service indicator MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 40 of 408

.

GENERALINFORMATIONAND MAINTENANCE l-41

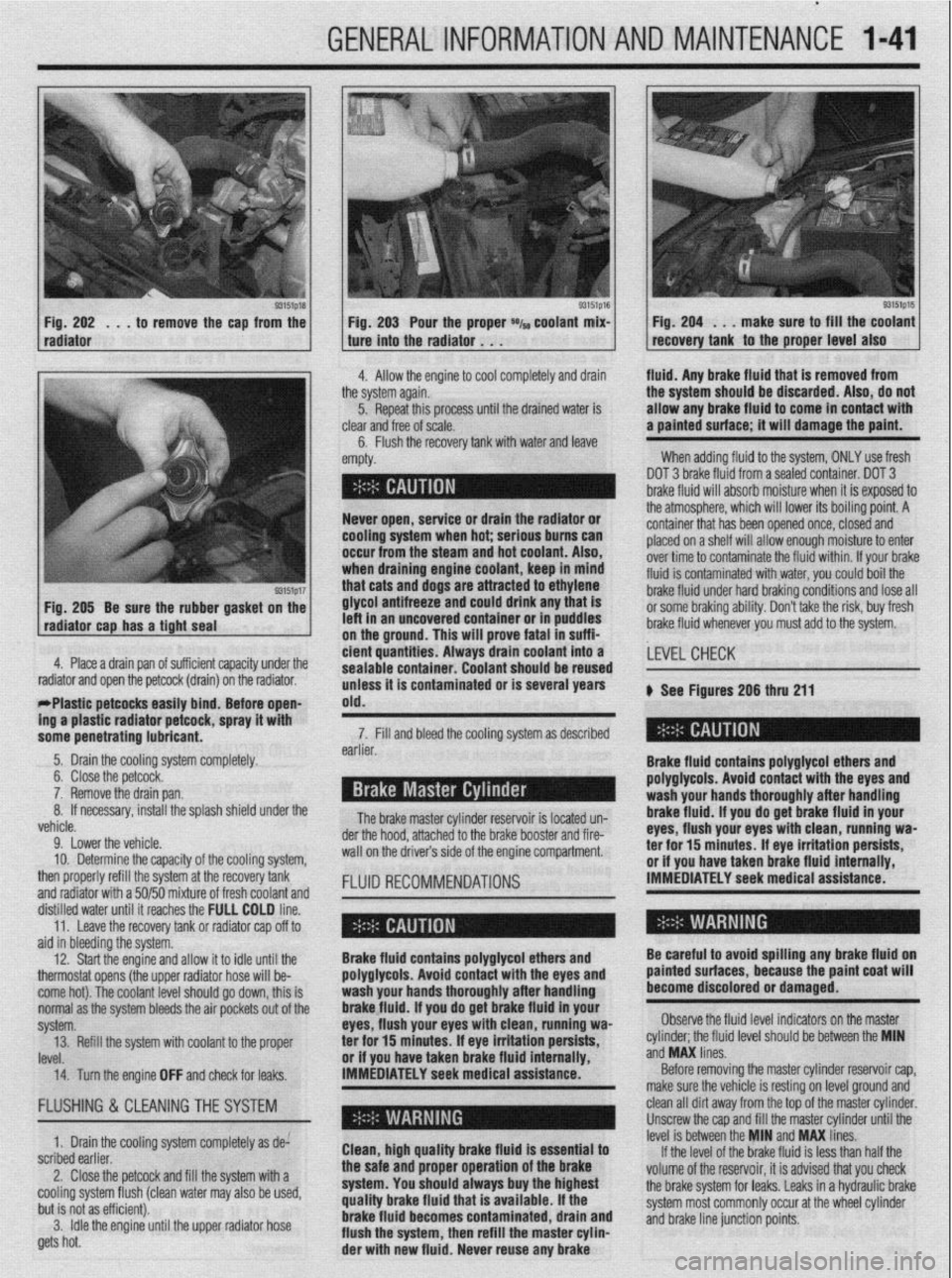

93151p18 Fig. 202 . , . to remove the cap from the

radiator

93151p17 Fig. 205 Be sure the rubber gasket on the

radiator cap has a tight seal e Fig. 203 Pour the proper *I~ coolant mix- 1 Fig. 204 . . . make sure to fill the coolant

recovery tank to the proper level also ture into the radiator . . .

.I

4. Allow the engine to cool completely and drain fluid. Any brake fluid that is removed from

ie system again.

5. Repeat this processuntil the drained water is

lear

and free of scale.

6. Flush the recovery tank with water and leave ’

mpty. the system should be discarded. Also, do not

allow any brake fluid to come in contact with

a painted surface; it will damage the paint.

When adding fluid to the system, ONLY use fresh

DOT 3 brake fluid from a sealed container. DOT 3

brake fluid will absorb moisture when it is exposed to

.a . . . , .*a. . . * .*. . .

- Never open, service or drain the radiator or

cooling system when hot; serious bums can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep In mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

4. Place a drain pan of suff i ’ 1 . . . ..I .I. 1,~ cient quantities. Always tne atmospnere, wnrcn wnr rower 1r.s oourng pomr. A

container that has been opened once, closed and

placed on a shelf will allow enough moisture to enter

over time to contaminate the fluid within. If your brake

fluid is contaminated with water, you could boil the

brake fluid under hard braking conditions and lose all

or some braking ability. Don’t take the risk, buy fresh

brake fluid whenever you must add to the system.

crenr capacrry unaer me

drain) on the radiator.

rrrasuc perwcss easuy bind; Before open-

ing a plastic radiator petcock, spray it with

some penetrating lubricant. drain coolant into a

earner. sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

The brake master cylinder ~a~~~~r,~~ :A I~nnL.4 n-n 7. Fill and bleed the cooling system as described

Brake fluid contains polyglycol ethers and

polyglycols. Avoid contact with the eyes and ,LEVEL CHECK

wash your hands thoroughly after handling

brake fluid. If vou do oet brake fluid in vour

eyes, flush your eyeswith clean, runniug wa-

a-.. ‘Y-- ar -l-..n-- II -.._ I____ k See Figures 206 thru 211

.a-11-- - __-PA._ radiator and open the petcock (

- w&1--x3_ --mm.._..- . . ..-I...

5. Drain the cooling system completely.

6. Close the petcock.

7. Remove the drain pan.

If necessary, install the splash shield under the 8.

L.-l

venicie.

9. Lower the vehicle.

10. Determine the capacity of the cooling system,

then properly refill the system at the recovery tank

and radiator with a 50/50 mixture of fresh coolant and

fKm”“ll 15 IUMLC” “II- brake booster and fire- der the hood, attached to the

wall on the drivers side of the engine compartment.

FLUID RECOMMENDATIONS rer mr 13 mmures. IT eye irriIauon persim, or if you have taken brake fluid internally,

IMMEDIATELY seek medical assistance.

ala in oreerring me sysrem.

12. Start the engine and allow it to idle until the

thermostat opens (the upper radiator hose will be-

come hot). The coolant level should go down, this is

normal as the system bleeds the air pockets out of the

svstem.

IRVf!l ._._. 14. Turn the engine OFF and check for leaks. IMMEDIATELY seek medical assistance.” Brake fluid contains polyglycol ethers and

polyglycols. Avoid contact with the eyes and

wash your hands thoroughly after handling

brakefluid. If you do get brake fluid in your

eyes, flush your eyes with clean, running wa-

or if vou have taken brake fluid internallv.

Before removing the master cylinder reservoir cap,

make sure the vehicle is resting on level ground and Be careful to avoid spilling any brake fluid on

painted surfaces, because the paint coat will

become discolored or damaged.

Observe the fluid level indicators on the master

._ ._ __

‘eve1 should be between the MIN

ano

ivw unes. 13. Refill the system with coolant to the proper ter for 15 minutes; If eye irritation persists, cylinder; the tluld II

..J ..I” I....

FLUSHING & CLEANINGTHE SYSTEM

1. Drain the cooling system completely as de:

scribed earlier.

2. Close the petcock and fill the system with a

cooling system flush (clean water may also be used,

but is not as efficient).

3. Idle the engine until the upper radiator hose

gets hot. Clean, high quality brake fluid is essential to

the safe and proper operation of the brake

system. You should always buy the highest

quality brake fluid that is available. If the

brake fluid becomes contaminated, drain and

flush the system, then refill the master cylin-

der with new fluid. Never reuse any brake clean all dirt away from the top of the master cylinder.

Unscrew the cap and fill the master cylinder until the

level is between the MIN and MAX lines.

If the level of the brake fluid is less than half the

volume of the reservoir, it is advised that you check

the brake system for leaks. Leaks in a hydraulic brake

system most commonly occur at the wheel cylinder

and brake line junction points.

Page 108 of 408

ENGINEANDENGINEOVERHAUL 3-47

DO NOT rotate or turn the camshafts when re-

moving the sprockets or severe engine dam-

age will result from internal component in-

terference.

22. Align the mark on the crankshaft sprocket

with the mark on the front case. Then, move the

crankshaft sprocket 1 tooth counterclockwise.

23. Align the timing marks of the camshafts with

the marks on the rear covers.

24. Using large paper clips to secure the timing

belt to the sprockets, install the timing belt in the fol-

lowing order. Be sure camshafts-to-cylinder heads

and crankshaft-to-front cover timing marks are

aligned. Install the timing belt around the pulleys in

the following order:

a. Exhaust camshaft sprocket (front bank).

b. Intake camshaft sprocket (front bank).

c. Water pump pulley.

d. Intake camshaft sprocket (rear bank).

e. Exhaust camshaft sprocket (rear bank).

f. Tensioner pulley.

g. Crankshaft pulley.

h. Idler pulley.

*Since the camshaft sprockets turn easily,

secure them with box wrenches when in-

stalling the timing belt.

25. Align all timing marks on the crankshaft and

raise the tensioner pulley against the belt to remove

slack, snug tensioner bolt.

26. Check the alignment of all the timing marks

and remove the clips that secure the timing belt to the

camshaft sprockets.

27. Rotate the engine 1/4 turn counterclockwise,

then rotate the engine clockwise to align the timing

marks. Check that all the timing marks are in align-

ment.

28. Loosen the center bolt on the tensioner pul-

ley.

29. Using tool MD998752 or equivalent and a

torque wrench, apply 84 inch Ibs. (10 Nm) to the tool

on the tensioner. Tighten the tensioner bolt to 35 ft.

Ibs. (49 Nm) and be sure the tensioner does not ro-

tate with the bolt. 30. Rotate the crankshaft two complete turns

clockwise and let it sit for approximately five minutes.

Then, check that the set pin can easily be inserted

and removed from the hole in the auto-tensioner.

31. Remove the set wire attached to the auto-ten-

sioner

32. Measure the auto-tensioner protrusion (the

distance between the tensioner arm and auto-ten-

sioner body) to ensure that it is within 0.15-0.18 in.

(3.8-4.5mm). If out of specification, repeat adjust-

ment procedure until the specified value is obtained.

