compression ratio MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 26 of 408

GENERALINFORMATIONAND MAlNTENANdE I-27

ADJUSTMENT

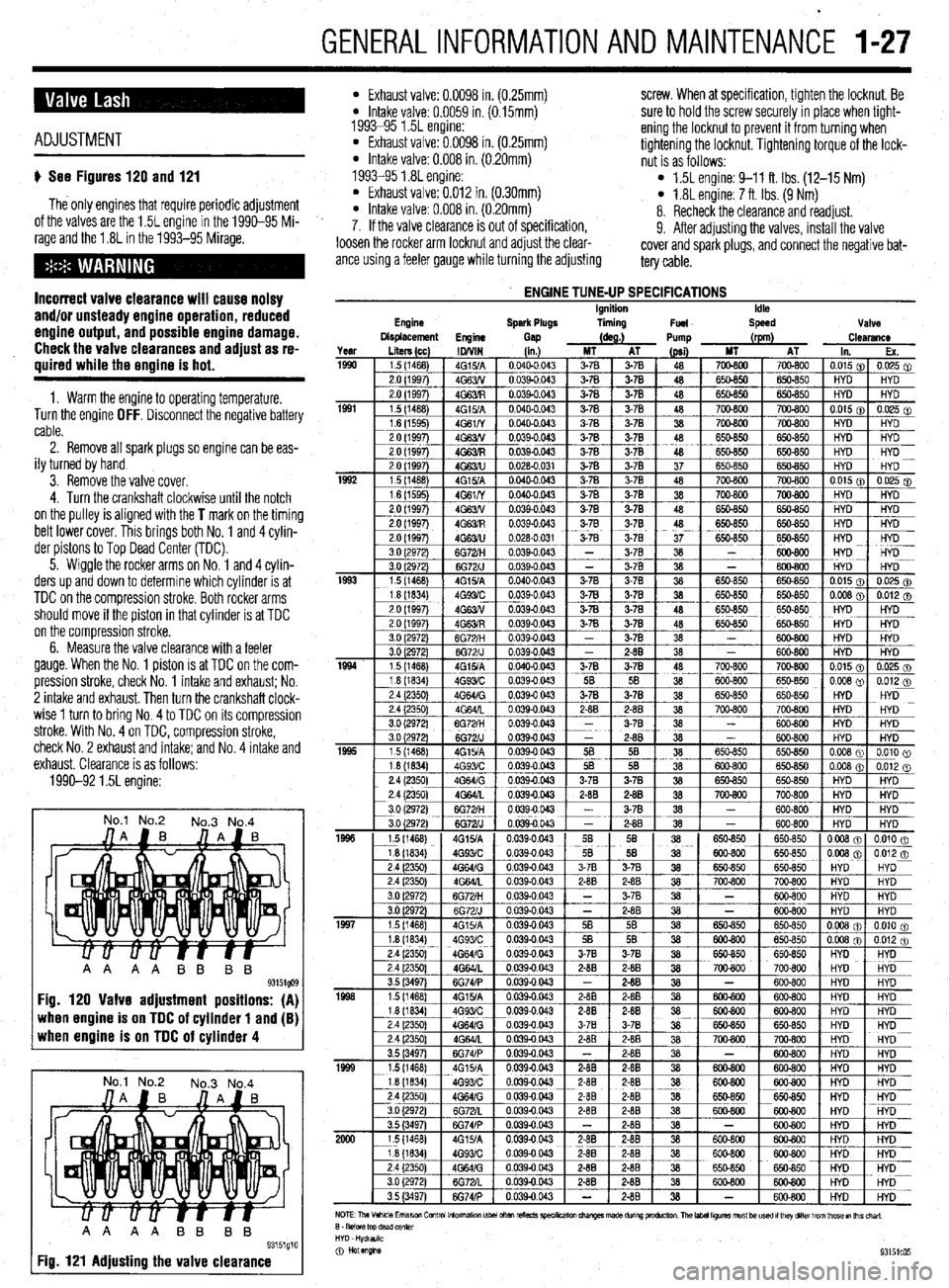

u See Figures 120 and 121

The only engines that require periodic adjustment

of the valves are the 1.5L engine in the 1990-95 Mi-

rage and the 1.8L in the 1993-95 Mirage.

Incorrect valve clearance will cause noisy

and/or unsteady engine operation, reduced

engine output, and possible engine damage.

Check the valve clearances and adjust as re-

quired while the engine is hot.

1. Warm the engine to operating temperature.

Turn the engine OFF. Disconnect the negative battery

cable.

2. Remove all spark plugs so engine can be eas-

ily turned by hand

3. Remove the valve cover.

4. Turn the crankshaft clockwise until the notch

on the pulley is aligned with the

T mark on the timing

belt lower cover. This brings both No. 1 and 4 cylin-

der pistons to Top Dead Center (TDC).

5. Wiggle the rocker arms on No. 1 and 4 cylin-

ders up and down to determine which cylinder is at

TDC on the compression stroke. Both rocker arms

should move if the piston in that cylinder is at TDC

on the compression stroke.

6. Measure the valve clearance with a feeler

gauge. When the No. 1 piston is at TDC on the com-

pression stroke, check No. 1 intake and

exhaust; No.

2 intake and exhaust. Then turn the crankshaft clock-

wise 1 turn to bring No. 4 to TDC on its compression

stroke. With No. 4 on TDC, compression stroke,

check No. 2 exhaust and intake; and No. 4 intake and

exhaust. Clearance is as follows:

1990-92 1.5L engine:

No.1 No.2

No.3 No.4

when engine is on TDC of cylinder 1 and (B) when engine is on TDC of cylinder 4

No.1 No.2

No.3 No.4

AA AA BB BB

93151g10 Fig. 121 Adjusting the valve clearance

l Exhaust valve: 0.0098 in. (0.25mm) screw. When at specification, tighten the locknut. Be l Intake valve: 0.0059 in. (0.15mm)

1993-95 1.5L engine: sure to hold the screw securely in place when tight-

l Exhaust valve: 0.0098 in. (0.25mm) ening the locknut to prevent it from turning when

* Intake valve: 0.008 in. (0.20mm) tightening the locknut. Tightening torque of the lock-

nut is as follows:

1993-95 1.8L engine:

l Exhaust valve: 0.012 in. (0.30mm) l 1.5L engine: 9-11 ft. Ibs. (12-15 Nm)

l Intake valve: 0.008 in. (0.20mm) l 1.8L engine: 7 ft. Ibs. (9 Nm)

8. Recheck the clearance and readjust.

7. If the valve clearance is out of specification,

9. After adjusting the valves, install the valve

loosen the rocker arm locknut and adjust the clear-

ante using a feeler gauge while turning the adjusting cover and spark plugs, and connect the negative bat-

tery cable.

Engine

ENGINE TUNE-UP SPECIFICATIONS Ignition

Spark Plugs liming

Fuel Idle

Speed Valve

Displacement

Engine

Gap (as.) Pump (rpm)

Clearance

Page 27 of 408

l-28 GENERALINFORMATIONAND MAINTENANCE

may result in skin or eye irritation or frostbite. Al- formed to help maintain the efficiency of the vehicle’s

though low in toxicity (due to chemical stability), in- A/C system. For preventive maintenance, perform the

The idle speed is factory set and usually no ad- halation of concentrated refrigerant fumes is danger- following:

justments are ever necessary. If an adjustment be- ous and can result in death; cases of fatal cardiac

l The easiest and most important preventive

comes necessary, first check that the spark plugs, in- arrhythmia have been reported in people accidentally maintenance for your A/C system is to be sure that it

jectors, idle air control servo and compression subjected to high levels of refrigerant. Some early is used on a regular basis. Running the system for

pressure are all normal. symptoms include loss of concentration and drowsi- five minutes each month (no matter what the season)

Data from various sensors and switches are used ness. + will help ensure that the seals and all internal compo-

by the ECU to determine the proper fuel/air mixture

for optimal engine performance. cGeneraiiy, the limit for exposure is lower nents remain lubricated.

for R-134a than it is for R-12. Exceptional *Some newer vehicles automatically oper-

care must be practiced when handling R- ate the A/C system compressor whenever the

134a. windshield defroster is activated. When run-

Also, refrigerants can decompose at high tempera- ning, the compressor lubricates the A/C sys

tures (near gas heaters or open flame), which may re- tern components; therefore, the A/C system

SYSTEM SERVICE& REPAIR suit in hydrofluoric acid, hydrochloric acid and phos- would not need to be operated each month.

gene (a fatal nerve gas). * In order to prevent heater core freeze-up during

R-12 refrigerant can damage the environment be- A/C operation, it is necessary to maintain proper an-

cause it is a Chlorofluorocarbon (CFC), which has tifreeze protection. Use a hand-held coolant tester

been proven to add to ozone layer depletion, leading (hydrometer) to periodically check the condition of

to increasing levels of UV radiation. UV radiation has the antifreeze in your engine’s cooling system.

been linked with an increase in skin cancer, suppres-

sion of the human immune system, an increase in *Antifreeze should not be used longer than

cataracts, damage to crops, damage to aquatic organ- the manufacturer specifies.

isms, an increase in ground-level ozone, and in- . For efficient operation of an air conditioned ve-

creased global warming. hicle’s cooling system, the radiator cap should have a

R-134a refrigerant is a greenhouse gas which, if holding pressure which meets manufacturers specifi-

allowed to vent into the atmosphere, will contribute to cations. A cap which fails to hold these pressures

global warming (the Greenhouse Effect). should be replaced.

