trunk release MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 190 of 408

FUELSYSTEM 513

l Always replace worn fuel fitting O-rings with

new. Do not substitute fuel hose or equivalent, where

I

The Multi-Point Injection (MPI) system is electroni-

rally controlled by the Engine Control Module (ECM),

based on data from various sensors. The ECM controls

the fuel flow, idle speed and ignition timing. fuel pipe is installed.

Fuel is supplied to the injectors by an electric in-

tank fuel pump and is distributed to the respective in-

jectors via the main fuel pipe. The fuel pressure ap-

plied to the injector is constant and higher than the

pressure in the intake manifold. The pressure is con-

trolled by the fuel pressure regulator. The excess fuel

is returned to the fuel tank through the fuel return pipe.

When an electric current flows in the injector, the

injector valve is fully opened to supply fuel. Since the

fuel pressure is constant, the amount of the fuel in-

jetted from the injector into the manifold is increased

or decreased in proportion to the time the electric

current flows. Based on ECU signals, the injectors in-

ject fuel to the cylinder manifold ports in firing order. Fuel injection systems remain under pres-

sure after the engine has been turned OFF.

Properly relieve fuel pressure before discon-

neeting any fuel lines. Failure to do so may

result in fire or personal injury.

1. Turn the ignition to the OFF position.

2. Loosen the fuel filler cap to release fuel tank

pressure.

I

The flow rate of the air drawn through the air

cleaner is measured by the air flow sensor. The air

enters the air intake plenum or manifold through the

throttle body. In the intake manifold, the air is mixed

with the fuel from the injectors and is drawn into the

cylinder, The air flow rate is controlled according to

the degree of the throttle valve and the servo motor

openings. The system is monitored through a num-

ber of sensors which feed information on engine con-

ditions and requirements to the ECM. The ECM cal-

culates the injection time and rate according to the

signals from the sensors,

Safety is the most important factor when perform-

ing not only fuel system maintenance but any type of

maintenance. Failure to conduct maintenance and re-

pairs in a safe manner may result in serious personal

injury or death. Maintenance and testing of the vehi-

cle’s fuel system components can be accomplished

safely and effectively by adhering to the following

rules and guidelines.

l To avoid the possibility of fire and personal in-

jury, always disconnect the negative battery cable un-

less the repair or test procedure requires that battery

voltage be applied.

l Always relieve the fuel system pressure prior to

disconnecting any fuel system component (injector,

fuel rail, pressure regulator, etc.), fitting or fuel line

connection. Exercise extreme caution whenever re- Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or va-

pors to come in contact with a spark or open

flame. Keep a dry chemical fire extinguisher

near the work area. Always keep fuel in a con-

tainer specifically designed for fuel storage;

also, always properly seal fuel containers to

avoid the possibility of fire or explosion.

3. For the Mirage, Diamante, and 1994-00

Galant, remove the rear seat cushion, then remove

the service cover and detach the fuel pump harness

connector.

4. For the 1990-93 FWD Galant, detach the fuel

pump harness connector located in the area of the

fuel tank. It may be necessary to raise the vehicle to

access the connector.

5. For the 1990-93 AWD Galant, remove the car-

pet from the trunk, locate the fuel tank wiring at the

pump access cover, then detach the wiring.

6. Start the vehicle and allow it to run until it

stalls from lack of fuel. Turn the key to the OFF posi-

tion.

7. Disconnect the negative battery cable, then at-

tach the fuel pump connector. Install the access .

cover, cushion or carpet as necessary.

8. Wrap shop towels around the fitting that is be-

ing disconnected to absorb residual fuel in the lines.

