parking brake MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 4 of 408

I-4 GENERALINFORMATIONAND MAINTENANCE

Fig. 12 A screw-in type compression gauge- Fig. 13 A vacuum/pressure tester is neces-

is recommended for compression testing sary for many testing procedures

Fig. 14 Most modern automotive multime-

ters incorporate many helpful features

your workbench. Some useful household items are: a

large turkey baster or siphon, empty coffee cans and

ice trays (to store parts), ball of twine, electrical tape

for wiring, small rolls of colored tape for tagging lines

or hoses, markers and pens, a note pad, golf tees (for

plugging vacuum lines), metal coat hangers or a roll

of mechanic’s wire (to hold things out of the way),

dental pick or similar long, pointed probe, a strong

magnet, and a small mirror (to see into recesses and

under manifolds).

A more advanced set of tools, suitable for tune-up

work, can be drawn up easily. While the tools are

lmvl Fig. 15 Proper information is vital, so at

ways have a Chiiton Total Car Care manua

handy

l Feeler aauoes for valve adiustment

* Timing-light.

The choice of a timing fight should be made

carefully. A light which works on the DC current

supplied by the vehicle’s battery is the best choice;

it should have a xenon tube for brightness. On any

vehicle with an electronic ignition system, a timing

light with an inductive pickup that clamps around

the No. 1 spark plug cable is preferred.

In addition to these basic tools, there are several

other tools and gauges you may find useful. These

include:

l Compression gauge. The screw-in type is

slower to use, but eliminates the possibility of a

fauliy reading due to escaping pressure.

l Manifold vacuum gauge. l 12V test light. l A combination volt/ohmmeter l induction Ammeter. This is used for determin-

ing whether or not there is current in a wire. These

are handy for use if a wire is broken somewhere in a

wiring harness.

As a final note, vou will orobablv find a torque

wrench necessary for all but the most basic work.

The beam type models are perfectly adequate, al-

though the newer click types (breakaway) are easier

to use. The click type torque wrenches tend to be

more expensive. Also keep in mind that all types of

torque wrenches should be periodically checked

and/or recalibrated. You will have to decide for your-

self which better fits your pocketbook, and purpose.

ilightly more sophisticated, they need not be outra-

feously expensive. There are several inexpensive

achldwell meters on the market that are every bit as

Toad for the average mechanic as a professional

nodel. Just be sure that it goes to a least 1200-1500

pm on the tach scale and that it works on 4,6 and 8-

:ylinder engines. The key to these purchases is to

nake them with an eye towards adaptability and wide

ange. A basic list of tune-up tools could include:

l Tach/dwell meter. l Spark plug wrench and gapping tool. Normally, the use of special factory tools is

avoided for repair procedures, since these are not

readily available for the do-it-yourself mechanic.

When it is possible to perform the job with more

commonly available tools, it will be pointed out, but

occasionally, a special tool was designed to perform

a specific function and should be used. Before sub-

stituting another tool, you should be convinced that

neither your safety nor the performance of the vehicle

will be compromised.

Special tools can usually be purchased from an

automotive parts store or from your dealer. In some

cases special tools may be available directly from the

tool manufacturer.

p See Figures 16, 17, 16, and 19

It is virtually impossible to anticipate all of the haz-

ards involved with automotive maintenance and ser-

vice, but care and common sense will prevent most

accidents.

The rules of safety for mechanics range from “don’t

smoke around gasoline,” to “use the proper tool(s) for

the job.” The trick to avoiding injuries is to develop

safe work habits and to take every possible precaution.

Do keep a fire extinguisher and first aid kit

l handy.

Do wear safety glasses or goggles when cut- l ting, drilling, grinding or prying, even if you have

20-20 vision. If you wear glasses for the sake of vi-

sion, wear safety goggles over your regular glasses.

l Do shield your eyes whenever you work around

the battery. Batteries contain sulfuric acid. In case of

contact with the eyes or skin, flush the area with water

or a mixture of water and baking soda, then seek im-

mediate medical attention.

l Do use safety stands (jackstands) for any un-

dervehicle service. Jacks are for raising vehicles;

jackstands are for making sure the vehicle stays

raised until you want it to come down. Whenever the

vehicle is raised, block the wheels remaining on the

ground and set the parking brake.

l Do use adequate ventilation when working

with any chemicals or hazardous materials, Like car-

bon monoxide, the asbestos dust resulting from

some brake lining wear can be hazardous in suffi-

cient quantities.

l Do disconnect the negative battery cable when

working on the electrical system. The secondary ig- nition system contains EXTREMELY HIGH VOLT-

AGE. In some cases it can even exceed 50,000 volts.

l Do follow manufacturer’s directions whenever

working with potentially hazardous materials. Most

chemicals and fluids are poisonous if taken inter-

nally.

l Do properly maintain your tools. Loose ham-

merheads, mushroomed punches and chisels, frayed

or poorly grounded electrical cords, excessively

worn screwdrivers, spread wrenches (open end),

cracked sockets, slipping ratchets, or faulty droplight

sockets can cause accidents.

* Likewise, keep your tools clean; a greasy

wrench can slip off a bolt head, ruining the bolt and

often harming your knuckles in the process.

l Do use the proper size and type of tool for the

job at hand. Do select a wrench or socket that fits the

nut or bolt. The wrench or socket should sit straight,

not cocked.

Page 5 of 408

1-6 GENERALINFORMATIONAND MAINTENANCE

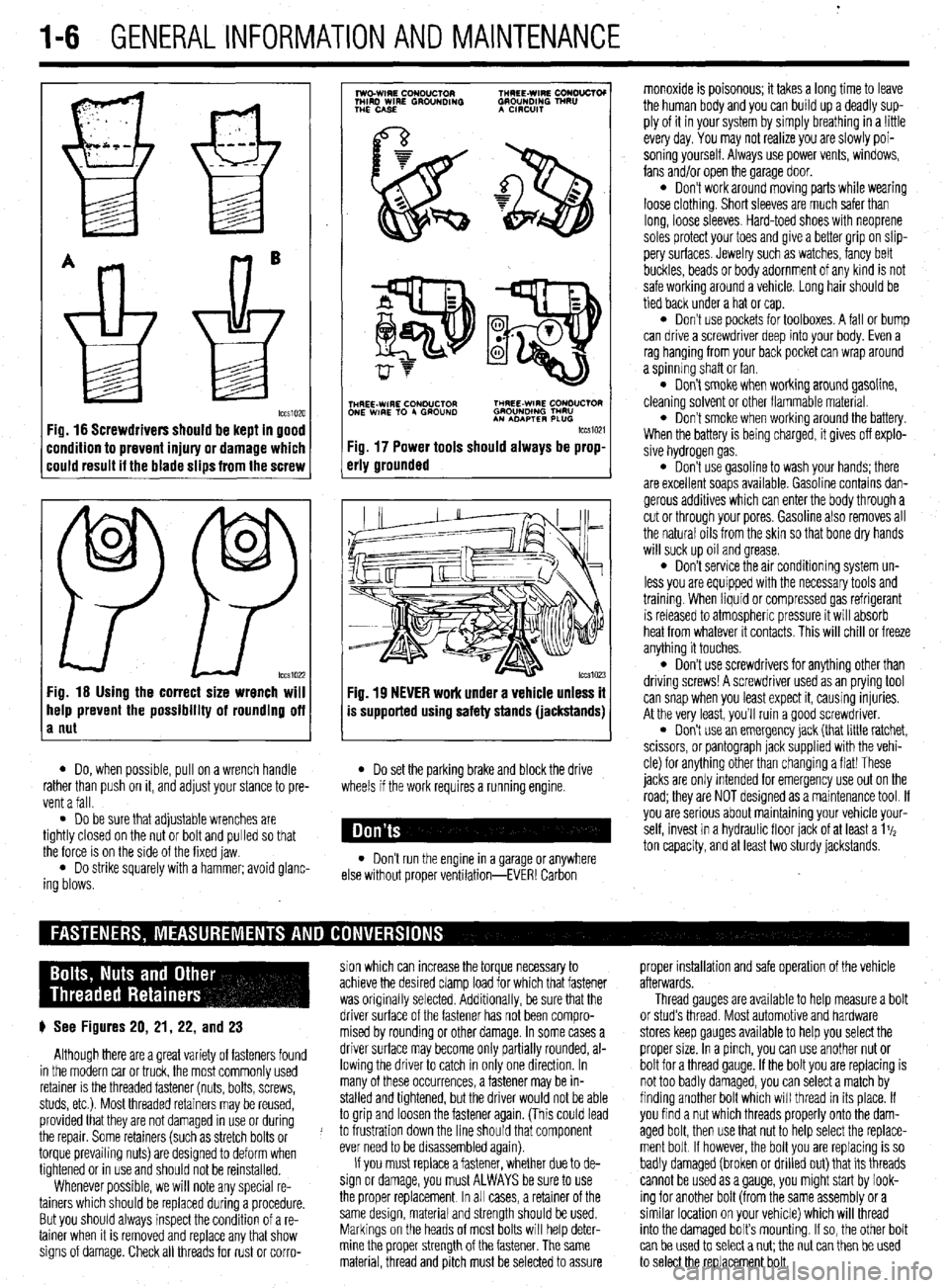

Fig. 16 Screwdrivers should be kept in good

:ondition to prevent injury or damage which

:ould result it the blade slips from the screw

0

0

PP tccs1022 Fig. 16 Using the correct size wrench will

help prevent the possibility of rounding off

a nut

7

lwo.WIRE CouDuClOR TMREE-WIRE CONO”CTOI

MIRD WIRE GROUNDING GROUNDING TNRU

THE CASE A CmxlIT

.