It is usually more economically feasible to have a

l Any obstruction of or damage to the condenser

certified MVAC automotive technician perform A/C configuration will restrict air flow which is essential

system service on your vehicle. Some possible rea- to its efficient operation. It is, therefore, a good rule

sons for this are as follows: to keep this unit clean and in proper physical shape.

l While it is illegal to service an A/C system

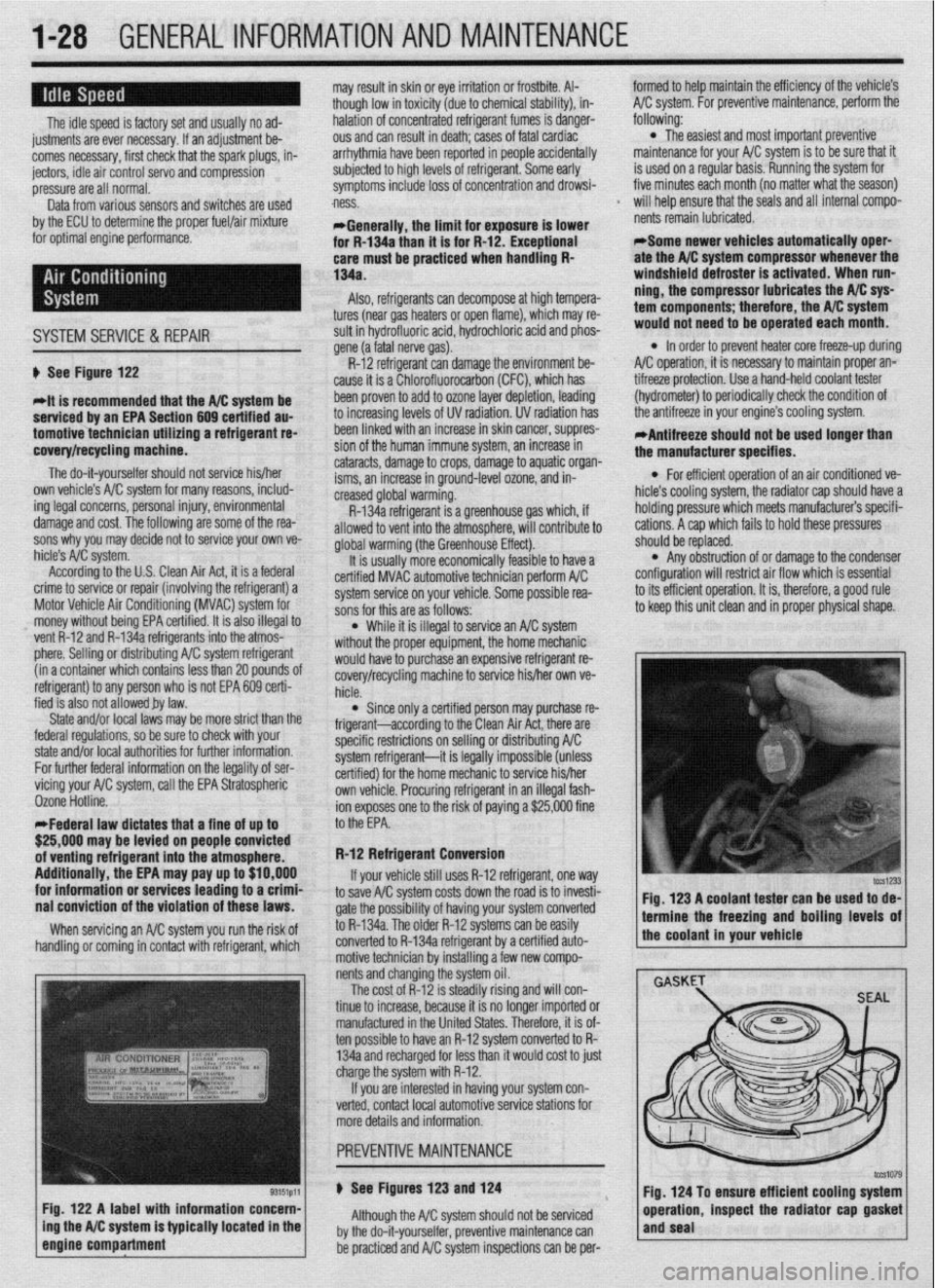

without the proper equipment, the home mechanic ti See Figure 122

*it is recommended that the A/C svstem be

serviced by an EPA Section 609 cehified au-

tomotivetechnicfan utilizing a refrigerant re-

covery/recycling machfne.

The do-it-yourselfer should not service his/her

own vehicle’s A/C system for many reasons, includ-

ing legal concerns, personal injury, environmental

damage and cost. The following are some of the rea-

sons why you may decide not to service your own ve-

hicle’s A/C system.

According to the U.S. Clean Air Act, it is a federal

crime to service or repair (involving the refrigerant) a

Motor Vehicle Air Conditioning (MVAC) system for

money without being EPA certified. It is also illegal to

vent R-12 and R-134a refrigerants into the atmos-

phere. Selling or distributing A/C system refrigerant

(in a container which contains less than 20 pounds oi

refrigerant) to any person who is not EPA 609 certi-

fied is also not allowed by law.

State and/or local laws may be more strict than the

federal regulations, so be sure to check with your

state and/or local authorities for further information.

For further federal information on the legality of ser-

vicing your AK system, call the EPA Stratospheric

Ozone Hotline.

*Federal law dictates that a fine of up to

$25,000 may be levied on people convicted

of venting refrigerant into the atmosphere.

Additionally, the EPA may pay up to $10,000

for information or services leading to a crimf

nai conviction of the violation of these laws.

When servicing an A/C system you run the risk of

handling or coming in contact with refrigerant, which

Fig. 122 A label with information concern-

ing the A/C system is typically located in the

engine compartment

f would haveto purchase an expensive refrigerant re-

covery/recycling machine to service his/her own ve-

hicle.

l Since only a certified person may purchase re-

frigerant-according to the Clean Air Act, there are

specific restrictions on selling or distributing A/C

system refrigerant-it is legally impossible (unless

certified) for the home mechanic to service his/her

own vehicle. Procuring refrigerant in an illegal fash-

ion exposes one to the risk of paying a $25,000 fine

to the EPA.

R-12 Refrigerant Conversion

If your vehicle still uses R-12 refrigerant, one

way to save A/C system costs down the road is to invesh-

gate the possibility of having your system converted

to R-134a. The older R-12 systems can be easily

converted to R-134a refrigerant by a certified auto-

motive technician by installing a few new compo-

nents and changing the system oil.

The cost of R-12 is steadily rising and will con-

tinue to increase, because it is no longer imported or

manufactured in the United States. Therefore, it is of-

ten possible to have an R-12 system converted to R-

134a and recharged for less than it would cost to just

charge the system with R-12.

If you are interested in having your system con-

verted, contact local automotive service stations for

more details and information.

u See Figures 123 and 124

Although the A/C system should not be serviced

by the do-it-yourselfer, preventive maintenance can

be practiced and A/C system inspections can be per- Fig. 123 A coolant tester can be used to de-

1 termine the freezing and boiling levels of

the coolant in your vehicle

Fig. 124 To ensure efficient cooling system

operation, inspect the radiator cap gasket

and seal

Page 51 of 408

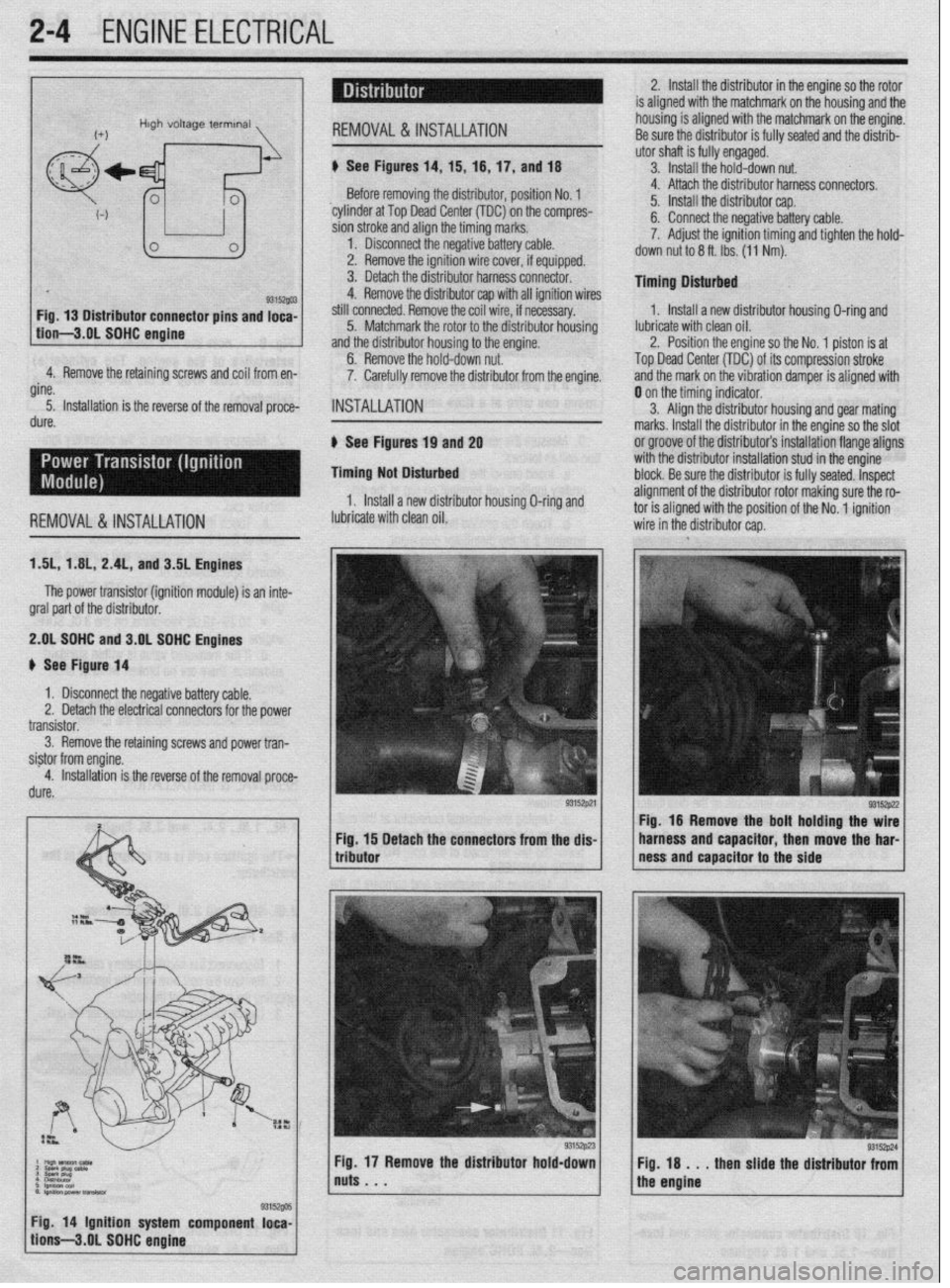

2-4 ENGINEELECTRICAL

2. Install the distributor in the engine so the rotor

is aligned with the matchmark on the housing and the

housing is aligned with the matchmark on the engine.