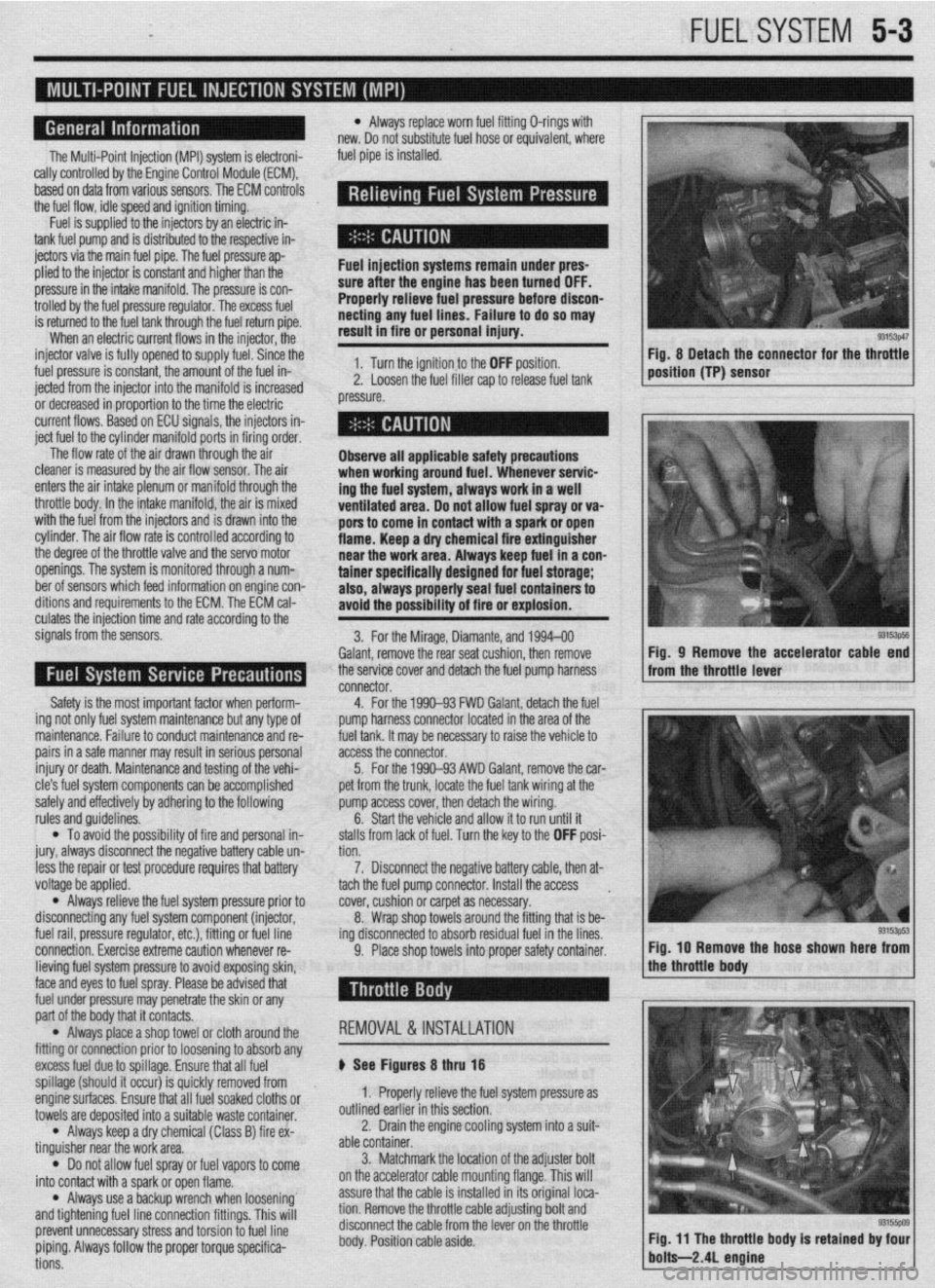

9. Place shop towels into proper safety container. Fig, 8 Detach the connector for the throttle

position (TP) sensor

93153ps5 Fig, 9 Remove the accelerator cable end

from the throttle lever

Fig. IO Remove the hose shown here from

lieving fuel system pressure to avoid exposing skin,

face and eyes to fuel spray. Please be advised that

fuel under pressure may penetrate the skin or any

part of the body that it contacts.

l Always place a shop towel or cloth around the

fitting or connection prior to loosening to absorb any

excess fuel due to spillage. Ensure that all fuel

spillage (should it occur) is quickly removed from

enginesurfaces. Ensure that all fuel soaked cloths or

towels are deposited into a suitable waste container.

l Always keep a dry chemical (Class B) fire ex-

tinguisher near the work area.

l Do not allow fuel spray or fuel vapors to come

into contact with a spark or open flame.

l Always use a backup wrench when loosening’

and tightening fuel line connection fittings. This will

prevent unnecessary stress and torsion to fuel line

piping. Always follow the proper torque specifica-

tions. REMOVAL &INSTALLATION

p See Figures 8 thru 18

1. Properly relieve the fuel system pressure as

outlined earlier in this section.

