tire type MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 20 of 408

GENERALINFORMATIONAND MAINTENANCE l-21

IWSIZXJ FM. 83 A hose clamn that is taa tiaht can

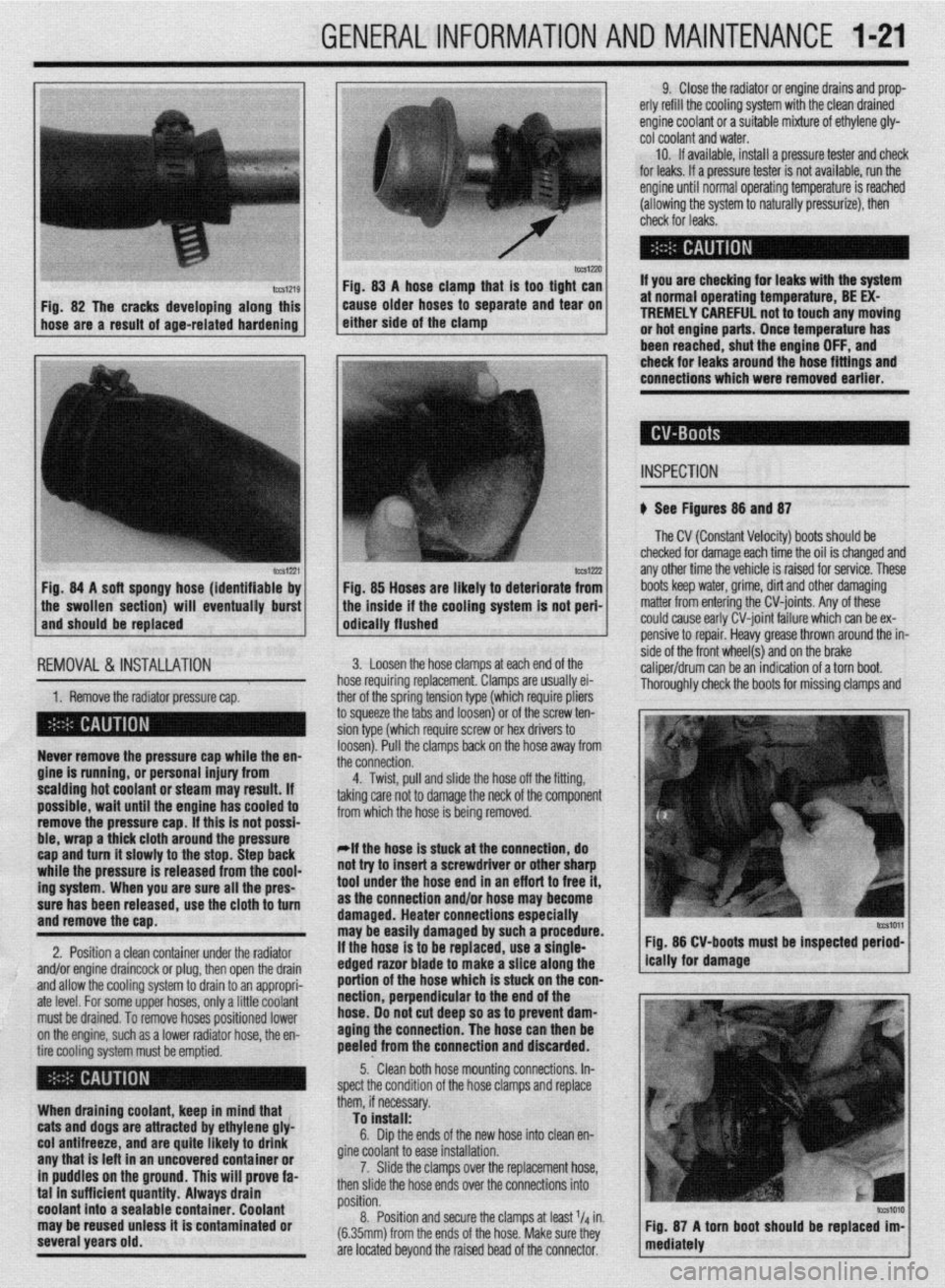

Fig. 82 The cracks developing along this

hose are a result of age-related hardening caise older hoses td separate and ‘iear on

either side of the clamp

lCCS1221 Fig. 84 A soft spongy hose (identifiable by

1 the swollen section) will eventually burst

and should be replaced

IEMOVAL &,INSTALLATION '

1. Remove the radiator pressure cap. her of the sorina tension tvoe (which reouire oliers

3 squeeze the 6bs and loosenj or of the’screw ten-

ion type (which require screw or hex drivers to

oosen). Pull the clamps back on the hose away from

he connection. Never remove the pressure cap while the en-

gine is running, or personal injury from

scalding hot coolant or steam may result. If

possible, wait until the engine has cooled to

remove the pressure cap. If this is not possi-

ble, wrap a thick cloth around the pressure

cap and turn it slowly to the stop. Step back

while the pressure is released from the cool-

ing system. When you are sure all the pres-

sure has been released, use the cloth to turn

and remove the cao.

2. Position a clean container under the radiator

and/or engine draincock or plug, then open the drain

and allow the cooling system to drain to an appropri-

ate level. For some upper hoses, only a little coolant

must be drained. To remove hoses positioned lower

on the engine, such as a lower radiator hose, the en-

tire cooling system must be emptied.

When draining coolant, keep in mind that

cats and dogs are attracted by ethylene gly-

col antifreeze, and are quite likely to drink

any that is left in an uncovered container or

in puddles on the ground. This will prove fa-

tal in sufficient quantity. Always drain

coolant into a sealable container. Coolant

may be reused unless it is contaminated or

several years old. 9. Close the radiator or engine drains and prop-

erly refill the cooling system with the clean drained

engine coolant or a suitable mixture of ethylene gly-

cot coolant and water.

10. If available, install a pressure tester and check

for leaks. If a pressure tester is not available, run the

engine until normal operating temperature is reached

(allowing the system to naturally pressurize), then

check for leaks.

If you are checking for leaks with the system

at normal operating temperature, BE EX-

TREMELY CAREFUL not to touch any moving

or hot engine parts. Once temperature has

been reached. shut the enaine OFF. and

Fig. 85 Hoses are likely to deteriorate from

the inside if the cooling system is not peri-

odically flushed check for leaks around the-hose fittings and

connections which were removed earlier.

INSPECTION

b See Figures 88 and 87

The CV (Constant Velocity) boots should be

checked for damage each time the oil is changed and

any other time the vehicle is raised for service. These

boots keep water, grime, dirt and other damaging

matter from entering the CV-joints. Any of these

could cause early CV-joint failure which can be ex-

pensive to repair. Heavy grease thrown around the in-

side of the front wheel(s) and on the brake

caliper/drum can be an indication of a torn boot.

Thorouahlv check the boots for missina clamos and 3. Loosen the hose clamps at each end of the

rose requiring replacement. Clamps are usually ei-

4. Twist, pull and slide the hose off the fitting,

sking care not to damage the neck of the component

rom which the hose is being removed.

*If the hose is stuck at the connection, do

lot try to insert a screwdriver or other sharp

ool under the hose end in an eff art to free it,

IS the connection and/or hose may become

lamaged. Heater connections especially

nay be easily damaged by such a procedure.

f the hose is to be replaced, use a single-

!dged razor blade to make a slice along the

lortion of the hose which is stuck on the con-

section, perpendicular to the end of the

lose. 00 not cut deep so as to prevent dam-

aging the connection. The hose can then be

keeled from the connection and discarded. Fig. 86 CV-boots must be inspected period-

5.. Clean both hose mounting connections. In-

,pect the condition of the hose clamps and replace

hem, if necessary.

To install:

6. Dip the ends of the new hose into clean en-

fine coolant to ease installation.

7. Slide the clamps over the replacement hose,

hen slide the hose ends over the connections into

rosition.

8. Position and secure the clamps at least l/d in.

6.35mm) from the ends of the hose. Make sure they

Ire located beyond the raised bead of the connector.

Page 29 of 408

.

l-30 GENERAL'INFORMATIONAND MAINTENANCE

n Pylon@ inserts, the clip

be removed prior to siidi then the insert can be re

After installing the replacement

strip and pull up while twisting counterclockwise.

The backing strip will snap out of the retaining tab.

Do this for the remaining tabs until the refill is free of

the blade. The length of these refills is molded into

the end and they should be replaced with identical

types. cate the front end is out of alignment or that the tires

are out of balance.

TIRE ROTATION

# See Figures 137 and 138

Tires must be rotated periodically to equalize wear

patterns that vary with a tire’s position on the vehicle.

Tires will also wear in an uneven way as the front

1 Fin 1% Tha Trinlarlna@

cle might have any kind. Aftermarket blades and arms

rarely use the exact same type blade or refill as the

original equipment. Here are some typiel aftermarket

blades; not all may be available for your vehicle:

The Anco@ type uses a release button that is

pushed down to allow the refill to slide out of the

yoke jaws. The new refill slides back into the frame

,

and locks in place.

Some Trico@ refills are removed by locating where

the metal backing strip or the refill is wider. Insert a

small screwdriver blade between the frame and metal

backing strip. Press down to release the refill from

the retaining tab.

Other types of Trico@’ refills have two metal tabs

which are unlocked by squeezing them together. The

rubber filler can then be withdrawn from the frame

iaws. A new refill is installed bv insertina the refill lowed to touch the olass steering/suspension system wears to the point where

the alianment should be reset.

# See Figure 138

Common sense and good driving habits will af-

ford maximum tire life. Fast starts, sudden stops

and hard cornering are hard on tires and will

shorten their useful life span. Make sure that you

don’t overload the vehicle or run with incorrect

pressure in the tires. Both of these practices will in-

crease tread wear.

*For optimum tire life, keep the fires prop

eriy inflated, rotate them often and have the

wheel alignment checked periodically.

