fuel pressure MITSUBISHI ECLIPSE 1990 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 121 of 391

FUEL SYSTEM -Fuel Supply and Fuel Pressure Control14-9

03Poo4:Diaphragm

from intake

4Fuel from delivery pipe

4m

B(42.7)QQ

2

sl -196 2

(26.4) g

t

$!a d

9

0)Positive5 z‘. pressure

(E.2)

w

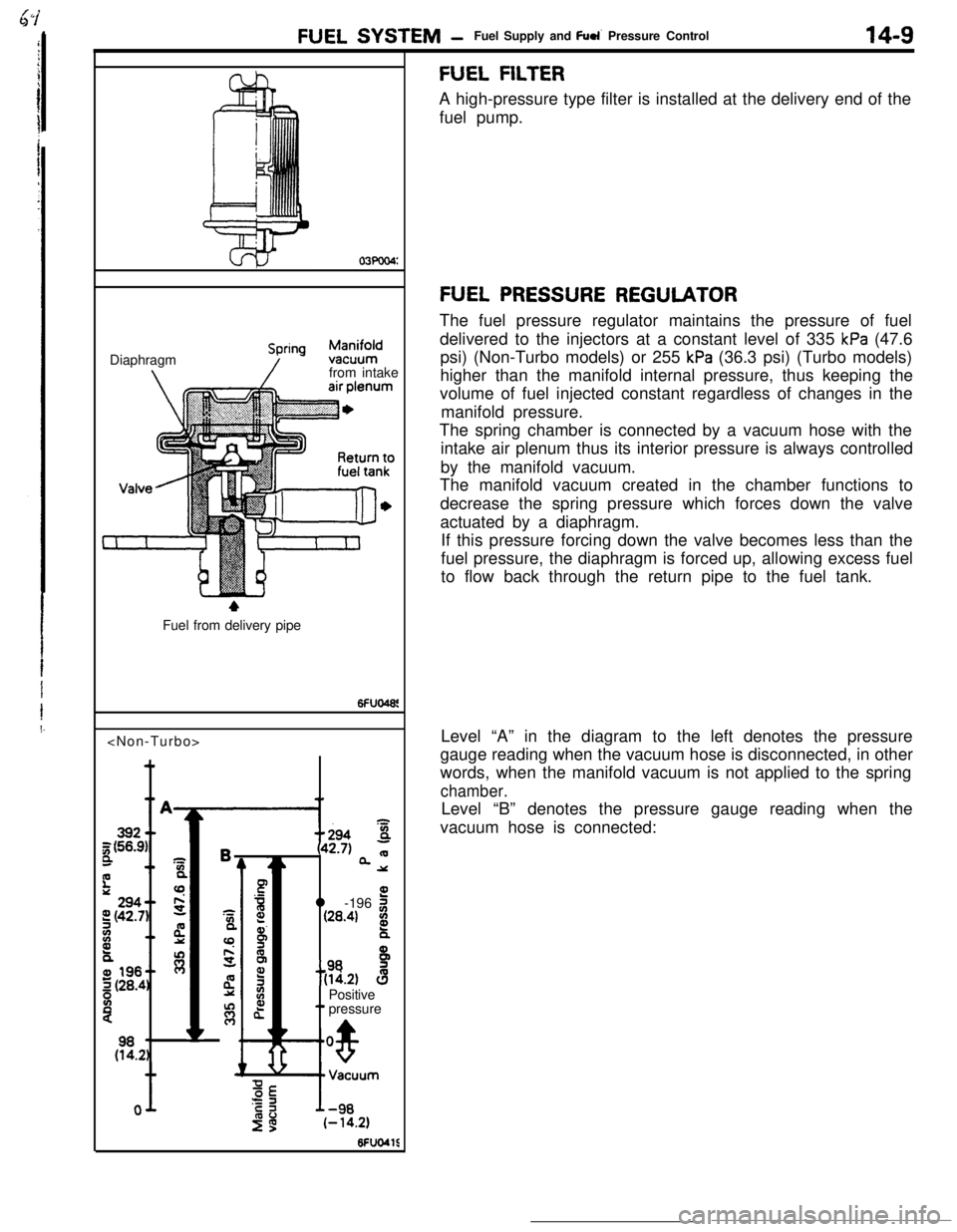

FUEL FILTERA high-pressure type filter is installed at the delivery end of the

fuel pump.

FUEL PRESSURE REGULATORThe fuel pressure regulator maintains the pressure of fuel

delivered to the injectors at a constant level of 335

kPa (47.6

psi) (Non-Turbo models) or 255

kPa (36.3 psi) (Turbo models)

higher than the manifold internal pressure, thus keeping the

volume of fuel injected constant regardless of changes in the

manifold pressure.

The spring chamber is connected by a vacuum hose with the

intake air plenum thus its interior pressure is always controlled

by the manifold vacuum.

The manifold vacuum created in the chamber functions to

decrease the spring pressure which forces down the valve

actuated by a diaphragm.

If this pressure forcing down the valve becomes less than the

fuel pressure, the diaphragm is forced up, allowing excess fuel

to flow back through the return pipe to the fuel tank.

Level “A” in the diagram to the left denotes the pressure

gauge reading when the vacuum hose is disconnected, in other

words, when the manifold vacuum is not applied to the spring

chamber.Level “B” denotes the pressure gauge reading when the

vacuum hose is connected:

