adjusts as the clutch wears and, with

the exception of the clutch pedal height, no adjustment is possible.

1. Differential makes a low pitched rumbling noise

a. Check fluid level type and amount. Replace the fluid with the recommended type and

amount of lubricant.

b. Check the differential bearings for wear or damage. Remove the bearings, inspect the

drive and driven gears for wear or damage, and replace components as necessary.

2. Differential makes a howling noise

a. Check fluid level type and amount. Replace the fluid with the recommended type and

amount of lubricant.

b. Check the differential drive and driven gears for wear or damage, and replace compo-

nents as necessary.

All Wheel and Four Wheel Drive Vehicles

1. Leaks fluid from seals or vent after being driven

a. Fluid level overfilled. Check and adjust transfer case fluid level.

b. Check for a restricted breather or breather tube, clear and check the fluid level and top

off as needed.

c. Check seal condition and replace worn, damaged, or defective seals. Check the fluid

level and top off as necessary.

2. Makes excessive noise while driving

a. Check the fluid for the correct type of lubricant. Drain and refill using the recom-

mended type and amount of lubricant.

b. Check the fluid level. Top off the fluid using the recommended type and amount of lu-

bricant.

c. If the fluid level and type of lubricant meet specifications, check for internal wear or

damage. Remove assembly and disassemble to inspect for worn, damaged, or defec-

tive components.

3. Jumps out of gear

a. Stop vehicle and make sure the unit is fully engaged.

b. Check for worn, loose or an improperly adjusted linkage. Replace and/or adjust link-

age as necessary.

c. Check for internal wear or damage. Remove assembly and disassemble to inspect for

worn, damaged, or defective components.

Rear Wheel, All Wheel and Four Wheel Drive Vehicles

1. Clunking noise from center of Vehicle shifting from forward to reverse

a. Worn universal joint. Remove driveshaft and replace universal joint.

2. Excessive vibration from center of vehicle when accelerating

a. Worn universal joint. Remove driveshaft and replace universal joint.

Page 393 of 408

TROUBLESHOOTlNGll-11

b. Driveshaft misaligned. Check for collapsed or damaged engine and transmission

mounts, and replace as necessary.

c. Driveshaft bent or out of balance. Replace damaged components and reinstall.

d. Driveshaft out of balance. Remove the driveshaft and have it balanced by a competent

professional, or replace the driveshaft assembly.

NOTE: Most driveshafts are linked together by universal joints; however,

some manufacturers use Constant Velocity (CV) joints or rubber flex cou-

plers.

All Wheel and Four Wheel Drive Vehicles

1. Front or rear wheel makes a clicking noise

a. Check for debris such as a pebble, nail or glass in the tire or tire tread. Carefully re-

move the debris. Small rocks and pebbles rarely cause a puncture; however, a sharp

object should be removed carefully at a facility capable of performing tire repairs.

b. Check for a loose, damaged or worn Constant Velocity (CV) joint and replace if defec-

tive.

2. Front or rear wheel vibrates wlth Increased speed

a. Check for a bent rim and replace, if damaged.

b. Check the tires for balance or internal damage and replace if defective.

c. Check for a loose, worn or damaged wheel bearing and replace if defective.

d. Check for a loose, damaged or worn Constant Velocity (CV) joint and replace if defec-

tive.

Front Wheel Drive Vehicles

3. Front wheel makes a c&kin@ noise

a. Check for debris such as a pebble, nail or glass in the tire or tire tread. Carefully re-

move the debris. Small rocks and pebbles rarely cause a puncture; however, a sharp

object should be removed carefully at a facility capable of performing tire repairs.

b. Check for a loose, damaged or worn Constant Velocity (CV) joint and replace if defec-

tive. 4. Rear wheel makes a clicking noise

a. Check for debris such as a pebble, nail or glass in the tire or tire tread. Carefully re-

move the debris. Small rocks and pebbles rarely cause a puncture; however, a sharp

object should be removed carefully at a facility capable of performing tire repairs.

