change wheel MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 1 of 408

HOW TO USE THIS BOOK 1-2

WHERE TOBEGIN l-2

AVOIDINGTROUBLE 1-2

MAINTENANCEORREPAIR? 1-2

AVOIDINGTHEMOSTCOMMONMISTAKES l-2

TOOLS AND EQUIPMENT 1-2

SPECIALTOOLS l-4

YOUR VEHICLE SAFELY 1-4

DON'TS l-6

FASTENERS, MEASUREMENTS AND

CONVERSIONS l-6

BOLTS,NUTSANDOTHERTHREADED

RETAINERS 1-6

TORQUE l-7

TORQUEWRENCHES l-7

TORQUEANGLEMETERS 1-9

STANDARDANDMETRIC MEASUREMENTS l-9

SERIAL NUMBER IDENTIFICATION l-10

VEHICLE IDENTIFICATION NUMBER l-10

ENGINE IDENTIFICATION NUMBER I-10

TRANSAXLEIDENTIFICATION I-10

DRlVEAXLE(AWDGALANTONLY) l-10

TRANSFERCASE(AWDGALANTONLY) l-10

ROUTINE MAINTENANCE AND TUNE-UP l-14

AIRCLEANER(ELEMENT) 1-14

REMOVAL&INSTALLATION 1-14

FUELFILTER 1-15

REMOVAL &INSTALLATION l-15

PCVVALVE l-15

REMOVAL&INSTALLATION l-15

EVAPORATIVECANISTER l-16

SERVICING 1-16

BATTERY 1-16

PRECAUTIONS I-16

GENERALMAINTENANCE 1-16

BEL BATTERYFLUID 1-16

CABLES I-17

CHARGING I-18

REPLACEMENT 1-18

TS 1-18

INSPECTiON l-18

ADJUSTMENT 1-18

REMOVAL&INSTALLATION 1-18

TIMINGBELTS l-20

INSPECTION l-20

HOSES I-20

INSPECTION l-20

REMOVAL&INSTALLATION

CV-BOOTS 1-21

INSPECTION l-21

SPARKPLUGS l-22

SPARKPLUGHEATRANGE

REMOVAL&INSTALLATION

INSPECTION &GAPPING 1.

SPARKPLUG WIRES 1-24

TESTING 1-24

REMOVAL&INSTALLATION

DISTRIBUTORCAPANDROTOR

REMOVAL&INSTALLATION

INSPECTION 1-25

IGNITIONTIMING 1-25

. GENERALINFORAMTION l-

lNSPECTlON&ADJUSTMENl

VALVE LASH l-27

ADJUSTMENT l-27

IDLESPEED 1-28 1-21

l-22

l-22

-23

1-24

l-25

l-25

.25

1-26

AIR CONDITIONING SYSTEM 1-28

SYSTEMSERVlCEiiREPAlR l-28

PREVENTIVEMAINTENANCE 1-28

SYSTEM INSPECTION l-29

WINDSHIELD WIPERS l-29

ELEMENT(REFILL)CARE&

REPLACEMENT l-29

TIRESANDWHEELS l-30

TIRE ROTATION I-30

TIRE DESIGN 1-31

TIRESTORAGE l-31

INFLATION &INSPECTION l-31

CARE OFSPECIALWHEELS l-32 OPERATION INFOREIGNCOUNTRIES l-33

ENGINE l-33

OILLEVELCHECK 1-33

OIL& FILTER CHANGE l-34

MANUALTRANSAXLE l-35

FLUIDRECOMMENDATIONS l-35

LEVELCHECK l-35

DRAIN&REFILL l-36

AUTOMATICTRANSAXLE l-36

FLUIDRECOMMENDATIONS l-36

LEVELCHECK 1-36

DRAIN&REFILL l-36

PAN & FILTERSERVICE 1-36

TRANSFERCASE(AWDGAlANT ONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

REARDRlVEAXLE(AWDGALANTONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

COOLINGSYSTEM l-39

FLUIDRECOMMENDATIONS l-39

iM-41

FLUIDS AND LUBRICANTS 1-33

FLUID DISPOSAL 1-33

FlJELANDENGlNEOILRECOMMENDATlONS

ENGINE OIL l-33

FUEL l-33

Page 20 of 408

GENERALINFORMATIONAND MAINTENANCE l-21

IWSIZXJ FM. 83 A hose clamn that is taa tiaht can

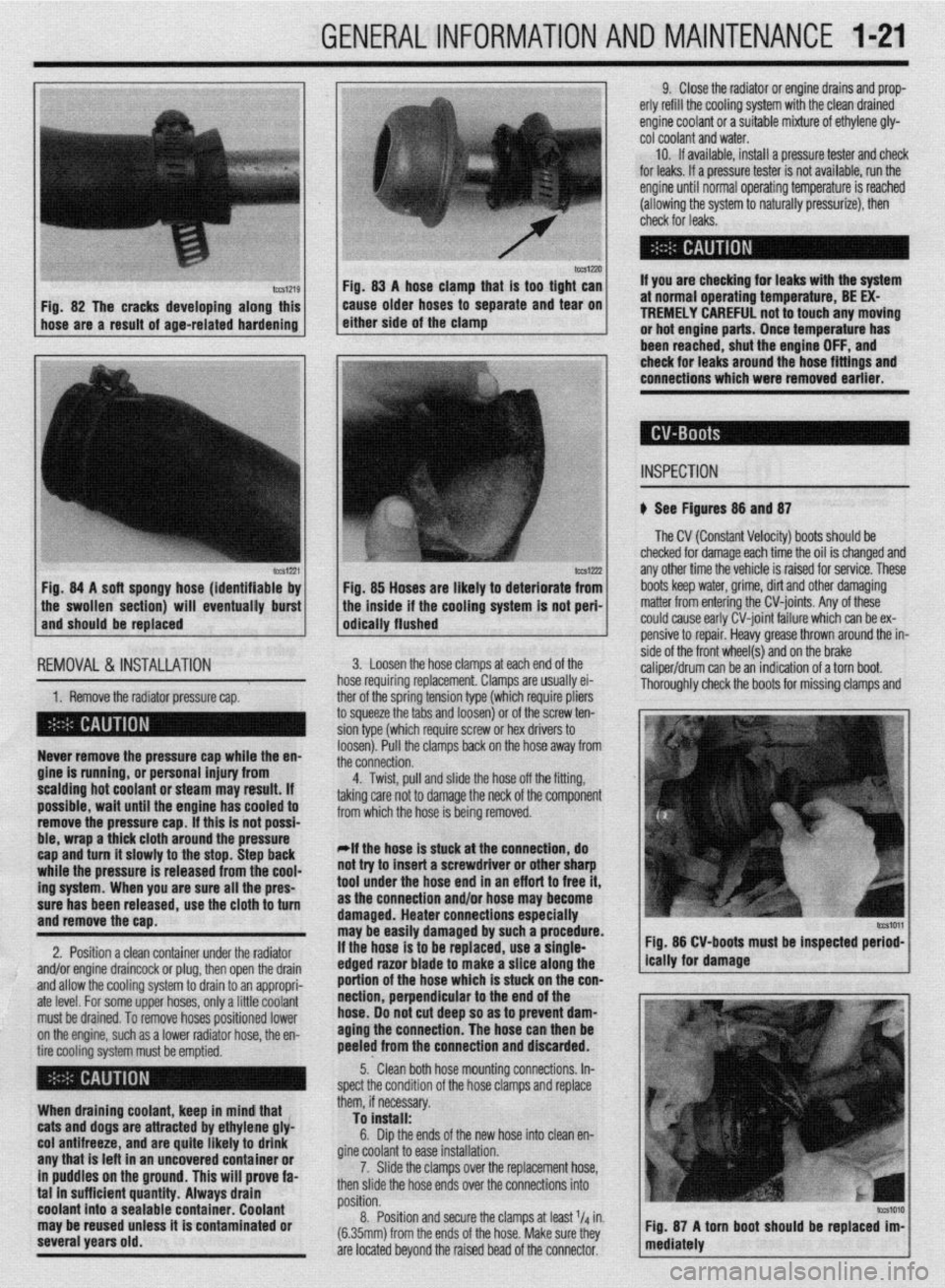

Fig. 82 The cracks developing along this

hose are a result of age-related hardening caise older hoses td separate and ‘iear on

either side of the clamp

lCCS1221 Fig. 84 A soft spongy hose (identifiable by

1 the swollen section) will eventually burst

and should be replaced

IEMOVAL &,INSTALLATION '

1. Remove the radiator pressure cap. her of the sorina tension tvoe (which reouire oliers

3 squeeze the 6bs and loosenj or of the’screw ten-

ion type (which require screw or hex drivers to

oosen). Pull the clamps back on the hose away from

he connection. Never remove the pressure cap while the en-

gine is running, or personal injury from

scalding hot coolant or steam may result. If

possible, wait until the engine has cooled to

remove the pressure cap. If this is not possi-

ble, wrap a thick cloth around the pressure

cap and turn it slowly to the stop. Step back

while the pressure is released from the cool-

ing system. When you are sure all the pres-

sure has been released, use the cloth to turn

and remove the cao.

2. Position a clean container under the radiator

and/or engine draincock or plug, then open the drain

and allow the cooling system to drain to an appropri-

ate level. For some upper hoses, only a little coolant

must be drained. To remove hoses positioned lower

on the engine, such as a lower radiator hose, the en-

tire cooling system must be emptied.