i$Y$$pQ

p-+

TNHREE-WIRE CONDUCTOR THREE-WIRE CONDUCTOR

ONE WIRE TO 4 GROUND GROUNOlNG TMRU

AN ADAPTER PLUG

tccm21

Fig. 17 Power tools should always be prop-

erly grounded

Fig. 19 NEVER work under a vehicle unless it

is supported using safety stands (jackstands)

l Do, when possible, pull on a wrench handle l Do set the parking brake and block the drive

rather than push on it, and adjust your stance to pre-

vent a fall. wheels if the work requires a running engine.

l Do be sure that adjustable wrenches are

tightly closed on the nut or bolt and pulled so that

the force is on the side of the fixed jaw.

l Do strike squarely with a hammer; avoid glanc-

ing blows. l Don’t run the engine in a garage or anywhere

else without proper ventilation-EVER! Carbon monoxide is poisonous; it takes a long time to leave

the human body and you can build up a deadly sup-

ply of it in your system by simply breathing in a !ittle

every day. You may not realize you are slowly poi-

soning yourself. Always use power vents, windows,

fans and/or open the garage door.

l Don’t work around moving parts while wearing

loose clothing. Short sleeves are much safer than

long, loose sleeves. Hard-toed shoes with neoprene

soles protect your toes and give a better grip on slip-

pery surfaces. Jewelry such as watches, fancy belt

buckles, beads or body adornment of any kind is not

safe working around a vehicle. Long hair should be

tied back under a hat or cap.

l Don’t use pockets for toolboxes. A fall or bump

can drive a screwdriver deep into your body. Even a

rag hanging from your back pocket can wrap around

a spinning shaft or fan.

l Don’t smoke when working around gasoline,

cleaning solvent or other flammable material.

l Don’t smoke when workrng around the battery.

When the battery is being charged, it gives off explo-

sive hydrogen gas.

l Don’t use gasoline to wash your hands; there

are excellent soaps available. Gasoline contains dan-

gerous additives which can enter the body through a

cut or through your pores. Gasoline also removes all

the natural oils from the skin so that bone dry hands

will suck up oil and grease.

l Don’t service the air conditioning system un-

less you are equipped with the necessary tools and

trainmg. When liquid or compressed gas refrigerant

is released to atmospheric pressure it will absorb

heat from whatever it contacts. This will chill or freeze

anything it touches.

l Don’t use screwdrivers for anything other than

driving screws! A screwdriver used as an prying tool

can snap when you least expect it, causing injuries.

At the very least, you’ll ruin a good screwdriver.

. Don’t use an emergency jack (that little ratchet,

scissors, or pantograph jack supplied with the vehi-

cle) for anything other than changing a flat! These

jacks are only Intended for emergency use out on the

road; they are NOT designed as a maintenance tool. If

you are serious about mamtaining your vehicle your-

self, invest in a hydraulic floor jack of at least a 1%

ton capacity, and at least two sturdy jackstands.

sion which can increase the torque necessary to proper installation and safe operation of the vehicle

achieve the desired clamp load for which that fastener afterwards.

was originally selected. Additionally, be sure that the Thread gauges are available to help measure a bolt

p See Figures 20, 21, 22, and 23 driver surface of the fastener has not been compro- or stud’s thread. Most automotive and hardware

mised by rounding or other damage. In some cases a stores keep gauges available to help you select the

Although there are a great variety of fasteners found driver surface may become only partially rounded, al- proper size. In a pinch, you can use another nut or

in the modern car or truck, the most commonly used lowing the driver to catch in only one direction. In bolt for a thread gauge. If the bolt you are replacing is

retainer is the threaded fastener (nuts, bolts, screws, many of these occurrences, a fastener may be in- not too badly damaged, you can select a match by

studs, etc.). Most threaded retainers may be reused, stalled and tightened, but the driver would not be able finding another bolt which will thread in its place. If

provided that they are not damaged in use or during to grip and loosen the fastener again. (This could lead you find a nut which threads properly onto the dam-

the repair. Some retainers (such as stretch bolts or J to frustration down the line should that component aged bolt, then use that nut to help select the replace-

torque prevailing nuts) are designed to deform when ever need to be disassembled again). ment bolt If however, the bolt you are replacing is so

tightened or in use and should not be reinstalled. If you must replace a fastener, whether due to de- badly damaged (broken or drilled out) that its threads

Whenever possible, we will note any special re- sign or damage, you must ALWAYS be sure to use cannot be used as a gauge, you might start by look-

tainers which should be replaced during a procedure. the proper replacement In all cases, a retainer of the ing for another bolt (from the same assembly or a

But you should always inspect the condition of a re- same design, material and strength should be used. similar location on your vehicle) which will thread

tainer when It is removed and replace any that show Markings on the heads of most bolts will help deter- into the damaged bolt’s mounting. If so, the other bolt

signs of damage. Check all threads for rust or corro- mine the proper strength of the fastener. The same

can be used to select a nut; the nut can then be used

material, thread and pitch must be selected to assure

to select the replacement bolt.

Page 25 of 408

.

1-26 GENERALINFORMATIONAND MAINTENANCE

TDC of the compression stroke. If this happens, the

piston WIII be at the beginning of the power stroke

just as the compressed and ignited air/fuel mixture

forces the piston down and turns the crankshaft. Be-

cause it takes a fraction of a second for the spark

plug to ignite the mixture in the cylinder, the spark

plug must fire a little before the piston reaches TDC.

Otherwise, the mixture will not be completely ignited

as the piston passes TDC and the full power of the

explosion will not be used by the engine.

The timing measurement is given in degrees of

crankshaft rotation before the piston reaches TDC

(BTDC). If the setting for the ignition timing is 10”

BTDC, each spark plug must fire 10 degrees before

each piston reaches TDC. This only holds true, how-

ever, when the engine is at idle speed. The combus-

tion process must be complete by 23”ATDC to main-

tain proper engine performance, fuel mileage, and

low emissions.

As the engine speed increases, the pistons go

faster. The spark plugs have to ignite the fuel even

sooner if it IS to be completely ignited when the pis-

ton reaches TDC. If the ignition is set too far ad-

vanced (BTDC), the ignition and expansion of the fuel

in the cylinder wtll occur too soon and tend to force

the piston down while it is still traveling up. Thus

causes pre ignition or “knockmg and pinging”. If the

ignition spark is set too far retarded, or after TDC

(ATDC), the piston will have already started on its

way down when the fuel is ignited. The piston will be

forced down for only a portion of its travel, resulting

in poor engine performance and lack of power.

Timing marks or scales can be found on the rim of

the crankshaft pulley and the timing cover. The marks

on the pulley correspond to the posrtion of the piston

in the No. 1 cylinder. A stroboscopic (dynamic) tim-

ing light is hooked onto the No. 1 cylinder spark plug

wrre. Every time the spark plug fires, the timing light

flashes. By aiming the light at the timing marks while

the engine is running, the exact position of the piston

within the cylinder can be easily read (the flash of

light makes the mark on the pulley appear to be

standing still). Proper timing is indicated when the

mark and scale are in specified alignment.

When checking timing with the engine run-

ning, take care not to get the timing light

wires tangled in the tan blades and/or drive

belts.

