mirror MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 4 of 408

I-4 GENERALINFORMATIONAND MAINTENANCE

Fig. 12 A screw-in type compression gauge- Fig. 13 A vacuum/pressure tester is neces-

is recommended for compression testing sary for many testing procedures

Fig. 14 Most modern automotive multime-

ters incorporate many helpful features

your workbench. Some useful household items are: a

large turkey baster or siphon, empty coffee cans and

ice trays (to store parts), ball of twine, electrical tape

for wiring, small rolls of colored tape for tagging lines

or hoses, markers and pens, a note pad, golf tees (for

plugging vacuum lines), metal coat hangers or a roll

of mechanic’s wire (to hold things out of the way),

dental pick or similar long, pointed probe, a strong

magnet, and a small mirror (to see into recesses and

under manifolds).

A more advanced set of tools, suitable for tune-up

work, can be drawn up easily. While the tools are

lmvl Fig. 15 Proper information is vital, so at

ways have a Chiiton Total Car Care manua

handy

l Feeler aauoes for valve adiustment

* Timing-light.

The choice of a timing fight should be made

carefully. A light which works on the DC current

supplied by the vehicle’s battery is the best choice;

it should have a xenon tube for brightness. On any

vehicle with an electronic ignition system, a timing

light with an inductive pickup that clamps around

the No. 1 spark plug cable is preferred.

In addition to these basic tools, there are several

other tools and gauges you may find useful. These

include:

l Compression gauge. The screw-in type is

slower to use, but eliminates the possibility of a

fauliy reading due to escaping pressure.

l Manifold vacuum gauge. l 12V test light. l A combination volt/ohmmeter l induction Ammeter. This is used for determin-

ing whether or not there is current in a wire. These

are handy for use if a wire is broken somewhere in a

wiring harness.

As a final note, vou will orobablv find a torque

wrench necessary for all but the most basic work.

The beam type models are perfectly adequate, al-

though the newer click types (breakaway) are easier

to use. The click type torque wrenches tend to be

more expensive. Also keep in mind that all types of

torque wrenches should be periodically checked

and/or recalibrated. You will have to decide for your-

self which better fits your pocketbook, and purpose.

ilightly more sophisticated, they need not be outra-

feously expensive. There are several inexpensive

achldwell meters on the market that are every bit as

Toad for the average mechanic as a professional

nodel. Just be sure that it goes to a least 1200-1500

pm on the tach scale and that it works on 4,6 and 8-

:ylinder engines. The key to these purchases is to

nake them with an eye towards adaptability and wide

ange. A basic list of tune-up tools could include:

l Tach/dwell meter. l Spark plug wrench and gapping tool. Normally, the use of special factory tools is

avoided for repair procedures, since these are not

readily available for the do-it-yourself mechanic.

When it is possible to perform the job with more

commonly available tools, it will be pointed out, but

occasionally, a special tool was designed to perform

a specific function and should be used. Before sub-

stituting another tool, you should be convinced that

neither your safety nor the performance of the vehicle

will be compromised.

Special tools can usually be purchased from an

automotive parts store or from your dealer. In some

cases special tools may be available directly from the

tool manufacturer.

p See Figures 16, 17, 16, and 19

It is virtually impossible to anticipate all of the haz-

ards involved with automotive maintenance and ser-

vice, but care and common sense will prevent most

accidents.

The rules of safety for mechanics range from “don’t

smoke around gasoline,” to “use the proper tool(s) for

the job.” The trick to avoiding injuries is to develop

safe work habits and to take every possible precaution.

Do keep a fire extinguisher and first aid kit

l handy.

Do wear safety glasses or goggles when cut- l ting, drilling, grinding or prying, even if you have

20-20 vision. If you wear glasses for the sake of vi-

sion, wear safety goggles over your regular glasses.

l Do shield your eyes whenever you work around

the battery. Batteries contain sulfuric acid. In case of

contact with the eyes or skin, flush the area with water

or a mixture of water and baking soda, then seek im-

mediate medical attention.

l Do use safety stands (jackstands) for any un-

dervehicle service. Jacks are for raising vehicles;

jackstands are for making sure the vehicle stays

raised until you want it to come down. Whenever the

vehicle is raised, block the wheels remaining on the

ground and set the parking brake.

l Do use adequate ventilation when working

with any chemicals or hazardous materials, Like car-

bon monoxide, the asbestos dust resulting from

some brake lining wear can be hazardous in suffi-

cient quantities.

l Do disconnect the negative battery cable when

working on the electrical system. The secondary ig- nition system contains EXTREMELY HIGH VOLT-

AGE. In some cases it can even exceed 50,000 volts.

l Do follow manufacturer’s directions whenever

working with potentially hazardous materials. Most

chemicals and fluids are poisonous if taken inter-

nally.

l Do properly maintain your tools. Loose ham-

merheads, mushroomed punches and chisels, frayed

or poorly grounded electrical cords, excessively

worn screwdrivers, spread wrenches (open end),

cracked sockets, slipping ratchets, or faulty droplight

sockets can cause accidents.

* Likewise, keep your tools clean; a greasy

wrench can slip off a bolt head, ruining the bolt and

often harming your knuckles in the process.

l Do use the proper size and type of tool for the

job at hand. Do select a wrench or socket that fits the

nut or bolt. The wrench or socket should sit straight,

not cocked.

Page 42 of 408

GENERALINFORMATIONAND MAINTENANCE l-43

l Special car washing detergent is the best to

use. Liquid dishwashing detergent can remove wax

and leave the car’s paint unprotected and in addition

some liquid detergents contains abrasives which can

scratch the paint.

l Bird droppings should be removed from the

paintwork as soon as possible, otherwise the finish

may be permanently stained.

When the car is driven immediately after be-

ing washed, apply the brakes several times

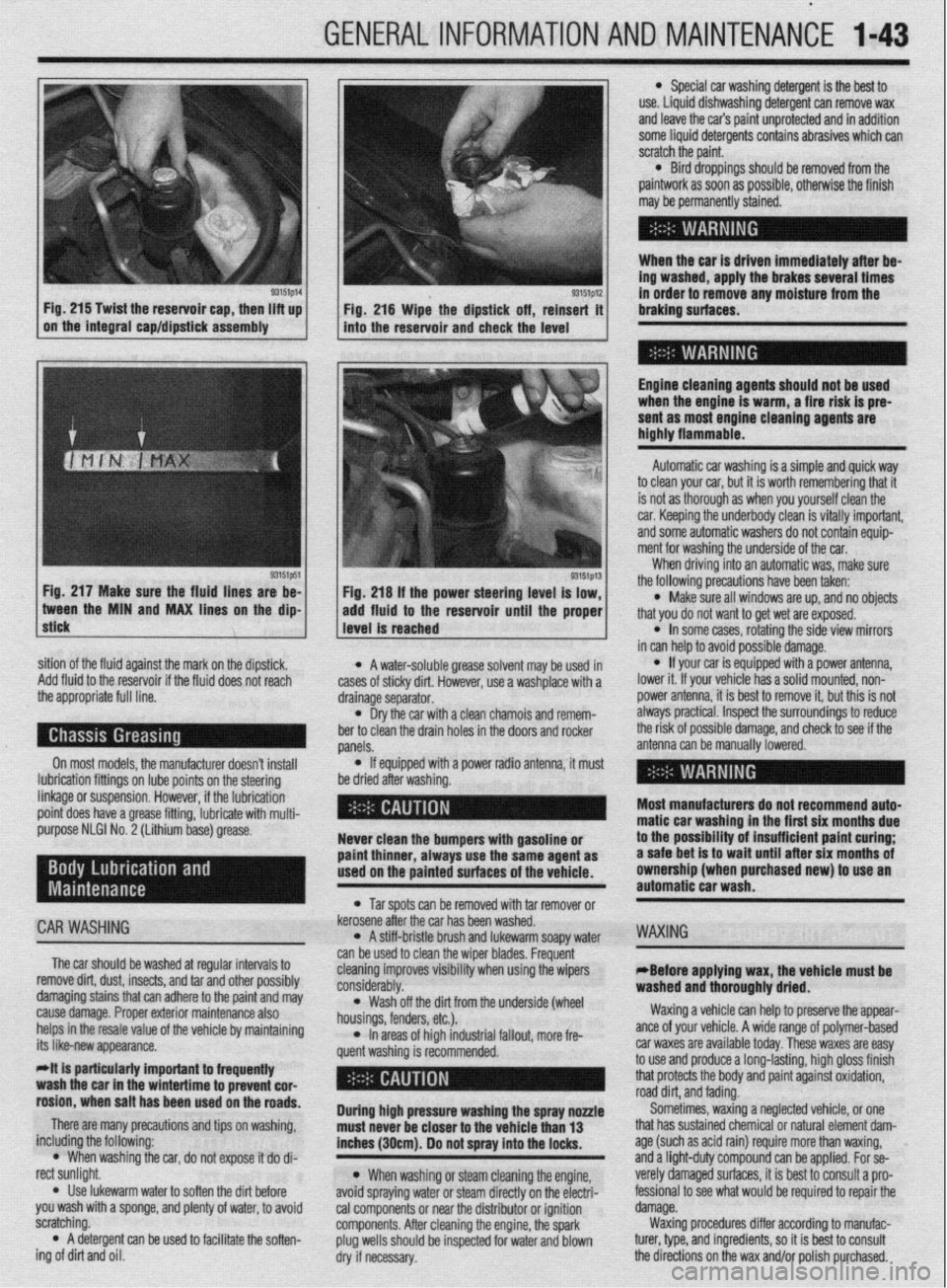

93151p14 93151p12 Fig. 215 Twist the reservoir cap, then lift up

I I

in order to remove any moisture from the

Fig. 216 Wipe the dipstick off, reinsert it braking surfaces.

on the integral cap/dipstick assembly

into the reservoir and check the level

I

Engine cleaning agents should not be used

when the engine is warm, a fire risk is pre-

sent as most engine cleaning agents are

highly flammable.

sition of the fluid against the mark on the dipstick,

Add fluid to the reservoir if the fluid does not reach

the appropriate full line.