When draining coolant, keep in mind that

cats and dogs are attracted by ethylene gly-

col antifreeze, and are quite likely to drink

any that is left in an uncovered container or

in puddles on the ground. This will prove fa-

tal in sufficient quantity. Always drain

coolant into a sealable container. Coolant

may be reused unless it is contaminated or

several years old. 9. Close the radiator or engine drains and prop-

erly refill the cooling system with the clean drained

engine coolant or a suitable mixture of ethylene gly-

cot coolant and water.

10. If available, install a pressure tester and check

for leaks. If a pressure tester is not available, run the

engine until normal operating temperature is reached

(allowing the system to naturally pressurize), then

check for leaks.

If you are checking for leaks with the system

at normal operating temperature, BE EX-

TREMELY CAREFUL not to touch any moving

or hot engine parts. Once temperature has

been reached. shut the enaine OFF. and

Fig. 85 Hoses are likely to deteriorate from

the inside if the cooling system is not peri-

odically flushed check for leaks around the-hose fittings and

connections which were removed earlier.

INSPECTION

b See Figures 88 and 87

The CV (Constant Velocity) boots should be

checked for damage each time the oil is changed and

any other time the vehicle is raised for service. These

boots keep water, grime, dirt and other damaging

matter from entering the CV-joints. Any of these

could cause early CV-joint failure which can be ex-

pensive to repair. Heavy grease thrown around the in-

side of the front wheel(s) and on the brake

caliper/drum can be an indication of a torn boot.

Thorouahlv check the boots for missina clamos and 3. Loosen the hose clamps at each end of the

rose requiring replacement. Clamps are usually ei-

4. Twist, pull and slide the hose off the fitting,

sking care not to damage the neck of the component

rom which the hose is being removed.

*If the hose is stuck at the connection, do

lot try to insert a screwdriver or other sharp

ool under the hose end in an eff art to free it,

IS the connection and/or hose may become

lamaged. Heater connections especially

nay be easily damaged by such a procedure.

f the hose is to be replaced, use a single-

!dged razor blade to make a slice along the

lortion of the hose which is stuck on the con-

section, perpendicular to the end of the

lose. 00 not cut deep so as to prevent dam-

aging the connection. The hose can then be

keeled from the connection and discarded. Fig. 86 CV-boots must be inspected period-

5.. Clean both hose mounting connections. In-

,pect the condition of the hose clamps and replace

hem, if necessary.

To install:

6. Dip the ends of the new hose into clean en-

fine coolant to ease installation.

7. Slide the clamps over the replacement hose,

hen slide the hose ends over the connections into

rosition.

8. Position and secure the clamps at least l/d in.

6.35mm) from the ends of the hose. Make sure they

Ire located beyond the raised bead of the connector.

Page 30 of 408

GENERALINFORMATIONAND MAlNTENANdE 1-31

When rotating “unidirectional tires,” make sure

that they always roll in the same direction. This

means that a tire used on the left side of the vehicle

must not be switched to the right side and vice-versa.

Such tires should only be rotated front-to-rear or

rear-to-front, while always remaining on the same

side of the vehicle. These tires are marked on the

sidewall as to the direction of rotation; observe the

marks when reinstalling the tire(s).

Some styled or “mag” wheels may have different

offsets front to rear. In these cases, the rear wheels

must not be used up front and vice-versa. Further-

more, if these wheels are equipped with unidirectional

tires, they cannot be rotated unless the tire is re-

mounted for the proper direction of rotation.

*The compact or space-saver spare is

strictly for emergency use. it must never be

included in the tire rotation or placed on the

vehicle for everyday use. check the installed tire for any sign of interference

with the body or suspension while the vehicle is stop-

ping, turning sharply or heavily loaded.

Snow Tires

Good radial tires can produce a big advantage in

slippery weather, but in snow, a street radial tire does

not have sufficient tread to provide traction and con-

trol. The small grooves of a street tire quickly pack

with snow and the tire behaves like a billiard ball on a

marble floor, The more open, chunky tread of a snow

tire will self-clean as the tire turns, providing much

better grip on snowy surfaces.

To satisfy municipalities requiring snow tires dur-

ing weather emergencies, most snow tires carry either

an M + S designation after the tire size stamped on

the sidewall, or the designation “all-season.” In gen-

eral, no change in tire size is necessary when buying

snow tires.

Most manufacturers stronqlv recommend the use styled wheels, see if inexpensive steel

wheels are available, Although the look of

the vehicle will change, the expensive

wheels will be protected from salt, curb hits

and pothole damage.

TIRESTORAGE

If they are mounted on wheels, store the tires at

proper inflation pressure. All tires should be kept in a

cool, dry place. If they are stored in the garage or

basement, do not let them stand on a concrete floor;

set them on strips of wood, a mat or a large stack of

newspaper. Keeping them away from direct moisture

is of paramount importance. Tires should not be

stored upright, but in a flat position.

INFLATION & INSPECTION

b See Figures 140 thru 147

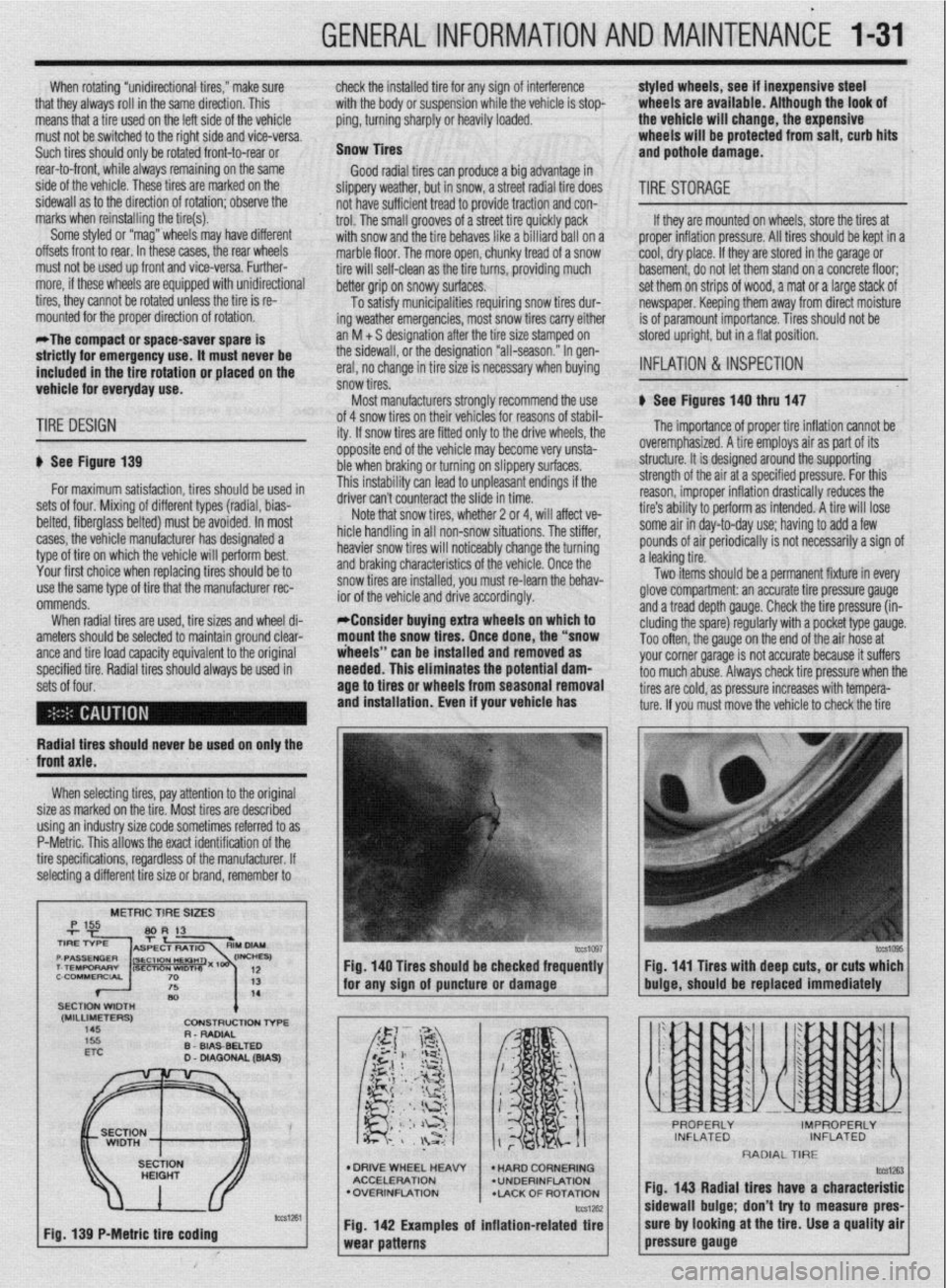

TIRE DESIGN

p See Figure 139

for maximum satisfaction, tires should be used in

sets of four. Mixing of different types (radial, bias-

belted, fiberglass belted) must be avoided. In most

cases, the vehicle manufacturer has designated a

type of tire on which the vehicle will perform best.

Your first choice when replacing tires should be to

use the same type of tire that the manufacturer rec-

ommends.

When radial tires are used, tire sizes and wheel di-

ameters should be selected to maintain ground clear-

ante and tire load caoacitv eauivalent to the oriainal

specified tire. Radial tiresshould always be used in

sets of four. of 4 snow tires on their

lehicies for reasons of stabil-

ity. If snow tires are fitter

1 only to the drive wheels, the

opposite end of the vehil cle may become very unsta-

ble when braking or turn

ring on slippery surfaces.

