oil MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 313 of 391

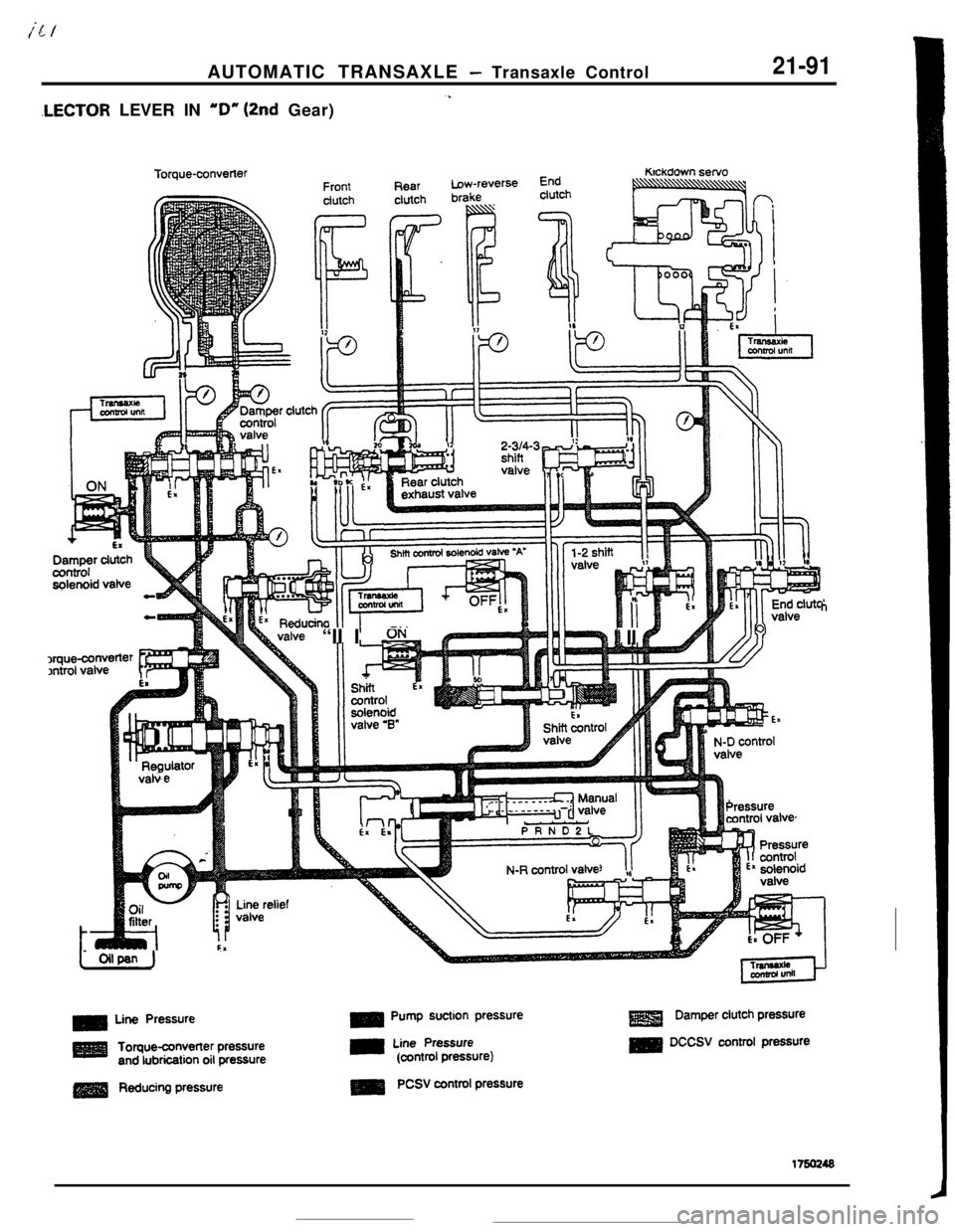

AUTOMATIC TRANSAXLE - Transaxle Control21-91

.LECTOR LEVER IN ‘D” (2nd Gear)Torque-converter

FrontdutchKEkctown servoRearLow-reverseEnd

clutchbrakeclutch

ri

t

valr

hvalve

“II I

ON-II II

LOUpan)-

N-D controlvalve

Pressurecontrol valve

N-R control valve

118 Line Pressure

Torqueconverter pressureand lubrication oil pressure

m Pump suction pressure

m Line Pressure(control pressure)Damper clutch pressurem DCCSV control pressureReducing pressure

