ABS MITSUBISHI ECLIPSE 1990 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 107 of 391

9-22ENGINE- Mounts

Principalaxi? of inertia

The

::I: indicates mount positions.01 RO77OlAbsorption action during minute vibrations

ICavity

CavityOlRcl767l

Absorption during large vibrations or “rolling”

Cavity

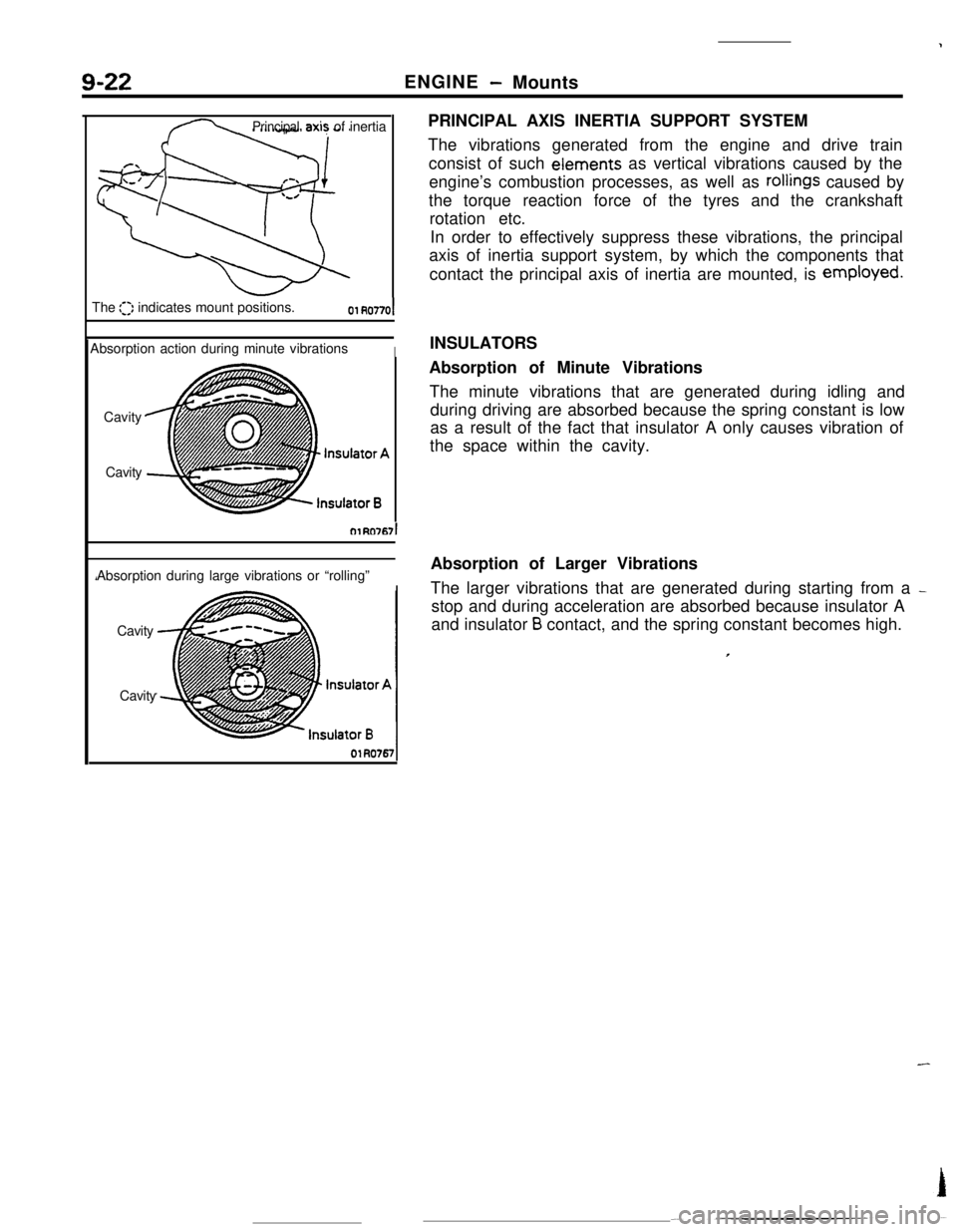

CavityPRINCIPAL AXIS INERTIA SUPPORT SYSTEM

The vibrations generated from the engine and drive train

consist of such eiements as vertical vibrations caused by the

engine’s combustion processes, as well as

rollings caused by

the torque reaction force of the tyres and the crankshaft

rotation etc.

In order to effectively suppress these vibrations, the principal

axis of inertia support system, by which the components that

contact the principal axis of inertia are mounted, is employed.

INSULATORS

Absorption of Minute Vibrations

The minute vibrations that are generated during idling and

during driving are absorbed because the spring constant is low

as a result of the fact that insulator A only causes vibration of

the space within the cavity.

Absorption of Larger Vibrations

The larger vibrations that are generated during starting from a

_stop and during acceleration are absorbed because insulator A

and insulator

B contact, and the spring constant becomes high.