This instability can lead to unpleasant endings if the

A*:,,“- r-..l, ^_.. ..& ^_^^, &I.

UIIVU MII I LUUII~~MLL iue slide in time.

Note that snow tires, whether 2 or 4, will affect ve-

hicle handling in all non-snow situations. The stiffer,

heavier snow tires will noticeably change the turning

and braking characteristics of the vehicle. Once the

snow tires are installed, you must re-learn the behav-

ior of the vehicle and drive accordingly.

*Consider buying extra wheels on which to

mount the snow tires. Once done, the “snow

iheeis” can be installed and removed as

needed. This eliminates the potential

dam- age to tires or wheels from seasonal removal

and installation. Even if your vehicle has

lb The importance of proper tire inflation cannot be

overemphasized. A tire employs air as part of its

structure. It is designed around the supporting

strength of the air at a specified pressure. For this

reason, improper inflation drastically reduces the

tire’s ability to perform as intended. A tire will lose

some air in day-to-day use; having to add a few

pounds of air periodically is not necessarily a sign of

a leaking tire.

Two items should be a permanent fixture in every

glove compartment: an accurate tire pressure gauge

and a tread depth gauge. Check the tire pressure (in-

eluding the spare) regularly with a pocket type gauge.

Too often, the gauge on the end of the air hose at

vnr rr corner narane is not accurate because it suffers

~rs check tire oressure when the

Radial tires should never be used on only the

XI I._.

‘-’ --“‘“’ J s too much abuse. Alwa!

tires are cold, as pressure increases with tempera-

ture. If you must move the vehicle to check the tire

front axle.

When selecting tires, pay attention to the original

size as marked on the tire. Most tires are described

using an industry size code sometimes referred to as

P-Metric. This allows the exact identification of the

tire specifications, regardless of the manufacturer. If

selecting a different tire size or brand, remember to

METRIC TIRE SIZES

(MILLIMETERS)

145 CDNStRUCtlDN l-6-E

R - RADIAL

D

WA9

Fig. 139 P-Metric tire coding Fig. 140 Tires should be checked frequently

I I Fig. 141 Tires with deep cuts, or cuts which

for any sion of auncture or damaoe

buioe, should be replaced immediately

l DRIVE WHEEL HEAW

ACCELERATION

l OVERINFLATION

*LACK OF ROTATION

Fig. 142 Examples of inflation-related tire

RADIAL TIRE

fig. 143 Radial tires have a characteristic

sidewall bulge; don’t try to measure pres-

sure by looking at the tire. Use a quality air

pressure gauge

Page 31 of 408

.

1-32 GENERALINFORMATIONAND MAINTENANCE

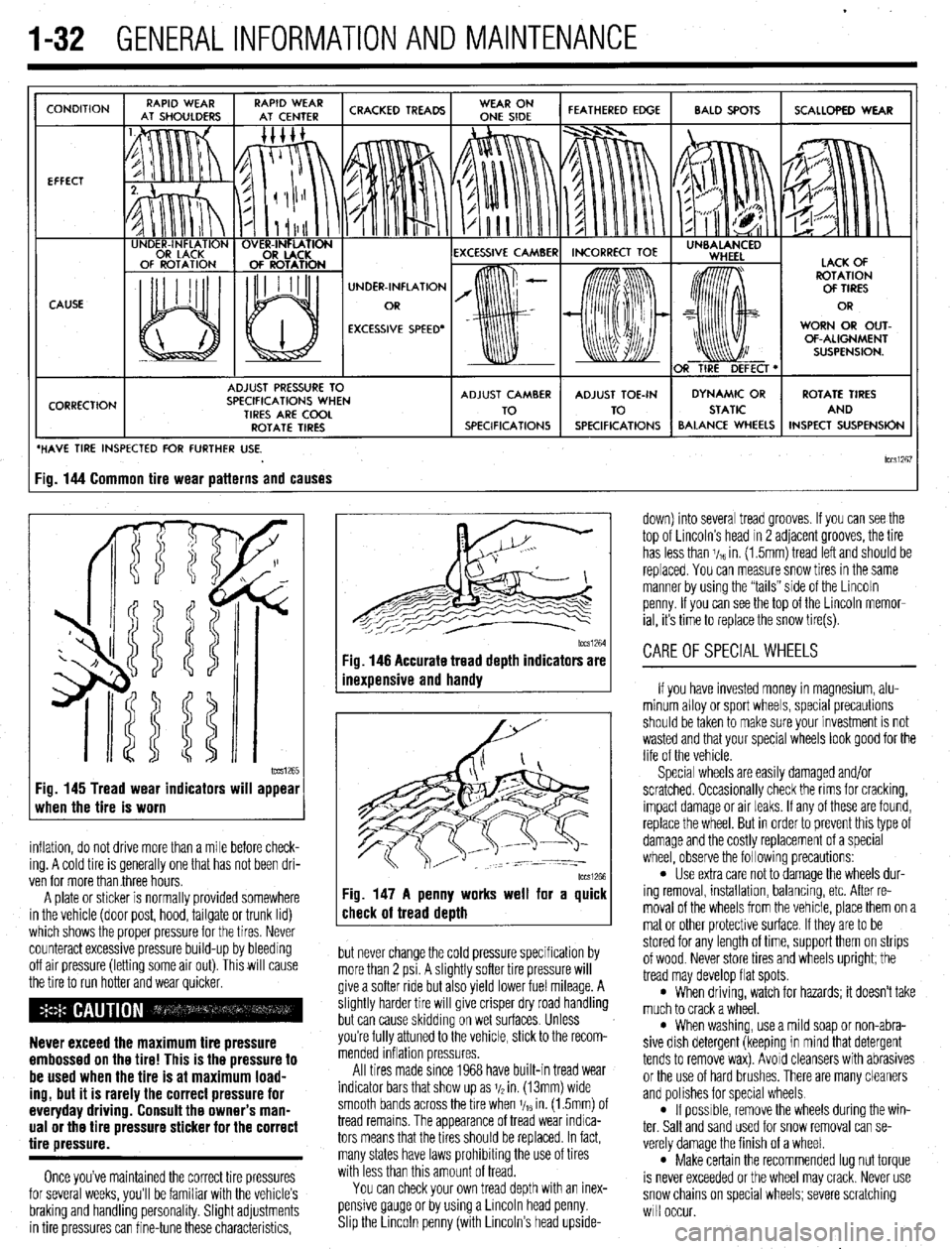

CONDITION

EFFECT

CAUSE

CORRECTION UNDER-INFLATION

EXCESSIVE SPEED’ WORN OR OUT-

OF-ALIGNMENT

ADJUST PRESSURE TO

SPECIFICATIONS WHEN

TIRES ARE COOL

ROTATE TIRES

/ BALANCE WHEELS INSPECT SUSPENSION

HAVE TIRE INSPECTED FOR FURTHER USE.

lCCSi267 ig. 144 Common tire wear patterns and causes

1~~~1265 Fig. 145 Tread wear indicators will appear

when the tire is worn

inflation, do not drive more than a mile before check-

ing. A cold tire is generally one that has not been dri-

ven for more than three hours.

A plate or sticker is normally provided somewhere

in the vehicle (door post, hood, tailgate or trunk lid)

which shows the proper pressure for the tires. Never

counteract excessive pressure build-up by bleeding

off air pressure (letting some air out). This will cause

the tire to run hotter and wear quicker.

Never exceed the maximum tire pressure

embossed on the tire! This is the pressure to

be used when the tire is at maximum load-

ing, but it is rarely the correct pressure for

everyday driving. Consult the owner’s man-

ual or the tire pressure sticker for the correct

tire pressure.

Once you’ve maintained the correct tire pressures

for several weeks, you’ll be familiar with the vehicle’s

braking and handling personality. Slight adjustments

in tire pressures can fine-tune these characteristics,

1~~~1264 Fig. 146 Accurate tread depth indicators are

inexuensive and handv

Fig. 147 A penny works well for a quick

check of tread death

but never change the cold pressure specification by

more than 2 psi. A slightly softer tire pressure will

give a softer ride but also yield lower fuel mileage. A

slightly harder tire will give crisper dry road handling

but can cause skidding on wet surfaces. Unless

you’re fully attuned to the vehicle, stick to the recom-

mended inflation pressures.

All tires made since 1968 have built-in tread wear

indicator bars that show up as j/2 in. (13mm) wide

smooth bands across the bre when V,~ in. (1.5mm) of

tread remains. The appearance of tread wear indica-

tors means that the tires should be replaced. In fact,

many states have laws prohibiting the use of tires

with less than this amount of tread.

You can check your own tread depth with an inex-

pensive gauge or by using a Lincoln head penny.

Shp the Lrncoln penny (with Lincoln’s head upside- down) into several tread grooves. If you can see the

top of Lincoln’s head in 2 adjacent grooves, the tire

has less than V,~ in. (1.5mm) tread left and should be

replaced. You can measure snow tires in the same

manner by using the “tails” side of the Lincoln

penny. If you can see the top of the Lincoln memor-

ial, its time to replace the snow tire(s).

CAREOFSPECIALWHEELS

If you have invested money in magnesium, alu-

minum alloy or sport wheels, special precautions

should be taken to make sure your investment is not

wasted and that your special wheels look good for the

life of the vehicle.