PCSV control pressure

Page 314 of 391

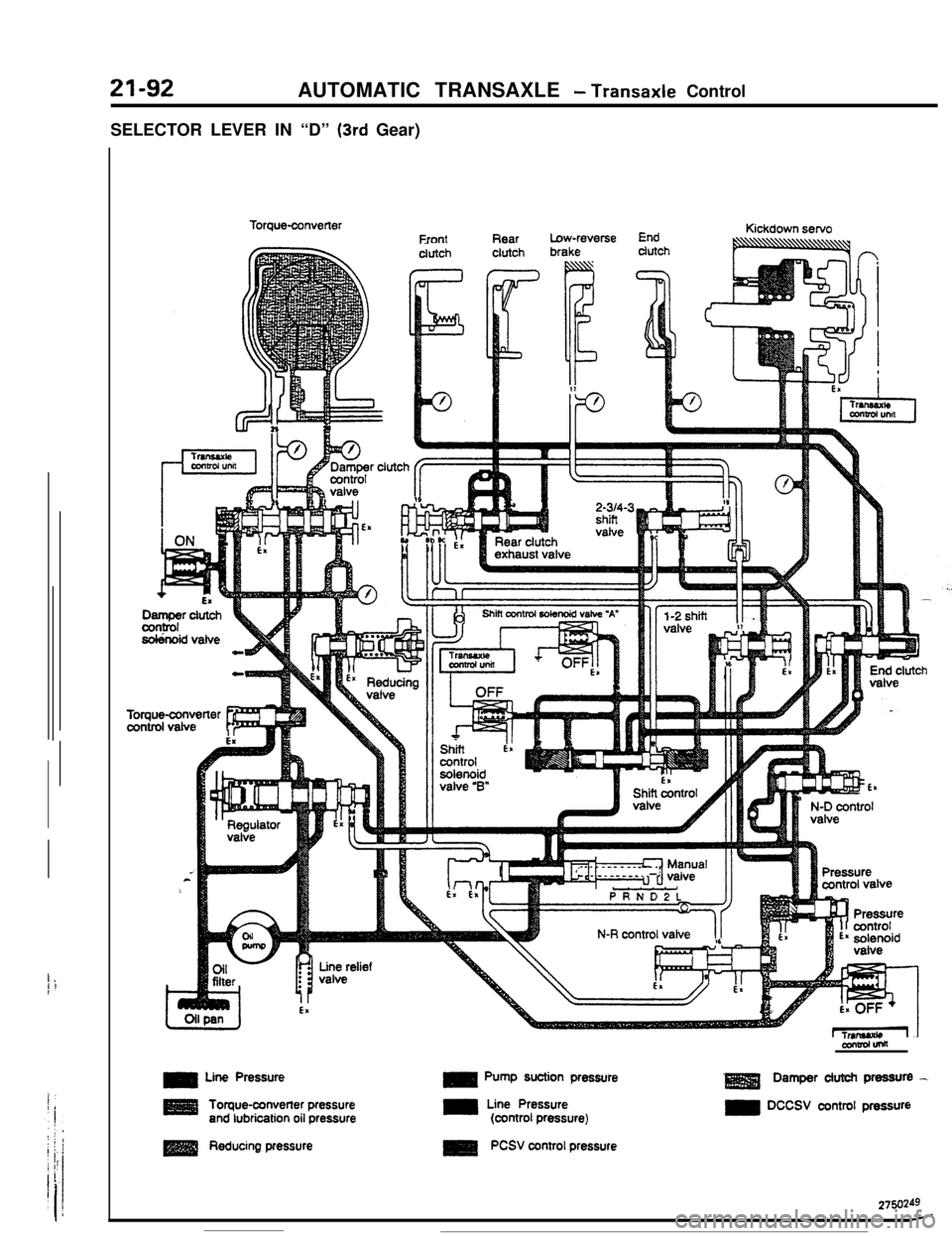

21-92AUTOMATIC TRANSAXLE - Ttansaxle Control

I ,0SELECTOR LEVER IN “D”

(3rd Gear)Torque-convefierFront

.-utchRearclutchLow-reverseEndKickdown servobrakeclutch

h

N-R control valvePressurecontrol.mHIsolenoidvalve..-.

-..-conlrolunn

m Line Pressurem Pump suction pressureDamper clutch pressure -.Torque-converter pressureand lubrication

oil pressurem Line Pressure(control pressure)m DCCSV control pressureReducing

pressurePCSV control pressure

Page 315 of 391

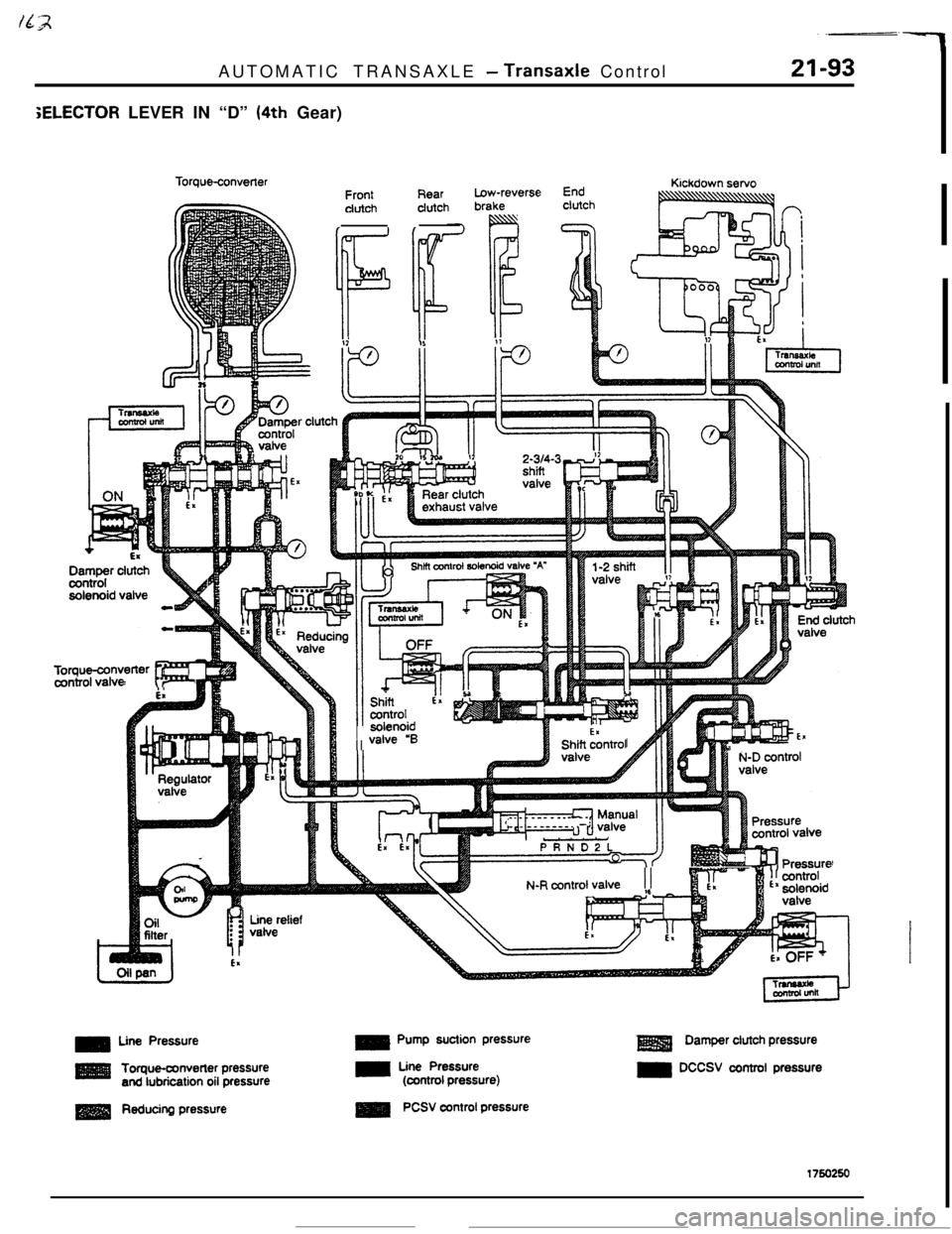

AUTOMATIC TRANSAXLE - Transaxle Control21-93

SELECTOR LEVER IN “D” (4th Gear)

FrontclutchRearclutchlow-reverseEndbrakeclutchTorque-converterKickdown servon-i

Y DamperuxitrolDamper clutchcontrol

Asolenoid valveTorque-convertercontrol vafve

I-llvalve

‘BShift &rtrolvalveN-D controlvalvePressure

N-R control valvecontrol!! rVWw.solenoid-valve

M: . Li;cerelief:

EI

= tine Pressure13s Pump suction pressureDamper clutch pressure

m tine Pressure(control pressure)m DCCSV control pressureTorque-converter pressureand lubrication oil pressureReducing pressure

PCSV control pressure

1720250

Page 316 of 391

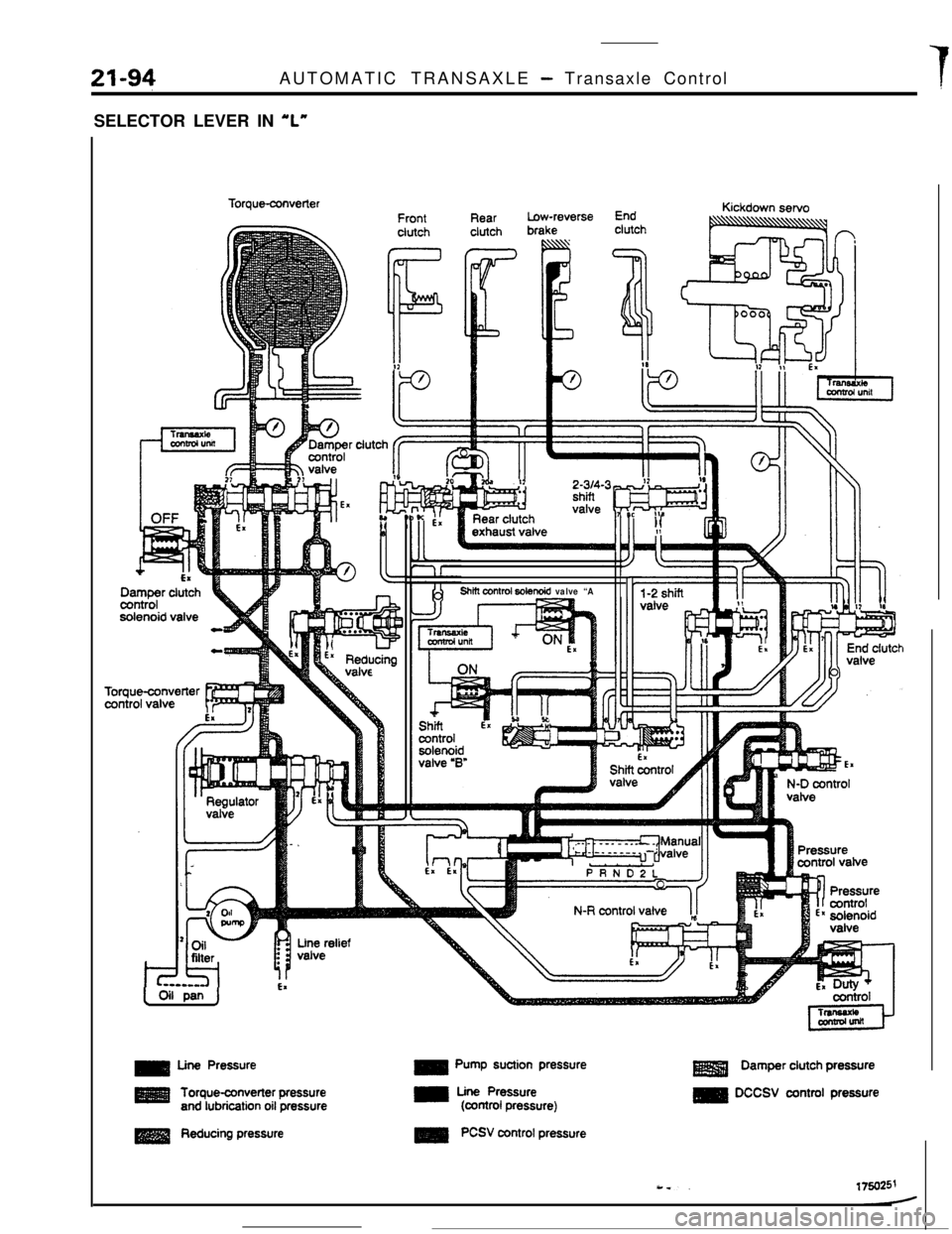

21-94AUTOMATIC TRANSAXLE - Transaxle Control

SELECTOR LEVER IN

“L”