4.‘ Remove the retaining screws and coil from en-

gine.

5. Installation is the reverse of the removal proce-

dure. Before removing the distributor, position No. 1

‘cylinder at Top Dead Center (TDC) on the compres-

sion stroke and align the timing marks.

1. Disconnect the negative battery cable.

2. Remove the ignition wire cover, if equipped.

3. Detach the distributor harness connector.

4. Remove the distributor cap with all ignition wires

still connected. Remove the coil wire, if necessary.

5. Matchmark the rotor to the distributor housing

and the distributor housing to the engine.

6. Remove the hold-down nut.

7. Carefully remove the distributor from the engine.

INSTALLATION

6 See Figures 19 and 2g

Timing Not Disturbed

1, Install a new distributor housing O-ring and 4. Attach the distributor harness connectors.

5. Install the distributor cap.

6. Connect the negative battery cable.

7. Adjust the ignition timing and tighten the hold-

down nut to 6 ft. Ibs. (11 Nm).

Timing Dlsturbed

1. Install a new distributor housing O-ring and

lubricate with clean oil.

2. Position the engine so the No. 1 piston is at

Top Dead Center (TDC) of its compression stroke

and the mark on the vibration damper is aligned with

REMOVALS& INSTALLATION lubricate with clean oil. 0 on the timing indicator.

3. Align the distributor housing and gear mating

marks. Install the distributor in the engine so the slot

or groove of the distributor’s installation flange aligns

with the distributor installation stud in the engine

block. Be sure the distributor is fully seated. Inspect

alignment of the distributor rotor making sure the ro- tnr ic dinnnd with thn qn,c$nn of the Nn innitinn

ISL, 1 AIL, 2.4L, and 3.5L Engines

The power transistor (ignition module) is an inte-

gral part of the distributor.

2.gL SDHC and 3.OL SOHC Engines

# See Figure 14

1 x Disconnect the negative battery cable.