Rear Wheel Drive Vehicles

5. Front or rear wheel makes a clicking noise

a. Check for debris such as a pebble, nail or glass in the tire or tire tread. Carefully re-

move the debris. Small rocks and pebbles rarely cause a puncture; however, a sharp

object should be removed carefully at a facility capable of performing tire repairs.

6. Rear wheel shudders or vibrates

a. Check for a bent rear wheel or axle assembly and replace defective components.

b. Check for a loose, damaged or worn rear wheel bearing and replace as necessary.

1. Burning odor from center of vehicle when accelerating

a. Check for a seizing brake hydraulic component such as a brake caliper. Check the

caliper piston for surface damage such as rust, and measure for out-of-round wear

and caliper-to-piston clearance. For additional information on brake related odors, re-

fer to section 3-A, condition number 9.

b. On vehicles with a manual transmission, check for a slipping clutch. For possible

causes and additional information, refer to section Z-C, condition number 1.

c. On vehicles with an automatic transmission, check the fluid level and condition, Top

off or change the fluid and filter using the recommended replacement parts, lubricant

type and amount. If the odor persists, transmission removal and disassembly will be

necessary.

2. Engine accelerates, but vehicle does not gain speed

a. On vehicles with a manual transmission, check for a slipping or damaged clutch. For

possible causes and additional information refer to section Z-C, condition number 1.

b. On vehicles with an automatic transmission, check the fluid level and condition. Top

off or change the fluid and filter using the recommended replacement parts, lubricant

type and amount. If the slipping continues, transmission removal and disassembly will

be necessary.

1. Brake pedal pulsates or shimmies when pressed

a. Check wheel lug nut torque and tighten evenly to specification.

b. Check the brake rotor for trueness and thickness variations. Replace the rotor if it is

too thin, warped, or if the thickness varies beyond specification. Some rotors can be

machined: consult the manufacturer’s specifications and recommendations before us-

ing a machined brake rotor.

c. Check the brake caliper or caliper bracket mounting bolt torque and inspect for loose-

ness. Torque the mounting bolts and inspect for wear or any looseness, including

worn mounting brackets, bushings and sliding pins.

d. Check the wheel bearing for looseness. If the bearing is loose, adjust if possible, oth-

erwise replace the bearing.

2. Brakes make a squealing noise

a. Check the brake rotor for the presence of a ridge on the outer edge; if present, remove

the ridge or replace the brake rotor and brake pads.

b. Check for debris in the brake lining material, clean and reinstall.

c. Check the brake linings for wear and replace the brake linings if wear is approaching

the lining wear limit.

d. Check the brake linings for glazing. Inspect the brake drum or rotor surface and re-

place, along with the brake linings, if the surface is not smooth or even.

e. Check the brake pad or shoe mounting areas for a lack of lubricant or the presence of

surface rust. Clean and lubricate with a recommended high temperature brake grease.

3. Brakes make a flrindinfl noise

a. Check the brake linings and brake surface areas for severe wear or damage. Replace

worn or damaged parts.

b. Check for a seized or partially seized brake causing premature or uneven brake wear,

excessive heat and brake rotor or drum damage. Replace defective parts and inspect

the wheel bearing condition, which could have been damaged due to excessive heat.

4. Vehicle pulls to one side during braking

a. Check for air in the brake hydraulic system. Inspect the brake hydraulic seals, fluid

lines and related components for fluid leaks. Remove the air from the brake system by bleeding the brakes. Be sure to use fresh brake fluid that meets the manufacturers rec-

ommended standards.

b. Check for an internally restricted flexible brake hydraulic hose. Replace the hose and

flush the brake system.

c. Check for a seizing brake hydraulic component such as a brake caliper. Check the

caliper piston for surface damage such as rust, and measure for out-of-round wear

and caliper-to-piston clearance. Overhaul or replace failed parts and flush the brake

system.

d. Check the vehicle’s alignment and inspect for suspension wear. Replace worn bush-

ings, ball joints and set alignment to the manufacturers specifications.

e. If the brake system uses drum brakes front or rear, check the brake adjustment. Inspect

for seized adjusters and clean or replace, then properly adjust.