Special wheels are easily damaged and/or

scratched. Occasionally check the rims for cracking,

impact damage or air leaks. If any of these are found,

replace the wheel. But in order to prevent this type of

damage and the costly replacement of a special

wheel, observe the following precautions:

l Use extra care not to damage the wheels dur-

ing removal, installation, balancing, etc. After re-

moval of the wheels from the vehicle, place them on a

mat or other protective surface. If they are to be

stored for any length of time, support them on strips

of wood. Never store tires and wheels upright; the

tread may develop flat spots.

l When driving, watch for hazards; it doesn’t take

much to crack a wheel.

l When washing, use a mild soap or non-abra-

sive dish detergent (keeping in mind that detergent

tends to remove wax). Avoid cleansers with abrasives

or the use of hard brushes. There are many cleaners

and polishes for special wheels.

l If possrble, remove the wheels during the win-

ter. Salt and sand used for snow removal can se-

verely damage the finish of a wheel.

l Make certain the recommended lug nut torque

is never exceeded or the wheel may crack. Never use

snow chains on special wheels; severe scratching

will occur.

Page 37 of 408

t

1-38 GENERALINFORMATIONAND MAINTENANCE

11 I Add the recommended automatic transaxle

fluid to the transaxle through the dipstick tube. You

will need a long necked funnel, or a funnel and tube

to do this. A quick check of the capacities chart later

in this Section will reveal the capacity of the transaxle

in your vehicle. On a first fill after removing the pan

and filter, this number should be cut into a ‘hand

checked on the dipstick before refilling.

12. With the transaxle in P, put on the parking

brake, block the front wheels, start the engine and let

it idle. DO NOT RACE THE ENGINE. DO NOT MOVE

THE LEVER THROUGH ITS RANGES.

13. With the lever in Park, check the fluid level. If

it’s OK, take the car out for a short drive, park on a

level surface, and check the level again, as outlined

earlier in this section. Add more fluid if necessary. Be

careful not to overfill, which will cause foaming and

w fluid loss. n of the transfer case filler

3. Remove the filler and the drain plug and allow

the oil to drain into the drain pan.

4. After the fluid has drained completely, install

the drain plug and tighten to 24 ft. Ibs. (32 Nm).

5. Refill the transfer case to the proper level with

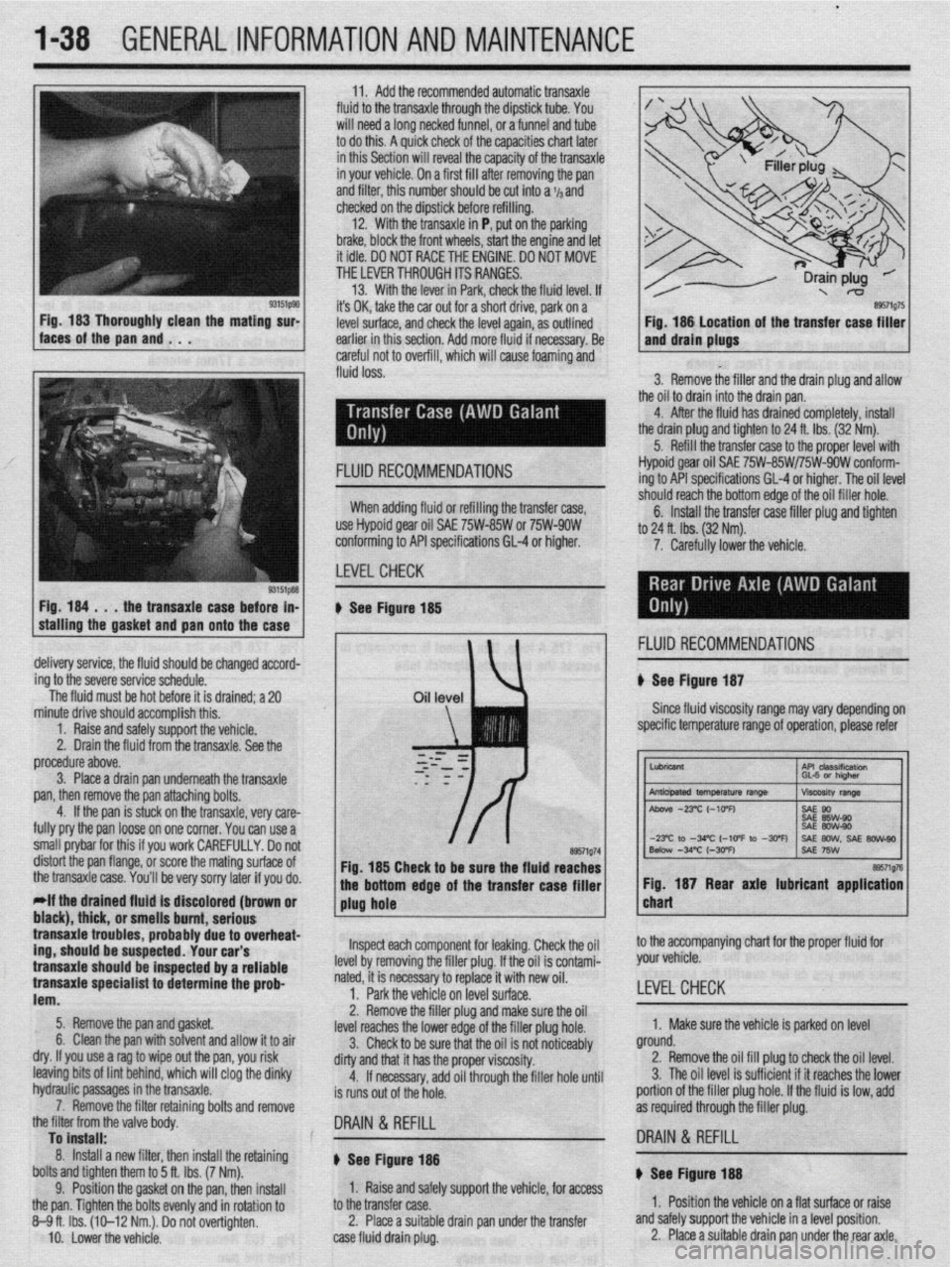

Fig. 184 . . .

the transaxle case before in-

stalling the gasket

and pan onto the case FLUID RECOMMENDATIONS Hypoid gear oil SAE 75W-85W/75W-9OW conform-

ing to API specifications GL-4 or higher. The oil level

-‘-,*I’ -nnnh +‘* “%om edge of the oil filler hole.

nxfer raw filler nlm and tinhtm When adding fluid or refilling the transfer case,

use Hypoid gear oil SAE 75W-85W or 75W-9OW

conforming to API specifications 61-4 or higher.

LEVELCHECK 6. Install the tra .._._. ____ .._. T.-J _.._ .lJ . .._..

to 24 ft. lbs. (32 Nm).

7. Carefully lower the vehicle.

u See Figure 185

, 1 FLUID RECOMMENDATIONS

delivery service, the fluid should be changed accord-

ing to the severe service schedule.

The fluid must be hot before it is drained; a 20 u See Figure 187

Since fluid viscosity range may

vary depending on

specific temperature range of operation, please refer

~~

tne transaxle case.

You’ll be very sorry later if you do. bottom edge of the transfer case filler 1 1 Fig. 187 Rear axle lubricant application I

*If the drained fluld is discolored (brown or

1 plug hole chart black), thick, or pmmll~ hmmt nnrinmm I transaxle trouble .llln3llU ““III., url,““P s, probably due to overheat-

,r..rr,rA “#.a.- rrdr

trig, should be susp~~lr;u. lvUl vLlr J

transaxle should be inspected by a reliable

transaxle specialist to determine the prob-

lem.

5. Remove the pan and gasket.

6. Clean the pan with solvent and allow it to air

dry. If you use a rag to wipe out the pan, you risk

leaving bits of lint behind, which will clog the dinky

hydraulic passages in the bansaxle.

7. Remove the filter retaining bolts and remove

the filter from the valve bodv. lnsoect each component for leaking. Check the oil

he filler plug. If the oil is contami-

ry to replace it with new oil.

if% nn IPVPI z11rf2r~

level by removing t

nated, it is necessa

1. Park the vehi,., -.. ,-.“, __. ,“-_.

2. Remove the filler plug and make sure the oil

level reaches the lower edge of the filler plug hole.

3. Check to be sure that the oil is not noticeably

dirty and that it has the proper viscosity.

4. If necessary, add oil through the filler hole until

is runs out of the hole. to the accompanying chart for the proper fluid for

your vehicle.

LEVEL CHECK

1. Make sure the vehicle is parked on level

ground.

2. Remove the oil fill plug to check the oil level.

3. The oil level is sufficient if it reaches the lower

portion of the filler plug hole. If the fluid is low, add

as required through the filler plug.

To install: .

8. Install a new filter, then install the retaining

bolts and tighten them to 5 ft. Ibs. (7 Nm).

9. Position the gasket on the pan, then install

the pan. Tighten the bolts evenly and in rotation to

8-9ft. Ibs. (10-12 Nm.). Do not overtighten.

IO. Lower the vehicle. DRAIN & REFILL

I8 DRAIN & REFILL

u See Figure 188 ) See Figure- 14

1. Raise and safely support the vehicle, for access

to the transfer case.

2. Place a suitable drain pan under the transfer

case fluid drain plug. 1. Position the vehicle on a flat surface or raise

and safely support the vehicle in a level position.

