warning light MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 7 of 408

.

l-8 GENERALINFORMATIONAND MAINTENANCE

tccsio15 Fig. 24 Various styles of torque wrenches

are usually available at your local automo-

tive supply store

and should be used with caution. Again, the general

rule of “if you are using the right tool for the job, you

should not have to strain to tighten a fastener” ap-

plies here.

Beam Type

# See Figure 26

The beam type torque wrench is one of the most

popular types. It consists of a pointer attached to the

head that runs the length of the flexible beam (shaft)

to a scale located near the handle. As the wrench is

pulled, the beam bends and the pointer indicates the

torque using the scale.

Click (Breakaway) Type

$ See Figure 27

Another popular design of torque wrench IS the

click type. To use the click type wrench you pre-ad-

just it to a torque setting. Once the torque is reached,

the wrench has a reflex signaling feature that causes

a momentary breakaway of the torque wrench body,

sending an impulse to the operator’s hand.

Pivot Head Type

# See Figure 27 and 28

Some torque wrenches (usually of the click type)

may be equipped with a pivot head which can allow it

to be used in areas of limited access. BUT, it must be

used properly. To hold a pivot head wrench, grasp

the handle lightly, and as you pull on the handle, it

should be floated on the pivot point. If the handle

comes in contact with the yoke extension during the

process of pulling, there is a very good chance the

torque readings will be inaccurate because this could

alter the wrench loading point. The design of the han-

dle is usually such as to make it inconvenient to de-

liberately misuse the wrench.

*It should be mentioned that the use of any

U-joint, wobble or extension will have an ef-

fect on the torque readings, no matter what

type of wrench you are using. For the most

accurate readings, install the socket directly

on the wrench driver. If necessary, straight

extensions (which hold a socket directly un-

der the wrench driver) will have the least ef-

fect on the torque reading. Avoid any exten-

sion that alters the length of the wrench from

the handle to the head/driving point (such as

a crow’s foot). U-joint or wobble extensions

can greatly affect the readings; avoid their

use at all times.

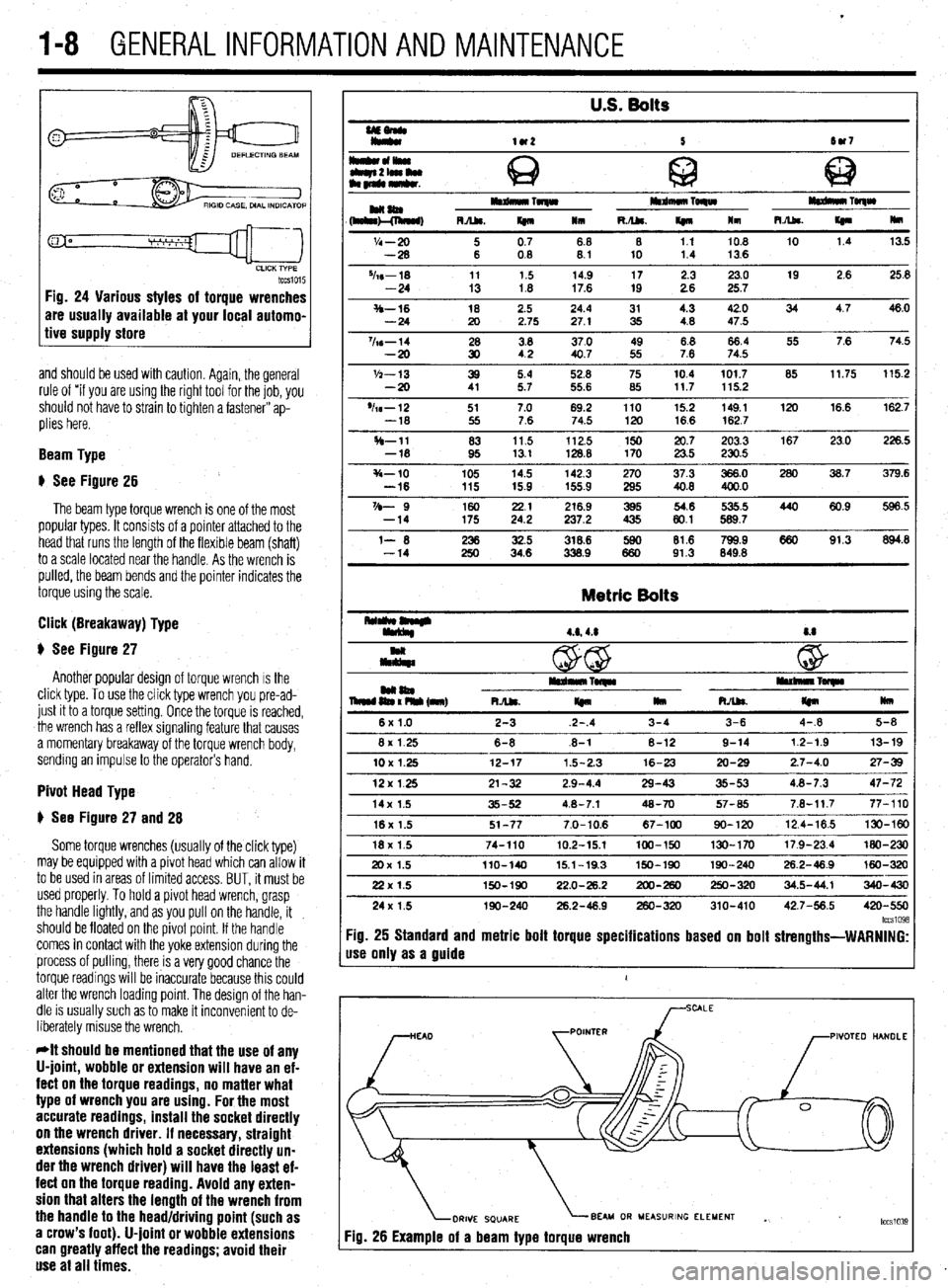

U.S. Bolts

UEonlr

Iy*

lU2 5 tw7

I*cll*olwu

Q c

tbqn2lamlu

am~mkr. @ 63

HaaIm Toqw mdmuo TORW

(h&l!&, RA&. m 111 R./U. If410 lm m TolqW

R.Abs.

I(n Hm

'I4 - 20 i 0.7 68 8 1.1 10.8 10 1.4 13.5

-28 08 8.1 10 1.4 13.6

%s-18 11 1.5 14.9 17 2.3 23.0 19 2.6 25.8

-24 13 1.8 17.6 19 2.6 25.7

S-16 18 2.5 24.4 31 4.3 42.0 34 4.7 46.0

-24 20 2.75 27.1 35 4.8 47.5

%s-14 28 3.8 37.0 49 8.8 66.4 55 7.6 74.5

-20 30 42 40.7 55 7.6 74.5

'h-13 39 5.4 52.8 75 10.4 101.7 85 11.75 115.2

-20 41 5.7 55.6 85 117 115.2

'h-12 51 7.0 69.2 110 15.2 149.1 120 16.6 162.7

-18 55 7.6 74.5 120 16.6 162.7

H-11 83 11.5 112.5 150 20.7 203.3 167 23.0 226.5

-18 95 13.1 128.8 170 23.5 230.5

s-10 105 14.5 142.3 270 37.3 366.0 280 36.7 379.6

-16 115 15.9 155.9 295 40.8 400.0

VD- 9 160 2.: 216.9 395 54.6 535.5 440 60.9 596.5

-14 175 237.2 435 80.1 589.7

l- 6 iti 32.5 318.6 lE 81.6 799.9 660 91.3 894.8

-14 34.6 338.9 91.3 849.8

Metric Bolts

4.6,4.8 8.8

c

@ w

mm04 iEn% (nnr) I*rdn*lrTwlr rullllllnl~

RJU.

I(n llm RAk

m mu

6x1.0 2-3 2-.4 3-4 3-6 4-.8 5-8

8x 1.25 6-8 .6-l 8-12 9-14 12-1.9 13-19

10X1.25 12-17 1.5-2.3 16-23 20-29 2.7-4.0 27-39

12x125 21-32 2.9-4.4 29-43 35-53 4.8-7.3 47-72

14x 1.5 35-52 4.8-7.1 48-70 57-65 7.8-11.7 77-110

16x 1.5 51-77 7.0-10.6 67-100 90-120 12.4-16.5 130-W

18x 1.5 74-110 10.2-15.1 100-150 130-170 17.9-23.4 MO-230

20x 1.5 llO-140 15.1-19.3 150-190 190-240 26.2-46.9 160-320

22x 1.5 150-190 22.0-26.2 200-260 250-320 34.5-44.1 340-430

24x 1.5 190-240 26.2-48.9 260-320 310-410 42.7-56.5 420-550

lccs1098 :ig. 25 Standard and metric bolt torque specifications based on bolt strengths-WARNING:

Ise only as a guide

1

PIVOTEO HANDLE

BEAU OR MEASURING ELEMENT

Yg. 26 Example of a beam type torque wrench . tccslo3~

Page 59 of 408

.

2-12 ENGINEELECTRICAL

*This section describes the operating prina

ciples of sending units, warning lights and

gauges. Sensors which provide information

to the Enafne Control Unit (ECU) or Electronic

or Power&in Control Module (FCM/PCM) are

covered in Section 4 of this manual.

Instrument panels contain a number of indicating

devices (gauges and warning lights). These devices

are composed of two separate components. One is

the sending unit, mounted on the engine or other re-

mote part of the vehicle, and the other is the actual

gauge or light in the instrument panel.

Several types of sending units exist, however most

can be characterized as being either a pressure type

or a resistance type. Pressure type sending units

convert liquid pressure into an electrical signal which

is sent to the gauge. Resistance type sending units

are most often used to measure temperature and use

variable resistance to control the current flow back to

the indicatinq device. Both types of sendinq units are

connected inseries by a wimto the batteryithiough

the ignition switch). When the ignition is turned ON,

current flows from the battery through the indicating

device and on to the sending unit.