Remove the retaining screws and power tran-

Detach the connectors from the dis- Fig. 16 Remove the bolt holding the wire

harness and capacitor, then move the har-

ness and capacitor to the side

Fig. 18 . . . then slide the distributor from

the engine

/ tion’s-3.gL SOHC engine g3is~@ 1 Fig 14 Ignition system component loca-

Page 62 of 408

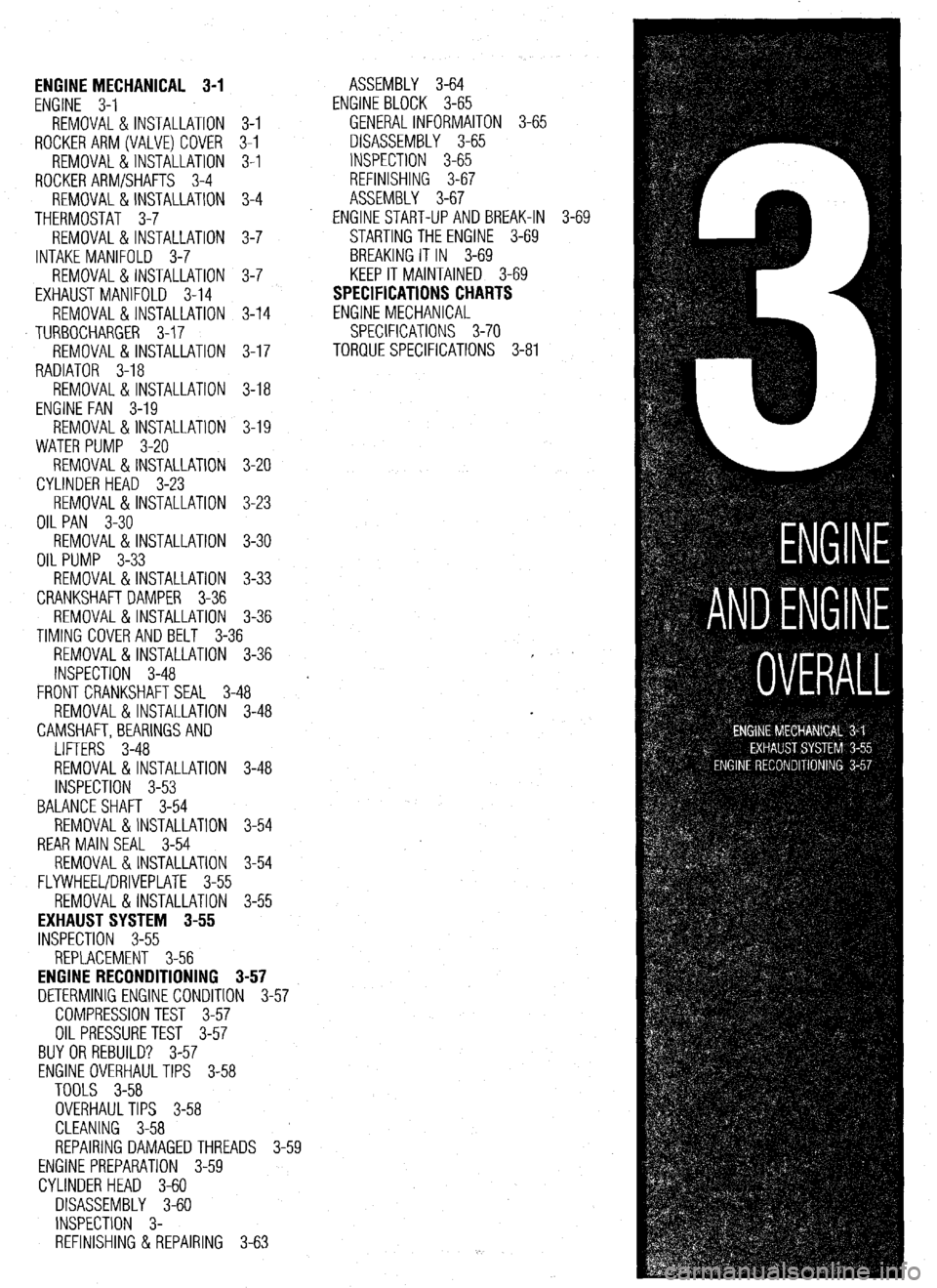

ENGINE MECHANICAL 3-1

ENGINE 3-1

REMOVAL &INSTALLATION 3-l

ROCKERARM(VALVE)COVER 3-l

REMOVAL &INSTALLATION 3-l

ROCKER ARM/SHAFTS 3-4

REMOVAL & INSTALLATION 3-4

THERMOSTAT 3-7

REMOVAL & INSTALLATION 3-7

INTAKE MANIFOLD 3-7

REMOVAL & INSTALLATION 3-7

EXHAUSTMANIFOLD 3-14

REMOVAL &INSTALLATION 3-14

TURBOCHARGER 3-17

REMOVAL & INSTALLATION 3-17

RADIATOR 3-18

REMOVAL & INSTALLATION 3-18

ENGINE FAN 3-19

REMOVAL &INSTALLATION 3-19

WATER PUMP 3-20

REMOVAL & INSTALLATION 3-20

CYLINDER HEAD 3-23

REMOVAL &INSTALLATION 3-23

OIL PAN 3-30

REMOVAL & INSTALLATION 3-30

OIL PUMP 3-33

REMOVAL &INSTALLATION 3-33

CRANKSHAFT DAMPER 3-36

REMOVAL &INSTALLATION 3-36

TIMING COVERAND BELT 3-36

REMOVAL & INSTALLATION 3-36

INSPECTION 3-48

FRONT CRANKSHAFTSEAL 3-48

REMOVAL & INSTALLATION 3-48

CAMSHAFT,BEARlNGSAND

LIFTERS 3-48

REMOVAL & INSTALLATION 3-48

INSPECTION 3-53

BALANCE SHAFT 3-54

REMOVAL &INSTALLATION 3-54

REAR MAIN SEAL 3-54

REMOVAL&INSTALLATION 3-54

FLYWHEEL/DRIVEPLATE 3-55

REMOVAL &INSTALLATION 3-55

EXHAUST SYSTEM 3-55

INSPECTION 3-55

REPLACEMENT 3-56

ENGINE RECONDITIONING 3-57

DETERMINIG ENGINE CONDITION 3-57

COMPRESSION TEST 3-57

OIL PRESSURETEST 3-57

BUYOR REBUILD? 3-57

ENGINE OVERHAULTIPS 3-58

TOOLS 3-58

OVERHAULTIPS 3-58

CLEANING 3-58

REPAIRING DAMAGEDTHREADS 3-59

ENGINE PREPARATION 3-59

CYLINDER HEAD 3-60

DISASSEMBLY 3-60

INSPECTION 3-

REFINISHING & REPAIRING 3-63 ASSEMBLY 3-64

ENGINE BLOCK 3-65

GENERALINFORMAITON 3-65

DISASSEMBLY 3-65

INSPECTION 3-65

REFINISHING 3-67

ASSEMBLY 3-67

ENGINE START-UP AND BREAK-IN 3-

STARTING THE ENGINE 3-69

BREAKING IT IN 3-69

KEEP IT MAINTAINED 3-69

SPECIFICATIONS CHARTS

ENGINE MECHANICAL

SPECIFICATIONS 3-70

TORQUE SPECIFICATIONS 3-81 .69

Page 99 of 408

3-38 ENGINEANDENGINEOVERHAUL

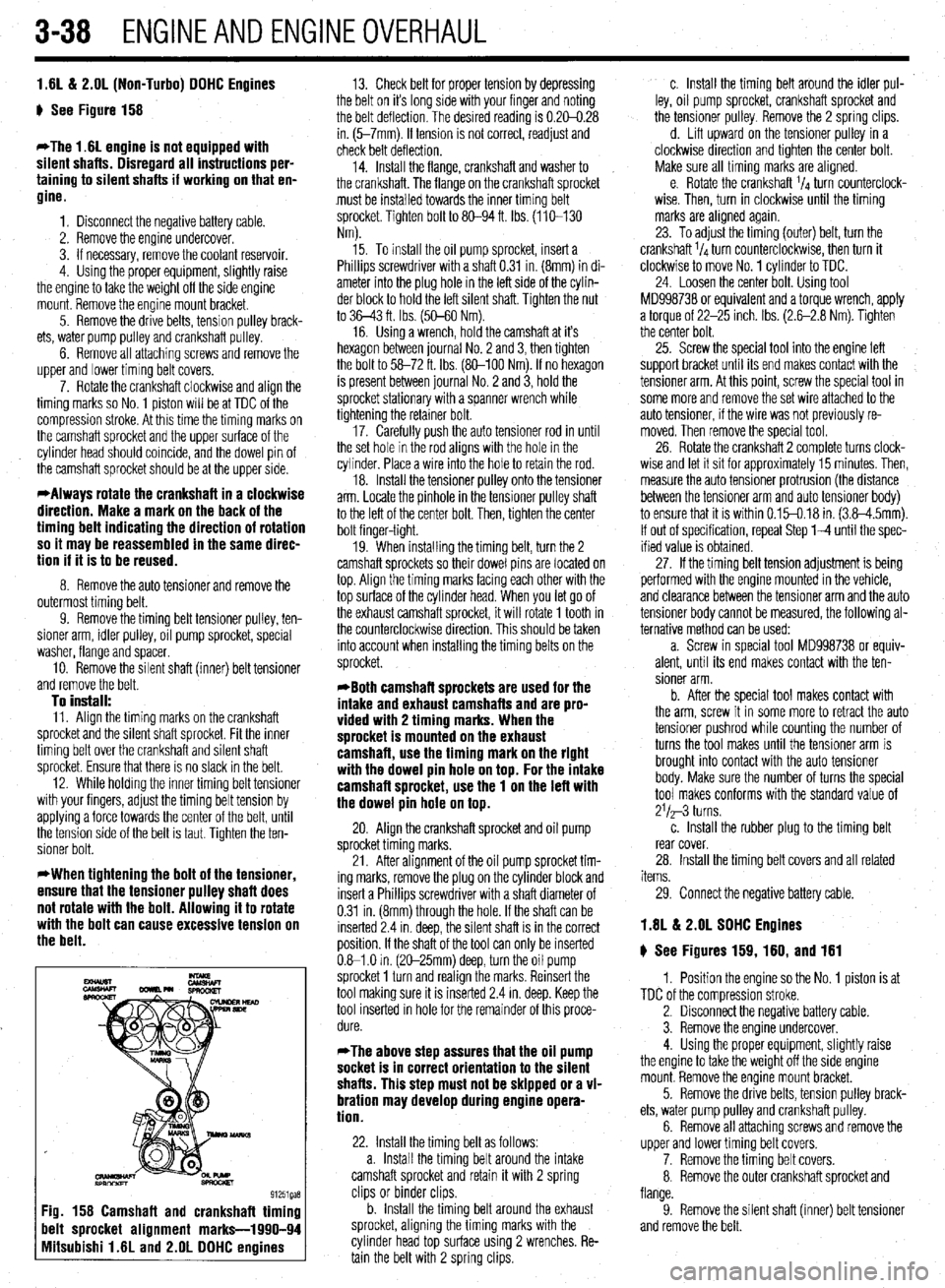

1.61&? 2.OL (Non-Turbo) DOHC Engines

g See Figure 158

*The 1.6L engine is not equipped with

silent shafts. Disregard all instructions per-

taining to silent shafts if working on that en-

gine.

1. Disconnect the negative battery cable.

2. Remove the engine undercover.

3. If necessary, remove the coolant reservoir.

4. Using the proper equipment, slightly raise

the engine to take the weight off the side engine

mount. Remove the engine mount bracket.

5. Remove the drive belts, tension pulley brack-

ets, water pump pulley and crankshaft pulley.

6. Remove all attaching screws and remove the

upper and lower timing belt covers.

7. Rotate the crankshaft clockwise and align the

timing marks so No. 1 piston will be at TDC of the

compression stroke. At this time the timing marks on

the camshaft sprocket and the upper surface of the

cylinder head should coincide, and the dowel pin of

the camshaft sprocket should be at the upper side.

*Always rotate the crankshaft in a clockwise

direction. Make a mark on the back of the

timing belt indicating the direction of rotation

so it may be reassembled in the same direc-

tion if it is to be reused.

8. Remove the auto tensioner and remove the

outermost timing belt.

9. Remove the timing belt tensioner pulley, ten-

sioner arm, idler pulley, oil pump sprocket, special

washer, flange and spacer.

10. Remove the silent shaft (inner) belt tensioner

and remove the belt.

To install: 11. Align the timing marks on the crankshaft

sprocket and the silent shaft sprocket. Fit the inner

timing belt over the crankshaft and silent shaft

sprocket. Ensure that there is no slack in the belt.

12. While holding the inner timing belt tensioner

with your fingers, adjust the timing belt tension by

applying a force towards the center of the belt, until

the tension side of the belt is taut. Tighten the ten-

sioner bolt.

*When tightening the bolt of the tensioner,

ensure that the tensioner pulley shaft does

not rotate with the bolt. Allowing it to rotate

with the bolt can cause excessive tension on

the belt.

13. Check belt for proper tension by depressing

the belt on it’s long side with your finger and noting

the belt deflection. The desired reading is 0.20-0.28

in. (5-7mm). If tension is not correct, readjust and

check belt deflection.

14. Install the flange, crankshaft and washer to

the crankshaft. The flange on the crankshaft sprocket

must be installed towards the inner trming belt

sprocket. Tighten bolt to 80-94 ft. Ibs. (110-130

Nm).

15. To install the oil pump sprocket, insert a

Phillips screwdriver with a shaft 0.31 in. (8mm) in di-

ameter into the plug hole in the left side of the cylin-

der block to hold the left silent shaft. Tighten the nut

to 36-43 ft. Ibs. (50-60 Nm).

16. Using a wrench, hold the camshaft at it’s

hexagon between journal No. 2 and 3, then tighten

the bolt to 58-72 ft. Ibs. (80-100 Nm). If no hexagon

is present between journal No. 2 and 3, hold the

sprocket stationary with a spanner wrench while

tightening the retainer bolt.

17. Carefully push the auto tensioner rod in until

the set hole in the rod aligns with the hole in the

cylinder. Place a wire into the hole to retain the rod.

18. Install the tensioner pulley onto the tensioner

arm. Locate the pinhole in the tensioner pulley shaft

to the left of the center bolt. Then, tighten the center

bolt finger-tight.

19. When installing the timing belt, turn the 2

camshaft sprockets so their dowel pins are located on

top. Align the timing marks facing each other with the

top surface of the cylinder head. When you let go of

the exhaust camshaft sprocket, it will rotate 1 tooth in

the counterclockwise direction. This should be taken

into account when installing the timing belts on the

sprocket.

*Both camshaft sprockets are used for the

intake and exhaust camshafts and are pro-

vided with 2 timing marks. When the

sprocket is mounted on the exhaust

camshaft, use the timing mark on the right

with the dowel pin hole on top. For the intake

camshafl sprocket, use the 1 on the left with

the dowel pin hole on top.

20. Align the crankshaft sprocket and oil pump

sprocket timing marks.

21. After alignment of the oil pump sprocket tim-

ing marks, remove the plug on the cylinder block and

insert a Phillips screwdriver with a shaft diameter of

0.31 in. (8mm) through the hole. If the shaft can be

inserted 2.4 in. deep, the silent shaft is in the correct

position. If the shaft of the tool can only be inserted

0.61 .O in. (2C-25mm) deep, turn the oil pump

sprocket 1 turn and realign the marks. Reinsert the

tool making sure it is inserted 2.4 in. deep. Keep the

tool inserted in hole for the remainder of this proce-

dure.

*The above step assures that the oil pump

socket is in correct orientation to the silent

shafts. This step must not be skipped or a vi-

bration may develop during engine opera-

tion.

22. Install the timing belt as follows:

a. Install the timing belt around the intake

camshaft sprocket and retain it with 2 spring

clips or binder clips.

b. Install the timing belt around the exhaust

sprocket, aligning the timing marks with the

cylinder head top surface using 2 wrenches. Re-

tain the belt with 2 spring clips. c. Install the timing belt around the idler pul-

ley, oil pump sprocket, crankshaft sprocket and

the tensioner pulley. Remove the 2 spring clips.

d. Lift upward on the tensioner pulley in a

clockwise direction and tighten the center bolt.