Page 128 of 391

14-16FUEL SYSTEM - Sensors

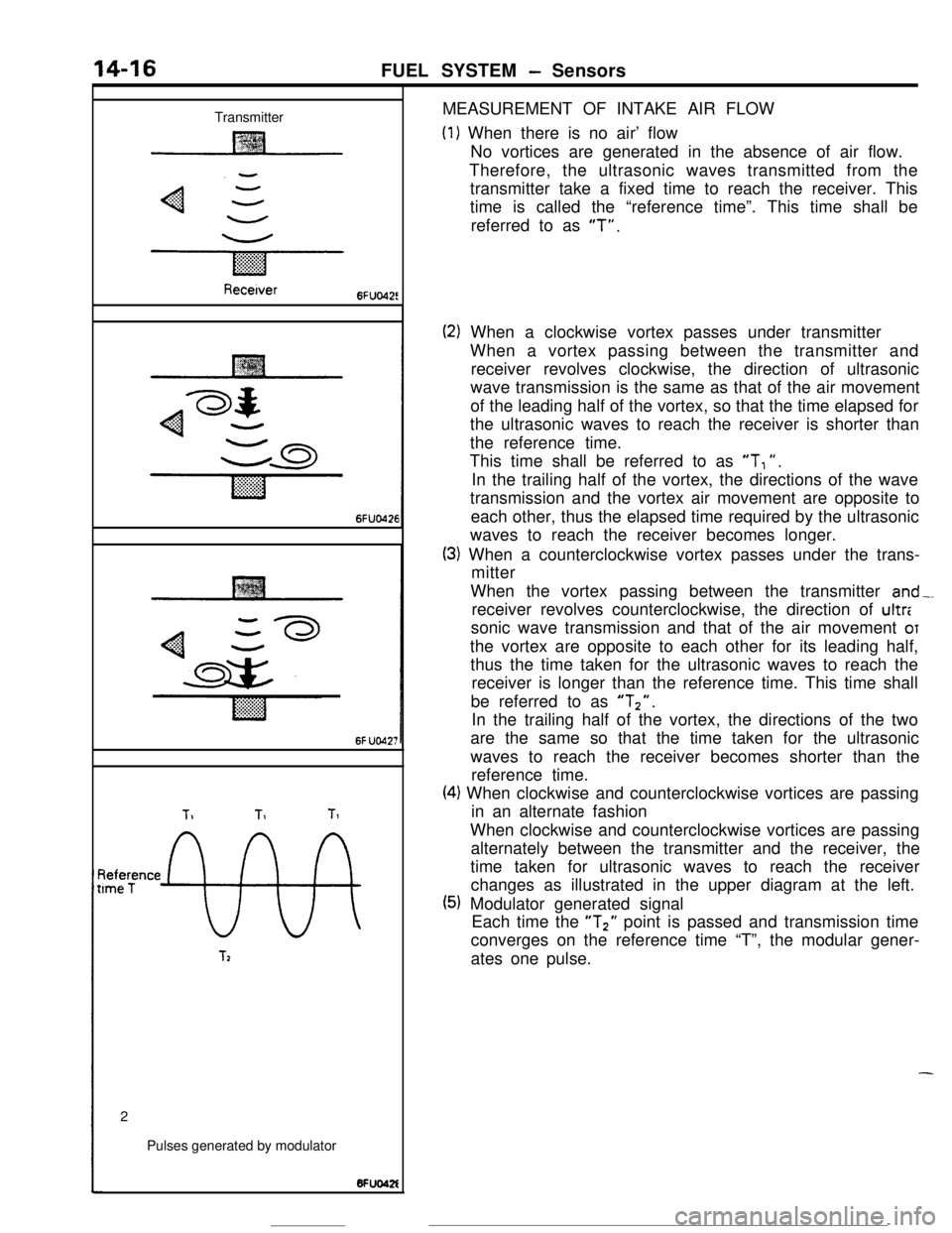

TransmitterMEASUREMENT OF INTAKE AIR FLOW

(1) When there is no air’ flow

No vortices are generated in the absence of air flow.

Therefore, the ultrasonic waves transmitted from the

transmitter take a fixed time to reach the receiver. This

time is called the “reference time”. This time shall be

referred to as

“T”.

Recetver6FUo42!

6FUO426

6f UO42;

TIT1Tl

~tee;ence

9%

T22

Pulses generated by modulator

(2) When a clockwise vortex passes under transmitter

When a vortex passing between the transmitter and

receiver revolves clockwise, the direction of ultrasonic

wave transmission is the same as that of the air movement

of the leading half of the vortex, so that the time elapsed for

the ultrasonic waves to reach the receiver is shorter than

the reference time.

This time shall be referred to as

“T, “.

In the trailing half of the vortex, the directions of the wave

transmission and the vortex air movement are opposite to

each other, thus the elapsed time required by the ultrasonic

waves to reach the receiver becomes longer.

(3) When a counterclockwise vortex passes under the trans-

mitter

When the vortex passing between the transmitter

and-.receiver revolves counterclockwise, the direction of ultr:

sonic wave transmission and that of the air movement

OTthe vortex are opposite to each other for its leading half,

thus the time taken for the ultrasonic waves to reach the

receiver is longer than the reference time. This time shall

be referred to as

“Tz”.In the trailing half of the vortex, the directions of the two

are the same so that the time taken for the ultrasonic

waves to reach the receiver becomes shorter than the

reference time.

(4) When clockwise and counterclockwise vortices are passing

in an alternate fashion

When clockwise and counterclockwise vortices are passing

alternately between the transmitter and the receiver, the

time taken for ultrasonic waves to reach the receiver

changes as illustrated in the upper diagram at the left.

(5) Modulator generated signal

Each time the “T2” point is passed and transmission time

converges on the reference time “T”, the modular gener-

ates one pulse.

