octane MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 32 of 408

GENERALINFORMATIONAND MAINTENANC-E 1133

Used fluids such as engine oil, transaxle fluid, an-

tifreeze and brake fluid are hazardous wastes and

must be disposed of properly. Before draining any

fluids, consult with your local authorities; in many ar-

eas, waste oil, antifreeze, etc. is being accepted as a

part of recycling programs. A number of service sta-

tions and auto parts stores are also accepting waste

fluids for recycling.

Be sure of the recycling center’s policies before

draining any fluids, as many will not accept different

fluids that have been mixed together.

ENGINE OIL

6 See Figure 148

WMitsubishi recommends that SAE 5W-30

viscosity engine oil should be used for all clia

mate conditions, however, SAE low-30 is ac

ceptable for vehicles operated in moderate-

to-hot climates. the SAE number, the lighter the oil; the lower the vis-

cosity, the easier it is to crank the engine in cold

weather but the less the oil will lubricate and protect

the engine in high temperatures. This number is

marked on every oil container.

Oil viscosity’s should be chosen from those oils

recommended for the lowest anticipated temperatures

during the oil change interval. Due to the need for an

oil that embodies both good lubrication at high tem-

peratures and easy cranking in cold weather, multi-

grade oils have been developed. Basically, a multi-

grade oil is thinner at low temperatures and thicker at

high temperatures. For example, a low-40 oil (the W

stands for winter) exhibits the characteristics of a 10

weight (SAE 10) oil when the car is first started and

the oil is cold. Its lighter weight allows it to travel to

the lubricating surfaces quicker and offer less resis-

tance to starter motor cranking than, say, a straight

30 weight (SAE 30) oil. But atier the ensine reaches

operating temperature, the low-40 oil begins acting

like straight 40 weight (SAE 40) oil, its heavier weight

providing greater lubrication with less chance of

foaming than a straight 30 weight oil. Synthetic oil is not for every car and every type of

driving, so you should consider your engine’s condi-

tion and your type of driving. Also, check your car’s

warranty conditions regarding the use of synthetic oils.

FUEL

All models equipped with a SOHC (Single Over-

head Camshaft) engine are designed to operate using

regular unleaded fuel with a minimum of 87 octane.

All models equipped with a DOHC (Dual Overhead

Camshaft) engine are designed to operate using reg-

ular unleaded fuel with a minimum of 91 octane. Mit-

subishi warns that using gasoline with a lower octane

rating can cause persistent and heavy knocking, and

may cause internal engine damage.

If your vehicle is having problems with rough idle

or hesitation when the enoine is cold, it mav be

caused by low volatility fuel. If this occurs, iry a dif-

ferent grade or brand of fuel.