Page 122 of 391

14-10

INJECTORFUEL SYSTEM

-Fuel Supply and Fuel Pressure Control

Intake port

lelivelYPipte

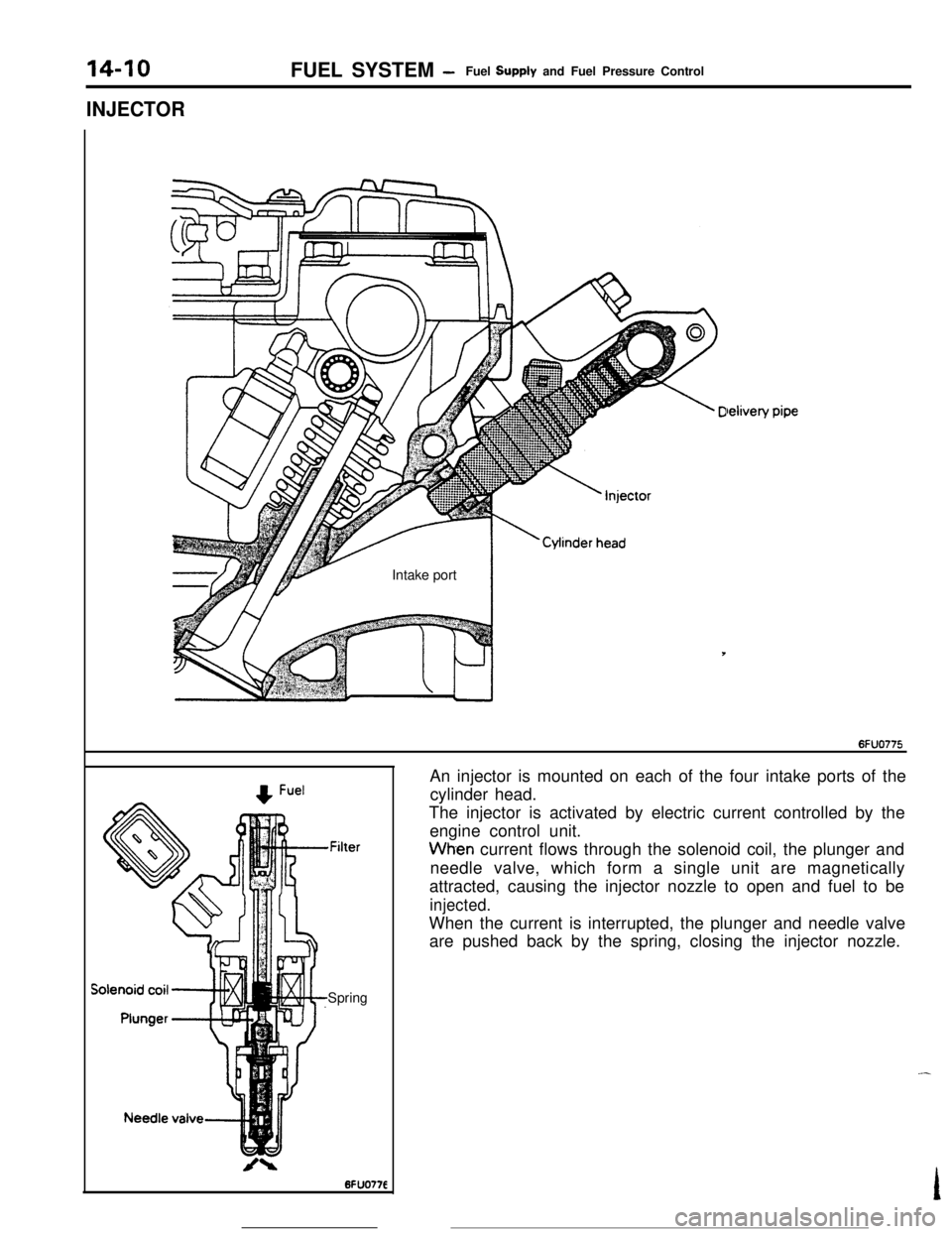

,FilterSpringAn injector is mounted on each of the four intake ports of the

cylinder head.

The injector is activated by electric current controlled by the

engine control unit.Wh-en current flows through the solenoid coil, the plunger and

needle valve, which form a single unit are magnetically

attracted, causing the injector nozzle to open and fuel to be

injected.When the current is interrupted, the plunger and needle valve

are pushed back by the spring, closing the injector nozzle.

