power steering fluid MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 10 of 408

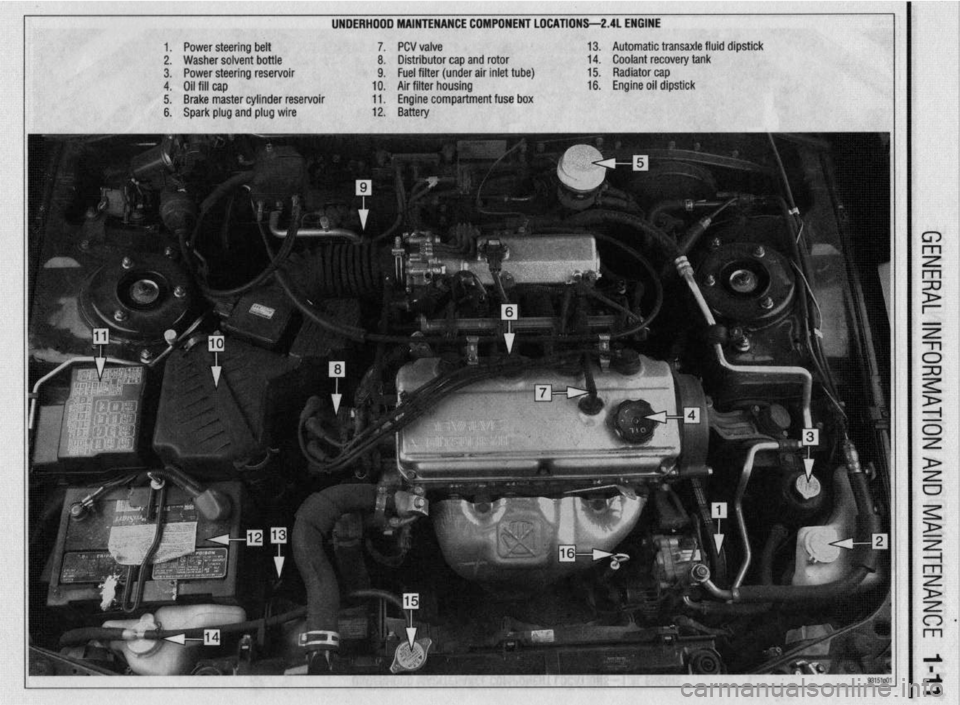

UNDERHDDD MAINTENANCE COMPONENT LOCATIONS-2AL ENGINE

II

1. Power steering belt 7. PCV valve

2. Washer solvent bottle 8. Distributor cap and rotor

3. Power steering reservoir 9. Fuel filter (under air inlet tube)

4. Oil fill cap 10. Air filter housing

5. Brake master cylinder reservoir 11. Engine compartment fuse box

6. Spark plug and plug wire 12. Battery 13. Automatic transaxle fluid dipstick

14. Coolant recovery tank

15. Radiator cap

16. Engine oil dipstick

Page 11 of 408

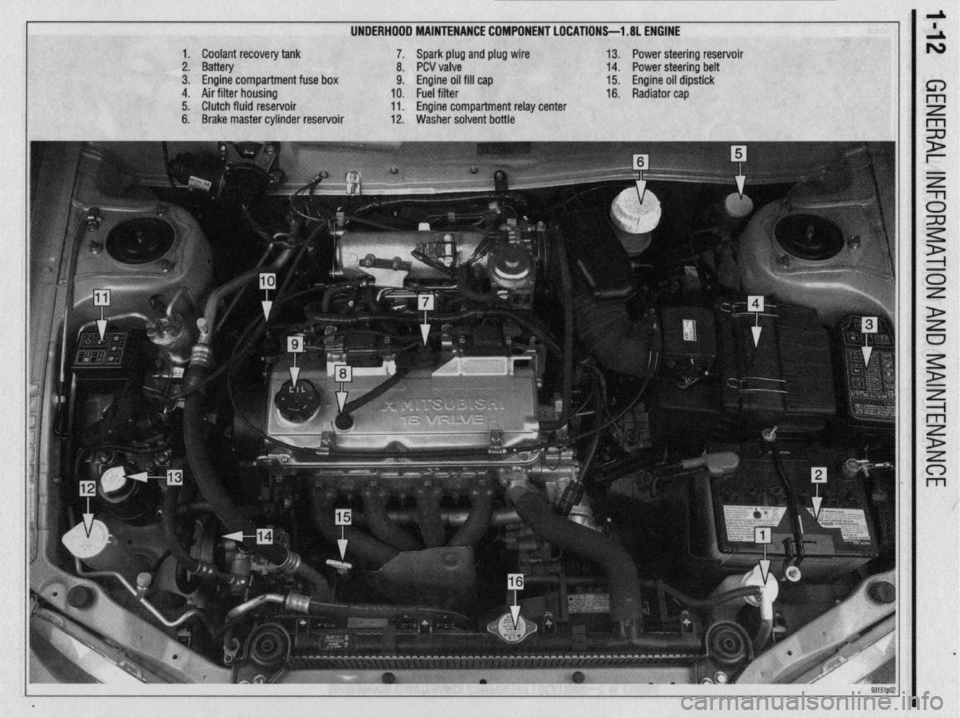

UNDERHOOD MAINTENANCE COMPONENT LOCATIONS-l .8L ENGINE

1. Coolant recovery tank

2. Battery

3. Engine compartment fuse box

4. Air filter housing

5. Clutch fluid reservoir

6. Brake master cylinder reservoir 7. Spark plug and plug wire

8. PCV valve

9. Engine oil fill cap

10. Fuel filter

11. Engine compartment relay center

12. Washer solvent bottle 13. Power steering reservoir

14. Power steering belt

15. Engine oil dipstick

16. Radiator cap

Page 41 of 408

1-42 GENERAL~INFORMATION AND MAINTENANCE

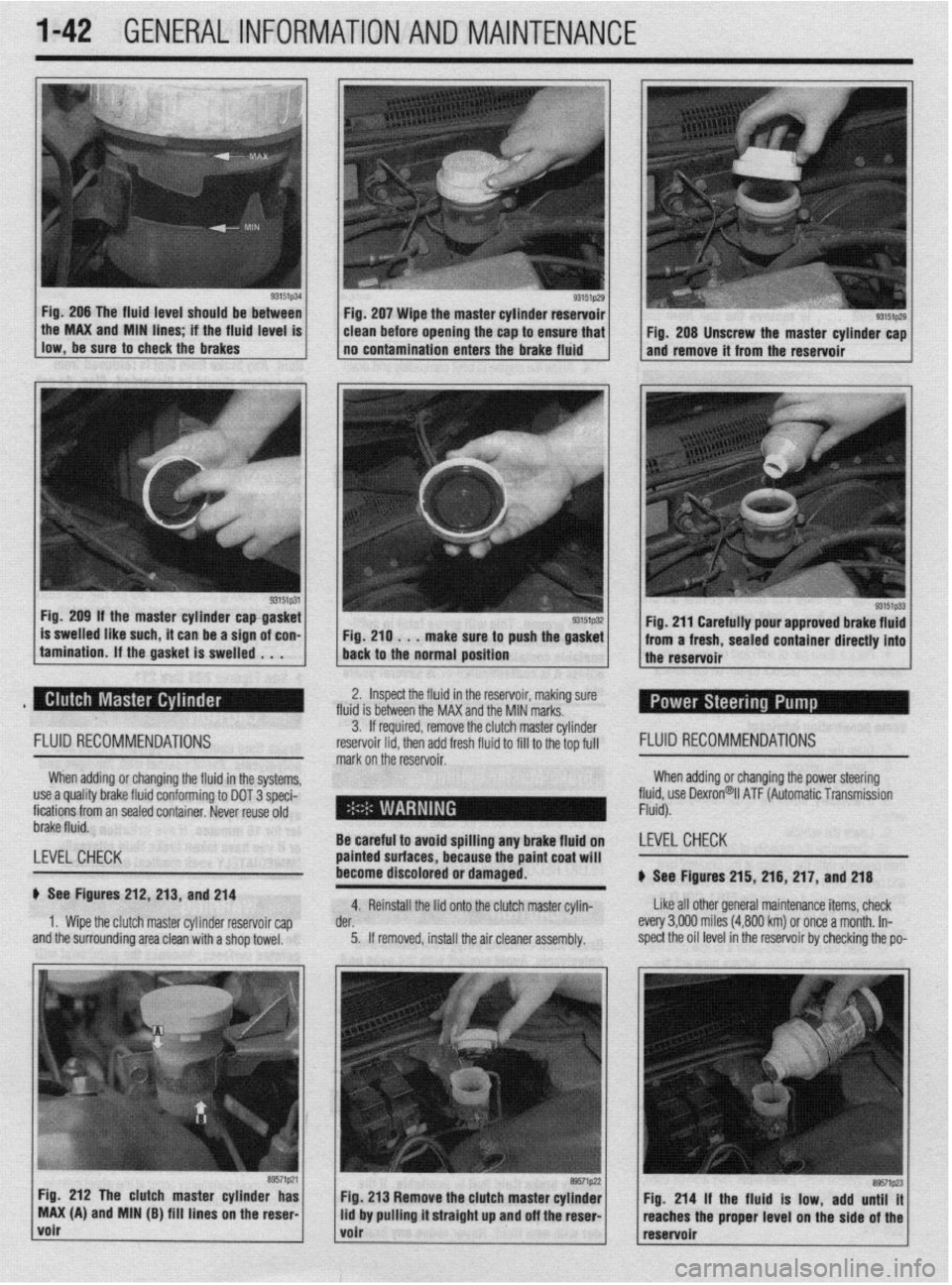

Fig. 206 The fluid level should be between

llow,be*“retoch~ckiebrake~ . the MAX and MIN hnes if the fhud level IS

93151p31 Fig. 209 If the master cylinder capgasket

is swelled like such, it can be a sign of con-

tamination. If the gasket is swelled . . . Fig. 207 Wipe the master cylinder reservoir

clean before opening the cap to ensure that

no contamination enters the brake fluid

Fig. 210 . . .