INSPECTION &ADJUSTMENT

1990-96 Models

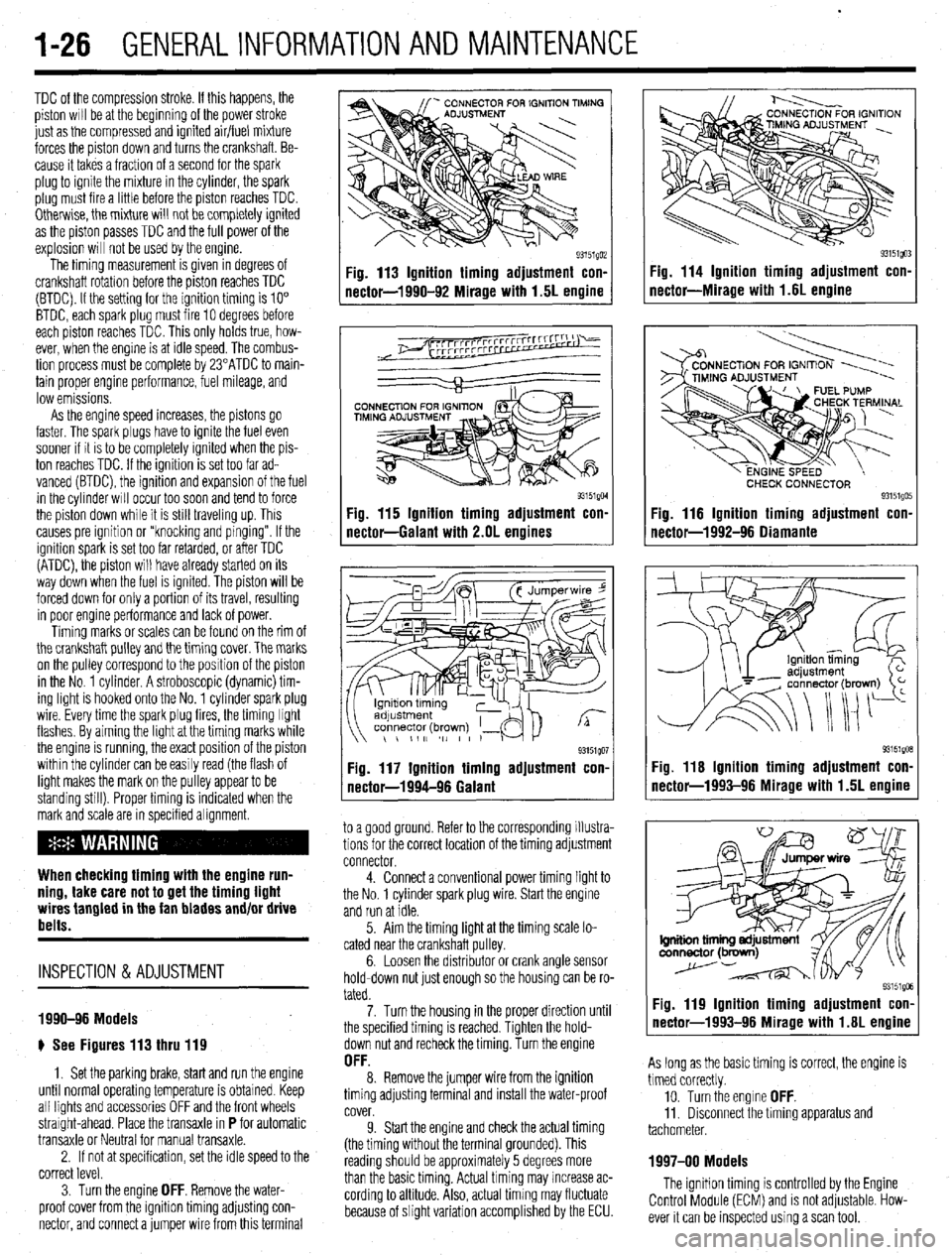

e See Figures 113 thru 119

1. Set the parking brake, start and run the engine

until normal operating temperature is obtained. Keep

all lights and accessories OFF and the front wheels

straight-ahead. Place the transaxle in

P for automatic

transaxle or Neutral for manual transaxle.

2. If not at specification, set the idle speed to the

correct level.

3. Turn the engine

OFF. Remove the water-

proof cover from the igmtion timing adjusting con-

nector, and connect a jumper wire from this terminal

Fig. 113 Ignition timing adjustment con-

nector-1990-92 Mirage with 1.5L engine

93151QM Fig. 115 Ignition timing adjustment con-

nectar-Galant with 2.OL engines

93151QO1 Fig. 117 Ignition timing adjustment con.

nectar-1994-96 Galant

to a good ground. Refer to the corresponding illustra-

tions for the correct location of the timing adjustment

connector.

4. Connect a conventional power timing light to

the No. 1 cylinder spark plug wire. Start the engine

and run at idle.

5. Aim the timing light at the timing scale lo-

cated near the crankshaft pulley.

6. Loosen the distributor or crank angle sensor

hold-down nut just enough so the housing can be ro-

tated.

7. Turn the housing in the proper direction until

the specified timing is reached. Tighten the hold-

down nut and recheck the timing. Turn the engine

OFF. 8. Remove the jumper wire from the ignition

timing adjusting terminal and install the water-proof

cover.

9. Start the engine and check the actual timing

(the timing without the terminal grounded). This

reading should be approximately 5 degrees more

than the basic timing. Actual timing may increase ac-

cording to altitude. Also, actual timing may fluctuate

because of slight variation accomplished by the ECU.

Fig. 114 Ignition timing adjustment con-

nectar-Miracle with 1.6L enaine

CHECK CONNECTOR 93151QO! Fig. 116 Ignition timing adjustment con.

nectar-1992-96 Oiamante

93151gOB Fig. 116 Ignition timing adjustment con-

nector-1993-96 Mirage with 1.5L engine

Fig. 119 Ignition timing adjustment con-

nector-1993-96 Mirage with 1.6L engine

As long as the basic timing is correct, the engine is

timed correctly.

10. Turn the engine

OFF. 11. Disconnect the timing apparatus and

tachometer.

1997-00 Models

The ignition timing is controlled by the Engine

Control Module (ECM) and is not adjustable. How-

ever it can be inspected using a scan tool.

Page 35 of 408

.

l-36 GENERALINFORMATIONAND MAINTENANCE

Install the drain plug and tighten to 22 ft. Ibs.

(304Nm)

5. Refill the transaxle to the proper level, as

shown in the Capacities chart, with the appropriate

fluid. The oil level should be at the bottom of the oil

filler hole. I

6. When the oil reaches the orooer level, install

the filler plug and tighten to 22 ft. Ibs. (30 Nm).

FLUID RECOMMENDATIONS

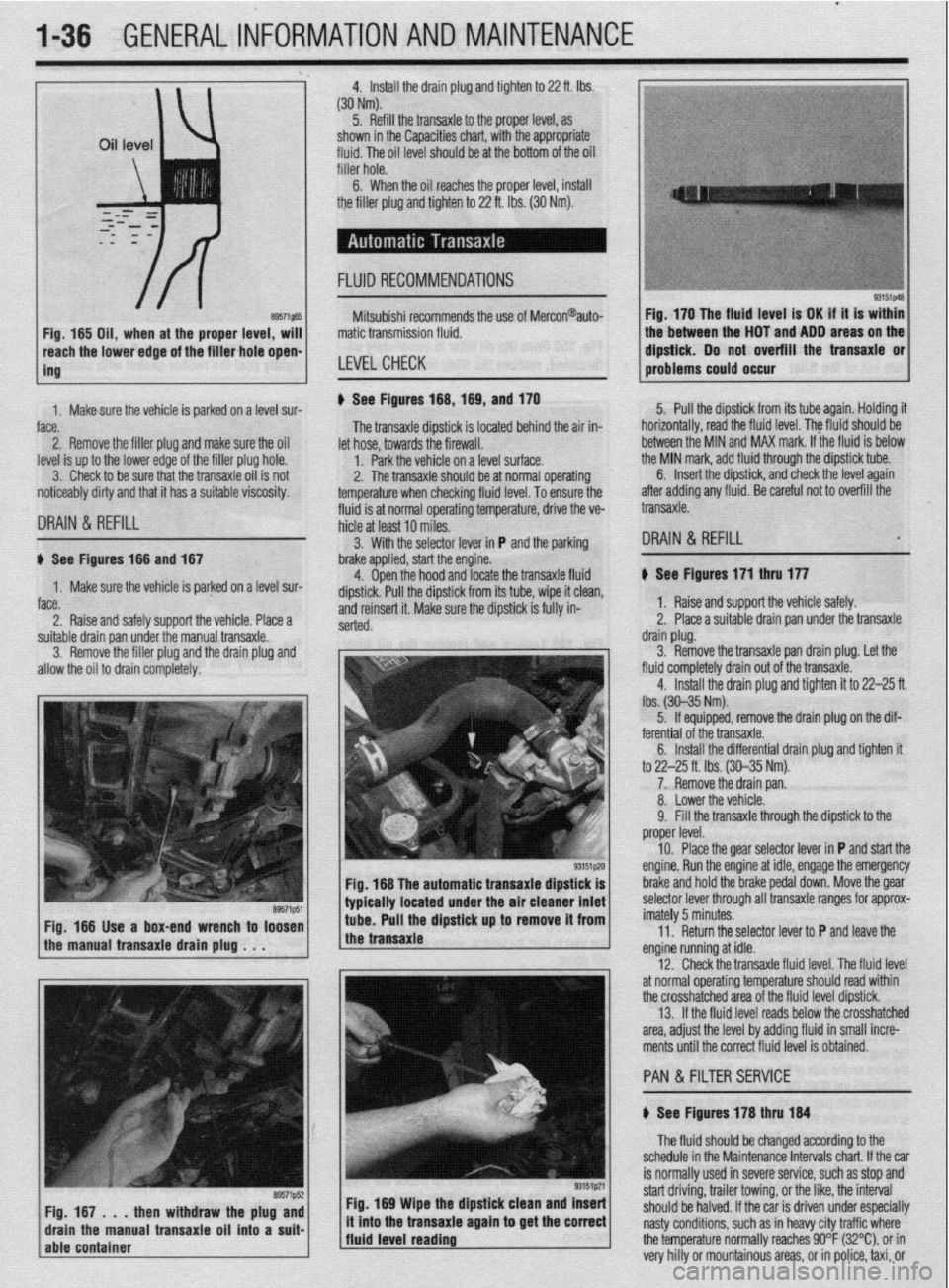

8957i565 Fig, 165 Oil, when at the proper level, will

reach the lower edge of tC=+ frfr*r u*rn -non-

ing Mitsubishi recommends the use of Mercon@auto-

matic transmission fluid.