Page 123 of 391

FUEL SYSTEM -Fuel Supply and Fuel Pressure Control

FUEL-PRESSURE CONTROL VALVE

14-11To fuel

-

Fuel-pressureregulatorFuel-pressurecontrol valve

Intake-airEnginecontrol

unit

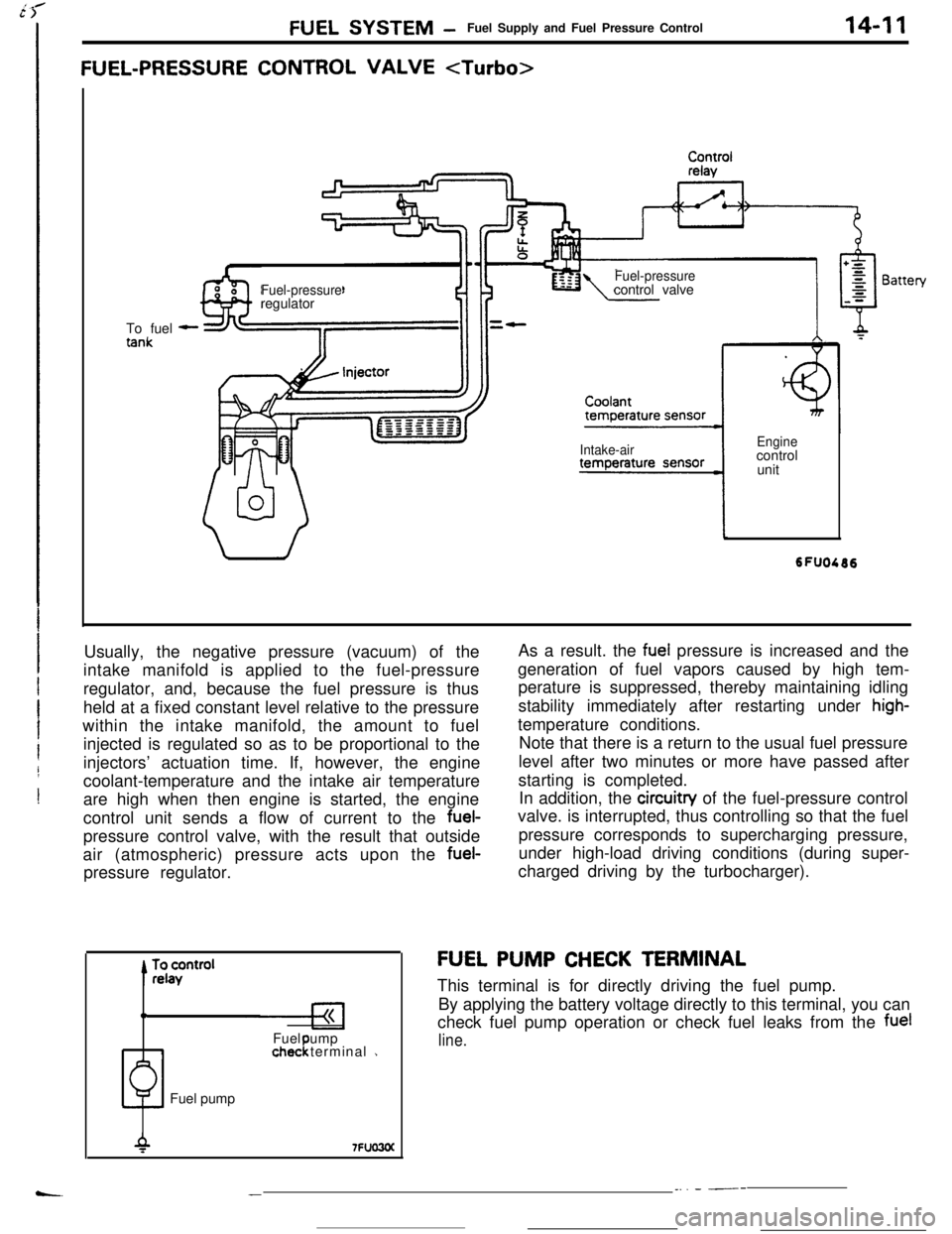

Usually, the negative pressure (vacuum) of the

intake manifold is applied to the fuel-pressure

regulator, and, because the fuel pressure is thus

held at a fixed constant level relative to the pressure

within the intake manifold, the amount to fuel

injected is regulated so as to be proportional to the

injectors’ actuation time. If, however, the engine

coolant-temperature and the intake air temperature

are high when then engine is started, the engine

control unit sends a flow of current to the fuel-

pressure control valve, with the result that outside

air (atmospheric) pressure acts upon the fuel-

pressure regulator.

0Fuel ump

1chec terminal 1!Fuel pumpAs a result. the

fuel pressure is increased and the

generation of fuel vapors caused by high tem-

perature is suppressed, thereby maintaining idling

stability immediately after restarting under

high-temperature conditions.

Note that there is a return to the usual fuel pressure

level after two minutes or more have passed after

starting is completed.

In addition, the circuitry of the fuel-pressure control

valve. is interrupted, thus controlling so that the fuel

pressure corresponds to supercharging pressure,

under high-load driving conditions (during super-

charged driving by the turbocharger).

FU,EL PUMP CHECK TERMINAL

This terminal is for directly driving the fuel pump.

By applying the battery voltage directly to this terminal, you can

check fuel pump operation or check fuel leaks from the

fuel

line.

__. - ---

Page 126 of 391

14-14

.._~- ---.FUEL SYSTEM

- Sensors

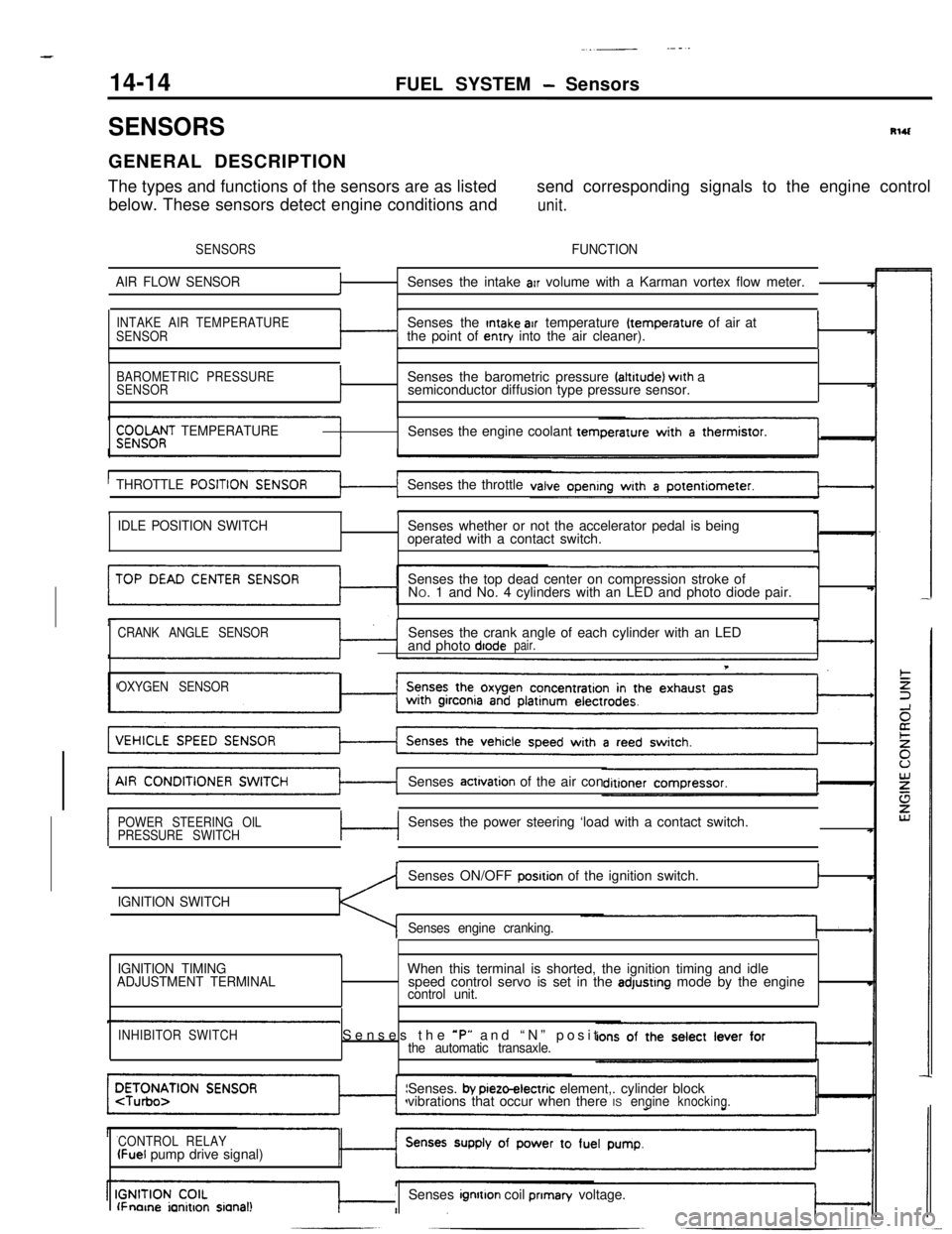

SENSORSRlUGENERAL DESCRIPTION

The types and functions of the sensors are as listedsend corresponding signals to the engine control

below. These sensors detect engine conditions and

unit.

SENSORSFUNCTION

AIR FLOW SENSOR

fSenses the intake arr volume with a Karman vortex flow meter.

INTAKE AIR TEMPERATURE

SENSORSenses the Intake air temperature (temperature of air at

the point of entry into the air cleaner).I

BAROMETRIC PRESSURE

SENSORISenses the barometric pressure faltrtude) wrth a

semiconductor diffusion type pressure sensor.