On most models, the manufacturer doesn’t install

lubrication fittings on lube points on the steering

linkage or suspension. However, if the lubrication

point does have a grease fitting, lubricate with multi-

purpose NLGI No. 2 (Lithium base) grease.

CAR WASHING

The car should be washed at regular intervals to

remove dirt, dust, insects, and tar and other possibly

damaging stains that can adhere to the paint and may

cause damage. Proper exterior maintenance also

helps in the resale value of the vehicle by maintaining

its like-new appearance.

Mt is particularly important ta frequentiy

wash the car in the wintertime to prevent cor-

rosion, when salt has been used on the roads.

There are many precautions and tips on washing,

including the following:

l When washing the car, do not expose it do di-

rect sunlight.

. Use lukewarm water to soften the dirt before

you wash with a sponge, and plenty of water, to avoid

scratching.

l A detergent can be used to facilitate the soften-

ing of dirt and oil. * A water-soluble grease solvent may be used in

cases of sticky dirt. However, use a washplace with a

drainage separator.

l Dry the car with a clean chamois and remem-

ber to clean the drain holes in the doors and rocker

panels.

l If equipped with a power radio antenna, it must

be dried after washing.

Never clean the bumpers with gasoline or

paint thinner, always use the same agent as

used on the painted surfaces of the vehicle.

l Tar spots can be removed with tar remover or

kerosene after the car has been washed.

l A stiff-bristle brush and lukewarm soapy water

can be used to clean the wiper blades. Frequent

cleaning improves visibility when using the wipers

considerably.

l Wash off the did from the underside (wheel

housings, fenders, etc.).

l In areas of high industrial fallout, more fre-

quent washing is recommended.

During high pressure washing the spray nonle

must never be closer to the vehicle than 13

inches (30cm). Do not spray into the locks.

l When washing or steam cleaning the engine,

avoid spraying water or steam directly on the electri-

cal components or near the distributor or ignition

components. After cleaning the engine, the spark

plug wells should be inspected for water and blown

dry if necessary. Automatic car washing is a simple and quick way

to clean your car, but it is worth remembering that it

is not as thorough as when you yourself clean the

car. Keeping the underbody clean is vitally important,

and some automatic washers do not contain equip-

ment for washing the underside of the car.

When driving into an automatic was, make sure

the following precautions have been taken:

l Make sure all windows are up, and no objects

that you do not want to get wet are exposed.

l In some cases, rotating the side view mirrors

in can help to avoid possible damage.

l If your car is equipped with a power antenna,

lower it. If your vehicle has a solid mounted, non-

power antenna, it is best to remove it, but this is not

always practical. Inspect the surroundings to reduce

the risk of possible damage, and check to see if the

antenna can be manually lowered.

Most manufacturers do not recommend auto-

matic car washing in the first six months due

to the possibility of insufficient paint curing;

a safe bet is to wait until after six months of

ownership (when purchased new) to use an

automatic car wash.

WAXING

eBefore applying wax, the vehicle must be

washed and thoroughly dried.

Waxing a vehicle can help to preserve the appear-

ante of your vehicle. A wide range of polymer-based

car waxes are available today. These waxes are easy

to use and produce a long-lasting, high gloss finish

that protects the body and paint against oxidation,

road dirt, and fading.

Sometimes, waxing a neglected vehicle, or one

that has sustained chemical or natural element dam-

age (such as acid rain) require more than waxing,

and a light-duty compound can be applied. For se-

verely damaged surfaces, it is best to consult a pro-

fessional to see what would be required to repair the

damage.

Waxing procedures differ according to manufac-

turer, type, and ingredients, so it is best to consult

the directions on the wax and/or polish purchased.

Page 214 of 408

CHASSIS ELECTRICAL 6-11

45. Install the heater hoses under the hood.

46. Install the mstrument panel by reversing its

removal procedure.

47. Install the center console.

48. install the upper and lower steering column

covers.

49. Install the center panel undercover.

50. Install the small column panel.

51. Install the steering wheel.

52. Fill the cooling system.

53. Connect the negative battery cable and check

the entire climate control system for proper operation

and leaks.

Mirage

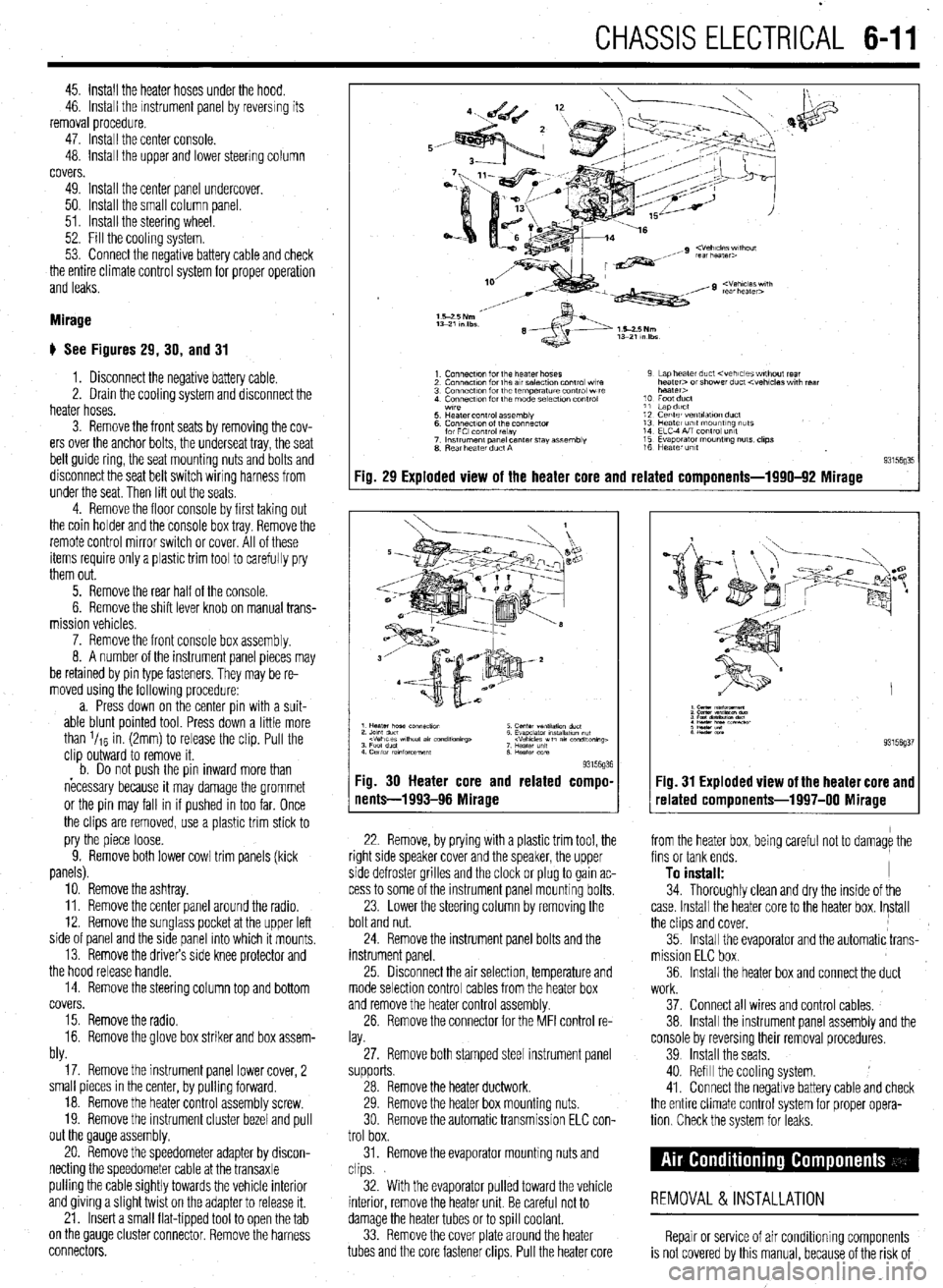

# See Figures 29, 30, and 31

1. Disconnect the negative battery cable.

2. Drain the cooling system and disconnect the

heater hoses.

