fuel pressure MITSUBISHI ECLIPSE 1990 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 142 of 391

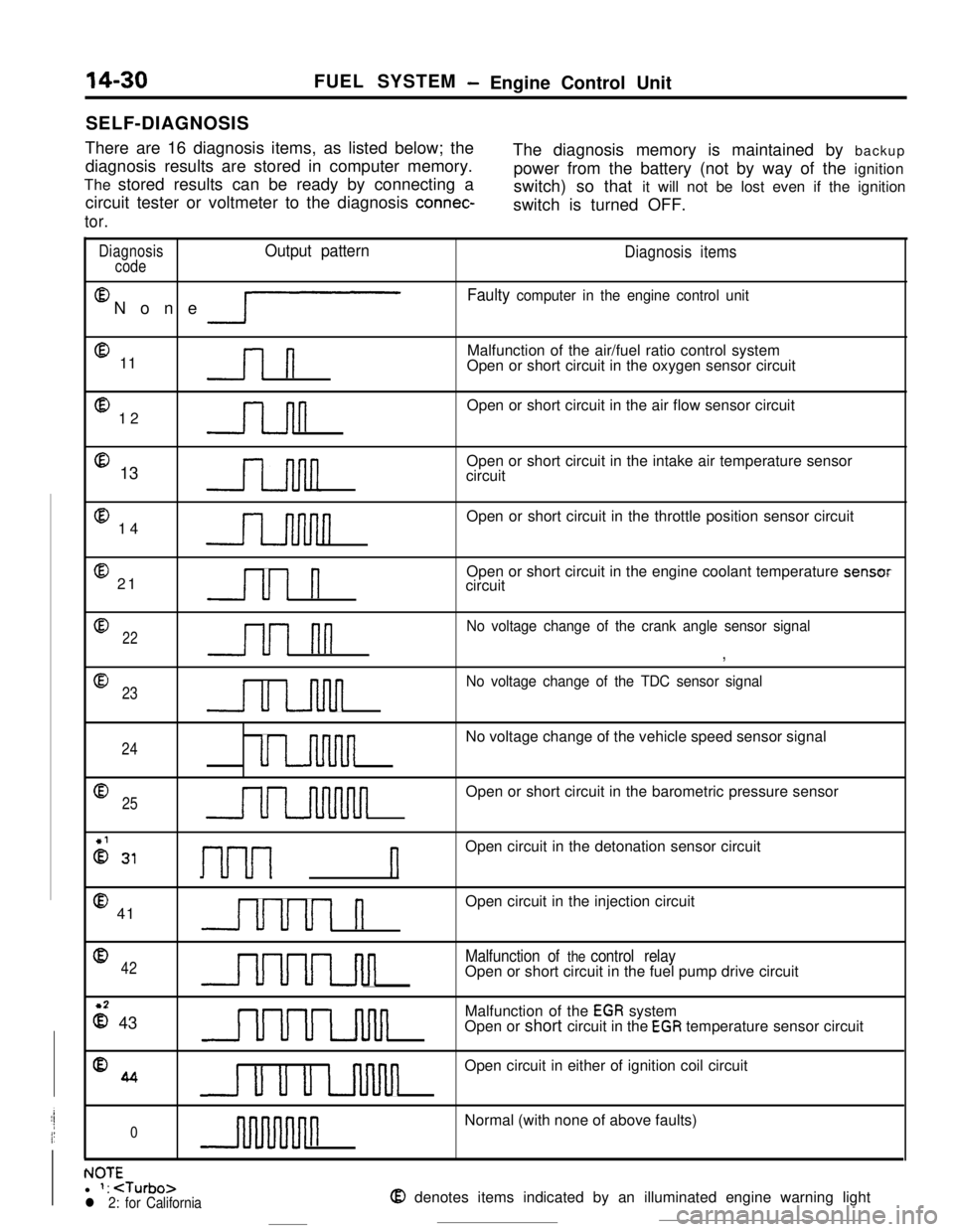

14-30SELF-DIAGNOSISFUEL SYSTEM- Engine Control Unit

There are 16 diagnosis items, as listed below; the

diagnosis results are stored in computer memory.The diagnosis memory is maintained by backup

The stored results can be ready by connecting apower from the battery (not by way of the ignition

circuit tester or voltmeter to the diagnosis

connec-switch) so that it will not be lost even if the ignition

switch is turned OFF.

tor.