-

Page 152 of 391

14-40FUEL SYSTEM - Fuel Injection Control

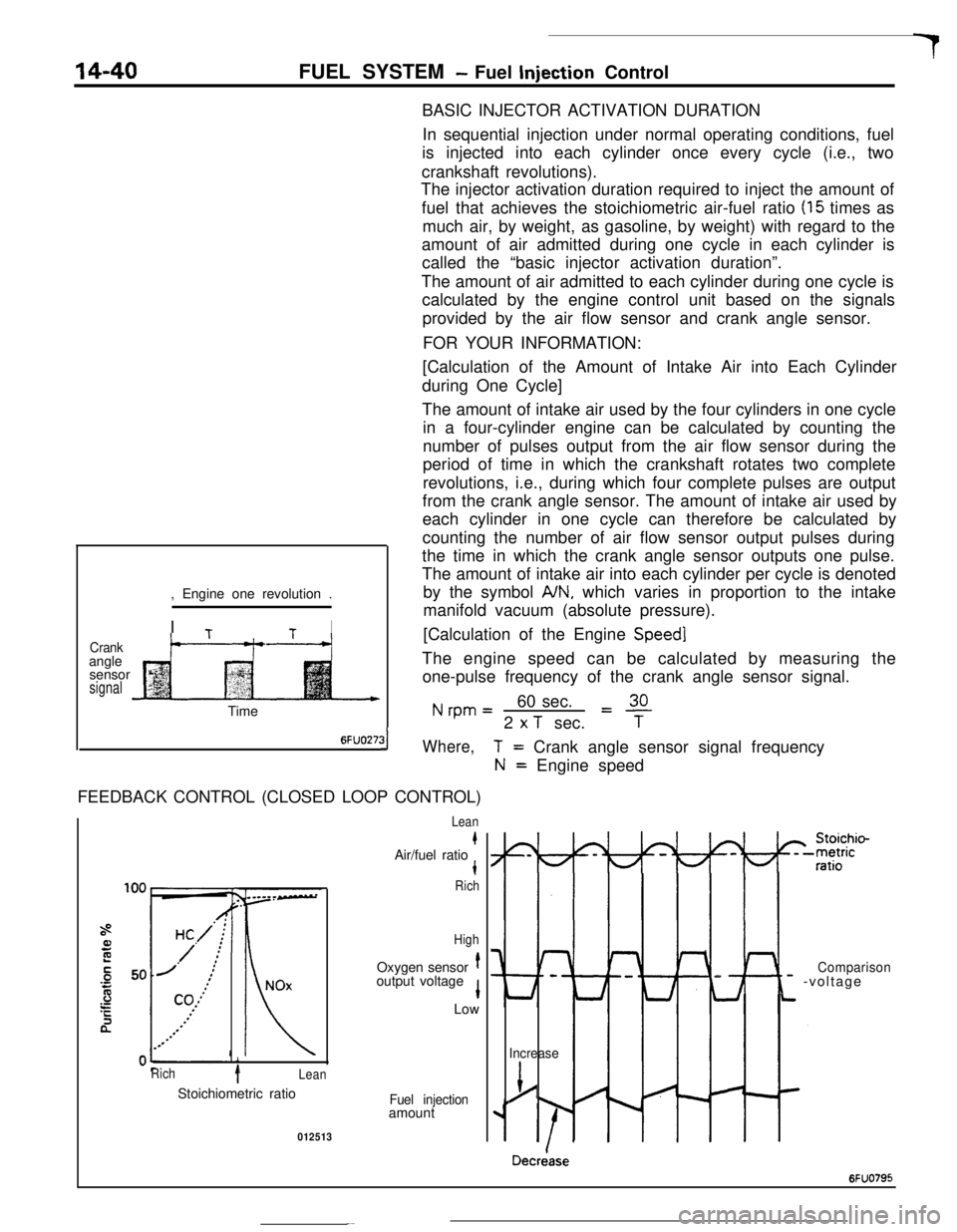

BASIC INJECTOR ACTIVATION DURATION

In sequential injection under normal operating conditions, fuel

is injected into each cylinder once every cycle (i.e., two

crankshaft revolutions).

The injector activation duration required to inject the amount of

fuel that achieves the stoichiometric air-fuel ratio

(15 times as

much air, by weight, as gasoline, by weight) with regard to the

amount of air admitted during one cycle in each cylinder is

called the “basic injector activation duration”.

The amount of air admitted to each cylinder during one cycle is

calculated by the engine control unit based on the signals

provided by the air flow sensor and crank angle sensor.

FOR YOUR INFORMATION:

Crankangle

sensor

signal, Engine one revolution .

I

TtI

t--“---t-+[Calculation of the Amount of Intake Air into Each Cylinder

during One Cycle]

The amount of intake air used by the four cylinders in one cycle

in a four-cylinder engine can be calculated by counting the

number of pulses output from the air flow sensor during the

period of time in which the crankshaft rotates two complete

revolutions, i.e., during which four complete pulses are output

from the crank angle sensor. The amount of intake air used by

each cylinder in one cycle can therefore be calculated by

counting the number of air flow sensor output pulses during

the time in which the crank angle sensor outputs one pulse.

The amount of intake air into each cylinder per cycle is denoted

by the symbol

A/N, which varies in proportion to the intake

manifold vacuum (absolute pressure).

[Calculation of the Engine

Speed]The engine speed can be calculated by measuring the

one-pulse frequency of the crank angle sensor signal.

Nrpm=60 sec.L!!L2

x T sec.TTime

6FUO27:31Where,FEEDBACK CONTROL (CLOSED LOOP CONTROL)

i

Rich1Lean

T= Crank angle sensor signal frequency

N= Engine speed

Lean

kAir/fuel ratiot

Rich

HighOxygen sensor

toutput voltage

1Low

Stoichiometric ratio

Fuel injectionamount

012513

I-

Lt

Comparison- -voltage

Increase

j/

Decriase

6FUO795

Page 164 of 391

--

14-52FUEL SYSTEM - Idle Speed Control

4

Start of deceleration

DLhq ON

position

I*2 to 6

Time sec.6FUO295

II)