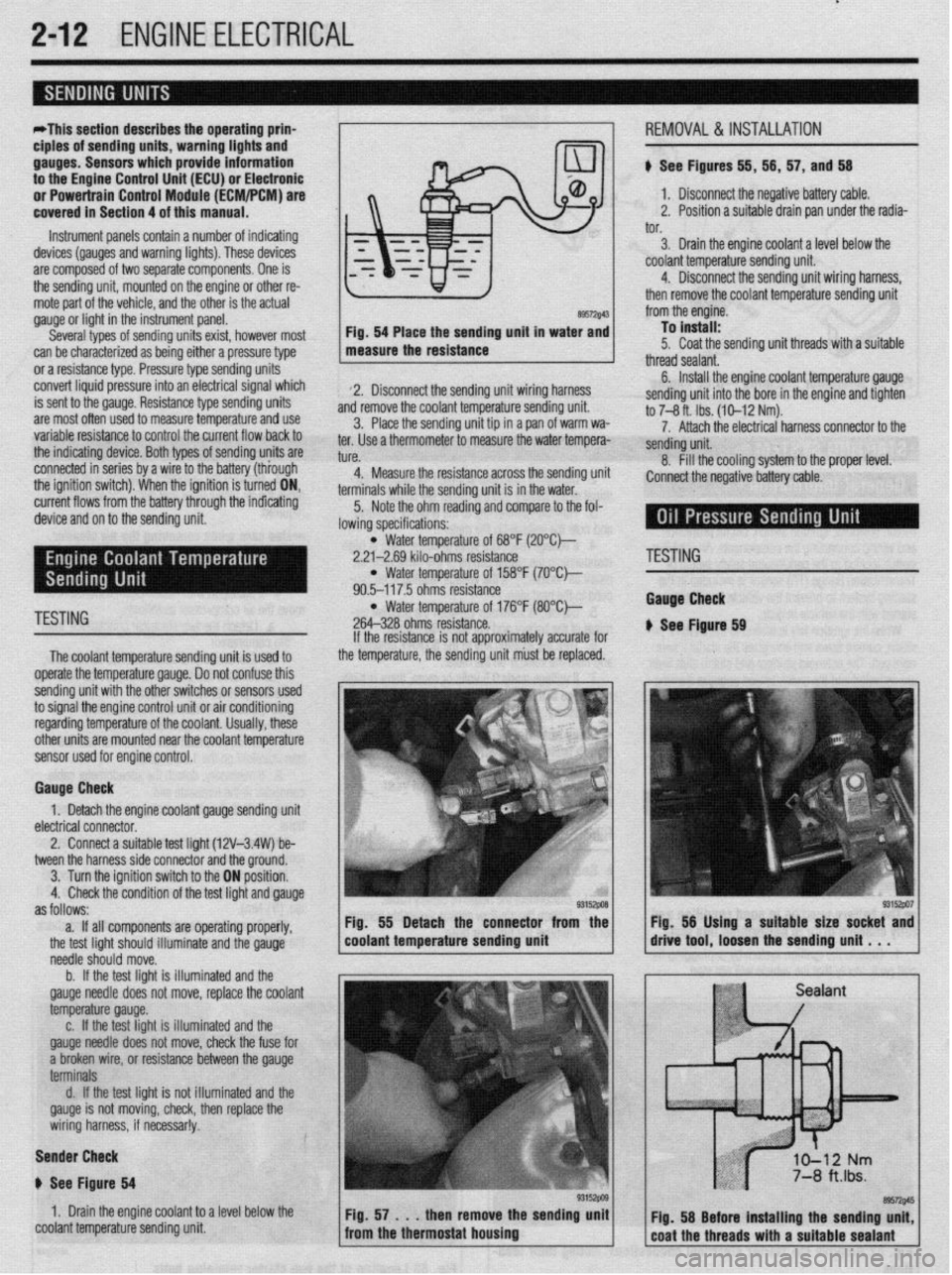

89572$43 Fig. 54 Place the sending unit in water and

measure the resistance

2. Disconnect the sending unit wiring harness

and remove the coolant temperature sending unit.

3. Place the sending unit tip in a pan of warm wa-

ter. Use a thermometer to measure the water tempera-

tl KP

L”,“.

4. Measure the resistance across the sending uni

terminals while the sending unit is in the water.

5. Note the ohm reading and compare to the fol-

lowing specifications: i, 56, 57, and 56

1. Disconnect the negative battery cable.

2. Position a suitable drain pan under the radia-

tor.

3. Drain the engine coolant a level below the

coolant temperature sending unit.

4. Disconnect the sending unit wiring harness,

then remove the coolant temperature sending unit

from the engine.

To install:

5. Coat the sending unit threads with a suitable

thread sealant.

6. Install the engine coolant temperature gauge

sending unit into the bore in the engine and tighten

to 7-8 ft. Ibs. (10-12 Nm).

7. Attach the electrical harness connector to the

sendina unit.

8. fill the cooling system to the proper level.

:onnect the negative battery cable.

l Water temperature of 68°F (2O”C)-

2.21-2.69 kilo-ohms resistance

l Water temperature of 158°F (7O’Ck

90.5-117.5 ohms resistance

TESTING l Water temperature of 176°F (8O”C)-

264-328 ohms resistance.

The coolant temperature sendina unit is used to

operate the temperature gauge. Donot confuse this

sending unit with the other switches or sensors used

to signal the engine control unit or air conditioning

regarding temperature of the coolant. Usually, these

other units are mounted near the coolant temoerature

sensor used for engine control. If the resistance is not approximately accurate for

the temperature, the sending unit must be replaced.

Gauge Check

1. Detach the engine coolant gauge sending unit

electrical connector.

2. Connect a suitable test liaht (12V-3.4W) be-

tween the harness side connector and the around.

I

3. Turn the ignition switch to the ON position.

4. Check the condition of the test light and gauge

as follows:

a. If all components are operating properly,

the test light should illuminate and the gauge

needle should move.

b. If the test light is illuminated and the

gauge needle does not move, replace the coolant

temperature gauge.

c. If the test light is illuminated and the

gauge needle does not move, check the fuse for

a broken wire, or resistance between the gauge

terminals

d. If the test light is not illuminated and the

gauge is not moving, check, then replace the

wiring harness, if necessar!y.

Sender Check

p See Figure 64

1. Drain the engine coolant to a level below the

coolant temperature sending unit Fig. 55 Detach the connector from the

coolant temperature sending unit

'ESTING

tauga Check

See Ftgure 69

Page 149 of 408

the temperature of the gas passing through +h

control valve. It converts the detected temf

Ierature

into an electrical voltage signal which is sent the ve-

hicle’s Powertrain Control Module (PCM). If the cir-

cuit of the EGR temperature sensor is broken, the

warning light will come on.

1. Remove the EGR temperature sensor from the

engine.

2. Place the EGR sensor into water. While in-

creasing the temperature of the water, measure the

sensor resistance. Compare the values to following

specifications:

a. 122°F 50°C

b. 212°F 100” )-11-14 kohms resistance

t P O-83 kohms resistance

3. If the resistance obtained varies significantly ,

.,. . .

i, replace the sensor, nom specmcaoom

Thermal Vacuum Valva

therm0 valve.

2. Connect a hand held vacuum pump to the vac-

uum hose on the therm0 valve.

3. Apply vacuum and check the air passage

through the therm0 vOrL’n %ults to the fnrm

lowinq specifications:

ant temperature of 122°F

vacuum leaks

lant temoerature of 176’F 4 n;rm.nnnn+ +h.n s,r,,~,,,,rn hnm frnm ‘h.n +hrotle

body EGR vacuum nipple. Connect a hand-held

vac-

uum pump to the nipple.

2. Start the engine, then slowly raise the speed

and compare with the following specifications.

a. For 1990-93 vehides, check to be sure the

vacuum raised proportionally with the rise in en-

gine s eed.

b. Ior 199450 vehicles, the vacuum reading

on the pump should remain constant.