make sure to push the gasket

back to the normal position

93151p29 I Fig. 208 Unscrew the master cylinder cap

and remove it from the reservoir

Fig. 211 Carefully pour approved brake fluid

from a fresh, sealed container directly into

the reservoir

2. Inspect the fluid in the reservoir, making sure

fluid is between the MAX and the MIN marks.

FLUID RECOMMENDATIONS

When adding or changing the fluid in the systems,

use a quality brake fluid conforming to DOT 3 speci-

fications from an sealed container. Never reuse old

brake fluid.

LEVEL CHECK

b See Figures 212, 213, and 214

1. Wipe the clutch master cylinder reservoir cap

and the surrounding area clean with a shop towel. 3. If required, remove the clut ch master cylinder

reservoir lid. then add fresh fluid I FLUID RECOMMENDATIONS

mark on the’reservoir. to fill to the top full

When adding or changing the power steering

fll$,“” Dexron@il ATF (Automatic Transmission

-

- .

Be careful to avoid sf Billing any brake fluid on LEVELCHECK

painted surfaces, bet

:ause the paint coat will

become discolored or damaged.

b See Figures 215, 216, 217, and 218

4. Reinstall the lid onto the clutch master cylin- Like all other general maintenance items, check

der. every 3,OOfl miles (4,800 km) or once a month. In-

5. If removed, install the air cleaner assembly. spect the oil level in the reservoir by checking the po-

Fig. 212 The clutch master cylinder has

MAX (A) and MIN (B) fill lines on the reser

volr

Page 42 of 408

GENERALINFORMATIONAND MAINTENANCE l-43

l Special car washing detergent is the best to

use. Liquid dishwashing detergent can remove wax

and leave the car’s paint unprotected and in addition

some liquid detergents contains abrasives which can

scratch the paint.

l Bird droppings should be removed from the

paintwork as soon as possible, otherwise the finish

may be permanently stained.

When the car is driven immediately after be-

ing washed, apply the brakes several times

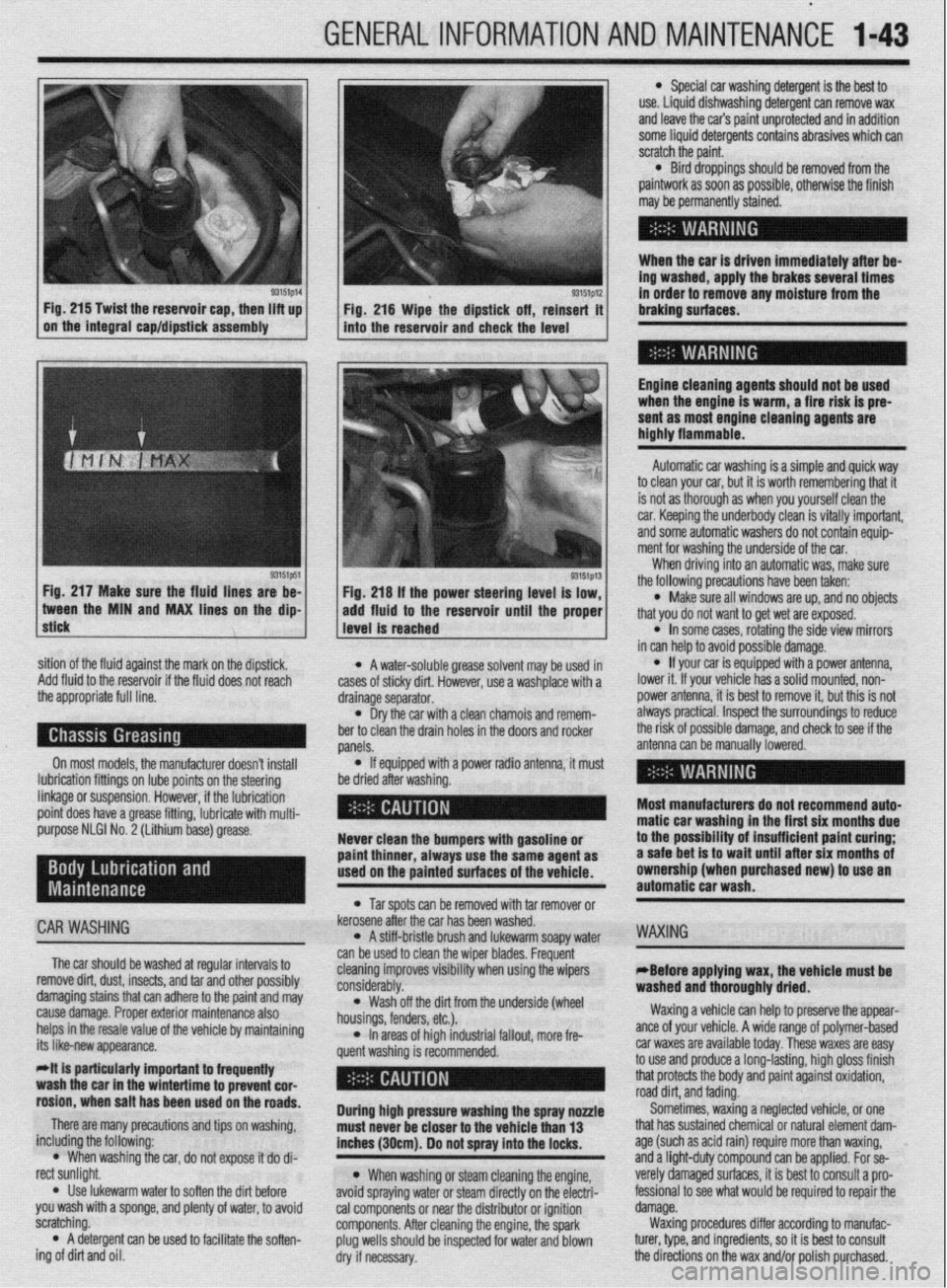

93151p14 93151p12 Fig. 215 Twist the reservoir cap, then lift up

I I

in order to remove any moisture from the

Fig. 216 Wipe the dipstick off, reinsert it braking surfaces.

on the integral cap/dipstick assembly

into the reservoir and check the level

I

Engine cleaning agents should not be used

when the engine is warm, a fire risk is pre-

sent as most engine cleaning agents are

highly flammable.

sition of the fluid against the mark on the dipstick,

Add fluid to the reservoir if the fluid does not reach

the appropriate full line.

On most models, the manufacturer doesn’t install

lubrication fittings on lube points on the steering

linkage or suspension. However, if the lubrication

point does have a grease fitting, lubricate with multi-

purpose NLGI No. 2 (Lithium base) grease.

CAR WASHING

The car should be washed at regular intervals to

remove dirt, dust, insects, and tar and other possibly

damaging stains that can adhere to the paint and may

cause damage. Proper exterior maintenance also

helps in the resale value of the vehicle by maintaining

its like-new appearance.

Mt is particularly important ta frequentiy

wash the car in the wintertime to prevent cor-

rosion, when salt has been used on the roads.

There are many precautions and tips on washing,

including the following:

l When washing the car, do not expose it do di-

rect sunlight.

. Use lukewarm water to soften the dirt before

you wash with a sponge, and plenty of water, to avoid

scratching.

l A detergent can be used to facilitate the soften-

ing of dirt and oil. * A water-soluble grease solvent may be used in

cases of sticky dirt. However, use a washplace with a

drainage separator.

l Dry the car with a clean chamois and remem-

ber to clean the drain holes in the doors and rocker

panels.

l If equipped with a power radio antenna, it must

be dried after washing.