3. Remove the front seats by removing the cov-

ers over the anchor bolts, the underseat tray, the seat

belt guide ring, the seat mounting nuts and bolts and

disconnect the seat belt switch wiring harness from

under the seat. Then lift out the seats

4. Remove the floor console by first taking out

the coin holder and the console box tray. Remove the

remote control mirror switch or cover. All of these

items require only a plastic trim tool to carefully pry

them out.

5. Remove the rear half of the console.

6. Remove the shift lever knob on manual trans-

mission vehicles.

7. Remove the front console box assembly.

8. A number of the instrument panel pieces may

be retamed by pin type fasteners. They may be re-

moved using the following procedure:

a. Press down on the center pin with a suit-

able blunt pointed tool. Press down a little more

than l/re in. (2mm) to release the clip. Pull the

clip outward to remove it.

b. Do not oush the oin inward more than

necessary because it may damage the grommet

or the pin may fall in if pushed in too far. Once

the clips are removed, use a plastic trim stick to

pry the piece loose.

9. Remove both lower cowl trim panels (kick

panels).

10. Remove the ashtray.

11. Remove the center panel around the radio.

12. Remove the sunglass pocket at the upper left

side of panel and the side panel into which it mounts,

13. Remove the drivers side knee protector and

the hood release handle.

14. Remove the steering column top and bottom

covers.

15. Remove the radio.

16. Remove the glove box striker and box assem-

bly.

17. Remove the instrument panel lower cover, 2

small pieces in the center, by pulling forward.

18. Remove the heater control assembly screw.

19. Remove the instrument cluster bezel and pull

out the Qauge assembly.

20. Remove the speedometer adapter by discon-

necting the speedometer cable at the transaxle

pulling the cable Sightly towards the vehicle interior

and giving a Slight twist on the adapter to release it.

21. Insert a small flat-tipped tool to open the tab

on the QauQe cluster connector. Remove the harness

connectors.

Fig. 29 Exploded view of the heater core and related components-1990-92 Mirage

93l%Q% Fig. 30 Heater core and related compo-

nents-1993-96 Mirage

22. Remove, by prying with a plastic trim tool, the

right side speaker cover and the speaker, the upper

side defroster grilles and the clock or plug to gain ac-

cess to some of the instrument panel mounting bolts.

23. Lower the steering column by removing the

bolt and nut.

24. Remove the instrument panel bolts and the

instrument panel.

25 Drsconnect the air selection, temperature and

mode selection control cables from the heater box

and remove the heater control assembly.

26. Remove the connector for the MFI control re-

lay.

27. Remove both stamped steel instrument panel

supports.

28. Remove the heater ductwork.

29. Remove the heater box mounting nuts.

30 Remove the automatic transmission ELC con-

trol box.

31. Remove the evaporator mounting nuts and

clips.

32. With the evaporator pulled toward the vehicle

interior, remove the heater unit. Be careful not to

damage the heater tubes or to spill coolant.

33. Remove the cover plate around the heater

tubes and the core fastener clips. Pull the heater core 34. Thoroughly clean and dry the inside of the

case. Install the heater core to the heater box. Install

the clips and cover,

35. Install the evaporator and the automatic trans-

mission ELC box.

36. Install the heater box and connect the duct

Fig. 31 Exploded view of the heater core and

related components-1997-00 Mirage

from the heater box, being careful not to damage the

fins or tank ends.

To install: I

work.

37. Connect all wires and control cables,

38. Install the instrument panel assembly and the

console by reversmg their removal procedures.

39 Install the seats.

40. Refill the cooling system.

41. Connect the negative battery cable and check

the entire climate control system for proper opera-

tion Check the system for leaks.

REMOVAL &INSTALLATION

Repair or service of air Conditioning components

is not covered by this manual, because of the risk of

Page 218 of 408

CHASSIS ELECTRlCiL 6-15

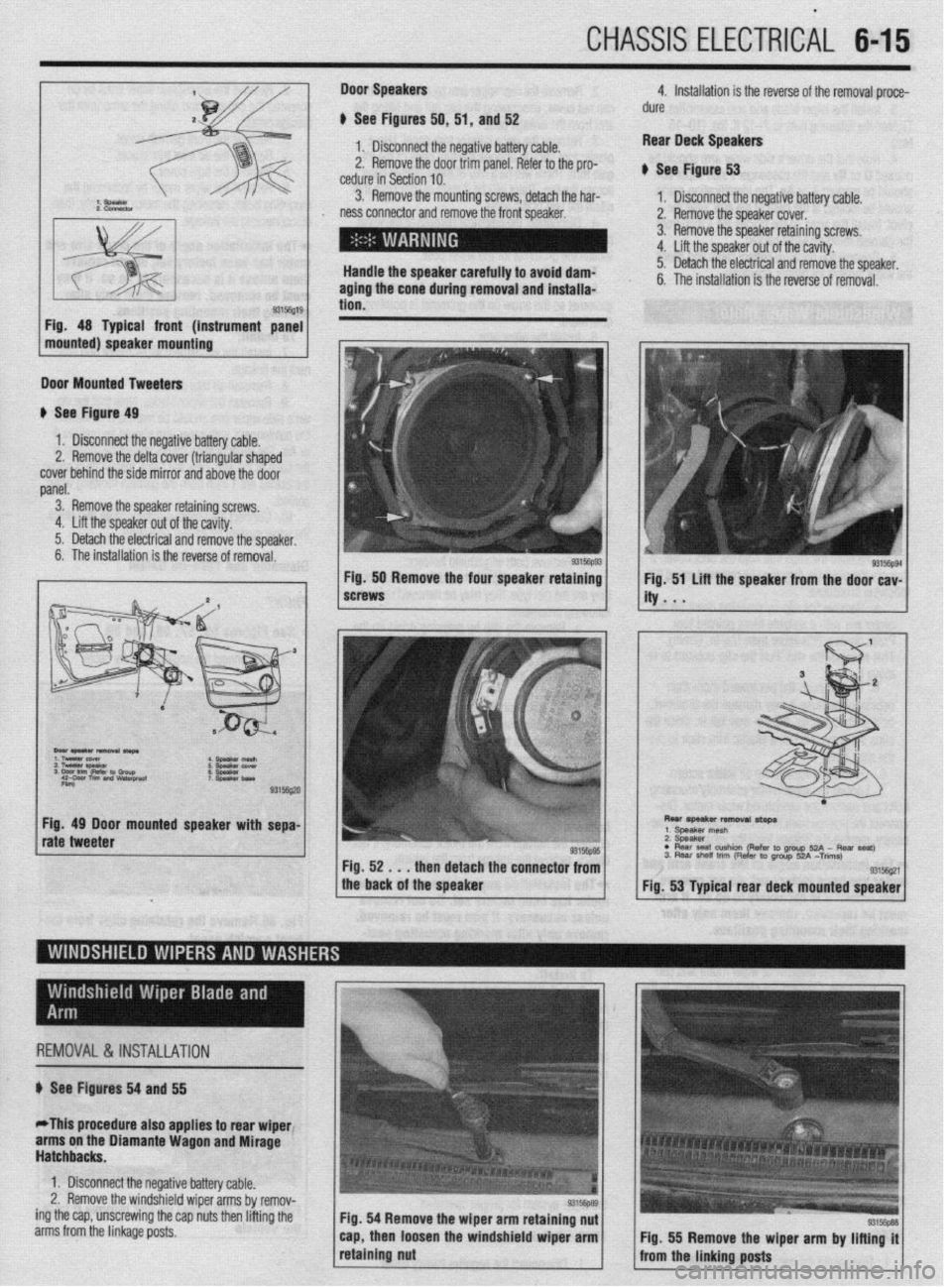

Door Speakers 4. Installation is the reverse of the removal proce-

) See Figures 50, 51, and 52 dure

-t

I. lJ13lr”IIIIObI IlIt: llaydwa n:n?.nnnnr, IL,^ ..^rr‘:.... battery &je, Rear Deck Speakers

2. Remove the door trim pa nel. Refer to the pro-

cedure in Section 10. # See Figure 53

3. Remove the mounting screws, detach the har-

1. Disconnect the negative battery cable.

ness connector and remove the front speaker. 2. Remove the speaker cover.

3. Remove the speaker retaining screws.

4. Lift the speaker out of the cavity.

Handle the speaker carefully to avoid dam- 5. Detach the electrical and remove the speaker,

aging the cone during removal and installa-

tion. 6. The installation is the reverse of removal.

93156g19

Fig. 48 Typical front (instrument panel

mounted) speaker mounting

Door Mounted Tweeters

# See Figure 49

1. Disconnect the negative battery cable.

2, Remove the delta cover (triangular shaped

cover behind the side mirror and above the door

panel.