'OPERATION 1~ FOREIGN COUNTRIES

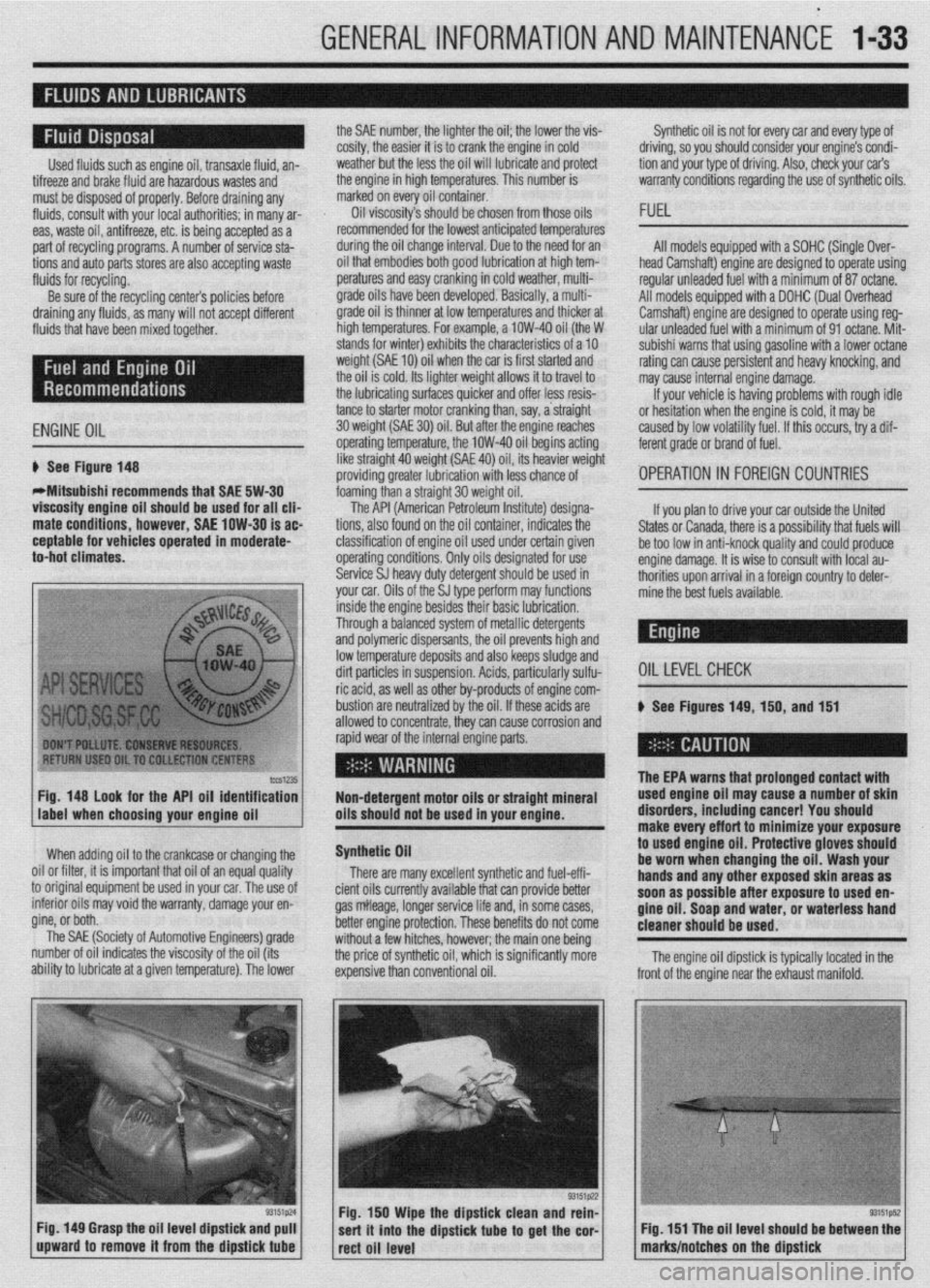

lccS1235 Fig. 148 look for the API oil identification

Non-detergent motor oils or straight mineral

label when choosing your enaine oil oils should not be used in your engine.