LEVELCHECK

Fig. 170 The fluid level is OK if it is within

the between the HOT and ADD areas on the

&&i& Do not overfill the transaxle or

-.*".."... -- .*"- problems could o ccur

1. Makesure the vehicle is oarked on a level sur-

face.

2. Remove the filler plug and make sure the oil

level is up to the lower edge of the filler plug hole.

3. Check to be sure that the transaxle oil is not

noticeably dirty and that it has a suitable viscosity. u See Figures 168,169, and 170

fluid is at normal operating temperature, drive the ve- The transaxle dipstick is located behind the air in-

hicle at least 10 miles. let hose, towards the firewall.

1. Park the vehicle on a level surface.

2. The transaxle should be at normal operating

temperature when checking fluid level. To ensure the 5. Pull the dipstick from its tube again. Holding it

horizontally, road the fluid level. The fkrid should be

between the MIN and MAX mark. If the fluid is below

the MIN mark, add fluid through the dipstick tube.

DRAIN & REFILL

6. Insert the dipstick, and check the level again

after adding any fluid. Be careful not to overfill the

transaxle.

3. With the selector lever in P and the parking

DRAIN & REFILL u See Figures 166 and 167

1. Make sure the vehicle is parked on a level sur-

face.

2. Raise and safely support the vehicle. Place a brake applied, start the engine.

4. Open the hood and locate the transaxle fluid

dipstick. Pull the dipstick from its tube, wipe it clean,

and reinsert it. Make sure the dipstick is fully in-

serted.

suitable drain pan under the manual transaxle.

3. Remove the filler plug and the drain plug and

allow the oil to drain completely.

Fig. 166 The automatic transaxle dipstick is

typically located under the air cleaner inlet

Fig. 166 Use a box-end wrench to loosen

the manual transaxle drain plug . . . tube. Pull the dipstick up to remove it from

the transaxle

Fig. 169 Wipe the dipstick clean and Insert

/fluid level reading ., it mto the transaxle agam to get the correct

j The fluid should be changed according to the

schedule in the Maintenance Intervals chart. If the car

is normally used in severe service, such as stop and

start driving, trailer towing, or the like, the interval

should be halved. If the car is driven under especially

nasty conditions, such as in heavy city traffic where

the temperature normally reaches 90°F (32%), or in

very hilly or mountainous areas, or in police, taxi, or b See Figures 171 thru 177

1. Raise and support the vehicle safely.

2. Place a suitable drain pan under the transaxle

drain plug.

3. Remove the transaxle pan drain plug. Let the

fluid completely drain out of the transaxle.

4. Install the drain plug and tighten it to 22-25 ft.

lbs. (30-35 Nm).

5. If equipped, remove the drain plug on the dif-

ferential of the transaxle.

6. Install the differential drain plug and tighten ft

to 22-25 ft. Ibs. (30-35 Nm).

7. Remove the drain pan.

8. Lower the vehicle.

9. Fill the transaxle through the dipstick to the

proper level.

10. Place the gear selector lever in P and start the

engine. Run the engine at idle, engage the emergency

brake and hold the brake pedal down. Move the gear

selector lever through all transaxle ranges for approx-

imately 5 minutes.

11. Return the selector lever to P and leave the

engine running at idle.

12. Check the transaxle fluid level. The fluid level

at normal operating temperature should read within

the crosshatched area of the fluid level dipstick.

13. If the fluid level reads below the crosshatched

area, adjust the level by adding fluid in small incre-

ments until the correct fluid level is obtained.

PAN &FILTER SERVICE

b See Figures 178 thru 184

Page 37 of 408

t

1-38 GENERALINFORMATIONAND MAINTENANCE

11 I Add the recommended automatic transaxle

fluid to the transaxle through the dipstick tube. You

will need a long necked funnel, or a funnel and tube

to do this. A quick check of the capacities chart later

in this Section will reveal the capacity of the transaxle

in your vehicle. On a first fill after removing the pan

and filter, this number should be cut into a ‘hand

checked on the dipstick before refilling.

12. With the transaxle in P, put on the parking

brake, block the front wheels, start the engine and let

it idle. DO NOT RACE THE ENGINE. DO NOT MOVE

THE LEVER THROUGH ITS RANGES.

13. With the lever in Park, check the fluid level. If

it’s OK, take the car out for a short drive, park on a

level surface, and check the level again, as outlined

earlier in this section. Add more fluid if necessary. Be

careful not to overfill, which will cause foaming and

w fluid loss. n of the transfer case filler

3. Remove the filler and the drain plug and allow

the oil to drain into the drain pan.

4. After the fluid has drained completely, install

the drain plug and tighten to 24 ft. Ibs. (32 Nm).

5. Refill the transfer case to the proper level with

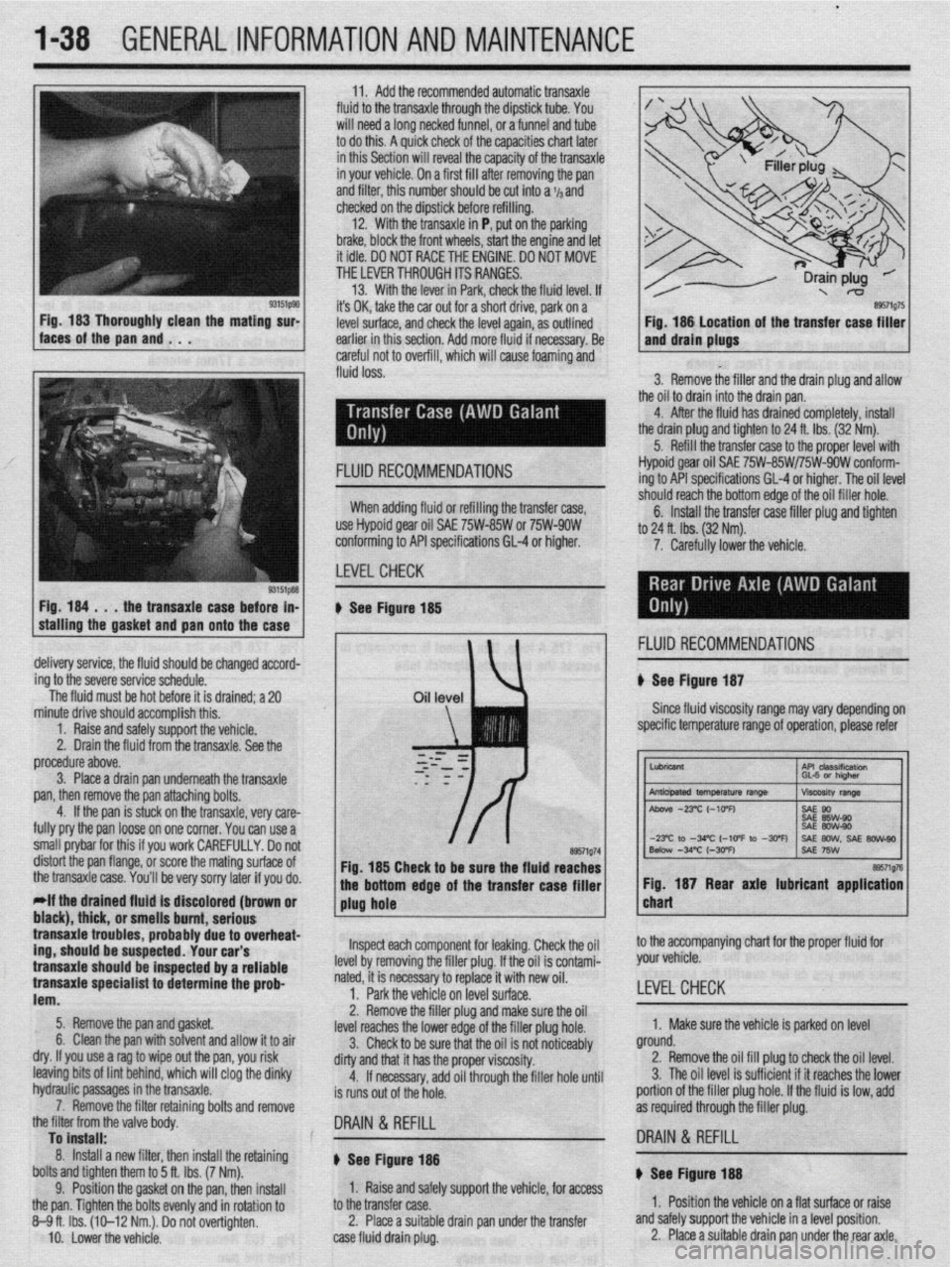

Fig. 184 . . .

the transaxle case before in-

stalling the gasket

and pan onto the case FLUID RECOMMENDATIONS Hypoid gear oil SAE 75W-85W/75W-9OW conform-

ing to API specifications GL-4 or higher. The oil level

-‘-,*I’ -nnnh +‘* “%om edge of the oil filler hole.

nxfer raw filler nlm and tinhtm When adding fluid or refilling the transfer case,

use Hypoid gear oil SAE 75W-85W or 75W-9OW

conforming to API specifications 61-4 or higher.