2. Place a suitable drain pan under the rear axle.

Page 46 of 408

GENERAL INFORMATION AND MAINTENANCE 1-47

ramps are also a handy and safe way to both raise l When the drive wheels are to remain on the

and support the vehicle. Be careful though, some ground, leave the vehicle in gear to help prevent it

ramps may be too steep to drive your vehicle onto

The following safety points cannot be overempha- from rolling.

without scraping the front bottom panels. Never sup-

sized:

l Always use jackstands to support the vehicle

port the vehicle on any suspension member (unless l Always block the opposite wheel or wheels to when you are working underneath. Place the stands

specifically instructed to do so by a repair manual) or

keep the vehicle from rolling off the jack. beneath the vehrcle’s jacking brackets Before climb-

by an underbody panel.

l When raising the front of the vehicle, firmly ap- ing underneath, rock the vehicle a bit to make sure it

ply the parking brake. is firmly supported.

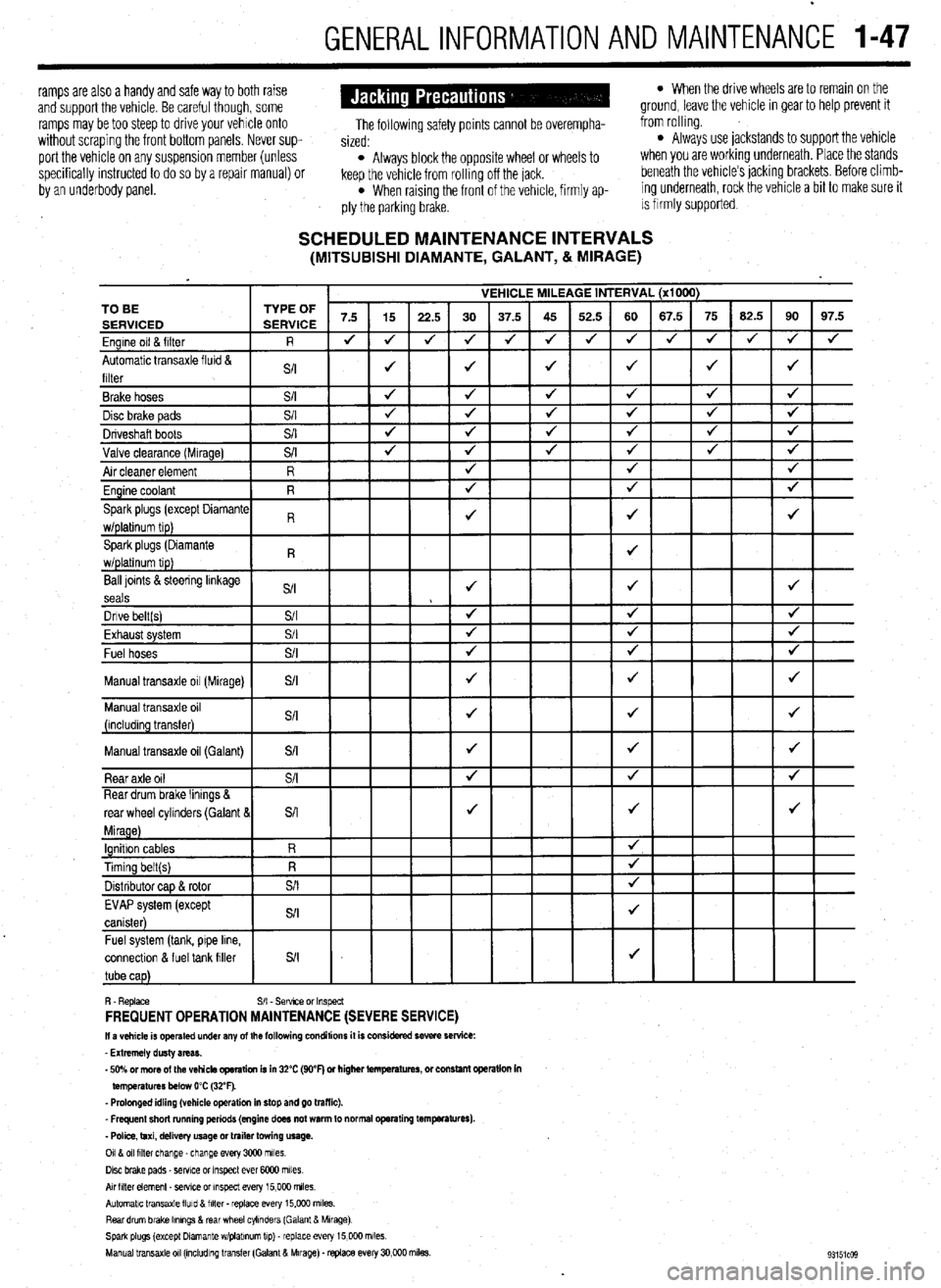

SCHEDULED MAINTENANCE INTERVALS (MITSUBISHI DIAMANTE, GALANT, & MIRAGE)

VEHICLE MILEAGE INTERVAL (x1000)

7.5 15

22.5 30 37.5 45 52.5 60 67.5 75 62.5 90 97.5

J J

J 4 J J 4 4 4 J J

J 4

4

J J J J 4 TO BE

Ball loints &steering linkage

S/I J J J

seals

Dnve belt(s) S/I 4 4 J

Fvha,,rt cvctom $/I

J J J LmI,..“w. “,YL”,‘. Fuel hoses

+

Manual transaxle oil (Galant)

connectlon & fuel tank filler

R. Replace S/I - Sefwce or Inspect FREQUENT OPERATION MAINTENANCE (SEVERE SERVICE) II a vehicle is operated under any of the following conditions it is considered severe service:

- Extremely dusty areas.

- 50% or more of the vehicle operation is in 32% (WF) or higher temperatures, or constant opsralion in

temperatures below 0% (32°F).

- Prolonged idling (vehicle operation in stop and go traffic).

_ Frequent short running periods (engine does not warm to normal operating temfwatures).

- Police, taxi, delivery usage or trailer towing usage.

0118 011 filter change-change every 3CQO miles.

Disc brake pads - sewce or Inspect ever 6COO miles

AN hlter element _ setwe or inspect every 15,000 miles.

Automatic transaxle lluld 8 filter . replace every 15,COO m&s.

Rear drum brake Ikmngs & rear wheel cylinders (Galant & Mirage)

Spark plugs (except Dlamante wlplabnum tip) - replace every 15,COO miles.

Manual transaxle 011 (mcludlng transfer (Galant & Mirage). replace every 30,000 miles.

Page 213 of 408

640 CHASSIS ELECTRICAL

careful not to allow anything to come in contact with

the air bag unit.

16. Remove the glove box lamp assembly.

17. Remove the remaining instrument panel

mounting screws and remove the instrument panel

from the vehicle.

18. Remove the left side foot shower ductwork,

lap cooler duct and center duct.

19. Remove the front and center reinforcements

and center stay assembly.

20. Remove the air distribution duct assembly.

21. Detach all connectors from heater-box-

mounted items.

22. Remove the heater box mounting screws and

nut, then remove the unit from the vehicle.

23. Disassemble on a workbench. Remove the

heater core from the heater case.

To install:

24. Thoroughly clean and dry the inside of the

case and install the heater core and all related parts.

25. Install the heater unit to the vehicle and install

the mounting screws and nut. Be sure the evaporator

case and heater case are fitted together properly. At-

tach all connectors to heater-box-mounted items.

26. Install the air distribution duct assembly. In-

stall the front and center reinforcements and center

stay assembly.

27. Install the center duct, lap cooler duct and left

side foot shower duct.

28. Install the instrument panel and mounting

screws.

29. Install the glove box lamp assembly.

30. Secure the steering column and attach all

steering column connectors.

31. Install the speedometer cable adapter to the

instrument panel.

32. Install the instrument cluster and the instru-

ment cluster bezel.

33. Install the speakers to the top of the instru-

ment panel.

34. Install the cup holder.

35. Install the climate control system control

head.

36. Install the stereo entertainment system and

bezel.

37. Install the screw below the glove box assem-

bly, and the entire glove box unit.

38. Install the steering column covers.

39. Install the knee protector support bracket, the

protector and the decorative plugs.

40. Install the console and the ashtray. 41. Install the right side foot shower duct.

42. Install the passenger side undercover.

43. Connect the heater hoses to the core tubes.

44. Fill the cooling system.

45. Connect the negative battery cable and check

the entire climate control system for proper operation

and leaks.