$;;OOf;T TEMPERATURESenses the engine coolant tern

THROTTLE

POSITISenses the throttle

tI

IDLE POSITION SWITCHSenses whether or not the accelerator pedal is being

operated with a contact switch.

Senses the top dead center on compression stroke of

NO. 1 and No. 4 cylinders with an LED and photo diode pair.

CRANK ANGLE SENSORSenses the crank angle of each cylinder with an LED

and photo diodepair.

T

OXYGEN SENSORSenses

actrvation of the air con

POWER STEERING OIL

PRESSURE SWITCHc-lSenses the power steering ‘load with a contact switch.

IGNITION SWITCHSenses ON/OFF

posrtion of the ignition switch.I

Senses engine cranking.

,

IGNITION TIMING

ADJUSTMENT TERMINALWhen this terminal is shorted, the ignition timing and idle

speed control servo is set in the adjustrng mode by the enginecontrol unit.

INHIBITOR SWITCHSenses the *P” and “N” positthe automatic transaxle.Senses.

by pieto-electric element,. cylinder block

vibrations that occur when there ISengineknocking.

CONTROL RELAY

(Fuel pump drive signal)

lFnorne ianitron sianal!Senses ignrtton coil prIman/ voltage.

Page 127 of 391

FUEL SYSTEM - Sensors

AIR FLOW SENSOR

IAir

0

Power supplyAir flow sensor(from control relay)

r-- Amplifier Few

L+--J Vortex ITo throttle

bodyEngine control unit

>- Power supply

e5 volts

6FUO493

EC1537

Karman vortex

(1) Slow air flow

6FUO423

(2) Fast air flow

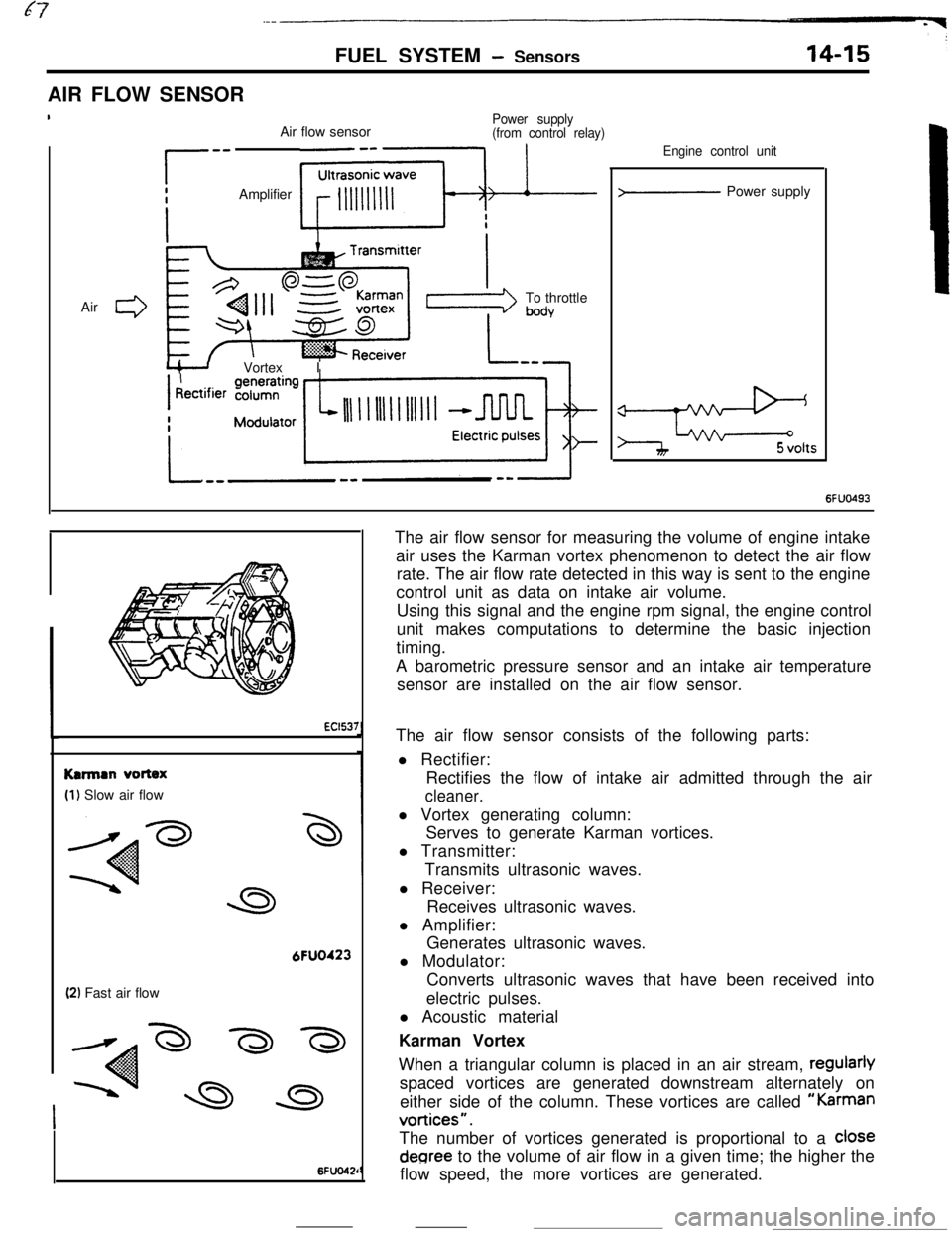

6Fuo42rThe air flow sensor for measuring the volume of engine intake

air uses the Karman vortex phenomenon to detect the air flow

rate. The air flow rate detected in this way is sent to the engine

control unit as data on intake air volume.

Using this signal and the engine rpm signal, the engine control

unit makes computations to determine the basic injection

timing.

A barometric pressure sensor and an intake air temperature

sensor are installed on the air flow sensor.

The air flow sensor consists of the following parts:

l Rectifier:

Rectifies the flow of intake air admitted through the air

cleaner.l Vortex generating column:

Serves to generate Karman vortices.

l Transmitter:

Transmits ultrasonic waves.

l Receiver:

Receives ultrasonic waves.

l Amplifier:

Generates ultrasonic waves.

l Modulator:

Converts ultrasonic waves that have been received into

electric pulses.

l Acoustic material

Karman Vortex

When a triangular column is placed in an air stream, regularly

spaced vortices are generated downstream alternately on

either side of the column. These vortices are called

“Karman

vortices”.The number of vortices generated is proportional to a

cloSedegree to the volume of air flow in a given time; the higher the

flow speed, the more vortices are generated.