0(32180(176)Temperature “C 1°F)6FUO29t

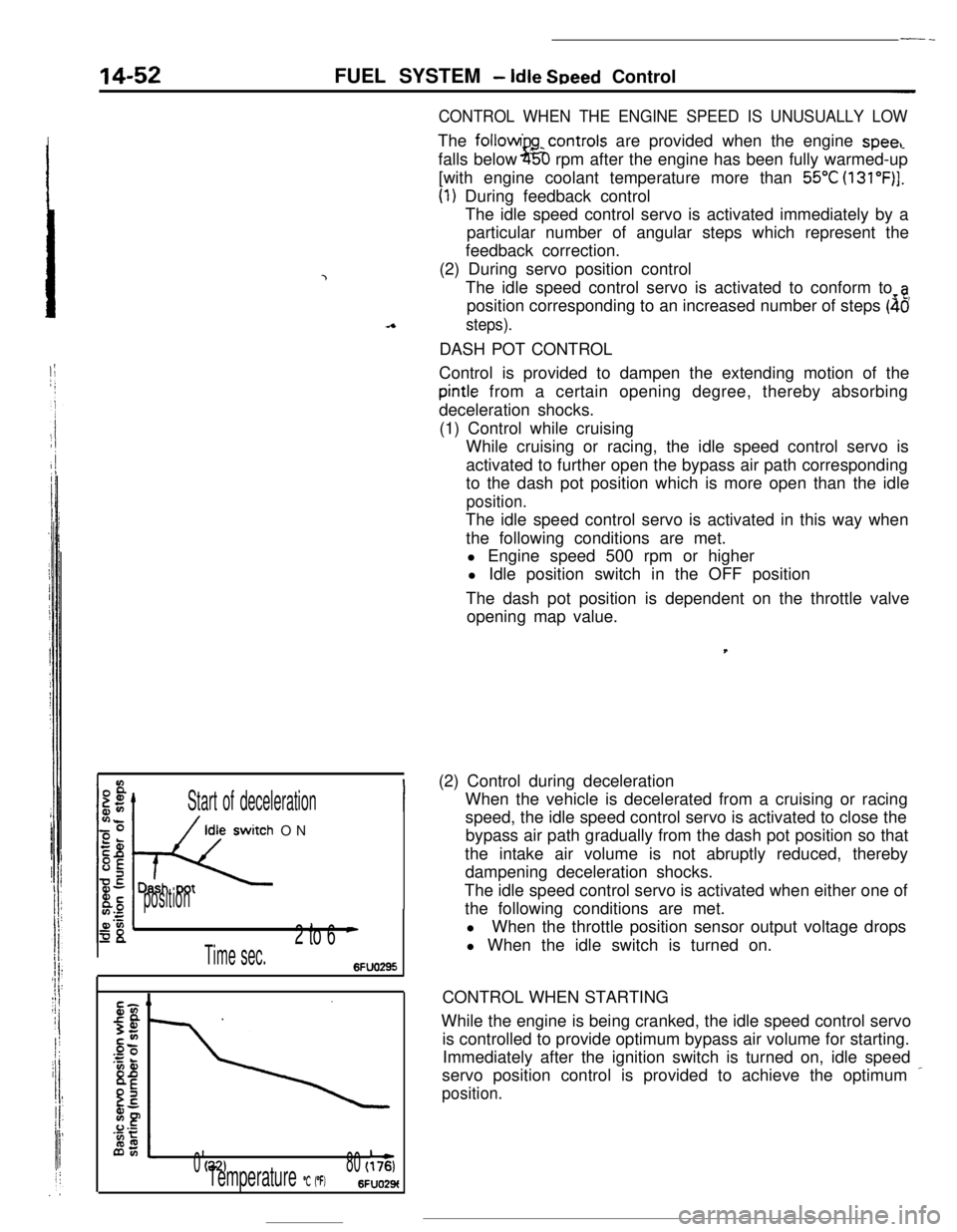

CONTROL WHEN THE ENGINE SPEED IS UNUSUALLY LOWThe followi

gcontrols are provided when the engine speecfalls below

i5;D rpm after the engine has been fully warmed-up

[with engine coolant temperature more than

55°C (131”F)].

(1) During feedback control

The idle speed control servo is activated immediately by a

particular number of angular steps which represent the

feedback correction.

(2) During servo position control

The idle speed control servo is activated to conform to

aposition corresponding to an increased number of steps

(46

steps).DASH POT CONTROL

Control is provided to dampen the extending motion of the

pintle from a certain opening degree, thereby absorbing

deceleration shocks.

(1) Control while cruising

While cruising or racing, the idle speed control servo is

activated to further open the bypass air path corresponding

to the dash pot position which is more open than the idle

position.The idle speed control servo is activated in this way when

the following conditions are met.

l Engine speed 500 rpm or higher

l Idle position switch in the OFF position

The dash pot position is dependent on the throttle valve

opening map value.,

(2) Control during deceleration

When the vehicle is decelerated from a cruising or racing

speed, the idle speed control servo is activated to close the

bypass air path gradually from the dash pot position so that

the intake air volume is not abruptly reduced, thereby

dampening deceleration shocks.

The idle speed control servo is activated when either one of

the following conditions are met.

lWhen the throttle position sensor output voltage drops

l When the idle switch is turned on.

CONTROL WHEN STARTING

While the engine is being cranked, the idle speed control servo

is controlled to provide optimum bypass air volume for starting.

Immediately after the ignition switch is turned on, idle speed

servo position control is provided to achieve the optimum

_

position.

Page 192 of 391

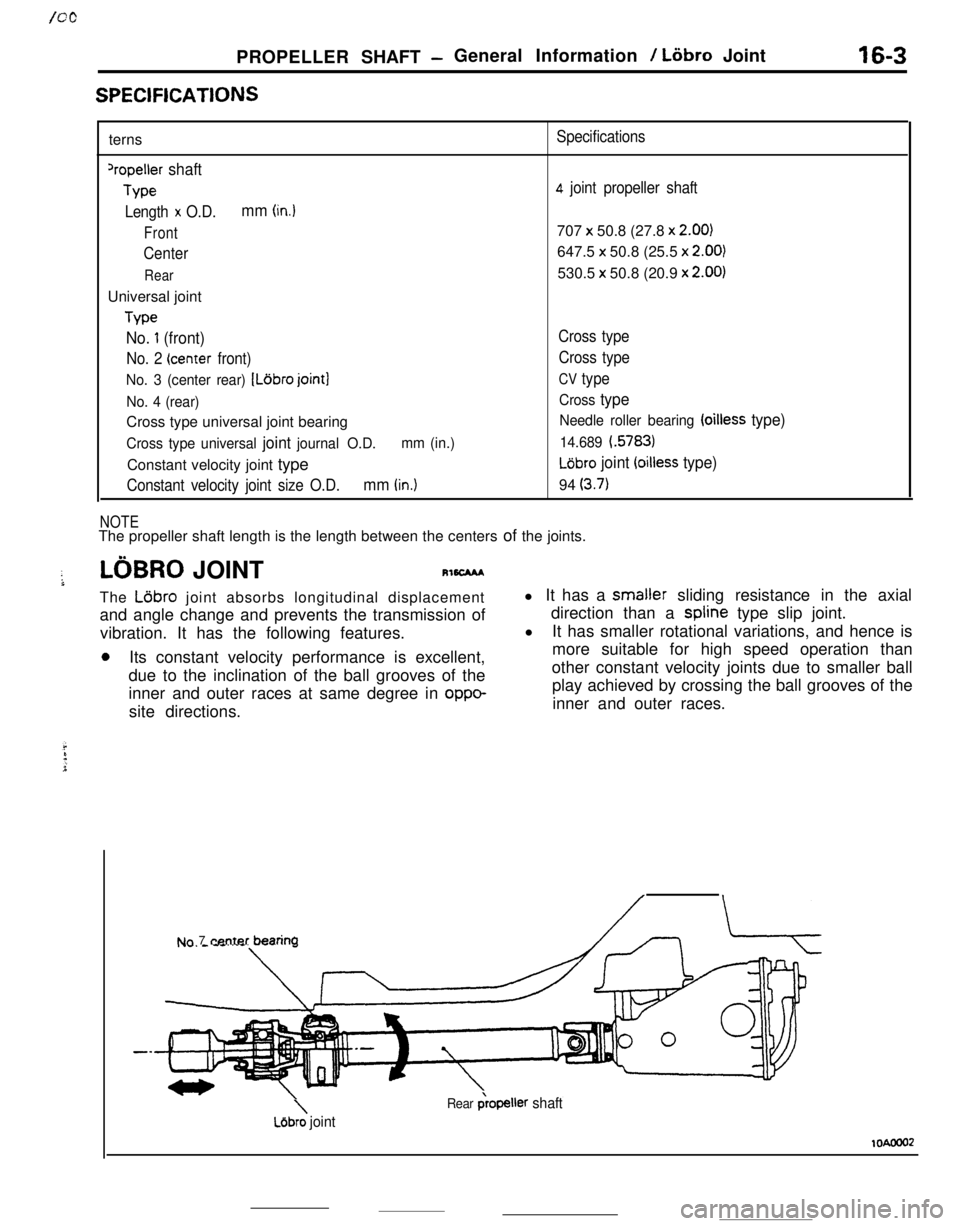

PROPELLER SHAFT -General Information / Liibro Joint16-3

SPEClFlCATlONSterns

‘repeller shaft

Type

Length

x O.D.mm (in.)