When adding oil to the crankcase or changing the

0 Nil or filter, it is important that oil of an equal quality

I original equipment be used in your car. The use of

. tc mtenor 011s may void the warranty, damage your en-

gine, or both. __

The SAE (Society of Automotive Engineers) grade

number of oil indicates the viscosity of the oil (its

ability to lubricate at a given temperature). The lower

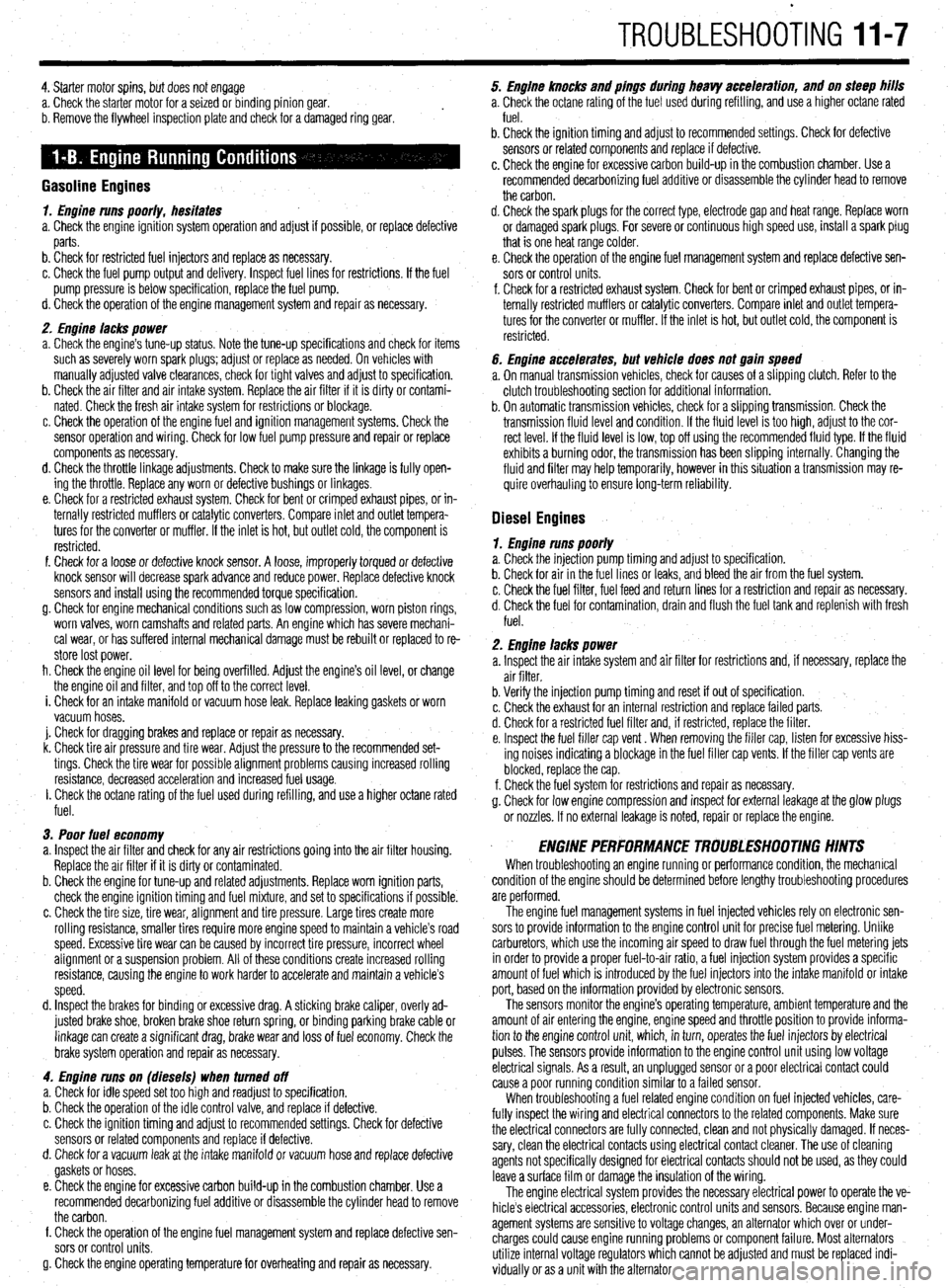

Fig. 149 Grasp the oil level dipstick and pull

upward to remove it from the dipstick

tube

The API (American Petroleum Institute) designa-

tions, also found on the oil container, indicates the

classification of engine oil used under certain given

operating conditions. Only oils designated for use

Service SJ heavy duty detergent should be used in

your car. Oils of the SJ type perform may functions If you plan to drive your car outside the United

States or Canada, there is a possibility that fuels will

be too low in anti-knock quality and could produce

engine damage. It is wise to consult with local au-

thorities upon arrival in a foreign country to deter-

mine the best fuels available.

inside the engine besides their basic lubrication.