DiagnosisOutput pattern

codeEl

None

lP

@ 11l-l

@ 12n@ 13

@ 14

@ 21Ul n

Diagnosis items

Faulty computer in the engine control unitMalfunction of the air/fuel ratio control system

Open or short circuit in the oxygen sensor circuit

Open or short circuit in the air flow sensor circuit

Open or short circuit in the intake air temperature sensor

circuit

Open or short circuit in the throttle position sensor circuit

Open or short circuit in the engine coolant temperature sensor

circuit

022u1 nn

No voltage change of the crank angle sensor signal

,

@

23

u u-inn

No voltage change of the TDC sensor signal

24uu-uvinnnnNo voltage change of the vehicle speed sensor signal

Q25uuuuuunnnnnOpen or short circuit in the barometric pressure sensor

2 31I-~-~---~ nOpen circuit in the detonation sensor circuit

@ 41uuul nOpen circuit in the injection circuit

042UUuLJul

Malfunction of the control relayOpen or short circuit in the fuel pump drive circuit

z 43UUULnlulMalfunction of the

EGR system

Open or short circuit in the EGR temperature sensor circuit

%4u u u uvinnOpen circuit in either of ignition coil circuit

0nNormal (with none of above faults)

. IA-r-NUltl 1:

Page 144 of 391

__.-~-..- -

FUEL SYSTEM- Ermine Control Unit

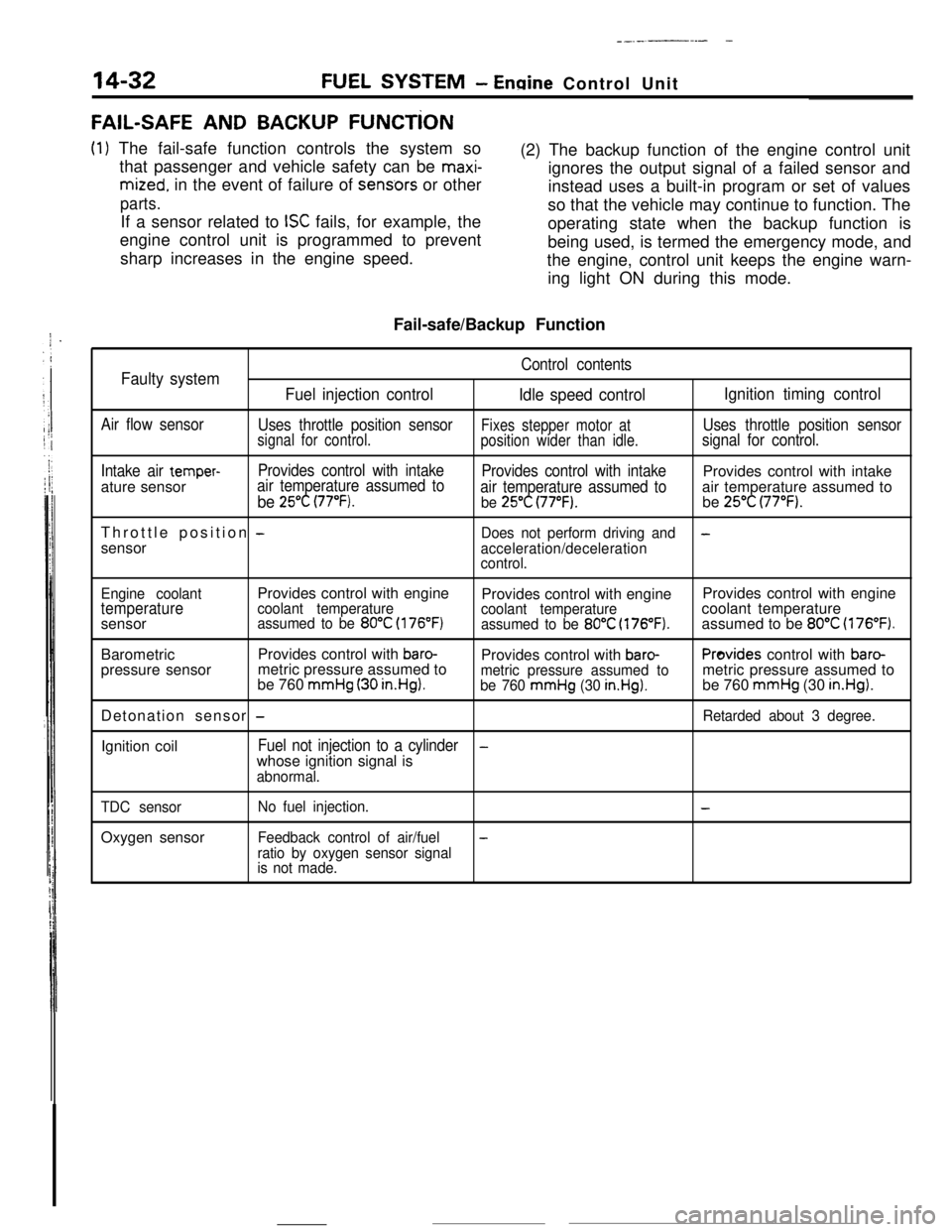

FAIL-SAFE AND BACKUP FUNCTiON

(1) The fail-safe function controls the system so

that passenger and vehicle safety can be

maxi-

mized. in the event of failure of sens.ors or other

parts.If a sensor related to

ISC fails, for example, the

engine control unit is programmed to prevent

sharp increases in the engine speed.(2) The backup function of the engine control unit

ignores the output signal of a failed sensor and

instead uses a built-in program or set of values

so that the vehicle may continue to function. The

operating state when the backup function is

being used, is termed the emergency mode, and

the engine, control unit keeps the engine warn-

ing light ON during this mode.