2. Drain the engine cooling system into a suit-

able container.

3. Matchmark the jocation of the adjuster bolt

on the accelerator cable mounting flange. This will

assure that the cable is installed in its original loca-

tion. Remove the throttle cable adjusting bolt and

disconnect the cable from the lever on the throttle

body. Position cable aside.

Page 225 of 408

6-22 CHASSIS ELECTRICAL

b

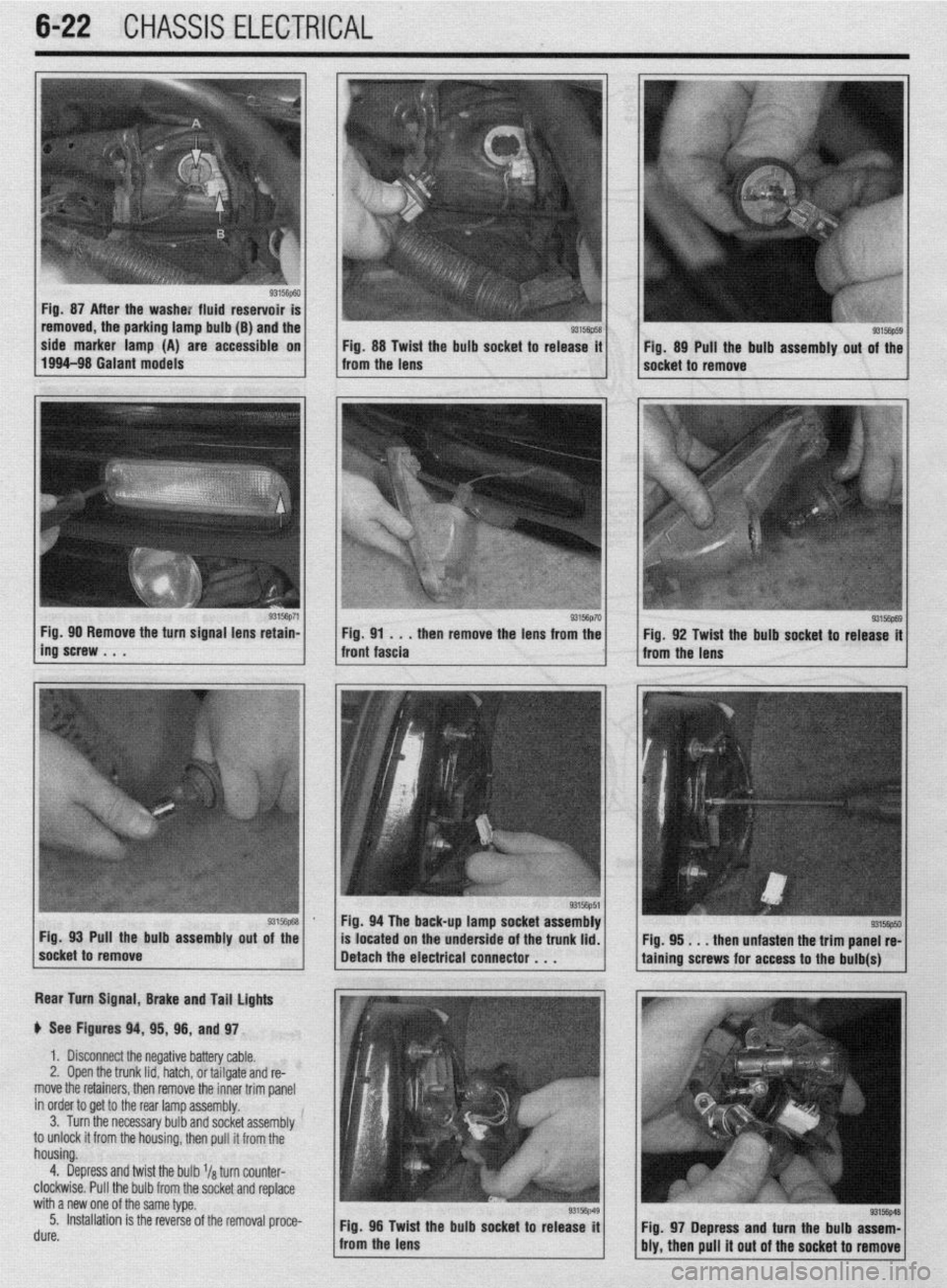

Fig. 87 After the washe: fluid reservoir

removed, the parking lamp bulb (B) and the

side marker lamp (A) are accessible on

Fig. 88 Twist the bulb socket to release it

1994-98 Galant models

from the lens Fig. 89 Pull the bulb assembly out of the

socket to remove

g3156p71 / Fig 90 Remove the turn signal lens retain-

ing’screw . . . . then remove the lens from the

Rear Turn Signal, Brake and Tail lights

p See Figures 94, 95, 96, and 97.

1. Disconnect the negative battery cable.

2, Open the trunk lid, hatch, or tailgate and re-

move the retainers, then remove the inner trim panel

in order to get to the rear lamp assembly.

3. Turn the necessary bulb and socket assembly

to unlock it from the housing, then pull it from the

housing.

4. Depress and twist the bulb l/a turn counter-

clockwise. Pull the bulb from the socket and replace

with a new one of the same type.

5. Installation is the reverse of the removal proce-

rl. ._^

UUIt?. Fig. 96 Twid

: the bulb socket to release it

from the lens

93156p69 Fig. 92 Twist the bulb socket to release it

from the lens

I

Fig. 94 The back-up lamp socket assembly

Pull the bulb assembly

out of the

located on the underside of the trunk lid.

. . . then unfasten the trim panel re-

Fig. 97 Depress and turn the bulb assem-

bly, then pull it out of the socket to remove

Page 226 of 408

![MITSUBISHI DIAMANTE 1900 Repair Manual CHASSIS ELECTRlCiL 6-23

93156P57 Fig. 98 The back-up lamp socket assembly Fig. 99 Twist the bulb socket to release the

is located on the underside of the trunk lid locking tabs from the lens *1W5y] MITSUBISHI DIAMANTE 1900 Repair Manual CHASSIS ELECTRlCiL 6-23