Page 130 of 391

14-18FUEL SYSTEM - Sensors

tBAROMETRIC PRESSURE SENSOR

Barometnc rxessure sensor

EC1537

Barometncpressure sensor

Enginecontrol unit

1OFUO576

/

760 (30)Barometric pressure mmHg

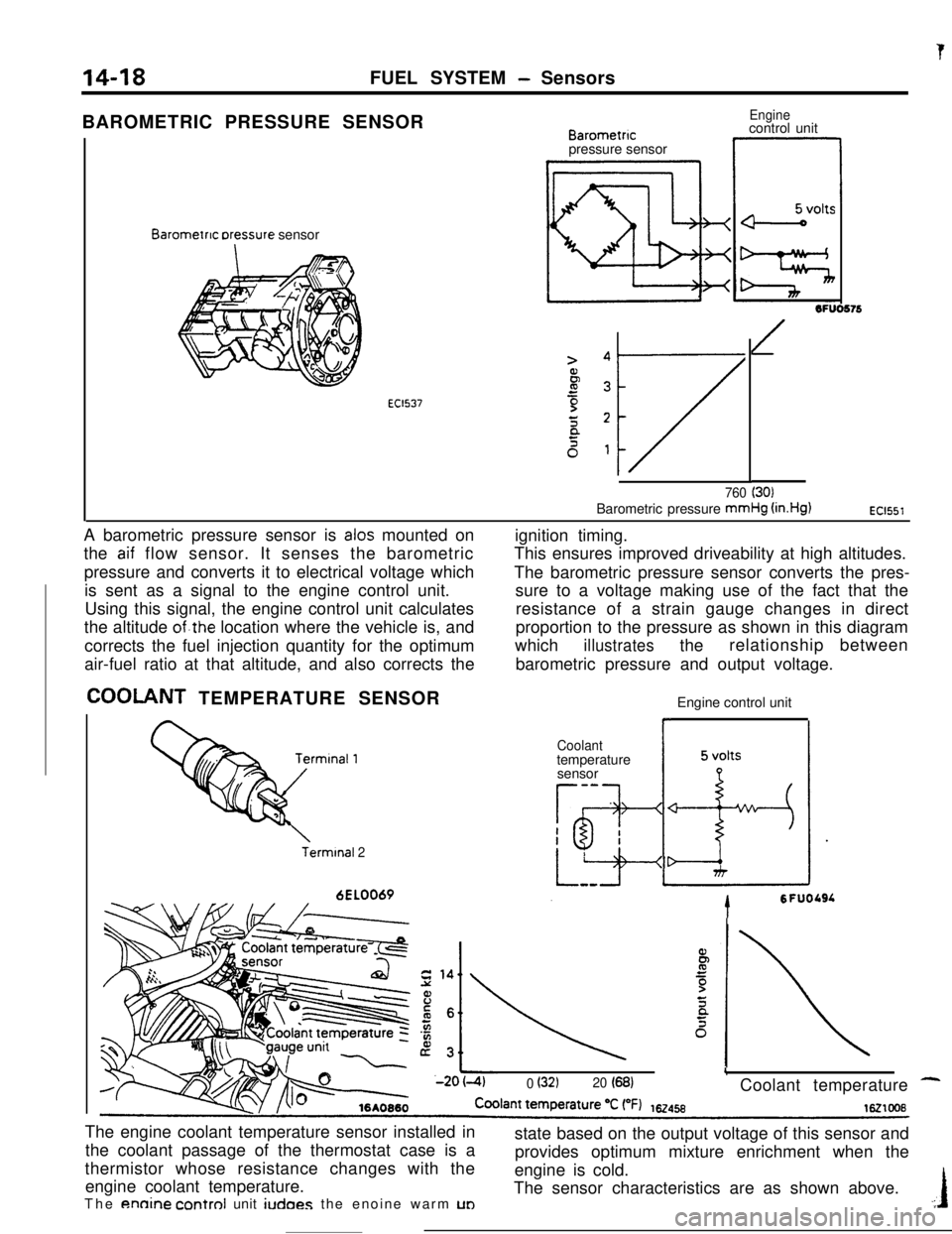

(in.Hg)EC1551A barometric pressure sensor is

alas mounted on

the

aif flow sensor. It senses the barometric

pressure and converts it to electrical voltage which

is sent as a signal to the engine control unit.

Using this signal, the engine control unit calculates

the altitude

of.the location where the vehicle is, and

corrects the fuel injection quantity for the optimum

air-fuel ratio at that altitude, and also corrects the

COOLANT TEMPERATURE SENSOR

Terminal 26EL0069ignition timing.

This ensures improved driveability at high altitudes.

The barometric pressure sensor converts the pres-

sure to a voltage making use of the fact that the

resistance of a strain gauge changes in direct

proportion to the pressure as shown in this diagram

which

illustratestherelationship between

barometric pressure and output voltage.

Engine control unit

Coolanttemperature

sensor

-a

Tg-I

h-esI

*

LizIdr

tSFUOLSL

L0 (32120 (68)Coolant temperature -The engine coolant temperature sensor installed in

the coolant passage of the thermostat case is a

thermistor whose resistance changes with the

engine coolant temperature.

The

annine control unit iudoes the enoine warm UDstate based on the output voltage of this sensor and

provides optimum mixture enrichment when the

engine is cold.