Inspect your tires frequently. Be especially care-

ful to watch for bubbles in the tread or sidewall,

deep cuts or underinflation. Replace any tires with

bubbles in the sidewall. If cuts are so deep that they

penetrate to the cords, discard the tire. Any cut in

the sidewall of a radial tire renders it unsafe. Also

look for uneven tread wear patterns that may indi- Rotating the tires will ensure maximum life for the

tires as a set, so you will not have to discard a tire

early due to wear on only part of the tread. Regular

DIRECTIONAL TIRES DIRECTIONAL TIRES

jnto the front frame jaws and &ding it rearward to

engage the remaining frame jaws. There are usually

four jaws; be certain when installing that the refill is

engaged in all of them. At the end of its travel, the

tabs will lock into place on the front jaws of the wiper

blade frame.

Another type of refill is made from polycarbonate.

The refill has a simple locking device at one end

which flexes downward out of the groove into which

the jaws of the holder fit, allowing easy release. By

sliding the new refill through all the jaws and push-

ing through the slight resistance when it reaches the

end of its travel, the refill will lock into position.

To replace the Tridon@ refill, it is necessary to re-

move the wiper blade. This refill has a plastic backing

strip with a notch about 1 in. (25mm) from the end.

Hold the blade (frame) on a hard surface so that the

frame is tightly bowed. Grip the tip of the backing Fig. 138 A label with information concern-

ing the tires is typically located on one of

the door pillars

tion”

Page 30 of 408

GENERALINFORMATIONAND MAlNTENANdE 1-31

When rotating “unidirectional tires,” make sure

that they always roll in the same direction. This

means that a tire used on the left side of the vehicle

must not be switched to the right side and vice-versa.

Such tires should only be rotated front-to-rear or

rear-to-front, while always remaining on the same

side of the vehicle. These tires are marked on the

sidewall as to the direction of rotation; observe the

marks when reinstalling the tire(s).

Some styled or “mag” wheels may have different

offsets front to rear. In these cases, the rear wheels

must not be used up front and vice-versa. Further-

more, if these wheels are equipped with unidirectional

tires, they cannot be rotated unless the tire is re-

mounted for the proper direction of rotation.

*The compact or space-saver spare is

strictly for emergency use. it must never be

included in the tire rotation or placed on the

vehicle for everyday use. check the installed tire for any sign of interference

with the body or suspension while the vehicle is stop-

ping, turning sharply or heavily loaded.

Snow Tires

Good radial tires can produce a big advantage in

slippery weather, but in snow, a street radial tire does

not have sufficient tread to provide traction and con-

trol. The small grooves of a street tire quickly pack

with snow and the tire behaves like a billiard ball on a

marble floor, The more open, chunky tread of a snow

tire will self-clean as the tire turns, providing much

better grip on snowy surfaces.

To satisfy municipalities requiring snow tires dur-

ing weather emergencies, most snow tires carry either

an M + S designation after the tire size stamped on

the sidewall, or the designation “all-season.” In gen-

eral, no change in tire size is necessary when buying

snow tires.

Most manufacturers stronqlv recommend the use styled wheels, see if inexpensive steel

wheels are available, Although the look of

the vehicle will change, the expensive

wheels will be protected from salt, curb hits

and pothole damage.

TIRESTORAGE

If they are mounted on wheels, store the tires at

proper inflation pressure. All tires should be kept in a

cool, dry place. If they are stored in the garage or

basement, do not let them stand on a concrete floor;

set them on strips of wood, a mat or a large stack of

newspaper. Keeping them away from direct moisture

is of paramount importance. Tires should not be

stored upright, but in a flat position.

INFLATION & INSPECTION

b See Figures 140 thru 147

TIRE DESIGN

p See Figure 139

for maximum satisfaction, tires should be used in

sets of four. Mixing of different types (radial, bias-

belted, fiberglass belted) must be avoided. In most

cases, the vehicle manufacturer has designated a

type of tire on which the vehicle will perform best.

Your first choice when replacing tires should be to

use the same type of tire that the manufacturer rec-

ommends.

When radial tires are used, tire sizes and wheel di-

ameters should be selected to maintain ground clear-

ante and tire load caoacitv eauivalent to the oriainal

specified tire. Radial tiresshould always be used in

sets of four. of 4 snow tires on their

lehicies for reasons of stabil-

ity. If snow tires are fitter

1 only to the drive wheels, the

opposite end of the vehil cle may become very unsta-

ble when braking or turn

ring on slippery surfaces.

This instability can lead to unpleasant endings if the

A*:,,“- r-..l, ^_.. ..& ^_^^, &I.

UIIVU MII I LUUII~~MLL iue slide in time.

Note that snow tires, whether 2 or 4, will affect ve-

hicle handling in all non-snow situations. The stiffer,

heavier snow tires will noticeably change the turning

and braking characteristics of the vehicle. Once the

snow tires are installed, you must re-learn the behav-

ior of the vehicle and drive accordingly.

*Consider buying extra wheels on which to

mount the snow tires. Once done, the “snow

iheeis” can be installed and removed as

needed. This eliminates the potential

dam- age to tires or wheels from seasonal removal

and installation. Even if your vehicle has

lb The importance of proper tire inflation cannot be

overemphasized. A tire employs air as part of its

structure. It is designed around the supporting

strength of the air at a specified pressure. For this

reason, improper inflation drastically reduces the

tire’s ability to perform as intended. A tire will lose

some air in day-to-day use; having to add a few

pounds of air periodically is not necessarily a sign of

a leaking tire.

Two items should be a permanent fixture in every

glove compartment: an accurate tire pressure gauge

and a tread depth gauge. Check the tire pressure (in-

eluding the spare) regularly with a pocket type gauge.

Too often, the gauge on the end of the air hose at

vnr rr corner narane is not accurate because it suffers

~rs check tire oressure when the

Radial tires should never be used on only the

XI I._.

‘-’ --“‘“’ J s too much abuse. Alwa!

tires are cold, as pressure increases with tempera-

ture. If you must move the vehicle to check the tire

front axle.

When selecting tires, pay attention to the original

size as marked on the tire. Most tires are described

using an industry size code sometimes referred to as

P-Metric. This allows the exact identification of the

tire specifications, regardless of the manufacturer. If

selecting a different tire size or brand, remember to

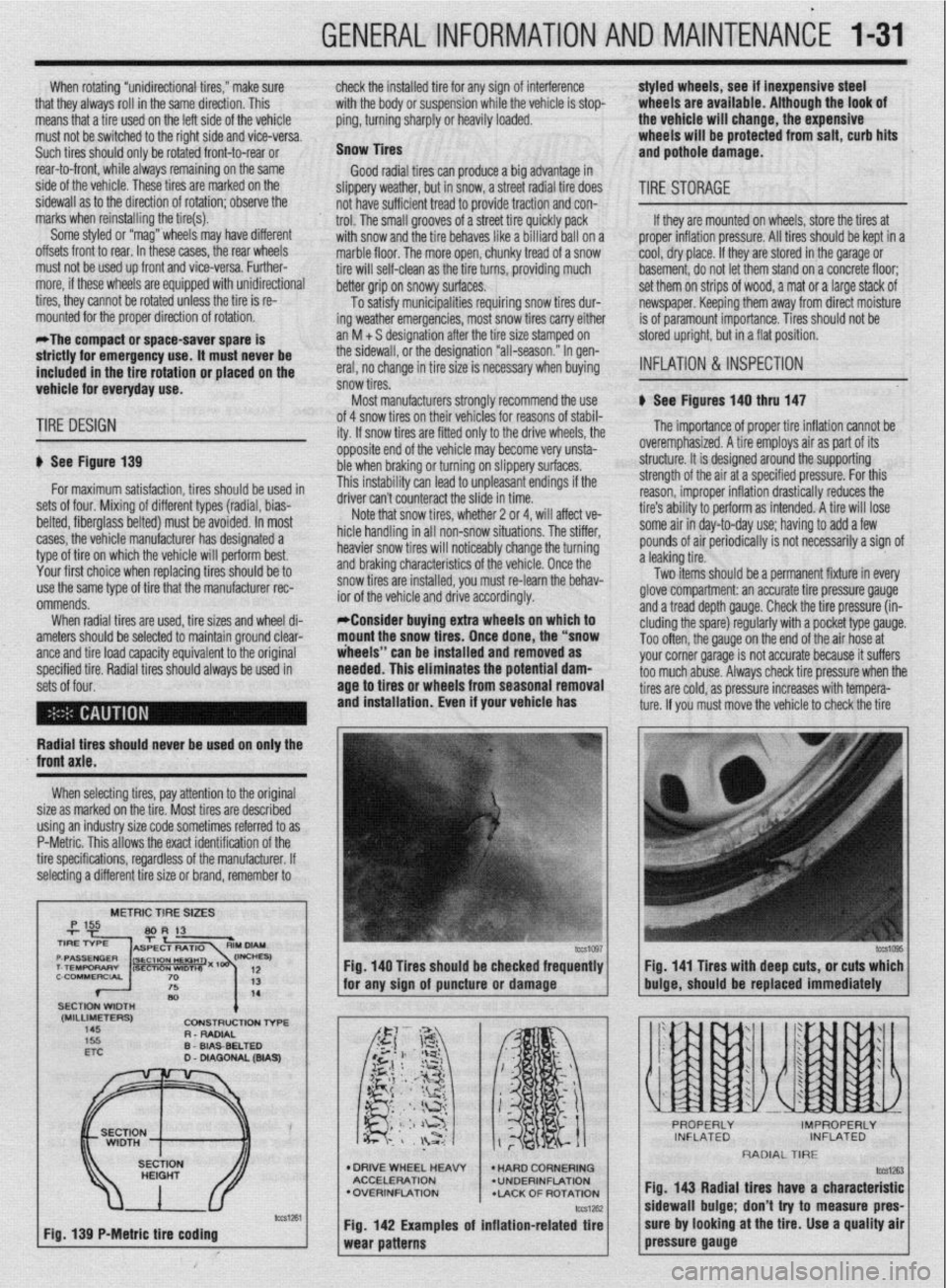

METRIC TIRE SIZES

(MILLIMETERS)

145 CDNStRUCtlDN l-6-E

R - RADIAL

D

WA9

Fig. 139 P-Metric tire coding Fig. 140 Tires should be checked frequently

I I Fig. 141 Tires with deep cuts, or cuts which

for any sion of auncture or damaoe

buioe, should be replaced immediately

l DRIVE WHEEL HEAW

ACCELERATION

l OVERINFLATION

*LACK OF ROTATION

Fig. 142 Examples of inflation-related tire

RADIAL TIRE

fig. 143 Radial tires have a characteristic

sidewall bulge; don’t try to measure pres-

sure by looking at the tire. Use a quality air

pressure gauge

Page 31 of 408

.