Through a balanced system of metallic detergents

and polymeric dispersants, the oil prevents high and

low temperature deposits and also keeps sludge and

dirt particles in suspension. Acids, particularly sulfu-

OILLEVELCHECK ric acid, as well as other by-products of engine com-

bustion are neutralized by the oil. If these acids are

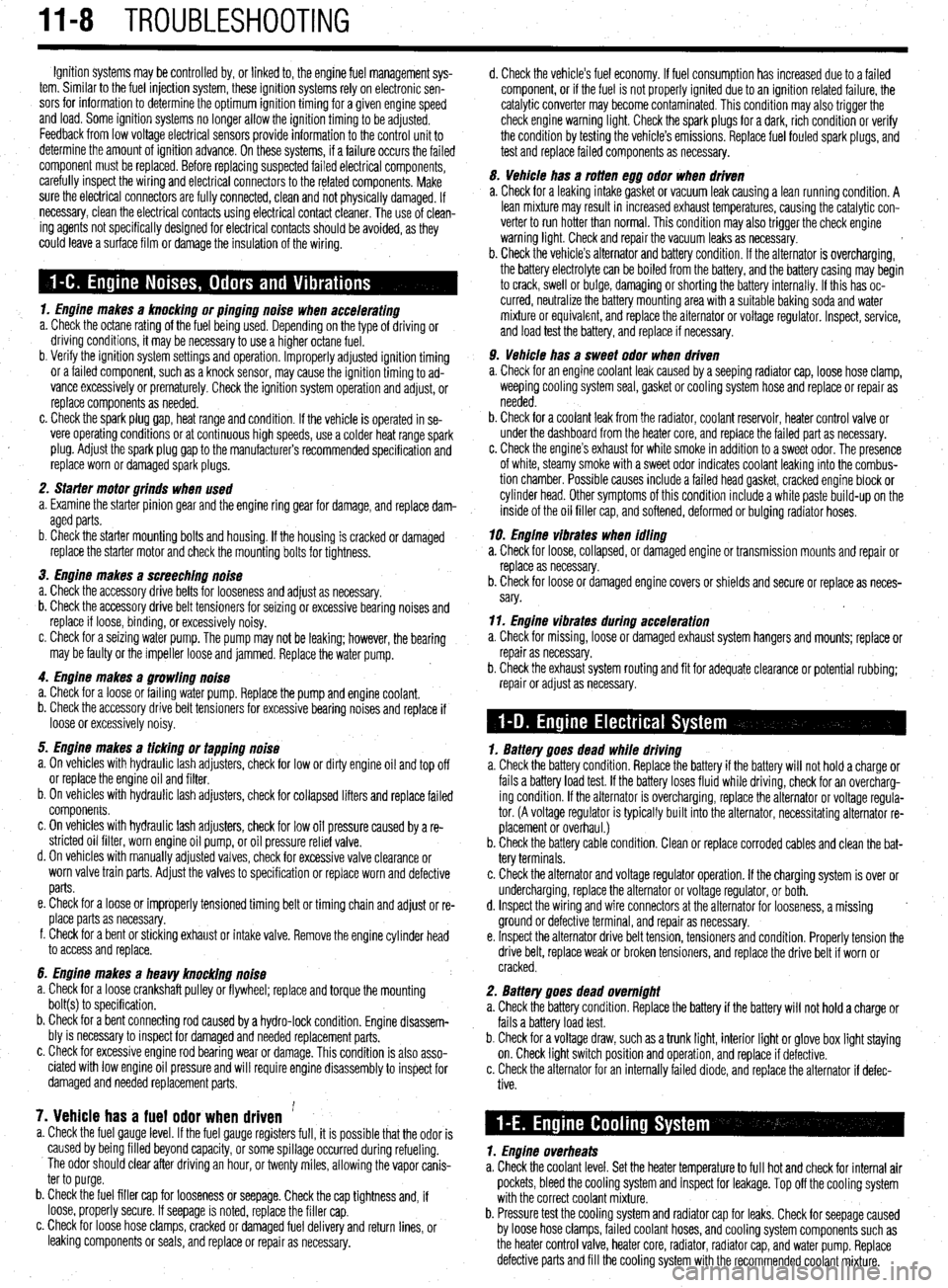

# See Figures 149, 150, and 151

allowed to concentrate, thev can cause corrosion and

rapid wear of the internal engine parts.

Synthetic Oil

There are many excellent synthetic and fuel-effi-

cient oils currently available that can provide better

gas mileage, longer service life and, in some cases,

better engine protection. These benefits do not come

without a few hitches, however; the main one being

the price of synthetic oil, which is significantly more

expensive than conventional oil.

.

The EPA warns that urolonoed contact with used engine oil ma; cause-a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to

used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

Fig. 150 Wipe the dipstick clean and rein-

sert it into the dipstick

tube to get the cor-

rect oil level The engine oil dipstick is typically located in the

Fig. 151 The oil level should be between the

marks/notches on the dipstick

Page 389 of 408

TROUBLESHOOiNG 11-7

4. Starter motor spins, but does not engage

a. Check the starter motor for a seized or binding pinion gear.

b. Remove the flywheel inspection plate and check for a damaged ring gear.