3. Remove the speaker retaining screws

4. Lift the speaker out of the cavity.

5. Detach the electrical and remove the speaker,

6. The installation is the reverse of removal.

rate tweeter Fig. 50 Remove the four speaker retaining Fig. 51 Lifl the speaker from the door cav-

screws ity . . .

REMOVAL&lNSTAL~TlON

I

n See Figures 54 and 55

*This procedure also applies to rear wiper1

arms on the Diamante Wagon and Mirage

Hatchbacks.

1. Disconnect the negative battery cable.

2. Remove the windshield wiper arms by remov-

ing the cap, unscrewing the cap nuts then lifting the

arms from the linkage posts. Fig. 54 Remove the wiper arm retaining nut

cap, then loosen the windshield wiper arm

. . .._S~.. .

1 rerauung nut

I

9315W38 Fig. 55 Remove the wiper arm by lifting it

#--- at.- ,:-n-1-- ---‘- 1 mfifl me ffffnfffg pusfs

Page 223 of 408

.

6-20 CHASSIS ELECTRICAL

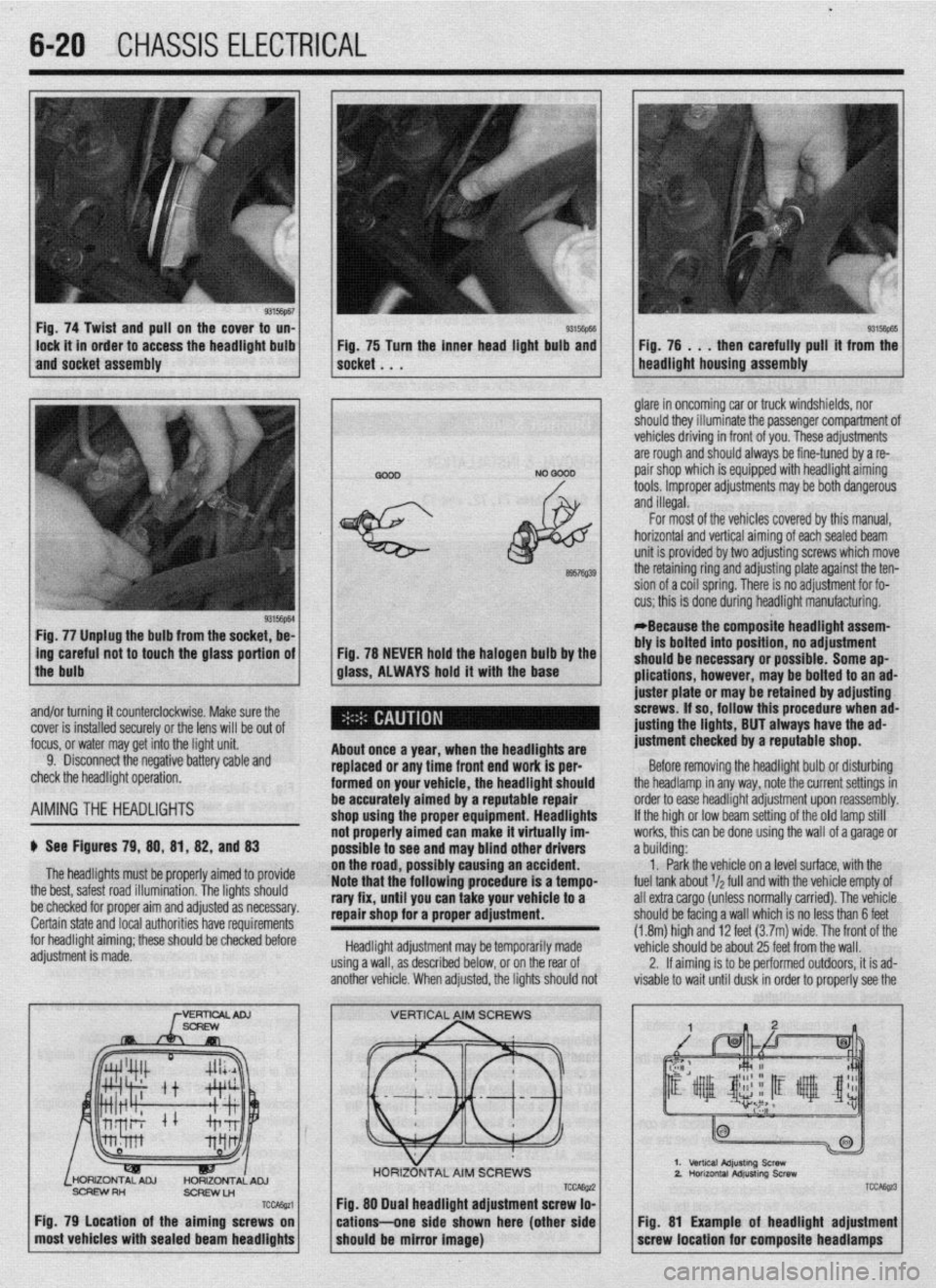

Fig. 74 Twist and pull on the cover to un-

lock it in order to access the headlight bulb

and socket assembly 93Mm Fig, 75 Turn the inner head light bulb and then carefully pull’ it from the

NO 0000 . glare in oncoming car or truck windshields, nor

should they illuminate the passenger compartment of

vehicles driving in front of you. These adjustments

are rough and should always be fine-tuned by a re-

pair shop which is equipped with headlight aiming

tools. Improper adjustments may be both dangerous

and illegal.

Fig. 77 Unplug the bulb from the socket, be-

L

ing careful not to touch the glass portion of

the bulb

I

6957Q39

Fig. 78 NEVER hold the halogen bulb by the

glass, ALWAYS hold it with the base

,

About once a year, when the headllgftts are

replaced or any time front end work is per-

formed on your vehicle, the headlight should

be accurately aimed by a reputable repair

shop uslng the proper equipment. Headlights

not properly aimed can make it virtually im-

possible to see ar Id may blind other drivers

ibly causing an accident.

Note that the’following procedure is a tempo-

rary fix, until you can take your vehicle to a

repair shop for a proper adjustment.

Headlight adjustment may be temporarily made

using a wall, as described below, or on the rear of

another vehicle. When adjusted, the lights should not For most of the vehicles covered by this manual,

horizontal and vertical aiming of eachsealed beam

unit is provided by two adjusting screws which move

the retaining ring and adjusting plate against the ten-

sion of a coil spring. There is no adjustment for fo-

cus; this is done during headlight manufacturing.

*Because the composite headlight assem-

bly is bolted into position, no adjustment

should be necessary or possible. Some ap-

plications, however, may be bolted to an ad-

juster plate or may be retained by adjusting

screws. If so, follow this procedure when ad-

@sting the lights, BUT always have the ad-

justment checked by a reputable shop.

Before removing the headlight bulb or disturbing

the headlamp in any way, note the current settings in

order to ease headlight adjustment upon reassembly.

If the high or low beam setting of the old lamp still

works, this can be done using the wall of a garage or

a building:

1. Park the vehicle on a level surface, with the

fuel tank about r/a full and with the vehicle empty of

all extra cargo (unless normally carried). The vehicle

should be facing a wall which is no less than 6 feet

(1.8m) high and 12 feet (3.7m) wide. The front of the

vehicle should be about 25 feet from the wall.

2. If aiming is to be performed outdoors, it is ad-

visable to wait until dusk in order to properly see the

% and/or turning it counterclockwise. Make sure the

cover is installed securely or the lens will be out of

focus, or water may get into the light unit.

9. Disconnect the negative battery cable and

check the headlight operation.