1-32 GENERALINFORMATIONAND MAINTENANCE

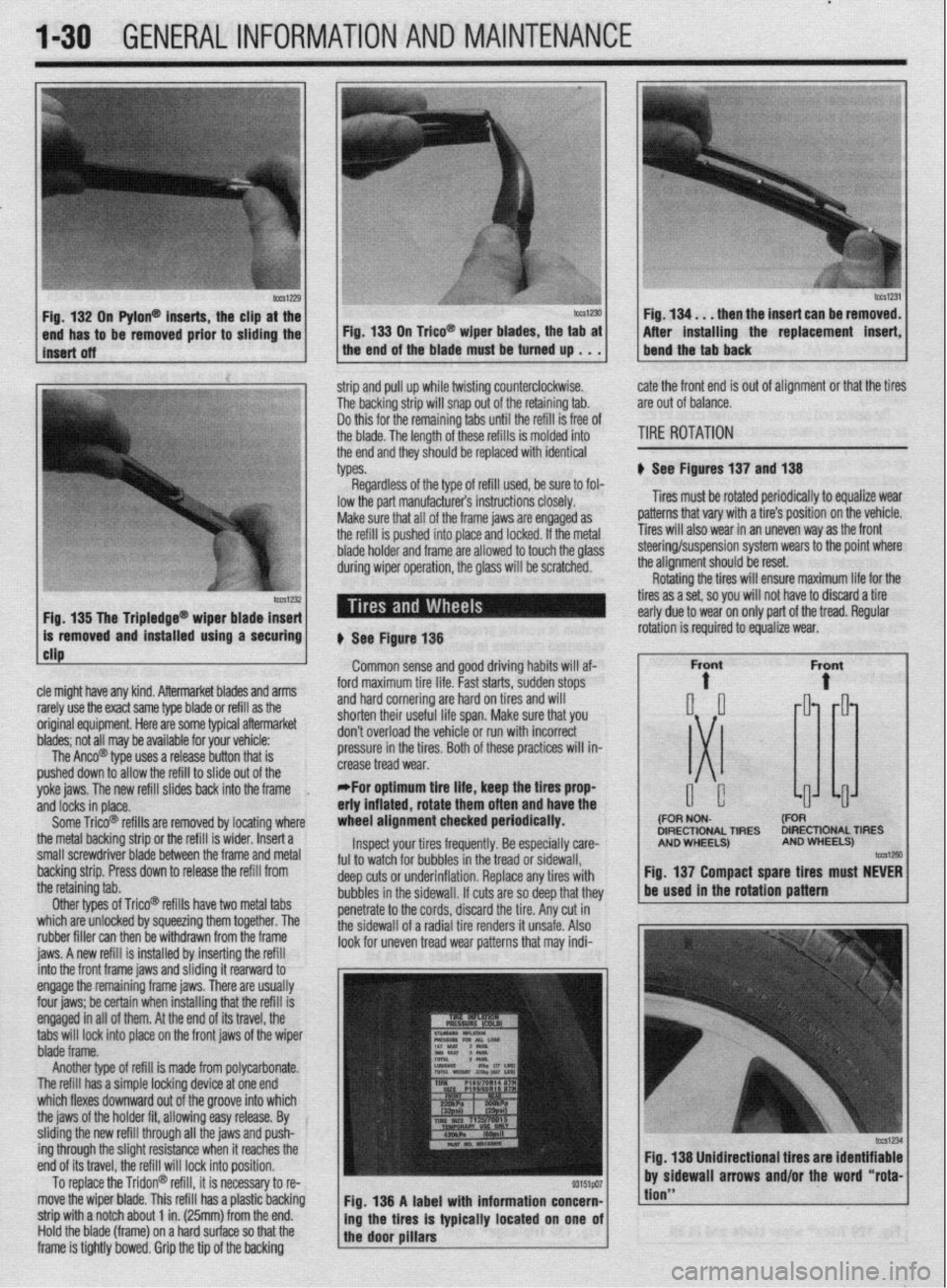

CONDITION

EFFECT

CAUSE

CORRECTION UNDER-INFLATION

EXCESSIVE SPEED’ WORN OR OUT-

OF-ALIGNMENT

ADJUST PRESSURE TO

SPECIFICATIONS WHEN

TIRES ARE COOL

ROTATE TIRES

/ BALANCE WHEELS INSPECT SUSPENSION

HAVE TIRE INSPECTED FOR FURTHER USE.

lCCSi267 ig. 144 Common tire wear patterns and causes

1~~~1265 Fig. 145 Tread wear indicators will appear

when the tire is worn

inflation, do not drive more than a mile before check-

ing. A cold tire is generally one that has not been dri-

ven for more than three hours.

A plate or sticker is normally provided somewhere

in the vehicle (door post, hood, tailgate or trunk lid)

which shows the proper pressure for the tires. Never

counteract excessive pressure build-up by bleeding

off air pressure (letting some air out). This will cause

the tire to run hotter and wear quicker.

Never exceed the maximum tire pressure

embossed on the tire! This is the pressure to

be used when the tire is at maximum load-

ing, but it is rarely the correct pressure for

everyday driving. Consult the owner’s man-

ual or the tire pressure sticker for the correct

tire pressure.

Once you’ve maintained the correct tire pressures

for several weeks, you’ll be familiar with the vehicle’s

braking and handling personality. Slight adjustments

in tire pressures can fine-tune these characteristics,

1~~~1264 Fig. 146 Accurate tread depth indicators are

inexuensive and handv

Fig. 147 A penny works well for a quick

check of tread death

but never change the cold pressure specification by

more than 2 psi. A slightly softer tire pressure will

give a softer ride but also yield lower fuel mileage. A

slightly harder tire will give crisper dry road handling

but can cause skidding on wet surfaces. Unless

you’re fully attuned to the vehicle, stick to the recom-

mended inflation pressures.

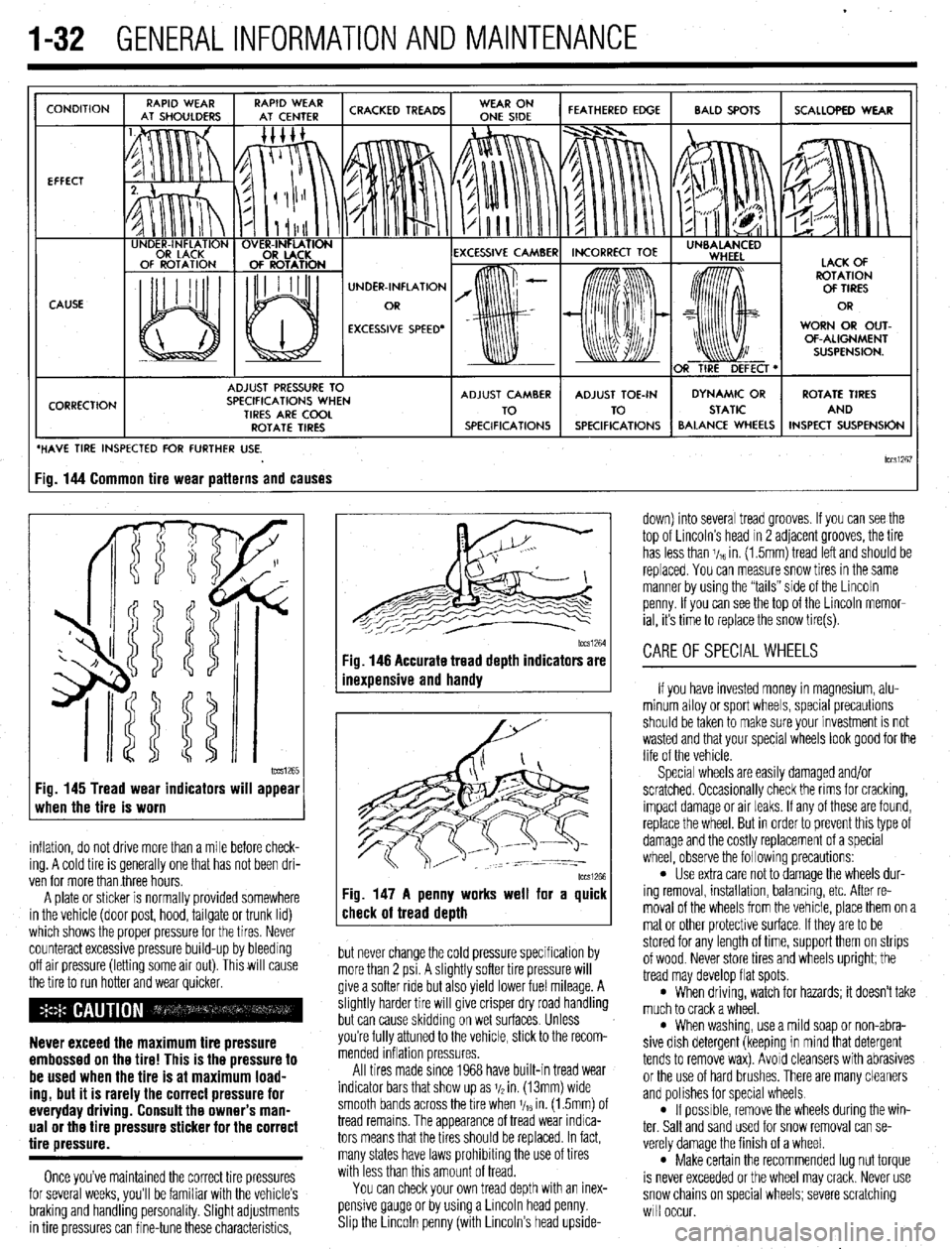

All tires made since 1968 have built-in tread wear

indicator bars that show up as j/2 in. (13mm) wide

smooth bands across the bre when V,~ in. (1.5mm) of

tread remains. The appearance of tread wear indica-

tors means that the tires should be replaced. In fact,

many states have laws prohibiting the use of tires

with less than this amount of tread.