5. Brake pedal feels spongy or has excessive travel

a. Check the brake fluid level and condition. If the fluid is contaminated or has not been

flushed every two years, clean the master cylinder reservoir, and bleed and flush the

brakes using fresh brake fluid that meets the manufacturers recommended standards.

b. Check for a weak or damaged flexible brake hydraulic hose. Replace the hose and

flush the brake system.

c. If the brake system uses drum brakes front or rear, check the brake adjustment. Inspect

for seized adjusters and clean or replace, then properly adjust.

6. Brake pedal feel is firm, but brakes lack sufficient stopping power or

fade

a. Check the operation of the brake booster and brake booster check valve: Replace worn

or failed parts.

b. Check brake linings and brake surface areas for glazing and replace worn or damaged

parts.

c. Check for seized hydraulic parts and linkages, and clean or replace as needed.

7. Vehicle has excessive front end dive or locks rear brakes too easily

a. Check for worn, failed or seized brake proportioning valve and replace the valve.

b. Check for a seized, disconnected or missing spring or linkage for the brake propor-

tioning valve. Replace missing parts or repair as necessary.

Page 394 of 408

IJront Wheel or Wheel Bearing Loose

All Wheel and Four Wheel Drive Vehicles a. Torque lug nuts and axle nuts to specification and recheck for looseness.

b. Wheel bearing worn or damaged. Replace wheel bearing.

Front Wheel Drive Vehicles

a. Torque lug nuts and axle nuts to specification and recheck for looseness.

b. Wheel bearing worn or damaged. Replace wheel bearing.

Rear Wheel Drive Vehicles a. Wheel bearing out of adjustment. Adjust wheel bearing to specification; if still loose,

replace.

b. Torque lug nuts to specification and recheck for looseness.

c. Wheel bearing worn or damaged. Replace wheel bearing.

2. Rear Wheel or Wheel Bearing Loose

All Wheel and Four Wheel Drive Vehicles a. Torque lug nuts and axle nuts to specification and recheck for looseness.

b. Wheel bearing worn or damaged. Replace wheel bearing.

Front Wheel Drive Vehicles a. Wheel bearing out of adjustment. Adjust wheel bearing to specification; if still loose,

replace.

b. Torque lug nuts to specification and recheck for looseness.

c. Wheel bearing worn or damaged. Replace wheel bearing.

Rear Wheel Drive Vehicles a. Torque lug nuts and to specification and recheck for looseness.

b. Wheel bearing worn or damaged. Replace wheel bearing.