AIMINGTHE HEADLIGHTS

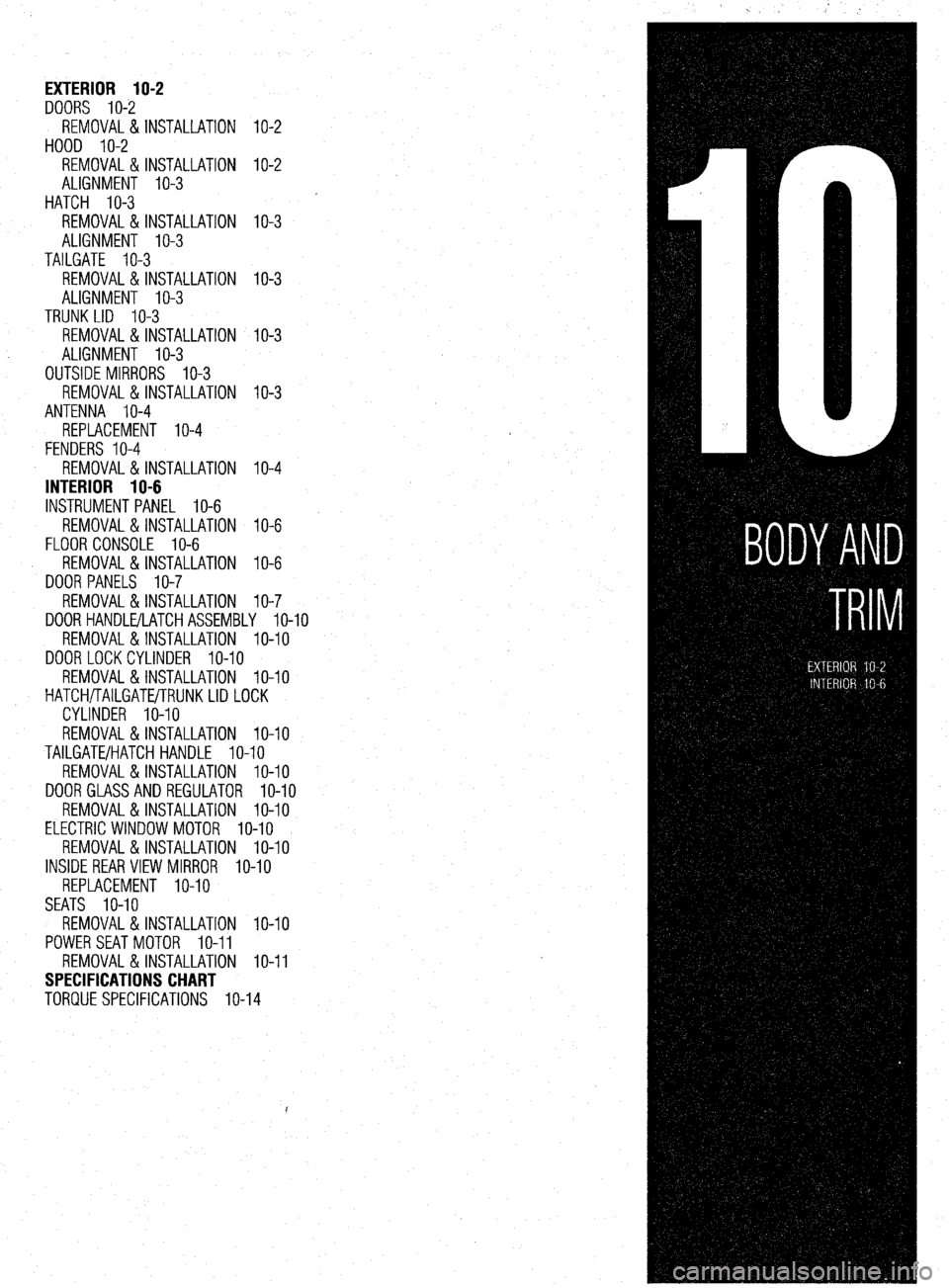

$ See Figures 79, 88, 81, 82, and 83

The headlights must be proper’ ’ ’ ’

the best, safest road illumination. ’ ’

ly armea IO provrae

The lights should

:.__1__1 __ - -___-_-. on the road, POSSI

be checked for proper aim and adfusreu as IlweSYdly. Certain state and local authorities have requirements

for headlight aiming; these should be checked before

adjustment is made.

SCFEWRH

ScFlEwLn

TCcAssa

Fig. 79 Location of the aiming screws on

most vehicles with sealed beam headlights

TCCAE@ Fig. 88 Dual headlight adjustment screw lo-

cations--one side shown here (other side

should be mirror image)

2.

TCC&z3

Fig. 81 Example of headlight adjustment

screw location for composite headlamps

Page 369 of 408

EXTERIOR IO-2

DOORS IO-2

REMOVAL&INSTALLATION IO-2

HOOD IO-2

REMOVAL&INSTALLATION IO-2

ALIGNMENT IO-3

HATCH IO-3

REMOVAL & INSTALLATION IO-3

ALIGNMENT IO-3

TAILGATE IO-3

REMOVAL & INSTALLATION IO-3

ALIGNMENT IO-3

TRUNK LID IO-3

REMOVAL &INSTALLATION IO-3

ALIGNMENT IO-3

OUTSIDE MIRRORS IO-3

REMOVAL &INSTALLATION IO-3

ANTENNA IO-4

REPLACEMENT IO-4

FENDERS IO-4

REMOVAL & INSTALLATION IO-4

INTERIOR 1

O-6 INSTRUMENTPANEL IO-6

REMOVAL & INSTALLATION IO-6

FLOOR CONSOLE IO-6

REMOVAL & INSTALLATION IO-6

DOOR PANELS IO-7

REMOVAL & INSTALLATION IO-7

DOORHANDLE/LATCHASSEMBLY IO-IO

REMOVAL &INSTALLATION IO-IO

DOOR LOCKCYLINDER IO-IO

REMOVAL &INSTALLATION IO-IO

HATCH/TAILGATE/TRUNKLID LOCK

CYLINDER IO-IO

REMOVAL &INSTALLATION IO-IO

TAILGATE/HATCH HANDLE IO-IO

REMOVAL &INSTALLATION IO-IO

DOORGLASSANDREGULATOR IO-IO

REMOVAL&INSTALLATION IO-IO

ELECTRIC WINDOW MOTOR IO-IO

REMOVAL &INSTALLATION IO-IO

INSIDE REAR VIEW MIRROR IO-IO

REPLACEMENT IO-IO

SEATS IO-IO

REMOVAL & INSTALLATION IO-IO

POWERSEATMOTOR IO-11

REMOVAL &INSTALLATION IO-11

SPECIFICATIONS CHART

TORQUE SPECIFICATIONS IO-14

4

Page 372 of 408

10-4 BODYANDTRIM

Fig. 8 Tailgate assembly mounting-Dia-

mante Wagon

6. Remove the tailgate from the vehicle and place

it in a safe place.

7. The installation is the reverse of removal.

Tighten the hinge

nuts to IO ft. Ibs. (14 Nm).

8. Check the alignment of the tailgate.

ALIGNMENT

To adjust the tailgate, loosen the tailgate hinge-to-

body bolts or tailgate latch assembly mounting

screws and adjust as necessary.

REMOVAL &INSTALLATION

1. Disconnect the negative battery cable.

2. Open the trunk lid. Identify the trunk release

cable running from the latch to the body.

3. Disconnect the cable from the latch.

4. Detach any necessary electrical connectors.

5. Outline the position of the hinges on the

trunk lid.

6. Support the trunk lid in the open position.

7. If equipped, insert a small prytool into the

lock cover slit, remove the lock covers, then remove

the trunk lid gas springs.

8. Unfasten the retaining bolts, then remove the

trunk lid hinges.

9. Remove the trunk lid from the vehicle

10. Installation is the reverse of the removal pro-

cedure.

11. If necessary, align the trunk lid.

ALIGNMENT

1. Close the lid and check both the seam width

all around and the closed height. The trunk lid must

be flush with the adjacent panels. Minor height ad-

justments may be made by turning the rubber

bumpers on the trunk lid. Additional adjustments re-

quire loosening and repositioning of the latch and/or

striker.