33. Check again that the timing marks on all

sprockets are in proper alignment.

34. Install the timing belt covers and all other ap-

plicable components.

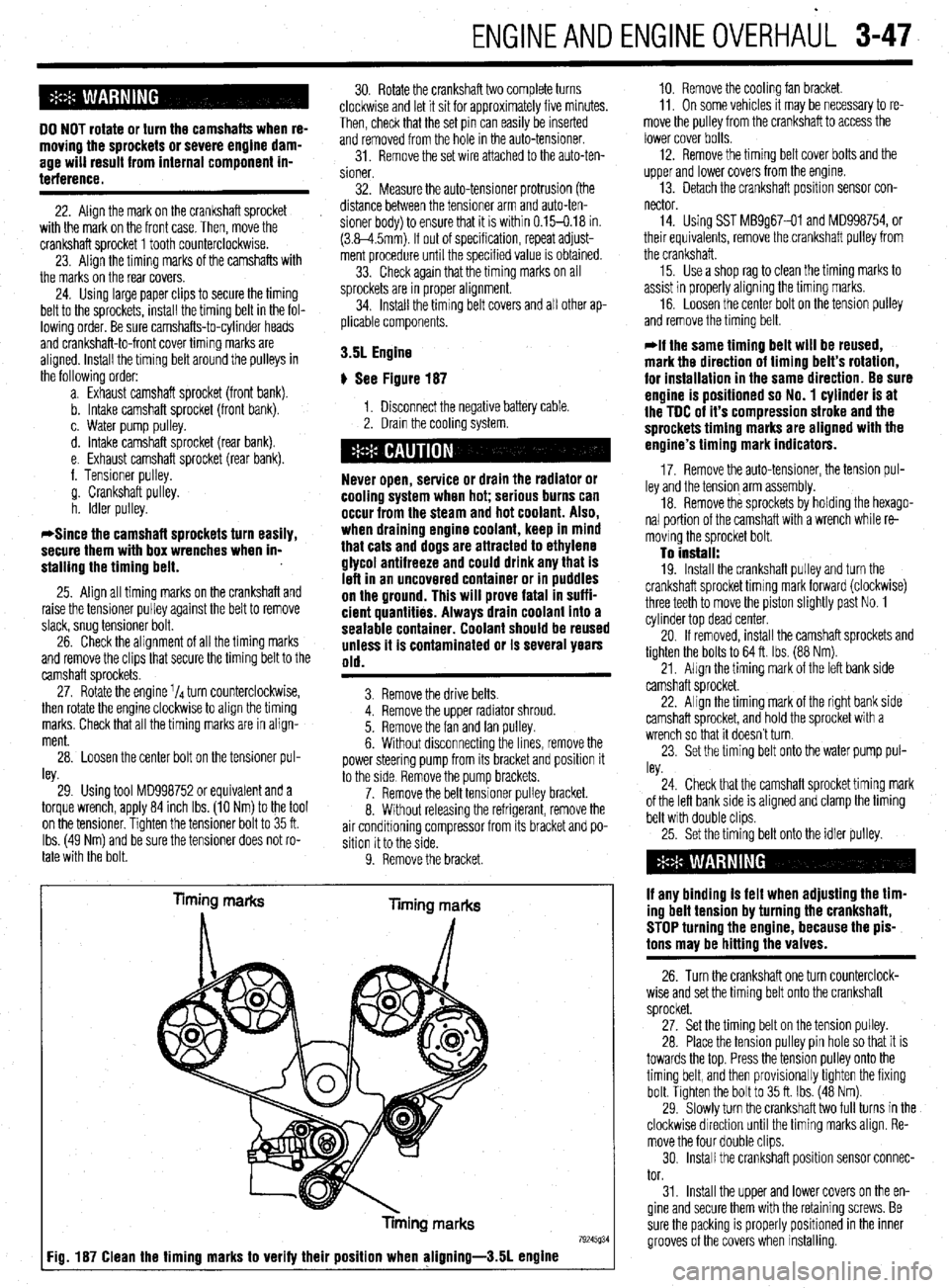

3.51 Engine

p See Figure 187

1. Disconnect the negative battery cable.

2. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

giycoi antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the drive belts.

4. Remove the upper radiator shroud.

5. Remove the fan and fan pulley.

6. Without disconnecting the lines, remove the

power steering pump from its bracket and position it

to the side Remove the pump brackets.

7. Remove the belt tensioner pulley bracket.

8. Without releasing the refrigerant, remove the

air conditioning compressor from its bracket and po-

sition it to the side.

9. Remove the bracket.

Timing marks

liming marks

Tinning marks

79245934 Fig. 187 Clean the timing marks to verify their position when aligning-3.51 engine

10. Remove the cooling fan bracket.

11, On some vehicles It may be necessary to re-

move the pulley from the crankshaft to access the

lower cover bolts.

12. Remove the timing belt cover bolts and the

upper and lower covers from the engme.

13. Detach the crankshaft position sensor con-

nector

14. Using SST MB9g67-01 and MD998754, or

their equivalents, remove the crankshaft pulley from

the crankshaft.

15. Use a shop rag to clean the timing marks to

assist in properly aligning the timing marks.

16. Loosen the center bolt on the tension pulley

and remove the timing belt.

@if the same timing belt will be reused,

mark the direction of timing belt’s rotation,

for installation in the same direction. Be sure

engine is positioned so No. 1 cylinder is at

the TDC of it’s compression stroke and the

sprockets timing marks are aligned with the

engine’s timing mark indicators.

17. Remove the auto-tensioner, the tension pul-

ley and the tension arm assembly.

18. Remove the sprockets by holding the hexago-

nal portion of the camshaft with a wrench while re-

moving the sprocket bolt.

To install: 19. Install the crankshaft pulley and turn the

crankshaft sprocket timing mark forward (clockwise)

three teeth to move the piston slightly past No. 1

cylinder top dead center.

20. If removed, install the camshaft sprockets and

tighten the bolts to 64 ft. Ibs. (88 Nm).

21, Align the timing mark of the left bank side

camshaft sprocket.

22. Align the timing mark of the right bank side

camshaft sprocket, and hold the sprocket with a

wrench so that it doesn’t turn.

23. Set the timing belt onto the water pump pul-

ley.

24. Check that the camshaft sprocket timing mark

of the left bank side is aligned and clamp the timing

belt with double clips.

25. Set the timing belt onto the idler pulley.

if any binding is felt when adjusting the tim-

ing belt tension by turning the crankshaft,

STOP turning the engine, because the pis-

tons may be hitting the valves.

26. Turn the crankshaft one turn counterclock-

wise and set the timing belt onto the crankshaft

sprocket.

27. Set the timing belt on the tension pulley.

28. Place the tension pulley pin hole so that it is

towards the top. Press the tension pulley onto the

timing belt, and then provisionally tighten the fixing

bolt. Tighten the bolt to 35 ft. Ibs. (48 Nm).

29. Slowly turn the crankshaft two full turns in the

clockwise direction until the timing marks align. Re-

move the four double clips.

30. Install the crankshaft position sensor connec-

tor.

31. Install the upper and lower covers on the en-

gine and secure them with the retaining screws. Be

sure the packing is properly positioned in the inner

grooves of the covers when installing.

Page 118 of 408

ENGINEANDENGINEOVERHAUL 3-57

Anything that generates heat and/or friction WIII

eventually burn or wear out (for example, a light bulb

generates heat, therefore its life span is limited). With

this in mind, a running engine generates tremendous

amounts of both; friction is encountered by the mov-

ing and rotating parts inside the engine and heat is

created by friction and combustion of the fuel How-

ever, the engine has systems designed to help reduce

the effects of heat and friction and provide added

longevrty. The oiling system reduces the amount of

friction encountered by the moving parts inside the

engine, while the cooling system reduces heat cre-

ated by friction and combustion If either system is

not maintained, a break-down will be inevitable.

Therefore, you can see how regular maintenance can

affect the service life of your vehicle, If you do not

drain, flush and refill your cooling system at the

proper intervals, deposits WIII begin to accumulate in

the radiator, thereby reducing the amount of heat it

can extract from the coolant The same applies to

your oil and filter; If it is not changed often enough it

becomes laden with contaminates and is unable to

properly lubricate the engine. This increases friction

and wear.