You can check your own tread depth with an inex-

pensive gauge or by using a Lincoln head penny.

Shp the Lrncoln penny (with Lincoln’s head upside- down) into several tread grooves. If you can see the

top of Lincoln’s head in 2 adjacent grooves, the tire

has less than V,~ in. (1.5mm) tread left and should be

replaced. You can measure snow tires in the same

manner by using the “tails” side of the Lincoln

penny. If you can see the top of the Lincoln memor-

ial, its time to replace the snow tire(s).

CAREOFSPECIALWHEELS

If you have invested money in magnesium, alu-

minum alloy or sport wheels, special precautions

should be taken to make sure your investment is not

wasted and that your special wheels look good for the

life of the vehicle.

Special wheels are easily damaged and/or

scratched. Occasionally check the rims for cracking,

impact damage or air leaks. If any of these are found,

replace the wheel. But in order to prevent this type of

damage and the costly replacement of a special

wheel, observe the following precautions:

l Use extra care not to damage the wheels dur-

ing removal, installation, balancing, etc. After re-

moval of the wheels from the vehicle, place them on a

mat or other protective surface. If they are to be

stored for any length of time, support them on strips

of wood. Never store tires and wheels upright; the

tread may develop flat spots.

l When driving, watch for hazards; it doesn’t take

much to crack a wheel.

l When washing, use a mild soap or non-abra-

sive dish detergent (keeping in mind that detergent

tends to remove wax). Avoid cleansers with abrasives

or the use of hard brushes. There are many cleaners

and polishes for special wheels.

l If possrble, remove the wheels during the win-

ter. Salt and sand used for snow removal can se-

verely damage the finish of a wheel.

l Make certain the recommended lug nut torque

is never exceeded or the wheel may crack. Never use

snow chains on special wheels; severe scratching

will occur.

Page 34 of 408

GENERALINFORMATIONAND MAINTENANCE l-35

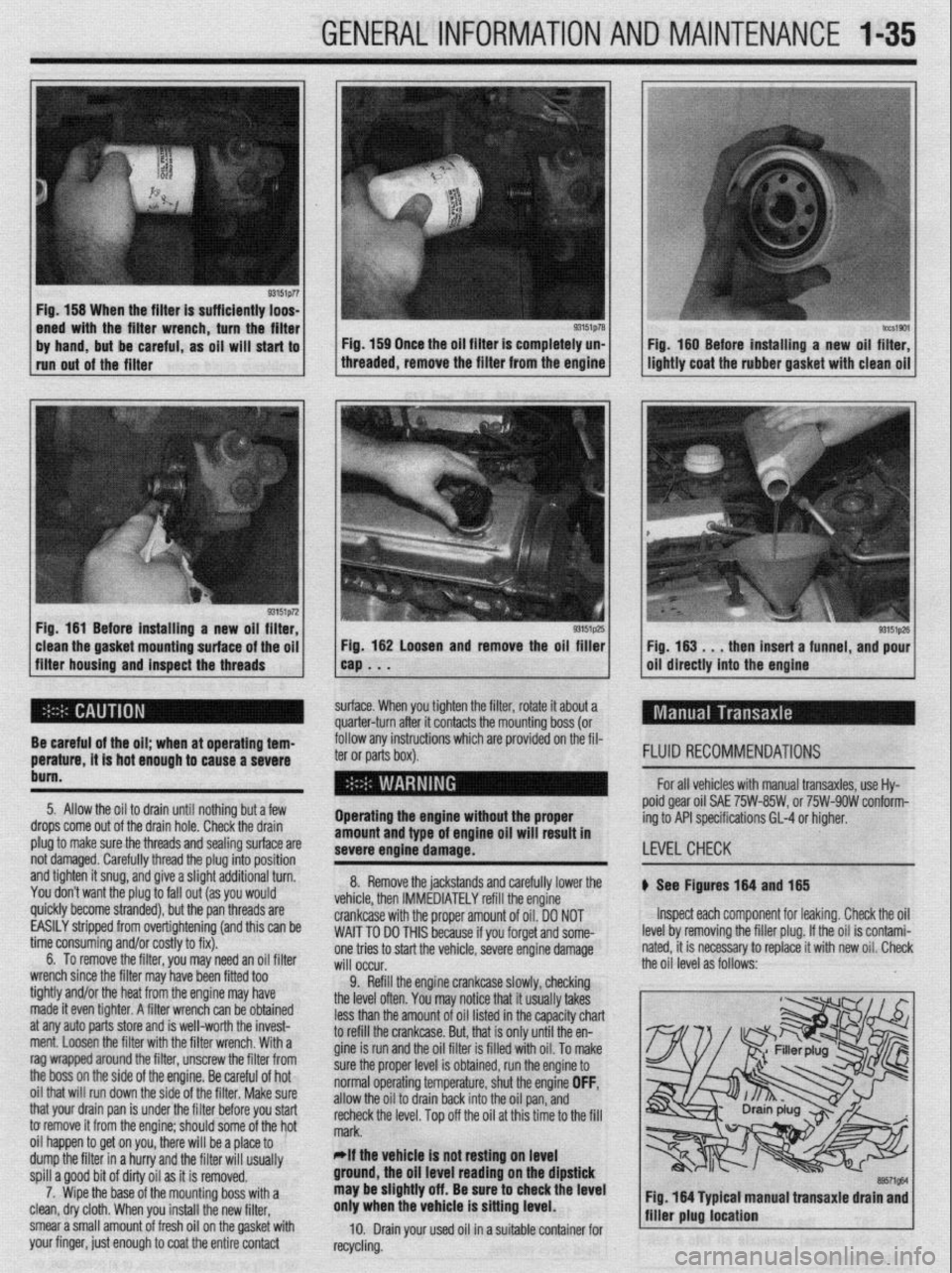

Fig. 158 When the filter is sufficiently loos-

Fig. 181 Before installing a new oil filter,

clean the gasket mounting surface of the oil

filter housing and inspect the threads Fig. 182 Loosen and remove the oil filler

cap . . .

surface. When you tighten the filter, rotate it about a

quarter-turn after it contacts the mounting boss (or Fig. 183 . , , then insert a funnel, and pour

oil directly into the engine

follow any instructions

which are provided on the fil-

ter or parts box).

Operating the engine without the proper

amount and type of engine oil will result In

severe engtne damage. FLUID RECOMMENDATIONS

For all vehicles with manual transaxles, use Hy-

poid gear oil SAE 75W-85W, or 75W-9OW conform-

ing to API specifications GL-4 or higher.

LEVELCHECK Be careful of the oil; when at operating tem-

perature, it is hot enough to cause a severe

bum.

5. Allow the oil to drain until nothing but a few

drops come out of the drain hole. Check the drain

plug to make sure the threads and sealing surface are

not damaged. Carefully thread the plug into position

and tighten it snug, and give a slight additional turn.

You don’t want the plug to fall out (as you would

quickly become stranded), but the pan threads are

EASILY stripped from overtightening (and this can be

time consuming and/or costly to fix).

6. To remove the filter, you may need an oil filter

wrench since the filter may have been fitted too

tightly and/or the heat from the engine may have

made it even tighter. A filter wrench can be obtained

at any auto parts store and is well-worth the invest-

ment. Loosen the filter with the filter wrench. With a

rag wrapped around the filter, unscrew the filter from

the boss on the side of the engine. Be careful of hot

oil that will run down the side of the filter. Make sure

that your drain pan is under the filter before you start

to remove it from the engine; should some of the hot

oil happen to get on you, there will be a place to

dump the filter in a hurry and the filter will usually

spill a good bit of dirty oil as it is removed.

7. Wipe the base of the mounting boss with a

clean, dry cloth. When you install the new filter,

smear a small amount of fresh oil on the gasket with

your finger, just enough to coat the entire contact 8. Remove the jackstands and carefully lower the

vehicle, then IMMEDIATELY refill the engine

crankcase with the proper amount of oil. DO NOT

WAIT TO DO THIS because if you forget and some-

one tries to start the vehicle, severe engine damage

will occur.

9. Refill the engine crankcase slowly, checking

the level oflen, you may r..‘:-- U.-1 :L ..-..” II.. .-L-e

lVL,VY II,UL II UUUU,,J ,“,\U.J

less than the amount of oil listed in the capacity chart

to refill the crankcase. But, that is only until the en-

gine is run and the oil filter is filled with oil. To make

sure the proper level is obtained, run the engine to

normal operating temperature, shut the engine OFF,

allow the oil to drain back into the oil pan, and

recheck the level. Top off the oil at this time to the fill

mark.

*If the vehicle Is not resting on level

ground, the oil level reading on the dipstick

may be slightly off. Be sure to check the level

only when the vehicle is sitting level.