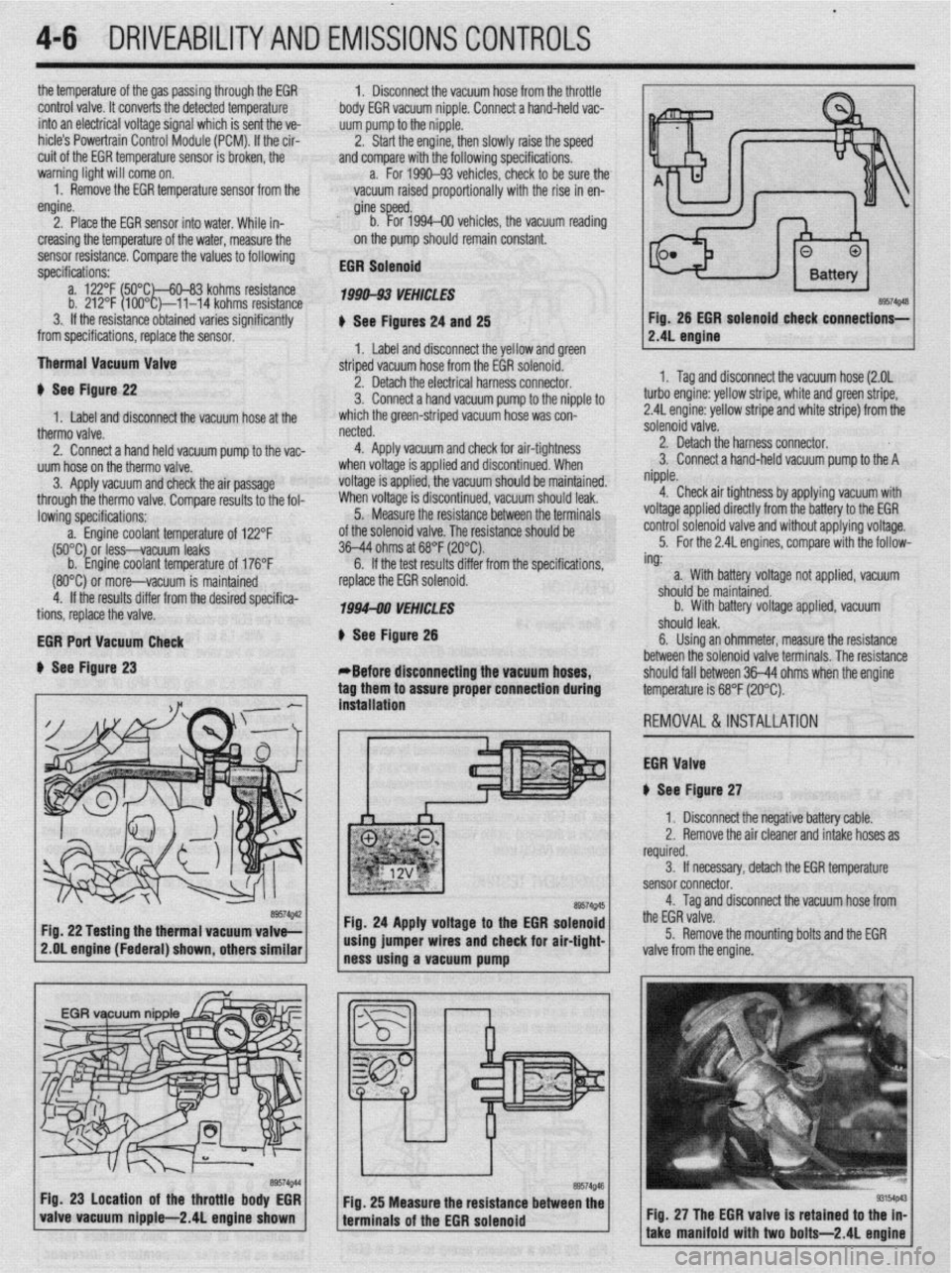

EGR Solenoid

1990-93 L’EHICL ES

# See Figures 24 and 25

1. Label and disconnect the yellow and green

striped vacuum hose from the EGR solenoid.

netted.

4. Apply vacuum and check for air-tightness

when voltage is applied and discontinued. When

voltage is applied, the vacuum should be maintained.

When voltage is discontinued, vacuum should leak.

5. Measure the resistance between the terminals

of the solenoid valve. The resistance should be

36-44 ohms at 68°F (20°C).

6. If the test results differ from the soecifications.

4-6 DRIVEABILITYAND EMISSIONSCONTROLS

Fig. 26 EGR solenoid

check connections-

# See Figure 22

1. Label and disconnect the vacuum hose at the 2. Detach the electrical harness connector.

3. Connect a hand vacuum pump to the nipple to

which the green-striped vacuum hose was con-

(80°C) 0; more-vacuum is maintained

4. If the results differ from the desired specifica-

tions, replace the valve.

EGR Port Vacuum Check

+ See Figure 23 replace the EGR solenoid.

1994-00 VEHICLES

# See Figure 26

*Before disconnecting the vacuum hoses,

tag them to assure proper connection during

. . ** *. 1. Tag and disconnect the vacuum hose (2.OL

turbo engine: yellow stripe, white and green stripe,

2.4L engine: yellow stripe and white stripe) from the

solenoid valve.

2. Detach the harness connector.

3. Connect a hand-held vacuum pump to the A

nipple.

4. Check air tightness by applying vacuum with

voltage applied directly from the battery to the EGR

control solenoid valve and without applying voltage.

5. For the 2.4L engines, compare with the follow-

ing:

. .

roltage not applied, vacuum a. With battery

should be maintainr

b. With battery

.I III I

snoura

iea~.

sd. -

/oltage applied, vacuum

6. Using an ohmmeter, measure the resistance

between the solenoid valve terminals. The resistance

should fall between 36-44 ohms when the enaine

temperature is 68°F (20°C).

REMOVAL&INSTALLATION

EGR Valve

iI See Figure 27 mslatlanon

1 I Disconnect the negative battery cable.

2. Remove the air cleaner and intake hoses as

required.

3. If necessary, detach the EGR temperature

sensor connector.

4. Tag and disconnect the vacuum hose from

the EGR valve.

5. Remove the mounting bolts and the EGR

2.OL engine (Federal) shown, others similar

valve from the engine.

Fig. 27 The EGR valve is retained to t

take manifold with two bolts-2.4L e

Page 169 of 408

4-26 DRIVEABILITYAND EMISSIONS CONTROLS

The Powertrain Control Module (PCM) monitors

the signals of input and output sensors, some all the

time and others at certain times and processes each

signal. When the PCM notices that an irregularity has

continued for a specified time or longer from when

the irregular signal was initially monitored, the PCM

judges that a malfunction has occurred and will

memorize the malfunction code. The code is then

stored in the memory of the PCM and is accessible

through the data link (diagnostic connector) with the

use of an electronic scan tool or a voltmeter.

CHECK ENGINE/MALFUNCTION

INDICATOR LIGHT

Among the on-board diagnostic items, a check

engine/malfunction indicator light comes on to notify

the driver of a emission control component irregular-

ity. If the irregularity detected returns to normal or the

PCM judges that the component has returned to nor-

mal, the check engine/malfunction indicator light will

be turned off Moreover, if the ignition is turned OFF

and then the engine is restarted, the check

engine/malfunction indicator light will not be turned

on unttl a malfunction is detected.

The check engine/malfunction indicator light will

come on immediately after the ignition switch is

turned ON. The light should stay lit for 5 seconds

and then will go off. This Indicates that the check en-

gine/malfunction indicator lamp is operating nor-

mally. This does not signify a problem with the sys-

tem.

*The check engine/malfunction indicator

lamp will come on when the terminal for the

ignition timing adjustment is shorted to

ground. Therefore, it is not abnormal that the

light comes on even when the terminal for ig-

nition timing is shorted at time of ignition

timing adjustment.

To test the light, perform the following:

1. Turn the ignition switch ON. Inspect the check

engine/malfunction indicator lamp for Illumination.

2. The light should be lit for 5 seconds and then

should go out.

3. If the lamp does not illuminate, check for open

circuit In the harness, blown fuse or blown bulb.

SERVICE PRECAUTIONS

l Before attachrng or detaching the PCM harness

connectors, make sure the ignition switch is OFF and

the negative battery cable is disconnected to avoid

the possibility of damage to the PCM.

l When performing PCM input/output signal di-

agnosis, remove the pin terminal retainer from the

connectors to make it easier to insert tester probes

into the connector.

l When attaching or detaching pin connectors ,

from the PCM, take care not to bend or break any pin

terminals. Check that there are no bends or breaks on

PCM pin terminals before attempting any connec-

tions.

l Before replacing any PCM, perform the PCM

input/output signal diagnosis to make sure the PCM

is functioning properly.

l When measuring supply voltage of PCM-con-

trolled components with a circuit tester, separate 1

tester probe from another. If the 2 tester probes acci-

dentally make contact with each other during mea-

surement, a short circuit WIII result and damage the

PCM.

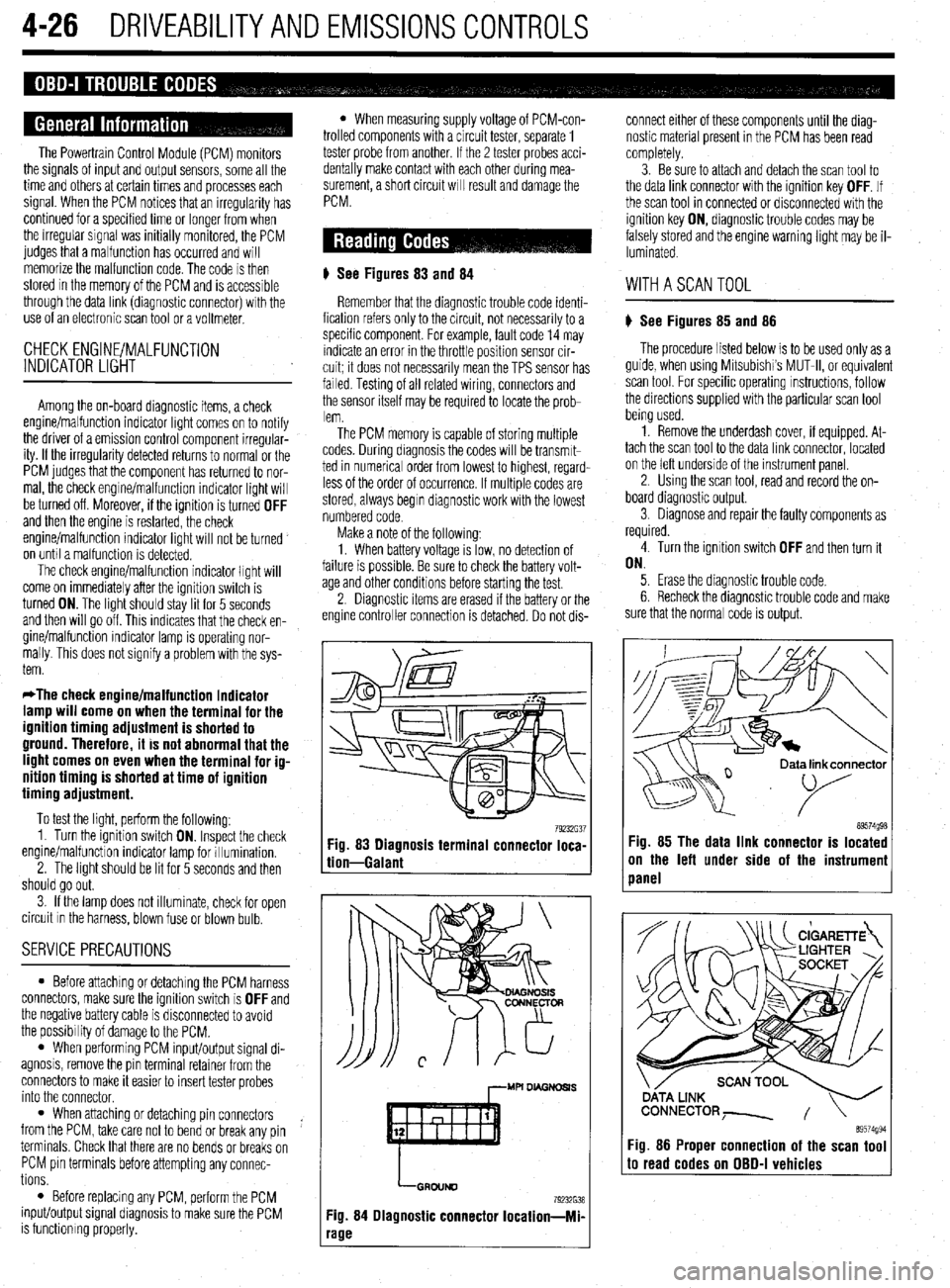

# See Figures 83

and 84

Remember that the diagnostic trouble code identi-

fication refers only to the circuit, not necessarily to a

specific component. For example, fault code 14 may

indicate an error in the throttle position sensor cir-

cuit; it does not necessarily mean the TPS sensor has

failed Testing of all related wiring, connectors and

the sensor itself may be required to locate the prob-

lem.