rsolenoid valveTorque-convertercontrol

valveFront

clutch

F

/

P

RearLow-reverseEnd

clutchbrakeclutch

-P+ nKickdown servo

rcing

Shin amtml eolanokl valve “Aexhaust

valve

1 Oil pan J

m Line PressureTorque-converter

pressureand lubrication oil pressuretalvePressurecontrol

valve

= Pump suction pressureDamper clutch pressure

m Line Pressure(control pressure)m DCCSV control pressureReducing

pressurePCSV control pressure

Page 317 of 391

.--_AUTOMATIC TRANSAXLE

- Transaxle Control

21-95

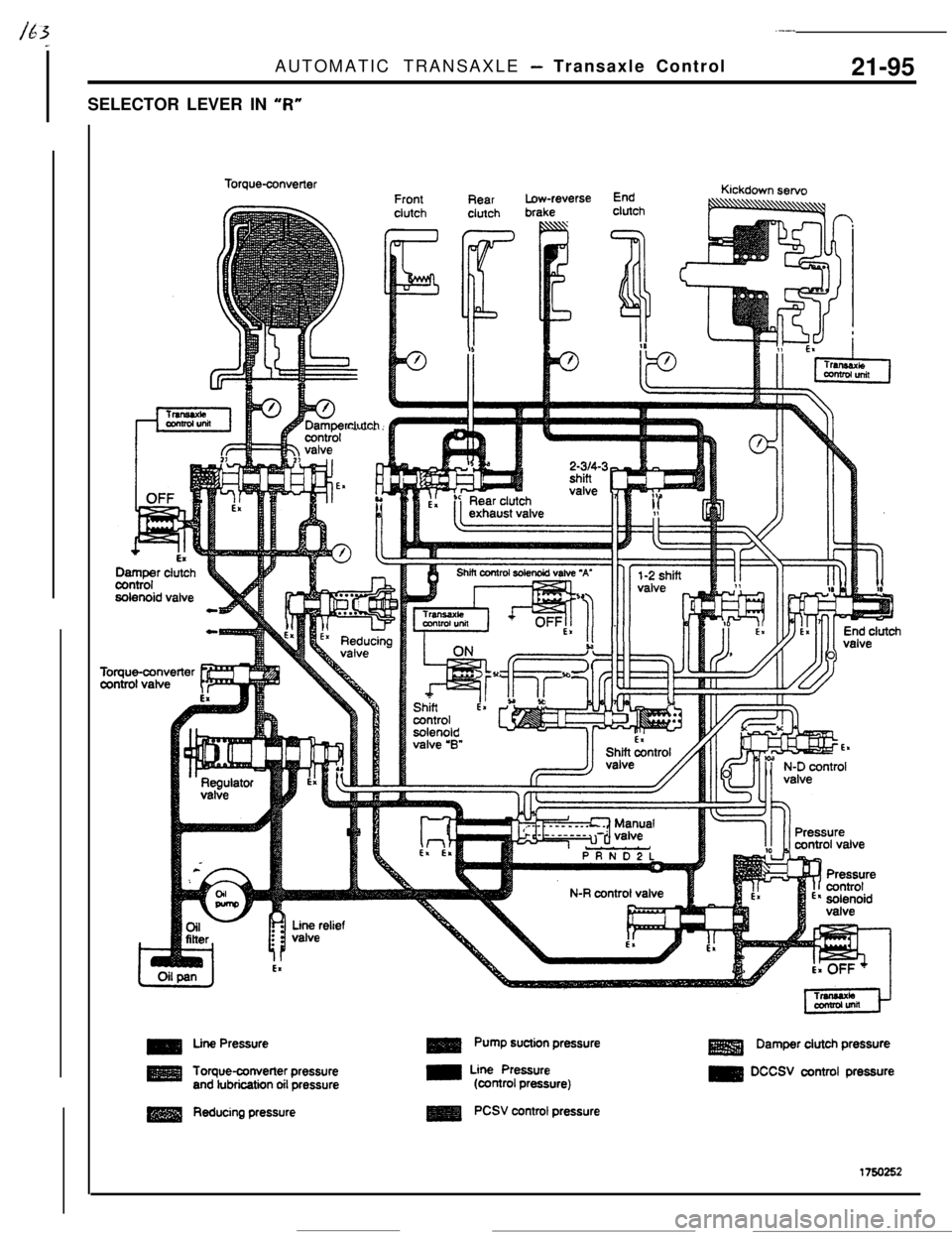

SELECTOR LEVER IN

“R”Torque-converter

IkamnerclutchFront

clutch

1RearclutchLow-reverse

EndbrakeclutchKickdown servoP=====Lsolenoid valve

- E’IIllllIIEnd clutchvalveTorque-convertercontrol

valve

Shiftmntrolsolenoid

valve ‘B”Shitt &trol/:

-0

1’ klPressure10control valve

N-R contr

ralve

Line PressurePump suction pressureDamper clutch pressureTorque-converter pressureand

lubricatiin oil pressureReducing

pressure

m Line Pressure(control pressure)