The sensor characteristics are as shown above..:I

Page 135 of 391

‘7JFUEL SYSTEM

- Sensors14-23AIR CONDITIONER SWITCH

Batten/

-31 .,Air conditioner unitlSAO735‘Air conditioner

control unitI”.._. ,voltage

Dual pressureswitch

-f@ -//Q.j

/

Coolanttemperature6FU1148

switch

Engine control unit

3Air conditioner

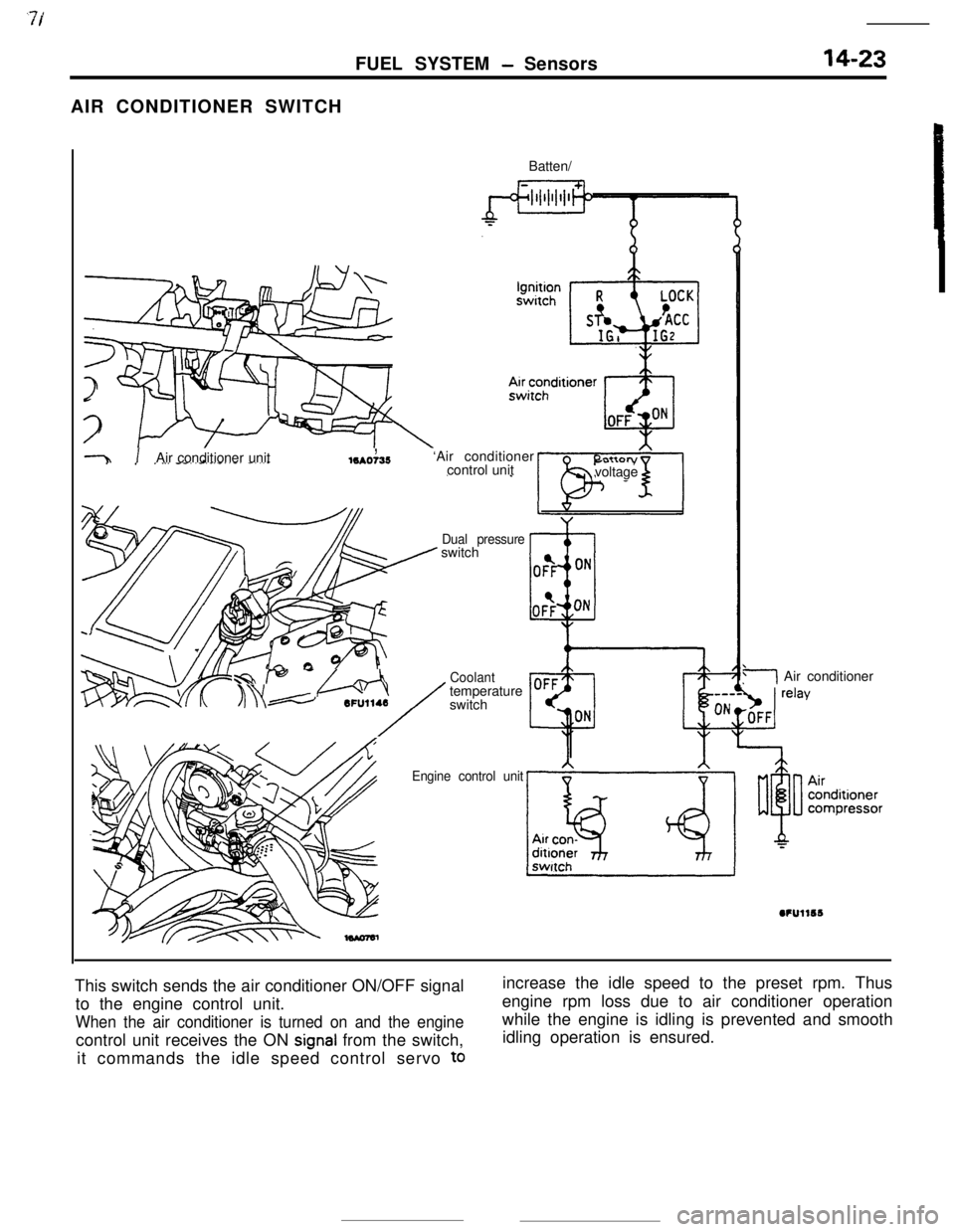

This switch sends the air conditioner ON/OFF signal

to the engine control unit.

When the air conditioner is turned on and the enginecontrol unit receives the ON

signal from the switch,

it commands the idle speed control servo

toincrease the idle speed to the preset rpm. Thus

engine rpm loss due to air conditioner operation

while the engine is idling is prevented and smooth

idling operation is ensured.