REMOVAL &INSTALLATION

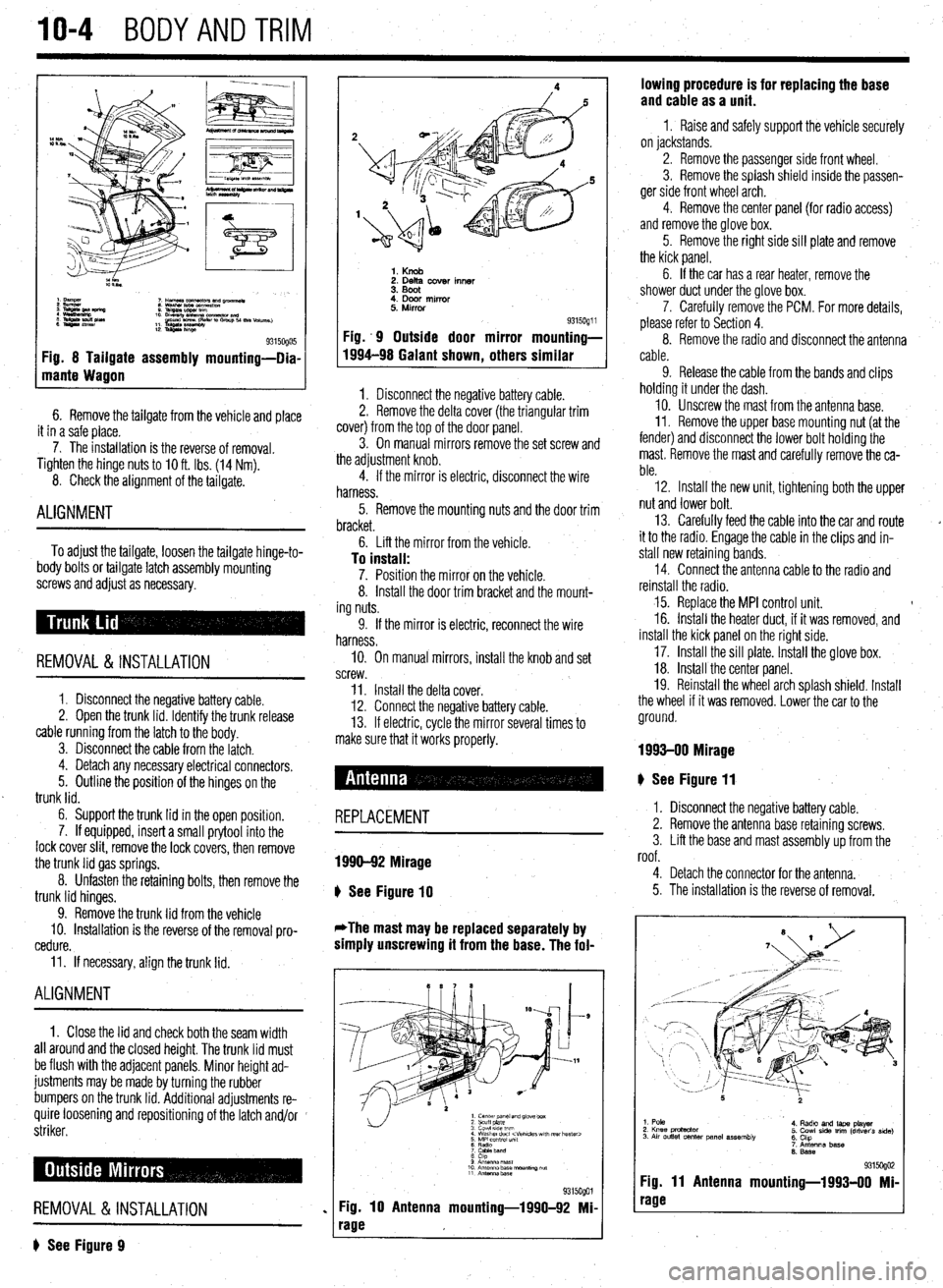

? See Figure 9

1. Knob 2. Delta cover inner

3. Boot

4. Door mirror

5. Mirror

Fig. .9 Outside door mirror

1994-98 Galant shown

, others 9315oQ1 i mounting-

similar

1. Disconnect the negative battery cable.

2. Remove the delta cover (the triangular trim

cover) from the top of the door panel.

3. On manual mirrors remove the set screw and

the adjustment knob.

4. If the mirror is electric, disconnect the wire

harness.

5. Remove the mounting nuts and the door trim

bracket.

6. Lift the mirror from the vehicle.

To install: 7. Position the mirror on the vehicle.

8. Install the door trim bracket and the mount-

ing nuts.

9. If the mirror is electric, reconnect the wire

harness.

IO. On manual mirrors, install the knob and set

screw.

11. Install the delta cover.

12. Connect the negative battery cable.

13. If electric, cycle the mirror several times to

make sure that it works properly.

# See Figure 11

REPLACEMENT

1990-92 Mirage

b

See Figure 10

*The mast may be replaced separately by

simply unscrewing it from the base. The fol-

1. center panel and glove box

2 scuff plate

3 cowl 51ae wm

4 Washer duct

7 CaMeband

8 cap

9 Anrsnna mast

10 Antenna base “ourmng ““f

11 Antennz.base

%i%Qol

Fig. 10 Antenna mounting-1990-92 Mi-

rage lowing procedure is for replacing the base

and cable as a unit.

1 I Raise and safely support the vehicle securely

on jackstands.

2. Remove the passenger side front wheel.

3. Remove the splash shield inside the passen-

ger side front wheel arch.

4. Remove the center panel {for radio access)

and remove the glove box.

5. Remove the right side sill plate and remove

the kick panel.

6. If the car has a rear heater, remove the

shower duct under the glove box.

7. Carefully remove the PCM. For more details,

please refer to Section 4.

8. Remove the radio and disconnect the antenna

cable.

9. Release the cable from the bands and clips

holding it under the dash.

10. Unscrew the mast from the antenna base.

II. Remove the upper base mounting nut (at the

fender) and disconnect the lower bolt holding the

mast. Remove the mast and carefully remove the ca-

ble.

12. Install the new unit, tightening both the upper

nut and lower bolt.

13. Carefully feed the cable into the car and route

it to the radio. Engage the cable in the clips and in-

stall new retaining bands.

14. Connect the antenna cable to the radio and

reinstall the radio.

15. Replace the MPI control unit. t

16. Install the heater duct, if it was removed, and

install the kick panel on the right side.

17. Install the sill plate. Install the glove box.

18. Install the center panel.

19. Reinstall the wheel arch splash shield. Install

the wheel if it was removed. Lower the car to the

ground.

1993-00 Mirage

I. Disconnect the negative battery cable.

2. Remove the antenna base retaining screws.

3. Lift the base and mast assembly up from the

roof.

4. Detach the connector for the antenna.

5. The installation is the reverse of removal.

1. Pole

2. Knee protactor

3. Air outlet center panel assembly 4. Radto and laps player

5. Cowl side trim (driver’s side)

6. Chp

7. Antenna base

6. Base

931 !iogo2 Fig. 11 Antenna mounting-1993-00 Mi-

rage

Page 375 of 408

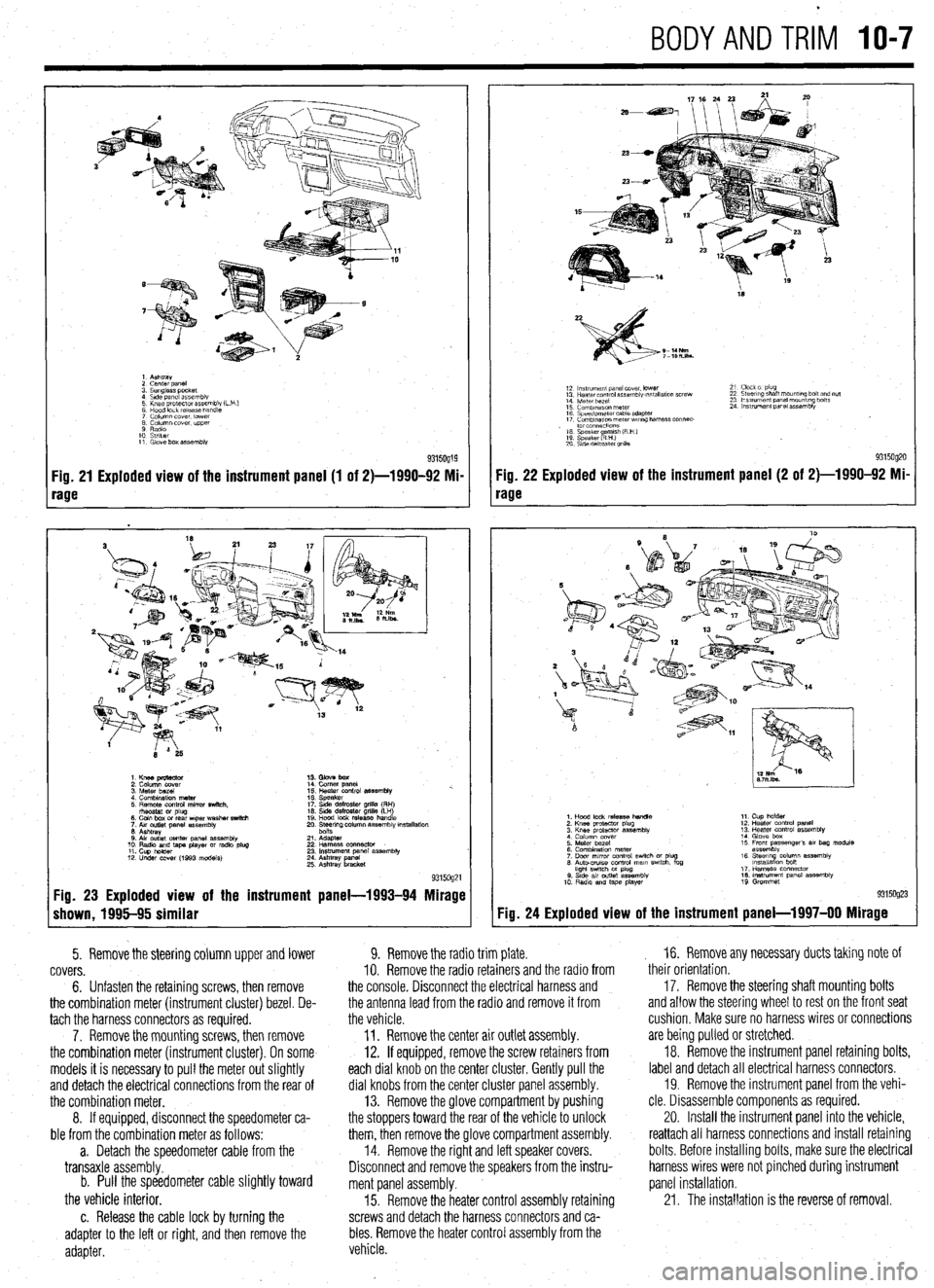

BODYANDTRIM IO-7

1. Ashtray

2 cenrer DaneI

3. Sunglass pocket

4 Side panel assembly

5 Knee protector assembly (L

6 Hood lock release handle

7 Column cover. lower

8 Column cover. upper

9 Radio

10 Striker

11. Glove box assembly

Fig. 21 Exploded view of the instrument panel (1 of 2)-1990-92 Mi-

rage

1. Knee pmtector

2. Column cover

3. Meter bezel

4. Combination meter

5. Remote control mirror switch.

rhsostat or plug

6. Coin box or rear wper washer switch

7. Aw outlet panel assembly

6. Ashtray

0. Air outlet center panel assembly

10. Radio and tape player or radio plug

11. Cup holder

12. Under COW (1993 models) 14. Comer panel

15. Heater control assembly %.

16. Speaker

17. Side defroster grille (RH)

16. Side defroster grille (LH)

19. Hood lock release handle

20. Ee$ng column assembly mstallation

21. Adapter

22 Harness oonnector

23. Instrument panel assembly

24. Ashtray panel

25. Ashtray bracket

9315og21 Fig. 23 Exploded view of the instrument panel-1993-94 Mirage

shown, 1995-95 similar

5. Remove the steering column upper and lower

covers.