LEVELCHECK 6. Install the tra .._._. ____ .._. T.-J _.._ .lJ . .._..

to 24 ft. lbs. (32 Nm).

7. Carefully lower the vehicle.

u See Figure 185

, 1 FLUID RECOMMENDATIONS

delivery service, the fluid should be changed accord-

ing to the severe service schedule.

The fluid must be hot before it is drained; a 20 u See Figure 187

Since fluid viscosity range may

vary depending on

specific temperature range of operation, please refer

~~

tne transaxle case.

You’ll be very sorry later if you do. bottom edge of the transfer case filler 1 1 Fig. 187 Rear axle lubricant application I

*If the drained fluld is discolored (brown or

1 plug hole chart black), thick, or pmmll~ hmmt nnrinmm I transaxle trouble .llln3llU ““III., url,““P s, probably due to overheat-

,r..rr,rA “#.a.- rrdr

trig, should be susp~~lr;u. lvUl vLlr J

transaxle should be inspected by a reliable

transaxle specialist to determine the prob-

lem.

5. Remove the pan and gasket.

6. Clean the pan with solvent and allow it to air

dry. If you use a rag to wipe out the pan, you risk

leaving bits of lint behind, which will clog the dinky

hydraulic passages in the bansaxle.

7. Remove the filter retaining bolts and remove

the filter from the valve bodv. lnsoect each component for leaking. Check the oil

he filler plug. If the oil is contami-

ry to replace it with new oil.

if% nn IPVPI z11rf2r~

level by removing t

nated, it is necessa

1. Park the vehi,., -.. ,-.“, __. ,“-_.

2. Remove the filler plug and make sure the oil

level reaches the lower edge of the filler plug hole.

3. Check to be sure that the oil is not noticeably

dirty and that it has the proper viscosity.

4. If necessary, add oil through the filler hole until

is runs out of the hole. to the accompanying chart for the proper fluid for

your vehicle.

LEVEL CHECK

1. Make sure the vehicle is parked on level

ground.

2. Remove the oil fill plug to check the oil level.

3. The oil level is sufficient if it reaches the lower

portion of the filler plug hole. If the fluid is low, add

as required through the filler plug.

To install: .

8. Install a new filter, then install the retaining

bolts and tighten them to 5 ft. Ibs. (7 Nm).

9. Position the gasket on the pan, then install

the pan. Tighten the bolts evenly and in rotation to

8-9ft. Ibs. (10-12 Nm.). Do not overtighten.

IO. Lower the vehicle. DRAIN & REFILL

I8 DRAIN & REFILL

u See Figure 188 ) See Figure- 14

1. Raise and safely support the vehicle, for access

to the transfer case.

2. Place a suitable drain pan under the transfer

case fluid drain plug. 1. Position the vehicle on a flat surface or raise

and safely support the vehicle in a level position.

2. Place a suitable drain pan under the rear axle.

Page 44 of 408

GENERALINFORMATIONAND MAINTENANCE 1-45

SLING TYPE

WHEEL LIFT TYPE

cles

SUNG TYPE

WHEEL LIFT TYPE

FLAT BED TYPE

Fig. 220 Rear towing position-FWD vehi

cles

personal injury. Remember that batteries contain a

small amount of explosive hydrogen gas which is a

by-product of battery charging. Sparks should always

be avoided when working around batteries, especially

when attaching jumper cables. To minimize the pos-

sibility of accidental sparks, follow the procedure

carefully.

NEVER hook the batteries up in a series cir-

cuit or the entire electrical system will go up

in smoke. includino the starter!

Vehicles equipped with a diesel engine may utilize

two 12 volt batteries. If so, the batteries are con-

nected in a parallel circuit (positive terminal to posi-

tive terminal, negative terminal to negative terminal).

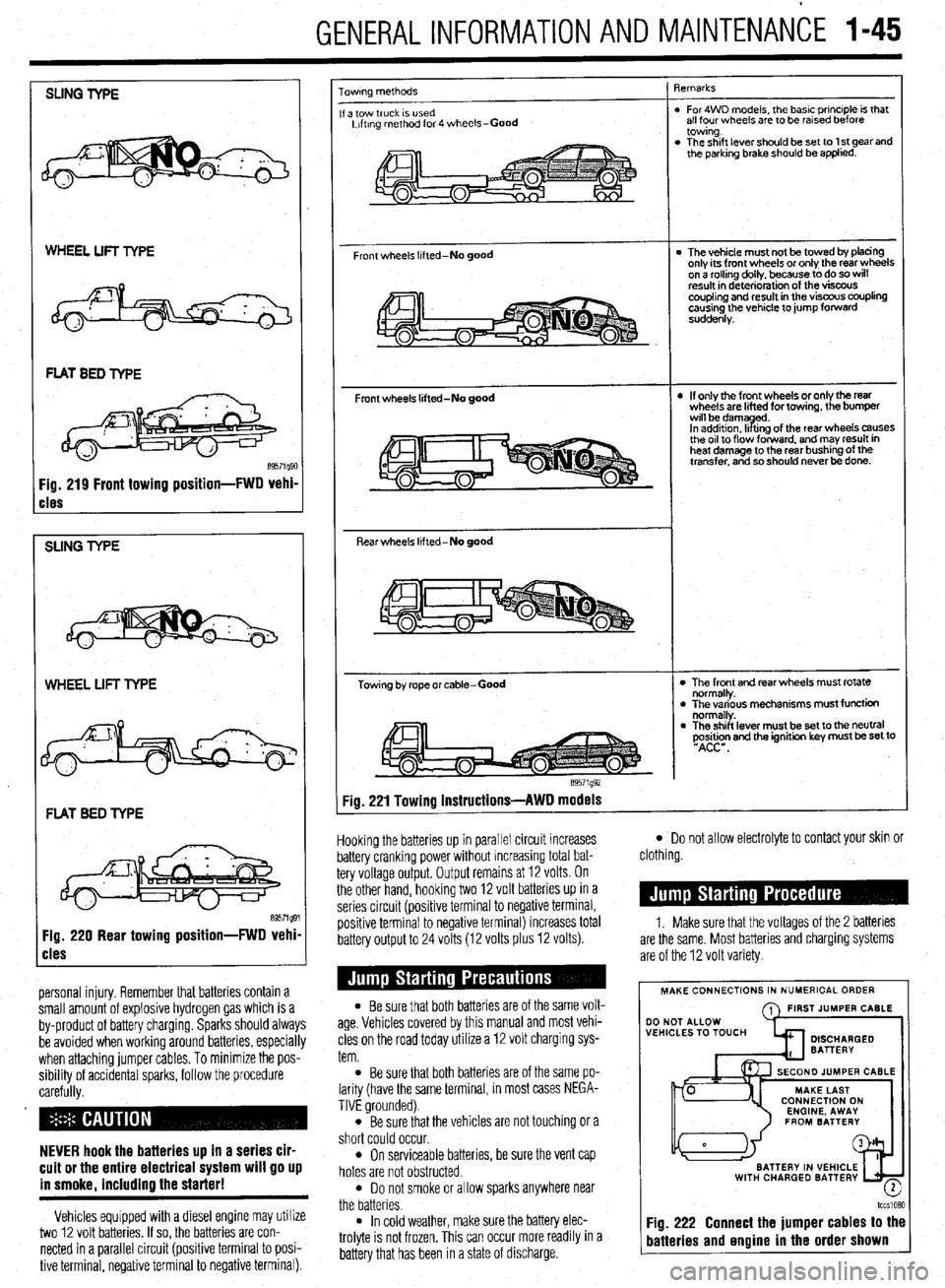

owrng methods

a tow truck IS used

Lrftrng method for 4 wheels-Good

Front wheels lifted-No good

Front wheels lifted-No good

Rear wheels lifted-No good

Towing by rope or cable-Good

e9571g92 qemarks

. For4WD models, the basic principle is that

all four wheels are to be rarsed before

towing.

. The shift lever should be set to 1 st gear and

the parking brake should be applied.

l The vehicle must not be towed by tofacing

only its front wheels or only the rear wheels

on a rollino dollv, because to do so will

result in d&e&ration of the visfx~s

coupling and result in the viscous coupling

causing the vehicle to jump forward

suddenly.

l If only the front wheels or only the rear

wheels are lifted for towing, the bumper

wrll bedamyd.

In addrtron. II trng of the rear wheels causes

the or1 to flow forward. and may result in

heat damage to the rear bushing of the

transfer, and so should never be done.

l The front and rear wheels must rotate

normally.

l The various mechanisms must function

normally.

l The shift lever must be set to the neutral

~Asi&n and the ignition key must be set to

Fig. 221 Towing instructions-AWD models

Hooking the batteries up in parallel circuit increases

battery cranking power without increasing total bat-

tery voltage output. Output remains at 12 volts. On

the other hand, hooking two 12 volt batteries up in a

series circuit (positive terminal to negative terminal,

positive terminal to negative terminal) increases total

battery output to 24 volts (12 volts plus 12 volts).

l Be sure that both batteries are of the same volt-

age. Vehicles covered by this manual and most vehi-

cles on the road today utilize a 12 volt charging sys-

tem.

l Be sure that both batteries are of the same po-

larity (have the same terminal, in most cases NEGA-

TIVE grounded).

l Be sure that the vehicles are not touching or a

short could occur.

l On serviceable batteries, be sure the vent cap

holes are not obstructed.

l Do not smoke or allow sparks anywhere near

the batteries.

l In cold weather, make sure the battery elec-

trolyte is not frozen, This can occur more readily in a

battery that has been in a state of discharge.

l Do not allow electrolyte to contact your skin or

clothing.