93156P57 Fig. 98 The back-up lamp socket assembly Fig. 99 Twist the bulb socket to release the

is located on the underside of the trunk lid locking tabs from the lens *1W5y]](/img/19/57096/w960_57096-225.png)

CHASSIS ELECTRlCiL 6-23

93156P57 Fig. 98 The back-up lamp socket assembly Fig. 99 Twist the bulb socket to release the

is located on the underside of the trunk lid locking tabs from the lens *1W5y] Fig 100 Pull the bulb assembly straight out

of the socket to remove it

Back-up light

u See Figures 98, 99, and 100

1 I Disconnect the negative battery cable.

2. Open the trunk lid.

3. If equipped, remove the trim on the underside

of the trunk lid.

4. Turn the socket counterclockwise ‘14 of a turn

to release it from the lens.

5. Pull the bulb out to remove it from the socket,

6. The installation is the reverse of removal.

7. Connect the negative battery cable.

8. Verify the operation of the lamp.

Side Marker light

# See Figures 101, lOi, 103, and 104 I. Remove the two retaining screws from the 2. Open the trunk lid and detach the electrical

lens. connector from the lamp assembly.

2. Remove the lens from the rear fascia. 3. Remove the retaining screw holding the lamp

’ 3. Grasp the bulb socket and rotate it counter- assembly.

clockwise to remove it from the lamp. 4. Lower the lamp assembly from the lamp lens.

4. Pull the bulb out to remove it from the’socket. 5. Rotate the bulb clockwise while pushing it

5. Installation is the reverse of removal. gently inward to remove it from the socket.

6. The installation is the reverse of removal. .

High-mount Brake light

199fH6 MIllAGE, 1990-93 GALANT, AND

799446 GALANT 7992-96 DlAMANTE

p See Figures 105, 106, 107, 108, and 109 1, Disconnect the negative battery cable.

2. On the Mirage and Galant, remove the square

1. Disconnect the negative battery cable.

*The lamp assembly is accessible from the

trunk underneath the package shelf. retainer clips or bolts from the high-mount brake

light cover and remove the cover.