The PCM memory is capable of storing multiple

codes. During diagnosis the codes will be transmlt-

ted in numerical order from lowest to highest, regard-

less of the order of occurrence. If multiple codes are

stored, always begin diagnostic work with the lowest

numbered code

Make a note of the following:

1. When battery voltage IS low, no detection of

failure is possible. Be sure to check the battery volt-

age and other conditions before starting the test.

2. Diagnostic items are erased if the battery or the

engine controller connection is detached. Do not dis- connect either of these components until the diag-

nostic material present in the PCM has been read

completely.

3. Be sure to attach and detach the scan tool to

the data link connector with the ignition key OFF. If

the scan tool in connected or disconnected with the

ignition key ON, diagnostic trouble codes may be

falsely stored and the engine warning light may be il-

luminated. WITHASCANTOOL

) See Figures 85 and 86

The procedure listed below is to be used only as a

guide, when using Mitsubishi’s MUT-II, or equivalent

scan tool. For specific operating instructions, follow

the directions supplied with the particular scan tool

bemg used.

1. Remove the underdash cover, if equipped. At-

tach the scan tool to the data link connector, located

on the left underside of the instrument panel.

2. Using the scan tool, read and record the on-

board diagnostic output.

3. Diagnose and repair the faulty components as

required

4. Turn the ignition switch OFF and then turn it

ON.

5. Erase the diagnostic trouble code.

6 Recheck the diaanostic trouble code and make

sure that the normal &de is output.

79232G37 89574g98 Fig. 83 Diagnosis terminal connector loca-

tion-Galant Fig. 85 The data link connector is located

on the left under side of the instrumeni

panel

,--MU DL4GNDSl.S

LGRDIJND

79232638

Fig. 84 Diagnostic connector Iocation-Mi-

‘age

ata link connector

89574994 Fig. 86 Proper connection of the scan tool to read codes on OBD-I vehicles

Page 222 of 408

CHASSIS ELECTRICAL 6-19

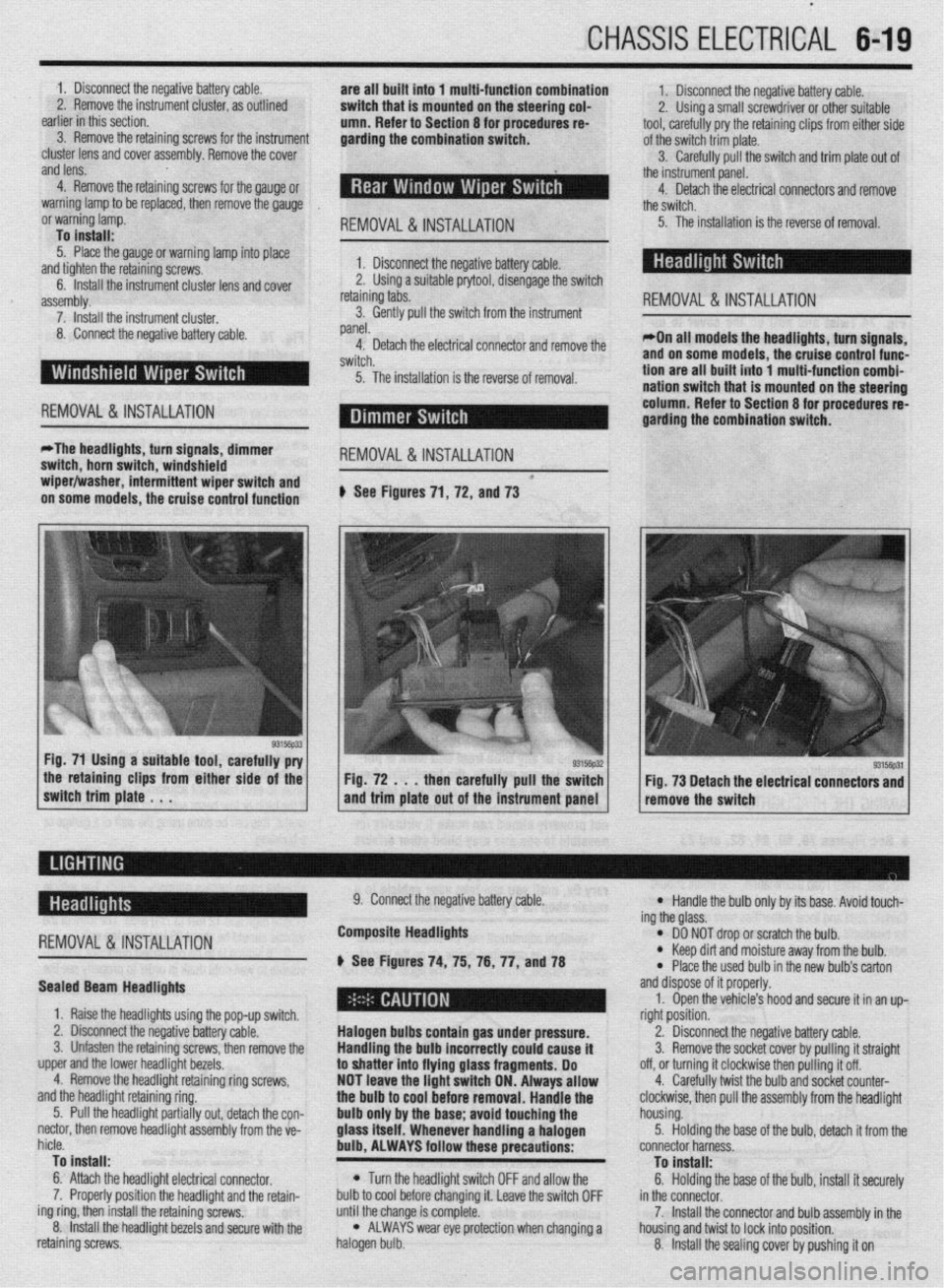

1. Disconnect the negative battery cable.

are all built into 1 multi-function combination

2. Remove the instrument cluster, as outlined 1. Disconnect the negative battery cable.

earlier in this section. switch that is mounted on the steering col-

2. Using a small screwdriver or other suitable

umn. Refer to Section 8 for procedures re-

3. Remove the retaining screws for the instrument tool, carefully pry the retaining clips from either side

garding the combination switch.

cluster lens and cover assembly. Remove the cover of the switch trim plate.

3.

and lens. Carefully pull the switch and trim plate out of

,

4. Remove the retaining screws for the gauge or the instrument panel.

4. Detach the electrical connectors and remove

warning lamp to be replaced, then remove the gauge

the switch.

or warning lamp.

REMOVAL&INSTALLATION : 5. The installation is the reverse of removal.

To install:

5. Place the gauge or warning lamp into place

and tighten the retaining screws. 1. Disconnect the negative battery cable.

6. Install the instrument cluster lens and cover 2. Using a suitable prytool, disengage the switch

assembly. retaining tabs.

REMOVAL &INSTALLATION 7. Install the instrument cluster. 3. Gently pull the switch from the instrument

8. Connect the negative battery cable. panel.

4. Detach the electrical connector and remove the *On all models the headlights, turn signals,

switch. and on some models, the cruise control func-

5. The installation is the reverse of removal. tion are all built into 1 multi-function combi-

nation switch that is mounted on the steerinq

REMOVAL &INSTALLATION column. Refer to Section 8 for procedures 6

garding the combination switch.

*The headlights, turn signals, dimmer

switch, horn switch, windshield

REMOVAL &INSTALLATION

wiper/washer, intermittent wiper switch and *

on some models, the cruise control function # See Figures 71, 72, and 73

the retaining clips from either side of the

switch trim plate . . . Fig. 72 . . . then carefully pull the switch

and trim plate out of the instrument panel Fig. 73 Detach the electrical connectors and

remove the switch

-

REMOVAL &INSTALLATION

Sealed Beam Headlights

1. Raise the headlights using the pop-up switch.

2. Disconnect the negative battery cable.

3. Unfasten the retaining screws, then remove the

upper and the lower headlight bezels.

4. Remove the headlight retaining ring screws,

and the headlight retaining ring.

5. Pull the headlight partially out, detach the con-

nectar, then remove headlight assembly from the ve-

hicle.

To install:

6. Attach the headlight electrical connector.

7. Properly position the headlight and the retain-

ing ring, then install the retaining screws.

8. Install the headlight bezels and secure with the

retaining screws. 9. Connect the negative battery cable.

Composite Headlights

6 See Figures 74, 75, 76, 77, anU78

Halogen bulbs contain gas under pressure.

Handling the

bulb incorrectly could cause it

to shatter into flying glass fragments. Do

NOT leave the light switch ON. Always allow

the bulb to cool before removal. Handle the

bulb only by the base; avoid touching the

glass itself. Whenever handling a halogen

bulb, ALWAYS follow these precautions:

l Turn the headlight switch OFF and allow the

bulb to cool before changing it. Leave the switch OFF

until the change is complete.

l ALWAYS wear eye protection when changing a

halogen bulb.

l Handle the bulb only by its base. Avoid touch-

ing the glass.

l DO NOT drop or scratch the bulb. l Keep dirt and moisture away from the bulb.

* Place the used bulb in the new bulb’s carton

and dispose of it properly.

1. Open the vehicle’s hood and secure it in an up-

right position.

2. Disconnect the negative battery cable.

3. Remove the socket cover by pulling it straight

off, or turning it clockwise then pulling it off.