1. Make sure that the voltages of the 2 batteries

are the same. Most batteries and charging systems

are of the 12 volt variety.

MAKE CONNECTIONS IN NUMERICAL ORDER

A FIRST JUMPER CABLE

WITH CHARGED BATTERY

-

lccslQ?,Q

Fig. 222 Connect the jumper cables to the

batteries and engine in the order shown

Page 45 of 408

.

I-46 GENERALINFORMATIONAND MAINTENANCE

2. Pull the jumping vehicle (with the good bat-

tery) into a position so the jumper cables can reach

the dead battery and that vehicle’s engine. Make sure

that the vehicles do NOT touch.

3. Place the transmissions/transaxles of both ve-

hicles in Neutral (MT) or P (AT), as applicable, then

firmly set their parking brakes.

*ff necessary for safety reasons, the hazard

lights on both vehicles may be operated

throughout the entire procedure without sig-

nificantiy increasing the diff icuity of jumping

the dead battery.

4. Turn all lights and accessories OFF on both

vehicles. Make sure the ignition switches on both ve-

hicles are turned to the OFF position.

5. Cover the battery cell caps with a rag, but do

not cover the terminals.

6. Make sure the terminals on both batteries are

clean and free of corrosion or proper electrical con-

nection will be impeded. If necessary, clean the bat-

tery terminals before proceeding.

7. Identify the positive (+) and negative (-) termi-

nals on both batteries.

8. Connect the first jumper cable to the positive

(t) terminal of the dead battery, then connect the

other end of that cable to the positive (t) terminal of

the booster (good) battery.

9. Connect one end of the other jumper cable to

the negative (−) terminal on the booster bat-

tery and the final cable clamp to an engine bolt head,

alternator bracket or other solid, metallic point on the

engine with the dead battery. Try to pick a ground on

the engine that is positioned away from the battery in

order to minimize the possibility of the 2 clamps

touching should one loosen during the procedure.

DO NOT connect this clamp to the negative (-) termi-

nal of the bad battery. cable on the donor battery. Disconnect the positive

cable from the donor battery and finally, disconnect

the positive cable from the formerly dead battery. Be

careful when disconnecting the cables from the posi-

tive terminals not to allow the alligator clips to touch

any metal on either vehicle or a short and sparks will

occur.

I

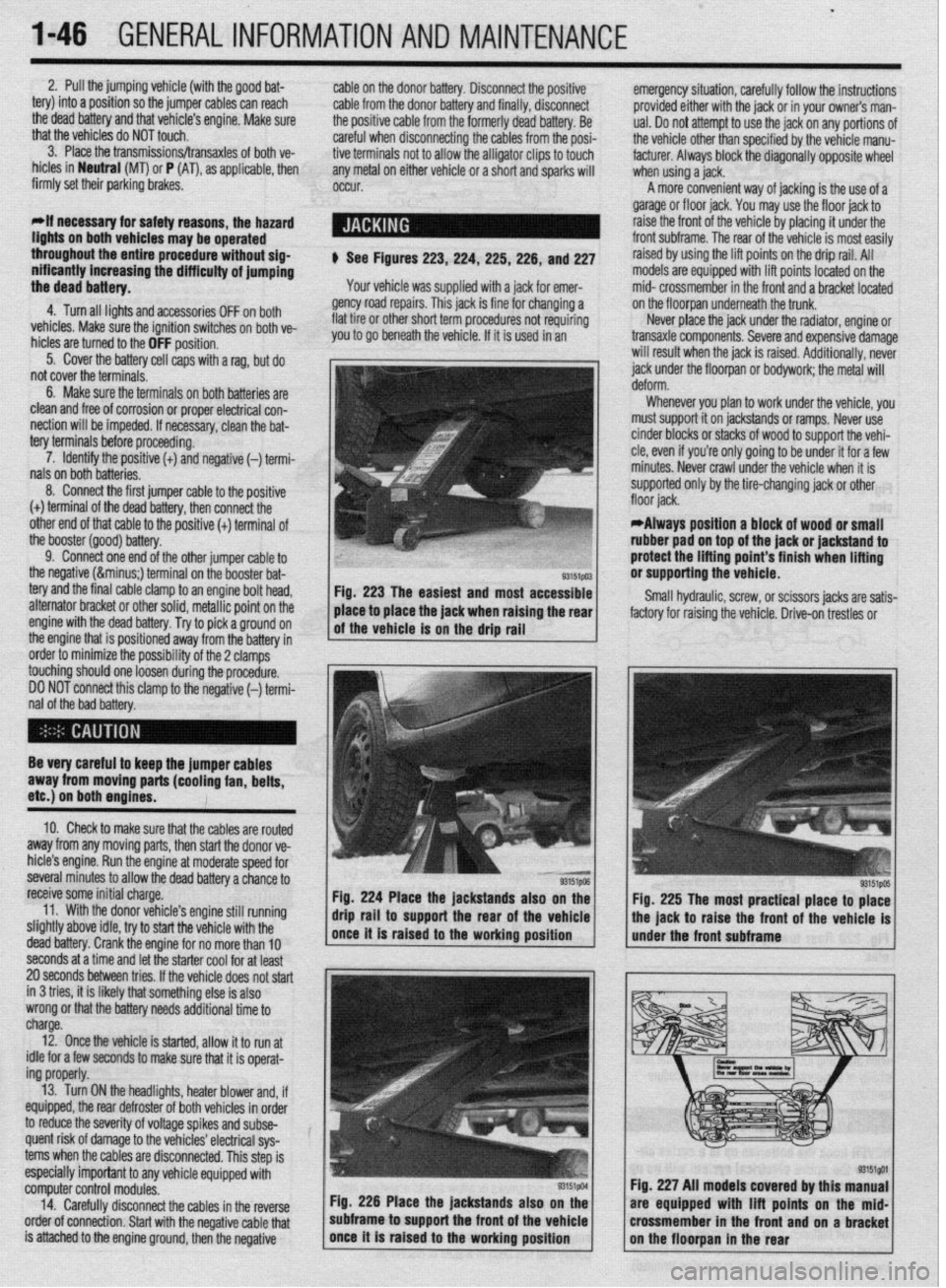

$ See Figures 223,224, 225,226, and 227

Your vehicle was supplied with a jack for emer-

gency road repairs. This jack is fine for changing a

flat tire or other short term procedures not requiring

you to go beneath the vehicle. If it is used in an emergency situation, carefully follow the instructions

provided either with the jack or in your owners man-

ual. Do not attempt to use the jack on any portions of

the vehicle other than specified by the vehicle manu-

facturer. Always block the diagonally opposite wheel

when using a jack.

A more convenient way of jacking is the use of a

garage or floor jack. You may use the floor jack to

raise the front of the vehicle by placing it under the

front subframe. The rear of the vehicle is most easily

raised by using the lift points on the drip rail. All

models are equipped with lift points located on the

mid- crossmember in the front and a bracket located

on the floorpan underneath the trunk.

Never place the jack under the radiator, engine or

transaxle components. Severe and expensive damage

will result when the jack is raised. Additionally, never

jack under the floorpan or

bodywork; the

metal will

Whenever you plan to work under the vehicle, you

must support it on jackstands or ramps. Never use

cinder blocks or stacks of wood to support the vehi-

cle, even if you’re only going to be under it for a few

minutes. Never crawl under the vehicle when it is

supported only by the tire-changing jack or other

*Always position a block of wood or small

rubber pad on top of the jack or jackstand to

protect the lifting point’s finish when lifting

or supporting the vehicle.

Small hydraulic, screw, or scissors jacks are satis-

factory for raising the vehicle. Drive-on trestles or

Be very careful to keep the jumper cables

away from moving parts (cooling fan, belts,

etc.) on both engines.

10. Check to make sure that the cables are routed

away from any moving parts, then start the donor ve-

hicle’s engine. Run the engine at moderate speed for

several minutes to allow the dead battery a chance to

receive some initial charge.

11. With the donor vehicle’s engine still running

slightly above idle, try to start the vehicle with the

dead battery. Crank the engine for no more than 10 &stands also on the

Fig. 225 The most practical place to place

front of the vehicle is

seconds at a time and let the starter cool for at least

20 seconds between tries. If the vehicle does not start

in 3 tries, it is likely thatsomething else is also

wrong or that the battery needs additional time to

charge.

12. Once the vehicle is started, allow it to run at

idle for a few seconds to make sure that it is operat-

ing properly.

13. Turn ON the headlights, heater blower and, if

equipped, the rear defroster of both vehicles in order

to reduce the severity of voltage spikes and subse-

quent risk of damage to the vehicles’ electrical sys-

tems when the cables are disconnected. This step is

especially important to any vehicle equipped with

computer control modules.