Front

Center

RearUniversal joint

Type

No. 1 (front)

No. 2 (center front)

No. 3 (center rear) [Ldbro joint]

No. 4 (rear)Cross type universal joint bearing

Cross type universal joint journal O.D.mm (in.)Constant velocity joint type

Constant velocity joint size O.D.mm (in.)

NOTE

Specifications

4 joint propeller shaft707

x 50.8 (27.8 x 2.00)647.5 x 50.8 (25.5 x

2.00)530.5 x 50.8 (20.9 x

2.00)

Cross type

Cross type

CV type

Cross type

Needle roller bearing (oilless type)

14.689 i.5783)

LGbro joint (oilless type)94

(3.7)The propeller shaft length is the length between the centers of the joints.

LOBRO JOINTRl6CMAThe

L6bro joint absorbs longitudinal displacement

and angle change and prevents the transmission of

vibration. It has the following features.

0Its constant velocity performance is excellent,

due to the inclination of the ball grooves of the

inner and outer races at same degree in

oppo-site directions.l It has a smaller sliding resistance in the axial

direction than a spline type slip joint.

l

It has smaller rotational variations, and hence is

more suitable for high speed operation than

other constant velocity joints due to smaller ball

play achieved by crossing the ball grooves of the

inner and outer races.

Nn 7 center bearina

\Lejbro joint

Rear &opeller shaft

lOAooo2

Page 193 of 391

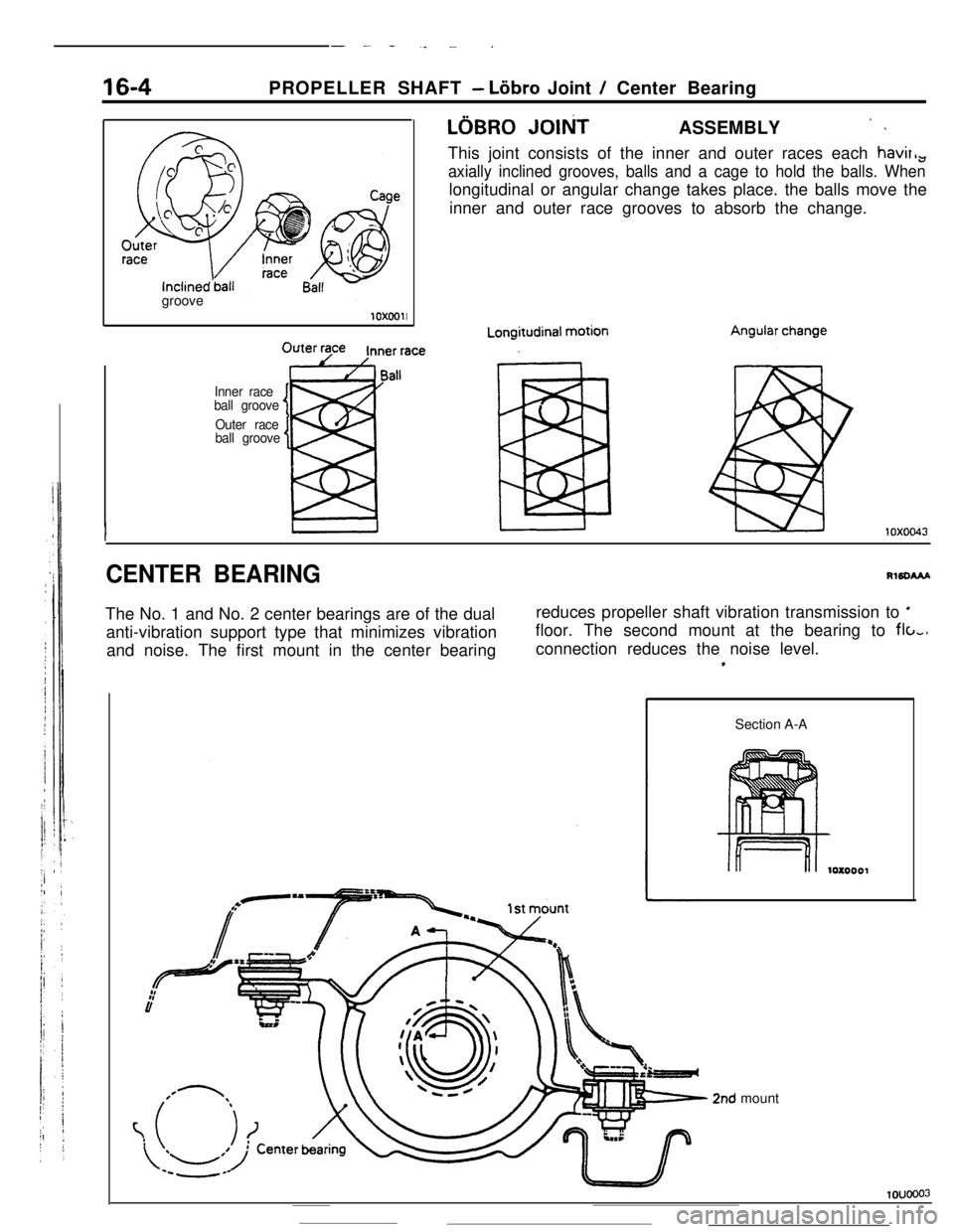

- --- -._ -...PROPELLER SHAFT

- LBbro Joint / Center Bearing

groove

Inner race

ball groove

Outer race

ball grooveLGBRO

JOltiT ASSEMBLY ’ IThis joint consists of the inner and outer races each havir,,

axially inclined grooves, balls and a cage to hold the balls. Whenlongitudinal or angular change takes place. the balls move the

inner and outer race grooves to absorb the change.