PCSV control pressure

m DCCSV oontrol pressure

1750252

Page 325 of 391

/E 7_.___-__----_BODY

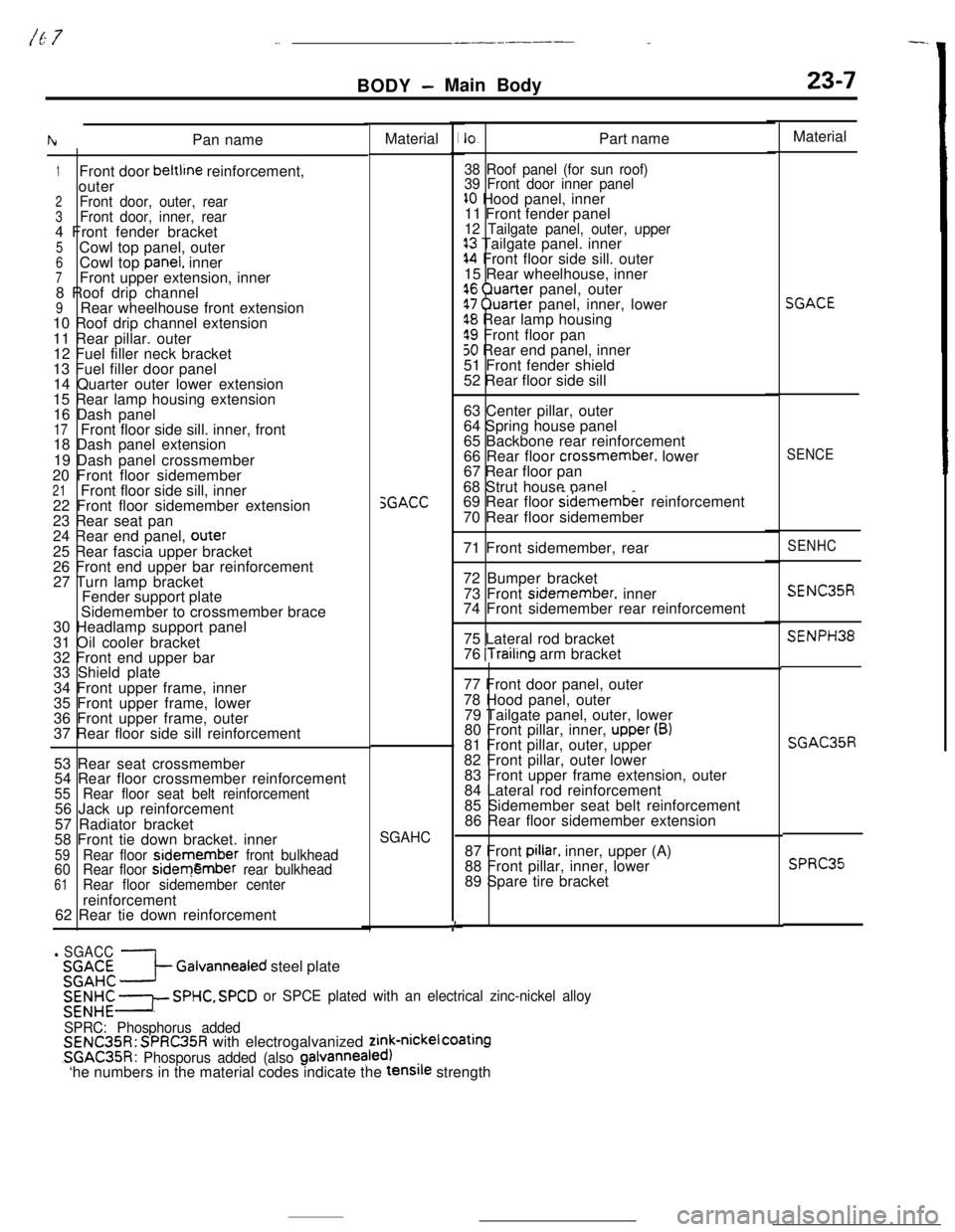

- Main Body23-7Material

IhPan name

1Front door beltline reinforcement,

outer

2Front door, outer, rear3Front door, inner, rear4 Front fender bracket

5Cowl top panel, outer6Cowl top panel. inner7Front upper extension, inner

8 Roof drip channel

9Rear wheelhouse front extension

10 Roof drip channel extension

11 Rear pillar. outer

12 Fuel filler neck bracket

13 Fuel filler door panel

14 Quarter outer lower extension

15 Rear lamp housing extension

16 Dash panel

17Front floor side sill. inner, front

18 Dash panel extension

19 Dash panel crossmember

20 Front floor sidemember

21Front floor side sill, inner

22 Front floor sidemember extension

23 Rear seat pan

24 Rear end panel,

outer25 Rear fascia upper bracket

26 Front end upper bar reinforcement

27 Turn lamp bracket

Fender support plate

Sidemember to crossmember brace

30 Headlamp support panel

31 Oil cooler bracket

32 Front end upper bar

33 Shield plate

34 Front upper frame, inner

35 Front upper frame, lower

36 Front upper frame, outer

37 Rear floor side sill reinforcement

SGACCIO.Part name

38 Roof panel (for sun roof)

39 Front door inner panel

10 Hood panel, inner

11 Front fender panel

12 Tailgate panel, outer, upper13 Tailgate panel. inner14 Front floor side sill. outer

15 Rear wheelhouse, inner

16 Quaner panel, outer17 Quarter panel, inner, lower18 Rear lamp housing

19 Front floor pan50 Rear end panel, inner

51 Front fender shield

52 Rear floor side sill

63 Center pillar, outer

64 Spring house panel

65 Backbone rear reinforcement

66 Rear floor

crossmember. lower

67 Rear floor pan

68 Strut house panel

69 Rear floor sidemember reinforcement

70 Rear floor sidemember

71 Front sidemember, rear

72 Bumper bracket

73 Front

sidemember. inner

74 Front sidemember rear reinforcement

75 Lateral rod bracket

76

ITrailing arm bracket

53 Rear seat crossmember

54 Rear floor crossmember reinforcement

55Rear floor seat belt reinforcement56 Jack up reinforcement

57 Radiator bracket

58 Front tie down bracket. inner

59Rear floor sidemember front bulkhead

60Rear floor sidemember rear bulkhead61Rear floor sidemember centerreinforcement77 Front door panel, outer

78 Hood panel, outer

79 Tailgate panel, outer, lower

80 Front pillar, inner, upper(B)

81 Front pillar, outer, upper

82 Front pillar, outer lower

83 Front upper frame extension, outer

84 Lateral rod reinforcement

85 Sidemember seat belt reinforcement

86 Rear floor sidemember extension

SGAHC87 Front pillar, inner, upper (A)

88 Front pillar, inner, lower

89 Spare tire bracket

62 Rear tie down reinforcement

i

l SGACC%;k; 3 Gaivannealed steel plate

;E;;E I SPHC, SPCD or SPCE plated with an electrical zinc-nickel alloy

SPRC: Phosphorus added

SENC35R: SPRC35R with electrogalvanized zink-nickel CoatingSGAC35R:

Phosporus added (also galvannealed)‘he numbers in the material codes indicate the tensile strengthMaterial