Make sure all timing marks are aligned.

e. Rotate the crankshaft ‘14 turn counterclock-

wise. Then, turn in clockwise until the timing

marks are alrgned again.

23. To adjust the timing (outer) belt, turn the

crankshaft ‘14 turn counterclockwise, then turn it

clockwise to move No. 1 cylinder to TDC.

24. Loosen the center bolt. Using tool

MD998738 or equivalent and a torque wrench, apply

a torque of 22-25 inch. Ibs. (2.6-2.8 Nm). Tighten

the center bolt.

25. Screw the special tool into the engine left

support bracket until its end makes contact with the

tensioner arm. At this point, screw the special tool in

some more and remove the set wire attached to the

auto tensioner, if the wire was not previously re-

moved. Then remove the specral tool.

26. Rotate the crankshaft 2 complete turns clock-

wise and let it sit for approximately 15 minutes. Then,

measure the auto tensioner protrusion (the distance

between the tensioner arm and auto tensioner body)

to ensure that it is within 0.15-0.18 in. (3.8-4.5mm).

If out of specification, repeat Step l-4 until the spec-

ified value is obtained.

27. If the timing belt tension adjustment is being

performed with the engine mounted in the vehicle,

and clearance between the tensioner arm and the auto

tensioner body cannot be measured, the following al-

ternative method can be used:

a. Screw in special tool MD998738 or equiv-

alent, until its end makes contact with the ten-

sioner arm.

b. After the special tool makes contact with

the arm, screw it in some more to retract the auto

tensioner pushrod while counting the number of

turns the tool makes until the tensioner arm is

brought into contact with the auto tensioner

body. Make sure the number of turns the special

tool makes conforms with the standard value of

21/a-3 turns.

c. Install the rubber plug to the timing belt

rear cover.

28. Install the timing belt covers and all related

items.

29. Connect the negative battery cable.

1.8L & 2.OL SOHC Engines

g See Figures 159, 160, and 161

1. Position the engine so the No. 1 piston is at

TDC of the compression stroke.

2. Disconnect the negative battery cable.

3. Remove the engine undercover.

4. Using the proper equipment, slightly raise

the engine to take the weight off the side engine

mount. Remove the engine mount bracket.

5. Remove the drive belts, tension pulley brack-

ets, water pump pulley and crankshaft pulley.

6. Remove all attaching screws and remove the

upper and lower timing belt covers.

7. Remove the timing belt covers.

8. Remove the outer crankshaft sprocket and

flange.

9. Remove the silent shaft (inner) belt tensioner

and remove the belt.

Page 103 of 408

.

3-42 ENGINEANDENGINEOVERHAUL

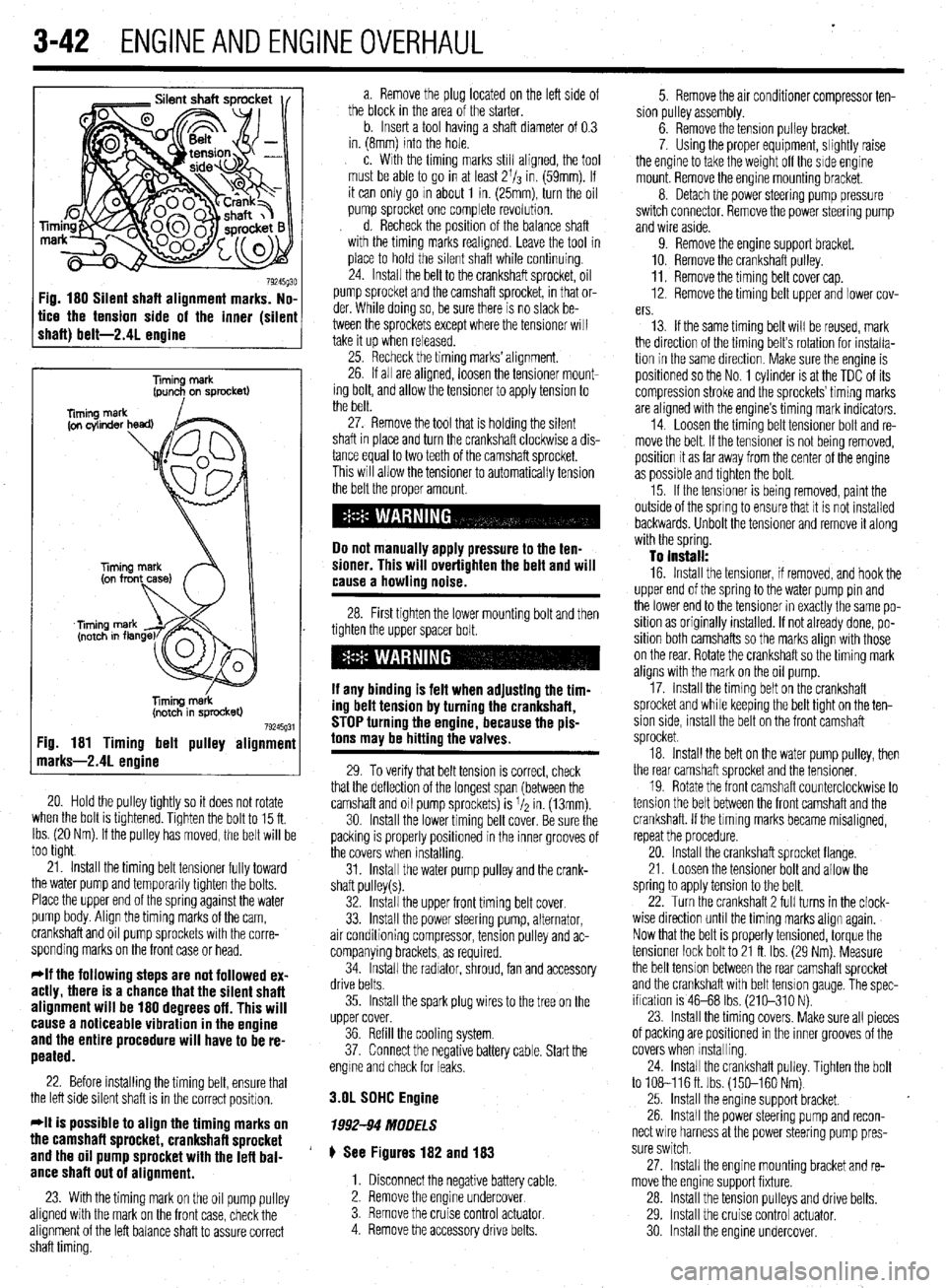

Fig. 180 Silent shaft alignment marks. No,

tice the tension side of the inner (silen

shaft) belt-2.41 enaine

Timing merk

(pun+ on sprocket)

liming m&k

(notch in sprocket)

79245g31 :ig. 181 Timing belt pulley alignmenl

narks-2.41 enoine

20. Hold the pulley tightly so it does not rotate

when the bolt is tlghtened. Tighten the bolt to 15 ft.

Ibs. (20 Nm). If the pulley has moved, the belt will be

too tight

21. Install the timing belt tensioner fully toward

the water pump and temporarily tighten the bolts.

Place the upper end of the spring against the water

pump body. Align the timing marks of the cam,

crankshaft and oil pump sprockets with the corre-

sponding marks on the front case or head.

*If the following steps are not followed ex-

actly, there is a chance that the silent shaft

alignment will be 180 degrees off. This will

cause a noticeable vibration in the engine

and the entire procedure will have to be re-

peated.

22. Before installing the timing belt, ensure that

the left side silent shaft is in the correct position.

*It is possible to align the timing marks on

the camshaft sprocket, crankshaft sprocket

and the oil pump sprocket with the lefl bal-

ance shaft out of alignment.

23. With the timing mark on the oil pump pulley

aligned with the mark on the front case, check the

alignment of the left balance shaft to assure correct

shaft timing. a. Remove the plug located on the left side of

the block in the area of the starter.

b. Insert a tool having a shaft diameter of 0.3

in. (8mm) into the hole.

c. With the timing marks still aligned, the tool

must be able to go in at least 2l/s in. (59mm). If

it can only go m about 1 in. (25mm), turn the oil

pump sprocket one complete revolution.

d. Recheck the position of the balance shaft

with the timing marks reahgned. Leave the tool in

place to hold the silent shaft while continuing.

24. Install the belt to the crankshaft sprocket, oil

pump sprocket and the camshaft sprocket, in that or-

der. While doing so, be sure there is no slack be-

tween the sprockets except where the tensioner will

take it up when released.

25. Recheck the timing marks’ alignment.

26. If all are aligned, loosen the tensioner mount-

ing bolt, and allow the tensioner to apply tension to

the belt.

27. Remove the tool that is holding the silent

shaft in place and turn the crankshaft clockwise a dis-

tance equal to two teeth of the camshaft sprocket.

This will allow the tensioner to automatically tension

the belt the proper amount.

Do not manually apply pressure to the ten-

sioner. This will overtighten the belt and will

cause a howling noise.

28. First tighten the lower mounting bolt and then

tighten the upper spacer bolt.

If any binding is felt when adiustino the tim-

ing delt tension by turning th;! crankshaft,

STOP turning the engine, because the pis-

tons may be hitting the valves.

29. To verify that belt tension is correct, check

that the deflection of the longest span (between the

camshaft and oil pump sprockets) is I/* in. (13mm).

30. Install the lower timing belt cover. Be sure the

packing is properly positioned in the inner grooves of

the covers when installing.

31. Install the water pump pulley and the crank-

shaft pulley(s).

32. Install the upper front timing belt cover.

33. Install the power steering pump, alternator,

air conditioning compressor, tension pulley and ac-

companying brackets, as required.

34. Install the radiator, shroud, fan and accessory

drive belts.

35. Install the spark plug wires to the tree on the

upper cover.