3. On the Diamante, press gently inward on the

sides of the liaht cover and remove it from the lamp.

1 taining screw . ~ . 93156p73 1 Fig 101 Remove the side marker light re-

93156p75 1 / ;;x,;;:,sdhen puii the lens awaG;:: 1 1 fror;l the iens Fig 103 Twist the bulb socket to release it

Fig. 104 Pull the bulb assembly straight out

of the socket to remove Fig. 105 Detach the high-mount brake

light electrical connector Fig. 106 Remove the lamp retaining screws

. a *

Page 372 of 408

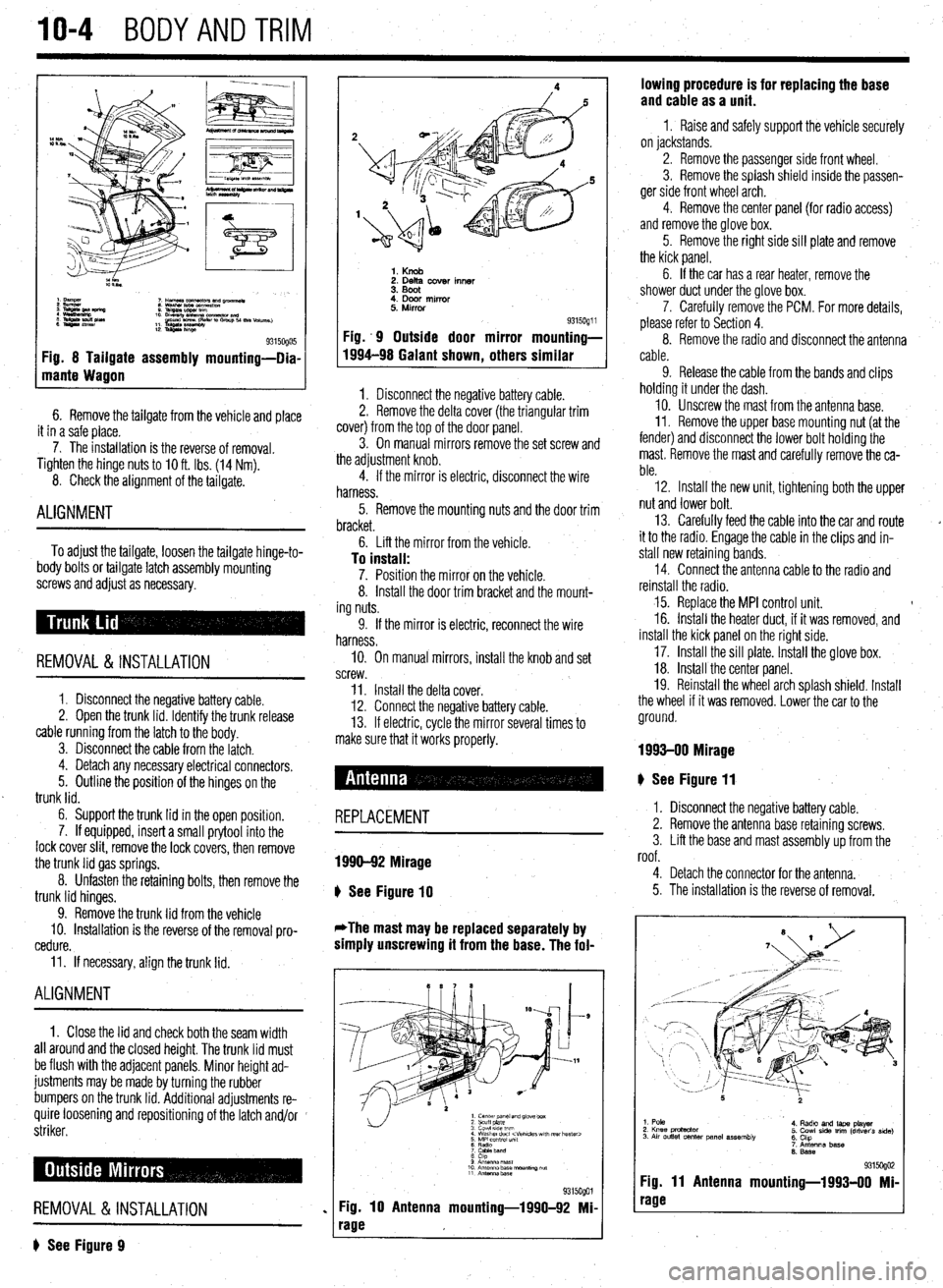

10-4 BODYANDTRIM

Fig. 8 Tailgate assembly mounting-Dia-

mante Wagon

6. Remove the tailgate from the vehicle and place

it in a safe place.