There are a number of methods for evaluating the

condition of your engine. A compression test can re-

veal the condition of your pistons, piston rings,

cylinder bores, head gasket(s), valves and valve

seats. An oil pressure test can warn you of possible

engine bearing, or oil pump failures. Excessrve oil

consumption, evidence of oil in the engine air intake

area and/or bluish smoke from the tailpipe may indi-

cate worn piston rings, worn valve guides and/or

valve seals. As a general rule, an engine that uses no

more than one quart of oil every 1000 miles is in

good condition. Engines that use one quart of oil or

more in less than 1000 miles should first be checked

for oil leaks. If any oil leaks are present, have them

fixed before determining how much oil is consumed

by the engine, especrally if blue smoke is not visible

at the tailpipe

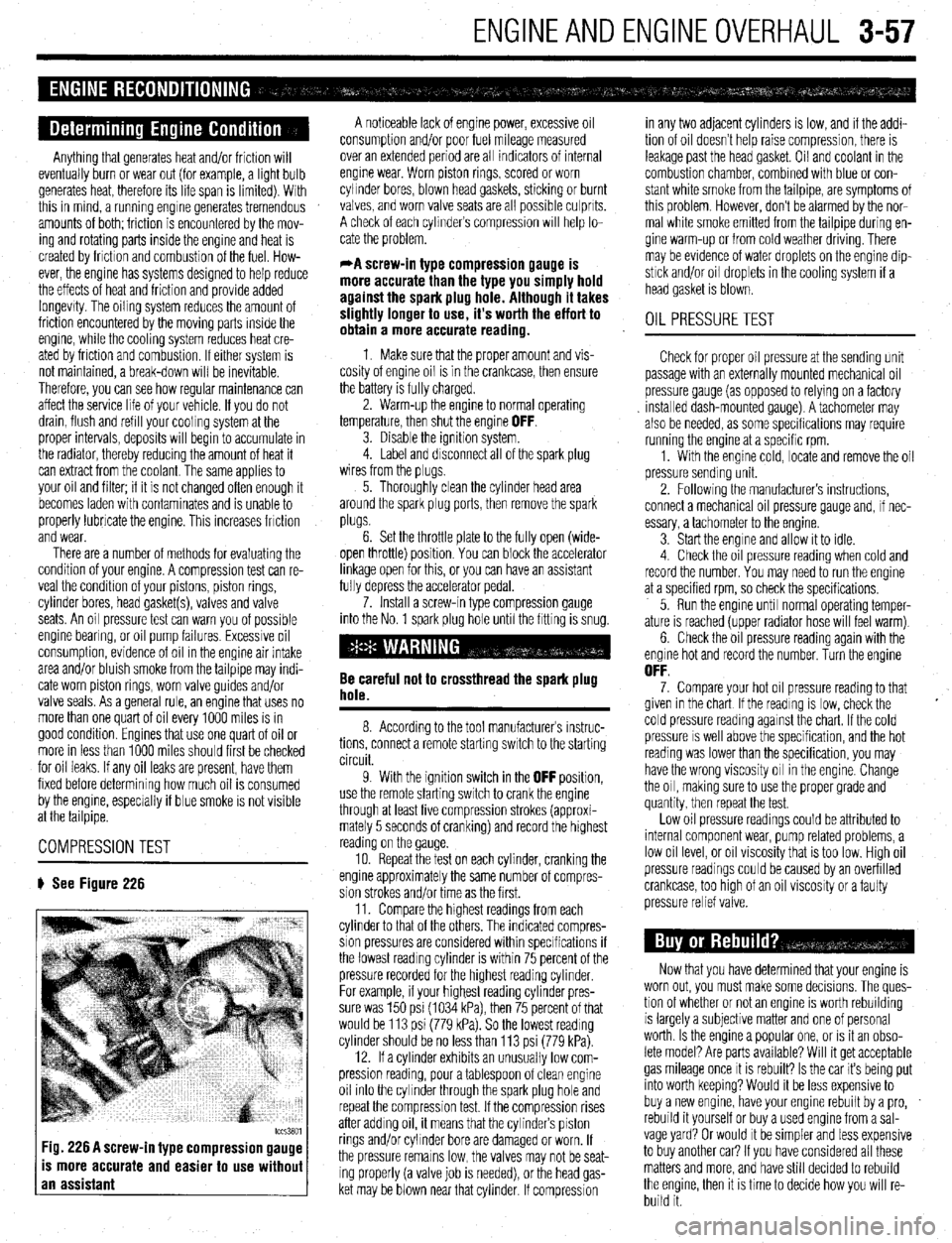

COMPRESSION TEST

# See Figure 226

tccs3801 Fig. 226 A screw-in type compression gauge

is more accurate and easier to use without

an assistant

A noticeable lack of engine power, excessive oil

consumption and/or poor fuel mileage measured

over an extended period are all indicators of internal

engine wear. Worn piston rings, scored or worn

cylinder bores, blown head gaskets, sticking or burnt

valves, and worn valve seats are all possible culprits.

A check of each cylinders compression WIII help lo-

cate the problem.

*A screw-in type compression gauge is

more accurate than the type you simply hold

against the spark plug hole. Although it takes

slightly longer to use, it’s worth the effort to

obtain a more accurate reading.

1 Make sure that the proper amount and vis-

cosity of engine oil is in the crankcase, then ensure

the battery is fully charged.

2. Warm-up the engine to normal operating

temperature, then shut the engine

OFF. 3. Disable the ignition system.

4. Label and disconnect all of the spark plug

wires from the plugs,

5. Thoroughly clean the cylinder head area

around the spark plug ports, then remove the spark

plugs.

6. Set the throttle plate to the fully open (wide-

open throttle) position You can block the accelerator

linkage open for this, or you can have an assistant

fully depress the accelerator pedal.

7. Install a screw-in type compression gauge

into the No. 1 spark plug hole until the fitting is snug.

Be careful not to crossthread the spark plug

hole.

8. According to the tool manufacturers instruc-

tions, connect a remote starting switch to the starting

circuit.

9. With the ignition switch in the

OFF position,

use the remote starting switch to crank the engine

through at least five compression strokes (approxi-

mately 5 seconds of cranking) and record the highest

reading on the gauge

10. Repeat the test on each cylinder, cranking the

engine approximately the same number of compres-

sion strokes and/or time as the first.

11. Compare the hrghest readings from each

cylinder to that of the others. The indicated compres-

sion pressures are considered within specifications if

the lowest reading cylinder is within 75 percent of the

pressure recorded for the highest reading cylinder

For example, if your highest reading cylinder pres-

sure was 150 psi (1034 kPa), then 75 percent of that

would be 113 psi (779 kPa). So the lowest reading

cylinder should be no less than 113 psi (779 kPa).

12. If a cylinder exhibits an unusually low com-

pression reading, pour a tablespoon of clean engine

oil into the cylinder through the spark plug hole and

repeat the compression test. If the compression rises

after adding oil, it means that the cylinder’s piston

rings and/or cylinder bore are damaged or worn, If

the pressure remains low, the valves may not be seat-

ing properly (a valve job is needed), or the head gas-

ket may be blown near that cylinder. If compression in any two adjacent cylinders is low, and if the addi-

tion of oil doesn’t help raise compression, there is

leakage past the head gasket. Oil and coolant in the

combustion chamber, combined with blue or con-

stant white smoke from the tailpipe, are symptoms of

this problem. However, don’t be alarmed by the nor-

mal white smoke emitted from the tailpipe during en-

gine warm-up or from cold weather driving. There

may be evidence of water droplets on the engine dip-

stick and/or oil droplets in the cooling system if a

head gasket is blown.

OIL PRESSURETEST

Check for proper oil pressure at the sending unit

passage with an externally mounted mechanical oil

pressure gauge (as opposed to relying on a factory

Installed dash-mounted gauge). A tachometer may

also be needed, as some specifications may require

running the engine at a specific rpm.

1. With the engine cold, locate and remove the oil

pressure sending unit.

2. Followrng the manufacturers instructions,

connect a mechanical oil pressure gauge and, if nec-

essary, a tachometer to the engine.

3 Start the engine and allow it to idle.

4 Check the oil pressure reading when cold and

record the number. You may need to run the engine

at a specified rpm, so check the specifications,

5. Run the engine until normal operating temper-

ature is reached (upper radiator hose will feel warm)

6. Check the oil pressure reading again with the

engine hot and record the number. Turn the engine

OFF. 7. Compare your hot oil pressure reading to that

given in the chart If the reading is low, check the

cold pressure reading against the chart. If the cold

pressure IS well above the specification, and the hot

reading was lower than the specification, you may

have the wrong viscosity oil in the engine. Change

the oil, making sure to use the proper grade and

quantity, then repeat the test.

Low oil pressure readings could be attributed to

internal component wear, pump related problems, a

low oil level, or oil viscosity that is too low. High oil

pressure readings could be caused by an overfilled

crankcase, too htgh of an oil viscosity or a faulty

pressure relief valve.

Now that you have determined that your engine is

worn out, you must make some decisions. The ques-

tion of whether or not an engine IS worth rebuilding

is largely a subjective matter and one of personal

worth. Is the engine a popular one, or IS it an obso-

lete model? Are parts available? Will it get acceptable

gas mileage once It is rebuilt? Is the car its being put

into worth keeping? Would it be less expensive to

buy a new engine, have your engine rebuilt by a pro,

rebuild it yourself or buy a used engine from a sal-

vage yard? Or would It be simpler and less expensive

to buy another car? If you have considered all these

matters and more, and have still decided to rebuild

the engine, then it is time to decide how you will re-

build it.

Page 119 of 408

3-58 ENGINEANDENGINEOVERHAUL '

*The editors at Chilton feel that most engine

machining should be performed by a profes-

sional machine shop. Don’t think of it as

wasting money, rather, as an assurance that

the job has been done right the first time.

There are many expensive and specialized

tools required to perform such tasks as bor-

ing and honing an engine block or having a

valve job done on a cylinder head. Even in-

specting the parts requires expensive mi-

crometers and gauges to properly measure

wear and clearances. Also, a machine shop

can deliver to you clean, and ready to as-

semble parts, saving you time and aggrava-

tion. Your maximum savings will come from

performing the removal, disassembly, as-

sembly and installation of the engine and

purchasing or renting only the tools required

to perform the above tasks. Depending on

the particular circumstances, you may save

40 to 60 percent of the cost doing these your-

self.

A complete rebuild or overhaul of an engine in-

volves replacing all of the moving parts (pistons,

rods, crankshaft, camshaft, etc.) with new ones and

machining the non-moving wearing surfaces of the

block and heads. Unfortunately, this may not be cost

effective. For instance, your crankshaft may have

been damaged or worn, but it can be machined un-

dersize for a minimal fee.

So, as you can see, you can replace everything in-

side the engine, but, it is wiser to replace only those

parts which are really needed, and, if possible, repair

the more expensive ones. Later in this section, we

will break the engine down into its two main compo-

nents: the cylinder head and the engine block. We

will discuss each component, and the recommended

parts to replace during a rebuild on each. spect the component, buy the necessary parts and OVERHAULTIPS

deliver these to a shop for actual machine work.

Much of the assembly work (crankshaft, bearings, Aluminum has become extremely popular for use

piston rods, and other components) is well within the in engines, due to its low weight. Observe the follow-

scope of the do-it-yourself mechanic’s tools and abil- ing precautions when handling aluminum parts:

ities. You will have to decide for yourself the depth of

l Never hot tank aluminum parts (the caustic hot

involvement you desire in an engine repair or rebuild. 6nk solution will eat the aluminum.

l Remove all aluminum parts (identification tag,

TOOLS etc.) from engine parts prior to the tanking.

l Always coat threads lightly with engine oil or

The tools required for an engine overhaul or parts

anti-seize compounds before installation, to prevent

replacement will depend on the depth of your in-

seizure.

volvement. With a few exceptions, they will be the

l Never overtighten bolts or spark plugs espe-

tools found in a mechanic’s tool kit (see Section 1 of

this manual). More in-depth work will require some cially in aluminum threads.

When assembling the engine, any parts that will

or all of the following:

be exposed to frictional contact must be prelubed to

l A dial indicator (reading in thousandths)

provide lubrication at initial start-up. Any product

mounted on a universal base

specifically formulated for this purpose can be used,

l Micrometers and telescope gauges

* Jaw and screw-type pullers but engine oil is not recommended as a prelube in

most cases.

‘ Scraper

When semi-permanent (locked, but removable) in-

l Valve spring compressor

stallation of bolts or nuts is desired, threads should l Ring groove cleaner l Piston ring expander and compressor be cleaned and coated with Loctite@ or another simi- l Ridge reamer , lar, commercial non-hardening sealant. l Cylinder hone or glaze breaker l Plastigage@ l Engine stand

The use of most of these tools is illustrated in

this section. Many can be rented for a one-time use

from a local parts jobber or tool supply house spe-

cializing in automotive work.

Occasionally, the use of special tools is called for.