Never clean the bumpers with gasoline or

paint thinner, always use the same agent as

used on the painted surfaces of the vehicle.

l Tar spots can be removed with tar remover or

kerosene after the car has been washed.

l A stiff-bristle brush and lukewarm soapy water

can be used to clean the wiper blades. Frequent

cleaning improves visibility when using the wipers

considerably.

l Wash off the did from the underside (wheel

housings, fenders, etc.).

l In areas of high industrial fallout, more fre-

quent washing is recommended.

During high pressure washing the spray nonle

must never be closer to the vehicle than 13

inches (30cm). Do not spray into the locks.

l When washing or steam cleaning the engine,

avoid spraying water or steam directly on the electri-

cal components or near the distributor or ignition

components. After cleaning the engine, the spark

plug wells should be inspected for water and blown

dry if necessary. Automatic car washing is a simple and quick way

to clean your car, but it is worth remembering that it

is not as thorough as when you yourself clean the

car. Keeping the underbody clean is vitally important,

and some automatic washers do not contain equip-

ment for washing the underside of the car.

When driving into an automatic was, make sure

the following precautions have been taken:

l Make sure all windows are up, and no objects

that you do not want to get wet are exposed.

l In some cases, rotating the side view mirrors

in can help to avoid possible damage.

l If your car is equipped with a power antenna,

lower it. If your vehicle has a solid mounted, non-

power antenna, it is best to remove it, but this is not

always practical. Inspect the surroundings to reduce

the risk of possible damage, and check to see if the

antenna can be manually lowered.

Most manufacturers do not recommend auto-

matic car washing in the first six months due

to the possibility of insufficient paint curing;

a safe bet is to wait until after six months of

ownership (when purchased new) to use an

automatic car wash.

WAXING

eBefore applying wax, the vehicle must be

washed and thoroughly dried.

Waxing a vehicle can help to preserve the appear-

ante of your vehicle. A wide range of polymer-based

car waxes are available today. These waxes are easy

to use and produce a long-lasting, high gloss finish

that protects the body and paint against oxidation,

road dirt, and fading.

Sometimes, waxing a neglected vehicle, or one

that has sustained chemical or natural element dam-

age (such as acid rain) require more than waxing,

and a light-duty compound can be applied. For se-

verely damaged surfaces, it is best to consult a pro-

fessional to see what would be required to repair the

damage.

Waxing procedures differ according to manufac-

turer, type, and ingredients, so it is best to consult

the directions on the wax and/or polish purchased.

Page 63 of 408

3-2 ENGINEANDENGINEOVERHAUL

REMOVAL &INSTALLATION

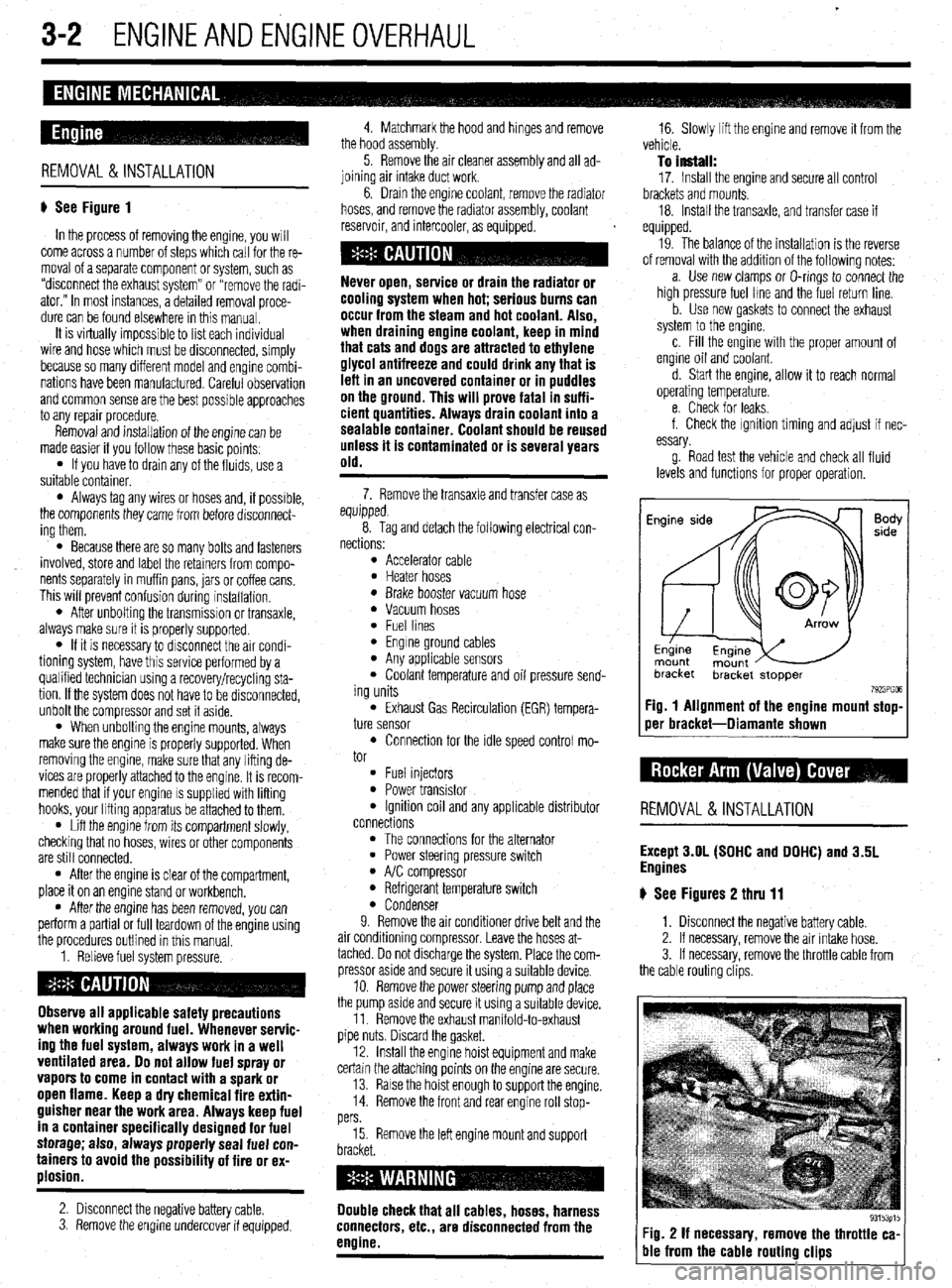

# See Figure 1

In the process of removing the engine, you will

come across a number of steps which call for the re-

moval of a separate component or system, such as

“disconnect the exhaust system” or “remove the radi-

ator.” In most instances, a detailed removal proce-

dure can be found elsewhere in this manual.

It is virtually impossible to list each individual

wire and hose which must be disconnected, simply

because so many different model and engrne combi-

nations have been manufactured Careful observation

and common sense are the best possible approaches

to any repair procedure.

Removal and installation of the engine can be

made easier if you follow these basic points:

l If you have to drain any of the fluids, use a

suitable container.

l Always tag any wires or hoses and, if possrble,

the components they came from before disconnect-

ing them.

l Because there are so many bolts and fasteners

involved, store and label the retainers from compo-

nents separately in muffin pans, jars or coffee cans.

This will prevent confusion during installatron.

l After unbolting the transmisston or transaxle,

always make sure it is properly supported.

l If it is necessary to disconnect the air condi-

tioning system, have this service performed by a

qualified technician using a recovery/recycling sta-

tion If the system does not have to be disconnected,

unbolt the compressor and set it aside.

l When unbolting the engine mounts, always

make sure the engine is properly supported. When

removing the engine, make sure that any lifting de-

vices are properly attached to the engine. It is recom-

mended that if your engine IS supplied with lifting

hooks, your lifting apparatus be attached to them.

l Lift the engine from its compartment slowly,

checking that no hoses, wires or other components

are still connected.

l After the engine is clear of the compartment,

place it on an engine stand or workbench.

l After the engine has been removed, you can

perform a partial or full teardown of the engine using

the procedures outlined in this manual.

1. Relieve fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect the negative battery cable.

3. Remove the engine undercover if equipped. 4. Matchmark the hood and hinges and remove

the hood assembly.

5. Remove the air cleaner assembly and all ad-

joining air intake duct work.

6. Drain the engine coolant, remove the radiator

hoses, and remove the radiator assembly, coolant

reservoir, and intercooler, as equipped.

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

7. Remove the transaxle and transfer case as

equipped.