Fail-safe/Backup Function

Control contentsFaulty system

Fuel injection control

Idle speed controlIgnition timing control

Air flow sensor

Uses throttle position sensorFixes stepper motor atUses throttle position sensorsignal for control.

position wider than idle.signal for control.

Intake air

temper-Provides control with intake

Provides control with intakeProvides control with intake

ature sensorair temperature assumed to

be 25°C (77°F).air temperature assumed toair temperature assumed tobe 25°C (77°F).be 25°C (77°F).Throttle position

-Does not perform driving and-sensor

acceleration/deceleration

control.

Engine coolantProvides control with engine

Provides control with engineProvides control with engine

temperaturecoolant temperature

coolant temperaturecoolant temperature

sensorassumed to be 80°C (176°F)assumed to be 80°C (176°F).assumed to be 80°C (176°F).BarometricProvides control with

baro-Provides control with baro-Provides control with baro-pressure sensormetric pressure assumed to

be 760

mmHg (30 in.HgI.metric pressure assumed tometric pressure assumed tobe 760 mmHg (30 in.Hg).be 760 mmHg (30 in.Hg).Detonation sensor

-Retarded about 3 degree.Ignition coil

Fuel not injection to a cylinder-whose ignition signal is

abnormal.

TDC sensorOxygen sensor

No fuel injection.-

Feedback control of air/fuel-

ratio by oxygen sensor signal

is not made.