7. The installation is the reverse of removal.

Tighten the hinge

nuts to IO ft. Ibs. (14 Nm).

8. Check the alignment of the tailgate.

ALIGNMENT

To adjust the tailgate, loosen the tailgate hinge-to-

body bolts or tailgate latch assembly mounting

screws and adjust as necessary.

REMOVAL &INSTALLATION

1. Disconnect the negative battery cable.

2. Open the trunk lid. Identify the trunk release

cable running from the latch to the body.

3. Disconnect the cable from the latch.

4. Detach any necessary electrical connectors.

5. Outline the position of the hinges on the

trunk lid.

6. Support the trunk lid in the open position.

7. If equipped, insert a small prytool into the

lock cover slit, remove the lock covers, then remove

the trunk lid gas springs.

8. Unfasten the retaining bolts, then remove the

trunk lid hinges.

9. Remove the trunk lid from the vehicle

10. Installation is the reverse of the removal pro-

cedure.

11. If necessary, align the trunk lid.

ALIGNMENT

1. Close the lid and check both the seam width

all around and the closed height. The trunk lid must

be flush with the adjacent panels. Minor height ad-

justments may be made by turning the rubber

bumpers on the trunk lid. Additional adjustments re-

quire loosening and repositioning of the latch and/or

striker.

REMOVAL &INSTALLATION

? See Figure 9

1. Knob 2. Delta cover inner

3. Boot

4. Door mirror

5. Mirror

Fig. .9 Outside door mirror

1994-98 Galant shown

, others 9315oQ1 i mounting-

similar

1. Disconnect the negative battery cable.

2. Remove the delta cover (the triangular trim

cover) from the top of the door panel.

3. On manual mirrors remove the set screw and

the adjustment knob.

4. If the mirror is electric, disconnect the wire

harness.

5. Remove the mounting nuts and the door trim

bracket.

6. Lift the mirror from the vehicle.

To install: 7. Position the mirror on the vehicle.

8. Install the door trim bracket and the mount-

ing nuts.

9. If the mirror is electric, reconnect the wire

harness.

IO. On manual mirrors, install the knob and set

screw.

11. Install the delta cover.

12. Connect the negative battery cable.

13. If electric, cycle the mirror several times to

make sure that it works properly.

# See Figure 11

REPLACEMENT

1990-92 Mirage

b

See Figure 10

*The mast may be replaced separately by

simply unscrewing it from the base. The fol-

1. center panel and glove box

2 scuff plate

3 cowl 51ae wm

4 Washer duct

7 CaMeband

8 cap

9 Anrsnna mast

10 Antenna base “ourmng ““f

11 Antennz.base

%i%Qol

Fig. 10 Antenna mounting-1990-92 Mi-

rage lowing procedure is for replacing the base

and cable as a unit.

1 I Raise and safely support the vehicle securely

on jackstands.

2. Remove the passenger side front wheel.

3. Remove the splash shield inside the passen-

ger side front wheel arch.

4. Remove the center panel {for radio access)

and remove the glove box.

5. Remove the right side sill plate and remove

the kick panel.

6. If the car has a rear heater, remove the

shower duct under the glove box.

7. Carefully remove the PCM. For more details,

please refer to Section 4.

8. Remove the radio and disconnect the antenna

cable.

9. Release the cable from the bands and clips

holding it under the dash.

10. Unscrew the mast from the antenna base.

II. Remove the upper base mounting nut (at the

fender) and disconnect the lower bolt holding the

mast. Remove the mast and carefully remove the ca-

ble.

12. Install the new unit, tightening both the upper

nut and lower bolt.

13. Carefully feed the cable into the car and route

it to the radio. Engage the cable in the clips and in-

stall new retaining bands.