CENTER BEARINGRlSDWThe No. 1 and No. 2 center bearings are of the dualreduces propeller shaft vibration transmission to ’

anti-vibration support type that minimizes vibrationfloor. The second mount at the bearing to

flo,,and noise. The first mount in the center bearingconnection reduces the noise level.

*Section A-A

2nd mount

1ouooo3

Page 199 of 391

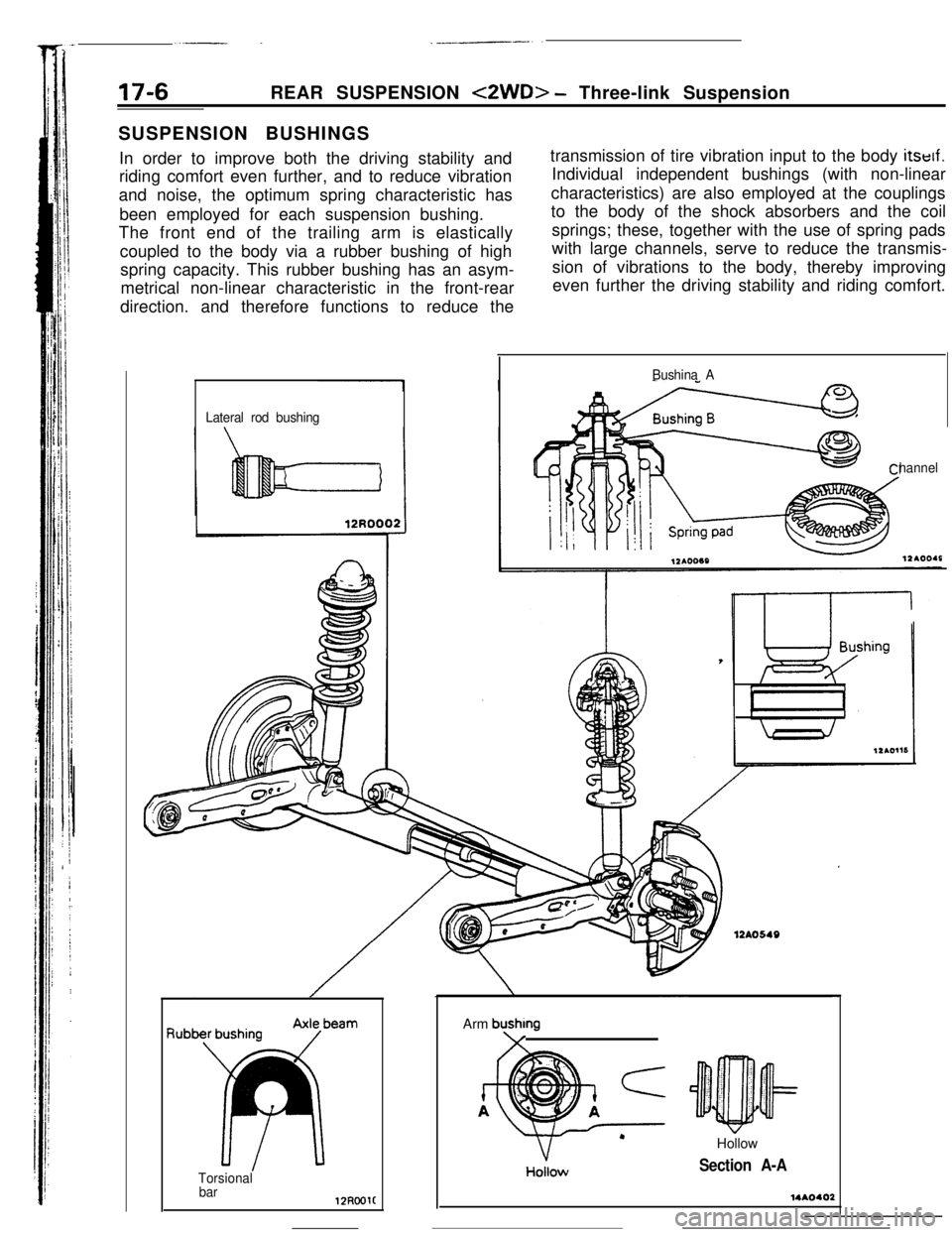

17-6REAR SUSPENSION <2WD> - Three-link Suspension

SUSPENSION BUSHINGS

In order to improve both the driving stability and

riding comfort even further, and to reduce vibration

and noise, the optimum spring characteristic has

been employed for each suspension bushing.

The front end of the trailing arm is elastically

coupled to the body via a rubber bushing of high

spring capacity. This rubber bushing has an asym-

metrical non-linear characteristic in the front-rear

direction. and therefore functions to reduce thetransmission of tire vibration input to the body itself.

Individual independent bushings (with non-linear

characteristics) are also employed at the couplings

to the body of the shock absorbers and the coil

springs; these, together with the use of spring pads

with large channels, serve to reduce the transmis-

sion of vibrations to the body, thereby improving

even further the driving stability and riding comfort.