Page 136 of 391

--

,

14-24FUEL SYSTEM - Sensors

POWER STEERING OIL PRESSURE SWITCHEngine control unit

Power steering oil

pressure switchBattery

voltage

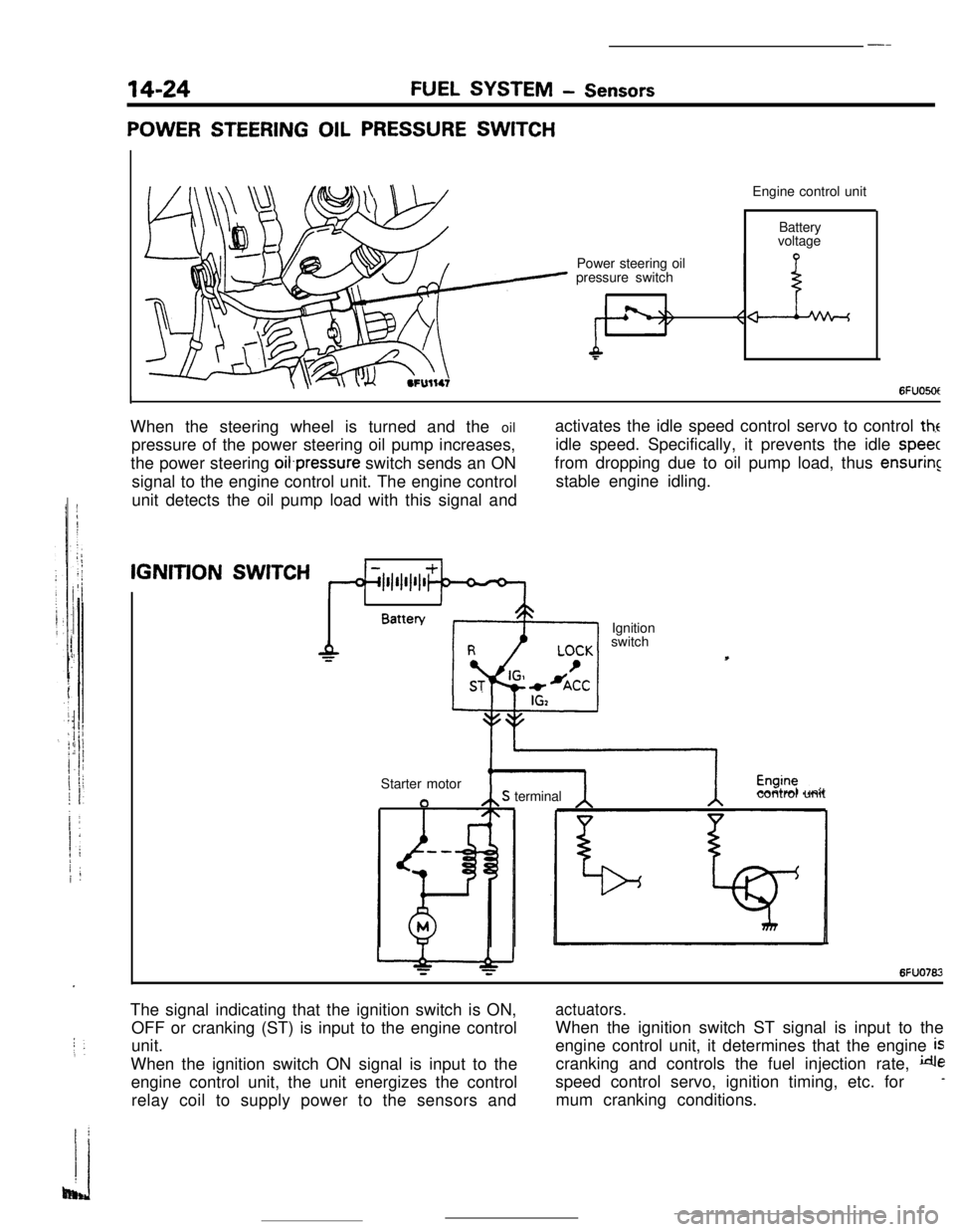

6FUO5OtIWhen the steering wheel is turned and the oil

pressure of the power steering oil pump increases,

the power steering oifpressure switch sends an ON

signal to the engine control unit. The engine control

unit detects the oil pump load with this signal andactivates the idle speed control servo to control

theidle speed. Specifically, it prevents the idle

speecfrom dropping due to oil pump load, thus

ensuringstable engine idling.IGNITION

SWITCH

1IBattery

Ignition

switch

Starter motor

aS terminalcontrol unit

6FUO762The signal indicating that the ignition switch is ON,

OFF or cranking (ST) is input to the engine control

unit.

When the ignition switch ON signal is input to the

engine control unit, the unit energizes the control

relay coil to supply power to the sensors and

actuators.When the ignition switch ST signal is input to the

engine control unit, it determines that the engine

iscranking and controls the fuel injection rate,

despeed control servo, ignition timing, etc. for

-mum cranking conditions.

Page 139 of 391

‘73.- .-_ _ .-__ .- -..- - .-----___. _____^. -._ __--.

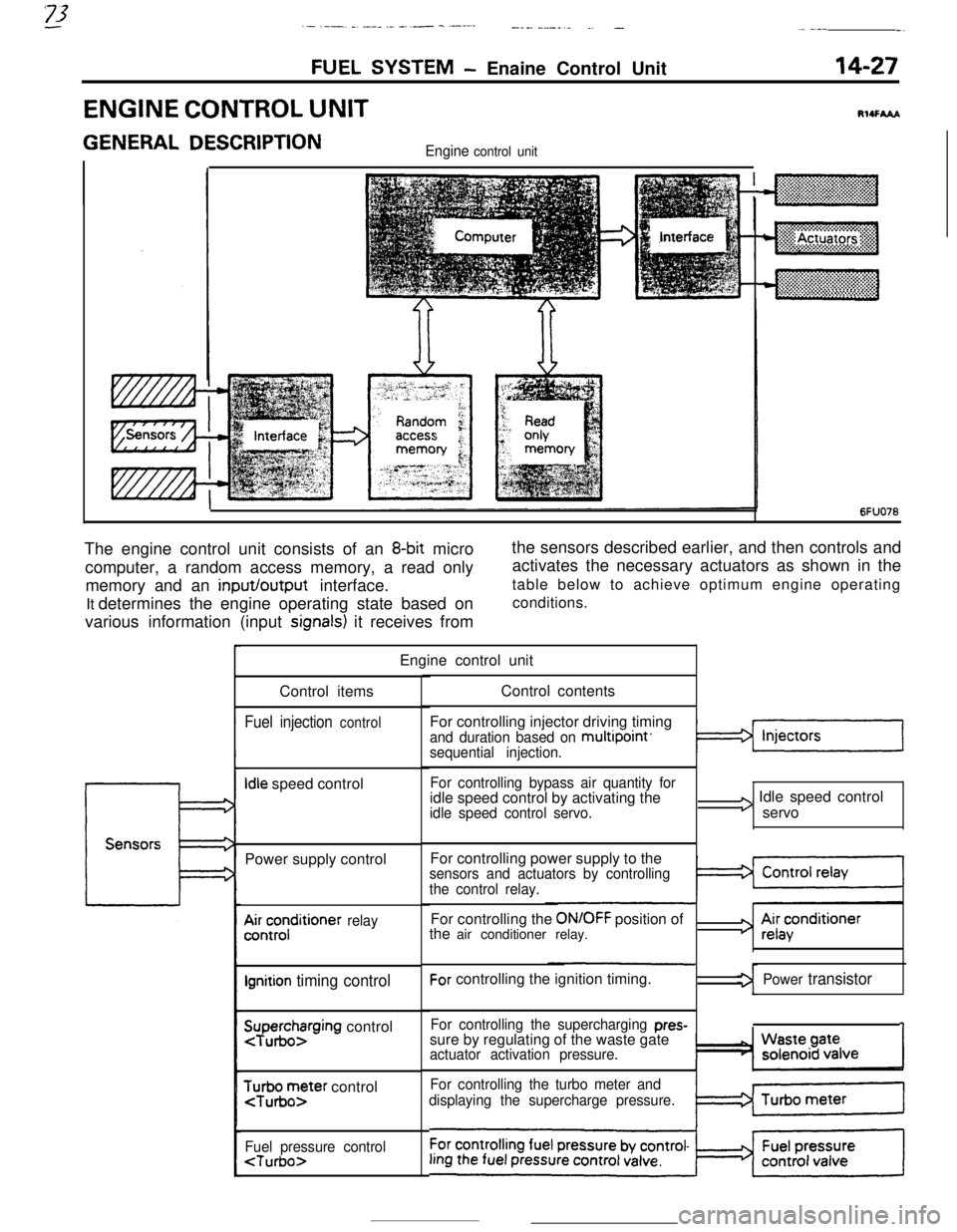

FUEL SYSTEM- Enaine Control Unit14-27

ENGINE CONTROL UNITRI4FhAA

GENERAL DESCRIPTIONEngine control unit

~

~~:~~~~~~~~~:~~

~. . . . .. .. . . . ... . . . . ... .. :+:.:.:.:.:.:.:.~.:.~+~.

6FUO76The engine control unit consists of an

8-bit micro

computer, a random access memory, a read only

memory and an input/output interface.