8. Tag and detach the following electrical con-

nections:

l Accelerator cable l Heater hoses l Brake booster vacuum hose l Vacuum hoses l Fuel lines l Engine ground cables l Any applicable sensors l Coolant temperature and oil pressure send-

ing units

l Exhaust Gas Recirculation (EGR) tempera-

ture sensor

l Connection for the idle speed control mo-

tor

l Fuel injectors l Power transistor l Ignition coil and any applicable distributor

connections

l The connections for the alternator l Power steering pressure switch l A/C compressor l Refrigerant temperature switch l Condenser

9. Remove the air conditioner drive belt and the

air conditioning compressor. Leave the hoses at-

tached. Do not discharge the system. Place the com-

pressor aside and secure it using a suitable device.

10. Remove the power steering pump and place

the pump asrde and secure it using a surtable device.

11. Remove the exhaust manifold-to-exhaust

pipe nuts. Discard the gasket.

12. Install the engine hoist equipment and make

certain the attaching points on the engine are secure.

13. Raise the hoist enough to support the engine.

14. Remove the front and rear engine roll stop-

pers

15. Remove the left engine mount and support

Double check that all cables, hoses, harness

connectors, etc., are disconnected from the

engine.

16. Slowly lift the engine and remove it from the

vehicle.

To install:

17. Install the engine and secure all control

brackets and mounts.

18. Install the transaxle, and transfer case if

equipped.

19. The balance of the installation is the reverse

of removal with the addition of the following notes:

a. Use new clamps or O-rings to connect the

high pressure fuel lme and the fuel return line.

b. Use new gaskets to connect the exhaust

system to the engine.

c. Fill the engine with the proper amount of

engine oil and coolant.

d. Start the engine, allow it to reach normal

operating temperature.

e. Check for leaks.

f. Check the ignition timing and adjust if nec-

essary.

g. Road test the vehicle and check all fluid

levels and functions for proper operation.

Fig. 1 Alignment of the engine mount stop-

oer bracket-Diamante shown

REMOVAL &INSTALLATION

Except 3.OL (SOHC and DOHC) and 3.5L

Engines

# See Figures 2 thru 11

1. Disconnect the negative battery cable.

2. If necessary, remove the air intake hose.

3. If necessary, remove the throttle cable from

the cable routing clips.

Fig. 2 If necessary, remove the throttle ca-

ble from the cable routing clips

Page 81 of 408

.

3-20 ENGINEANDENGINEOVERHAUL

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the overflow hose and disconnect

the upper radiator hose.

*It is recommended that each clamp be

matchmarked to the hose. Observe the marks

and reinstall the clamps exactly when rein-

stalling the radiator.

4. If equipped with an automatic transaxle, re-

move and plug the fluid cooler hoses.

5. Unplug the electrical connector(s) from the

coolant fan motor.

6. Remove the mounting bolts, then remove the

fan and shroud assembly from the vehicle.

7. Remove the fan blade retainer nut from the

shaft on the fan motor and separate the fan from the

motor.

8. Remove the motor to shroud attaching

screws and the motor from the shroud.

To tnstall: 9. Install the motor to the shroud and secure

with the mounting bolts.

10. Install the remaining components in the re-

verse order of removal.

11. Fill the coohng system. Connect the negative

battery cable and check the cooling fan for proper op-

eration.

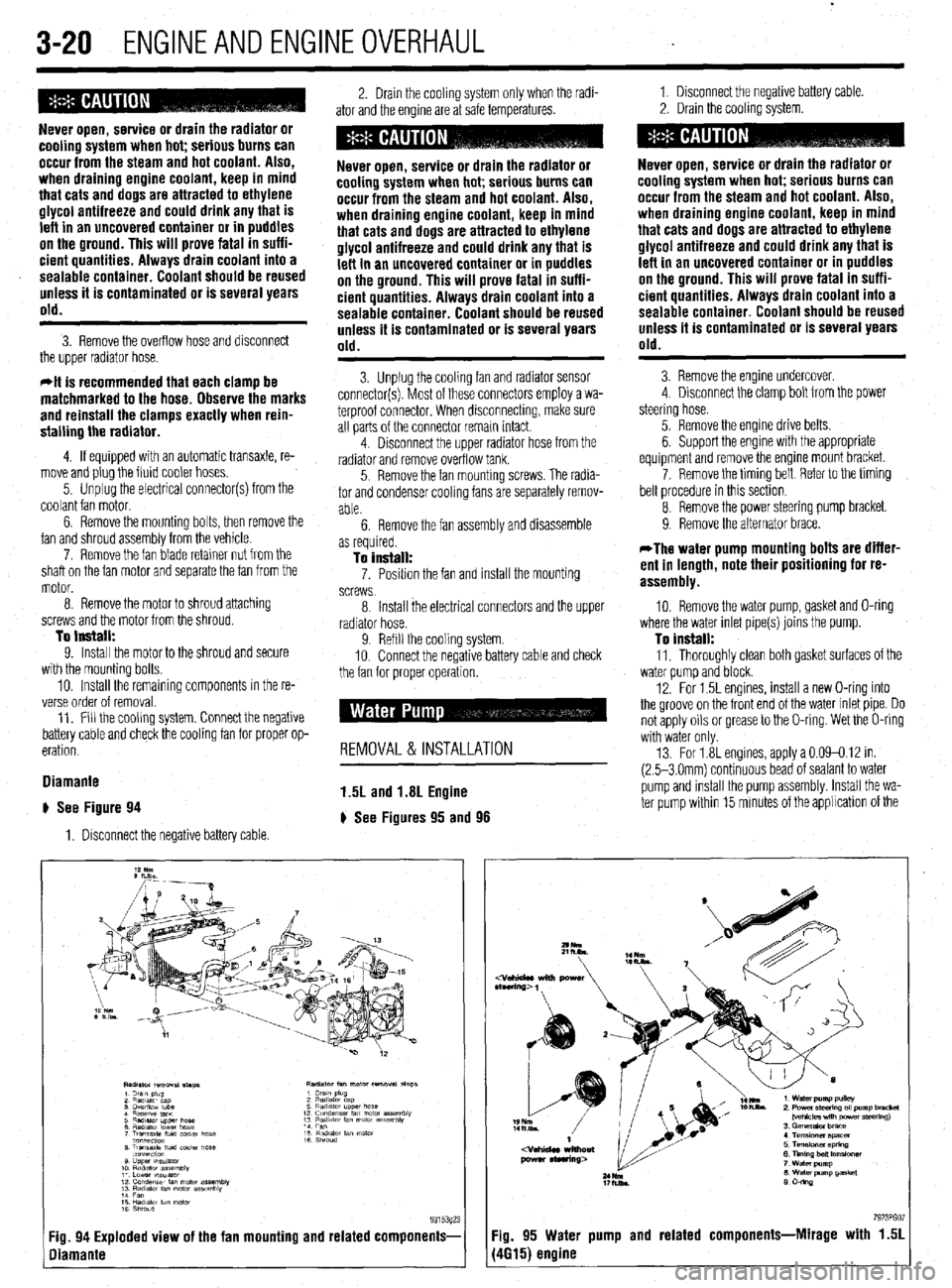

Diamante

# See Figure 94

1. Disconnect the negative battery cable 2. Drain the cooling system only when the radi-

ator and the engine are at safe temperatures. 1. Disconnect the negative battery cable

2. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Unplug the cooling fan and radiator sensor

connector(s). Most of these connectors employ a wa-

terproof connector. When disconnecting, make sure

all parts of the connector remain intact.

4. Disconnect the upper radiator hose from the

radiator and remove overflow tank.

5. Remove the fan mounting screws. The radia-

tor and condenser cooling fans are separately remov-

able.

6. Remove the fan assembly and disassemble

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the engine undercover.

4 Disconnect the clamp bolt from the power

steering hose.

5. Remove the engine drive belts.

6. Support the engine with the appropriate

equipment and remove the engine mount bracket.

7. Remove the timing belt Reier to the timing

belt procedure in this section

8 Remove the power steering pump bracket.

9. Remove the alternator brace.

as required.

To install: 7. Posrtion the fan and install the mounting

screws

*The water pump mounting bolts are differ-

ent in length, note their positioning for re-

assembly.

8 Install the electrical connectors and the upper

radiator hose.

9. Refill the cooling system.

IO. Connect the negative battery cable and check

the fan for orooer ooeration. 10. Remove the water pump, gasket and O-ring

where the water inlet pipe(s) joins the pump.

To install: 11, Thoroughly clean both gasket surfaces of the

water oumo and block.