10. Drain your used oil in a suitable container for

recycling. b See Flgures 184 and 185

Inspect each component for leaking. Check the oil

level by removing the filler plug. If the oil is contami-

nated, it is necessary to replace it with new oil. Check

the oil level as follows:

89571gM Fig. 164 Typtcal manual transaxle drain and

filler plug location

Page 44 of 408

GENERALINFORMATIONAND MAINTENANCE 1-45

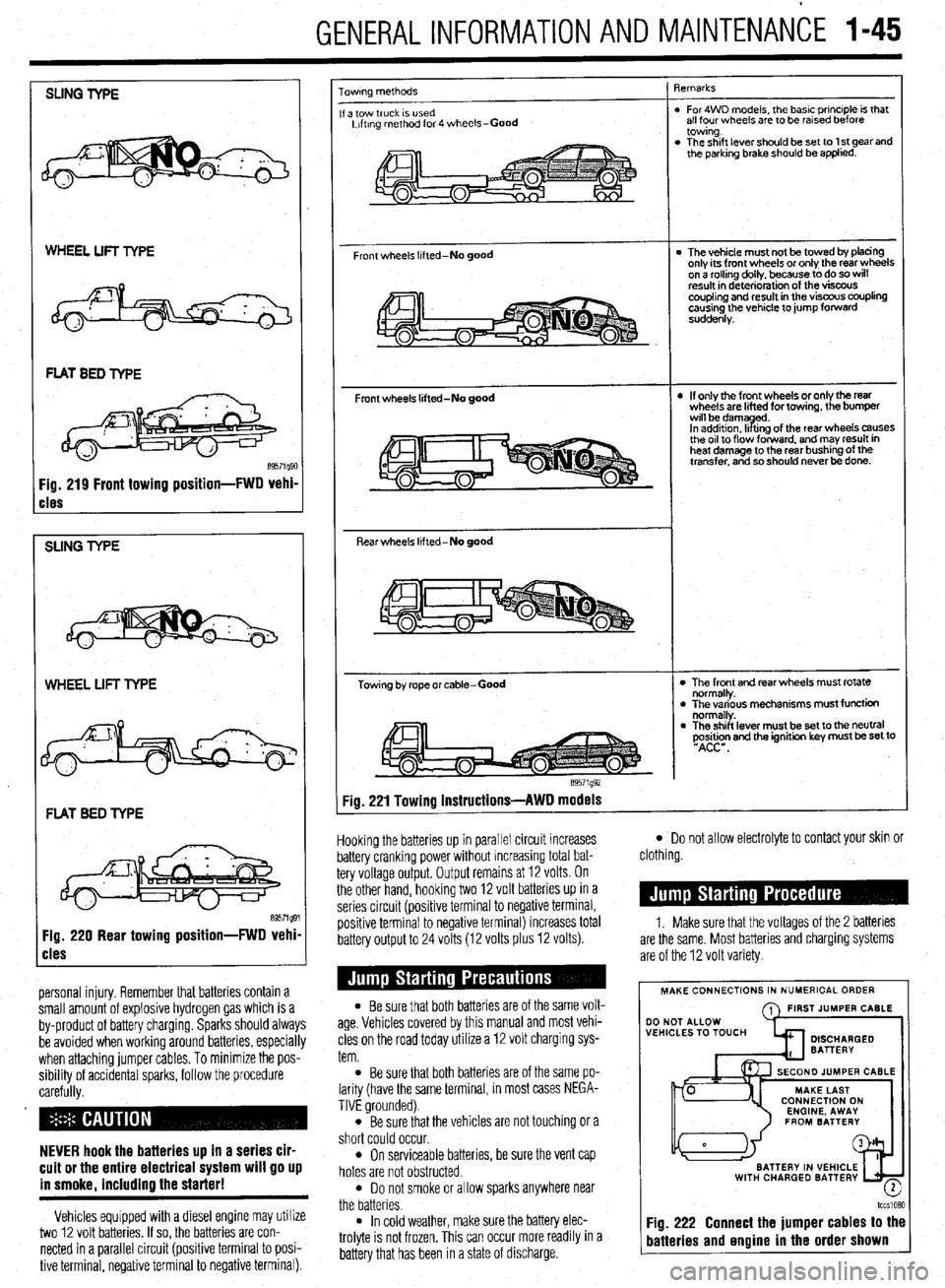

SLING TYPE

WHEEL LIFT TYPE

cles

SUNG TYPE

WHEEL LIFT TYPE

FLAT BED TYPE

Fig. 220 Rear towing position-FWD vehi

cles

personal injury. Remember that batteries contain a

small amount of explosive hydrogen gas which is a

by-product of battery charging. Sparks should always

be avoided when working around batteries, especially

when attaching jumper cables. To minimize the pos-

sibility of accidental sparks, follow the procedure

carefully.

NEVER hook the batteries up in a series cir-

cuit or the entire electrical system will go up

in smoke. includino the starter!

Vehicles equipped with a diesel engine may utilize

two 12 volt batteries. If so, the batteries are con-

nected in a parallel circuit (positive terminal to posi-

tive terminal, negative terminal to negative terminal).

owrng methods

a tow truck IS used

Lrftrng method for 4 wheels-Good

Front wheels lifted-No good

Front wheels lifted-No good

Rear wheels lifted-No good

Towing by rope or cable-Good

e9571g92 qemarks

. For4WD models, the basic principle is that

all four wheels are to be rarsed before

towing.

. The shift lever should be set to 1 st gear and

the parking brake should be applied.

l The vehicle must not be towed by tofacing

only its front wheels or only the rear wheels

on a rollino dollv, because to do so will

result in d&e&ration of the visfx~s

coupling and result in the viscous coupling

causing the vehicle to jump forward

suddenly.

l If only the front wheels or only the rear

wheels are lifted for towing, the bumper

wrll bedamyd.

In addrtron. II trng of the rear wheels causes

the or1 to flow forward. and may result in

heat damage to the rear bushing of the

transfer, and so should never be done.

l The front and rear wheels must rotate

normally.

l The various mechanisms must function

normally.

l The shift lever must be set to the neutral

~Asi&n and the ignition key must be set to

Fig. 221 Towing instructions-AWD models

Hooking the batteries up in parallel circuit increases

battery cranking power without increasing total bat-

tery voltage output. Output remains at 12 volts. On

the other hand, hooking two 12 volt batteries up in a

series circuit (positive terminal to negative terminal,

positive terminal to negative terminal) increases total

battery output to 24 volts (12 volts plus 12 volts).

l Be sure that both batteries are of the same volt-

age. Vehicles covered by this manual and most vehi-

cles on the road today utilize a 12 volt charging sys-

tem.

l Be sure that both batteries are of the same po-

larity (have the same terminal, in most cases NEGA-

TIVE grounded).

l Be sure that the vehicles are not touching or a

short could occur.

l On serviceable batteries, be sure the vent cap

holes are not obstructed.

l Do not smoke or allow sparks anywhere near

the batteries.

l In cold weather, make sure the battery elec-

trolyte is not frozen, This can occur more readily in a

battery that has been in a state of discharge.

l Do not allow electrolyte to contact your skin or

clothing.

1. Make sure that the voltages of the 2 batteries

are the same. Most batteries and charging systems

are of the 12 volt variety.