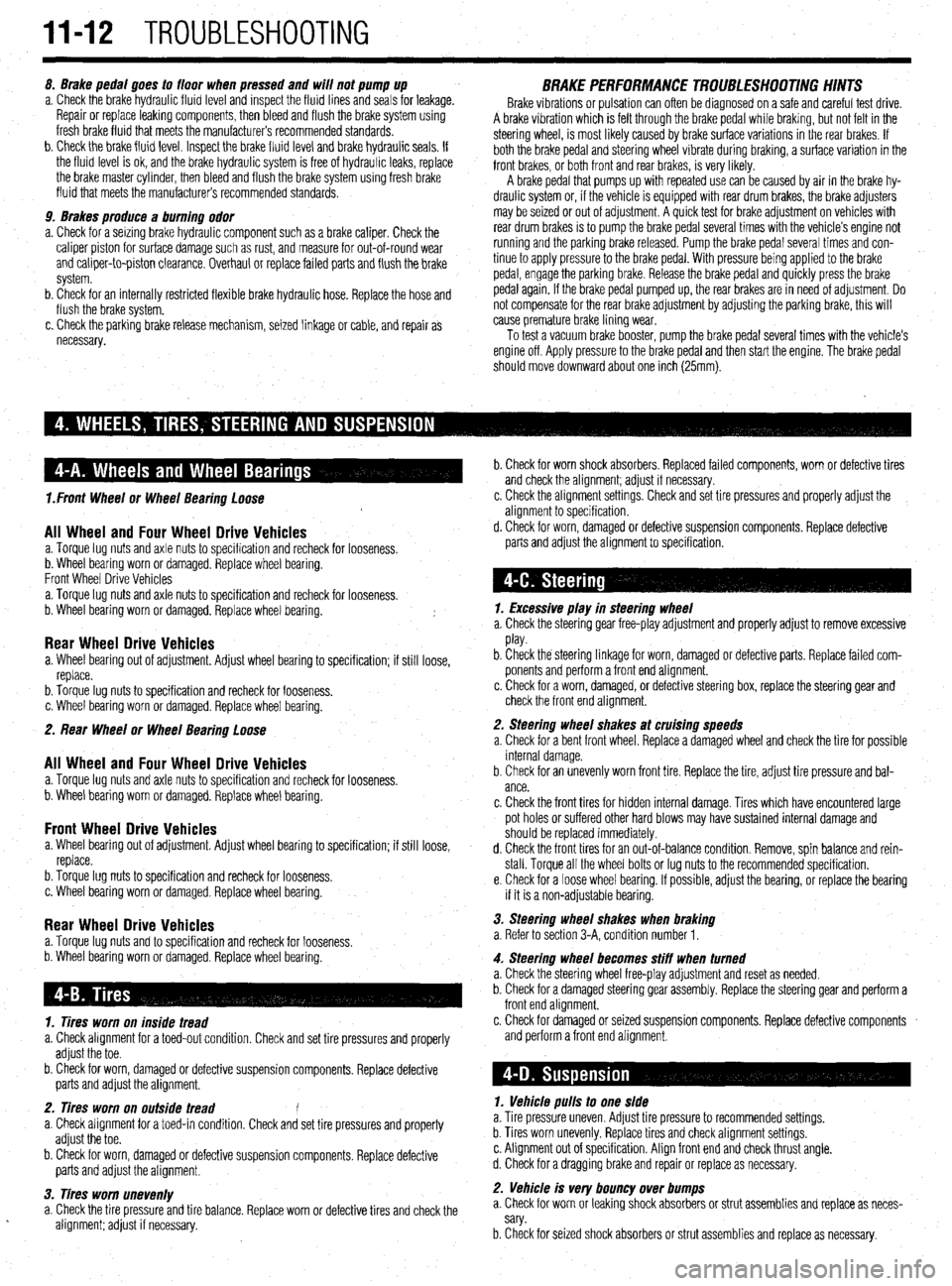

11-12 TROUBLESHOOTING

8. Brake pedal goes to floor when pressed and will not pump up

a. Check the brake hydraulic fluid level and inspect the fluid lines and seals for leakage.

Repair or replace leaking components, then bleed and flush the brake system using

fresh brake fluid that meets the manufacturer’s recommended standards.

b. Check the brake fluid level. Inspect the brake fluid level and brake hydraulic seals. If

the fluid level is ok, and the brake hydraulic system is free of hydraulic leaks, replace

the brake master cylinder, then bleed and flush the brake system using fresh brake

fluid that meets the manufacturer’s recommended standards.

9. Brakes produce a burning odor

a. Check for a seizing brake hydraulic component such as a brake caliper. Check the

caliper piston for surface damage such as rust, and measure for out-of-round wear

and caliper-to-piston clearance. Overhaul or replace failed parts and flush the brake

system.

b. Check for an internally restricted flexible brake hydraulic hose. Replace the hose and

flush the brake system.

c. Check the parking brake release mechanism, seized linkage or cable, and repair as

necessary. BRAKE PERFORMANCE TROU5LESHOOTINc; HIIVTS Brake vibrations or pulsation can often be diagnosed on a safe and careful test drive.