12. For 1.5L engines, install a new O-ring into

the groove on the front end of the water inlet pipe. Do

not apply oils or grease to the O-ring. Wet the O-ring

with water only

13. For 1.8L engines, apply a 0.09-0.12 in.

(2.5-3 Omm) continuous bead of sealant to water

pump and rnstall the pump assembly. Install the wa-

ter pump within 15 minutes of the applrcation of the

REMOVAL & INSTALLATION

1.5L and 1.8L Engine

) See Figures 95 and 98

7923PGO :ig. 94 Exploded view of the fan mounting and related components- Fig. 95 Water pump and related components-Mirage with 1.51

liamante (4615) engine

Page 106 of 408

ENGlNEANDENGlNEOVERHiUL 3-45

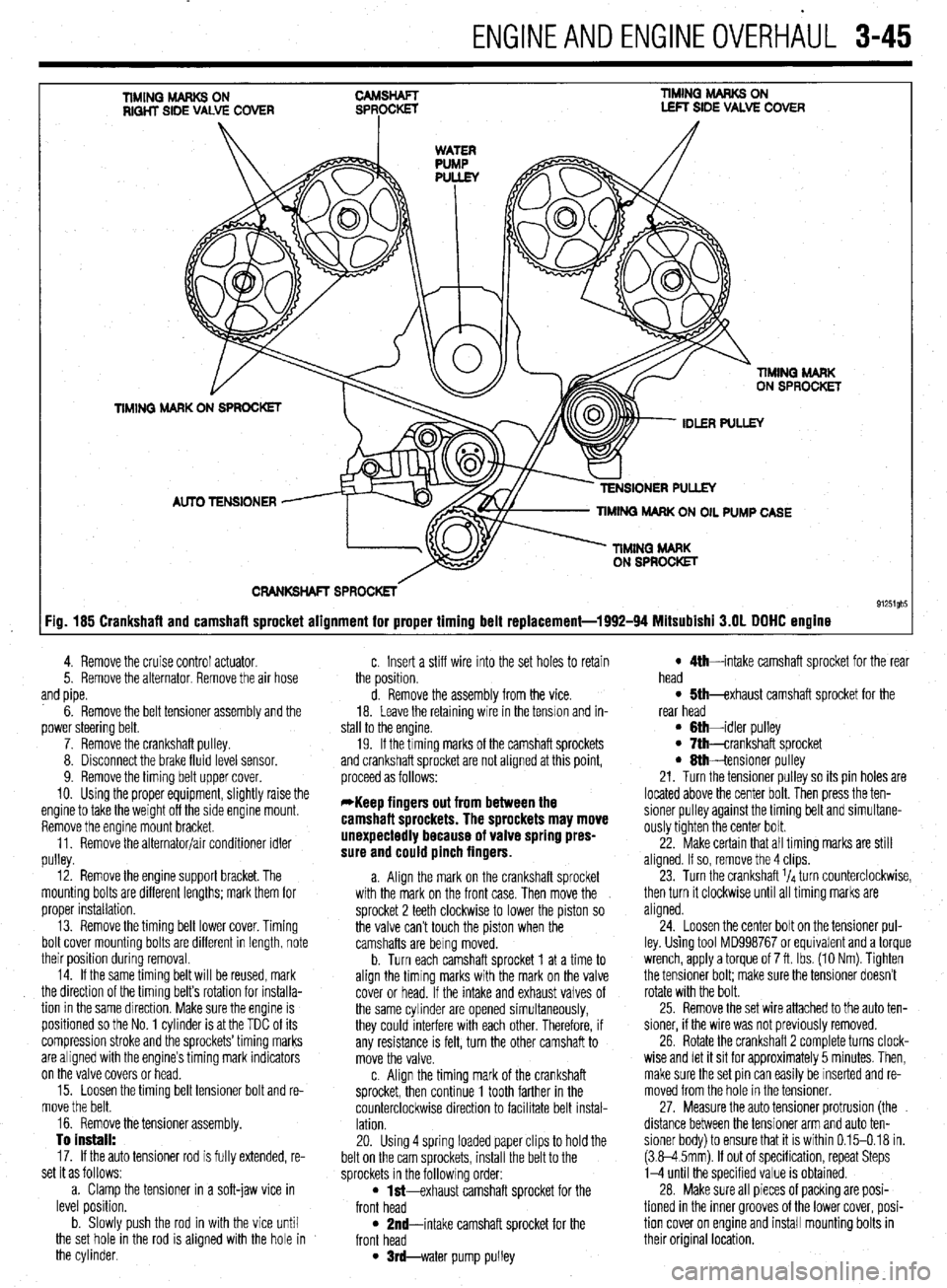

TIMINQ MARKS ON RIQHT SIDE VALVE COVER TIMING MARKS ON LEFT SIDE VALVE COVER

CRANKSHAFT SPROCKETS

91251gb5 :ig. 185 Crankshaft and camshaft sprocket alignment for proper timing belt replacement-1992-94 Mitsubishi 3.OL DOHC engine

4. Remove the cruise control actuator.

5. Remove the alternator. Remove the air hose

and pipe.

6. Remove the belt tensioner assembly and the

power steering belt.

7. Remove the crankshaft pulley.

8. Disconnect the brake fluid level sensor.

9. Remove the timing belt upper cover.

10. Using the proper equipment, slightly raise the

engine to take the weight off the side engine mount.

Remove the engine mount bracket.

11. Remove the alternator/air conditioner idler

pulley.

12. Remove the engine support bracket. The

mounting bolts are different lengths; mark them for

proper installation.

13. Remove the timing belt lower cover. Timing

bolt cover mounting bolts are different in length, note

their position during removal.

14. If the same timing belt will be reused, mark

the direction of the timing belt’s rotation for installa-

tion in the same dlrection. Make sure the engine is

positioned so the No. 1 cylinder is at the TDC of its

compression stroke and the sprockets’timing marks

are aligned with the engine’s timing mark indicators

on the valve covers or head.

15. Loosen the timing belt tensioner bolt and re-

move the belt.

16. Remove the tensioner assembly.

To install:

17. If the auto tensioner rod is fully extended, re-

set it as follows:

a. Clamp the tensioner in a soft-jaw vice in

level position.

b. Slowly push the rod in with the vice until

the set hole in the rod is aligned with the hole in

the cylinder. c. Insert a stiff wire into the set holes to retain

the position.

d. Remove the assembly from the vice.

18. Leave the retaining wire in the tension and in-

stall to the engine.

19. If the timing marks of the camshaft sprockets

and crankshaft sprocket are not aligned at this point,

proceed as follows:

*Keep fingers out from between the

camshaft sprockets. The sprockets may move

unexpectedly because of valve spring pres-

sure and could pinch fingers.

a. Align the mark on the crankshaft sprocket

with the mark on the front case. Then move the

sprocket 2 teeth clockwise to lower the piston so

the valve can’t touch the piston when the

camshafts are being moved.

b. Turn each camshaft sprocket 1 at a time to

align the timing marks with the mark on the valve

cover or head. If the intake and exhaust valves of

the same cylinder are opened simultaneously,

they could interfere with each other. Therefore, if

any resistance is felt, turn the other camshaft to

move the valve.

c. Align the timing mark of the crankshaft

sprocket, then continue 1 tooth farther in the

counterclockwise direction to facilitate belt instal-

lation.

20. Using 4 spring loaded paper clips to hold the

belt on the cam sprockets, install the belt to the

sprockets in the following order:

l M-exhaust camshaft sprocket for the

front head

l 2nd-intake camshaft sprocket for the

front head

l trd-water pump pulley

l 5th-exhaust camshaft sprocket for tile

rear head

l Ah-intake camshaft sprocket for the rear

l Gth-idler pulley head l 7th-crankshaft sprocket l 8th-tensioner pulley

21. Turn the tensioner pulley so its pin holes are

located above the center bolt. Then press the ten-

sioner pulley against the timing belt and simultane-

ously tighten the center bolt.

22. Make certain that all timing marks are still

aligned. If so, remove the 4 clips.

23. Turn the crankshaft l/d turn counterclockwise,

then turn it clockwise until all timing marks are

aligned.

24. Loosen the center bolt on the tensioner pul-

ley. Using tool MD998767 or equivalent and a torque

wrench, apply a torque of 7 ft. Ibs. (10 Nm). Tighten

the tensioner bolt; make sure the tensioner doesn’t

rotate with the bolt.

25. Remove the set wire attached to the auto ten-

sioner, if the wire was not previously removed.

26. Rotate the crankshaft 2 complete turns clock-

wise and let it sit for approximately 5 minutes. Then,

make sure the set pin can easily be inserted and re-

moved from the hole in the tensioner.

27. Measure the auto tensioner protrusion (the

distance between the tensioner arm and auto ten-

sioner body) to ensure that it is within 0.15-0.18 in.

(3.8-4 5mm). If out of specification, repeat Steps

l-4 until the specified value is obtained.

28. Make sure all pieces of packing are posi-

tioned in the inner grooves of the lower cover, posi-

tion cover on engine and install mounting bolts in

their original location.

Page 107 of 408

3-46 ENGINEANDENGINEOVERHAUL

29. Install the engine support bracket and secure

using mounting bolts in their original location. Lubri-

cate the reaming area of the reamer bolt and tighten

slowly.

30. Install the idler pulley.

31. Install the engine mount bracket. Remove the

engine support fixture.