MAKE CONNECTIONS IN NUMERICAL ORDER

A FIRST JUMPER CABLE

WITH CHARGED BATTERY

-

lccslQ?,Q

Fig. 222 Connect the jumper cables to the

batteries and engine in the order shown

Page 92 of 408

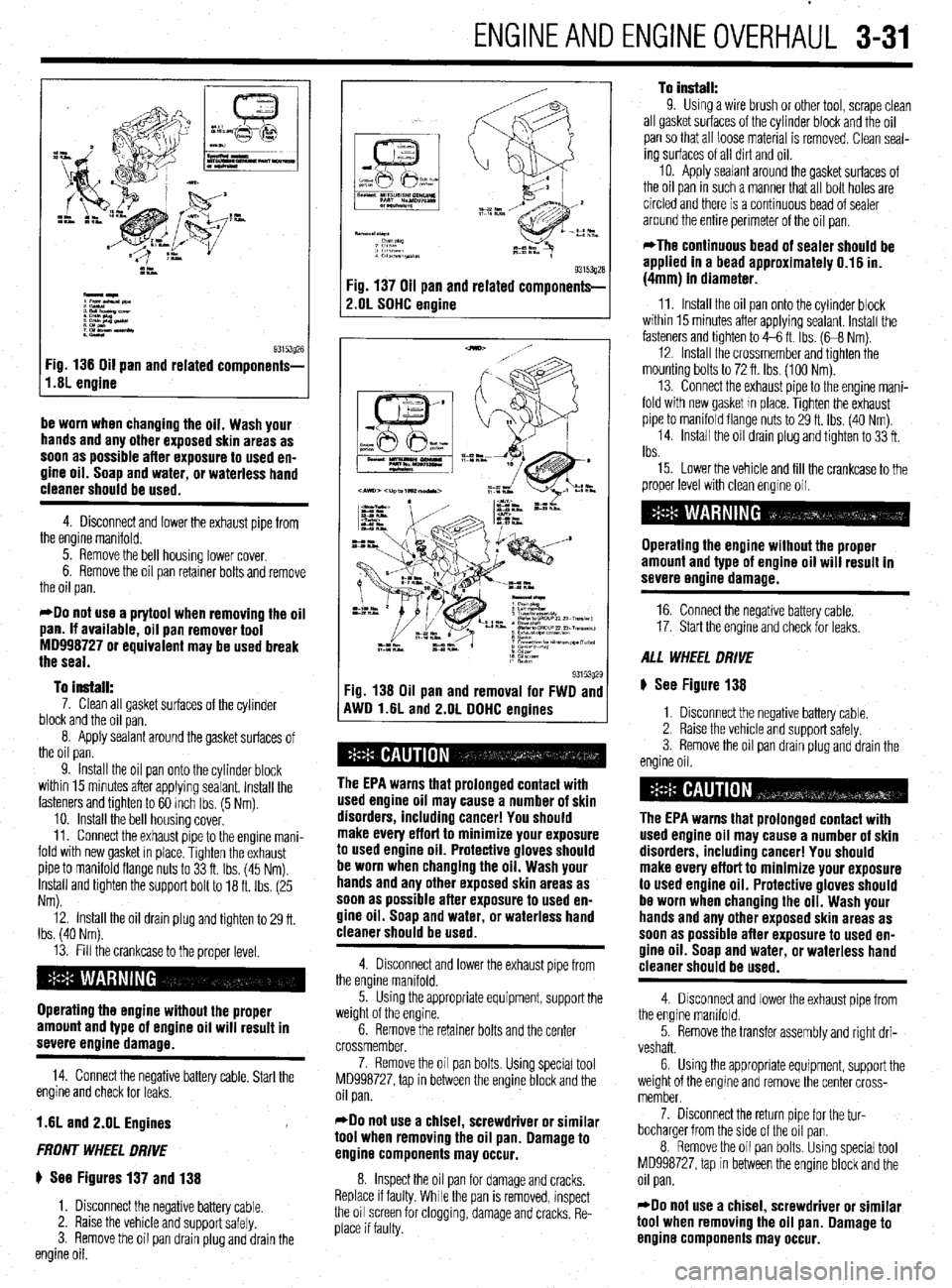

ENGINEANDENGINEOVERHAUL 3-31

I,.s; engine g3i53g26

Fig 136 Oil pan and related components-

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

4. Disconnect and lower the exhaust pipe from

the engine manifold.

5. Remove the bell housing lower cover.

6. Remove the oil pan retainer bolts and remove

the oil pan.

*Do not use a prytool when removing the oil

pan. If available, oil pan remover tool

MD998727 or equivalent may be used break

the seal.

To install:

7. Clean all gasket surfaces of the cylinder

block and the oil pan.

8. Apply sealant around the gasket surfaces of

the oil pan.

9. Install the oil pan onto the cylinder block

within 15 minutes after applying sealant. Install the

fasteners and tighten to 60 inch Ibs. (5 Nm).

10. install the bell housing cover.

11. Connect the exhaust pipe to the engine mani-

fold with new gasket in place. Tighten the exhaust

pipe to manifold flange nuts to 33 ft. Ibs. (45 Nm).

Install and tighten the support bolt to 18 ft. Ibs. (25

Nm).

12. Install the oil drain plug and tighten to 29 ft.

Ibs. (40 Nm).

13. Fill the crankcase to the proper level.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

14. Connect the negative battery cable. Start the

engine and check for leaks.

1.6L and 2.OL Engines

FRONT WHEEL DRIVE

ti See Figures 137 and 138

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely.

3. Remove the oil pan drain plug and drain the

engine oil.

93153gza Fig. 137 Oil pan and related components-

2.OL SOHC engine

93153g29 Fig. 138 Oil pan and removal for FWD and

AWD l.liL and 2.OL DDHC enoines

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

4. Disconnect and lower the exhaust pipe from

the engine manifold.

5. Using the appropriate equipment, support the

weight of the engine.

6. Remove the retainer bolts and the center

crossmember,

7. Remove the oil pan bolts. Using special tool

MD998727, tap in between the engine block and the

oil pan.

*Do not use a chisel, screwdriver or similar

tool when removing the oil pan. Damage to

engine components may occur.

8. Inspect the oil pan for damage and cracks.

Replace if faulty. While the pan is removed, inspect

the oil screen for clogging, damage and cracks. Re-

place if faulty.

To install: 9. Using a wire brush or other tool, scrape clean

all gasket surfaces of the cylinder block and the oil

pan so that all loose material is removed. Clean seal-

ing surfaces of all dirt and oil.

10. Apply sealant around the gasket surfaces of

the oil pan in such a manner that all bolt holes are

circled and there is a continuous bead of sealer

around the entire perimeter of the oil pan.

*The continuous bead of sealer should be

applied in a bead approximately 0.16 in.

(4mm) in diameter.

11. Install the oil pan onto the cylinder block

within 15 minutes after applying sealant. Install the

fasteners and tighten to 4-6 ft. Ibs. (G8 Nm).

12. Install the crossmember and tighten the

mounting bolts to 72 ft. Ibs. (100 Nm).

13. Connect the exhaust pipe to the engine mani-

fold with new gasket In place. Tighten the exhaust

pipe to manifold flange nuts to 29 ft. Ibs. (40 Nm)

14. Install the oil drain plug and tighten to 33 ft.

Ibs.

15. Lower the vehicle and fill the crankcase to the

proper level with clean engine oil.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

16. Connect the negative battery cable.

17. Start the engine and check for leaks.

ALL WHEEL DRIVE

ti See Figure 138

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely.

3. Remove the oil pan drain plug and drain the

engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

4. Disconnect and lower the exhaust pipe from

the engine manifold.

5. Remove the transfer assembly and right dri-

veshaft.

6. Using the appropriate equipment, support the

weight of the engine and remove the center cross-

member.

7. Disconnect the return pipe for the tur-

bocharger from the side of the oil pan.

8. Remove the oil pan bolts. Using special tool

MD998727, tap In between the engine block and the

oil pan.

*Do not use a chisel, screwdriver or similar

tool when removing the oil pan. Damage to

engine components may occur.

Page 93 of 408

.

3-32 ENGINEANDENGINEOVERHAUL

9. Inspect the oil pan for damage and cracks.

Replace if faulty, While the pan is removed, inspect

the oil screen for clogging, damage and cracks, Re-

place if faulty.

To install: 10. Using a wire brush or other tool, scrape clean

all gasket surfaces of the cylinder block and the oil

pan so that all loose material is removed. Clean seal-

ing surfaces of all dirt and oil.

11, Apply sealant around the gasket surfaces of

the oil pan in such a manner that all bolt holes are

circled and there is a continuous bead of sealer

around the entire perimeter of the oil pan.

*The continuous bead of sealer should be

applied in a bead approximately 0.16 in.

(4mm) in diameter.

12. Install the oil pan onto the cylinder block

within 15 minutes after applying sealant. Install the

fasteners and tighten to 4-6 ft. Ibs. (68 Nm).

13. Install the oil return pipe using a new gasket,

if removed. Tighten retainers to 5-7 ft. Ibs. (7-10

Nm).

14. Install the left member and tighten the forward

retainer bolts to 72 ft. Ibs. (100 Nm). Tighten the

rearward left member bolts to 58 ft. Ibs. (80 Nm).

15. Install the transfer assembly and right drive-

shaft.

16. Connect the exhaust pipe from the engine

manifold with new gasket in place. Tighten the ex-

haust pipe to manifold flange nuts to 29 ft. Ibs. (40

Nm).

17. Install the oil drain plug and tighten to 33 ft.

Ibs.

18. Lower the vehicle and fill the crankcase to the

proper level with clean engine oil.

Operating the engine without the proper

amount and type of engine oil will result in

severe enaine damage.

19. Connect the negative battery cable. Start the

engine and check for leaks.

2.4L Engine

) See Figure 139

1, Disconnect the negative battery cable. -

,(L.. K%

2 mM_

-Ip

t 8*t.almcwr

:y&pn

::Elm

93153g30 Fig. 139 Oil pan and related components-

2.4L engine

2. Remove the oil pan drain plug and drain the

engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

3. Remove the oil dipstick and tube assembly.

4. Detach the Heated Oxygen (HOaS) sensor

connector.

5. Remove the front exhaust pipe from the vehi-

cle.

6. Remove the bell housing cover.

7. Remove the oil pan retainer bolts. Using spe-

cial tool MD998727 or equivalent, tap in between the

engine block and the oil pan.

*Do not use a prytool when removing the oil

pan. Damage to engine components may oc-

cur.

To install:

8. Apply sealant around the gasket surfaces of

the oil pan.

9. Install the oil pan onto the cylinder block

within 15 minutes after applying sealant. Install the

fasteners and tighten to 6 ft. Ibs. (8 Nm).

10. Install the oil drain plug and tighten to 29 ft.

Ibs. (39 Nm).

11. Install the bell housing cover, and tighten the

mounting bolts to 7 ft. Ibs. (9 Nm).

12. Install the front exhaust pipe and tighten the

bolts at the catalytic converter to 36 ft. Ibs. (49 Nm).

Tighten the nuts at the exhaust manifold to 32 ft. Ibs.

(44 Nm).

13. Reconnect the HOPS sensor connector.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

15. Connect the negative battery cable. Start the

engine and check for leaks.