See the information on Special Tools and the Safety

Notice in the front of this book before substituting

another tool. CLEANING

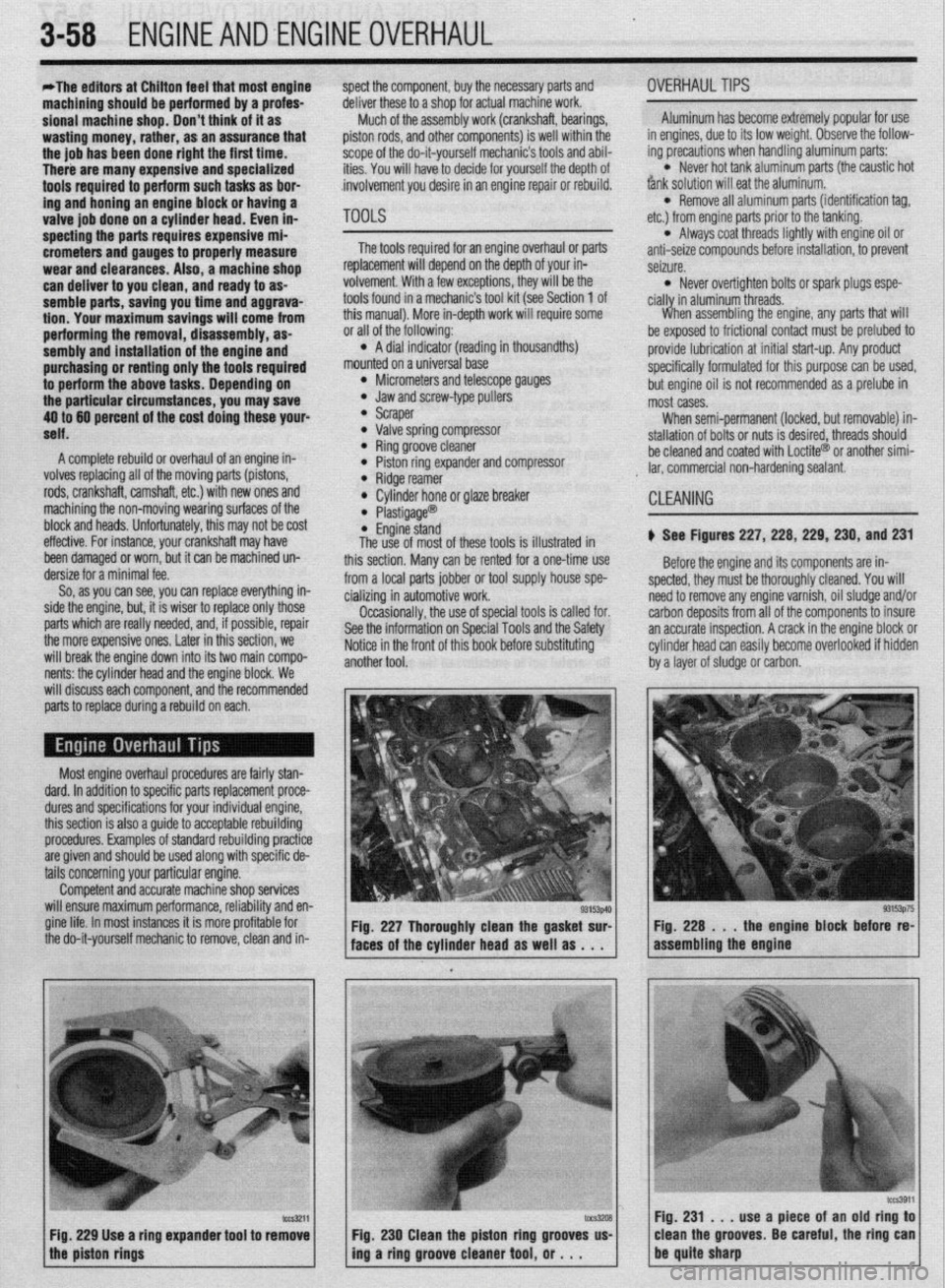

) See Figures 227, 228, 229, 230, and 231

Before the engine and its components are in-

spected, they must be thoroughly cleaned. You will

need to remove anv enaine varnish, oil sludoe and/or

c arbon deposits from ail of the componentsio insure

a In accurate inspection. A crack in the engine block or

c :ylinder head can easily become overlooked if hidden

t ry a layer of sludge or carbon.

Most engine overhaul procedures are fairly stan-

dard. In addition to specific parts replacement proce-

dures and specifications for your individual engine,

this section is also a guide to acceptable rebuilding

procedures. Examples of standard rebuilding practice

are given and should be used along with specific de-

tails concerning your particular engine.

Competent and accurate machine shop services

will ensure maximum performance, reliability and en-

gine life. In most instances it is more profitable for

the do-it-yourself mechanic to remove, clean and in- Fig. 227 Thoroughly clean the gasket sur-

faces of the cylinder head as well as . . .

Fig. 229 Use a ring expander tool to remove

the piston rings

fccs3911 ::“,z s,rpuse,a piece of fn old ring to 1

clean the grooves Be careful the ring can

230 Clean the piston ring grooves us-

ing a ring groove cleaner tool, or . . .

Page 124 of 408

ENGINEANDENGINEOVERHAUL 3-63

Place a straightedge across the gasket surface. Valves

Using feeler gauges, determine the clearance at the

center of the straightedge and across the cylinder Any valves that were not replaced should be

head at several points. Check along the centerline refaced and the tips ground flat. Unless you have ac-

and diagonally on the head surface. If the warpage cess to a valve grinding machine, this should be

exceeds 0.003 in. (0.076mm) within a 6.0 in. done by a machine shop. If the valves are in ex-

(152cm) span, or 0.006 in. (0.152mm) over the total tremely good condition, as well as the valve seats

length of the head, the cylinder head must be resur- and guides, they may be lapped in without petform-

,

I mg macnme worK.

4

It is a recnmmended practice to lap the valves faced. After resurfacing the heads of a V-type engine

the intake manifold flange surface should be checker,

and if necessary, milled proportionally to allow for

the change in its mounting position. _ - _ _ _ .- - - _

even after machine work has been p&formed and/or

new valves have been purchased. This insures a pos-

itive seal between the valve and seat.

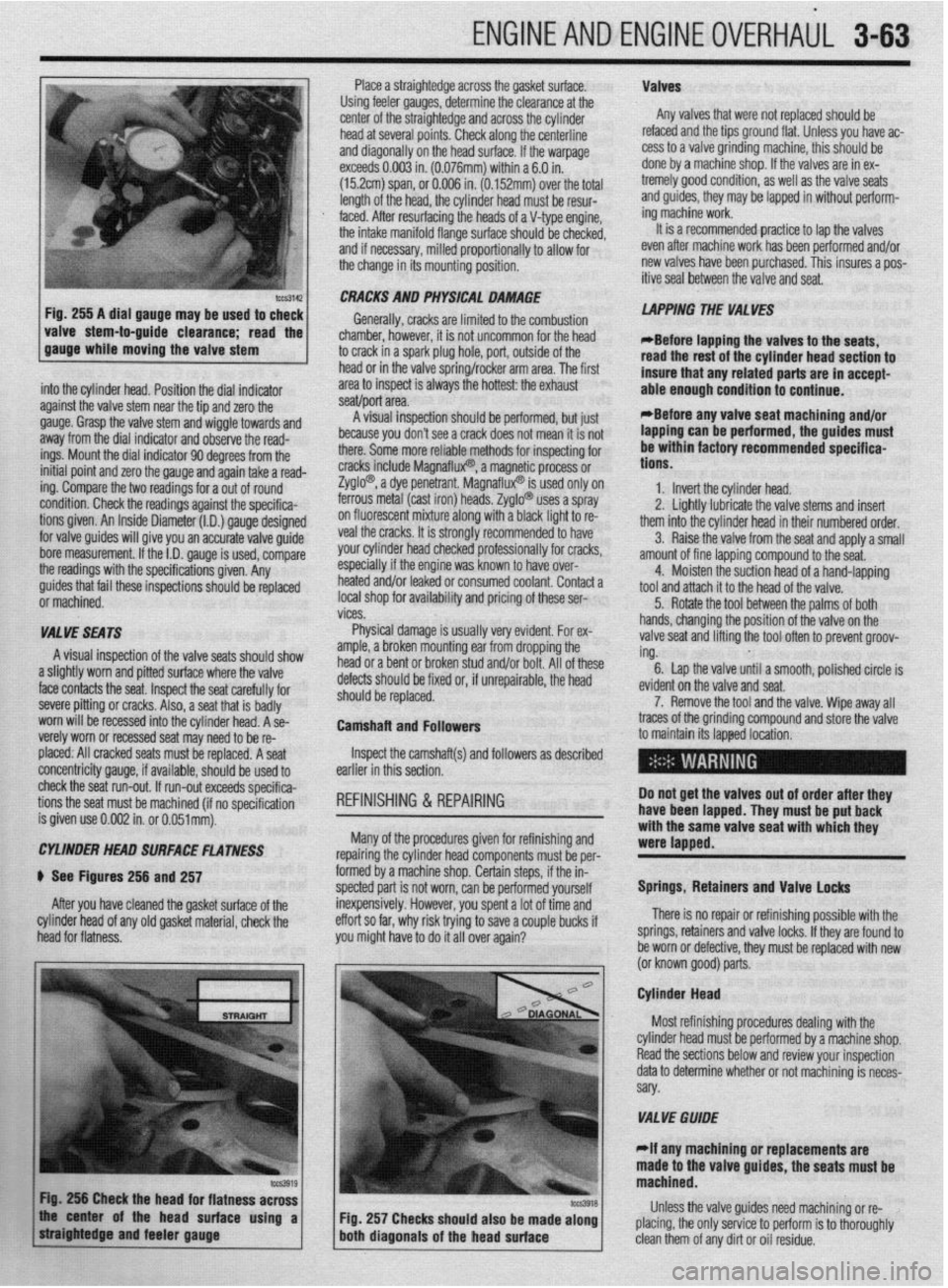

-guide clearance; the 1

read

. .

into the cylinder head. Position the dial indicator

against the valve stem near the tie and zero the

gauge. Grasp the valve stem and’wiggle towards and

away from the dial indicator and observe the read-

ings. Mount the dial indicator 90 degrees from the

initial point and zero the gauge and again take a read-

ing. Compare the two readings for a out of round

condition. Check the readings against the specifica-

tions given. An Inside Diameter (I.D.) gauge designed

for valve guides will give you an accurate valve guide

bore measurement. If the I.D. gauge is used, compare

the readings with the specifications given. Any CRACKS AND PHYSICAL DAMAGE

Generally, cracks are limited to the combustion

chamber, hbwever, it is not uncommon for the head

to crack in a spark plug hole, port, outside of the

head or in the valve spring/rocker arm area. The first

area to inspect is always the hottest: the exhaust

.I *

seawpon area.

8 I .,“““I llly”Lv”l~ .ml”“l” - plr”llll”“, ““I ,“a’

because you don’t see a crack does not mean it is not

there. Some more reliable methods for inspecting for

cracks include Magnaflux? a magn$i,c process or

Zyglo? a dye penetrant. Ma{ -’

InatluxW IS used only on

ferrous metal (cast iron) heat Is. Zyglo@ uses a spray

on fluorescent mixture along with a black light to re-

veal the cracks. It is strongly recommended to have

your cylinder head checked professionally for cracks,

especially if the engine was known to have over-

I .* I,. ..^.. LAPPING THE VALVES

*Before iaoaino the valves to the seats,

read the rest of the cylinder head section to

insure that any related parts are in accept-

able enough condition to continue.

*Before anv valve seat machining and/or

lapping can be performed, the guides must

be within factory recommended specifica-

tions.