32. Make sure all pieces of packing are posi-

tioned in the inner grooves of the upper cover and in-

stall.

33. Connect the brake fluid level sensor.

34. Install the crankshaft pulley. Tighten the bolt

to 130-137ft. Ibs. (180-190 Nm).

35. install the belt tensioner assembly and the

power steering belt.

36 install the air hose and pipe.

37 Install the alternator.

38. Install the cruise control actuator.

39. Install the engine undercover.

40. Connect the negative battery cable.

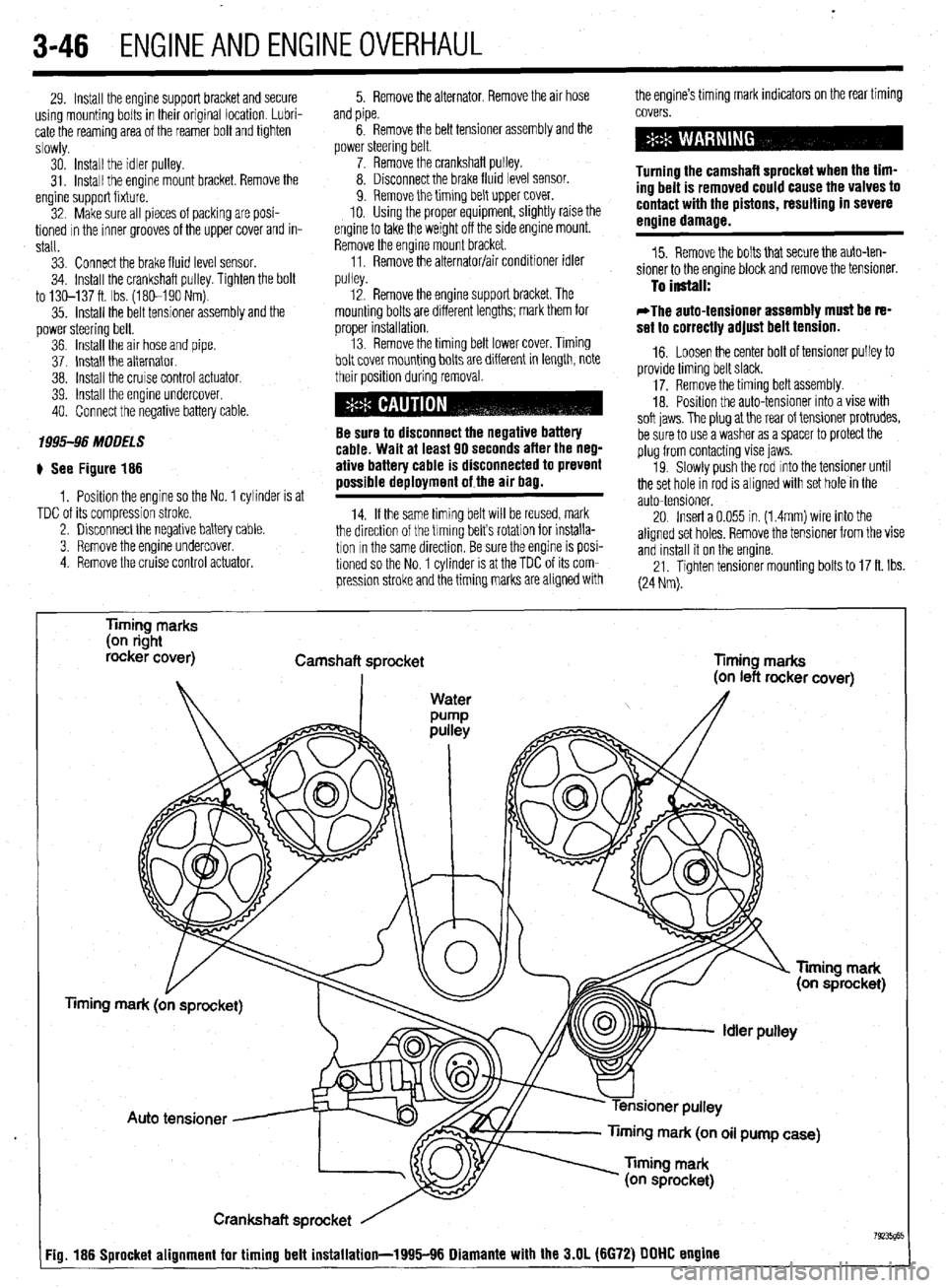

199546 MODELS

# See Figure 186

1, Position the engine so the No. 1 cylinder is at

TDC of its compression stroke.

2. Disconnect the negative battery cable.

3. Remove the engine undercover.

4 Remove the cruise control actuator. 5. Remove the alternator, Remove the air hose the engine’s timing mark indicators on the rear timing

and pipe.

6. Remove the belt tensioner assembly and the

power steering belt.

7. Remove the crankshaft pulley.

8. Disconnect the brake fluid level sensor.

9. Remove the timing belt upper cover.

10. Using the proper equipment, slightly raise the

engine to take the weight off the side engine mount.

Remove the engine mount bracket.

11, Remove the alternator/air conditioner idler

..,,ll^,. covers.

Turning the camshaft sprocket when the tim-

ing belt is removed could cause the valves to

contact with the pistons, resulting in severe

engine damage.

15. Remove the bolts that secure the auto-ten-

sioner to the engine block and remove the tensioner.

pu,ey. 12. Remove the engine support bracket. The To install:

mounting bolts are different lengths; mark them for

orooer installation. *The auto-tensioner assembly must be re-

set to correctlv adiust belt tension. , . 13. Remove the timing belt lower cover. Timing

bolt cover mounting bolts are different in length, note

their position during removal.

Be sure to disconnect the negative battery

cable. Wait at least 90 seconds after the neg-

ative battery cable is disconnected to prevent

possible deployment of the air bag.

14. If the same timing belt WIII be reused, mark

the direction of the trming belts rotation for installa-

tion In the same direction, Be sure the engine is posi-

tioned so the No. 1 cylinder is at the TDC of its com-

pression stroke and the timing marks are aligned with _ -

16. Loosen the center bolt of tensioner pulley to

provide timing belt slack.

17. Remove the timing belt assembly.

18. Posrtion the auto-tensioner into a vise with

soft iaws. The olua at the rear of tensioner protrudes,

be sure to usea v&her as a spacer to protect the

plug from contacting vise jaws.

19. Slowly push the rod mto the tensioner until

the set hole in rod is aligned with set hole in the

auto-tensioner.

20. Insert a 0.055 in. (1.4mm) wire into the

aligned set holes, Remove the tensioner from the vise

and install it on the engine.

21. Tighten tensioner mounting bolts to 17 ft. Ibs.

(24 Nm).

Timing marks

(on right

rocker cover)

Camshaft sprocket

Timing marks

mark (on oil pump case)

Crankshaft sprocket

Fig. 186 Sprocket alignment for timing belt installation-1995116 Diamante with the 3.N (6672) DDDD engine

Page 109 of 408

.

3-48 ENGINEANDENGINEOVERHAUL

32. Install the crankshaft pulley if it was removed.

Tighten the bolt to 110 ft. Ibs. (150 Nm).

33. Install the air conditioning bracket and com-

pressor on the engine. Install the belt tensioner.

34. Install the power steering pump into position.

Install the fan pulley and fan.