Gasoline Engines

1. Engine runs poor/y, hesiiates

a. Check the engine ignition system operation and adjust if possible, or replace defective

parts.

b. Check for restricted fuel injectors and replace as necessary.

c. Check the fuel pump output and delivery. Inspect fuel lines for restrictions. If the fuel

pump pressure is below specification, replace the fuel pump.

d. Check the operation of the engine management system and repair as necessary.

2. Enfline lacks power

a. Check the engine’s tune-up status. Note the tune-up specifications and check for items

such as severely worn spark plugs; adjust or replace as needed. On vehicles with

manually adjusted valve clearances, check for tight valves and adjust to specification.

b. Check the air filter and air intake system. Replace the air filter if it is dirty or contami-

nated. Check the fresh air intake system for restrictions or blockage.

c. Check the operation of the engine fuel and ignition management systems. Check the

sensor operation and wiring. Check for low fuel pump pressure and repair or replace

components as necessary.

d. Check the throttle linkage adjustments. Check to make sure the linkage is fully open-

ing the throttle. Replace any worn or defective bushings or linkages.

e. Check for a restricted exhaust system. Check for bent or crimped exhaust pipes, or in-

ternally restricted mufflers or catalytic converters. Compare inlet and outlet tempera-

tures for the converter or muffler. If the inlet is hot, but outlet cold, the component is

restricted.

f. Check for a loose or defective knock sensor. A loose, improperly torqued or defective

knock sensor will decrease spark advance and reduce power. Replace defective knock

sensors and install using the recommended torque specification.

g. Check for engine mechanical conditions such as low compression, worn piston rings,

worn valves, worn camshafts and related parts. An engine which has severe mechani-

cal wear, or has suffered internal mechanical damage must be rebuilt or replaced to re-

store lost power.

h. Check the engine oil level for being overfilled. Adjust the engine’s oil level, or change

the engine oil and filter, and top off to the correct level.

i. Check for an intake manifold or vacuum hose leak. Replace leaking gaskets or worn

vacuum hoses.

j. Check for dragging brakes and replace or repair as necessary.

k. Check tire air pressure and tire wear. Adjust the pressure to the recommended set-

tings. Check the tire wear for possible alignment problems causing increased rolling

resistance, decreased acceleration and increased fuel usage.

I. Check the octane rating of the fuel used during refilling, and use a higher octane rated

fuel.

3. Poor fuel economy

a. Inspect the air filter and check for any air restrictions going into the air filter housing.

Replace the air filter if it is dirty or contaminated.

b. Check the engine for tune-up and related adjustments. Replace worn ignition parts,

check the engine ignition timing and fuel mixture, and set to specifications if possible.

c. Check the tire size, tire wear, alignment and tire pressure. Large tires create more

rolling resistance, smaller tires require more engine speed to maintain a vehicle’s road

speed. Excessive tire wear can be caused by incorrect tire pressure, incorrect wheel

alignment or a suspension problem. All of these conditions create increased rolling

resistance, causing the engine to work harder to accelerate and maintain a vehicle’s

speed.

d. Inspect the brakes for binding or excessive drag. A sticking brake caliper, overly ad-

justed brake shoe, broken brake shoe return spring, or binding parking brake cable or

linkage can create a significant drag, brake wear and loss of fuel economy. Check the

brake system operation and repair as necessary.

4. Engine runs on (diesels) when turned off

a. Check for idle speed set too high and readjust to specification.

b. Check the operation of the idle control valve, and replace if defective.

c. Check the ignition timing and adjust to recommended settings.