Galant

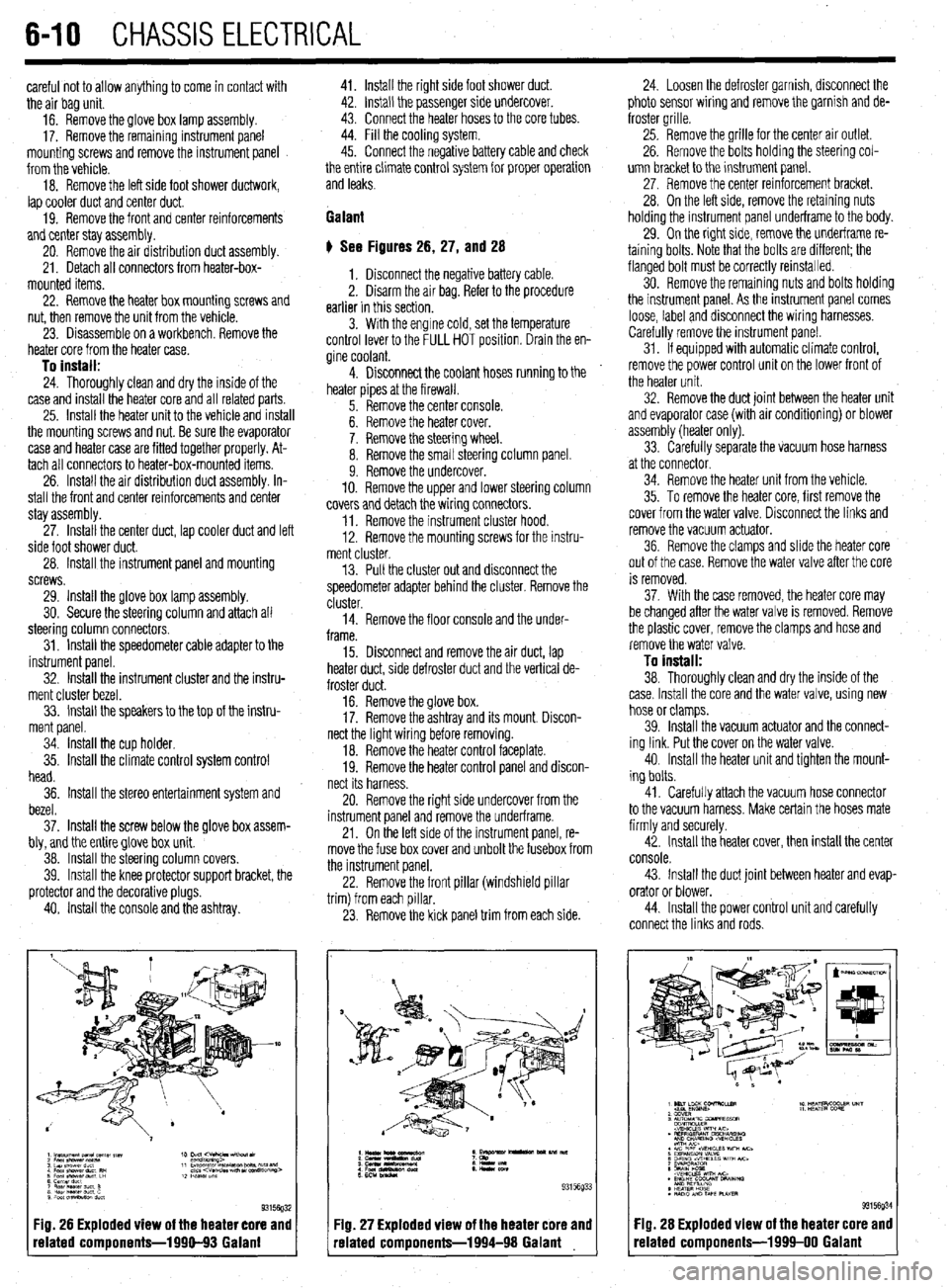

# See Figures 26, 27, and 28

1. Disconnect the negative battery cable.

2. Disarm the air bag. Refer to the procedure

earlier in this section.

3. With the engine cold, set the temperature

control lever to the FULL HOT position. Drain the en-

gine coolant.

4. Disconnect the coolant hoses running to the

heater pipes at the firewall.

5. Remove the center console.

6. Remove the heater cover.

7. Remove the steering wheel.

8. Remove the small steering column panel.

9. Remove the undercover.

10. Remove the upper and lower steering column

covers and detach the wiring connectors.

11. Remove the instrument cluster hood.

12. Remove the mounting screws for the instru-

ment cluster.

13. Pull the cluster out and disconnect the

speedometer adapter behind the cluster. Remove the

cluster.

14. Remove the floor console and the under-

frame.

15. Disconnect and remove the air duct, lap

heater duct, side defroster duct and the vertical de-

froster duct.

16. Remove the glove box.

17. Remove the ashtray and its mount. Discon-

nect the light wiring before removing.

18. Remove the heater control faceplate.

19. Remove the heater control panel and discon-

nect its harness.

20. Remove the right side undercover from the

instrument panel and remove the underframe.

21. On the left side of the instrument panel, re-

move the fuse box cover and unbolt the fusebox from

the instrument panel.

22. Remove the front pillar (windshield pillar

trim) from each pillar.

23. Remove the kick panel trim from each side.

Fig. 26 Exploded view of the heater core and

related components-1990-93 Galant

:IQ. 27 Exploded view of the heater core and

-elated components-1994-98 Galant 24. Loosen the defroster garnish, disconnect the

photo sensor wiring and remove the garnish and de-

froster grille.

25. Remove the grille for the center air outlet.

26. Remove the bolts holding the steering col-

umn bracket to the instrument panel.

27, Remove the center reinforcement bracket.

28. On the left side, remove the retaining nuts

holding the instrument panel underframe to the body.

29. On the right side, remove the underframe re-

taining bolts. Note that the bolts are different; the

flanged bolt must be correctly reinstalled.

30. Remove the remaining nuts and bolts holding

the instrument panel. As the instrument panel comes

loose, label and disconnect the wiring harnesses.

Carefully remove the instrument panel.

31. If equipped with automatic climate control,

remove the power control unit on the lower front of

the heater unit.

32. Remove the duct joint between the heater unit

and evaporator case (with air conditioning) or blower

assembly (heater only).

33. Carefully separate the vacuum hose harness

at the connector.

34. Remove the heater unit from the vehicle.

35. To remove the heater core, first remove the

cover from the water valve. Disconnect the links and

remove the vacuum actuator.

36. Remove the clamps and slide the heater core

out of the case. Remove the water valve after the core

is removed.

37. With the case removed, the heater core may

be changed after the water valve is removed. Remove

the plastic cover, remove the clamps and hose and

remove the water valve.

To install:

38. Thoroughly clean and dry the inside of the

case. Install the core and the water valve, using new

hose or clamps.

39. Install the vacuum actuator and the connect-

ing link. Put the cover on the water valve.

40. Install the heater unit and tighten the mount-

ing bolts.

41. Carefully attach the vacuum hose connector

to the vacuum harness. Make certain the hoses mate

firmly and securely.

42. Install the heater cover, then install the center

console.

43. Install the duct joint between heater and evap-

orator or blower.

44. Install the power control unit and carefully

connect the links and rods.

Fig. 28 Exploded view of the heater core and

related components-1999-00 Galant

Page 281 of 408

7-2 'DRIVETRAIN

Because of the way an internal combustron engine

breathes, it can produce torque, or twisting force,

only within a narrow speed range. Most modern,

overhead valve pushrod engines must turn at about

2500 rpm to produce their peak torque By 4500 rpm

they are producrng so lrttle torque that contrnued in-

creases in engine speed produce no power increases.

The torque peak on overhead camshaft engines IS

generally much higher, but much narrower.

The manual transaxle and clutch are employed to

vary the relationship between engine speed and the

speed of the wheels so that adequate engine power can

be produced under all crrcumstances. The clutch al-

lows engine torque to be applied to the transaxle input

shaft gradually, due to mechanical slippage. Conse-

quently, the vehicle may be started smoothly from a

full stop The transaxle changes the ratio between the

rotating speeds of the engine and the wheels by the

use of gears. The gear ratios allow full engine power to

be applied to the wheels during acceleration at low

speeds and at highway/passing speeds.

In a front wheel drive transaxle, power is usually

transmitted from the input shaft to a mainshaft or out-

put shaft located slightly beneath and to the side of

the input shaft. The gears of the mainshaft mesh with

gears on the input shaft, allowing power to be carried

from one to the other. All forward gears are in con-

stant mesh and are free from rotating with the shaft

unless the synchronizer and clutch IS engaged. Shaft-

ing from one gear to the next causes one of the gears

to be freed from rotating with the shaft and locks an-

other to it. Gears are locked and unlocked by internal

dog clutches which slide between the center of the

gear and the shaft. The forward gears employ syn-

chronizers; friction members which smoothly bring

gear and shaft to the same speed before the toothed

dog clutches are engaged.

SHIFT LINKAGE

1. Disconnect the shift linkage from the transaxle.

2. On the transaxle, put select lever in N and

move the shift lever in

4th gear. Depress the clutch,

if necessary, to shift.

3. Move the shift lever in the vehicle to the

4th gear position until it contacts the stop.

4. Turn the adjuster turnbuckle so the shift cable

eye aligns with the eye in the gear shift lever. When

installing the cable eye, make sure the flange side of

the plastic bushing at the shift cable end is on the

cotter pin side.

5 The cables should be adjusted so the clear-

ance between the shift lever and the 2 stoppers are

equal when the shift lever IS moved to 3rd and 4th

gear. Move the shift lever to each positron and check i

that the shifting is smooth

REMOVAL &INSTALLATION

1, Disconnect the negative battery cable 2. Remove any components necessary to access

the back-up light switch.

3. Unplug the back-up light switch connector.

4. Remove the switch from the case using the ap-

propriate size socket and drive tool.

To install: 5. Install the switch and tighten it to 22-25 ft. Ibs.

(30-35 Nm).

6. Attach the back-up light switch connector

7. Install any components removed to access the

back-up light switch

8. Connect the negative battery cable.

REMOVAL & INSTALLATION

Mirage

*If the vehicle is going to be roiled while the

halfshafts are out of the vehicle, obtain 2 outer

CV-joints or proper equivalent tools and install

to the hubs. If the vehicle is rolled without the

proper torque applied to the front wheel bear-

ings, the bearings will no longer be usable.

*The suspension components should not be

tightened until the vehicles weight is resting

on the ground.

1. Remove the battery and battery tray.

2. Remove the air cleaner assembly and vacuum

hoses.

3. Note the locations and disconnect the shifter

cables.