1. Invert the cylinder head.

2. Linhtlv Iuhrir;rB the valve stems and insert

-. _ ~ . . . . . .--.._-._

them into the cylinder head in their numbered order.

3. Raise the valve from the seat and apply a small

amount of fine lanninn compound to the seat.

4.

i guides that fail these inspections should be replaced nearea analor ieaKea or consumea coolant. Contact a Moisten the suction head of a hand-lapping

tool and attach it to the head of the valve.

i or machined. local shop for availability and pricing of these ser-

5. Rotate the tool between the palms of both

I vices.

I

VALVE SEATS Physical damage is usually very evident. For ex- hands, changing the position of the valve on the

valve seat and lifting the tool often to prevent groov-

A visual inspection of the valve seats should show

amnb P hrnbn mntlntinn ear from dropping the I and/or bolt. All of these ing.

.a,... . 6. Lap the valve until a smooth, polished circle is

a slightly worn and pitted surface where the valve

face contacts the seat. Inspect the seat carefully for

severe pitting or cracks. Also, a seat that is badly

worn will be recessed into the cylinder head. A se-

verely worn or recessed seat may need to be re- uetecIs SIIOUIO oe nxea or, IT unrepairaole, me neaa

should be replaced.

Camshaft and Followers evid

7

traces of the grinding corn

to maintain its lapped loca lent on the valve and seat.

‘. Remove the tool and the valve. Wipe away all

pound and store the valve

placed: All cracked seats must be replaced. A seat

concentricity gauge, if available, should be used to

check the seat run-out. If run-out exceeds specifica-

tions the seat must be machined (if no soecification

is given use 0.002 in. or O.O51mt$. Inspect the camshaft(s) and followers as described

earlier in this section.

REFINISHING & REPAIRING Do not get the valves out of order after they

have been lapped. They must be put back

: ..^^ I... --I:^:-L!-- --A

Many of the procedures gIveI

WI WIIIIISIIIIIIJ ~IIU repairing the cylinder head components must be per-

formed by a machine shop. Certain steps, if the in-

spected part is not worn, can be performed yourself

inexpensively. However, you spent a lot of time and

effort so far, why risk trying to save a couple bucks if

you might have to do it all over again?

I- with the same valve seat with which they

were lapped.

Springs, Retainers and Valve locks

There is no repair or refinishing possible with the

springs, retainers and valve locks. If they are found to

be worn or defective, they must be replaced with new

lor known nnod narts CYLtNDEt? HEAD SURFACE FLATNESS

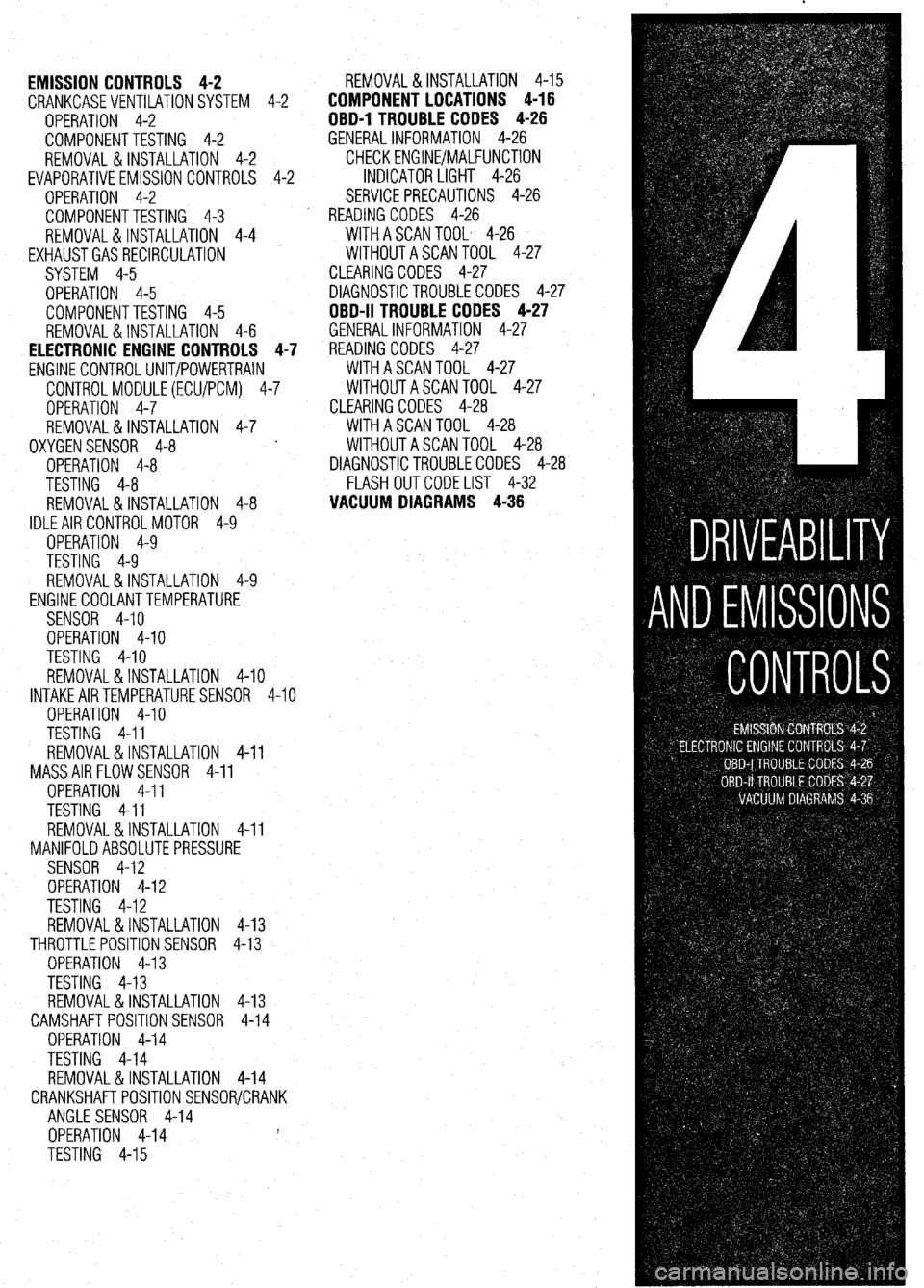

) See Figures 256 and 257

After you have cleaned the gasket surface of the

cylinder head of any old gasket material, check the

head for flatness.

\- - a---r r- .-.

Cylinder Head

Most refinishing procedures dealing with the

VALVE GWDE

elf any machining or replacements are

e valve guides, the seats must be

Fig. 257 Checks should also be made along Unless the valve guides need machining or re-

placing, the only service to perform is to thoroughly‘

clean them of any dirt or oil residue.

Page 144 of 408

EMISSION CONTROLS 4-2

CRANKCASEVENTILATIONSYSTEM 4-2

OPERATION 4-2

COMPONENTTESTING 4-2

REMOVAL &INSTALLATION 4-2

EVAPORATIVEEMISSIONCONTROLS 4-2

OPERATION 4-2

COMPONENTTESTING 4-3

REMOVAL&INSTALLATION 4-4

EXHAUSTGASRECIRCULATION

SYSTEM 4-5

OPERATION 4-5

COMPONENTTESTING 4-5

REMOVAL&INSTALLATION 4-6

ELECTRONIC ENGINE CONTROLS 4-7

ENGlNECONTROLUNIT/POWERTRAIN

CONTROLMODULE(ECU/PCM) 4-7

OPERATION 4-7

REMOVAL&INSTALLATION 4-7

OXYGENSENSOR 4-8

OPERATION 4-8

TESTING 4-8

REMOVAL&INSTALLATION 4-8

IDLEAIRCONTROLMOTOR 4-9

OPERATION 4-9

TESTING 4-9

REMOVAL&INSTALLATION 4-9

ENGINECOOLANTTEMPERATURE

SENSOR 4-10

OPERATION 4-10

TESTING 4-10

REMOVAL&INSTALLATION 4-10

INTAKEAIRTEMPERATURESENSOR 4-10

OPERATION 4-10

TESTING 4-11

REMOVAL&INSTALLATION 4-11

MASSAIRFLOWSENSOR 4-11

OPERATION 4-11

TESTING 4-11

REMOVAL&INSTALLATION 4-11

MANIFOLDABSOLUTEPRESSURE

SENSOR 4-12

OPERATION 4-12

TESTING 4-12

REMOVAL&INSTALLATION 4-13

THROTTLEPOSITIONSENSOR 4-13

OPERATION 4-13

TESTING 4-13

REMOVAL&INSTALLATION 4-13

CAMSHAFT POSITIONSENSOR 4-14

OPERATION 4-14

TESTING 4-14

REMOVAL&INSTALLATION 4-14

CRANKSHAFTPOSlTlONSENSOR/CRANK

ANGLE SENSOR 4-14

OPERATION 4-14 I

TESTING 4-15 REMOVAL&INSTALLATION 4-15

COMPONENT LOCATIONS 4-16

OBD-1 TROUBLE CODES 4-26

GENERALINFORMATION 4-26

CHECKENGINVMALFUNCTION

INDICATOR LIGHT 4-26

SERVICEPRECAUTIONS 4-26

READING CODES 4-26

WITHASCANTOOL 4-26

WITHOUTASCANTOOL 4-27

CLEARINGCODES 4-27

DIAGNOSTICTROUBLECODES 4-27

OBD-II TROUBLE CODES 4-27

GENERALINFORMATION 4-27

READING CODES 4-27

WITHASCANTOOL 4-27

WITHOUTASCANTOOL 4-27

CLEARINGCODES 4-28

WITHASCANTOOL 4-28

WITHOUTASCANTOOL 4-28

DIAGNOSTICTROUBLECODES 4-28

FLASH OUTCODELIST 4-32

VACUUM DIAGRAMS 4-36

Page 169 of 408

4-26 DRIVEABILITYAND EMISSIONS CONTROLS

The Powertrain Control Module (PCM) monitors

the signals of input and output sensors, some all the

time and others at certain times and processes each

signal. When the PCM notices that an irregularity has

continued for a specified time or longer from when

the irregular signal was initially monitored, the PCM

judges that a malfunction has occurred and will

memorize the malfunction code. The code is then

stored in the memory of the PCM and is accessible

through the data link (diagnostic connector) with the

use of an electronic scan tool or a voltmeter.

CHECK ENGINE/MALFUNCTION

INDICATOR LIGHT

Among the on-board diagnostic items, a check

engine/malfunction indicator light comes on to notify

the driver of a emission control component irregular-

ity. If the irregularity detected returns to normal or the

PCM judges that the component has returned to nor-

mal, the check engine/malfunction indicator light will

be turned off Moreover, if the ignition is turned OFF

and then the engine is restarted, the check

engine/malfunction indicator light will not be turned

on unttl a malfunction is detected.

The check engine/malfunction indicator light will

come on immediately after the ignition switch is

turned ON. The light should stay lit for 5 seconds

and then will go off. This Indicates that the check en-

gine/malfunction indicator lamp is operating nor-

mally. This does not signify a problem with the sys-

tem.