Check for defective

sensors or related components and replace if defective.

d. Check for a vacuum leak at the intake manifold or vacuum hose

and replace defective

gaskets or hoses.

e. Check the engine for excessive carbon build-up in the combustion chamber. Use a

recommended decarbonizing fuel additive or disassemble the cylinder head to remove

the carbon.

f. Check the operation of the engine fuel management system and replace defective sen-

sors or control units.

g. Check the engine operating temperature for overheating and repair as necessary. 5. Engine knocks and pinfls during heavy accele/ation, and on steep hills

a. Check the octane rating of the fuel used during refilling, and use a higher octane rated

fuel.

b. Check the ignition timing and adjust to recommended settings. Check for defective

sensors or related components and replace if defective.

c. Check the engine for excessive carbon build-up in the combustion chamber. Use a

recommended decarbonizing fuel additive or disassemble the cylinder head to remove

the carbon.

d. Check the spark plugs for the correct type, electrode gap and heat range. Replace worn

or damaged spark plugs. For severe or continuous high speed use, install a spark plug

that is one heat range colder.

e. Check the operation of the engine fuel management system and replace defective sen-

sors or control units.

f. Check for a restricted exhaust system. Check for bent or crimped exhaust pipes, or in-

ternally restricted mufflers or catalytic converters. Compare inlet and outlet tempera-

tures for the converter or muffler. If the inlet is hot, but outlet cold, the component is

restricted.

6. Engine atxelerates, but vehicle does not gain speed

a. On manual transmission vehicles, check for causes of a slipping clutch. Refer to the

clutch troubleshooting section for additional information.

b. On automatic transmission vehicles, check for a slipping transmission” Check the

transmission fluid level and condition. If the fluid level is too high, adjust to the cor-

rect level. If the fluid level is low, top off using the recommended fluid type. If the fluid

exhibits a burning odor, the transmission has been slipping internally. Changing the

fluid and filter may help temporarily, however in this situation a transmission may re-

quire overhauling to ensure long-term reliability.

Diesel Engines

1. Engine runs pOOr!y a. Check the injection pump timing and adjust to specification.

b. Check for air in the fuel lines or leaks, and bleed the air from the fuel system.

c. Check the fuel filter, fuel feed and return lines for a restriction and repair as necessary.

d. Check the fuel for contamination, drain and flush the fuel tank and replenish with fresh

fuel.

2. Enfline lacks power

a. Inspect the air intake system and air filter for restrictions and, if necessary, replace the

air filter.

b. Verify the injection pump timing and reset if out of specification.

c. Check the exhaust for an internal restriction and replace failed parts.

d. Check for a restricted fuel filter and, if restricted, replace the filter.

e. Inspect the fuel filler cap vent. When removing the filler cap, listen for excessive hiss-

ing noises indicating a blockage in the fuel filler cap vents, If the filler cap vents are

blocked, replace the cap.

f. Check the fuel system for restrictions and repair as necessary.

g. Check for low engine compression and inspect for external leakage at the glow plugs

or nozzles. If no external leakage is noted, repair or replace the engine.

ENGINE PERFORMANCE TROUBLESHOOTING HINTS When troubleshooting an engine running or performance condition, the mechanical

condition of the engine should be determined before lengthy troubleshooting procedures

are performed.

The engine fuel management systems in fuel injected vehicles rely on electronic sen-

sors to provide information to the engine control unit for precise fuel metering. Unlike

carburetors, which use the incoming air speed to draw fuel through the fuel metering jets

in order to provide a proper fuel-to-air ratio, a fuel injection system provides a specific

amount of fuel which is introduced by the fuel injectors into the intake manifold or intake

port, based on the information provided by electronic sensors.

The sensors monitor the engine’s operating temperature, ambient temperature and the

amount of air entering the engine, engine speed and throttle position to provide informa-

tion to the engine control unit, which, in turn, operates the fuel injectors by electrical

pulses. The sensors provide information to the engine control unit using low voltage

electrical signals. As a result, an unplugged sensor or a poor electrical contact could

cause a poor running condition similar to a failed sensor.

When troubleshooting a fuel related engine condition on fuel injected vehicles, care-

fully inspect the wiring and electrical connectors to the related components. Make sure

the electrical connectors are fully connected, clean and not physically damaged. If neces-

sary, clean the electrical contacts using electrical contact cleaner. The use of cleaning

agents not specifically designed for electrical contacts should not be used, as they could

leave a surface film or damage the insulation of the wiring.

The engine electrical system provides the necessary electrical power to operate the ve-

hicle’s electrical accessories, electronic control units and sensors. Because engine man-

agement systems are sensitive to voltage changes, an alternator which over or under-

charges could cause engine running problems or component failure. Most alternators

utilize internal voltage regulators which cannot be adjusted and must be replaced indi-

vidually or as a unit with the alternator.