36. Refill the cooling system.

37. Connect the negative battery cable. Start the

engme and check for leaks.

3.OL SDHC Engine

1992-94 MODELS

# See Figures 182 and 183

1. Disconnect the negative battery cable.

2. Remove the engine undercover

3. Remove the cruise control

actuator 4. Remove the accessory drive belts. 5. Remove the air conditioner compressor ten-

sion pulley assembly.

6. Remove the tension pulley bracket.

7. Using the proper equipment, slightly raise

the engine to take the weight off the side engine

mount. Remove the engine mounting bracket.

8. Detach the power steering pump pressure

switch connector. Remove the power steering pump

and wire aside.

9. Remove the engine support bracket.

10. Remove the crankshaft pulley.

11. Remove the timing belt cover cap.

12. Remove the timing belt upper and lower cov-

ers.

13. If the same timing belt will be reused, mark

the direction of the timing belt’s rotation for installa-

tion in the same direction. Make sure the engine is

positioned so the No. 1 cylinder is at the TDC of its

compression stroke and the sprockets’ timing marks

are aligned with the engine’s timing mark indicators.

14. Loosen the timing belt tensioner bolt and re-

move the belt. If the tensioner is not being removed,

position it as far away from the center of the engine

as possible and tighten the bolt.

15. If the tensioner is being removed, paint the

outside of the spring to ensure that it is not installed

backwards. Unbolt the tensioner and remove it along

with the spring.

To install:

16. Install the tensioner, if removed, and hook the

upper end of the spring to the water pump pin and

the lower end to the tensioner in exactly the same po-

sition as originally installed. If not already done, po-

sition both camshafts so the marks align with those

on the rear. Rotate the crankshaft so the timing mark

aligns with the mark on the oil pump.

17. Install the timing belt on the crankshaft

sprocket and while keeping the belt tight on the ten-

sion side, install the belt on the front camshaft

sprocket.

18. Install the belt on the water pump pulley, then

the rear camshaft sprocket and the tensioner.

19. Rotate the front camshaft counterclockwise to

tension the belt between the front camshaft and the

crankshaft. If the tlmlng marks became misaligned,

repeat the procedure.

20. Install the crankshaft sprocket flange.

21. Loosen the tensioner bolt and allow the

spring to apply tension to the belt.

22. Turn the crankshaft 2 full turns in the clock-

wise direction until the timing marks align again.

Now that the belt is properly tensioned, torque the

tensioner lock bolt to 21 ft. Ibs. (29 Nm). Measure

the belt tension between the rear camshaft sprocket

and the crankshaft with belt tension gauge, The spec-

ification is 46-68 Ibs. (210-310 N).

23. Install the timing covers. Make sure all pieces

of packing are positioned in the inner grooves of the

covers when Installing.

24. install the crankshaft pulley. Tighten the bolt

to 108-116ft. Ibs. (150-160 Nm)

25. Install the engine support bracket.

26. Install the power steering pump and recon-

nect wire harness at the power steering pump pres-

sure switch.

27. Install the engine mounting bracket and re-

move the engine support fixture.

28. Install the tension pulleys and drive belts.

29. Install the cruise control actuator.

30 Install the engine undercover.

Page 388 of 408

II-6 TROUBLESHOOTING

DIAGhUSTIC PROCEDURES

Gasoline Engines

1. Engine turns over, but wilt not start

a. Check fuel level in fuel tank, add fuel if empty.

b. Check battery condition and state of charge. If voltage and load test below specifica-

tion, charge or replace battery.

c. Check battery terminal and cable condition and tightness. Clean terminals and replace

damaged, worn or corroded cables.

d. Check fuel delivery system. If fuel is not reaching the fuel injectors, check for a loose

electrical connector or defective fuse, relay or fuel pump and replace as necessary.

e. Engine may have excessive wear or mechanical damage such as low cylinder cranking

pressure, a broken camshaft drive system, insufficient valve clearance or bent valves.

f. Check for fuel contamination such as water in the fuel. During winter months, the wa-

ter may freeze and cause a fuel restriction. Adding a fuel additive may help, however

the fuel system may require draining and purging with fresh fuel.

g. Check for ignition system failure. Check for loose or shorted wires or damaged igni-

tion system components. Check the spark plugs for excessive wear or incorrect elec-

trode gap. If the problem is worse in wet weather, check for shorts between the spark

plugs and the ignition coils.

h. Check the engine management system for a failed sensor or control module.

2. Engine does not turn over when attempting to start

a. Check the battery state of charge and condition. If the dash lights are not visible or

very dim when turning the ignition key on, the battery has either failed internally or

discharged, the battery cables are loose, excessively corroded or damaged, or the al-

ternator has failed or internally shorted, discharging the battery. Charge or replacethe

battery, clean or replace the battery cables, and check the alternator output.

b. Check the operation of the neutral safety switch. On automatic transmission vehicles,

try starting the vehicle in both Park and Neutral. On manual transmission vehicles, de-

press the clutch pedal and attempt to start. On some vehicles, these switches can be

adjusted. Make sure the switches or wire connectors are not loose or damaged. Re-

place or adjust the switches as necessary.

c. Check the starter motor, starter solenoid or relay, and starter motor cables and wires.

Check the ground from the engine to the chassis. Make sure the wires are not loose,

damaged, or corroded. If battery voltage is present at the starter relay, try using a re-

mote starter to start the vehicle for test purposes only. Replace any damaged or cor-

roded cables, in addition to replacing any failed components.

d. Check the engine for seizure. If the engine has not been started for a long period of

time, internal parts such as the rings may have rusted to the cylinder walls. The engine

may have suffered internal damage, or could be hydro-locked from ingesting water.

Remove the spark plugs and carefully attempt to rotate the engine using a suitable

breaker bar and socket on the crankshaft pulley. If the engine is resistant to moving, or

moves slightly and then binds, do not force the engine any further before determining

the problem.

3. Enpine stalls immediately when started

a. Check the ignition switch condition and operation. The electrical contacts in the run

position may be worn or damaged. Try restarting the engine with all electrical acces-

sories in the off position. Sometimes turning the key on an off will help in emergency

situations, however once the switch has shown signs of failure, it should be replaced

as soon as possible.

b. Check for loose, corroded, damaged or shorted wires for the ignition system and re-

pair or replace.

c. Check for manifold vacuum leaks or vacuum hose leakage and repair or replace parts

as necessary.

d. Measure the fuel pump delivery volume and pressure. Low fuel pump pressure can

also be noticed as a lack of power when accelerating. Make sure the fuel pump lines

are not restricted. The fuel pump output is not adjustable and requires fuel pump re-

placement to repair.

e. Check the engine fuel and ignition management system. Inspect the sensor wiring and

electrical connectors. A dirty, loose or damaged sensor or control module wire can

simulate a failed component.

f. Check the exhaust system for internal restrictions.

4. Starter motor spins, but does not engage

a. Check the starter motor for a seized or binding pinion gear.

b. Remove the flywheel inspection plate and check for a damaged ring gear.

5. Engine is difficult to start when Gold

a. Check the battery condition, battery state of charge and starter motor current draw. Re-

place the battery if marginal and the starter motor if the current draw is beyond specifi-

cation. b. Check the battery cable condition. Clean the battery terminals and replace corroded or

damaged cables.

c. Check the fuel system for proper operation. A fuel pump with insufficient fuel pressure

or clogged injectors should be replaced.

d. Check the engine’s tune-up status. Note the tune-up specifications and check for items

such as severely worn spark plugs; adjust or replace as needed. On vehicles with

manually adjusted valve clearances, check for tight valves and adjust to specification.

e. Check for a failed coolant temperature sensor, and replace if out of specification.

f. Check the operation of the engine management systems for fuel and ignition; repair or

replace failed components as necessary.

6. En#ine is ditticutt to start when hot

a. Check the air filter and air intake system. Replace the air filter if it is dirty or contami-

nated. Check the fresh air intake system for restrictions or blockage.

b. Check for loose or deteriorated engine grounds and clean, tighten or replace as

needed.

c. Check for needed maintenance. Inspect tune-up and service related items such as

spark plugs and engine oil condition, and check the operation of the engine fuel and

ignition management system.

Diesel Engines

1. Engine turns over but won’t start

a. Check engine starting procedure and restart engine.

b. Check the glow plug operation and repair or replace as necessary.

c. Check for air in the fuel system or fuel filter and bleed the air as necessary.

d. Check the fuel delivery system and repair or replace as necessary.

e. Check fuel level and add fuel as needed.

f. Check fuel quality. If the fuel is contaminated, drain and flush the fuel tank.

g. Check engine compression. If compression is below specification, the engine may

need to be renewed or replaced.

h. Check the injection pump timing and set to specification.

i. Check the injection pump condition and replace as necessary.

j. Check the fuel nozzle operation and condition or replace as necessary.

2. Engine does

hot turn over when attempting to start

a. Check the battery state of charge and condition. If the dash lights are not visible or

very dim when turning the ignition key on, the battery has either failed internally or

discharged, the battery cables are loose, excessively corroded or damaged, or the al-

ternator has failed or internally shorted, discharging the battery. Charge or replace the

battery, clean or replace the battery cables, and check the alternator output.

b. Check the operation of the neutral safety switch. On automatic transmission vehicles,

try starting the vehicle in both Park and Neutral. On manual transmission vehicles, de-

press the clutch pedal and attempt to start. On some vehicles, these switches can be

adjusted. Make sure the switches or wire connectors are not loose or damaged. Re-

place or adjust the switches as necessary.

c. Check the starter motor, starter solenoid or relay, and starter motor cables and wires.