*The check engine/malfunction indicator

lamp will come on when the terminal for the

ignition timing adjustment is shorted to

ground. Therefore, it is not abnormal that the

light comes on even when the terminal for ig-

nition timing is shorted at time of ignition

timing adjustment.

To test the light, perform the following:

1. Turn the ignition switch ON. Inspect the check

engine/malfunction indicator lamp for Illumination.

2. The light should be lit for 5 seconds and then

should go out.

3. If the lamp does not illuminate, check for open

circuit In the harness, blown fuse or blown bulb.

SERVICE PRECAUTIONS

l Before attachrng or detaching the PCM harness

connectors, make sure the ignition switch is OFF and

the negative battery cable is disconnected to avoid

the possibility of damage to the PCM.

l When performing PCM input/output signal di-

agnosis, remove the pin terminal retainer from the

connectors to make it easier to insert tester probes

into the connector.

l When attaching or detaching pin connectors ,

from the PCM, take care not to bend or break any pin

terminals. Check that there are no bends or breaks on

PCM pin terminals before attempting any connec-

tions.

l Before replacing any PCM, perform the PCM

input/output signal diagnosis to make sure the PCM

is functioning properly.

l When measuring supply voltage of PCM-con-

trolled components with a circuit tester, separate 1

tester probe from another. If the 2 tester probes acci-

dentally make contact with each other during mea-

surement, a short circuit WIII result and damage the

PCM.

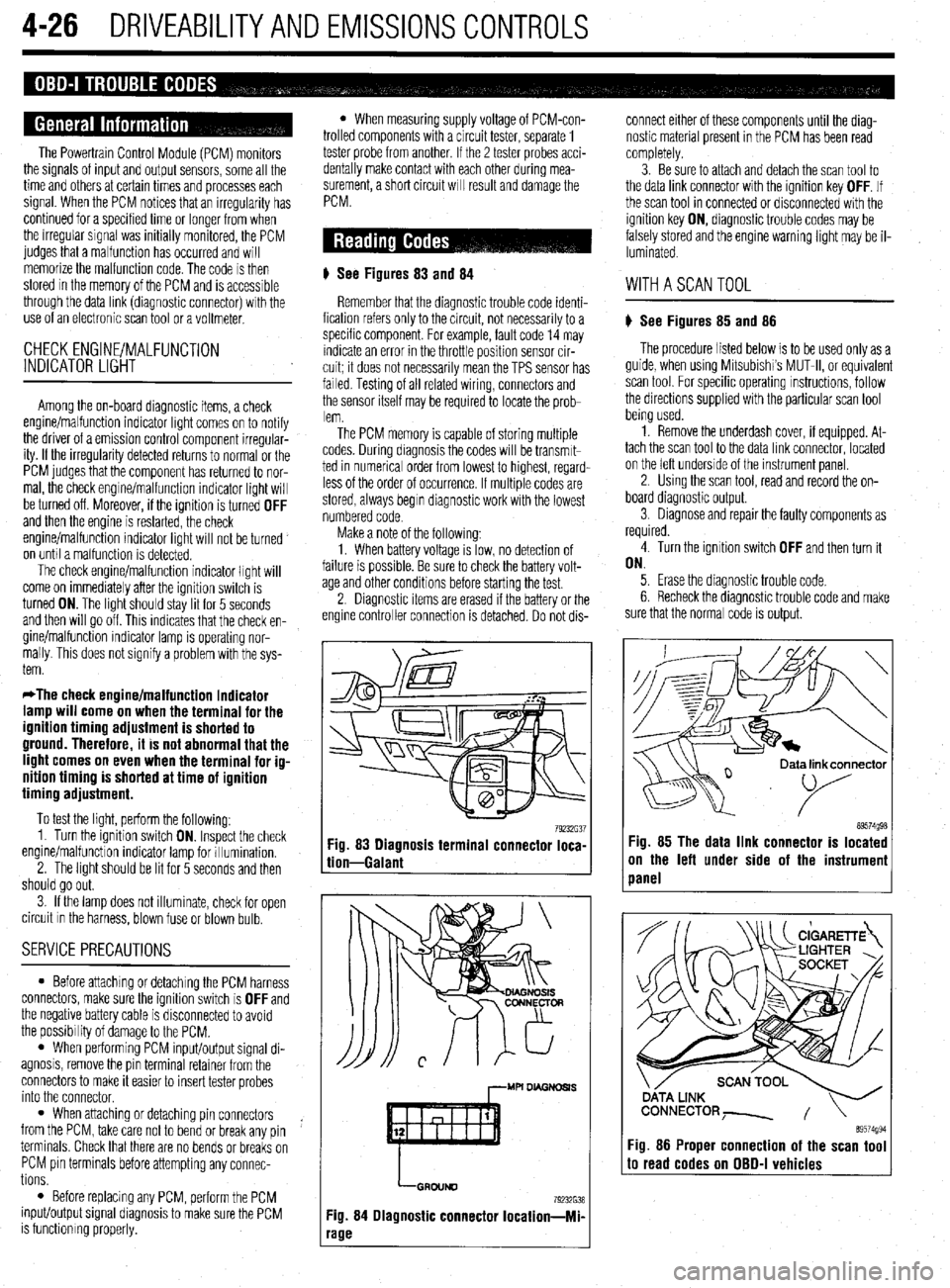

# See Figures 83

and 84

Remember that the diagnostic trouble code identi-

fication refers only to the circuit, not necessarily to a

specific component. For example, fault code 14 may

indicate an error in the throttle position sensor cir-

cuit; it does not necessarily mean the TPS sensor has

failed Testing of all related wiring, connectors and

the sensor itself may be required to locate the prob-

lem.

The PCM memory is capable of storing multiple

codes. During diagnosis the codes will be transmlt-

ted in numerical order from lowest to highest, regard-

less of the order of occurrence. If multiple codes are

stored, always begin diagnostic work with the lowest

numbered code

Make a note of the following:

1. When battery voltage IS low, no detection of

failure is possible. Be sure to check the battery volt-

age and other conditions before starting the test.

2. Diagnostic items are erased if the battery or the

engine controller connection is detached. Do not dis- connect either of these components until the diag-

nostic material present in the PCM has been read

completely.

3. Be sure to attach and detach the scan tool to

the data link connector with the ignition key OFF. If

the scan tool in connected or disconnected with the

ignition key ON, diagnostic trouble codes may be

falsely stored and the engine warning light may be il-

luminated. WITHASCANTOOL

) See Figures 85 and 86

The procedure listed below is to be used only as a

guide, when using Mitsubishi’s MUT-II, or equivalent

scan tool. For specific operating instructions, follow

the directions supplied with the particular scan tool

bemg used.

1. Remove the underdash cover, if equipped. At-

tach the scan tool to the data link connector, located

on the left underside of the instrument panel.

2. Using the scan tool, read and record the on-

board diagnostic output.

3. Diagnose and repair the faulty components as

required

4. Turn the ignition switch OFF and then turn it

ON.

5. Erase the diagnostic trouble code.

6 Recheck the diaanostic trouble code and make

sure that the normal &de is output.

79232G37 89574g98 Fig. 83 Diagnosis terminal connector loca-

tion-Galant Fig. 85 The data link connector is located

on the left under side of the instrumeni

panel

,--MU DL4GNDSl.S

LGRDIJND

79232638

Fig. 84 Diagnostic connector Iocation-Mi-

‘age

ata link connector

89574994 Fig. 86 Proper connection of the scan tool to read codes on OBD-I vehicles

Page 310 of 408

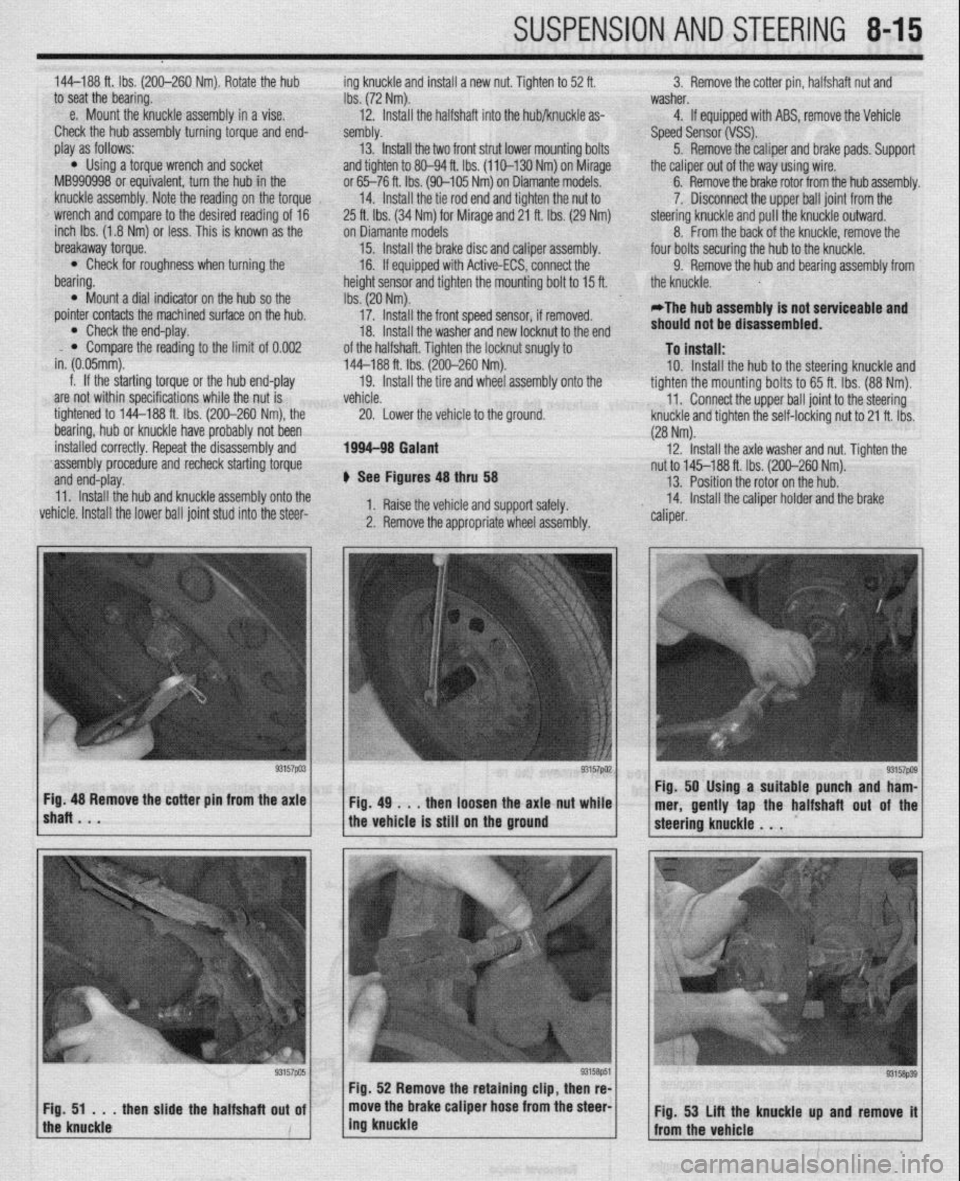

SUSPENSION AND STEERING 845

144-188 ft. Ibs. (200-260 Nm). Rotate the hub ing knuckle and install a new nut. Tighten to 52 ft. 3. Remove the cotter pin, halfshaft nut and

to seat the bearing.