It determines the engine operating state based on

various information (input

signals) it receives fromthe sensors described earlier, and then controls and

activates the necessary actuators as shown in the

table below to achieve optimum engine operating

conditions.

Engine control unit

Control items

Fuel injection control

Idle speed control

Power supply control

A&;;;ditioner relay

Ignition timing control

SuTpuegohzrging control

$r;ir;;ter control

Fuel pressure control

For controlling injector driving timing

and duration based on multipoint’sequential injection.

For controlling bypass air quantity foridle speed control by activating the

idle speed control servo.

I3 Idle speed control

servo

For controlling power supply to the

sensors and actuators by controlling

the control relay.For controlling the

ON/OFF position of

the air conditioner relay.For controlling the ignition timing.

For controlling the supercharging pres-sure by regulating of the waste gate

actuator activation pressure.

For controlling the turbo meter and

displaying the supercharge pressure.

3 Ai;acenditioner

Power transistor

1

Page 141 of 391

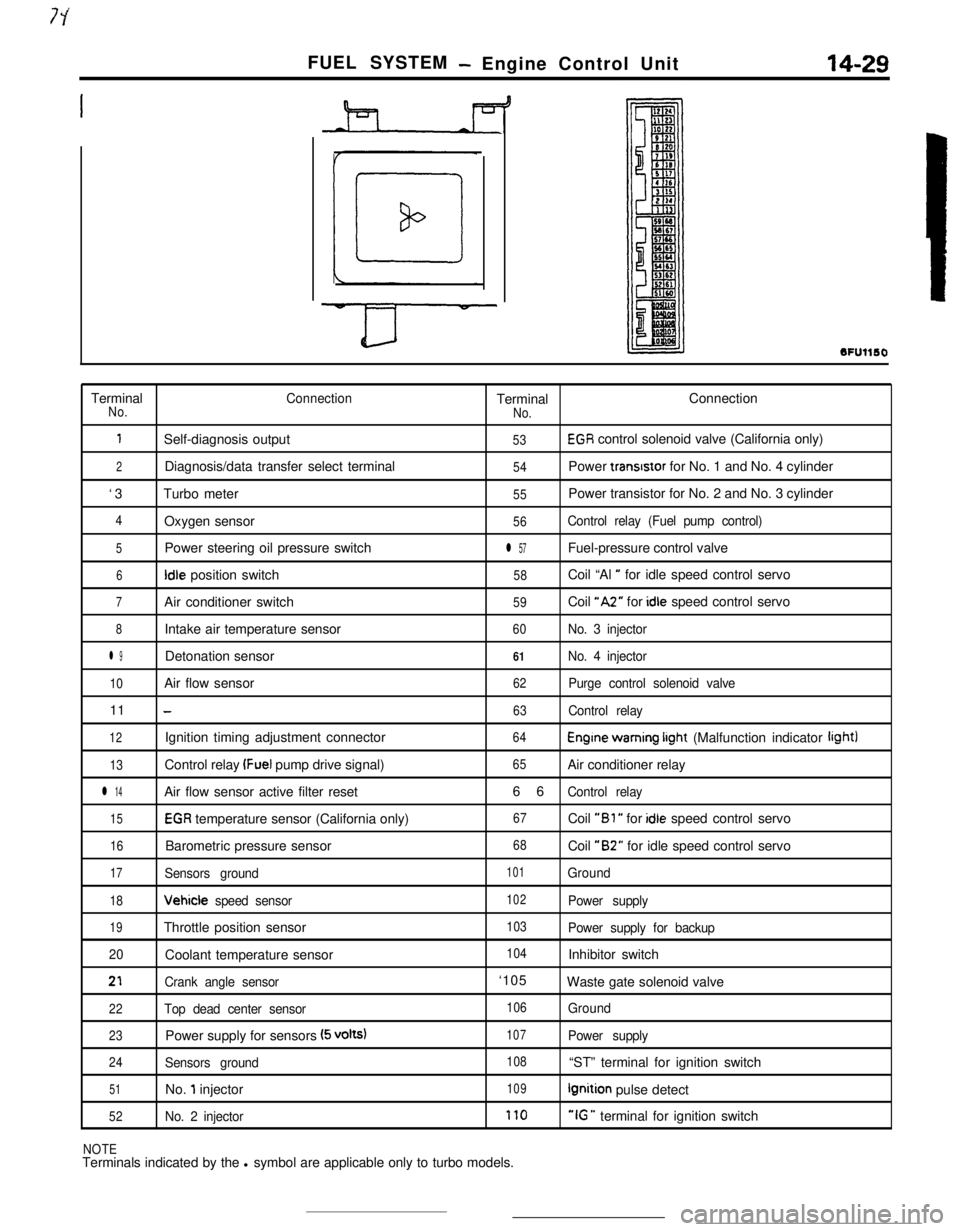

FUEL SYSTEM- Engine Control Unit14-29

SFUllSOTerminal

ConnectionTerminalConnectionNo.

No.

1Self-diagnosis output53EGR control solenoid valve (California only)

2Diagnosis/data transfer select terminal54Power transrstor for No. 1 and No. 4 cylinder

‘3Turbo meter

55Power transistor for No. 2 and No. 3 cylinder

4Oxygen sensor56Control relay (Fuel pump control)

5Power steering oil pressure switchl 57Fuel-pressure control valve

6Idle position switch58Coil “Al ” for idle speed control servo

7Air conditioner switch59Coil “A2” for idle speed control servo

8Intake air temperature sensor60No. 3 injector

l 9Detonation sensor61No. 4 injector

10Air flow sensor62Purge control solenoid valve11

-63Control relay

12Ignition timing adjustment connector64Engine warning irght (Malfunction indicator light)

13Control relay (Fuel pump drive signal)65Air conditioner relay

l 14Air flow sensor active filter reset66Control relay

15EGR temperature sensor (California only)67Coil “Bl ” for idle speed control servo

16Barometric pressure sensor68Coil “B2” for idle speed control servo

17Sensors ground101Ground

18Vehicle speed sensor102Power supply

19Throttle position sensor103Power supply for backup

20Coolant temperature sensor

104Inhibitor switch

21Crank angle sensor‘105

Waste gate solenoid valve

22Top dead center sensor106Ground

23Power supply for sensors (5 volts)107Power supply

24Sensors ground108“ST” terminal for ignition switch

51No. 1 injector109Ignition pulse detect

52No. 2 injector170“IG ” terminal for ignition switch

NOTETerminals indicated by the l symbol are applicable only to turbo models.