35. Install the fan shroud on the radiator.

36. Refill the cooling system.

I

37. Connect the negative battery cable.

38. Start the enaine and check for fluid leaks.

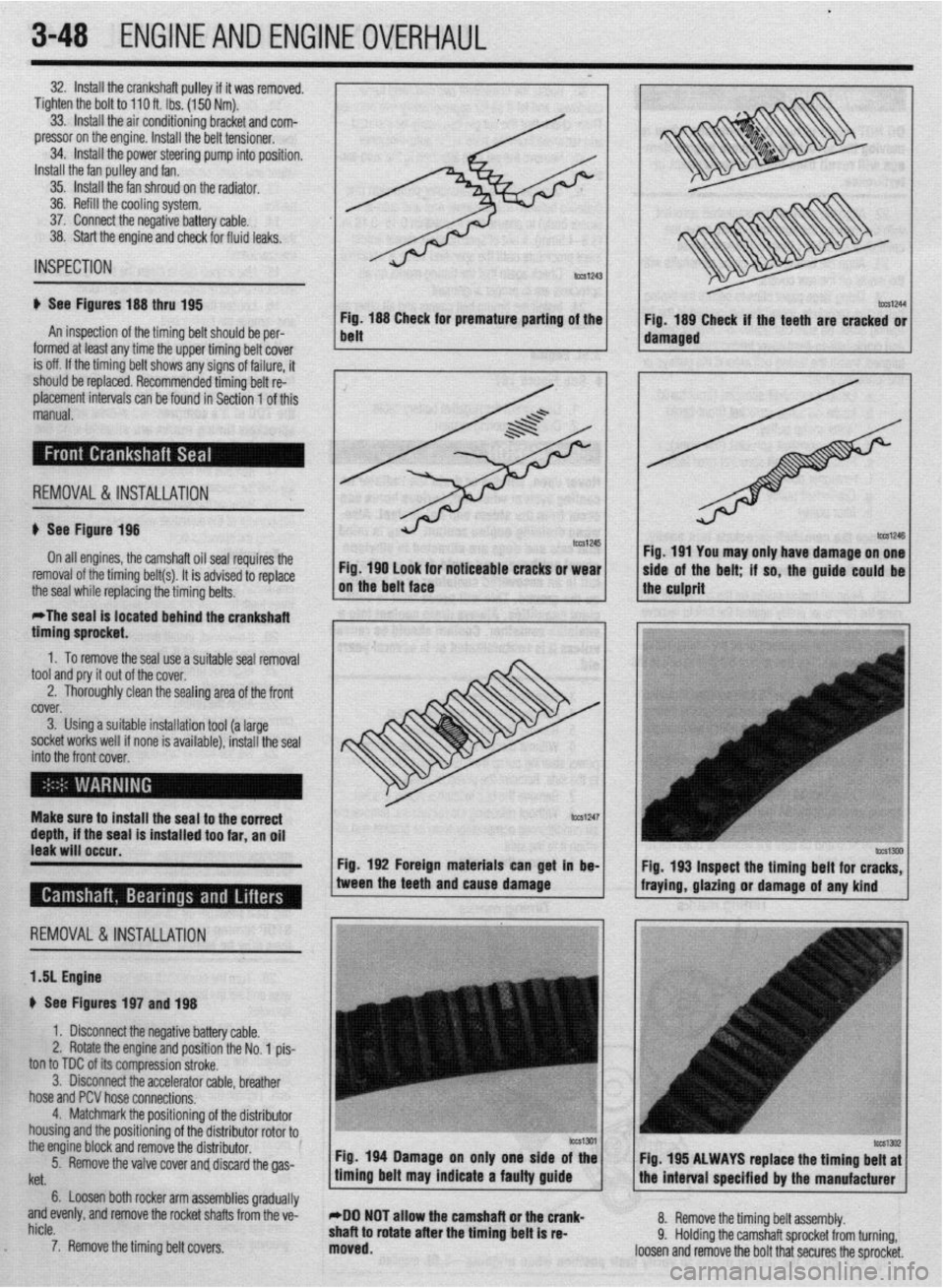

Fig. 188 CI ’ m

belt neeK ror premature panrng of the

Fig. 189 Check if the teeth are cracked or

IUIIII~U at IWSI

arly me me upper ommg oerr cover 1 1 damaged ,

I

is off. If the timina belt shows anv sians of failure. it INSPECTION

ti See Figures 188 thru 195

An inspection of the timing belt should be per-

I ^__^ -I ^I I---.-- I.-. II. .- I. . I I.

should be replaced. Recommended timing belt re:

placement intervals can be found in Section 1 of this

manual.

; REMOVAL&INSTALLATION

u See Figure 198

On all engines, the camshaft oil seal repuires the

Fig. 190 look for noticeable cracks or wear

removal of the timing belt(s). It is advised to replace

the seal while replacing the timing belts. on the belt face

*The seal is located behind the crankshaft

timino sorocket. I I Fig. 191 You may only have damage on one

side of the belt; if so, the guide-could be 1

the culprit

” .

1. To remove the seal use a suitable seal removal

tool and pry it out of the cover.

2. Thoroughly clean the sealing area of the front

fYi”f.V

i ““.“I. 3. Using a suitable installation tool (a large

socket works well if none is available), install the seal

into thr ? front cover,

EnI

Make surf! to install the seal to the correct

depth, if the seal is installed too far, an oil

leak will occur.

Fig. 192 Foreign materials can get in be-

REMOVAL &INSTALLATION

1 .!I Engine

+ See Figures 197 and 198

1. Disconnect the negative battery cable.

2. Rotate the engine and position the No. 1 pis-

ton to TDC of its compression stroke.

3. Disconnect the accelerator cable, breather

hose and PCV hose connections.

4. Matchmark the positionino of the distributor

housing and the positioning of thedistributor rotor to0

the engine block and remove the distributor.

5.

. Remove the valve cover and discard the gas- tween the teeth and cause damage

fraying, gla&g or damage of any kind

’

Itet.

6. Loosen both rocker arm assemblies gradually

and evenly, and remove the rocket shafts from the ve-

hicle.

7. Remove the timing belt covers.

c

Fig 194 Damage on only one side of the

timing belt may indicate a faulty guide Fig. 195 ALWAYS raplace the timing belt at

the interval soecified br the manufacturer

*DO NOT allow the camshaft or the crank-

shaft to rotate after the timing belt is re-

moved. 8. Remove the timing belt assembly.

9. Holding the camshaft sprocket from turning,

loosen and remove the bolt that secures the sprocket.