Page 146 of 391

-

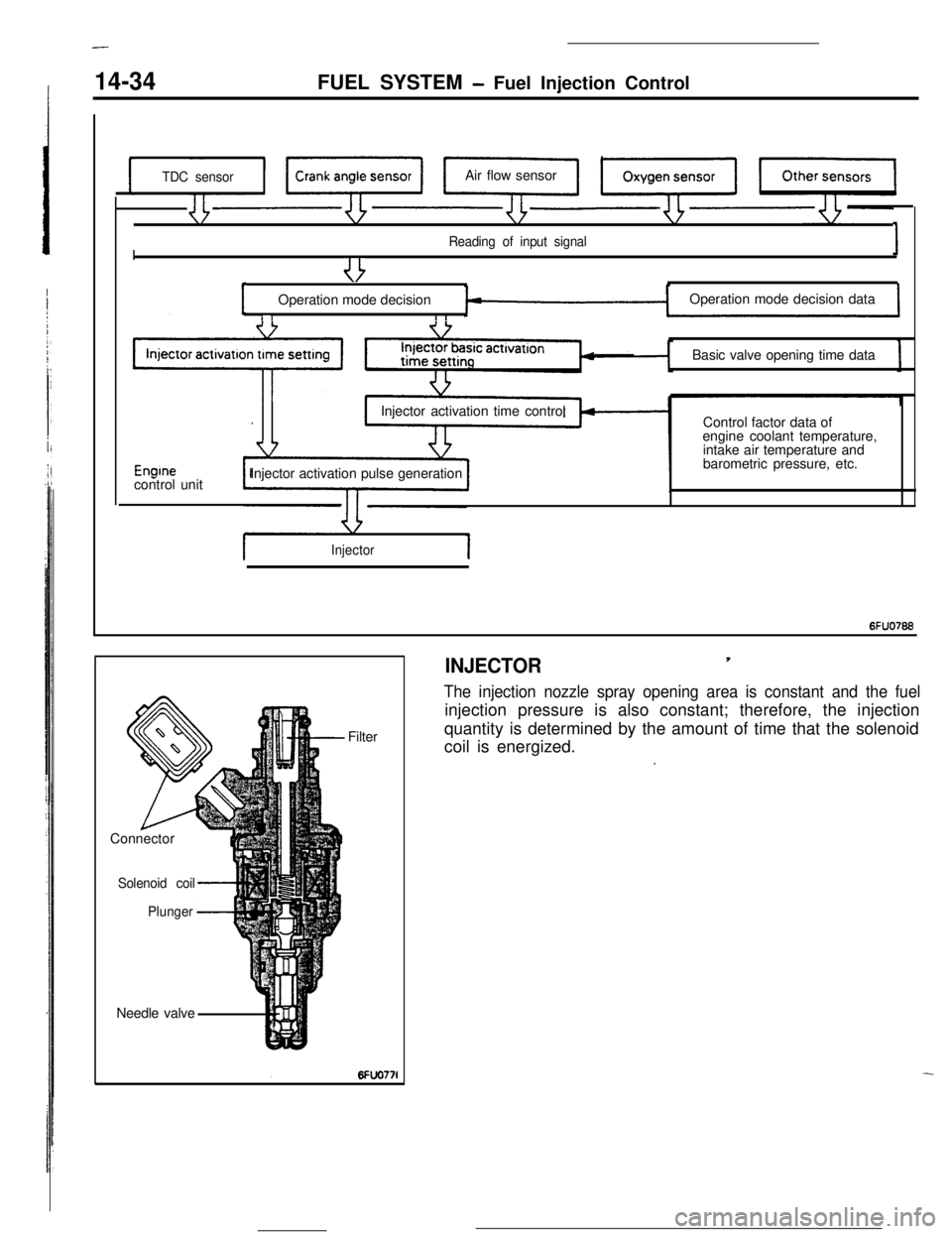

14-34FUEL SYSTEM - Fuel Injection Control

TDC sensorAir flow sensor

I

Reading of input signal1

I ,,

uOperation mode decisionOperation mode decision data

I rBasic valve opening time data

Enginecontrol unitInjector activation time control

Injector activation pulse generationControl factor data of

engine coolant temperature,

intake air temperature and

barometric pressure, etc.

Injector1

6FUO766Needle valveFilter

Connector

Solenoid coil

Plunger

-4

INJECTOR,

The injection nozzle spray opening area is constant and the fuelinjection pressure is also constant; therefore, the injection

quantity is determined by the amount of time that the solenoid

coil is energized.

.