SGACE

SENCE

SENHC

SENC35R

SENPH38

SGAC35R

SPRC35

Page 327 of 391

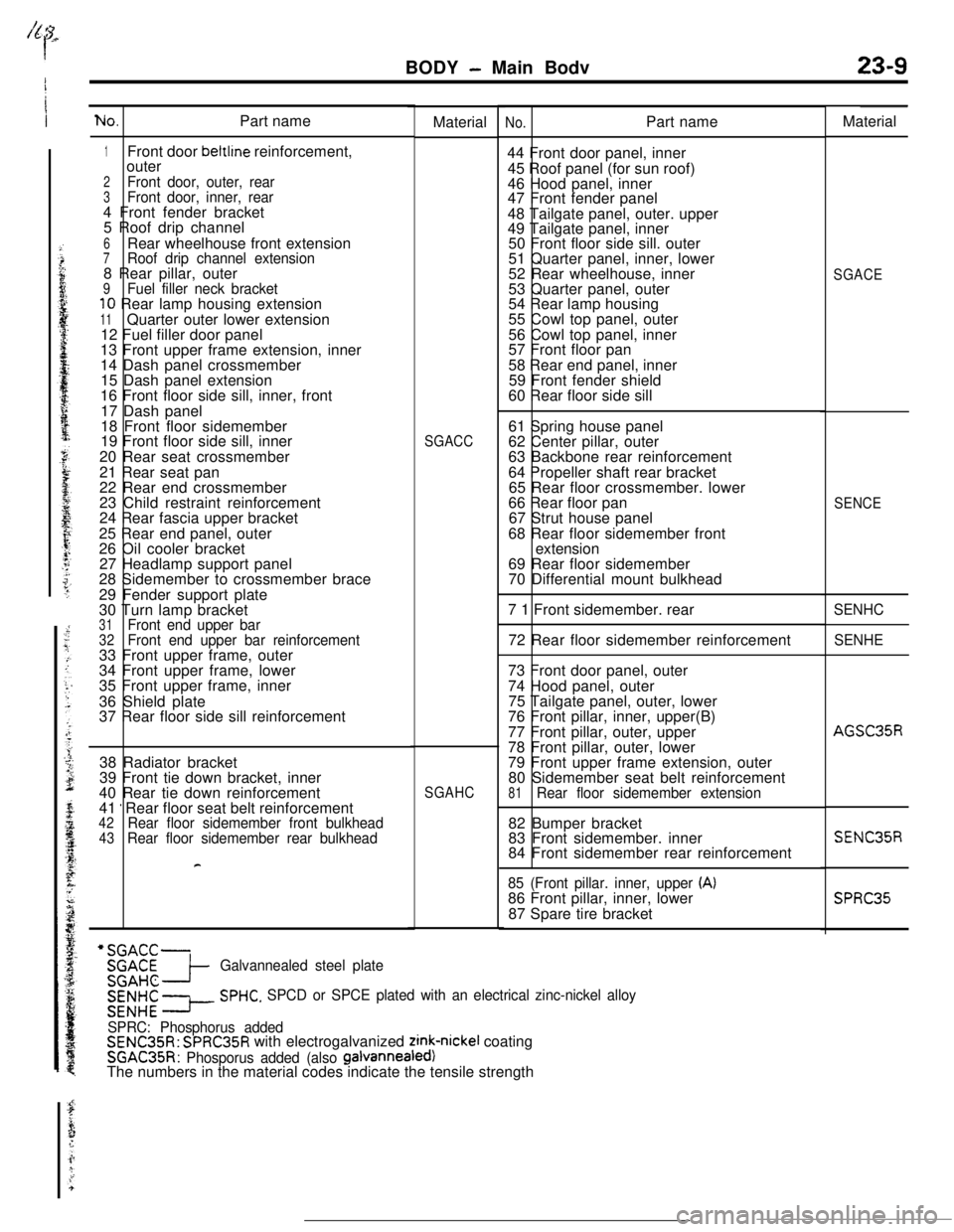

BODY - Main Bodv23-9

No.Part name

1Front door beltline reinforcement,

outer

2Front door, outer, rear3Front door, inner, rear4 Front fender bracket

5 Roof drip channel

6Rear wheelhouse front extension7Roof drip channel extension8 Rear pillar, outer

9Fuel filler neck bracket10 Rear lamp housing extension

11Quarter outer lower extension

12 Fuel filler door panel

13 Front upper frame extension, inner

14 Dash panel crossmember

15 Dash panel extension

16 Front floor side sill, inner, front

17 Dash panel

18 Front floor sidemember

19 Front floor side sill, inner

20 Rear seat crossmember

21 Rear seat pan

22 Rear end crossmember

23 Child restraint reinforcement

24 Rear fascia upper bracket

25 Rear end panel, outer

26 Oil cooler bracket

27 Headlamp support panel

28 Sidemember to crossmember brace

29 Fender support plate

30 Turn lamp bracket

31Front end upper bar32Front end upper bar reinforcement33 Front upper frame, outer

34 Front upper frame, lower

35 Front upper frame, inner

36 Shield plate

37 Rear floor side sill reinforcementMaterial

No.Part name

44 Front door panel, inner

45 Roof panel (for sun roof)

46 Hood panel, inner

47 Front fender panel

48 Tailgate panel, outer. upper

49 Tailgate panel, inner

50 Front floor side sill. outer

51 Quarter panel, inner, lower

52 Rear wheelhouse, inner

53 Quarter panel, outer

54 Rear lamp housing

55 Cowl top panel, outer

56 Cowl top panel, inner

57 Front floor pan

58 Rear end panel, inner

59 Front fender shield

60 Rear floor side sill

SGACC61 Spring house panel

62 Center pillar, outer

63 Backbone rear reinforcement

64 Propeller shaft rear bracket

65 Rear floor crossmember. lower

66 Rear floor pan

67 Strut house panel

68 Rear floor sidemember front

extension

69 Rear floor sidemember

70 Differential mount bulkhead

7 1 Front sidemember. rear

72 Rear floor sidemember reinforcement

38 Radiator bracket

39 Front tie down bracket, inner

40 Rear tie down reinforcement

41

’ Rear floor seat belt reinforcement42Rear floor sidemember front bulkhead43Rear floor sidemember rear bulkhead

F

SGAHC73 Front door panel, outer

74 Hood panel, outer

75 Tailgate panel, outer, lower

76 Front pillar, inner, upper(B)

77 Front pillar, outer, upper

78 Front pillar, outer, lower

79 Front upper frame extension, outer

80 Sidemember seat belt reinforcement81Rear floor sidemember extension82 Bumper bracket

83 Front sidemember. inner

84 Front sidemember rear reinforcement

85 (Front pillar. inner, upper (A)86 Front pillar, inner, lower

87 Spare tire bracket

x::-SGAHC-I-Galvannealed steel plate

E% x--

SPHC. SPCD or SPCE plated with an electrical zinc-nickel alloy

SPRC: Phosphorus added

SENC35R: SPRC35R with electrogalvanized zink-nickel coating

SGAC35R: Phosporus added (also galvanneafed)The numbers in the material codes indicate the tensile strengthMaterial