Ibs. (72 Nm). washer.

e. Mount the knuckle assembly in a vise.

12. Install the halfshaft into the hub/knuckle as- 4. If equipped with ABS, remove the Vehicle

Check the hub assembly turning torque and end- sembly.

Speed Sensor (VSS).

play as follows: 13. Install the two front strut lower mounting bolts

5. Remove the caliper and brake pads. Support

l Using a torque wrench and socket

and tighten to 80-94 ft. Ibs. (110-130 Nm) on Mirage

the caliper out of the way using wire.

MB990998 or equivalent, turn the hub in the or 65-76 ft. Ibs. (90-105 Nm) on Diamante models. 6. Remove the brake rotor from the hub assembly.

knuckle assembly. Note the reading on the torque

14. Install the tie rod end and tighten the nut to 7. Disconnect the upper ball joint from the

wrench and compare to the desired reading of 16

25 ft. lbs. (34 Nm) for Mirage and 21 ft. Ibs. (29 Nm) steering knuckle and pull the knuckle outward.

inch Ibs. (1.8 Nm) or less. This is known as the ‘on Diamante models

8. From the back of the knuckle, remove the

breakaway torque.

15. Install the brake disc and caliper assembly. ‘four bolts securing the hub to the knuckle.

l Check for roughness when turning the

16. If equipped with Active-ECS, connect the

9. Remove the hub and bearing assembly from

bearing.

height sensor and tighten the mounting bolt to 15 ft.

the knuckle.

0 Mount a dial indicator on the hub so the

Ibs. (20 Nm).

pointer contacts the machined surface on the hub.

17. Install the front speed sensor, if removed.

*The hub assembly is not serviceable and

l Check the end-play.

18. Install the washer and new locknut to the end should not be disassembled.

l Compare the reading to the limit of 0.002

in. (0.05mm). of the halfshaft. Tighten the locknut snugly to To install: 144-188 ft. Ibs. (200-260 Nm).

f. If the starting torque or the hub end-play

19. Install the tire and wheel assembly onto the 10. Install the hub to the steering knuckle and

are not within specifications while the nut is tighten the mounting bolts to 65 ft. Ibs. (88 Nm).

vehicle.

11.

tightened to 144-188 ft. Ibs. (200-260 Nm), the

Lower the vehicle to the ground. Connect the upper ball joint to the steering

20.

bearing, hub or knuckle have probably not been ‘knuckle and tighten the self-locking nut to 21 ft. Ibs.

(28 Nm).

installed correctly. Repeat the disassembly and 1994-98 Galant 12.

‘assembly procedure and recheck starting torque Install the axle washer and nut. Tighten the

and end-play. nut to 145-188 ft. Ibs. (200-260 Nm).

+ See Figures 48 thru 58 13. Position the rotor on the hub.

11. Install the hub and knuckle assembly onto the

vehicle. Install the lower ball joint stud into the steer- 1. Raise the vehicle and support safely. 14. Install the caliper holder and the brake

2. Remove the appropriate wheel assembly. ” caliper.

lshaRBmV * “57pa3~ ~Fig.4g~..thenloosehtheaxlattut~~;.~ Fig. 48 Remove the cotter pm from the axle Fig. 50 Using a suitable punch and ham-

mer, gently tap the halfshaft out of the

the vehicle is still on the ground

Page 320 of 408

SUSPENSION AND STEERING 8-25

1994-00 Galant and 1997-00 Diamante

4. Remove the retainer bolts and the stabilizer

..- 8, Loosely in”,“,, +I?,, r+&,il;7nr kn- h.~r.l,,d” -..

1. Raise and safely support the vehicle securely he bushing.

the vehicle.

on jackstands.

7er hnr with FI wmnph Remnun (1 Alinn th

2. Remove the wheel and tire assembly.

3. Support the rear axle using a jack or other

suitable device.

4. Remove the trailing arm-to-knuckle connec-

tion,

5. Remove the trailing arm-to-body mounting

n~~““yll-““!~ (1II” fWll”“C LllG llcllllll$j a,,,,. To install:

6. Install the trailing arm and install the trailing

arm-to-body mounting through-bolt. Tighten the bolt

to 99-114 ft. Ibs. (137-157 Nm).

7. Install the trailing arm-to-knuckle connection. Dar brackets. Hemove t

5. Hold the stabilL_. __. . . _ . .._..“... ..I . .._._

the self-locking nut.

6. Once the stabilizer bar nut is removed, re-

move the joint cups and stabilizer rubber bushing.

7. Hold the stabilizer link with a wrench and re-

move the self-locking nuts. Remove the stabilizer

link.

8. Lower the jack supporting the rear axle

in a slight gap between the rear sus-

? body of the vehicle.

! the stabilizer bar.

IL_ L__ I__ _)----- .-- .-J JAI.... slightly. Mainta

pension and thf

9. Remow

10. Inspect LIIB uar 101 uamage, wear ana aereno-

ration and replace as required.

-Fe c--a-...

1 IIIJMII UK 3La”III‘w “ill “lduKm “II

“. , ,,LY,, ,,ie side locating markings on the stabi-

lizer bar, so that the marking on the bar extends ap-

proximately 0.39 inches (1Omm) from the outer edge

of the mounting bracket, on both sides.

10. With the stabilizer bar properly aligned,

tighten the mounting bracket bolts to 28 ft. Ibs. (39

Nm).

11. Connect the stabilizer links to the damper fork

andihe stabilizer bar. Tighten the locking nuts to 28

ft. Ibs. (38 Nm).

12. Lower the vehicle and connect the negative

8.. Ia

mery came.

Tighten the bolt to 85-99 ft. Ibs. (118-137 Nm).

nemove me axle suppon

9. Install the wheel and tire

10. Lower the vehicle. aewce.

assembly.

I 0 Insran: 11, Install the stabilizer bar into the vehicle. Raise

the rear axle and suspension into place.

12. Install the stabilizer link into the stabilizer ba

Ir

ADJUSTMENT anfi indc4ll 33 ft. Ibs. (45 Nm).

13. Install the ioint __-_ _.._ __

1. Raise and safely support the vehicle securely the link. Ins’

..I.,

Mlhiln hnlrii, tall a rkW self~locking n

lll~llG llUlulng the stabi” ” ’ ’ ’

wrench, tighten the self,

of the stabilizer link is v

ihe hub and bearing assembly.

5. Support the rear axle using a jack or other

suitable device.

6. Remove the lower shock absorber-to-trailing

arm connection. ocking nut. Tighten the nut to

ClrnC 2nd ?$bilizer rubber to

ut onto the link.

nzer nnK oall studs with a

-locking nut so the protrusion

within 0.354-0.433 in.

I stabilizer bar bushings,

>+nn thn hnk In -I A u (9-llmm).

14. Install the cente

brackets and bolts. Tiqt Mirage

*Never disassemble the rear hub bearing.

The wheel bearing is serviced by replace-

ment of the hub.

1. Raise and safely support the vehicle.

2. Remove the rear wheel.

3. Remove the caliper and brake disc of brake 1992-96 biamante

on IacKsranos.

2. Remove the wheel and tire assembly

3, Remove thn hralm rntnr 4. Remove1

7. Remove the stabilizer bar link-to-trailing arm

connection.

8. Remove the tie rod end-to-trailing arm con-

nection.

9. Remove the lower control arm-to-trailing arm

connection.

10. Remove the trailing arm-to-body mounting

through-bolt and remove the trailing arm. Nm).

15. Install the parking

sensor installation bolt.

, , I oraxe cat * ale ar

member bracket and tighten

i Nm). Tighten the crossmem-

A to 94 ft. Ibs. (130 Nm). 16. Install the cross

the bolt to 61 ft. Ibs. (8!

ber bracket mounting nl

17. Install the rubbe

locking nuts onto the cro:

the nuts to 80-94 fl. Ibs. (

18. Lower the vehicle. id rear speed drum.

4. Remove the dust cab and tighten the flange ll”, *lb+ to 130 ft. Ibs. (180 Nm).

5. Using a dial indicator, measure wheel bear-

!r insulators and new seif-

ismemoer ’ brackets. Tighten

[110-130 Nm). ing end-play. The maximum limit for end-play is

o.oc-- ‘^ -- rzu mcnes (u.usmm).

arol

tanc

sisk 6. Using a spring scale and a rope wrapped

md the bolts, measure the rotary sliding resis-

e of the bearing/hub. The maximum limit for re-

mce is 4 Ibs. (19 N).

7. If any of the readings exceed the specifica-

To install:

11. Install the trailing arm and install the trailina Diamante and 1994-98 Gal&i

t tions, replacement of the hub is required.

8. Install the dust cap.

9. Install the brake disc and caliper, or brake

negative battery ( sble.

;“I,-.

I support the vbhlblG.

stabilizer links by removing

Alizer bar mounting brackets

from the vehicle.

lonents for wear or damage,

ded. drum.

10. Install the rear wheel assembly and lower the

vehicle to the floor.

*

1990-93 Galant

*Vehicles equipped with rear disc brakes

use a sealed hub and bearing assembly,

which requires no adjustment. Drum brake

models are

adjusted using the following pro- arm-to-body mounting through-bolt. Tighten the bolt

to 101-116 ft. Ibs. (140-160 Nm). ) See Figure 72

12. Install the trailing arm-to-lower control arm

1. Disconnect the I

connection. Tighten the bolt to 101-116 ft. Ibs.

(140-160 Nm). 2. Raise and safely

13. Install the tie rod end-to-trailing arm connec- 3. Disconnect the I

tion. Tighten the nut to 21 ft. Ibs. (29 Nm). the self-locking nuts.

14. Install the stabilizer bar link-to-trailing arm 4. Remove the stat

connection. Tighten the nut to 29 ft. Ibs. (40 Nm). and bushings.

15. Install the lower shock absorber-to-trailing

5. Remove the bar

arm connection. Tighten the bolt to 65 ft. Ibs. (90 6. Inspect all comr

. and replace parts as nee

Nrn).

16. Remove the axle support device.

17. Install the hub and bkaring assembly,

18. Install the brake rotor.

19. Install the wheel and tire assembly.

20. Lower the vehicle.

REMOVALANDINSTALLATION

1990-93 Gaiant

1. Raise and support the vehicle safely.

2. Place a jack under the rear axle and suspen- To install:

7 InstA the dnhili cedure. ._._ . . .._ -.--.. lzer bar into the vehicle.

1. Raise the vehicle and support it safely.

2. Remove the wheel and tire assemblies.

3. If equipped with rear disc brakes, remove the

caliper assembly.