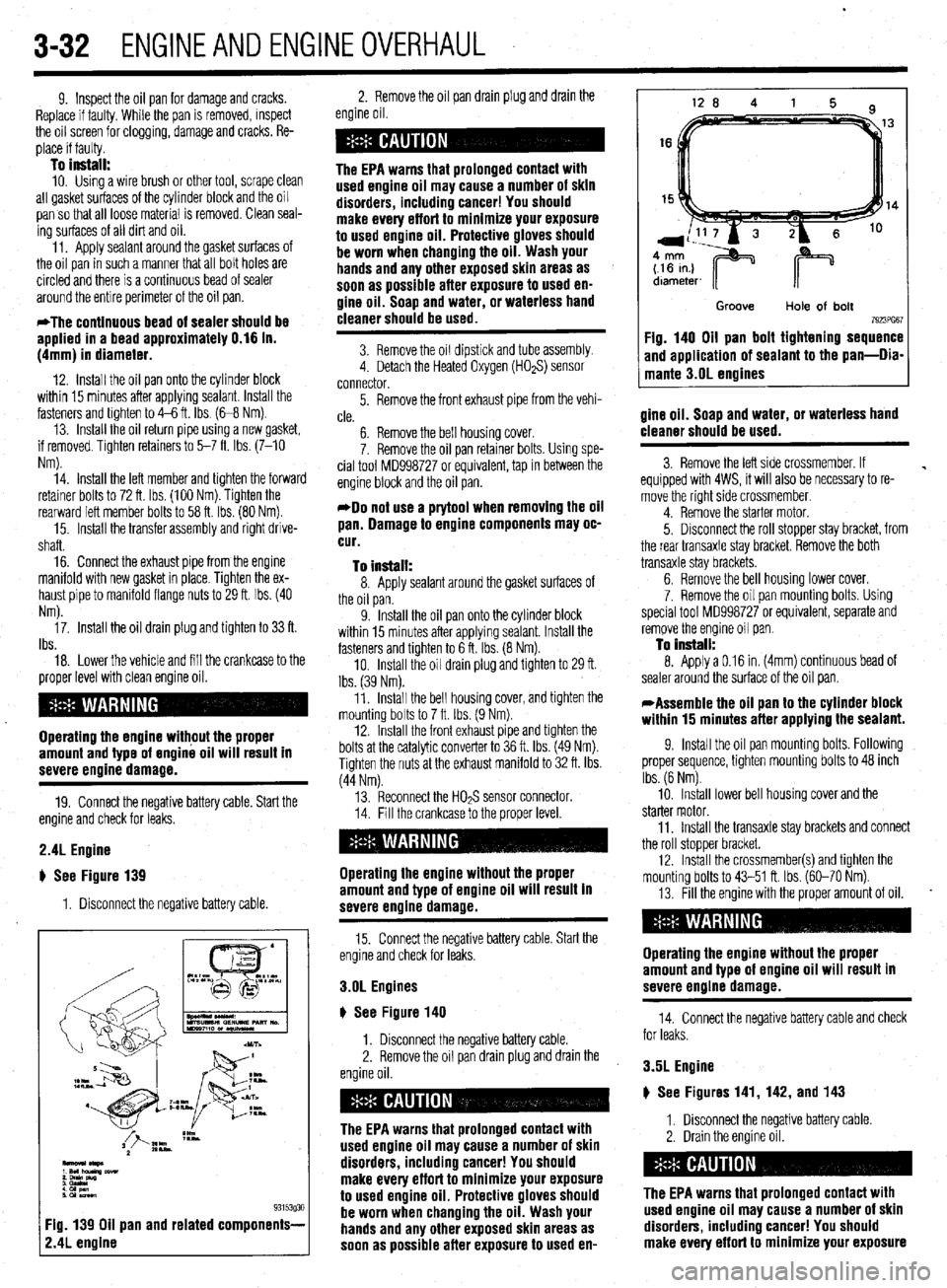

3.OL Engines

u See Figure 140

1. Disconnect the negative battery cable.

2. Remove the oil pan drain plug and drain the

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

Groove

Hole of bolt 7923PG67 Fig. 140 Oil pan bolt tightening sequence

and application of sealant to the pan-Dia-

mante 3.OL engines

gine oil. Soap and water, or waterless hand

cleaner should be used.

3. Remove the left side crossmember. If

equipped with 4WS, it will also be necessary to re-

move the right side crossmember.

4. Remove the starter motor.

5. Disconnect the roll stopper stay bracket, from

the rear transaxle stay bracket. Remove the both

transaxle stay brackets.

6. Remove the bell housing lower cover.

7. Remove the oil pan mounting bolts. Using

special tool MD998727 or equivalent, separate and

remove the engine oil pan.

To install: 8. Apply a 0.16 in. (4mm) continuous bead of

sealer around the surface of the oil pan.

*Assemble the oil pan to the cylinder block

within 15 minutes after applying the sealant.

9. Install the oil pan mounting bolts. Following

proper sequence, tighten mounting bolts to 48 inch

Ibs. (6 Nm).

10. Install lower bell housing cover and the

starter motor.

11, Install the transaxle stay brackets and connect

the roll stopper bracket.

12. Install the crossmember and tighten the

mounting bolts to 43-51 ft. Ibs. (60-70 Nm).

13. Fill the engine with the proper amount of oil.

.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

14. Connect the negative battery cable and check

for leaks.

3.5L Engine

p See Figures 141, 142, and 143

1, Disconnect the negative battery cable.

2. Drain the engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, includina cancer! You should

make eve’ry effort to minimize your exposure

Page 96 of 408

ENGINEANDENGINEOVERHAUL 3-35

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

33. Connect the negative battery cable and start

the engine.

34. Verify correct oil pressure

35. Inspect for leaks.

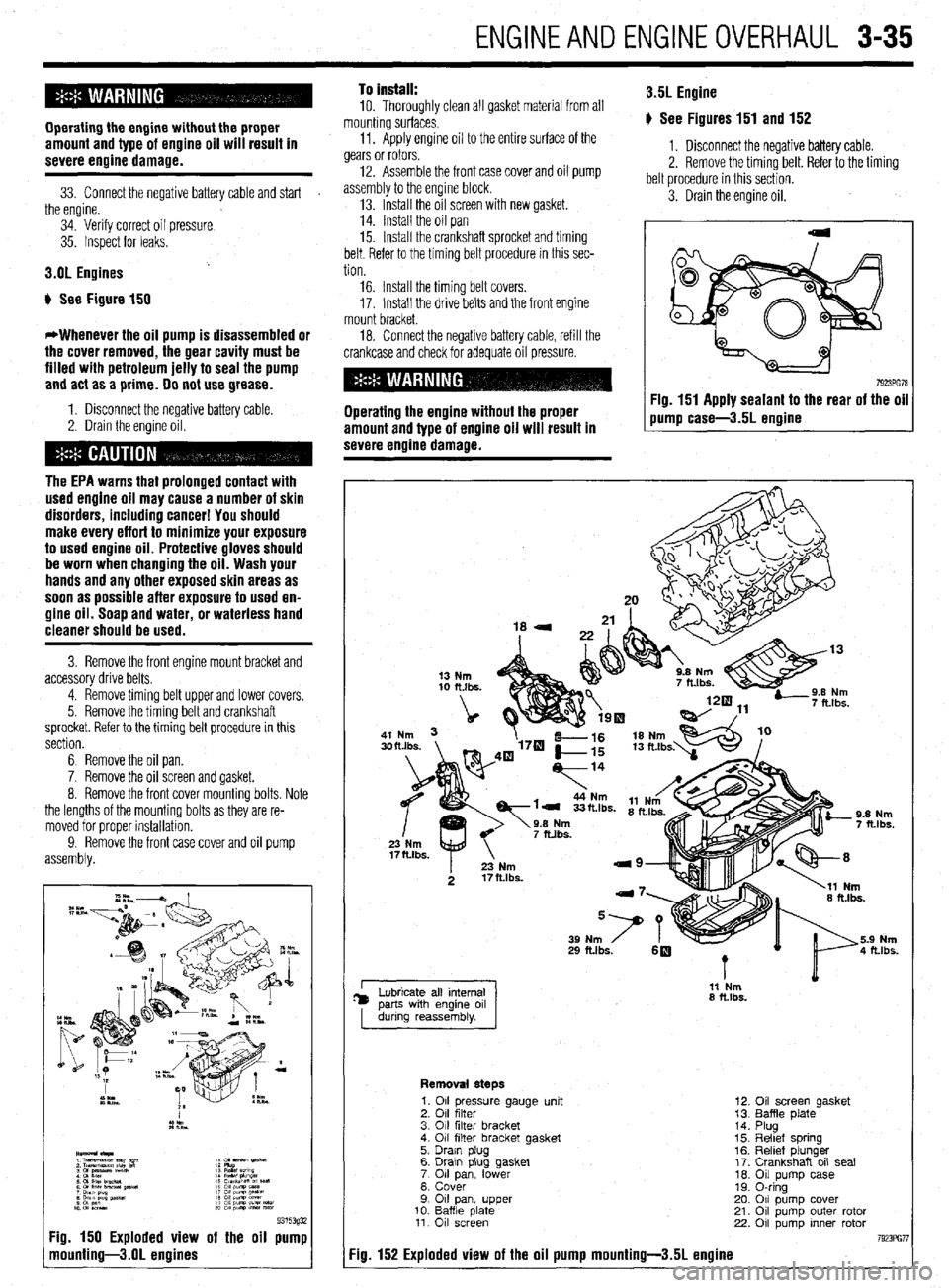

3.OL Engines

b See Figure 150

*Whenever the oil pump is disassembled or

the cover removed, the gear cavity must be

filled with petroleum jelly to seal the pump

and act as a prime. 00 not use grease.

1. Disconnect the negative battery cable.

2. Drain the engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

3. Remove the front engine mount bracket and

accessory drive belts.

4. Remove timing belt upper and lower covers.

5. Remove the timing belt and crankshaft

sprocket. Refer to the timing belt procedure in this

section.

6 Remove the oil pan.

7. Remove the oil screen and gasket.

8. Remove the front cover mounting bolts. Note

the lengths of the mounting bolts as they are re-

moved for proper installation.

9. Remove the front

assembly. and oil pump

9315393i 7g. 150 Exploded view of the oil pump

nounting-3.01 engines

To install:

10. Thoroughly clean all gasket material from all

mounting surfaces.

11. Apply engine oil to the entire surface of the

gears or rotors.

12. Assemble the front case cover and oil pump

assembly to the engine block.

13. Install the oil screen with new gasket.

14. Install the oil pan

15. Install the crankshaft sprocket and timing

belt. Refer to the timing belt procedure in this sec-

tion 3.5L Engine

p See Figures 151 and 152

1. Disconnect the negative battery cable.

2. Remove the timing belt. Refer to the timing

belt procedure in this section.