4. Carefully twist the bulb and socket counter-

clockwise, then pull the assembly from the headlight

housing.

5. Holding the base of the bulb, detach it from the

connector harness.

To install:

6. Holding the base of the bulb, install it securely

in the connector.

7. Install the connector and bulb assembly in the

housing and twist to lock into position.

8. Install the sealing cover by pushing it on

Page 324 of 408

. . . ,.x ..-~ .-....,, _s_s”., .._ ” *

8-28 SUSPENSION AND STEERING

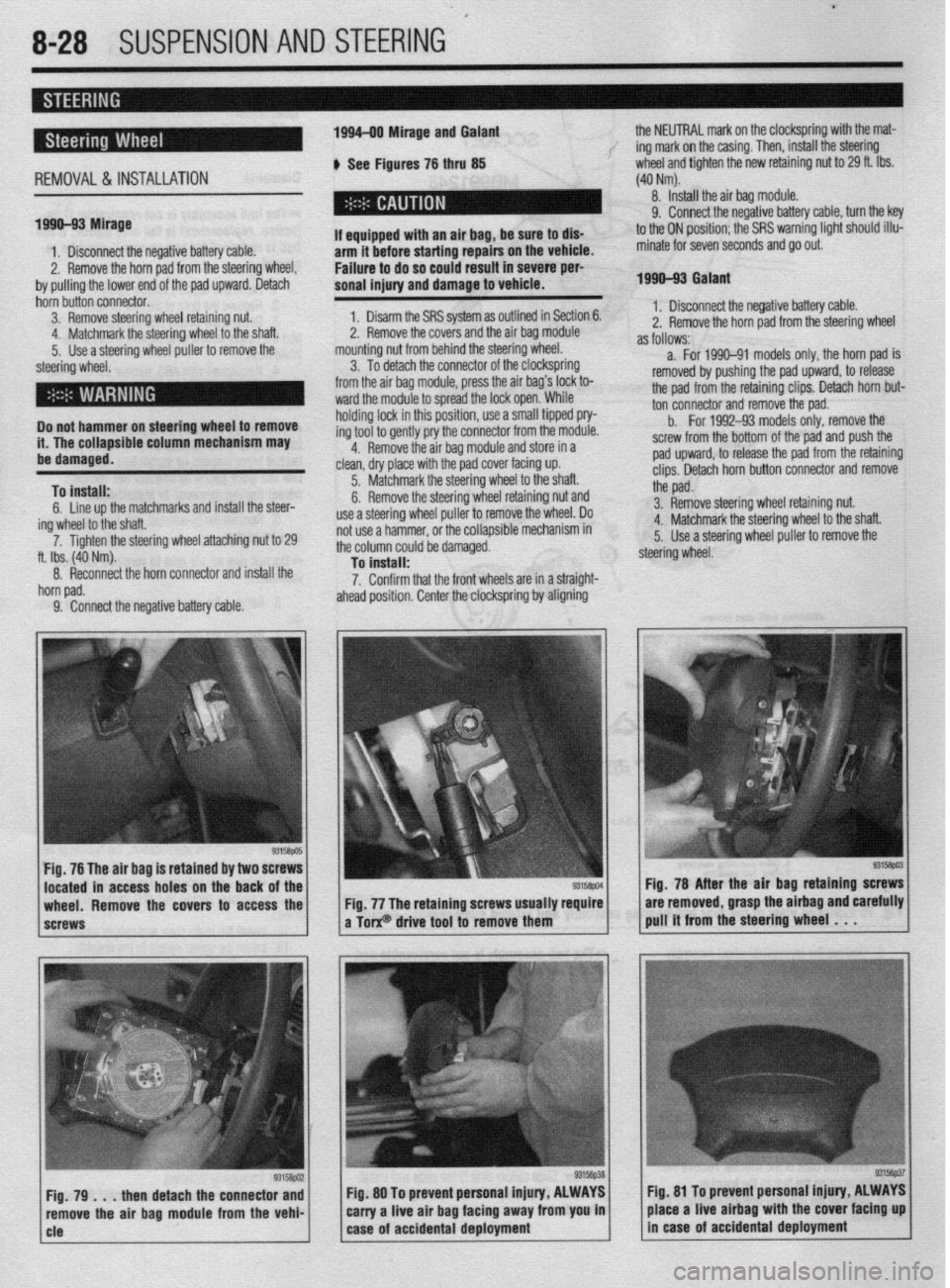

REMOVAL&INSTALLATION

199%93 Mirage 1994-00 Mirage and Galant

b See Figures 76 thru 85 the NEUTRAL mark on the clockspring with the mat-

f ing mark on the casing. Then, install the steering

wheel and tighten the new retaining nut to 29 ft. Ibs.

(40 Nm).

8. Install the air bag module.

1. Disconnect the negative battery cable.

2. Remove the horn pad from the steering wheel,

by pulling the lower end of the pad upward. Detach I

If aqui

arm it --.-.- ---.-...= .-r-.‘- -.. _..- ._.. - -

Failure to do so could result in severe per-

sonal injury and damage to vehicle. pped with an air bag, be sure to dls- hnfnra sfarfinn rmairs on the vehicle.

9. Connect the negative battery cable, turn the key

to the ON position; the SRS warning light should illu-

minate for seven seconds and go out.

1990-93 Galant

hbin butin connector.

3. Remove steering wheel retaining nut:

. . . .‘ .

a. .a I <.

4. Matcnmarlc me steering wneel to me snan.

5. Use a steering wheel puller to remove the

steering wheel.

Do not hammer on steering wheel to remove

it. The collapsible column mechanism may

ha rlsmwmd.

To install:

6. Line up the matchmarks and install the steer-

ing wheel to the shaft.

7. Ti flhten the steering wheel attaching nut to 29

ft. Ibs. (40 Nm).

8. Reconnect the horn connector and install the

horn pad.

9. Connect the neaative battetv cable. 1. Disarm the SRS system as outlined in Section 6.

^ m *I

sand the air bag module

.,A +L. m++-,g w,,eel,

*. I z. Remove me cover

mounting nut from behill” ~IK ~(G~G!I

3. To detach the connector of the clocKsprmfl

from the air bag module, press the air bag’s lock to-

ward the module to spread the lock open. While

holding lock in this position, use a small tipped pry-

ing tool to gently pry the connector from the module.

4. Remove the air bag module and store in a

clean, dry place with the pad cover facing up.

5. Matchmark the steering wheel to the shaft.

6. Remove the steering wheel retaining nut and

use a steering wheel puller to remove the wheel. Do

not use a hammer, or the collapsible mechanism in

the column could be damaged.

To install:

7. Confirm that the front wheels are in a straight-

ahead position. Center the clocksprinfl by aligning 1. Disconnect the negative battery cable.

2. Remove the horn oad from the steerino wheel

as follows:- - - - r d

a. For 1990-91 models only, the horn pad is

removed by pushing the pad upward, to release

the pad from the retaining clips. Detach horn but-

ton connector and remove the pad.

b.

For 1992-93 models only, remove the

screw from the bottom of the pad and push the

pad upward, to release the pad from the retaining

clips. Detach horn button connector and remove

the pad.

3. Remove steering wheel retaining nut.

4. Matchmark the steering wheel to the shaft.

5. Use a steering wheel puller to remove the

steering wheel.

Fig. 76 The air bag is retained by two 8

located in access holes on the back

wheel. Remove the covers to access the

screws Fig. 78 After the air baa

retainino screws

Fig. 77 The retaining screws usually require are removed, grasp the airbag andiarefully

a Torx@ drive tool to remove them pull it from the steering wheel . . .

then detach the connector and Fig. 80 To prevent personal injury, ALWAYS fig. 81 To prevent personal Injury, ALWAYS

ove the air bag module from the vehi- carry a live air bag facing away from you in place a live airbag with the cover facing up