SGACE

SENCE

SENHC

SENHE

AGSC35R

SENC35R

SPRC35

Page 338 of 391

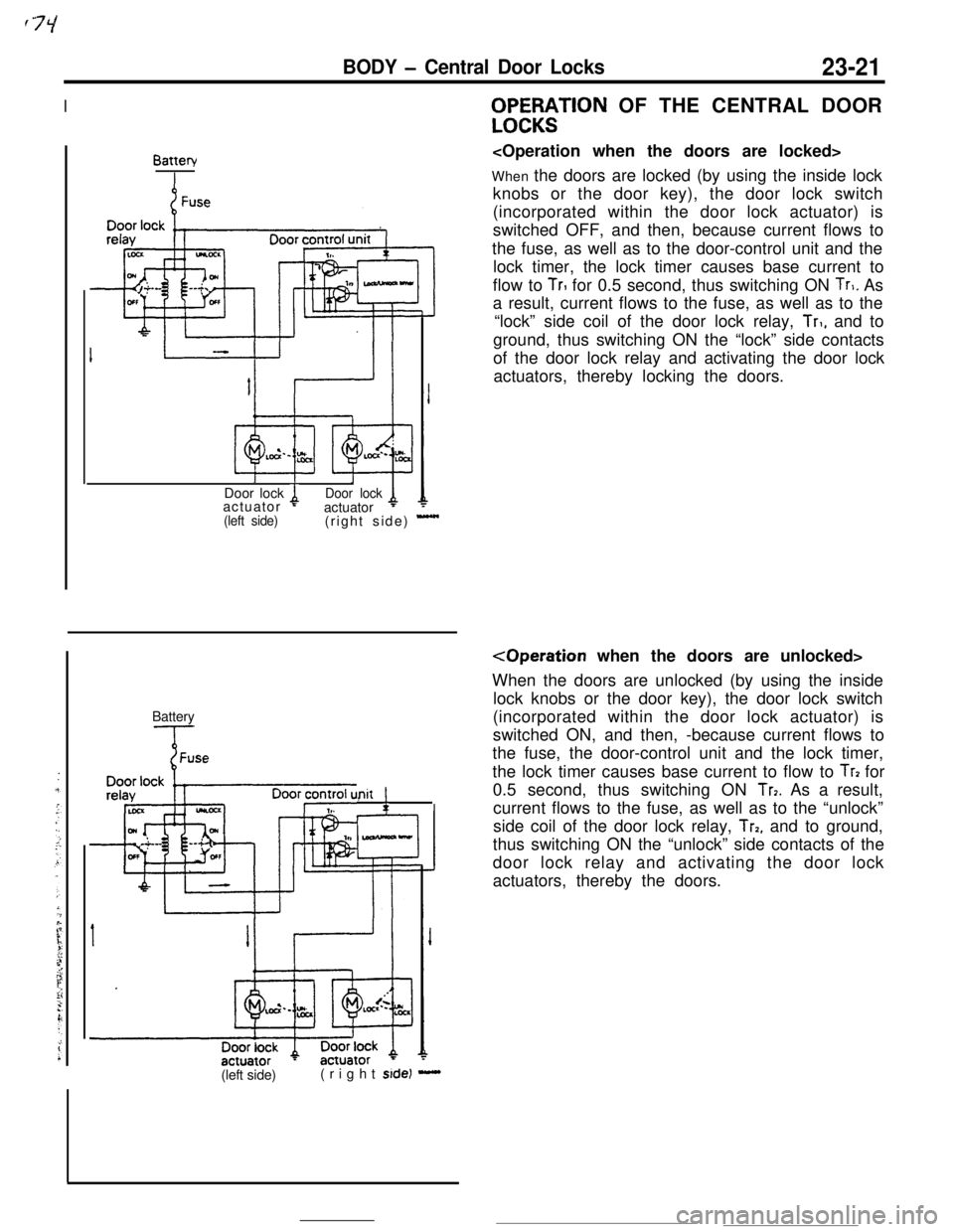

BODY - Central Door Locks23-21

IBattery

1IJDoor lock 4Door lockactuator t(left side)actuator

(right side) -Battery

Init !,WF%;$TlON OF THE CENTRAL DOOR

When the doors are locked (by using the inside lock

knobs or the door key), the door lock switch

(incorporated within the door lock actuator) is

switched OFF, and then, because current flows to

the fuse, as well as to the door-control unit and the

lock timer, the lock timer causes base current to

flow to

TrI for 0.5 second, thus switching ON Tr,. As

a result, current flows to the fuse, as well as to the

“lock” side coil of the door lock relay,

Tr,, and to

ground, thus switching ON the “lock” side contacts

of the door lock relay and activating the door lock

actuators, thereby locking the doors.

When the doors are unlocked (by using the inside

lock knobs or the door key), the door lock switch

(incorporated within the door lock actuator) is

switched ON, and then, -because current flows to

the fuse, the door-control unit and the lock timer,

the lock timer causes base current to flow to

Tr? for

0.5 second, thus switching ON

Tr7. As a result,

current flows to the fuse, as well as to the “unlock”

side coil of the door lock relay,

Trp, and to ground,

thus switching ON the “unlock” side contacts of the

door lock relay and activating the door lock

actuators, thereby the doors.

(left side)(right

side) -

Page 340 of 391

BODY - Power Windows23-23

IBatterv

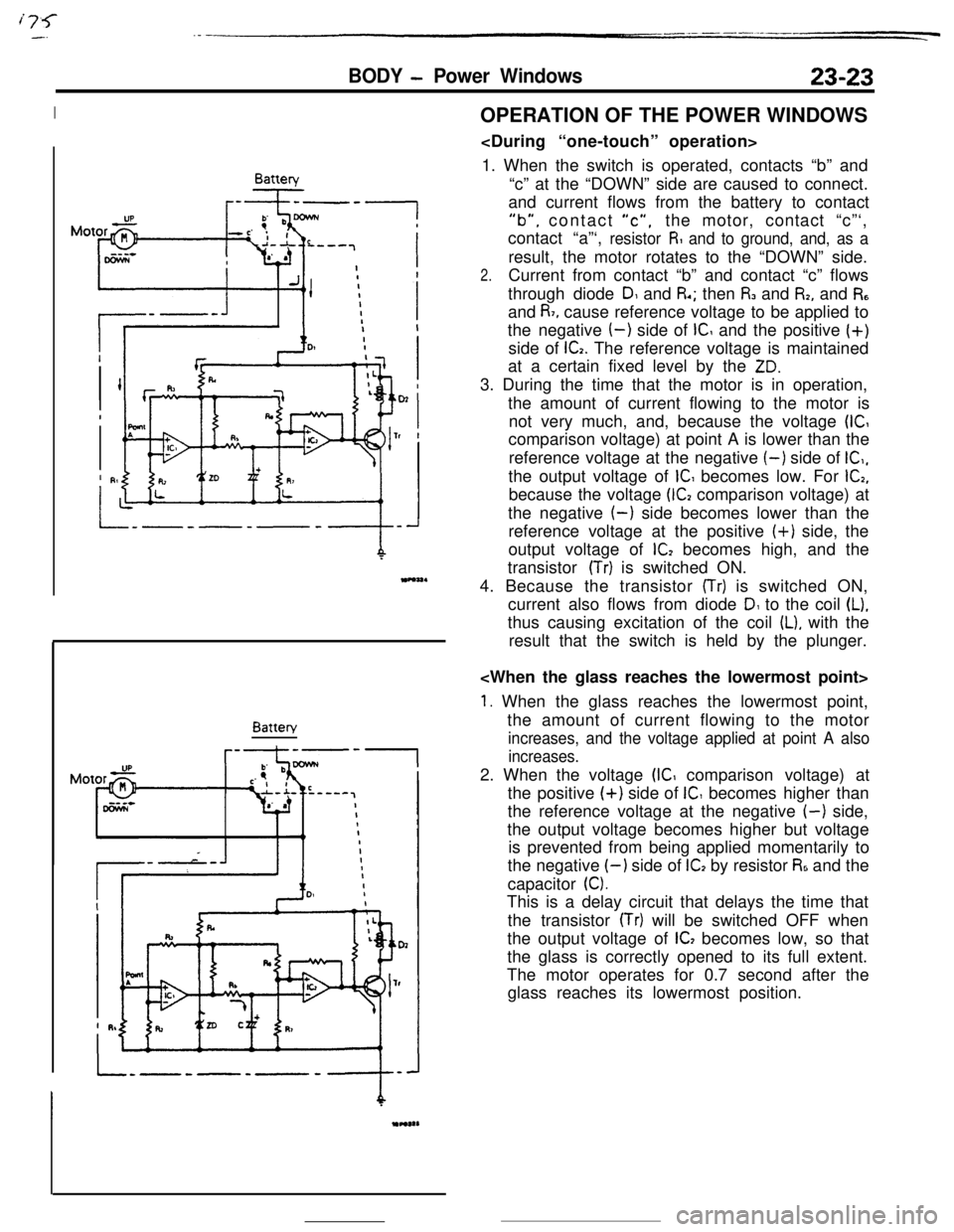

---IBatteryOPERATION OF THE POWER WINDOWS

1. When the switch is operated, contacts “b” and

“c” at the “DOWN” side are caused to connect.

and current flows from the battery to contact

“b”, contact “c”,the motor, contact “c”‘,

contact “a”‘,

resistor R and to ground, and, as aresult, the motor rotates to the “DOWN” side.