6. Unfasten the retaining screws, then remove

the combination meter (instrument cluster) bezel. De-

tach the harness connectors as required.

7. Remove the mounting screws, then remove

the combination meter (instrument cluster). On some

models it is necessary to pull the meter out slightly

and detach the electrical connections from the rear of

the combination meter.

8. If equipped, disconnect the speedometer ca-

ble from the combination meter as follows:

a. Detach the speedometer cable from the

transaxle assembly.

b. Pull the speedometer cable slightly toward

the vehicle interior.

c. Release the cable lock by turning the

adapter to the left or right, and then remove the

adapter.

18

S-14Nm

7-lOh.lbs.

12 ln~v~rnent panel cover. lower

13 Hearer control assembly w,tallatlon screw

14 Meter bezel

15 Combination meter

16 Speedometer cable adapter

17 Comblnawn meterwr~ng harness connec-

. to1 co”“ectlo”s

16 Speaker amlsh (R H )

19 Speaker RHI e

20 S\de defroster grllla 21 Clock 01 plug

22 Steering shaft mount,ng bolt and nut

23 Ins!rument panel mounting bolts

24 Instrument panel assembly

9315og20 Fig. 22 Exploded view of the instrument panel (2 of 2)-1990-92 Mi-

rage

Fig. 24

1. Hood lock release handle

2. Knee protactor plug

3. Knee protector assembly

4 Column cover

5. Meter bezel

6. Combination meter

7. Door mrror control swich or plug

6. Auto-CNISO control mam swtch. fog

hght swtch M plug

0. Stde av outlet assembly

10 Radio and tape player 11. Cup holder

12. Heater control panel

13. Heater control assembly

14. Glove box

15 Front passenger’s 81, bag module

assembly

16. Steerq column assembly

lnstallatlon bon

17. Harness connector

16. Instrument panel assembly

19 Grommet

Exploded view of the instrument panel-l 997-00 Mirage

9. Remove the radio trim plate.

IO. Remove the radio retainers and the radio from

the console. Disconnect the electrical harness and

the antenna lead from the radio and remove it from

the vehicle.

11. Remove the center air outlet assembly.

12. If equipped, remove the screw retainers from

each dial knob on the center cluster. Gently pull the

dial knobs from the center cluster panel assembly.

13. Remove the glove compartment by pushing

the stoppers toward the rear of the vehicle to unlock

them, then remove the glove compartment assembly.

14. Remove the right and left speaker covers.

Disconnect and remove the speakers from the instru-

ment panel assembly.

15. Remove the heater control assembly retaining

screws and detach the harness connectors and ca-

bles. Remove the heater control assembly from the

vehicle. , 16. Remove any necessary ducts taking note of

their orientation,

17. Remove the steering shaft mounting bolts

and allow the steering wheel to rest on the front seat

cushion, Make sure no harness wires or connections

are being pulled or stretched.

18. Remove the instrument panel retaining bolts,

label and detach all electrical harness connectors.

19. Remove the instrument panel from the vehi-

cle. Disassemble components as required.

20. Install the instrument panel into the vehicle,

reattach all harness connections and install retaining

bolts. Before installing bolts, make sure the electrical

harness wires were not pinched during instrument

panel installation.

21. The installation is the reverse of removal.

Page 380 of 408

.

1042 BODYANDTRIM

P

I. i%lllUVt: LIE UUUI yldbb Uy lllllll!J It up ana out ot me ease, wnicn IS glueo onto tne wmasnlela. 1 ne

of the door.

installation is the reverse of the removal procedure. If

8. Remove the installation bolts holding the

the mirror base falls off of the windshield it can be in-

regulator to the door.

stalled as follows:

I

9. If equipped with electric windows discnnnad

1. Scrape the base mounting area with a razor

LllC vvllllly L” t,te Wlll”“W lll”l”l.

blade to remove the old adhesive.

I 10. Remove the regulator through the access hole

2. Thoroughly clean the base mounting ara.

’ in the door.

3. Obtain a mirror adhesive kit. Apply the clean-

To install:

ing compound to the windshield in the area that the

11. When reinstalling the regulator, apply a light

base is to be mounted. Allow to dry.

coat of multipurpose grease to the moving parts.

4. Apply the adhesive to both the base plate and

12. Install the regulator and tighten the bolts fin-

the windshield. Install the base to the glass. Hold in

ger-tight.

position until the adhesive has a chance to set. Make

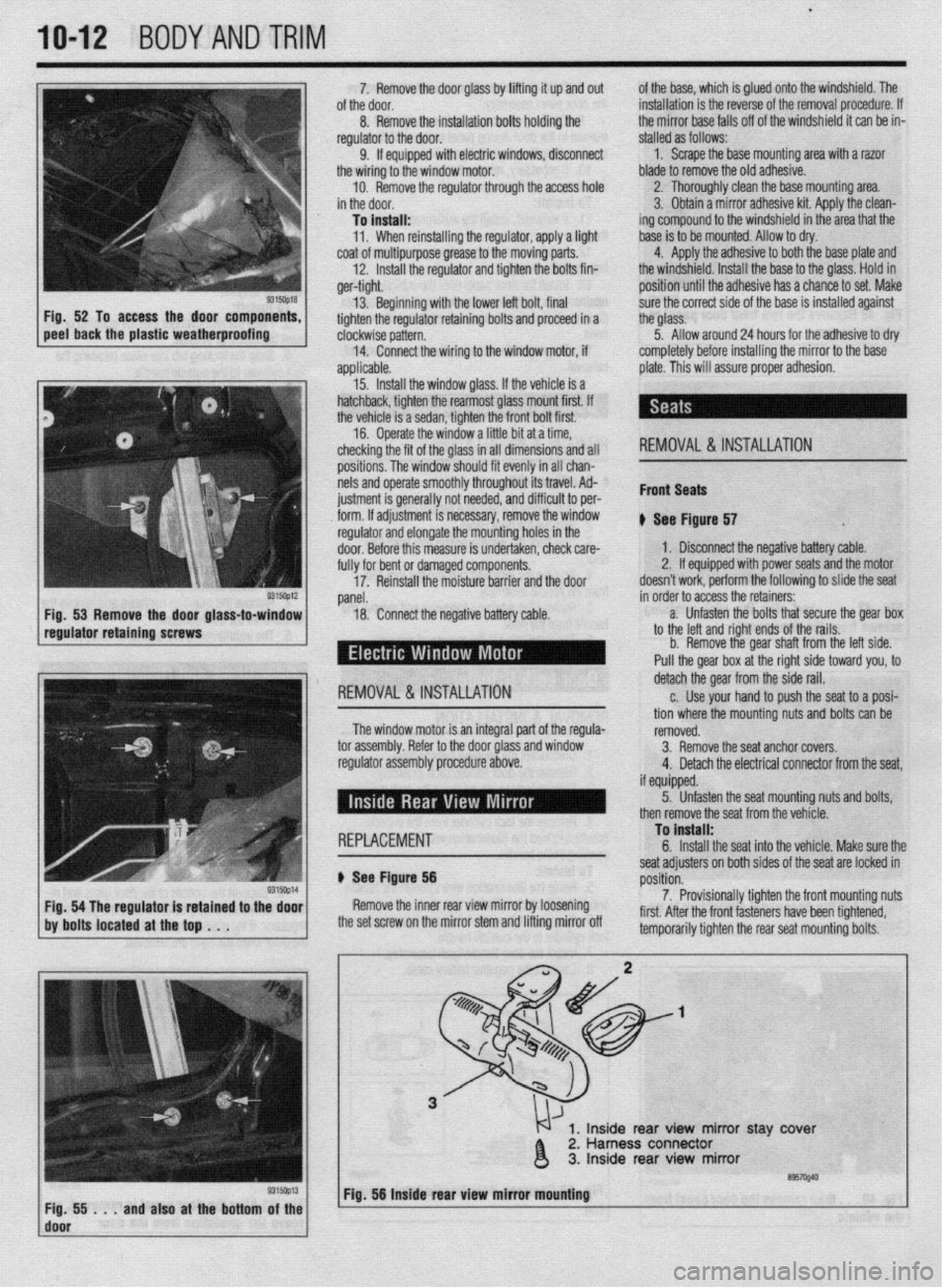

5315oQ18 Fig. 52 To access the door components,

peel back the plastic weatherproofing 13. Beginning with the lower left bolt, final

tighten the regulator retaining bolts and p

clockwise pattern.