Page 152 of 391

14-40FUEL SYSTEM - Fuel Injection Control

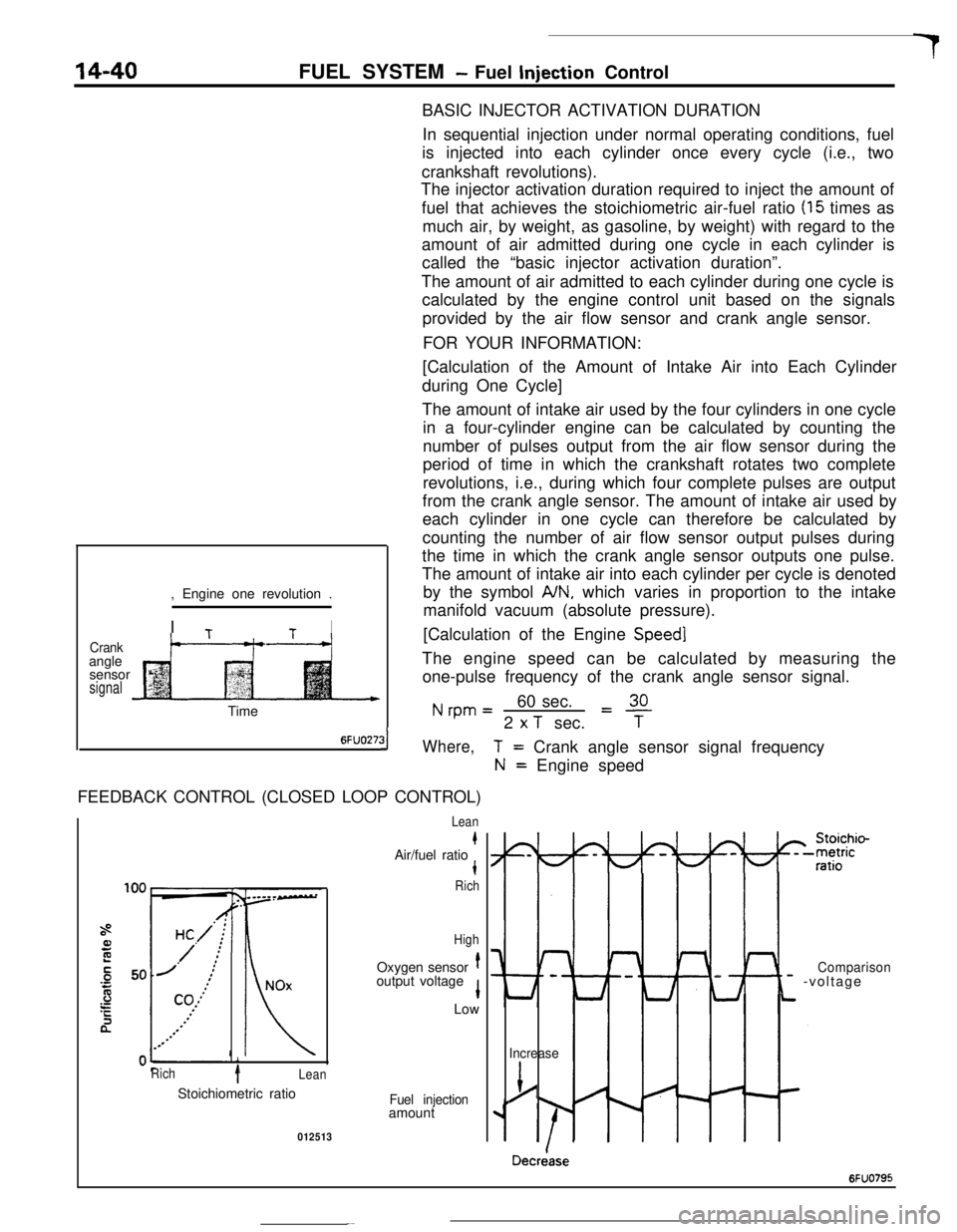

BASIC INJECTOR ACTIVATION DURATION

In sequential injection under normal operating conditions, fuel

is injected into each cylinder once every cycle (i.e., two

crankshaft revolutions).

The injector activation duration required to inject the amount of

fuel that achieves the stoichiometric air-fuel ratio

(15 times as

much air, by weight, as gasoline, by weight) with regard to the

amount of air admitted during one cycle in each cylinder is

called the “basic injector activation duration”.

The amount of air admitted to each cylinder during one cycle is

calculated by the engine control unit based on the signals

provided by the air flow sensor and crank angle sensor.

FOR YOUR INFORMATION:

Crankangle

sensor

signal, Engine one revolution .

I

TtI

t--“---t-+[Calculation of the Amount of Intake Air into Each Cylinder

during One Cycle]

The amount of intake air used by the four cylinders in one cycle

in a four-cylinder engine can be calculated by counting the

number of pulses output from the air flow sensor during the

period of time in which the crankshaft rotates two complete

revolutions, i.e., during which four complete pulses are output

from the crank angle sensor. The amount of intake air used by

each cylinder in one cycle can therefore be calculated by

counting the number of air flow sensor output pulses during

the time in which the crank angle sensor outputs one pulse.

The amount of intake air into each cylinder per cycle is denoted

by the symbol

A/N, which varies in proportion to the intake

manifold vacuum (absolute pressure).

[Calculation of the Engine

Speed]The engine speed can be calculated by measuring the

one-pulse frequency of the crank angle sensor signal.

Nrpm=60 sec.L!!L2

x T sec.TTime

6FUO27:31Where,FEEDBACK CONTROL (CLOSED LOOP CONTROL)

i

Rich1Lean

T= Crank angle sensor signal frequency

N= Engine speed

Lean

kAir/fuel ratiot

Rich

HighOxygen sensor

toutput voltage

1Low

Stoichiometric ratio

Fuel injectionamount

012513

I-

Lt

Comparison- -voltage

Increase

j/

Decriase

6FUO795

Page 154 of 391

14-42

FUEL SYSTEM- Fuel Injection Control

4

Fz.or.c

4:0/

E

{!*760 (301Barometric pressure

mmHg (in.Hg) 6Fuo9z

c

Timet

6FUO279Drivecurrent

0: bri

F2JJ’ ipe; II

I+-JValve opening timi16240:

E‘C

F

.-

is

3

3:\Battery voltage

V162406

80 (176)Coolant temperature

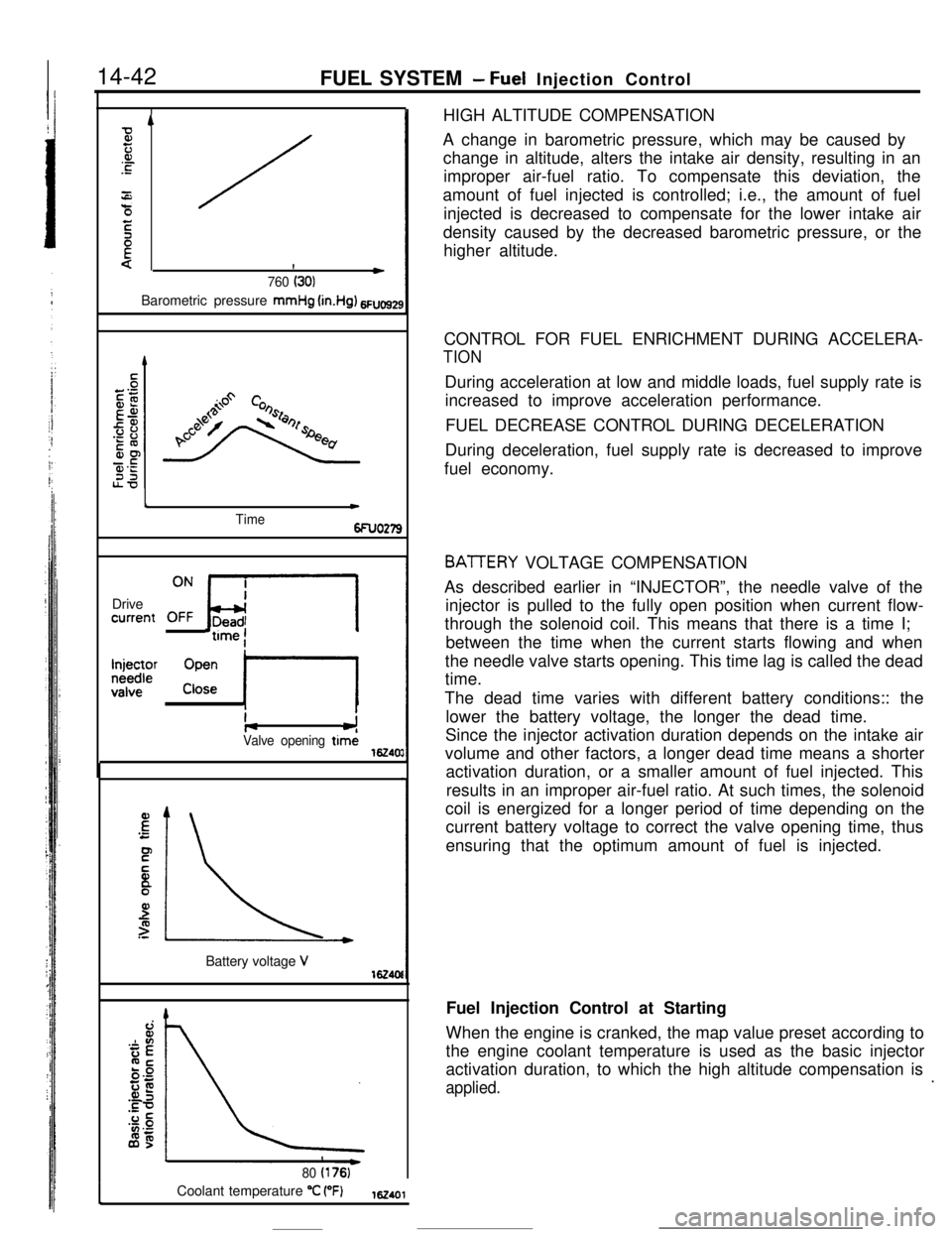

“C (“F)162401HIGH ALTITUDE COMPENSATION

A change in barometric pressure, which may be caused by

change in altitude, alters the intake air density, resulting in an

improper air-fuel ratio. To compensate this deviation, the

amount of fuel injected is controlled; i.e., the amount of fuel

injected is decreased to compensate for the lower intake air

density caused by the decreased barometric pressure, or the

higher altitude.

CONTROL FOR FUEL ENRICHMENT DURING ACCELERA-

TIONDuring acceleration at low and middle loads, fuel supply rate is

increased to improve acceleration performance.

FUEL DECREASE CONTROL DURING DECELERATION

During deceleration, fuel supply rate is decreased to improve

fuel economy.

BATTERY VOLTAGE COMPENSATION

As described earlier in “INJECTOR”, the needle valve of the

injector is pulled to the fully open position when current flow-

through the solenoid coil. This means that there is a time I;

between the time when the current starts flowing and when

the needle valve starts opening. This time lag is called the dead

time.

The dead time varies with different battery conditions:: the

lower the battery voltage, the longer the dead time.

Since the injector activation duration depends on the intake air

volume and other factors, a longer dead time means a shorter

activation duration, or a smaller amount of fuel injected. This

results in an improper air-fuel ratio. At such times, the solenoid

coil is energized for a longer period of time depending on the

current battery voltage to correct the valve opening time, thus

ensuring that the optimum amount of fuel is injected.

Fuel Injection Control at Starting

When the engine is cranked, the map value preset according to

the engine coolant temperature is used as the basic injector

activation duration, to which the high altitude compensation is

applied..

Page 155 of 391

FUEL SYSTEM - Fuel Injection Control14-43

Time

6FUO26

Engine has started.