4. If equipped with 1.61 engine, remove the ten-

sion rod.

5. Detach the backup lamp switch connector,

speedometer cable connection and remove the starter

motor.

6. Raise the vehicle and support safely.

7. Remove the front wheels and the inner wheel

panels.

8. Remove the undercover and splash pan.

9. Drain the transaxle oil into a suitable con-

tainer

10. Support the engine and remove the cross-

member.

11. Remove the upper transaxle mounting bolt

and bracket.

12 Disconnect the stabilizer bar, tie rod ends and

the lower ball joint connections.

13 Remove the clutch release cylinder and clutch

oil line bracket. Do not disconnect the fluid lines and

secure the slave cylinder with wire.

14 Disconnect the clutch cable, if equipped with

cable controlled clutch system.

15. Remove the halfshafts by inserting a prybar

between the transaxle case and the driveshaft and

prying the shaft from the transaxle. Do not pull on the

driveshaft Doing so damages the inboard joint. Do

not insert the prybar so far the oil seal in the case is

damaged.

*It is not necessary to disconnect the half-

shafts from the steering knuckle. Remove the

shaft with the hub and knuckle as an assem-

bly. Tie the shafts aside. Note the circle clip

on the end of the inboard shafts should not

be reused.

16. Remove the bellhousing lower cover.

17 Remove the transaxle to engine bolts and

lower the transaxle from the vehrcle.

To install:

*When installing the transaxle, be sure to

align the splines of the transaxle with the

clutch disc.

18 Install the transaxle to the engine and install

the mounting bolts. Tighten the bolts to 31-40 ft. Ibs.

(43-55 Nm) on 1990-92 models and 35 ft. Ibs. (48

Nm) on 1993-00 models.

19 Install the bellhousing cover.

*When installing the halfshafts, use new

circlips on the axle ends. Care must be taken

to ensure that the oil seal lip of the transaxle

is not damaged by the serrated part of the

driveshaft.

20. Install and fully seat the halfshafts into the

transaxle.

21. Install the slave cylinder.

22. Connect the ball joints, tie rod ends and the

stabilizer bar connections.

23. Install the upper transaxle mounting bracket

and bolt.

24. Install the crossmember.

25. Install the undercover.

26. Install the upper transaxle-to-engine mount-

ing bolts, Tighten the bolts to 31-40 ft. Ibs. (43-55

Nm) on 199C-92 models and 35 ff. Ibs. (48 Nm) on

1993-00 models.

27. Install the starter motor.

28 Connect the backup light switch connector

and speedometer cable.

29 Connect and adjust the shifter cables.

30 Install the air cleaner assembly.

31. Install the front wheels.

32 Make sure the vehicle is level when refilling

the transaxle Use Hypoid gear oil or equivalent, GL-

4 or higher.

33. Connect the negative battery cable and check

the transaxle for proper operation. Make sure the re-

verse lights operate when in reverse.

Galant

1999-93 MODELS

rlf the vehicle is going to be rolled on its

wheels while the halfshafts are out of the ve-

hicle, obtain two outer CV-joints or proper

equivalent tools and install to the hubs. If the

vehicle is rolled without the proper torque

applied to the front wheel bearings, the bear-

ings will no longer be usable.

1. Remove the battery and the air intake hoses.

2. If equipped with Active-ECS, unplug the

compressor wiring.

3. Remove the auto-cruise actuator and under-

hood bracket, located on the passenger side inner

fender well.

4. Drain the transaxle and transfer case fluid, if

equipped, into a suitable waste container.

5. Remove the retainer bolt and pull the

speedometer cable from the transaxle assembly.

6. Remove the cotter pin securing the select and

shift cables and remove the cable ends from the

transaxle.

Page 289 of 408

7-10 DRIVETRAIN

The automatic transaxle allows engine torque and

power to be transmitted to the front wheels within a

narrow range of engine operating speeds. It will allow

the engine to turn fast enough to produce plenty of

power and torque at very low speeds, while keeping it

at a sensible rpm at high vehicle speeds (and it does

this job without driver assistance). The transaxle uses

a light fluid as the medium for the transmission of

power. This fluid also works in ths operation of vari-

ous hydraulic control circuits and as a lubricant. Be-

cause the transaxle fluid performs all of these func-

tions, trouble within the unit can easily travel from one

part to another For this reason, and because of the

complexity and unusual operating principles of the

transaxle, a very sound understanding of the basic

principles of operation will simplify troubleshooting

REMOVAL &INSTALLATION

Pan removal, fluid and filter

in Section 1 of this manual changes are covered

REMOVAL &INSTALLATION

1990-97 Mirage and 1990-93 Galant

# See Figure 44

1. Disconnect the negative battery cable.

2. Disconnect the selector cable from the lever

3. Remove the two retaining screws and lift off

the switch.

To install: 4. Mount and position new switch. Do not tighten

the bolts until the switch is adjusted.

5. Connect selector cable and adjust switch.

6. After installation and adjustment make sure the

engine only starts in the

P and N selections. Also check

that the reverse lights operate only in the R selectlon.

1994-00 Galant and 1998-00 Mirage

e See Figure 44

93157pm Fig. 44 Typically, the park/neutral position

switch is located on the top of the transaxle

1. Disconnect the negative battery cable.

2. Remove the nut attaching the shift control ca-

ble from the transaxle manual shaft lever. Position

the control cable out of the way.

3. Place the manual shaft lever in the Neutral

position, remove the nut and the manual shaft lever.

4. Detach the park/neutral switch electrical con-

nector.

5. Remove the park/neutral switch mounting

bolts and remove the switch from the transaxle man-

ual shaft.

To install: 6. Install the park/neutral switch to the transaxle

manual shaft and install the switch mounting bolts

Do not tighten the mounting bolts unh the switch is

adjusted.

7. Install the manual shaft lever to the park/neu-

tral switch with the nut. Make sure that the shaft lever

is in the Neutral position.

8. Adjust the switch in the following manner:

turn the switch body until the hole in the body of the

switch aligns with the hole in the manual shaft lever.

Insert a drill bit or equivalent into the holes. Tighten

the switch mounting bolts to 8 ft. Ibs. (11 Nm).

9. Attach the electrical connector.

10. Install the control cable to the manual shaft

lever with the nut. Adjust the cable so that there is no

slack in the cable and that the selector lever moves

smoothly

11. Reconnect the negative battery cable Check

for proper starting and proper reverse light operatron.

Diamante

ti See Figure 44

1. Disconnect the negative battery cable.

Wait at least 90 seconds after the negative

battery cable is disconnected to prevent pos-

sible deployment of the air bag.

2. Disconnect the selector cable from the lever.

3. Remove the two retaining screws and lift off

the switch.

To install: 4. Install the lever, tighten the bolts only hand

tight.

5. Rotate switch body so the manual control lever

0.20 inch (5mm) hole and the switch body 0.20 inch

(5mm) holes are aligned.

6. Tighten the mounting bolts to 7-8 ft. Ibs.

(10-12 Nm).

7. Connect the selector cable to the lever.

8. Connect the negative battery cable.

9. After installahon and adjustment make sure the

engine only starts in the

P and N selections. Also

check that the reverse lights operate only in the R se- lection.

ADJUSTMENT

1990-97 Mirage and 1990-93 Galant

1. Disconnect the negative battery cable and lo-

cate the neutral safety switch on the top of the

transaxle.

*Apply parking brake and chock wheels be-

fore placing transaxle into the N position

2. At the transmission, loosen the shift cable ad-

justment nut. Inside the vehicle place the gearshift

selector lever in N

3. Place the manual shift control lever in N.

4. Loosen neutral safety switch mounhng screws

and rotate switch body so the manual control lever

0.20 in. (5mm) hole and the switch body 0.20 in.

(5mm) holes are aligned.

5. Tighten switch body mounting bolts to 7-8 ft.

Ibs. (lo-12 Nm).

6. At the shift cable adjusting nut, gently pull ca-

ble to remove any slack. Tighten locknut to 8 ft. Ibs.

(12 Nm)

7. Verify that the switch lever moves to positions

corresponding to each position of the selector lever.

Connect the negative battery terminal.

8. Make sure the engine only starts in the

P and

N positions. Also make sure the reverse lights oper-

ate only in

R selection.

REMOVAL&INSTALLATION

Diamante

) See Figures 45, 46, 47, and 48

1. Properly disarm the SRS system (air bag).

Refer to Section 6.

2. Raise and safely support the vehicle.

3. Remove the front wheels.

4. Remove the engine side cover and undercov-

ers.

5. Drain the transaxle assembly into a suitable

container.

6. If equipped, remove the front catalytic con-

verter.

7. Remove the exhaust pipe, main muffler and

catalytic converter.

8. Disconnect the tie rod end and ball joint from

the steering knuckle.

9. Unbolt the support bearing for the left side

halfshaft.

10. Remove the halfshafts by inserting a prybar

between the transaxle case and the driveshaft and

prying the shaft from the transaxle.

11. Remove the air cleaner assembly and adjoin-

ing duct work.

12. Detach the engine harness connection.

13. If the vehicle is equipped with Active Elec-

tronlc Controlled Suspension (Active-ECS), remove

the compressor assembly from the transaxle and sus-

pend with wire. Do not allow the compressor to hang

from the air hose.

14. If equipped, remove the roll stopper stay

bracket.

15. Disconnect the speedometer cable from the

transaxle.

16. Remove the clip that secures the shifter and

disconnect the shifter control cable from the

transaxle.