3. Drain the engine oil.

16. Install the timing belt covers.

17. Install the drive belts and the front engine

mount bracket.

18. Connect the negative battery cable, refill the

crankcase and check for adequate oil pressure.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage. Fig. 151 Apply sealant to the rear of the oil

pump case-3.5L ermine

I 11 Nm

8 ft.lbs.

Removal steps

7g. 152 Exploded view of the oil pump mounting-3.51 engine

1. 011 pressure gauge unit

2. 011 filter

3. 011 filter bracket

4. 011 filter bracket gasket

5. Drain plug

6. Drawn plug gasket

7 011 lower pan,

8. Cover

9 011 pan, upper

10. Baffle date 11. 011 screen

12.

13.

14.

15.

16.

17.

10.

19.

20.

21.

22. Oil screen gasket

Baffle plate

Plug

Reltef spring

Relief plunger

Crankshaft oil seal

Oil pump case

0-ring

011 pump cover

011 pump outer rotor

011 pump inner rotor

Page 128 of 408

ENGINEANDENGINEOVERHAUL 3-67

CONNECTING ROD

You should have the connecting rod checked for

StraiQhtness at a machine shop. If the connecting rod

is bent, it will unevenly wear the bearing and piston,

as well as place greater stress on these components.

Any bent or twisted connecting rods must be re-

placed. If the rods are straight and the wrist pin clear-

ance is within specifications, then only the bearing

end of the rod need be checked. Place the connecting

rod into a vice, with the bearing inserts in place, in-

stall the cap to the rod and torque the fasteners to

specifications. Use a telescoping gauge and carefully

measure the inside diameter of the bearings. Com-

pare this reading to the rods original crankshaft jour-

nal diameter measurement. The difference is the oil

clearance. If the oil clearance is not within specifica-

tions, install new bearings in the rod and take another

.

specifica- L

need to

shop as the pistons must be installed in the con measurement. it the Clearance is still out of :

tions, and the crankshaft is not, the rod will

be reconditioned by a machine shop.

*You can also use Plastigage’

@to check the

bearing clearances. The assen- . ...= - _______

Mm sectinn has complete instructions on its use.

Camshaft

Inspect the camshaft and lifters/followers as de

scribed earlier in this section.

Bearings

All of the enaine bearinos should be visuallv in-

~~~ I~ .- - -- ..-_-..,

spected for we; and/or damage. The bearing should

look evenly worn all around with no deep scores or

pits. If the bearing is severely worn, scored, pitted or

heat blued, then the bearing, and the components

that use it, should be brought to a machine shop for

block. ,ect

relationshipto the rod or engine damage can occur,

Pistons and Connecting Rods

I

b See Fiaute 264 --- --*------

Only pistons with the wrist pin retained by C-clips

are serviceable by the home-mechanic. Press fit pis-

tons require special presses and/or heaters to re- I”

rr

rove/install the connecting rod and should only be

PC srformed by a machine shop.

All pistons will have a mark indicating the direc-

tir 9n to the front of the engine and the must be in-

stalled into the engine in that manner. Usually it is a

notch or arrow on the top of the piston, or it may be

the letter F cast or stamped into the piston.

ASEtiBlY

1

crankshaft. Replace any freeze or oil galley plugs

which were removed during disassembly.

Crankshaft

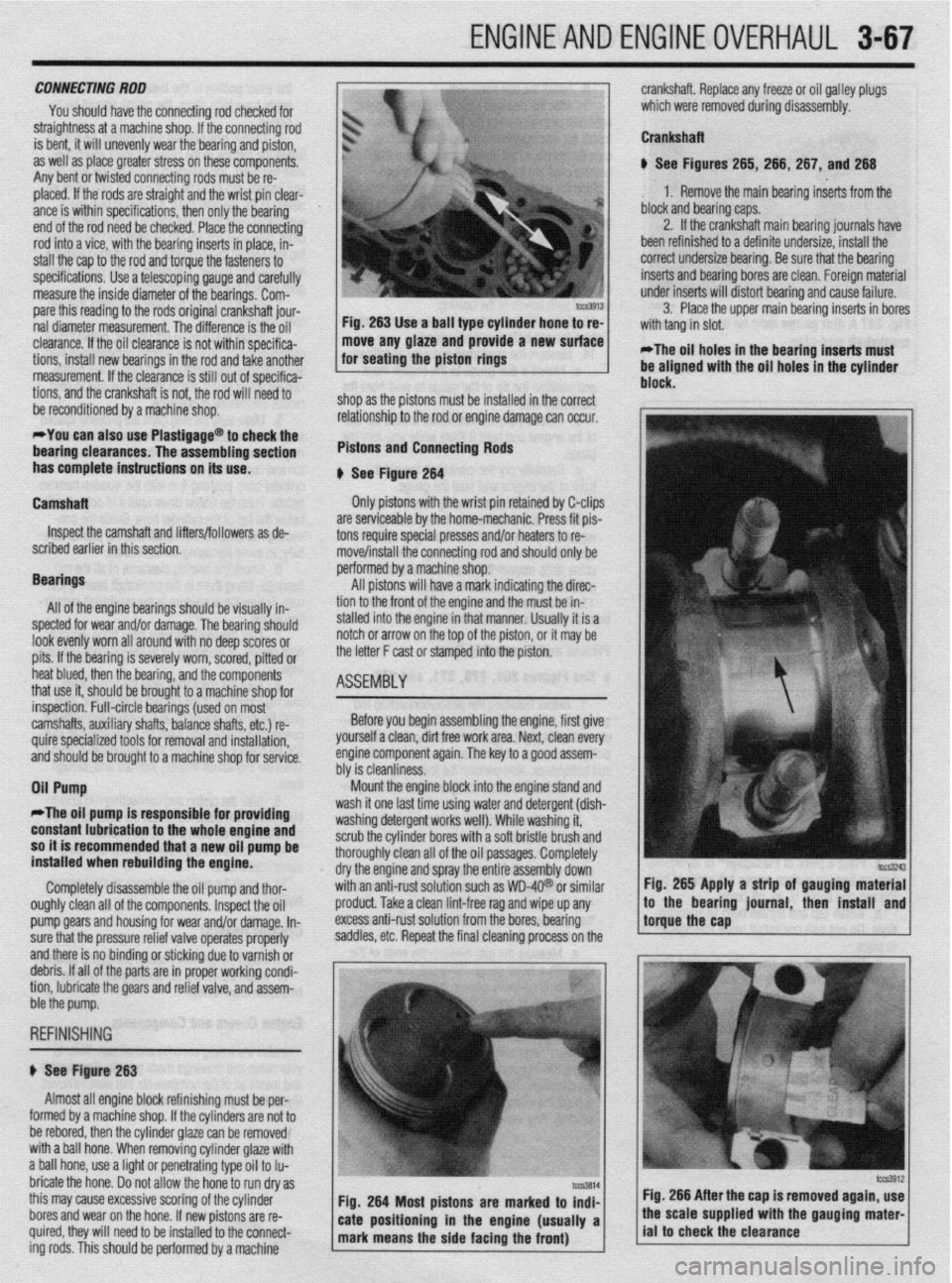

u See Figures 265, 266, 267, and 266

1. Remove the main bearing inserts from the

block and bearing caps.

2. If the crankshaft main bearing journals have

been refinished to a definite undersize, install the

correct undersize bearina. Be sure that the bearina

inserts and bearing bores are clean. Foreign mateiial

under inserts will distort bearinq and cause failure.

3. Place the upper main bearing inserts in bores

*The oil holes in the bearing inserts must

be aligned with the oil holes in the cylinder

. . .

inspection. Full-circle bearings (used on most

camshafts, auxiliary shafts, balance shafts, etc.) re-

quire specialized tools for removal and installation, ’

and should be brought to a machine shop for service.

Oil Pump Before you begin assembling the engine, first give

yourself a clean, dirt free work area. Next, clean every

engine component again. The key to a QOOd assem-

hhr io da~nlinmw “‘I Ia ~rGiOllll,lc7.Ja. Mount the engine block into the engine stand and

II

*The oil pump is responsible fo

r providing wasn It one last time usmg water and detergent (dish-

unrhinn rldarnant ~nrirc well), While washing it, with a soft bristle brush and

: oil oassaoes. Comoletelv constant lubrication to the whole engine and 1ILl.M 0, ,y “GSGl ycx II ““1 n

so it is recommended that a new oil pump be scrub the cylinder bore:

installed when rebuilding the engine. thoroughly clean all oft

dry the engine and spra

Completely disassemble the oil pump and thor- with an anti-rust solutio

oughly clean all of the components. Inspect the oil

pro

pump Qears and housing for wear and/or damage. In- exe

sure that the pressure relief valve operates properly sac

and there is no binding or sticking due to varnish or

debris. If all of the parts are in proper working condi-

tion, lubricate the gears and relief valve, and assem-

r

j ht

y the entire assembly down’

in such as WD-4Q@ or similar Fig. 265 Apply a strip of gauging material

Iduct. Take a clean lint-free rag and wipe up any

less anti-rust solution from the bores, bearing

Idles, etc. Repeat the final cleaning process on the !torguethe~~p * ,’ / to the bearmg lournal, then mstall and

ble the pump.

REFINISHING

# See Figure 263

Almost all engine block refinishing must be per-

I

IUIIII~U uy a macnme snap. ir me cynnoers are nor ro

be rebored, then the cylinder glaze can be removed

with a ball hone. When removing cylinder glaze with

a ball hone, use a light or penetrating type oil to Iu-

bricate the hone. Do not allow the hone to run dry as

this may cause excessive scoring of the cylinder

bores and wear on the hone. If new pistons are re-

quired, they will need to be installed to the connect-

ing rods. This should be oerformed bv a machine Fig. 266 After the cap is removed again, use