Lateral rod bushingBushina A

hannel

f3ub

Torsional

barArm

bushmg\/HollowHoilow

Section A-A

Page 201 of 391

.-_. -

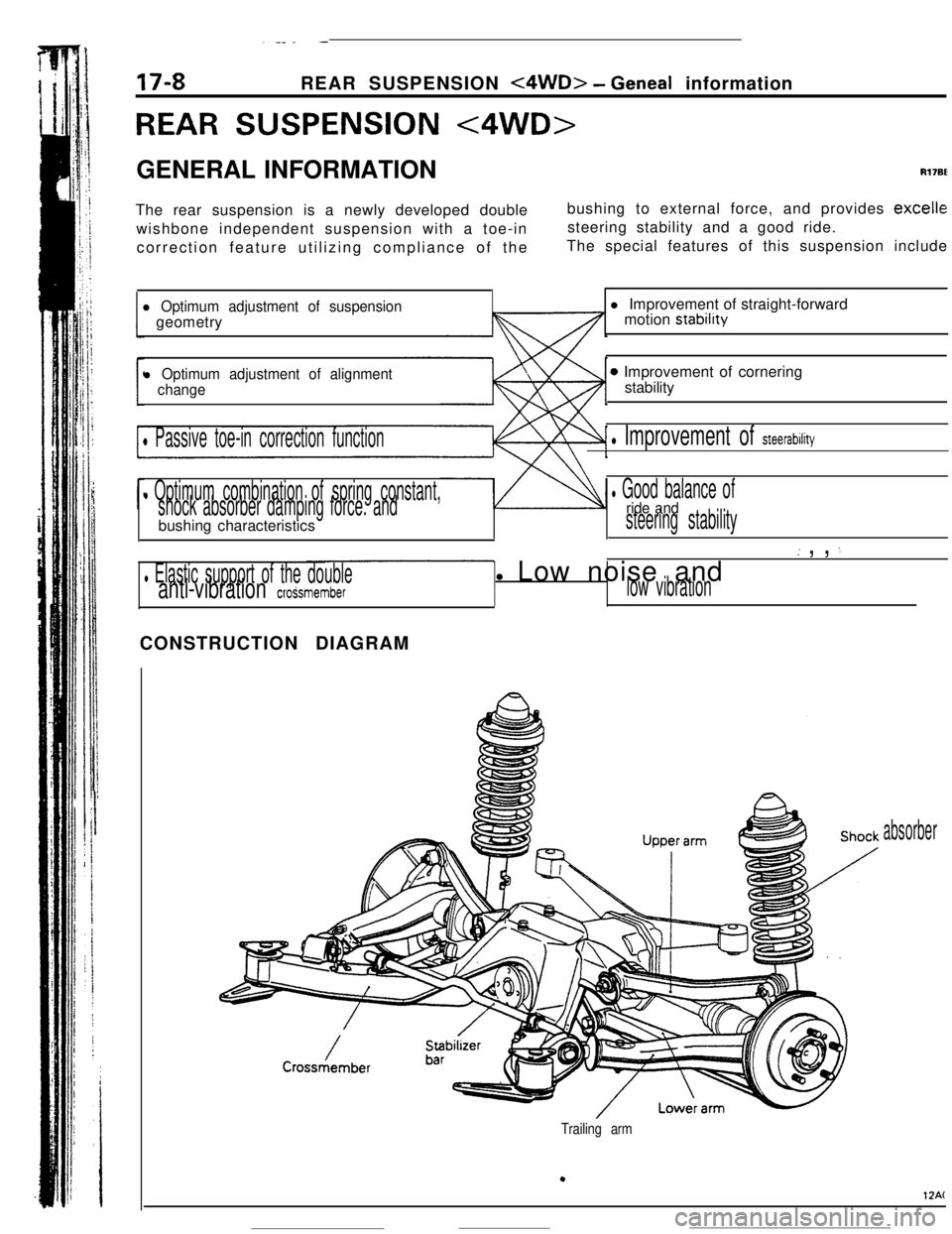

17-8REAR SUSPENSION <4WD> - Geneal information

REAR SUSPENSION <4WD>GENERAL INFORMATION

Rl7BEThe rear suspension is a newly developed double

wishbone independent suspension with a toe-in

correction feature utilizing compliance of thebushing to external force, and provides

excellesteering stability and a good ride.

The special features of this suspension include

l Optimum adjustment of suspensiongeometry

l Optimum adjustment of alignment

change

0 Passive toe-in correction function

l Optimum combination of spring constant,

shock absorber damping force. andbushing characteristics

l Elastic support of the doubleanti-vibration croSsmemberl Improvement of straight-forward

motion stability

0 Improvement of cornering

stability

l Improvement of steerability

l Good balance ofride andsteering stability

( , , :l Low noise and

low vibrationCONSTRUCTION DIAGRAM

absorber

Trailing arm

.