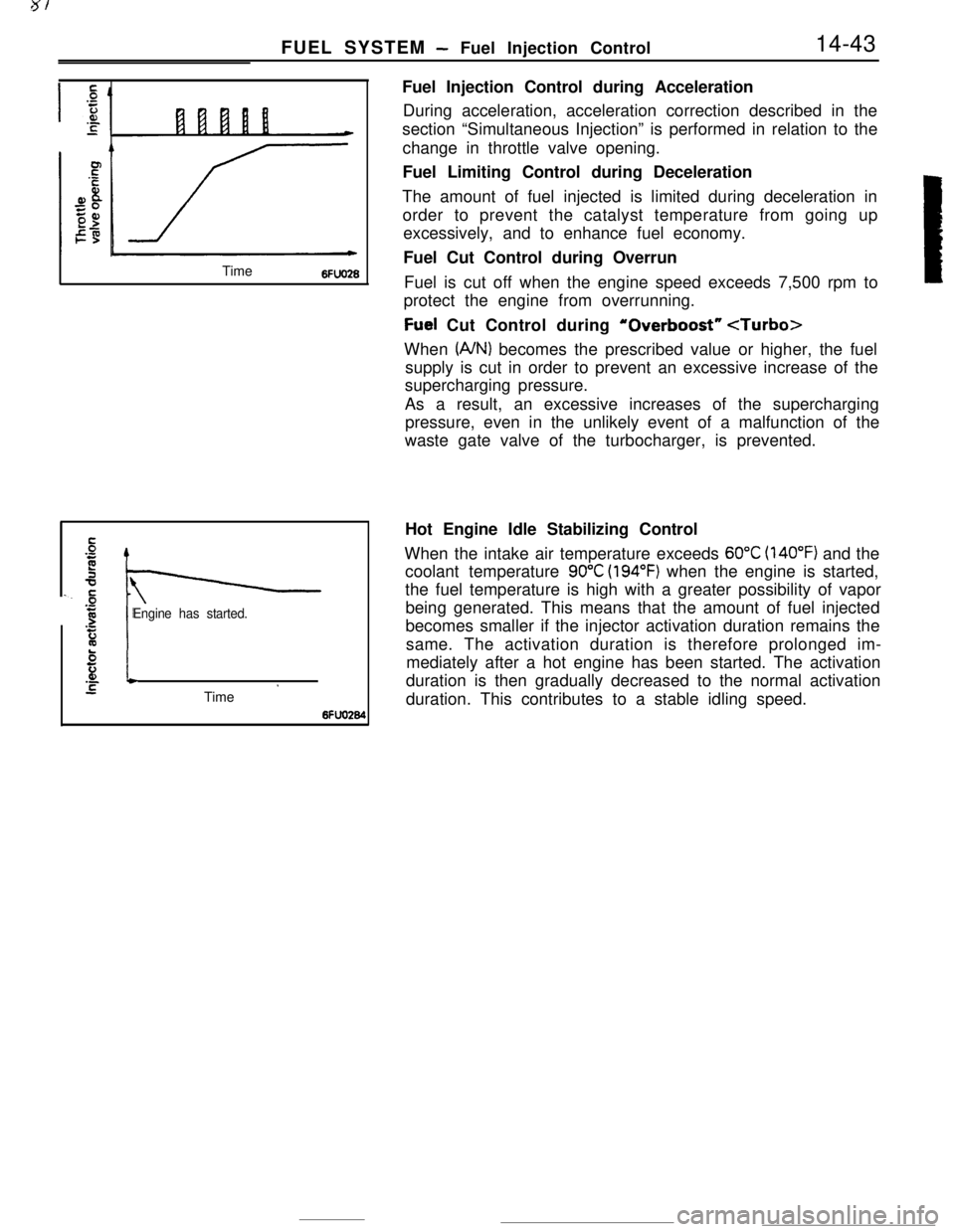

El.-*STime ’6fFuel Injection Control during Acceleration

During acceleration, acceleration correction described in the

section “Simultaneous Injection” is performed in relation to the

change in throttle valve opening.

Fuel Limiting Control during Deceleration

The amount of fuel injected is limited during deceleration in

order to prevent the catalyst temperature from going up

excessively, and to enhance fuel economy.

Fuel Cut Control during Overrun

Fuel is cut off when the engine speed exceeds 7,500 rpm to

protect the engine from overrunning.

Fuel Cut Control during ‘Overboost”

(A/N) becomes the prescribed value or higher, the fuel

supply is cut in order to prevent an excessive increase of the

supercharging pressure.

As a result, an excessive increases of the supercharging

pressure, even in the unlikely event of a malfunction of the

waste gate valve of the turbocharger, is prevented.

Hot Engine Idle Stabilizing Control

When the intake air temperature exceeds

60°C (140°F) and the

coolant temperature

90°C (194°F) when the engine is started,

the fuel temperature is high with a greater possibility of vapor

being generated. This means that the amount of fuel injected

becomes smaller if the injector activation duration remains the

same. The activation duration is therefore prolonged im-

mediately after a hot engine has been started. The activation

duration is then gradually decreased to the normal activation

duration. This contributes to a stable idling speed.