17. Disconnect and plug the oil cooler hoses

from the transaxle.

18. Detach the following:

Page 334 of 408

- 8-38 SUSPENSION AND STEERING

11. Adjust the power steering belt for proper ten-

sion and tighten the adjusting bolts.

12. Reconnect the negative battery cable.

13. Refill the reservoir and bleed the system.

3. Of EIJGINE

1. Disconnect the battery negative cable. 2. Disconnect the return fluid line. Remove the

reservoir cap and allow the return line to drain the

fluid from the reservoir. If the fluid is contaminated,

disconnect the ignition high tension cable and crank

the engine several times to drain the fluid from the

gear box.

3. Remove the power steering pump drive belt.

4. Remove the pressure switch connector from

the side of the pump.

5. If the alternator is located under the oil pump,

cover it with a shop towel to protect it from oil.

6. Disconnect the high pressure hose and the

return hose from the pump.

7. Remove the pump drive belt and unbolt the

pump from its bracket and remove the pump.

To install: 8. Install the pump, *rap the belt around the

pulley and tighten the bolts that secure the pump to

17 ft. Ibs. (24 Nm).

9. Replace the O-rings and connect the high

pressure hose. Connect the pressure line so the

notch in the fitting aligns and contacts the pump’s

guide bracket. Tighten the mounting nut with lock-

washer to 17 ft. Ibs. (24 Nm).

IO. Using a new hose clamp, connect the return

line.

11. Attach the pressure switch connector.

12. Adjust the belt tension and tighten the

adjust- ing bolts.

13. Refill the reservoir and bleed the system.

Diamante *

FRONT

. 1. Disconnect the battery negative cable. 2. Disconnect the return fluid line. Remove the

reservoir cap and allow the return line to drain the

fluid from the reservoir. If the fluid is contaminated,

disconnect the ignition high tension cable and crank

the engine several times to drain the fluid from the

gearbox.

3. Remove the power steering pump drive belt.

4. Remove the pressure switch connector from

the side of the pump.

5. If the alternator is located under the oil pump,

cover it with a shop towel to protect it from oil.

6. Disconnect the high pressure hose and the

return hose from the pump.

7. Remove the pump drive belt and unbolt the

pump from its bracket and remove the pump.

To install: 8. Install the pump, wrap the belt around the

pulley and tighten the bolts that secure the pump to

17 ft. Ibs. (24 Nm).

9. Replace the O-rings and connect the high

pressure hose. Connect the pressure line so the

notch in the fitting aligns and contacts the pump’s

guide bracket. Tighten the mounting nut with lock-

washer to 17 ft. Ibs. (24 Nm).

10. Using a new hose clamp, connect the return

line.

Il. Attach the pressure switch connector.

12. Adjust the belt tension and tighten the adjust-

ing bolts.

13. Refill the reservoir and bleed the system.

REAR

1. Disconnect the negative battery cable.

2. Drain the power steering fluid.

3. Remove the rear power steering pump heat

protector, located on the engine side of the differen-

tial on the transaxle.

4. Disconnect the pressure line from the pump.

5. Disconnect the suction hose from the pump.

6. Remove the mounting bolts and remove the

pump from the transaxle.

44

33

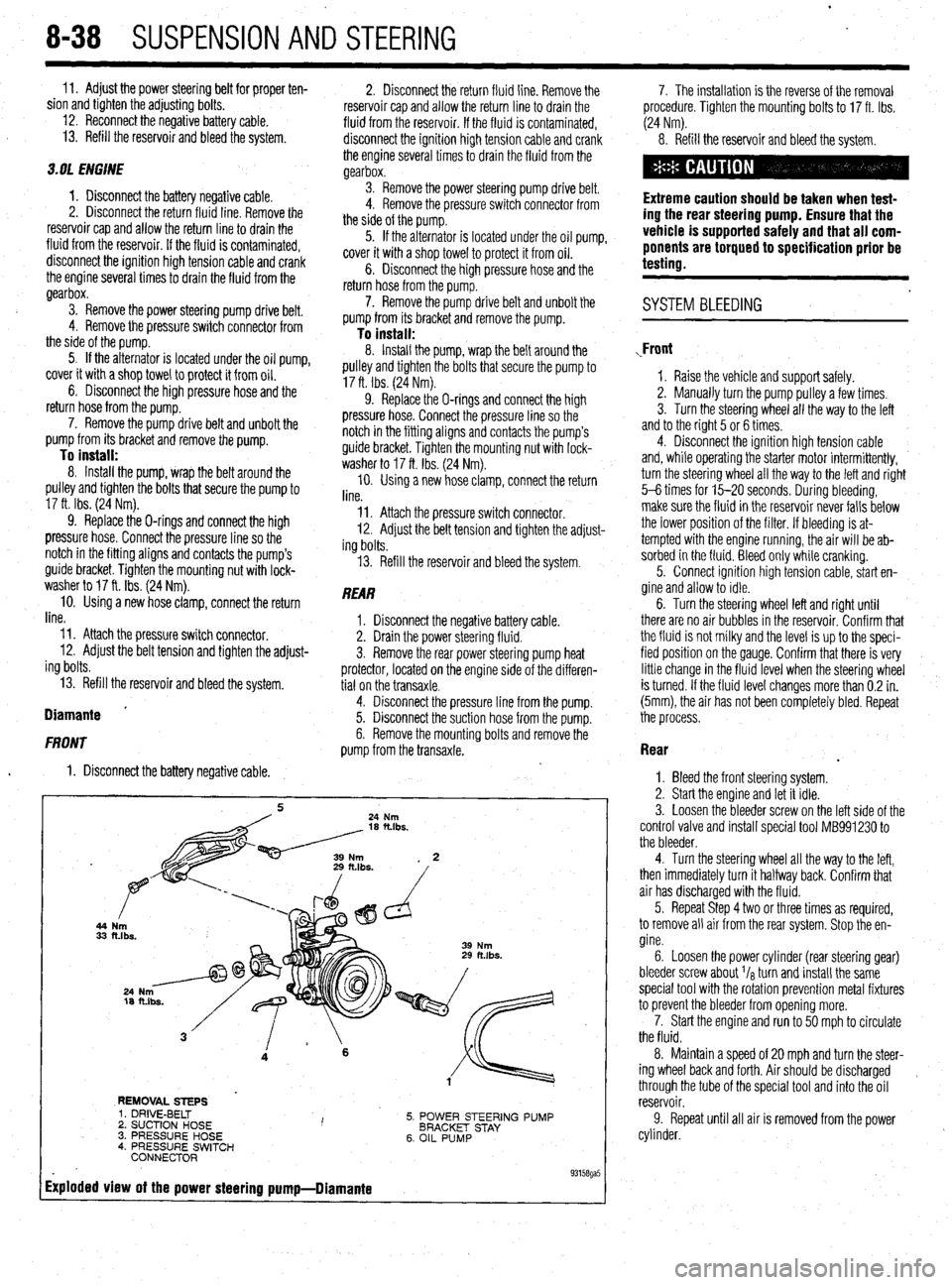

REMOVAL STEPS

5. POWER STEERING PUMP

BRACKET STAY

6. OIL PUMP 1. DRIVE-BELT

2. SUCTION HOSE I ’ 3. PRESSURE HOSE

4. PRESSURE SWITCH

CONNECTOR

Exploded view of the power steering pump-Diamante

. 93158ga5

7. The installation is the reverse of the removal

procedure. Tighten the mounting bolts to 17 ft. Ibs.

(24 Nm).

8. Refill the reservoir and bleed the system.

Extreme caution should be taken when test-

ing the rear steering pump. Ensure that the

vehicle is supported safely and that all com-

ponents are torqued to specification prior be

testing.

. SYSTEM BLEEDING

,Front

1. Raise the vehicle and support safely.

2. Manually turn the pump pulley a few times.

3. Turn the steering wheel all the way to the left

and to the right 5 or 6 times.

4. Disconnect the ignition high tension cable

and, while operating the starter motor intermittently,

turn the steering wheel all the way to the letI and right

5-6 times for 15-20 seconds. During bleeding,

make sure the fluid in the reservoir never falls below

the lower position of the filter. If bleeding is at-

tempted with the engine running, the air will be ab-

sorbed in the fluid. Bleed only while cranking.

5. Connect ignition high tension cable, start en-

gine and allow to idle.

6. Turn the steering wheel left and right until

there are no air bubbles in the reservoir. Confirm that

the fluid is not milky and the level is up to the speci-

fied position on the gauge. Confirm that there is very

little change in the fluid level when the steering wheel

is turned. If the fluid level changes more than 0.2 in.

(5mm), the air has not been completely bled. Repeat

the process.

Rear

.

1. Bleed the front steering system.

2. Start the engine and let it idle.

3. Loosen the bleeder screw on the left side of the

control valve and install special tool MB991230 to

the bleeder.

4. Turn the steering wheel all the way to the left,

then immediately turn it halfway back. Confirm that

air has discharged with the fluid.

5. Repeat Step 4 two or three times as required,

to remove all air from the rear system. Stop the en-

gine.

6. Loosen the power cylinder (rear steering gear)

bleeder screw about I/* turn and install the same

special tool with the rotation prevention metal fixtures

to prevent the bleeder from opening more.

7. Start the engine and run to 50 mph to circulate

the fluid.

8. Maintain a speed of 20 mph and turn the steer-

ing wheel back and forth. Air should be discharged ,

through the tube of the special tool and into the oil

reservoir.

9. Repeat until all air is removed from the power

cylinder.