A brake vibration which is felt through the brake pedal while braking, but not felt in the

steering wheel, is most likely caused by brake surface variations in the rear brakes. If

both the brake pedal and steering wheel vibrate during braking, a surface variation in the

front brakes, or both front and rear brakes, is very likely.

A brake pedal that pumps up with repeated use can be caused by air in the brake hy-

draulic system or, if the vehicle is equipped with rear drum brakes, the brake adjusters

may be seized or out of adjustment. A quick test for brake adjustment on vehicles with

rear drum brakes is to pump the brake pedal several times with the vehicle’s engine not

running and the parking brake released. Pump the brake pedal several times and con-

tinue to apply pressure to the brake pedal. With pressure being applied to the brake

pedal, engage the parking brake. Release the brake pedal and quickly press the brake

pedal again. If the brake pedal pumped up, the rear brakes are in need of adjustment. Do

not compensate for the rear brake adjustment by adjusting the parking brake, this will

cause premature brake lining wear.

To test a vacuum brake booster, pump the brake pedal several times with the vehicle’s

engine off. Apply pressure to the brake pedal and then start the engine. The brake pedal

should move downward about one inch (25mm).

1. Tires worn on inside tread

a. Check alignment for a toed-out condition. Check and set tire pressures and properly

adjust the toe.

b. Check for worn, damaged or defective suspension components. Replace defective

parts and adjust the alignment.

2. Tires worn on outside tread e

a. Check alignment for a toed-in condition. Check and set tire pressures and properly

adjust the toe.

b. Check for worn, damaged or defective suspension components. Replace defective

parts and adjust the alignment.

3. Tires worn unevenly

a. Check the tire pressure and tire balance. Replace worn or defective tires and check the

.

alignment; adjust if necessary. b. Check for worn shock absorbers. Replaced failed components, worn or defective tires

and check the alignment; adjust if necessary.

c. Check the alignment settings. Check and set tire pressures and properly adjust the

alignment to specification.

d. Check for worn, damaged or defective suspension components. Replace defective

parts and adjust the alignment to specification,

1. Excessive play in steering wheel

a. Check the steering gear free-play adjustment and properly adjust to remove excessive

play.

b. Check the steering linkage for worn, damaged or defective parts. Replace failed com-

ponents and perform a front end alignment.

c. Check for a worn, damaged, or defective steering box, replace the steering gear and

check the front end alignment.

2. Steering wheel shakes at cruising speeds

a. Check for a bent front wheel. Replace a damaged wheel and check the tire for possible

internal damage.

b. Check for an unevenly worn front tire. Replace the tire, adjust tire pressure and bal-

ance.

c. Check the front tires for hidden internal damage. Tires which have encountered large

pot holes or suffered other hard blows may have sustained internal damage and

should be replaced immediately.

d. Check the front tires for an out-of-balance condition. Remove, spin balance and rein-

stall. Torque all the wheel bolts or lug nuts to the recommended specification.

e. Check for a loose wheel bearing. If possible, adjust the bearing, or replace the bearing

if it is a non-adjustable bearing.

3. Steering wheel shakes when braking

a. Refer to section 3-A, condition number 1.

4. Steering wheel becomes stiff when turned

a. Check the steering wheel free-play adjustment and reset as needed.

b. Check for a damaged steering gear assembly. Replace the steering gear and perform a

front end alignment.

c. Check for damaged or seized suspension components. Replace defective components

and perform a front end alignment.

1. Vehicle pulls to one side

a. Tire pressure uneven. Adjust tire pressure to recommended settings.

b. Tires worn unevenly. Replace tires and check alignment settings.

c. Alignment out of specification. Align front end and check thrust angle.

d. Check for a dragging brake and repair or replace as necessary.

2. Vehicle is very bouncy over bumps

a. Check for worn or leaking shock absorbers or strut assemblies and replace as neces-

sary.

b. Check for seized shock absorbers or strut assemblies and replace as necessary.