14. Connect the antenna cable to the radio and

reinstall the radio.

15. Replace the MPI control unit. t

16. Install the heater duct, if it was removed, and

install the kick panel on the right side.

17. Install the sill plate. Install the glove box.

18. Install the center panel.

19. Reinstall the wheel arch splash shield. Install

the wheel if it was removed. Lower the car to the

ground.

1993-00 Mirage

I. Disconnect the negative battery cable.

2. Remove the antenna base retaining screws.

3. Lift the base and mast assembly up from the

roof.

4. Detach the connector for the antenna.

5. The installation is the reverse of removal.

1. Pole

2. Knee protactor

3. Air outlet center panel assembly 4. Radto and laps player

5. Cowl side trim (driver’s side)

6. Chp

7. Antenna base

6. Base

931 !iogo2 Fig. 11 Antenna mounting-1993-00 Mi-

rage

Page 379 of 408

BODYANDTRiVl 1041

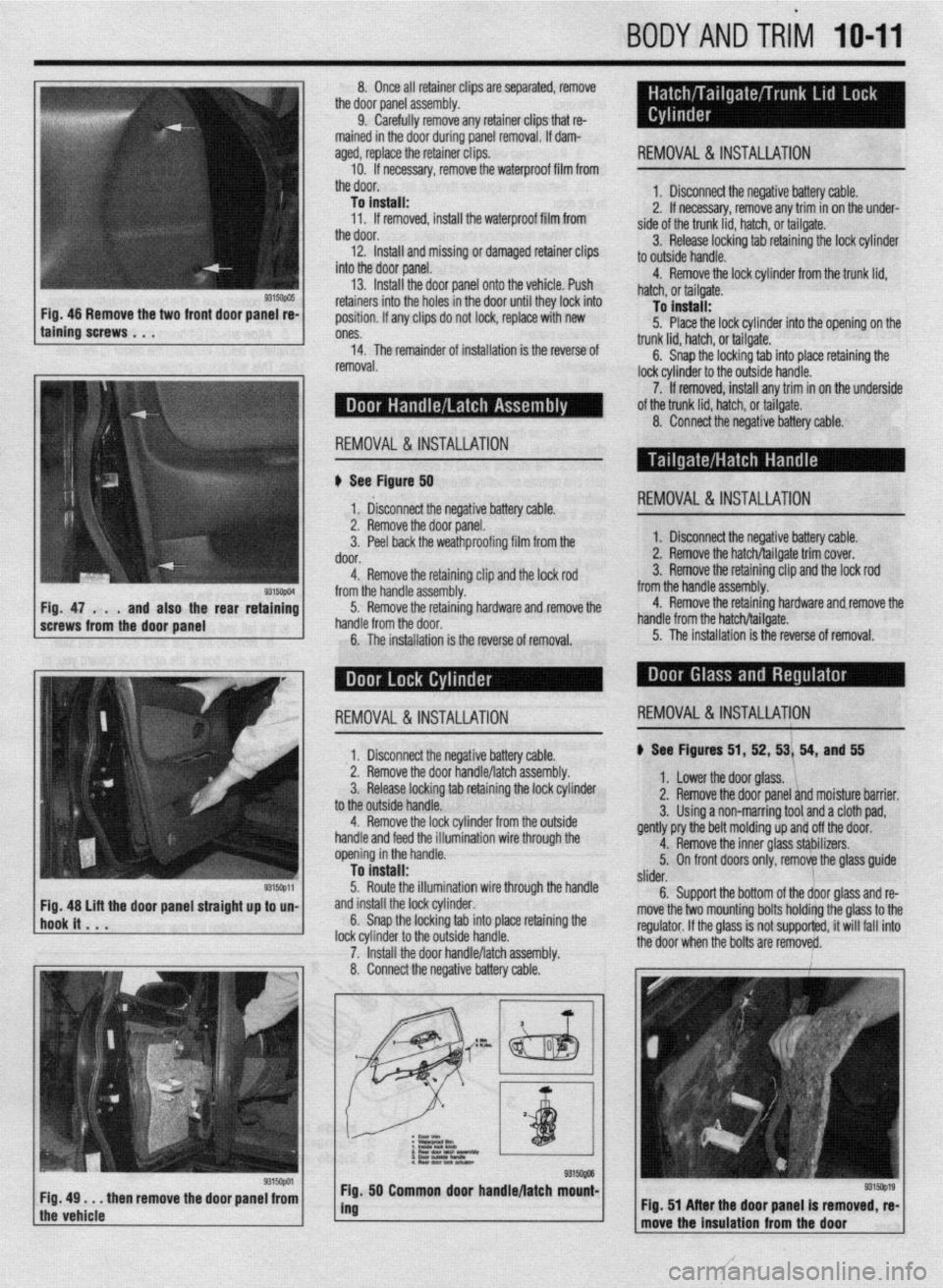

8. llnm all mtainar din!: xc! .wnnratmi rmnnve -.*I-_.. .I._. ..I. -..r-~.--“* -.-.- I( .” .I._._ the dot jr panel assembly.

9. Carefully remove any retainer clips that re-

mained in the door during panel removal. If dam-

aaed. reolace the retainer clios.

- 10. if necessary, remove’the waterproof film from

the door.

To install:

11. If removed, install the waterproof film from

. .

tne aoor.

12. Install and missing or damaged retainer clips

into the door panel.

- .- ” - 13. . - Install the door panel onto the vehicle. Push . - -. ” - ret;liners intn the hnlss in the rlnnr until thev lnck intn . - - - -. -. . . . “, - ” . .- position. If any clips do not lock, replace with new 4. Remove the lock cylinder from the trunk lid,

hatch, or tailgate. T- 1-a-11.

REMOVAL &INSTALLATION

1. Disconnect the r

negative battery cable.

2. If necessary, ren love any trim in on the under-

side of the trunk lid, hz

Itch, or tailgate.

3. Release locking tab retaining the lock cylinder

to outside handle.

9315opo5 1 Fig. 46 Remove the two front door panel re-

taining screws . , . IU Inrlall; 5. Place the lock cylinder into the opening on the

ones.

14. The remainder of installation is the reverse of

removal. trunk lid, hatch, or tailsate. -

6. Snap the locking tab into place retaining the