12AC

Page 202 of 391

_ -. ..__ .-

REAR SUSPENSION

<4WD> - Geneal (nformation

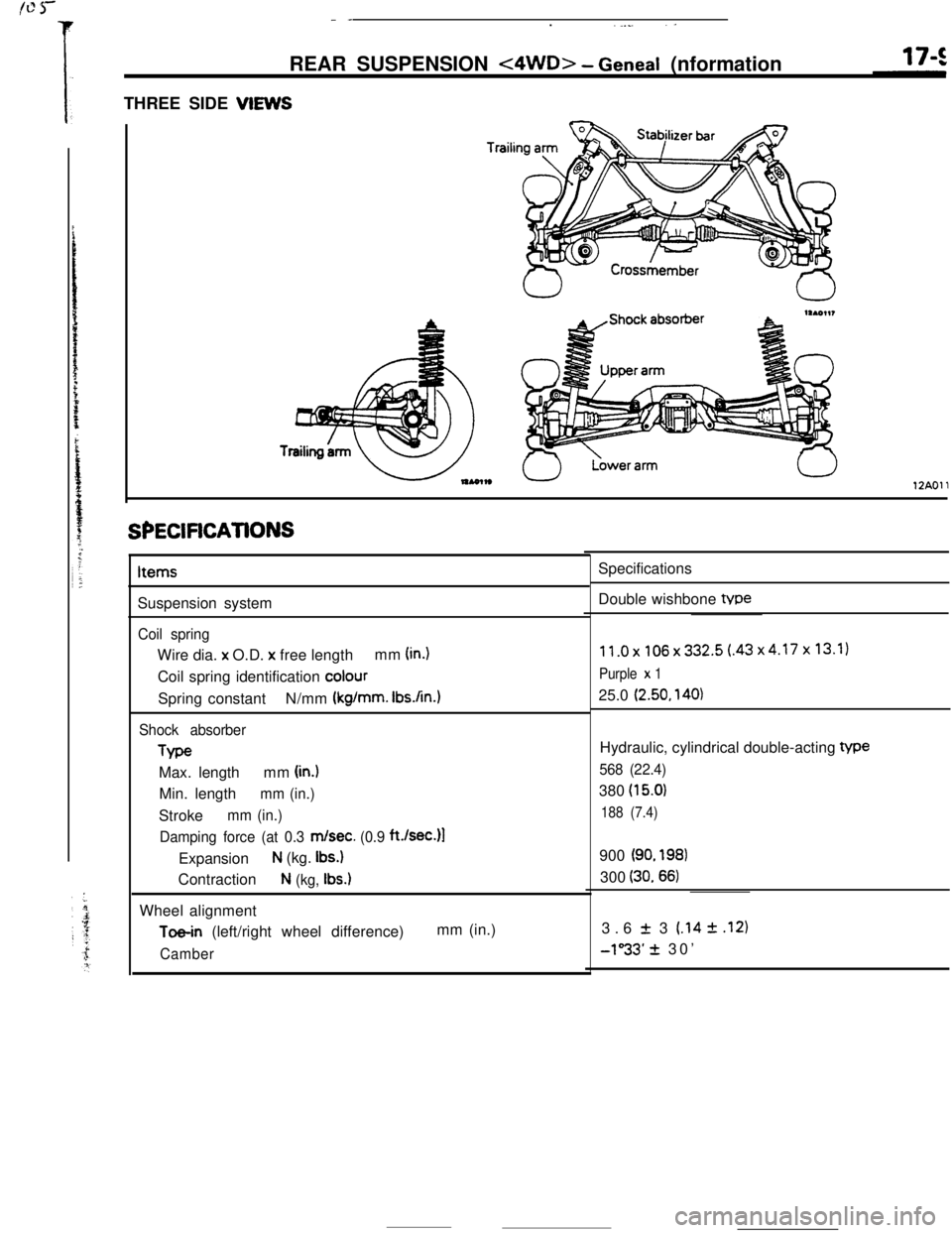

THREE SIDE VIEWS

Trailil

12AOll

SPECiFiCATiONSItems

Suspension system

Coil springWire dia. x O.D.

x free lengthmm (in.)Coil spring identification

colourSpring constantN/mm

(kg/mm. Ibs.An.1

Shock absorberType

Max. lengthmm

(in.)Min. length

mm (in.)Stroke

mm (in.)

Damping force (at 0.3

m/set. (0.9 ft./sec.)l

Expansion

N (kg. Ibs.)Contraction

N (kg, Ibs.)Wheel alignment

Toe-in (left/right wheel difference)mm (in.)

CamberSpecifications

Double wishbone tvpe

11.0x106x332.5(.43x4.17x13.1)

Purple x 125.0

(2.50, 140)Hydraulic, cylindrical double-acting

We

568 (22.4)380

(15.0)

188 (7.4)900

(90. 198)300

(30.66)3.6

f 3 (.14 2 .I21

-1”33’ + 30’

Page 207 of 391

17-14REAR SUSPENSION - Double Wishbone Suwension

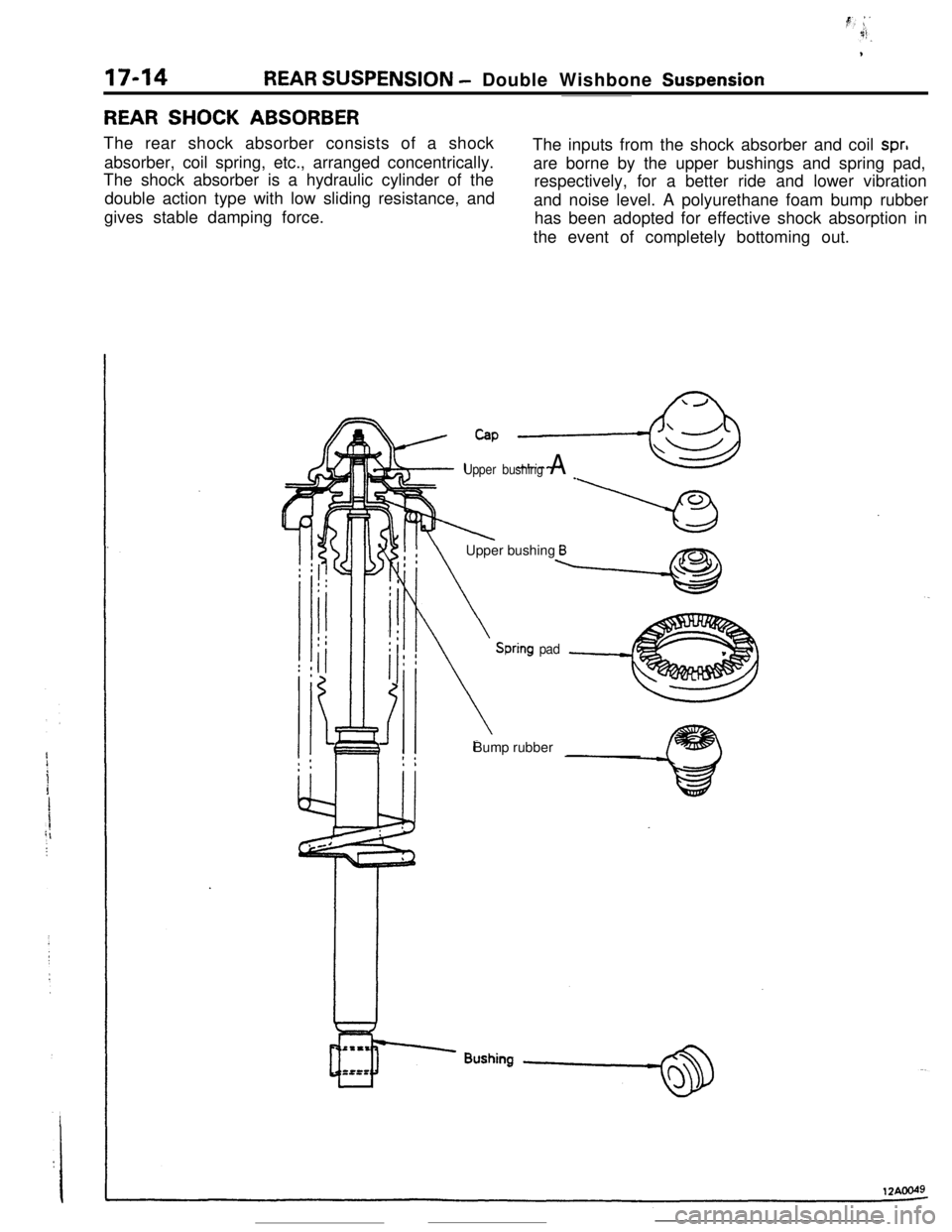

REAR SHOCK ABSORBERThe rear shock absorber consists of a shock

absorber, coil spring, etc., arranged concentrically.

The shock absorber is a hydraulic cylinder of the

double action type with low sliding resistance, and

gives stable damping force.The inputs from the shock absorber and coil

spr,are borne by the upper bushings and spring pad,

respectively, for a better ride and lower vibration

and noise level. A polyurethane foam bump rubber

has been adopted for effective shock absorption in

the event of completely bottoming out.

Cap ,-&

Upper bushing A _

IlXk!! \Upper bushing Bx?nb

Spring padBump rubber