Page 325 of 408

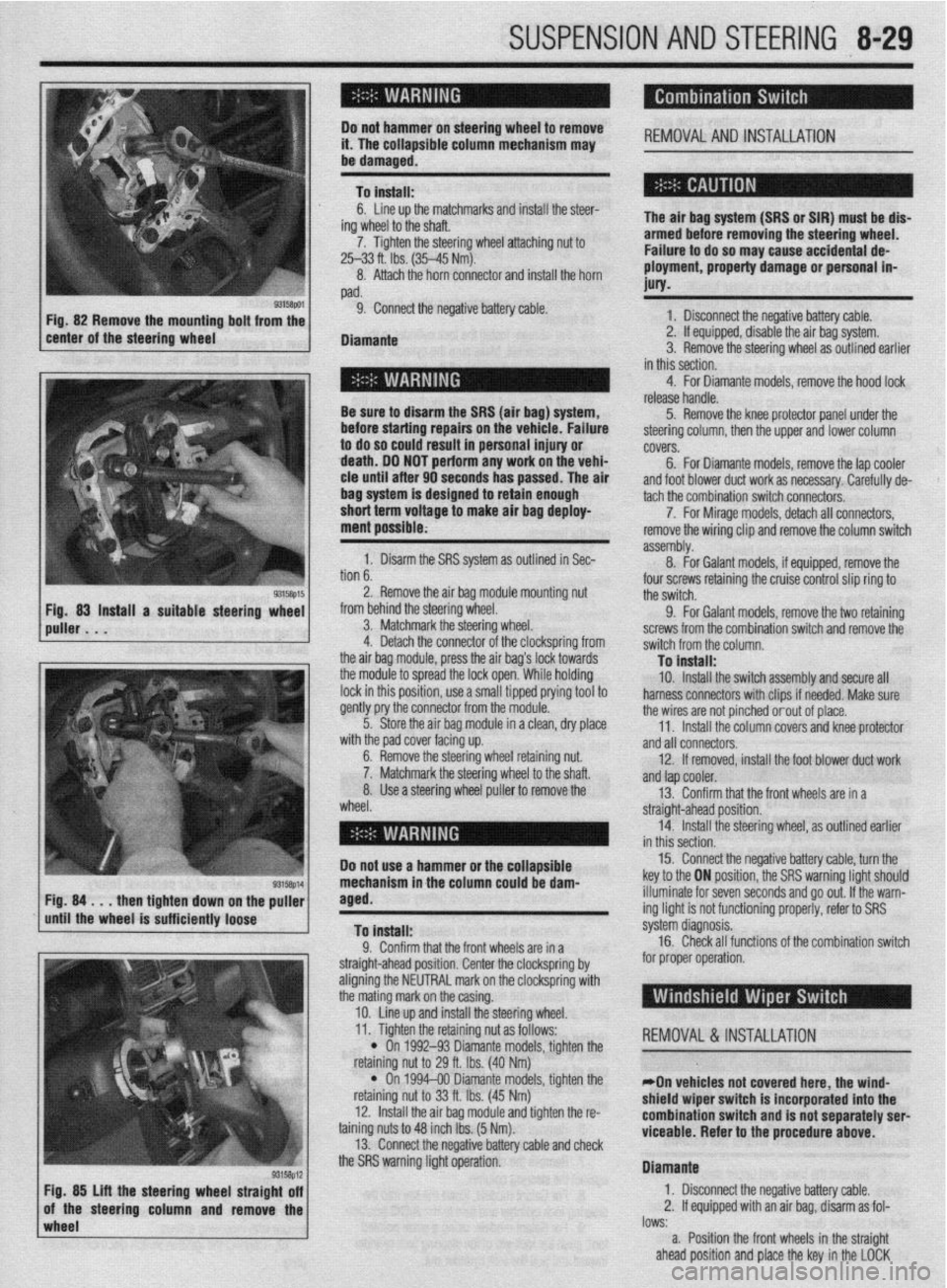

SUSPENSION AND STEERING 8-29

i ’

Do not hamme i4 l-ha nnlhnr !r on steering wheel to remove

,,. , II= ,,,,,,Jfble column mechanism may REMOVALANDINSTALLATION

I

be damaged.

To install:

ing

7.

6. Line up the matchmarks and install the steer-

/heel to the shaft.

Tighten the steering wheel attaching nut to

25-33 ft. Ibs. (35-45 Mm).

8. Attach the horn connector and install the horn

pad.

9. Connect the negative battery cable.

Diamante The air bag system (SRS or SIR) must be dis-

armed before removing the steering wheel.

Failure to do so may cause accidental de-

ployment, property damage or personal in-

MY.

1 Rscnnnnd the nnmtivn hattm rJhle . I._“” . ..I_. . ..I *.-~ _...” ““.‘“‘, _““._. 2. If equipped, disable the air bag system.

3. Remove the steering wheel as outlined earlier

in this section.

Be sure to disarm the SRS (air bag

before starting repairs OI

to do so could result in p

death. DO NOT perform ;

cle until after 90 seconds has passed. The ai

bag system is designed to retain enough

short term voltage to make air bag deploy-

ment possible; I) system,

n the vehicle. Failure

lersonal injury or

any work on the vehi-

ir 4. For Diamante models, remove the hood lock

release handle.

5. Remove the knee protector panel under the

steering column, then the upper and lower column

covers.

6. For Diamante models, remove the lap cooler

and foot blower duct work as necessary. Carefully de-

non

b. 1. Disarm the SRS system as outlined in Sec-

. . ^ I assembly. tach the combination switch connecto&.

8. -

7. For Mirage models, detach all connectors,

For Galant models, if equipped, remove the remove the wiring clip and remove the column switch

2. Remove the air bag module mounting nut

from behind the steering wheel.

3. Matchmark the steering wheel.

4. Detach the connector of the clockspring from

the air baq module, press the air baa’s lock towards four screws retaining the cruise control slip ring to

the switch.

9. For Galant models, remove the two retaining

screws from the combination switch and remove the

switch from the column.

Tn install: the modub to spread the lock open:While holding

lock in this position, use a small tipped prying tool to

gently pry the connector from the module.

5. Store the air bag module in a clean, dry place

..# ,I I I .

ut.

Iaft. wlrn me paa cover racmg up.

6. Remove the steering wheel retaining nl

7. Matchmark the steering wheel to the sl

8. Use a steering wheel puller to remove the

wheel. - . . - _-. . _

10. Install the switch assembly and secure all

harness connectors with clips if needed. Make sure

the wires are not pinched orout of place.

11. Install the column covers and knee protector

and all connectors.

12. If removed, install the foot blower duct work

anfl tan cnnler -..- .-

r --- ”

13. Confirm that the front wheels are in a

straight-ahead position.

14. Install the steering wheel, as outlined earlier

in thir

Do not use a hammer or the ~r”---‘~‘- 15. Connect the negative battery cable, turn the

key to the ON position, the SRS warning light should

NW down

rinntlv

wImpl* the puller

iem Fig. 84 . . . then tighte

until the wheel is suffL,,,,, lVvoV

To install:

0 Pnnfirm that thn frnnt whnalc ,?A in , .I. ““llllllll u,a, ,110 ll”lll I.ll~rJlJ CnIj 111 a

straight-ahead position. Center the clockspring by

aligning the NEUTRAL mark on the clockspring with

the mating mark on the casing.

10. Line up and install the steering wheel. illuminate for seven seconds and go out. If the warn-

ing light is not functioning properly, refer to SRS

s’ .’ ystem cllagnosls.

16. Check all functions of the combination switch

for proper operation.

wheel lows:

a. Position the front wheels in the straight

ahead position and place the key in the LOCK

93158p12 Fig. 85 Lift the steering wheel straight off

of the steering column and remove the 11. Tighten the retaining nut as follows:

REMOVAL &INSTALLATION

l On 1992-93 Diamante models, tighten the

nut to 29 ft. Ibs. (40 Nm) retammg I

l On

retaining I

12. lnstal

taining nuts 1

13. Conn

“... . ..” .‘“J...*.” ‘&.“WSJ Y..“.” . ..rn” VII”“..

the SRS warning light operation. 1994-00 Diamante models, tighten the

iut to 33 ft. Ibs. (45 Nm)

II the air bag module and tighten the r&

:o 48 inch Ibs. (5 Nm).

wt the rwnative hatim rahle ami rhwk

*On vehicles not covered here, the wind-

shield wiper switch is incorporated into the

combination switch and is not separately serl

viceable. Refer to the procedure

above.

Diamante

1. Disconnect the negative battery cable.

2. If equipped with an air bag, disarm as fol-

I” .L

Page 338 of 408

9-2 BRAKES

Hydraulic systems are used to actuate the brakes

of all modern automobiles. The system transports the

power required to force the frictional surfaces of the

braking system together from the pedal to the indi-

vidual brake units at each wheel. A hydraulic system

is used for two reasons.

First, fluid under pressure can be carried to all

parts of an automobile by small pipes and flexible

hoses without taking up a significant amount of room

or posing routing problems.

Second, a great mechanical advantage can be

given to the brake pedal end of the system, and the

foot pressure required to actuate the brakes can be

reduced by making the surface area of the master

cylinder pistons smaller than that of any of the pis-

tons in the wheel cylinders or calipers.

The master cylinder consists of a fluid reservoir

along with a double cylinder and piston assembly.

Double type master cylinders are designed to sepa-

rate the front and rear braking systems hydraulically

in case of a leak. The master cylinder converts me-

chanical motion from the pedal into hydraulic pres-

sure within the lines. This pressure is translated back

into mechanical motion at the wheels by either the

wheel cylinder (drum brakes) or the caliper (disc

brakes).

Steel lines carry the brake fluid to a point on the

vehicle’s frame near each of the vehicle’s wheels. The

fluid is then carried to the calipers and wheel cylin-

ders by flexible tubes in order to allow for suspen-

sion and steering movements.

In drum brake systems, each wheel cylinder con-

tains two pistons, one at either end, which push out-

ward in opposite directions and force the brake shoe

into contact with the drum.

In disc brake systems, the cylinders are part of the

calipers. At least one cylinder in each caliper is used

to force the brake pads against the disc.

All pistons employ some type of seal, usually

made of rubber, to minimize fluid leakage. A rubber

dust boot seals the outer end of the cylinder against

dust and dirt. The boot fits around the outer end of

the piston on disc brake calipers, and around the

brake actuating rod on wheel cylinders.

The hydraulic system operates as follows: When at

rest, the entire system, from the piston(s) in the mas-

ter cylinder to those in the wheel cylinders or

calipers, is full of brake fluid. Upon application of the

brake pedal, fluid trapped in front of the master cylin-

der piston(s) is forced through the lines to the wheel

cylinders. Here, it forces the pistons outward, in the

case of drum brakes, and inward toward the disc, in

the case of disc brakes. The motion of the pistons is

opposed by return springs mounted outside the

cylinders in drum brakes, and by spring seals, in disc

brakes.

Upon release of the brake pedal, a spring located

inside the master cylinder immediately returns the

master cylinder pistons to the normal position. The

pistons contain check valves and the master cylinder

I

has compensating ports drilled in it. These are un-

covered as the pistons reach their normal position.

The piston check valves allow fluid to flow toward the

wheel cylinders or calipers as the pistons withdraw.

Then, as the return springs force the brake pads or

shoes into the released position, the excess fluid

reservoir through the compensating ports. It is during the time the pedal is in the released position that any

fluid that has leaked out of the system will be re-

placed through the compensating ports.

Dual circuit master cylinders employ two pistons,

located one behind the other, in the same cylinder.

The primary piston is actuated directly by mechanical

linkage from the brake pedal through the power

booster. The secondary piston is actuated by fluid

trapped between the two pistons. If a leak develops in

front of the secondary piston, it moves forward until it

bottoms against the front of the master cylinder, and

the fluid trapped between the pistons will operate the

rear brakes. If the rear brakes develop a leak, the pri-

mary piston will move forward until direct contact

with the secondary piston takes place, and it will

force the secondary piston to actuate the front brakes.

In either case, the brake pedal moves farther when the

brakes are applied, and less braking power is avail-

able.

All dual circuit systems use a switch to warn the

driver when only half of the brake system is opera-

tional. This switch is usually located in a valve body

which is mounted on the firewall or the frame below

the master cylinder. A hydraulic piston receives pres-

sure from both circuits, each circuits pressure being

applied to one end of the piston. When the pressures

are in balance, the piston remains stationary. When

one circuit has a leak, however, the greater pressure

in that circuit during application of the brakes will

push the piston to one side, closing the switch and

activating the brake warning light.