Page 174 of 408

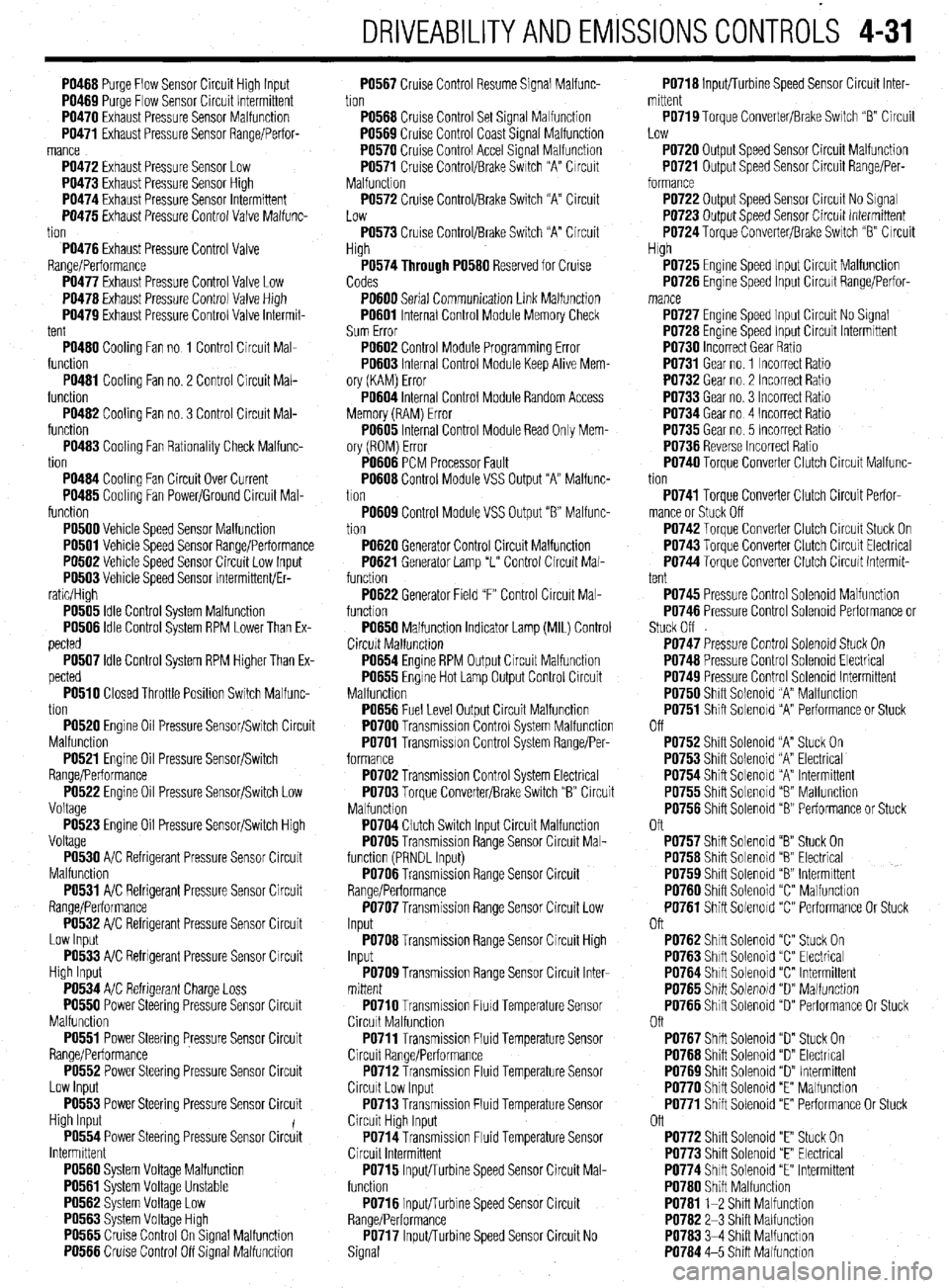

DRIVEABILITYAND EMISSIONSCONTROL-S 4-31

PO466 Purge Flow Sensor Circuit High Input

PO469 Purqe Flow Sensor Circuit Intermittent

PO470 Exhaust Pressure Sensor Malfunction

PO471 Exhaust Pressure Sensor Range/Perfor-

mance

PO472 Exhaust Pressure Sensor Low

PO473 Exhaust Pressure Sensor Hiah

PO474 Exhaust Pressure Sensor lnirmittent

PO475 Exhaust Pressure Control Valve Malfunc-

tion

PO476 Exhaust Pressure Control Valve

Range/Performance

PO477 Exhaust Pressure Control Valve Low

PO476 Exhaust Pressure Control Valve High

PO479 Exhaust Pressure Control Valve Intermit-

tent

PO460 Cooling Fan no 1 Control Circuit Mal-

function

PO461 Cooling Fan no. 2 Control Circuit Mal-

function

PO462 Cooling Fan no. 3 Control Circuit Mal-

function

PO463 Cooling Fan Rationality Check Malfunc-

tion

PO464 Cooling Fan Circuit Over Current

PO465 Cooling Fan Power/Ground Circuit Mal-

function

PO500 Vehicle Speed Sensor Malfunction

PO501 Vehicle Speed Sensor Range/Performance

PO502 Vehicle Speed Sensor Circuit Low Input

PO503 Vehicle Speed Sensor Intermittent/Er-

ratic/High

PO505 Idle Control System Malfunction

PO506 Idle Control System RPM Lower Than Ex-

pected

PO507 Idle Control System RPM Higher Than Ex-

pected

PO510 Closed Throttle Position Switch Malfunc-

tion

PO520 Engine Oil Pressure Sensor/Switch Circuit

Malfunction

PO521 Engine Oil Pressure Sensor/Switch

Range/Performance

PO522 Engine Oil Pressure Sensor/Switch Low

Voltage

PO523 Engine Oil Pressure Sensor/Switch High

Voltage

PO530 A/C Refrigerant Pressure Sensor Circuit

Malfunction

PO531 A/C Refrigerant Pressure Sensor Circuit

Range/Performance

PO532 A/C Refrigerant Pressure Sensor Circuit

Low Input

PO533 A/C Refrigerant Pressure Sensor Circuit

High Input

PO534 A/C Refrigerant Charge Loss

PO550 Power Steering Pressure Sensor Circuit

Malfunction

PO551 Power Steering Pressure Sensor Circuit

Range/Performance

PO552 Power Steering Pressure Sensor Circuit

Low Input

PO553 Power Steering Pressure Sensor Circuit

High Input

PO554 Power Steering Pressure Sensor Circiit

Intermittent

PO560 System Voltage Malfunction

PO561 System Voltage Unstable

PO562 System Voltage Low

PO563 Svstem Voltaoe Hlah

PO565 Ciuise Control On%ignal Malfunction

PO566 Cruise Control Off Signal Malfunction PO567 Cruise Control Resume Signal Malfunc-

tion

PO566 Cruise Control Set Signal Malfunction

PO569 Cruise Control Coast Signal Malfunction

PO570 Cruise Control Accel Signal Malfunction

PO571 Cruise Control/Brake Switch “A” Circuit

Malfunction

PO572 Cruise Control/Brake Switch “A” Circuit

Low

PO573 Cruise Control/Brake Switch “A” Circuit

High

P0574Through PO560 Reserved for Cruise

Codes

PO600 Serial Communication Link Malfunction

PO601 Internal Control Module Memory Check

Sum Error

PO602 Control Module Programming Error

PO603 Internal Control Module Keep Alive Mem-

ory (KAM) Error

PO604 Internal Control Module Random Access

Memory (RAM) Error

PO605 Internal Control Module Read Only Mem-

ory (ROM) Error

PO606 PCM Processor Fault

PO606 Control Module VSS Output “A” Malfunc-

tion

PO609 Control Module VSS Output “6” Malfunc-

tion

PO620 Generator Control Circuit Malfunction

PO621 Generator Lamp “L” Control Circuit Mal-

function

PO622 Generator Field “F” Control Circuit Mal-

function

PO650 Malfunction Indicator Lamp (MIL) Control

Circuit Malfunctron

PO654 Engine RPM Output Circuit Malfunction

PO655 Engine Hot Lamp Output Control Circuit

Malfunction

PO656 Fuel Level Output Circuit Malfunction

PO700 Transmission Control System Malfunction

PO701 Transmission Control System Range/Per-

formance

PO702 Transmission Control System Electrical

PO703 Torque Converter/Brake Switch “B” Circuit

Malfunction

PO704 Clutch Switch Input Circuit Malfunction

PO705 Transmission Range Sensor Circuit Mal-

function (PRNDL Input)

PO706 Transmission Range Sensor Circuit

Range/Performance

PO707 Transmission Range Sensor Circuit Low

Input

PO706 Transmission Range Sensor Circuit High

Input

PO709 Transmission Range Sensor Circuit Inter-

mittent

PO710 Transmission FluId Temperature Sensor

Circuit Malfunction

PO711 Transmission Fluid Temperature Sensor

Circuit Range/Performance

PO712 Transmission Fluid Temperature Sensor

Circuit Low Input

PO713 Transmission Fluid Temperature Sensor

Circuit High Input

PO714 Transmission Fluid Temperature Sensor

Circuit Intermittent

PO715 Input/Turbine Speed Sensor Circuit Mal-

function

PO716 Input/Turbine Speed Sensor Circuit

Range/Performance

PO717 InpWurbine Speed Sensor Circuit No

Signal PO716 Inputflurbine Speed Sensor Circuit Inter-

mittent

PO719 Torque Converter/Brake Switch “B” Circuit

Low

PO720 Output Speed Sensor Circuit Malfunction

PO721 Output Speed Sensor Circuit Range/Per-

formance

PO722 Output Speed Sensor Circuit No Signal

PO723 Output Speed Sensor Circuit Intermittent

PO724 Toraue Converter/Brake Switch “B” Circuit

High

PO725 Engine Speed Input Circuit Malfunction

PO726 Engine Speed Input Circuit Range/Perfor-

PO727 Engine Speed Input Circuit No Signal

PO726 Engine Speed Input Circuit Intermittent

PO730 Incorrect Gear Ratio

PO731 Gear no. 1 Incorrect Ratio

PO732 Gear no. 2 Incorrect Ratio

PO733 Gear no. 3 Incorrect Ratio

PO734 Gear no 4 Incorrect Ratio

PO735 Gear no. 5 Incorrect Ratio

PO736 Reverse Incorrect Ratio

PO740 Torque Converter Clutch Circuit Malfunc-

tion

PO741 Torque Converter Clutch Circuit Perfor-

mance or Stuck Off

PO742 Torque Converter Clutch Circuit Stuck On

PO743 Torque Converter Clutch Circuit Electrical

PO744 Torque Converter Clutch Circuit Intermit-

tent

PO745 Pressure Control Solenoid Malfunction

PO746 Pressure Control Solenoid Performance or

Stuck Off

PO747 Pressure Control Solenoid Stuck On

PO746 Pressure Control Solenoid Electrical

PO749 Pressure Control Solenoid Intermittent

PO750 Shift Solenoid “A” Malfunction

PO751 Shift Solenoid “A” Performance or Stuck

Off

PO752 Shift Solenoid “A” Stuck On

PO753 Shift Solenoid “A” Electrical

PO754 Shift Solenoid “A” Intermittent

PO755 Shift Solenoid “8 Malfunction

PO756 Shift Solenoid “B” Performance or Stuck

Oft

PO757 Shift Solenoid “B” Stuck On

PO756 Shift Solenoid “6” Electrical

PO759 Shift Solenoid “8” Intermittent

PO760 Shift Solenoid “C” Malfunction

PO761 Shift Solenoid “C” Performance Or Stuck

Oft

PO762 Shift Solenoid “C” Stuck On

PO763 Shift Solenoid “C” Electrical

PO764 Shift Solenoid “C” Intermittent

PO765 Shift Solenoid “D” Malfunction

PO766 Shift Solenoid “D” Performance Or Stuck

Oft

PO767 Shift Solenoid “D” Stuck On

PO766 Shift Solenoid “D” Electrical

PO769 Shift Solenoid “D” Intermittent

PO770 Shift Solenoid “E” Malfunction

PO771 Shift Solenoid “E” Performance Or Stuck

Off

PO772 Shift Solenoid “E” Stuck On

PO773 Shift Solenoid “E” Electrical

PO774 Shift Solenoid “E” Intermittent

PO760 Shift Malfunction

PO761 l-2 Shift Malfunction

PO762 2-3 Shift Malfunction

PO763 3-4 Shift Malfunction

PO764 4-5 Shift Malfunction