14.

applic

+r roceed in a

Connect the wiring to the window motor, if

able.

Install the window glass. If the vehicle is a

lack, tighten the rearmost glass mount first. If

hicle is a sedan, tighten the front bolt first.

.

13. hatcht

the ve’

16. Uperate the window a little bit at a time,

checking the fit of the glass in all dimensions and all

positions. The window should fit evenly in all chan-

nels and operate smoothly throughout its travel. Ad-

ius~ment is rener;IIIv not needed. and diffirlllf +n nor- . ._ ~ _.._. - ., _.

___.-, - - _ lll”“ll I” pm

i&h. If adiustment is necessarv, remove thp win&N I..” . . . ..“1.. regulator and elongate the mointing holes in the

door. Before this measure is undertaken, check care-

fully for bent or damaged components.

17. Reinstall the moisture barrier and the door sure the correct side of the base is installed against

the glass.

5. Allow around 24 hours for the adhesive to dry

completely before installing the mirror to the base

plate. This will assure proper adhesion.

REMOVAL & INSTALLATION

Front Seats

* err ei

I ovv rlgure 57 .

1, Disconnect the negative battery cable.

2. If equipped with power seats and the motor

doesn’t work, perform the following to slide the seat

panel.

18. Conned the negative battery Cable. in order to acdess the retainers:

-

a. Unfasten the bolts that secure the gear box

to the left and right ends of the rails.

b. Remove the gear shaft from the left side.

Pull the gear box at the right side toward you, to

I REMOVAL & INSTALLATION detach the gear from the side rail.

c. Use your hand to push the seat to a posi-

tion where the mounting nuts and bolts can be

The window motor is an integral part nf the renlrla-

romnvPrl

-’ .“- ‘-J-.- tor assembly. Refer to the door Glass and window

regulator assembly procedure above. IYII,“.““. 3. Remove the seat anchor covers.

4. Detach the electrical connector from the seat,

if m~innd I I, “y”y~Y”. 5. Unfasten the seat mountina nuts and bolts.

1 REPLACEMENT To install:

c

b Ser f Floure 56

Yap- ~~

Remove the inner rear view mirror by loosening

the set screw on the mirror stem and lifting mirror off seat adjusters on both sides of the seat are locked in

rmritinn p”3111”ll.

7. Provisionally tighten the front mounting nuts

first. After the front fasteners have been tightened,

tomnnr.,rilw tinhton thn co.-ar co.,+ m qunting bolts. then remove the seat from the vehicle.

1, Inside rear view mirror stay ‘cover

2. Harness connector

3. Inside rear view mirror

’ ~;f!i!i...andalsoatthebottom~~~~ Fig. 56 Inside rear view mirror mbuntlng

I

Page 406 of 408

l

II-24 MASTER INDEX

ADJUSTMENT 8-25

REMOVAL &INSTALLATION 8-25

HYDRAULIC CONTROL UNIT 9-25

REMOVAL & INSTALLATION 9-25

IDLE AIR CONTROLMOTOR 4-9

OPERATION 4-9

REMOVAL&INSTALLATION 4-9

TESTING 4-9

IDLESPEED 1-28

PREVENTIVEMAINTENANCE 1-28

SYSTEM INSPECTION 1-29

SYSTEMSERVlCE&REPAlR 1-28

IGNITION LOCK CYLINDER 8-29

REMOVAL & INSTALLATION 8-29

IGNITION SWITCH 8-30

REMOVAL & INSTALLATION 8-30

IGNITION COIL(s) 2-5

REMOVAL&INSTALLATION 2-6

TESTING . 2-5

IGNITION COIL 2-3

REMOVAL&INSTALLATION 2-3

TESTING 2-3

IGNITION TIMING l-25

GENERALINFORAMTION l-25

INSPECTION&ADJUSTMENT l-26

INSIDE REAR VIEW MIRROR

IO-IO

REPLACEMENT IO-IO

INSPECTION 3-55

REPLACEMENT 3-56

INSTRUMENT CLUSTER 6-17

REMOVAL&INSTALLATION 6-I;

INSTRUMENTPANEL IO-6

REMOVAL &INSTALLATION IO-6

INSTRUMENTS AND SWITCHES 6-17

INTAKE MANIFOLD 3-7

REMOVAL &INSTALLATION 3-7

INTAKEAIRTEMPERATURESENSOR 4-10

OPERATION 4-10

REMOVAL&INSTALLATION 4-11

TESTING 4-11

INTERIOR 1 O-6

JACKING I-46

. JACKING PRECAUTIONS 1-47

JUMP STARTING A DEAD BATTERY 1-44

JUMPSTARTING PRECAUTIONS l-45

JUMPSTARTING PROCEDURE l-45

KNUCKLE,HUB, AND BEARING 8-13

REMOVAL &INSTALLATION 8-13

LIGHTING 6-19

LOWER BALLJOINT 8-10

INSPECTION 8-10

REMOVAL & INSTALLATION 8-10

LOWER CONTROLARM 8-10

REMOVAL&INSTALLATION 8-10

LOWER CONTROL ARMS 8-23

REMOVAL & INSTALLATION 8-23

MACPHERSONSTRUTAND COILSPRING

8-7

OVERHAUL 8-7

REMOVAL & INSTALLATION 8-7

MAINTENANCEORREPAIR? l-2

MANIFOLDABSOLUTEPRESSURESENSOR

4-12

OPERATION 4-12

REMOVAL&INSTALLATION 4-13

TESTING 4-12

MANUAL RACK AND PINION STEERING GEAR

8-31

REMOVAL & INSTALLATION 8-31

MANUALTRANSAXLEASSEMBLY 7-2

REMOVAL & INSTALLATION. 7-2

MANUAL TRANSAXLE 7-2 MANUALTRANSAXLE l-35

DRAIN &REFILL l-36

FLUID RECOMMENDATIONS l-35

LEVEL CHECK l-35

MASSAIRFLOWSENSOR 4-11

OPERATION 4-11

REMOVAL&INSTALLATION 4-11

TESTING 4-11

MASTER CYLINDER 9-3

BRAKE PEDALADJUSTMENTS 9-4

REMOVAL & INSTALLATION 9-3

MULTI-POINT FUEL INJECTION SYSTEM (MPI) 5-3

DBD-1 TROUBLE CODES 4-26

OBD-II TROUBLE CODES 4-27

OIL PAN 3-30

REMOVAL & INSTALLATION 3-30

OIL PUMP 3-33

REMOVAL & INSTALLATION 3-33

OIL PRESSURESENDING UNIT 2-12@T

REMOVAL&INSTALLATION 2-1.2

TESTING 2-12

OUTSIDE MIRRORS IO-3

REMOVAL&INSTALLATION IO-3

OXYGENSENSOR 4-8

OPERATION 4-8

REMOVAL&INSTALLATION 4-8

TESTING 4-8

PARK/NEUTRAL POSITIONSWITCH 7-10

ADJUSTMENT 7-10

REMOVAL & INSTALLATION 7-10

PARKING BRAKE 9-20

PCVVALVE l-15

REMOVAL&INSTALLATION I-15

PINION SEAL 7-16

REMOVAL &INSTALLATION 7-16

POWER BRAKEBOOSTER 9-5

REMOVAL &INSTALLATION 9-5

POWER RACK AND PINION STEERING GEAR 8-32

REMOVAL &INSTALLATION 8-32

POWERSEATMOTOR IO-11

REMOVAL & INSTALLATION IO-11

POWER STEERING PUMP 8-34

REMOVAL & INSTALLATION 8-34

SYSTEM BLEEDING 8-36

POWER TRANSlSTOR(IGNITION MODULE) 2-7

REMOVAL&INSTALLATION 2-7

POWERSTEERING PUMP l-42

FLUID RECOMMENDATIONS l-42

LEVELCHECK l-42

POWER TRANSlSTOR(Ignition Module) 2-4

REMOVAL&INSTALLATION 2-4

PRESSURERELIEFVALVE 5-9

REMOVAL&INSTALLATION 5-9

PROPORTIONING VALVE 9-6

REMOVAL & INSTALLATION 9-6 *

RADIATOR 3-18

REMOVAL &INSTALLATION 3-18

RADIO RECEIVER/AMPLIFIER/TAPE PLAYER/CD PLAYER 6-14

READING CODES 4-26

WITHASCANTOOL 4-26

WITHOUTASCANTOOL 4-27

READING CODES 4-27

WITHASCANTOOL 4-27

WITHOUTASCANTOOL 4-27

REAR AXLE DIFFERENTIAL 7-15

REAR HALFSHAFTAND SEAL 7-15

REMOVAL&INSTALLATION 7-15

REAR MAIN SEAL 3-54

REMOVAL & INSTALLATION 3-54