In disc brake systems, this valve body also con-

tains a metering valve and, in some cases, a propor-

tioning valve. The metering valve keeps pressure

from traveling to the disc brakes on the front wheels

until the brake shoes on the rear wheels have con-

tacted the drums, ensuring that the front brakes will

never be used alone. The proportioning valve con-

trols the pressure to the rear brakes to lessen the

chance of rear wheel lock-up during very hard brak-

ing.

Warning lights may be tested by depressing the

brake pedal and holding it while opening one of the

wheel cylinder bleeder screws. If this does not cause

the light to go on, substitute a new lamp, make conti-

nuity checks, and, finally, replace the switch as nec-

essary.

The hydraulic system may

be checked for leaks by applying pressure to the pedal gradually and steadily.

If the pedal sinks very slowly to the floor, the system

has a leak. This is not to be confused with a springy

or spongy feel due to the compression of air within

the lines. If the system leaks, there will be a gradual

change in the position of the pedal with a constant

pressure.

Check for leaks along all lines and at wheel cylin-

ders. If no external leaks are apparent, the problem is

inside the master cylinder,

DISC BRAKES

Instead of the traditional expanding brakes that

press outward against a circular drum, disc brake

systems utilize a disc (rotor) with brake pads posi-

tioned on either side of it. An easily-seen analogy is

the hand brake arrangement on a bicycle. The pads

squeeze onto the rim of the bike wheel, slowing its

motion. Automobile disc brakes use the identical principle but apply the braking effort to a separate

disc instead of the wheel.

The disc (rotor) is a casting, usually equipped with

cooling fins between the two braking surfaces. This

enables air to circulate between the braking surfaces

making them less sensitive to heat buildup and more

resistant to fade. Dirt and water do not drastically af-

fect braking action since contaminants are thrown off

by the centrifugal action of the rotor or scraped off

the by the pads. Also, the equal clamping action of

the two brake pads tends to ensure uniform, straight

line stops. Disc brakes are inherently self-adjusting.

There are three general types of disc brake:

1. A fixed caliper.

2. A floating caliper.

3. A sliding caliper.

The fixed caliper design uses two pistons

mounted on either side of the rotor (in each side of

the caliper). The caliper is mounted rigidly and does

not move.

The sliding and floating designs are quite similar.

In fact, these two types are often lumped together. In

both designs, the pad on the inside of the rotor is

moved into contact with the rotor by hydraulic force.

The caliper, which is not held in a fixed position,

moves slightly, bringing the outside pad into contact

with the rotor. There are various methods of attaching

floating calipers. Some pivot at the bottom or top,

and some slide on mounting bolts. In any event, the

end result is the same.

DRUM BRAKES

Drum brakes employ two brake shoes mounted on

a stationary backing plate. These shoes are posi-

tioned inside a circular drum which rotates with the

wheel assembly. The shoes are held in place by

springs. This allows them to slide toward the drums

(when they are applied) while keeping the linings and

drums in alignment. The shoes are actuated by a

wheel cylinder which is mounted at the top of the

backing plate. When the brakes are applied, hydraulic

pressure forces the wheel cylinder’s actuating links

outward. Since these links bear directly against the

top of the brake shoes, the tops of the shoes are then

forced against the inner side of the drum. This action

forces the bottoms of the two shoes to contact the

brake drum by rotating the entire assembly slightly

(known as servo action). When pressure within the

wheel cylinder is relaxed, return springs pull the

shoes back away from the drum.

Most modern drum brakes are designed to self-

adjust themselves during application when the vehi-

cle is moving in reverse. This motion causes both

shoes to rotate very slightly with the drum, rocking

an adjusting lever, thereby causing rotation of the ad-

justing screw. Some drum brake systems are de-

signed to self-adjust during application whenever the

brakes are applied. This on-board adjustment system

reduces the need for maintenance adjustments and

keeps both the brake function and pedal feel satisfac-

tory.

POWER BOOSTERS

Virtually all modern vehicles use a vacuum as-

sisted power brake system to multiply the braking

force and reduce pedal effort. Since vacuum is always

available when the engine is operating, the system is

Page 361 of 408

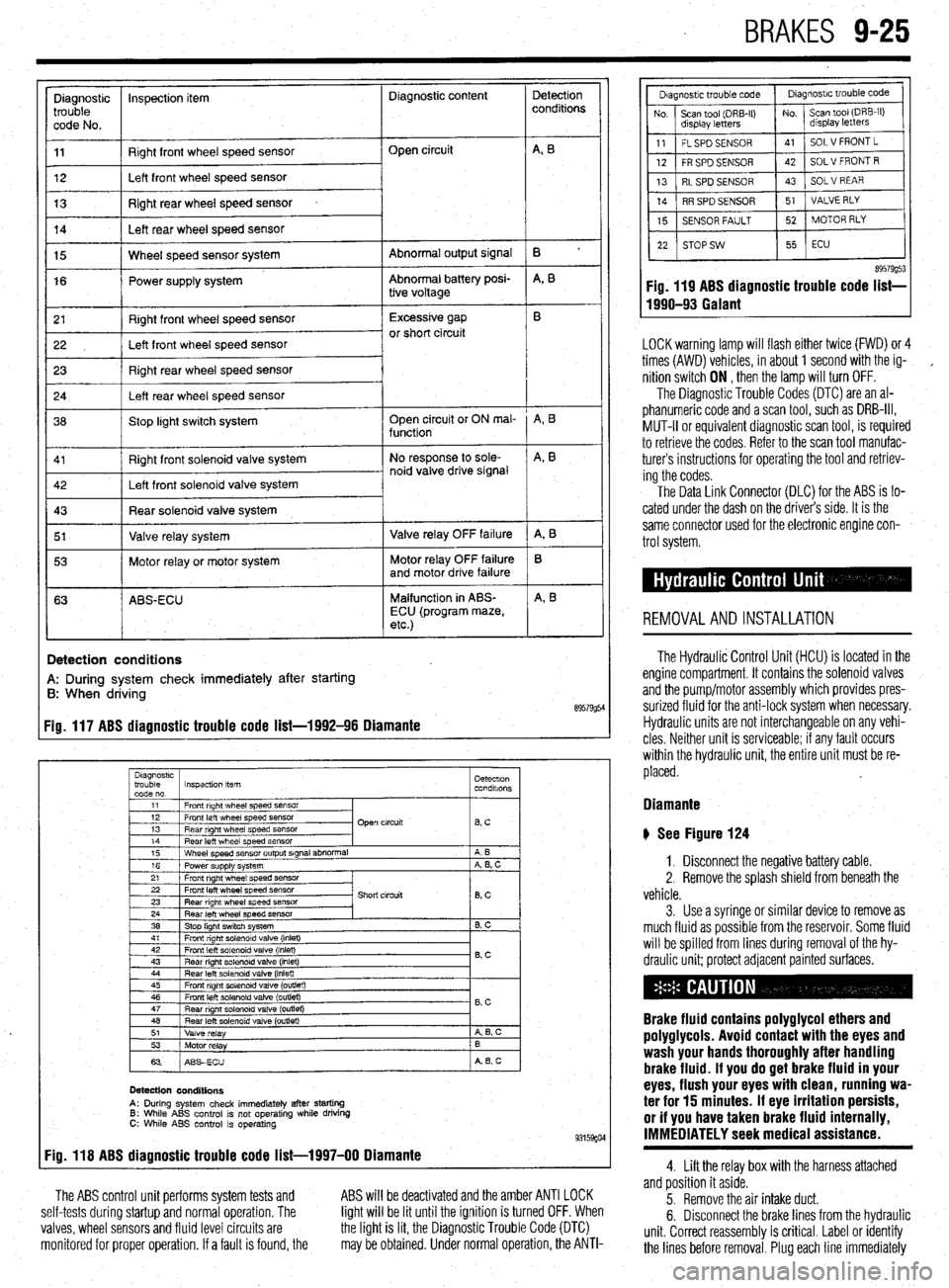

BRAKES 9-25

Diagnostic inspection item Diagnostic content

trouble

code No.

11 Right front wheel speed sensor

12 Left front wheel speed sensor Open circuit

13 Right rear wheel speed sensor

14 Left rear wheel speed sensor

Abnormal output signal

Abnormal battery posi-

tive voltage 15 Wheel speed sensor system

16 Power supply system

r 21

I Right front wheel speed sensor 1 Excessive gap

22 I Left front wheel speed sensor or short circuit

23 Right rear wheel speed sensor

24 Left rear wheel speed sensor

36 Stop light switch system Open circuit or ON mal-

function

Right front solenoid valve system

I 5’ I Valve relay system 1 Valve relay OFF failure

I 53 1 Motor relay or motor system Motor relay OFF failure

and motor drive failure

63 ABS-ECU Malfunction in ABS-

ECU (program maze,

etc.)

I

!

Detection

conditions

B ’

A, B

A, B

A, B

A, 8

B

A, B

Detection conditions

A: During system check immediately after starting

B: When driving

89579954 Fig. 117 ABS diagnostic trouble code list-1992-96 Diamante

Diagnostrc

trouble Inspection item Detectron

code no. condalons

1

11 1 Front right wheel speed SensOr

I

I I

12 1 Front left wheel speed sensor

13 1 Rear right wheel speed sensor Open circuit

lBsC I

14

Rear left wheel speed sensor

15 Wheel speed sensor output signal abnormal

16 Power supply system

21 Front right wheel speed sensor A B

A, B, C

22 Front left wheel speed sensor

23 Rear right wheel speed sensor

24 Rear left wheel speed sensor

38 Stop light switch system Short circuit

8, c

B. C

41 1 Front right solenoid valve (inlet)

I I

42

Front left solenoid valve (inlet)

43 Rear right solenord valve (inlet) 0.c

44 Rear left solenoid valve (inlet)

45 Front right solenoid valve (outlet)

46 Front left solenoid valve (outlet)

47

Rear nght solenoid valve (outret) - B,C

48 Rear left solenoid valve (outlet)

51

Valve relay A 6, c

53

Motor relay B

63 ABSECU A B, c

Detection conditions

A: During system check immediately after starting 6: While ABS control is not operating while driving C: While ABS control is operating 93159go4 Fig. 118 ABS diagnostic trouble code list-1997-00 Diamante

The ABS control unit performs system tests and

self-tests during startup and normal operation. The

valves, wheel sensors and fluid level circuits are

monitored for proper operation. If a fault is found, the ABS will be deactivated and the amber ANTI LOCK

light will be lit until the ignition is turned OFF. When

the light is lit, the Diagnostic Trouble Code (DTC)

may be obtained. Under normal operation, the ANTI-

89579g53 Fig. 119 ABS diagnostic trouble code list-

1990-93 Galant

LOCK warning lamp will flash either twice (FWD) or 4

times (AWD) vehicles, in about 1 second with the ig-

,

nition switch ON , then the lamp will turn OFF.