Page 390 of 408

11-8 TROUBLESHOOTING

Ignition systems may be controlled by, or linked to, the engine fuel management sys-

tem. Similar to the fuel injection system, these ignition systems rely on electronic sen-

sors for information to determine the optimum ignition timing for a given engine speed

and load. Some ignition systems no longer allow the ignition timing to be adjusted.

Feedback from low voltage electrical sensors provide information to the control unit to

determine the amount of ignition advance. On these systems, if a failure occurs the failed

component must be replaced. Before replacing suspected failed electrical components,

carefully inspect the wiring and electrical connectors to the related components. Make

sure the electrical connectors are fully connected, clean and not physically damaged. If

necessary, clean the electrical contacts using electrical contact cleaner. The use of clean-

ing agents not specifically designed for electrical contacts should be avoided, as they

could leave a surface film or damage the insulation of the wiring.

1. Engine makes a knocking or pinging noise when accelerating

a. Check the octane rating of the fuel being used. Depending on the type of driving or

driving conditions, it may be necessary to use a higher octane fuel.

b. Verify the ignition system settings and operation. Improperly adjusted ignition timing

or a failed component, such as a knock sensor, may cause the ignition timing to ad-

vance excessively or prematurely. Check the ignition system operation and adjust, or

replace components as needed.

c. Check the spark plug gap, heat range and condition. If the vehicle is operated in se-

vere operating conditions or at continuous high speeds, use a colder heat range spark

plug. Adjust the spark plug gap to the manufacturer’s recommended specification and

replace worn or damaged spark plugs.

2. Sfarter motor grinds when used

a. Examine the starter pinion gear and the engine ring gear for damage, and replace dam-

aged parts.

b. Check the starter mounting bolts and housing. If the housing is cracked or damaged

replace the starter motor and check the mounting bolts for tightness.

3. Engine makes a screeching noise

a. Check the accessory drive belts for looseness and adjust as necessary.

b. Check the accessory drive belt tensioners for seizing or excessive bearing noises and

replace if loose, binding, or excessively noisy.

c. Check for a seizing water pump. The pump may not be leaking; however, the bearing

may be faulty or the impeller loose and jammed. Replace the water pump.

4. Engine makes a growling noise

a. Check for a loose or failing water pump. Replace the pump and engine coolant.

b. Check the accessory drive belt tensioners for excessive bearing noises and replace if

loose or excessively noisy.

5. Engine makes a ticking or tapping noise

a. On vehicles with hydraulic lash adjusters, check for low or dirty engine oil and top off

or replace the engine oil and filter.

b. On vehicles with hydraulic lash adjusters, check for collapsed lifters and replace failed

components.

c. On vehicles with hydraulic lash adjusters, check for low oil pressure caused by a re-

stricted oil filter, worn engine oil pump, or oil pressure relief valve.

d. On vehicles with manually adjusted valves, check for excessive valve clearance or

worn valve train parts. Adjust the valves to specification or replace worn and defective

parts.

e. Check for a loose or improperly tensioned timing belt or timing chain and adjust or re-

place parts as necessary.

f. Check for a bent or sticking exhaust or intake valve. Remove the engine cylinder head

to access and replace.

6. Engine makes a heavy knocking noise

a. Check for a loose crankshaft pulley or flywheel; replace and torque the mounting

bolt(s) to specification.

b. Check for a bent connecting rod caused by a hydro-lock condition. Engine disassem-

bly is necessary to inspect for damaged and needed replacement parts.

c. Check for excessive engine rod bearing wear or damage. This condition is also asso-

ciated with low engine oil pressure and will require engine disassembly to inspect for

damaged and needed replacement parts,

7. Vehicle has a fuel odor when driven ’ a. Check the fuel gauge level. If the fuel gauge registers full, it is possible that the odor is

caused by being filled beyond capacity, or some spillage occurred during refueling.