2.Current from contact “b” and contact “c” flows

through diode

DI and R.; then I% and I%, and R,and

R7, cause reference voltage to be applied to

the negative

(-) side of IC and the positive (+)

side of

G. The reference voltage is maintained

at a certain fixed level by the

ZD.3. During the time that the motor is in operation,

the amount of current flowing to the motor is

not very much, and, because the voltage

(ICcomparison voltage) at point A is lower than the

reference voltage at the negative

(-) side of IC,,the output voltage of

IC becomes low. For G,because the voltage

(G comparison voltage) at

the negative

(-) side becomes lower than the

reference voltage at the positive (+) side, the

output voltage of

lC2 becomes high, and the

transistor

(Tr) is switched ON.

4. Because the transistor

(Tr) is switched ON,

current also flows from diode

D1 to the coil (L).thus causing excitation of the coil

IL), with the

result that the switch is held by the plunger.

1. When the glass reaches the lowermost point,

the amount of current flowing to the motor

increases, and the voltage applied at point A also

increases.2. When the voltage

(IC comparison voltage) at

the positive

(+) side of IC becomes higher than

the reference voltage at the negative

(-) side,

the output voltage becomes higher but voltage

is prevented from being applied momentarily to

the negative

I-) side of ICI by resistor R6 and the

capacitor

0.This is a delay circuit that delays the time that

the transistor

(Tr) will be switched OFF when

the output voltage of

IC, becomes low, so that

the glass is correctly opened to its full extent.

The motor operates for 0.7 second after the

glass reaches its lowermost position.

Page 341 of 391

23-24BODY - Power Windows / Bumpers

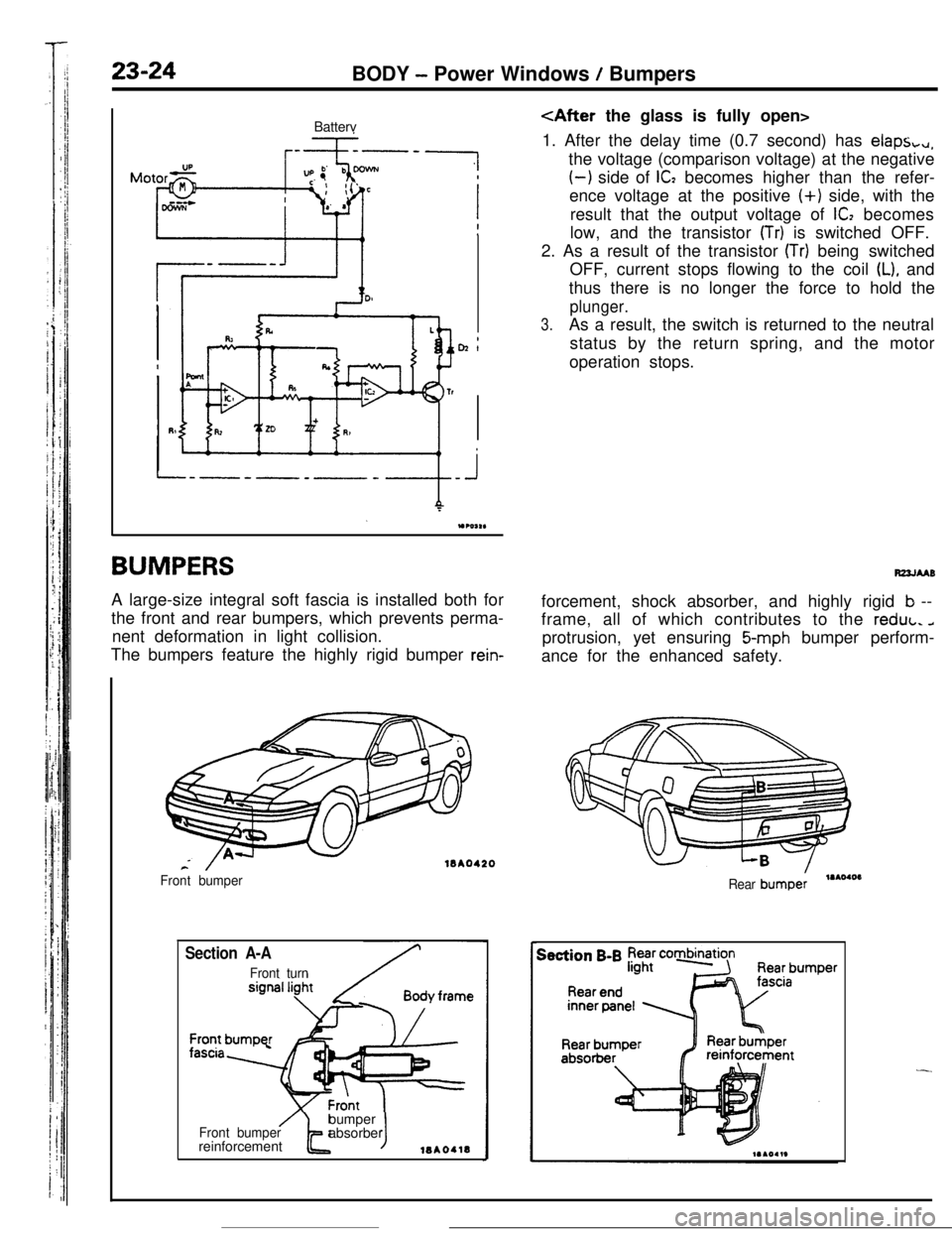

Batterv

r--+----

02’

BUMPERSA large-size integral soft fascia is installed both for

the front and rear bumpers, which prevents perma-

nent deformation in light collision.

The bumpers feature the highly rigid bumper

rein-

18A0420

Section A-A

Front turn Front bumper

/Front bumperbumper

t Jabsorber

reinforcement18AOllB

1. After the delay time (0.7 second) has

claps,+,,,the voltage (comparison voltage) at the negative

(-1 side of IC2 becomes higher than the refer-

ence voltage at the positive

(+) side, with the

result that the output voltage of

ICI becomes

low, and the transistor

(Tr) is switched OFF.

2. As a result of the transistor

(Tr) being switched

OFF, current stops flowing to the coil

(L), and

thus there is no longer the force to hold the

plunger.

3.As a result, the switch is returned to the neutral

status by the return spring, and the motor

operation stops.

R22JMBforcement, shock absorber, and highly rigid

b --

frame, all of which contributes to the reduL.

aprotrusion, yet ensuring

5-mph bumper perform-

ance for the enhanced safety.

Rear bumpe:,.AOIOI

-