14. Carefully disconnect the cables in the’reverse

order of connection. Start with the negative cable that

is attached to the engine ground, then the negative Fig. 226 Place the jackstands also

subframe to support the front of the Fig. 227 All models covered by this

are equipped with lift points on t

crossmember in the front and on a

Page 46 of 408

GENERAL INFORMATION AND MAINTENANCE 1-47

ramps are also a handy and safe way to both raise l When the drive wheels are to remain on the

and support the vehicle. Be careful though, some ground, leave the vehicle in gear to help prevent it

ramps may be too steep to drive your vehicle onto

The following safety points cannot be overempha- from rolling.

without scraping the front bottom panels. Never sup-

sized:

l Always use jackstands to support the vehicle

port the vehicle on any suspension member (unless l Always block the opposite wheel or wheels to when you are working underneath. Place the stands

specifically instructed to do so by a repair manual) or

keep the vehicle from rolling off the jack. beneath the vehrcle’s jacking brackets Before climb-

by an underbody panel.

l When raising the front of the vehicle, firmly ap- ing underneath, rock the vehicle a bit to make sure it

ply the parking brake. is firmly supported.

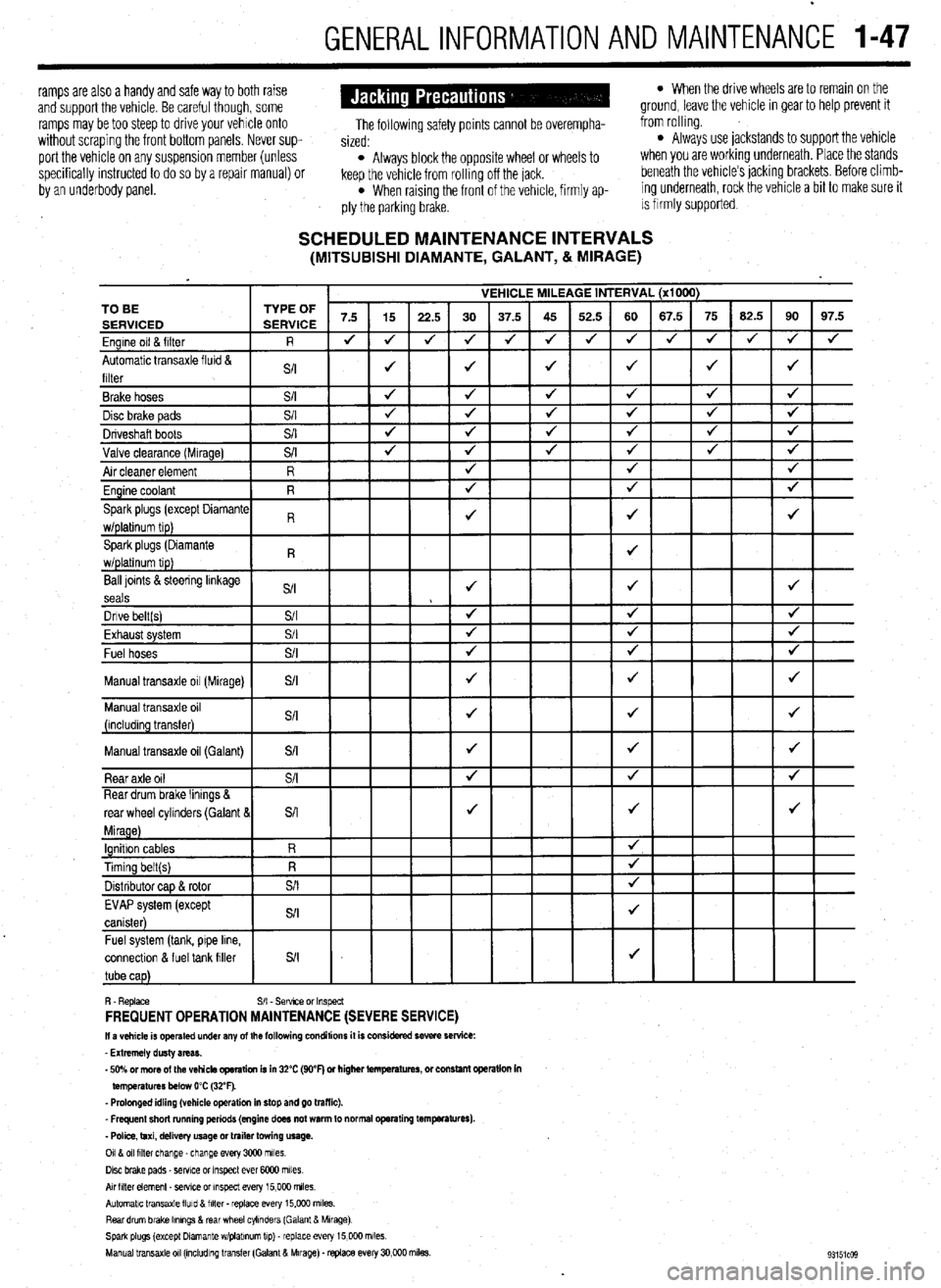

SCHEDULED MAINTENANCE INTERVALS (MITSUBISHI DIAMANTE, GALANT, & MIRAGE)

VEHICLE MILEAGE INTERVAL (x1000)

7.5 15

22.5 30 37.5 45 52.5 60 67.5 75 62.5 90 97.5

J J

J 4 J J 4 4 4 J J

J 4

4

J J J J 4 TO BE

Ball loints &steering linkage

S/I J J J

seals

Dnve belt(s) S/I 4 4 J

Fvha,,rt cvctom $/I

J J J LmI,..“w. “,YL”,‘. Fuel hoses

+

Manual transaxle oil (Galant)

connectlon & fuel tank filler

R. Replace S/I - Sefwce or Inspect FREQUENT OPERATION MAINTENANCE (SEVERE SERVICE) II a vehicle is operated under any of the following conditions it is considered severe service:

- Extremely dusty areas.

- 50% or more of the vehicle operation is in 32% (WF) or higher temperatures, or constant opsralion in

temperatures below 0% (32°F).

- Prolonged idling (vehicle operation in stop and go traffic).

_ Frequent short running periods (engine does not warm to normal operating temfwatures).

- Police, taxi, delivery usage or trailer towing usage.

0118 011 filter change-change every 3CQO miles.

Disc brake pads - sewce or Inspect ever 6COO miles

AN hlter element _ setwe or inspect every 15,000 miles.

Automatic transaxle lluld 8 filter . replace every 15,COO m&s.

Rear drum brake Ikmngs & rear wheel cylinders (Galant & Mirage)

Spark plugs (except Dlamante wlplabnum tip) - replace every 15,COO miles.

Manual transaxle 011 (mcludlng transfer (Galant & Mirage). replace every 30,000 miles.