Check the ground from the engine to the chassis. Make sure the wires are not loose,

damaged, or corroded. If battery voltage is present at the starter relay, try using a re-

mote starter to start the vehicle for test purposes only. Replace any damaged or cor-

roded cables, in addition to replacing any failed components.

d. Check the engine for seizure. If the engine has not been started for a long period of

time, internal parts such as the rings may have rusted to the cylinder walls. The engine

may have suffered internal damage, or could be hydro-locked from ingesting water.

Remove the injectors and carefully attempt to rotate the engine using a suitable

breaker bar and socket on the crankshaft pulley. If the engine is resistant to moving, or

moves slightly and then binds, do not force the engine any further before determining

the cause of the problem.

3. Engine stalls afier starting

a. Check for a restriction in the fuel return line or the return line check valve and repair as

necessary.

b. Check the glow plug operation for turning the glow plugs off too soon and repair as

necessary.

c. Check for incorrect injection pump timing and reset to specification.

d. Test the engine fuel pump and replace if the output is below specification.

e. Check for contaminated or incorrect fuel. Completely flush the fuel system and replace

with fresh fuel.

f. Test the engine’s compression for low compression. If below specification, mechanical

repairs are necessary to repair.

g. Check for air in the fuel. Check fuel tank fuel and fill as needed.

h. Check for a failed injection pump. Replace the pump, making sure to properly set the

pump timing.

Page 389 of 408

TROUBLESHOOiNG 11-7

4. Starter motor spins, but does not engage

a. Check the starter motor for a seized or binding pinion gear.

b. Remove the flywheel inspection plate and check for a damaged ring gear.

Gasoline Engines

1. Engine runs poor/y, hesiiates

a. Check the engine ignition system operation and adjust if possible, or replace defective

parts.

b. Check for restricted fuel injectors and replace as necessary.

c. Check the fuel pump output and delivery. Inspect fuel lines for restrictions. If the fuel

pump pressure is below specification, replace the fuel pump.

d. Check the operation of the engine management system and repair as necessary.

2. Enfline lacks power

a. Check the engine’s tune-up status. Note the tune-up specifications and check for items

such as severely worn spark plugs; adjust or replace as needed. On vehicles with

manually adjusted valve clearances, check for tight valves and adjust to specification.

b. Check the air filter and air intake system. Replace the air filter if it is dirty or contami-

nated. Check the fresh air intake system for restrictions or blockage.

c. Check the operation of the engine fuel and ignition management systems. Check the

sensor operation and wiring. Check for low fuel pump pressure and repair or replace

components as necessary.

d. Check the throttle linkage adjustments. Check to make sure the linkage is fully open-

ing the throttle. Replace any worn or defective bushings or linkages.

e. Check for a restricted exhaust system. Check for bent or crimped exhaust pipes, or in-

ternally restricted mufflers or catalytic converters. Compare inlet and outlet tempera-

tures for the converter or muffler. If the inlet is hot, but outlet cold, the component is

restricted.

f. Check for a loose or defective knock sensor. A loose, improperly torqued or defective

knock sensor will decrease spark advance and reduce power. Replace defective knock

sensors and install using the recommended torque specification.

g. Check for engine mechanical conditions such as low compression, worn piston rings,

worn valves, worn camshafts and related parts. An engine which has severe mechani-

cal wear, or has suffered internal mechanical damage must be rebuilt or replaced to re-

store lost power.

h. Check the engine oil level for being overfilled. Adjust the engine’s oil level, or change

the engine oil and filter, and top off to the correct level.

i. Check for an intake manifold or vacuum hose leak. Replace leaking gaskets or worn

vacuum hoses.

j. Check for dragging brakes and replace or repair as necessary.

k. Check tire air pressure and tire wear. Adjust the pressure to the recommended set-

tings. Check the tire wear for possible alignment problems causing increased rolling

resistance, decreased acceleration and increased fuel usage.

I. Check the octane rating of the fuel used during refilling, and use a higher octane rated

fuel.

3. Poor fuel economy

a. Inspect the air filter and check for any air restrictions going into the air filter housing.

Replace the air filter if it is dirty or contaminated.

b. Check the engine for tune-up and related adjustments. Replace worn ignition parts,

check the engine ignition timing and fuel mixture, and set to specifications if possible.

c. Check the tire size, tire wear, alignment and tire pressure. Large tires create more

rolling resistance, smaller tires require more engine speed to maintain a vehicle’s road

speed. Excessive tire wear can be caused by incorrect tire pressure, incorrect wheel

alignment or a suspension problem. All of these conditions create increased rolling

resistance, causing the engine to work harder to accelerate and maintain a vehicle’s

speed.

d. Inspect the brakes for binding or excessive drag. A sticking brake caliper, overly ad-

justed brake shoe, broken brake shoe return spring, or binding parking brake cable or

linkage can create a significant drag, brake wear and loss of fuel economy. Check the

brake system operation and repair as necessary.

4. Engine runs on (diesels) when turned off

a. Check for idle speed set too high and readjust to specification.

b. Check the operation of the idle control valve, and replace if defective.

c. Check the ignition timing and adjust to recommended settings.

Check for defective

sensors or related components and replace if defective.

d. Check for a vacuum leak at the intake manifold or vacuum hose

and replace defective

gaskets or hoses.

e. Check the engine for excessive carbon build-up in the combustion chamber. Use a

recommended decarbonizing fuel additive or disassemble the cylinder head to remove

the carbon.

f. Check the operation of the engine fuel management system and replace defective sen-

sors or control units.

g. Check the engine operating temperature for overheating and repair as necessary. 5. Engine knocks and pinfls during heavy accele/ation, and on steep hills

a. Check the octane rating of the fuel used during refilling, and use a higher octane rated

fuel.

b. Check the ignition timing and adjust to recommended settings. Check for defective

sensors or related components and replace if defective.

c. Check the engine for excessive carbon build-up in the combustion chamber. Use a

recommended decarbonizing fuel additive or disassemble the cylinder head to remove

the carbon.

d. Check the spark plugs for the correct type, electrode gap and heat range. Replace worn

or damaged spark plugs. For severe or continuous high speed use, install a spark plug

that is one heat range colder.

e. Check the operation of the engine fuel management system and replace defective sen-

sors or control units.

f. Check for a restricted exhaust system. Check for bent or crimped exhaust pipes, or in-

ternally restricted mufflers or catalytic converters. Compare inlet and outlet tempera-

tures for the converter or muffler. If the inlet is hot, but outlet cold, the component is

restricted.

6. Engine atxelerates, but vehicle does not gain speed

a. On manual transmission vehicles, check for causes of a slipping clutch. Refer to the

clutch troubleshooting section for additional information.

b. On automatic transmission vehicles, check for a slipping transmission” Check the

transmission fluid level and condition. If the fluid level is too high, adjust to the cor-

rect level. If the fluid level is low, top off using the recommended fluid type. If the fluid

exhibits a burning odor, the transmission has been slipping internally. Changing the

fluid and filter may help temporarily, however in this situation a transmission may re-

quire overhauling to ensure long-term reliability.

Diesel Engines

1. Engine runs pOOr!y a. Check the injection pump timing and adjust to specification.

b. Check for air in the fuel lines or leaks, and bleed the air from the fuel system.

c. Check the fuel filter, fuel feed and return lines for a restriction and repair as necessary.

d. Check the fuel for contamination, drain and flush the fuel tank and replenish with fresh

fuel.

2. Enfline lacks power

a. Inspect the air intake system and air filter for restrictions and, if necessary, replace the

air filter.

b. Verify the injection pump timing and reset if out of specification.

c. Check the exhaust for an internal restriction and replace failed parts.

d. Check for a restricted fuel filter and, if restricted, replace the filter.

e. Inspect the fuel filler cap vent. When removing the filler cap, listen for excessive hiss-

ing noises indicating a blockage in the fuel filler cap vents, If the filler cap vents are

blocked, replace the cap.

f. Check the fuel system for restrictions and repair as necessary.

g. Check for low engine compression and inspect for external leakage at the glow plugs

or nozzles. If no external leakage is noted, repair or replace the engine.

ENGINE PERFORMANCE TROUBLESHOOTING HINTS When troubleshooting an engine running or performance condition, the mechanical

condition of the engine should be determined before lengthy troubleshooting procedures

are performed.

The engine fuel management systems in fuel injected vehicles rely on electronic sen-

sors to provide information to the engine control unit for precise fuel metering. Unlike

carburetors, which use the incoming air speed to draw fuel through the fuel metering jets

in order to provide a proper fuel-to-air ratio, a fuel injection system provides a specific

amount of fuel which is introduced by the fuel injectors into the intake manifold or intake

port, based on the information provided by electronic sensors.

The sensors monitor the engine’s operating temperature, ambient temperature and the

amount of air entering the engine, engine speed and throttle position to provide informa-

tion to the engine control unit, which, in turn, operates the fuel injectors by electrical

pulses. The sensors provide information to the engine control unit using low voltage

electrical signals. As a result, an unplugged sensor or a poor electrical contact could

cause a poor running condition similar to a failed sensor.

When troubleshooting a fuel related engine condition on fuel injected vehicles, care-

fully inspect the wiring and electrical connectors to the related components. Make sure

the electrical connectors are fully connected, clean and not physically damaged. If neces-

sary, clean the electrical contacts using electrical contact cleaner. The use of cleaning

agents not specifically designed for electrical contacts should not be used, as they could

leave a surface film or damage the insulation of the wiring.

The engine electrical system provides the necessary electrical power to operate the ve-

hicle’s electrical accessories, electronic control units and sensors. Because engine man-

agement systems are sensitive to voltage changes, an alternator which over or under-

charges could cause engine running problems or component failure. Most alternators

utilize internal voltage regulators which cannot be adjusted and must be replaced indi-

vidually or as a unit with the alternator.

Page 400 of 408

11-18 GLOSSARY

COMBINATION MANIFOLD: An assembly which includes both the intake

and exhaust manifolds in one casting.