4. Remove the grease cap and the hub nut.

5. Tighten the wheel bearing nut to 20 ft. Ibs. (27

Nm) while rotatir ” ”

6. Back off th

load and then tighten it to 7 ft. Ibs. (10 Nm).

7. Install the nut lock and a new cotter pin.

8. If brake caliper was removed, reinstall.

9. Install the wheel and lower the vehicle.

Diamante and lQQ44 Galant 10 tne mum/hub.

ie adjusting nut to remove the pre-

Sian assembly.

3. Remove the self-locking nuts and crossmem-

ber bracket.

93158P61 Fig. 72 Remove the self-locking nuts from Measure the wheel bearing end-play using a dial

the stabilizer bar link indicator. The end-play should be 0.002 inches

a (0.05mm) or less with the wheel bearing locknut

Page 322 of 408

8-26 SUSPENSION AND STEERING

torqued to specifications. The wheel bearings are

sealed units and are not adjustable. If defective, re-

placement is the only option.

REMOVAL &INSTALLATION

Mirage

7996-92 MODELS

1. Raise the vehicle and support safely.

2. Remove the tire and wheel assembly.

3. If equipped with rear disc brakes, remove the

caliper from the disc and remove the brake disc.

4. Remove the dust cap and bearing nut. Do not

use an air gun to remove the nut.

5. Remove the outer wheel bearing.

6. Remove the drum and/or axle hub with the

inner wheel bearing and the grease seal.

7. Remove the grease seal and remove the inner

bearing.

To install: 8. Lubricate the inner bearing and install to the

drum or hub.

9. Install a new grease seal.

10. To determine if the self-locking nut is

reusable:

a. Screw in the self-locking nut until about

0.07-0.11 in. (2-3mm) of thread is visible under

the nut.

b. Measure the torque required to turn the

self-locking nut counterclockwise.

c. The lowest allowable torque is 48 inch Ibs.

(6 Nm). If the measured torque is less than the

specification, replace the nut.

11. Install the drum and/or hub to the vehicle.

12. Lubricate and install the outer wheel bearing

to the spindle.

13. Tighten the self-locking nut to 108-145 ft.

Ibs. (150-200 Nm).

14. Set up a dial indicator and measure the end-

play while moving the hub or drum in and out. If the

endplay exceeds 0.008 in. (0.002mm) retorque the

nut. If still beyond the limit, replace the bearings.

15. Install the grease cap and wheel assembly.

7993-60 MODELS

*Never disassemble the rear hub bearing.

The wheel bearing is serviced by replace-

ment of the hub.

1. If equipped with ABS, remove the wheel

speed sensor.

2. Raise and safely support the vehicle.

3. Remove the rear wheel.

4. Remove the caliper and brake disc or brake

drum.

5. Remove the dust cap and flange nut.

6. Remove the rear hub assembly.

To install: 7. Install the rear hub assembly using a new

flange nut. Tighten the flange nut to 130 ft. Ibs. (180

Nm).

8. install the dust cap.

9. Install the wheel speed sensor if removed.

The air gap should be 0.012-0.035 in. (0.3-0.9mm).

10. Install the brake disc and caliper, or brake

drum.

11. Install the rear wheel assembly and lower the

vehicle to the floor.

1990-93 Galant

DRUM BRAKE VEHICLES

1. Raise the vehicle and support it safely.

2. Remove the wheel and tire assemblies.

3. Remove the grease cap and the hub nut.

4. Remove the brake drum. The outer bearing

will fall out while the drum is coming off. Do not drop

it. Remove the hub and rotor assembly.

5. Pry out and discard the oil seal.

6. Remove the inner bearing.

*Check the bearing races. If any scoring,

heat checking or damage is noted, they

should be replaced. When bearing or races

need replacement, replace them as a set.

7. If the bearings and races are to be replaced,

drive out the race with a brass drift.

To install: 8. Before installing new races, coat them with

wheel bearing grease. Drive into place with proper

size driver. Make sure they are fully seated.

9. Thoroughly pack the bearings and lubricate

the hubs with wheel bearing grease. Install the inner

bearing and coat the lip and rim of the grease seal

with grease. Drive the seal into place with a seal dri-

ver.

10. Install the drum assembly on the axle.

11, Lubricate and install the outer wheel bearing,

washer and nut. To properly adjust the wheel bearing

preload:

a. Tighten the wheel bearing nut to 20 ft. Ibs.

(27 Nm) while rotating the drum.

b. Back off the adjusting nut to remove the

preload, then tighten it to 7 ft. Ibs. (10 Nm).

c. Install the nut lock and a new cotter pin.

12. Install the wheel and lower the vehicle.

O/SC BRAKE VEHICLES

1. Raise the vehicle and support safely.

2. Remove the tire and wheel assembly.

3. Remove the bolt(s) holding the speed sensor

bracket to the knuckle and remove the assembly from

the vehicle.

The speed sensor has a pole piece projecting

from it. This exposed tip must be protected

from impact or scratches. Do not allow the

oole oiece to contact the toothed wheel dur-

in0 removal or installation.

4. Remove the caliper from the brake disc and

suspend with a wire.

5. Remove the brake rotor.

6. Remove the grease cap, locking nut and

tongued washer.

7. Remove the rear hub and bearing assembly.

*The rear hub assembly can not be disas-

sembled. If bearing replacement is required,

replace the assembly as a unit.

8. If replacing the hub assembly, remove the

two bolts securing the speed sensor ring to the hub.

To install: 9. Install the speed sensor to the hub and bear-

ing assembly. Tighten the mounting bolts to 8 ft. Ibs.

(11 Nm). 10. Install the hub and bearing assembly to the

axle shaft.

11, Install the tongued washer and a new locking

nut. Tighten the locknut to 144-188 ft. Ibs. (200-260

Nm). Once the locknut has been properly torqued,

crimp the nut flange over the slot in the spindle, and

install the grease cap.

12. Install the brake caliper and rotor.

13. Install the speed sensor and tighten the

mounting bolt to 8 ft. Ibs. (11 Nm).

14. Install the tire and wheel assembly.

Be sure to pump the brake pedal until it’s

firm, before moving vehicle.

1994-00 Galant

DRUM BRAKE VEHICLES

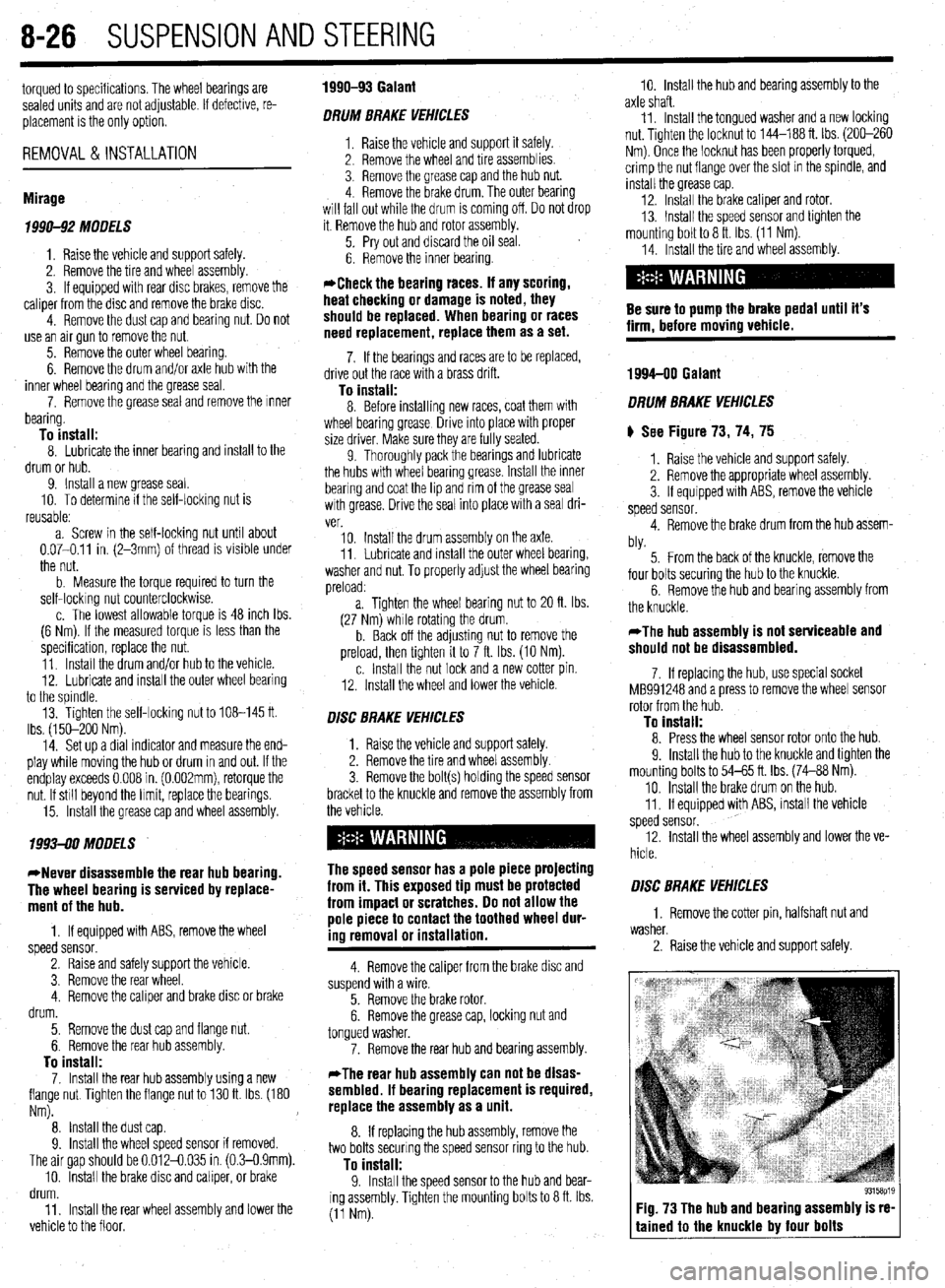

) See Figure 73, 74, 75

1. Raise the vehicle and support safely.

2. Remove the appropriate wheel assembly.

3. If equipped with ABS, remove the vehicle

speed sensor.

4. Remove the brake drum from the hub assem-

bly.

5. From the back of the knuckle, remove the

four bolts securing the hub to the knuckle.

6. Remove the hub and bearing assembly from

the knuckle.

*The hub assembly is not serviceable and

should not be disassembled.

7. If replacing the hub, use special socket

MB991248 and a press to remove the wheel sensor

rotor from the hub.

To install: 8. Press the wheel sensor rotor onto the hub.

9. Install the hub to the knuckle and tighten the

mounting bolts to 54-65 ft. Ibs. (74-88 Nm).

10. Install the brake drum on the hub.

11. If equipped with ABS, install the vehicle

speed sensor.

12. Install the wheel assembly and lower the ve-

hicle.

O/SC BRAKE VEHICLES

1. Remove the cotter pin, halfshaft nut and

washer.

2. Raise the vehicle and support safely.

Fig. 73 The hub and bearing assembly is re-

tained to the knuckle by four bolts