Page 225 of 408

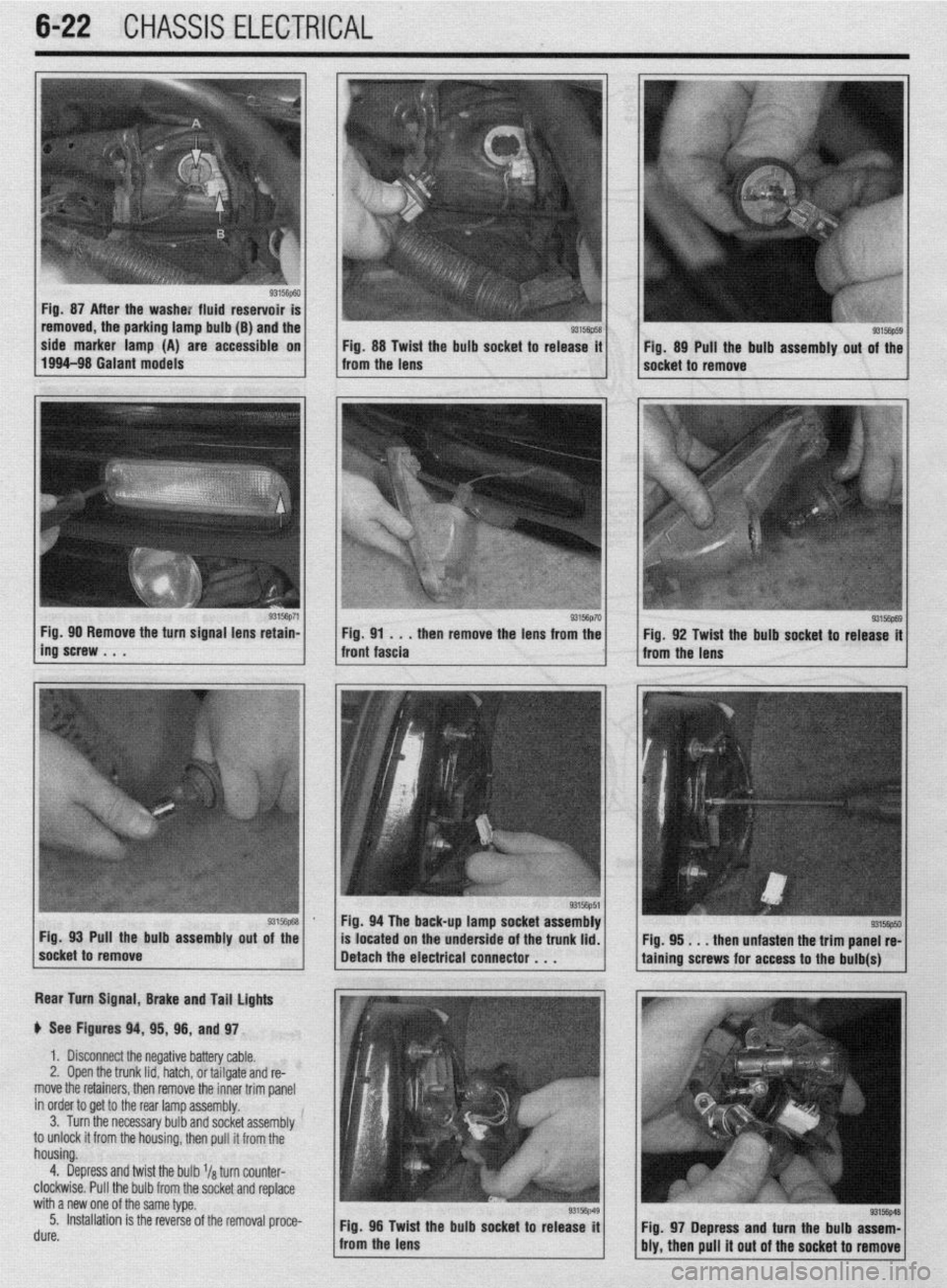

6-22 CHASSIS ELECTRICAL

b

Fig. 87 After the washe: fluid reservoir

removed, the parking lamp bulb (B) and the

side marker lamp (A) are accessible on

Fig. 88 Twist the bulb socket to release it

1994-98 Galant models

from the lens Fig. 89 Pull the bulb assembly out of the

socket to remove

g3156p71 / Fig 90 Remove the turn signal lens retain-

ing’screw . . . . then remove the lens from the

Rear Turn Signal, Brake and Tail lights

p See Figures 94, 95, 96, and 97.

1. Disconnect the negative battery cable.

2, Open the trunk lid, hatch, or tailgate and re-

move the retainers, then remove the inner trim panel

in order to get to the rear lamp assembly.

3. Turn the necessary bulb and socket assembly

to unlock it from the housing, then pull it from the

housing.

4. Depress and twist the bulb l/a turn counter-

clockwise. Pull the bulb from the socket and replace

with a new one of the same type.

5. Installation is the reverse of the removal proce-

rl. ._^

UUIt?. Fig. 96 Twid

: the bulb socket to release it

from the lens

93156p69 Fig. 92 Twist the bulb socket to release it

from the lens

I

Fig. 94 The back-up lamp socket assembly

Pull the bulb assembly

out of the

located on the underside of the trunk lid.

. . . then unfasten the trim panel re-

Fig. 97 Depress and turn the bulb assem-

bly, then pull it out of the socket to remove

Page 234 of 408

CHASSIS ELECTRICAL 6-31

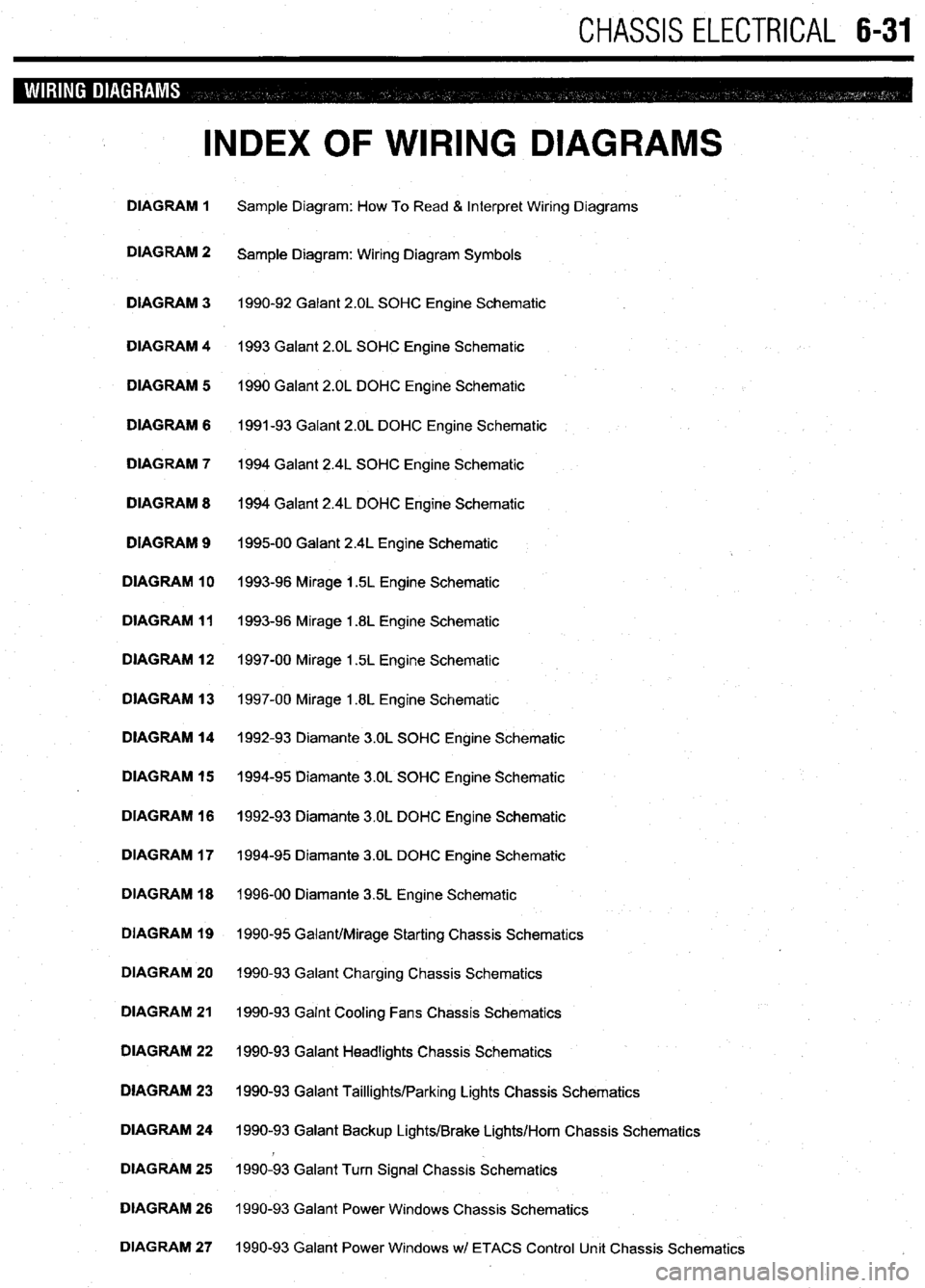

INDEX OF WIRING DIAGRAMS

DIAGRAM 1 Sample Diagram: How To Read & Interpret Wiring Diagrams

DIAGRAM 2

Sample Diagram: Wiring Diagram Symbols

DIAGRAM 3 1990-92 Galant 2.OL SOHC Engine Schematic

DIAGRAM 4 1993 Galant 2.OL SOHC Engine Schematic

DIAGRAM 5 1990 Galant 2.OL DOHC Engine Schematic

DIAGRAM 6 1991-93 Galant 2.OL DOHC Engine Schematic

DIAGRAM 7 1994 Galant 2.4L SOHC Engine Schematic

DIAGRAM 8 1994 Galant 2.4L DOHC Engine Schematic

DIAGRAM 9

199500 Galant 2.4L Engine Schematic

DIAGRAM 10 1993-96 Mirage 1.5L Engine Schematic

DIAGRAM 11 1993-96 Mirage 1.8L Engine Schematic

DIAGRAM 12 1997-00 Mirage 1.5L Engine Schematic

DIAGRAM 13 1997-00 Mirage 1.8L Engine Schematic

DIAGRAM 14 1992-93 Diamante 3.OL SOHC Engine Schematic

DIAGRAM 15 1994-95 Diamante 3.OL SOHC Engine Schematic

DIAGRAM 16 1992-93 Diamante 3.OL DOHC Engine Schematic

DIAGRAM 17 1994-95 Diamante 3.OL DOHC Engine Schematic

DIAGRAM 18 1996-00 Diamante 35L Engine Schematic

DIAGRAM 19 1990-95 Galant/Mirage Starting Chassis Schematics

DIAGRAM 20 1990-93 Galant Charging Chassis Schematics

DIAGRAM 21 1990-93 Galnt Cooling Fans Chassis Schematics

DIAGRAM 22 1990-93 Galant Headlights Chassis Schematics

DIAGRAM 23 1990-93 Galant Taillights/Parking Lights Chassis Schematics

DIAGRAM 24 1990-93 Galant Backup Lights/Brake Lights/Horn Chassis Schematics

DIAGRAM 25 1990-93 Galant Turn Signal Chassis Schematics

DIAGRAM 26 1990-93 Galant Power Windows Chassis Schematics

DIAGRAM 27 1990-93 Galant Power Windows wl ETACS Control Unit Chassis Schematics