COMBINATION VALVE: A device used in some fuel systems that routes fuel

vapors to a charcoal storage canister instead of venting them into the atmos-

phere. The valve relieves fuel tank pressure

and allows fresh air into the tank

as the fuel level drops to prevent a vapor lock situation.

COMPRESSION RATIO: The ratio of the volume between the piston and

cylinder head when the piston is at the bottom of its stroke (bottom dead cen-

ter) and when the piston is at the top of its stroke (top dead center).

CONDENSER: 1. An electrical device which acts to store an electrical charge,

preventing voltage surges. 2. A radiator-like device in the air conditioning sys-

tem in which refrigerant gas condenses into a liquid, giving off heat.

CONDUCTOR: Any material through which an electrical current can be trans-

mitted easily.

CONTINUITY: Continuous or complete circuit. Can be checked with an ohm-

meter.

COUNTERSHAFT: An intermediate shaft which is rotated by a mainshaft and

transmits, in turn, that rotation to a working part.

CRANKCASE: The lower part of an engine in which the crankshaft and re-

lated parts operate.

CRANKSHAFT: Engine component (connected to pistons by connecting rods)

which converts the reciprocating (up and down) motion of pistons to rotary

motion used to turn the driveshaft.

CYLINDER: In an engine, the round hole in the engine block in which the

piston(s) ride.

CYLINDER BLOCK: The main structural member of an engine in which is

found the cylinders, crankshaft and other principle parts.

DEAD CENTER: The extreme top or bottom of the piston stroke.

DETONATION: An unwanted explosion of the air/fuel mixture in the com-

bustion chamber caused by excess heat and compression, advanced timing,

or an overly lean mixture. Also referred to as “ping”.

DIAPHRAGM: A thin, flexible wall separating two cavities, such as in a vac-

uum advance unit.

c

DIESELING: The engine continues to run after the car is shut off; caused by

fuel continuing to be burned in the combustion chamber.

DIFFERENTIAL: A geared assembly which allows the transmission of mo-

tion between drive axles, giving one axle the ability to rotate faster than the

other, as in cornering.

DIODE: An electrical device that will allow current to flow in one direction

only.

DISC BRAKE: A hydraulic braking assembly consisting of a brake disc, or

rotor, mounted on an axleshaft, anda caliper assembly containing, usually two GEAR RATIO: A ratio expressing the number of turns a smaller gear will

make to turn a larger gear through one revolution. The ratio is found by di-

brake pads which are activated by hydraulic pressure. The pads are forced viding the number of teeth on the smaller gear into the number of teeth on the

against the sides of the disc, creating friction which slows the vehicle. larger gear. DISTRIBUTOR: A mechanically driven device on an engine which is re-

sponsible for electrically firing the spark plug at a pre-determined point of the

piston stroke.

DOWEL PIN: A pin, inserted in mating holes in two different parts allowing

those parts to maintain a fixed relationship. .

DRUM BRAKE: A braking system which consists of two brake shoes and one

or two wheel cylinders, mounted on a fixed backing plate, and a brake drum,

mounted on an axle, which revolves around the assembly.

ELECTRONIC CONTROL UNIT (ECU): A diqital computer that controls en-

gine (and sometimes transmission‘, brake or other vehicle system) functions

based on data received from various sensors. Examples used by some man-

ufacturers include Electronic Brake Control Module (EBCM), Engine Control

Module (ECM), Powertrain Control Module (PCM) or Vehicle Control Mod-

ule (VCM).

ELECTRONIC IGNITION: A system in which the timing and‘firing of the

spark plugs is controlled by an electronic control unit, usually called a mod-

ule. These systems have no points or condenser,

END-PLAY: The clearance/gap between two components that allows for ex-

pansion of the parts as they warm up, to prevent binding and to allow space

for lubrication.

ENGINE: The primary motor or power apparatus of a vehicle, which converts

liquid or gas fuel into mechanical energy.

EXHAUST MANIFOLD: A set of cast passages or pipes which conduct ex-

haust gases from the engine.

FEELER GAUGE: A blade, usually metal, of precisely predetermined thick-

ness, used to measure the clearance between two parts.

FIRING ORDER: The order in which combustion occurs in the cylinders

of an engine. Also the order in which spark is distributed to the plugs by the

distributor.

FLOODING: The presence of too much fuel in the intake manifold and com-

bustion chamber which prevents the air/fuel mixture from firing, thereby caus-

ing a no-start situation.

FLYWHEEL: A heavy disc of metal attached to the rear of the crankshaft. It

smoothes the firing impulses of the engine and keeps the crankshaft turning

during periods when no firing takes place. The starter also engages the fly-

wheel to start the engine.

FOOT POUND (ft. Ibs. or sometimes, ft. lb.): The amount of energy or

work needed to raise an item weighing one pound, a distance of one foot.

FUSE: A protective device in a circuit which prevents circuit overload by break-

ing the circuit when a specific amperage is present. The device is constructed

around a strip or wire of a lower amperage rating than the circuit it is designed

to protect. When an amperage higher than that stamped on the fuse is present

in the circuit, the strip or wire melts, opening the circuit.

Page 401 of 408

GLOSSARY 1149

GENERATOR: A device which produces direct current (DC) necessary to

charge the battery. OVERHEAD CAMSHAFT (OHC): An engine configuration in which the

camshaft is mounted on top of the cylinder head and operates the valve either

directly or by means of rocker arms.

HEAT RANGE: A term used to describe the ability of a spark plug to carry

away heat. Plugs with longer nosed insulators take longer to carry heat off

effectively.

HUB: The center part of a wheel or gear.

HYDROCARBON (HC): Any chemical compound made up of hydrogen

and carbon. A major pollutant formed by the engine as a by-product of

combustion.

HYDROMETER: An instrument used to measure the specific gravity of a so-

lution.

INCH POUND (inch Ibs.; sometimes in. lb. or in. Ibs.): One twelfth

.

of a foot pound.

INDUCTION: A means of transferring electrical energy in the form of a mag-

netic field. Principle used in the ignition coil to increase voltage.

INJECTOR: A device which receives metered fuel under relatively low pres-

sure and is activated to inject the fuel into the engine under relatively high

pressure at a predetermined time.

INPUT SHAFT: The shaft to which torque is applied, usually carrying the dri-

ving gear or gears.

INTAKE MANIFOLD: A casting of passages or pipes used to conduct air or

a fuel/air mixture to the cylinders.

JOURNAL: The bearing surface within which a shaft operates.

KEY: A small block usually fitted in a notch between a shaft and a hub to pre-

vent slippage of the two parts.

MANIFOLD: A casting of passages or set of pipes which connect the cylin-

ders to an inlet or outlet source.

MASTER CYLINDER: The primary fluid pressurizing device in a hydraulic

system. In automotive use, it is found in brake and hydraulic clutch systems

and is pedal activated, either directly or, in a power brake system, through the

power booster.

MODULE: Electronic control unit, amplifier or igniter of solid state or inte-

grated design which controls the current flow in the ignition primary circuit

based on input from the pick-up coil. When the module opens the primary cir-

cuit, high secondary voltage is induced in the coil.

NEEDLE BEARING: A bearing which consists of a number (usually a large

number) of long, thin rollers.

OHM: The unit used to measure the resistance of conductor-to-electrical flow.

One ohm is the amount of resistance that limits current flow to one ampere in

a circuit with one volt of pressure.

OHMMETER: An instrument used for measuring the resistance, in ohms, in

an electrical circuit.

OUTPUT SHAFT: The shaft which transmits torque from a device, such as a

transmission. OVERHEAD VALVE (OHV): An engine configuration in which all of the

valves are located in the cylinder head

and the camshaft is located in the cylin-

der block. The camshaft operates the valves via lifters and pushrods.

OXIDES OF NITROGEN (NOx): Chemical compounds of nitrogen produced

as a byproduct of combustion. They combine with hydrocarbons to produce

smog.

OXYGEN SENSOR: Used with a feedback system to sense the presence of

oxygen in the exhaust gas and signal the computer which can use the voltage

signal to determine engine operating efficiency and adjust the air/fuel ratio.

PINION: The smaller of two gears. The rear axle pinion drives the ring gear

which transmits motion to the axle shafts.

PISTON RING: An open-ended ring which fits into a groove on the outer di-

ameter of the piston. Its chief function is to form a seal between the piston and

cylinder wall. Most automotive pistons have three rings: two for compression

sealing; one for oil sealing.

PRELOAD: A predetermined load placed on a bearing during assembly or by

adjustment.

PRESS FIT: The mating of two parts under pressure, due to the inner diam-

eter of one being smaller than the outer diameter of the other, or vice versa;

an interference fit.

PRIMARY CIRCUIT: The low voltage side of the ignition system which con-

sists of the ignition switch, ballast resistor or resistance wire, bypass, coil,

electronic control unit and pick-up coil as well as the connecting wires and

harnesses.

RACE: The surface on the inner or otiter ring of a bearing on which the balls,

needles or rollers move.

REGULATOR: A device which maintains the amperage and/or voltage levels

of a circuit at predetermined values.

RELAY: A switch which automatically opens and/or closes a circuit.

RESISTANCE: The opposition to the flow of current through a circuit or elec-

trical device, and is measured in ohms. Resistance is equal to the voltage di-

vided by the amperage.

RESISTOR: A device, usually made of wire, which offers a preset amount of

resistance in an electrical circuit.

RING GEAR: The name given to a ring-shaped gear attached to a differential

case, or affixed to a flywheel or as part of a planetary gear set.

ROLLER BEARING: A bearing made up of hardened inner and outer races

between which hardened steel rollers move.

ROTOR: (1.) The disc-shaped part of a disc brake assembly, upon which the

brake pads bear; also called, brake disc. (2.) The device mounted atop the dis-

tributor shaft, which passes current to the distributor cap tower contacts.