The odor should clear after driving an hour, or twenty miles, allowing the vapor canis-

ter to purge.

b. Check the fuel filler cap for looseness or seepage. Check the cap tightness and, if

loose, properly secure. If seepage is noted, replace the filler cap.

c. Check for loose hose clamps, cracked or damaged fuel delivery and return lines, or

leaking components or seals, and replace or repair as necessary. d. Check the vehicle’s fuel economy. If fuel consumption has increased due to a failed

component, or if the fuel is not properly ignited due to an ignition related failure, the

catalytic converter may become contaminated. This condition may also trigger the

check engine warning light. Check the spark plugs for a dark, rich condition or verify

the condition by testing the vehicle’s emissions. Replace fuel fouled spark plugs, and

test and replace failed components as necessary.

5. Vehicle has a rotten egg odor when driven

a. Check for a leaking intake gasket or vacuum leak causing a lean running condition. A

lean mixture may result in increased exhaust temperatures, causing the catalytic con-

verter to run hotter than normal. This condition may also trigger the check engine

warning light. Check and repair the vacuum leaks as necessary.

b. Check the vehicle’s alternator and battery condition. If the alternator is overcharging,

the battery electrolyte can be boiled from the battery, and the battery casing may begin

to crack, swell or bulge, damaging or shorting the battery internally. If this has oc-

curred, neutralize the battery mounting area with a suitable baking soda and water

mixture or equivalent, and replace the alternator or voltage regulator. Inspect, service,

and load test the battery, and replace if necessary.

9. Vehicle has a sweet odor when driven

a. Check for an engine coolant leak caused by a seeping radiator cap, loose hose clamp,

weeping cooling system seal, gasket or cooling system hose and replace or repair as

needed.

b. Check for a coolant leak from the radiator, coolant reservoir, heater control valve or

under the dashboard from the heater core, and replace the failed part as necessary.

c. Check the engine’s exhaust for white smoke in addition to a sweet odor. The presence

of white, steamy smoke with a sweet odor indicates coolant leaking into the combus-

tion chamber. Possible causes include a failed head gasket, cracked engine block or

cylinder head. Other symptoms of this condition include a white paste build-up on the

inside of the oil filler cap, and softened, deformed or bulging radiator hoses.

19. Engine vibraies when idling

a. Check for loose, collapsed, or damaged engine or transmission mounts and repair or

replace as necessary.

b. Check for loose or damaged engine covers or shields and secure or replace as neces-

sary.

11. Engine vibrates during acceleration

a. Check for missing, loose or damaged exhaust system hangers and mounts; replace or

repair as necessary.

b. Check the exhaust system routing and fit for adequate clearance or potential rubbing;

repair or adjust as necessary.

7. Battery goes dead while driving

a. Check the battery condition. Replace the battery if the battery will not hold a charge or

fails a battery load test. If the battery loses fluid while driving, check for an overcharg-

ing condition. If the alternator is overcharging, replace the alternator or voltage regula-

tor. (A voltage regulator is typically built into the alternator, necessitating alternator re-

placement or overhaul.)

b. Check the battery cable condition. Clean or replace corroded cables and clean the bat-

tery terminals.

c. Check the alternator and voltage regulator operation. If the charging system is over or

undercharging, replace the alternator or voltage regulator, or both.

d. Inspect the wiring and wire connectors at the alternator for looseness, a missing .

ground or defective terminal, and repair as necessary.

e. Inspect the alternator drive belt tension, tensioners and condition. Properly tension the

drive belt, replace weak or broken tensioners, and replace the drive belt if worn or

cracked.

2. Battery goes dead overnight

a. Check the battery condition. Replace the battery if the battery will not hold a charge or

fails a battery load test.

b. Check for a voltage draw, such as a trunk light, interior light or glove box light staying

on. Check light switch position and operation, and replace if defective.

c. Check the alternator for an internally failed diode, and replace the alternator if defec-

tive.

1. Engine overheats

a. Check the coolant level. Set the heater temperature to full hot and check for internal air

pockets, bleed the cooling system and inspect for leakage. Top off the cooling system

with the correct coolant mixture.

b. Pressure test the cooling system and radiator cap for leaks. Check for seepage caused

by loose hose clamps, failed coolant hoses, and cooling system components such as

the heater control valve, heater core, radiator, radiator cap, and water pump. Replace

defective parts and fill the cooling system with the recommended coolant mixture.