lock cylinder to the outside handle.

7. If removed, install any trim in on the underside

of the trunk lid, hatch, or tailgate.

8. Connect the negative battery able:

REMOVAL &INSTALLATION

II See Figurd 50

1‘ &connect the negative battery cable. REMOVAL&INSTALLATION

9315ctpm Fig. 47 . . .

and also the rear retaining

screws from the door panel 2. Remove the door panel.

3. Peel back the weathproofing film from the

door.

4. Remove the retaining clip and the lock rod

from the handle assembly.

5. Remove the retaining hardware and remove the

handle from the door.

6. The installation is the reverse of removal. 1. Disconnect the negative battery cable.

2. Remove the hatch/tailgate trim cover.

3. Remove the retaining clip and the lock rod

from the handle assembly.

4. Remove the retaining hardware and.remove the

handle from the hatch/tailgate.

5. The installation is the reverse of removal.

I 1. Disconnect the neaative batterv cable. ) See Figures 51, 52, 53/ 54, and 55 REMOVAL&INSTALLATION REMOVAL&INSTALLATION

2. Remove the door ~andle/latchassembly.

3. Release locking tab retaining the lock cylinder

to the outside handle.

4. Remove the lock cylinder from the outside

handle and feed the illumination wire through the

opening in the handle.

To install:

5. Route the illumination wire through the handle

and install the lock cylinder.

6. Snap the locking tab into place retaining the

lock cvlinder to the outside handle.

7. ‘Install the door handle/latch assembly.

8. Connect the negative battery cable. 1. Lower the door glass. ‘1,

2. Remove the door panel and moisture barrier.

3. Using a non-marring tool and a cloth pad,

gently pry the belt molding up and off the door.

4. Remove the inner glass sthbilizers.

5. On front doors only, remove the glass guide

/

slider.

6. Support the bottom of the door glass and re-

move the two mounting bolts holdirtg the glass to the

regulator. If the glass is not supporfed, it will fail into

+I%? Ann. . ..hmn hr. l..4+s are remove&.

9315opa Fig, 49 . . . then remove the door panel from

the vehicle 50 Common door handle/latch mount-

I

, Flg. 51 After the door panel is removed, re-

move the Insulation from the door