The Diagnostic Trouble Codes (DTC) are an al-

phanumeric code and a scan tool, such as DRB-III,

MUT-II or equivalent diagnostic scan tool, is required

to retrieve the codes. Refer to the scan tool manufac-

turers instructions for operating the tool and retriev-

ing the codes.

The Data Link Connector (DLC) for the ABS is lo-

cated under the dash on the driver’s side. It is the

same connector used for the electronic engine con-

trol system.

REMOVALANDINSTALLATION

The Hydraulic Control Unit (HCU) is located in the

engine compartment. It contains the solenoid valves

and the pump/motor assembly which provides pres-

surized fluid for the anti-lock system when necessary.

Hydraulic units are not interchangeable on any vehi-

cles Neither unit is serviceable; if any fault occurs

within the hydraulic unit, the entire unit must be re-

placed.

Diamante

b See Figure 124

1. Disconnect the negative battery cable.

2. Remove the splash shield from beneath the

vehicle.

3. Use a syringe or similar device to remove as

much fluid as possible from the reservoir. Some fluid

will be spilled from lines during removal of the hy-

draulic unit; protect adjacent painted surfaces.

Brake fluid contains polyglycol ethers and

poly9lycols. Avoid contact with the eyes and

wash your hands thoroughly after handling

brake fluid. If you do 9et brake fluid in your

eyes, flush your eyes with clean, running wa-

ter for 15 minutes. If eye irritation persists,

or if you have taken brake fluid internally,

IMMEDIATELY seek medical assistance.

4. Lift the relay box with the harness attached

and position it aside.

5. Remove the air intake duct.

6. Disconnect the brake lines from the hydraulic

unit. Correct reassembly is critical. Label or identify

the lines before removal. Plug each line immediately

Page 376 of 408

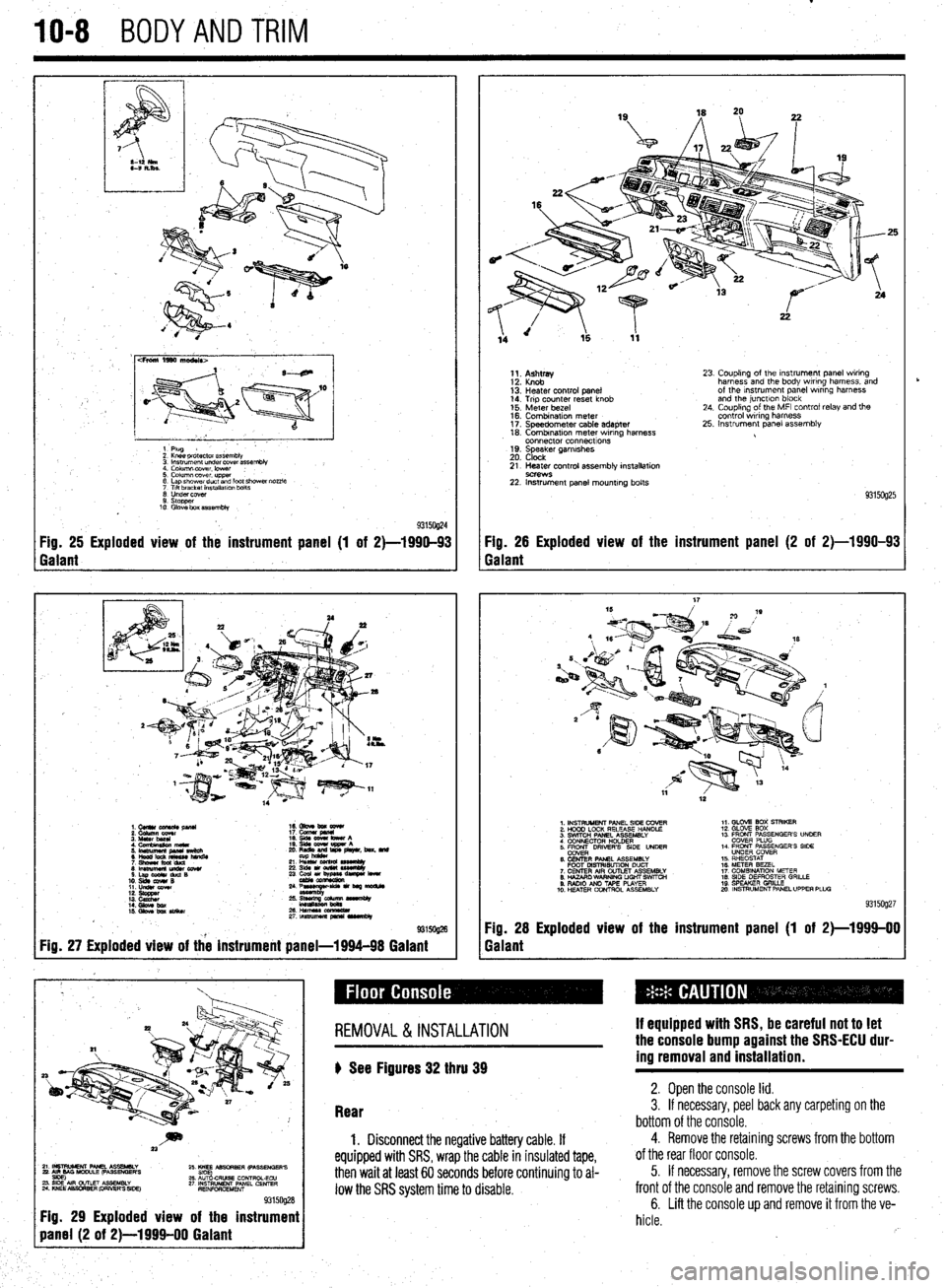

IO-8 BODYANDTRIM

cFroni 1990 ma&Is>

1 Plug

2 Knee pr&ctor assembb

3 lnsuumen~ under covet assembly

4. Column lxwer. lower :

5. Column cover upper

6 Lap shower duct and foot shcwai nozzle

7 Ttlt bracket installalm bolts

0 Undercover

9. stopper

10 Glove box assembly

93150@4 Fig. 25 Exploded view of the instrument panel (1 of 2)-1990-93 Fig. 26 Exploded view of the instrument panel (2 of 2)-1990-93

Galant Galant

1.CUllUCU+RC&pllU 16. Gbve bm eewr

i: iiiikz!!T 17. cucw gmnl

4. Cfnnbinuion meta 19. qds cww bww A

5 ‘~fiJzg%L L: ,“zr&, beat. md

21 L% sssemuy

8lmwmemu&cowr 236&1ou(W~

S.LapOdrduQB

10. slds cw4# B 23 ~u,~e-

11. LIdsI corn

::: s%ZZ

14. Gbw bx / ;:+q-=:-

kmasa

IS. Gkw ba SIiikw 2&HWSSCCl!ZL

2rtnsmlmuapr*lrvrnbly

@ma

Fig. 27 Exploded view of the instrument panel-1994-98 Galant

1;. p;;w

13: Heater control panel

14. Trip counter reset knob

15. Meter bezel

16. Combination meter

17. Speedometer cable adapter

18. Combrnatron meter wiring harness

connector connecttons

19. Speaker garnrshes

20. Clock 23. Coupling of the Instrument panel wiring

harness and the body wiring harness, and

of the Instrument panel wrring harness

and the junctlon block

24. Coupling of the MFI control relay and the

control wiring harness

25. Instrument panel assembly

21. Heater control assembly installation

9C?WS 22. Instrument panel mounting bolts

93150925

1. INSTRUMENT PANEL SIDE COVER

2. HOOD LOCK RELEASE HANDLE

3. SWITCH PANEL ASSEMBLY

4 CONNECTOR H+DER

5. ER DRIVERS SIDE UNDER

6. CENTER PANEL ASSEMBLY

FOOT MSTRISUTION DUCT

7. CENTER AIR OUTLET ASSEMBLY

8. HAZARO WARNING LIGHT SWfTCti

9. RADIO AN0 TAPE PLAYER

10. H!ZATER CONTROL ASSEMBLY 1,. GLOV2 BOX STRIKER

12. GLOVE SOX

13 FRONT PASSENGER’S UNOER

COVER PLUG

14. FRONT PASSENGER’S SIDE

UNDER COVER

15. RHEOSTAT

16. METER BEZEL

17. COMBINATION METER

18. SIDE DEFROSTER GRILLE

19 SPEAKER GRILLE

mo. INSTRUMENT PANEL UPPER PLUG

93159927

Fig. 28 Exploded view of the instrument panel (1 of 2)-1999-00

Galant

~~~~~~~~~

Fig. 29 Exploded view of the instrument

REMOVAL &INSTALLATION

) See Figures 32 thru 39 If equipped with SRS, be careful not to let

the console bump against the SRS-ECU dur-

ing removal and installation.

Rear 2. Open the console lid. 3. If necessary, peel back any carpeting on the

bottom of the console.

1. Disconnect the negative battery cable. If

equipped with SRS, wrap the cable in insulated tape,

then wait at least 60 seconds before continuing to al-

low the SRS system time to disable.

4. Remove the retaining screws from the bottom

of the rear floor console.

5. If necessary, remove the screw covers from the

front of the console and remove the retaining screws.

6. Lift the console up and remove it from the ve-

hicle.

rb