Page 156 of 391

- __..--

14-44FUEL SYSTEM- Idle Speed Control

IDLE SPEED CONTROL

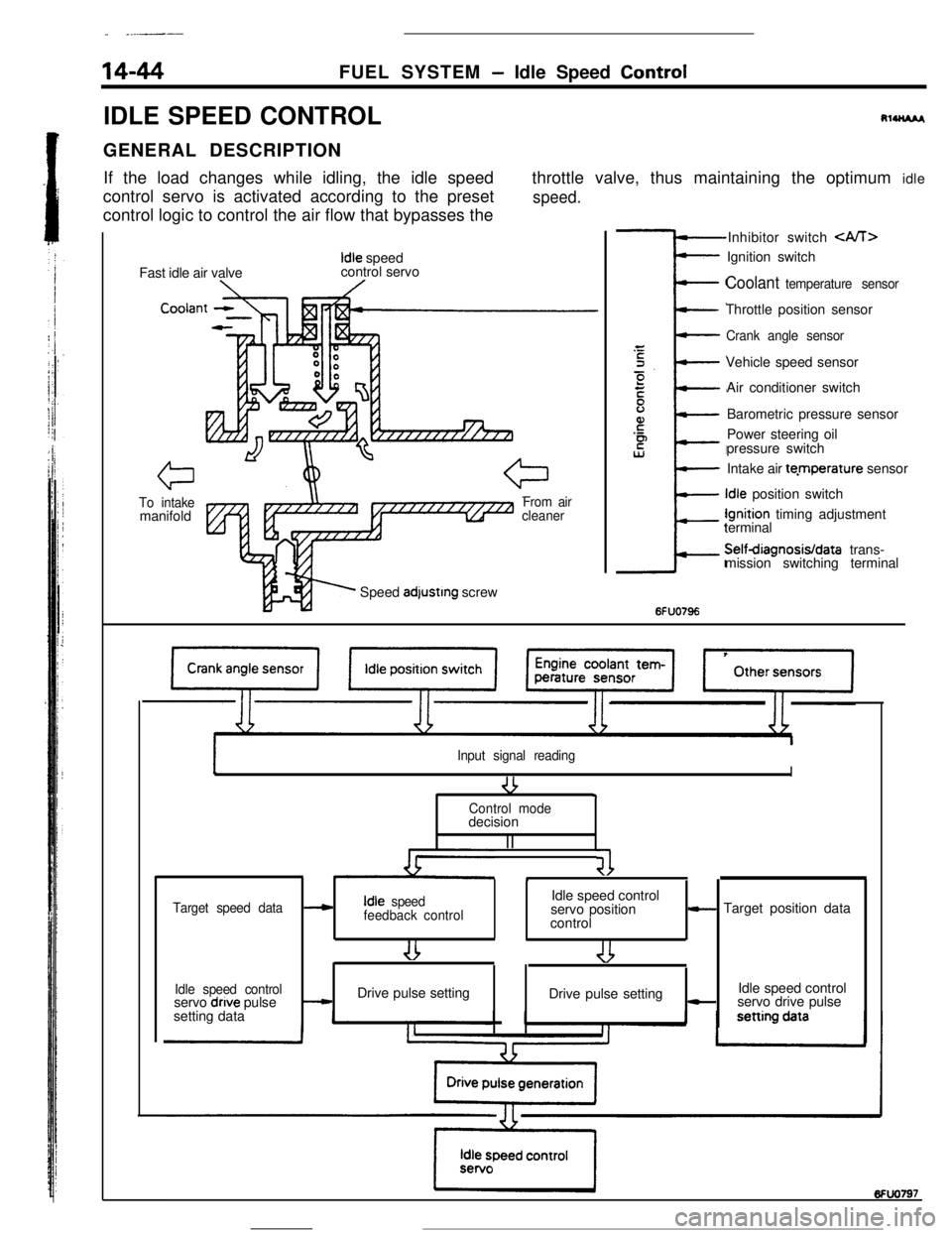

RlUU*I,GENERAL DESCRIPTION

If the load changes while idling, the idle speed

control servo is activated according to the preset

control logic to control the air flow that bypasses thethrottle valve, thus maintaining the optimum idle

speed.Fast idle air valve

Idle speed

control servo

Cooiar

To intakemanifoldFrom air

cleanerSpeed

adjustrng screwInhibitor switch

Coolant temperature sensorThrottle position sensor

Crank angle sensorVehicle speed sensor

Air conditioner switch

Barometric pressure sensor

Power steering oil

pressure switch

Intake air te.mperature sensorIdle position switchIgnition timing adjustment

terminalSelfdiagnosisIdata trans-

mission switching terminal

6FUO796

Input signal reading

-3I9Control modedecision

II

41*

Target speed dataIdle speed control---cIdle speed

feedback controlservo position- Target position data

control

Idle speed controlIdle speed control

servo dnve pulse-Drive pulse setting

Drive pulse setting-servo drive pulse

setting data

Page 161 of 391

FUEL SYSTEM -Idle Speed Control14-49

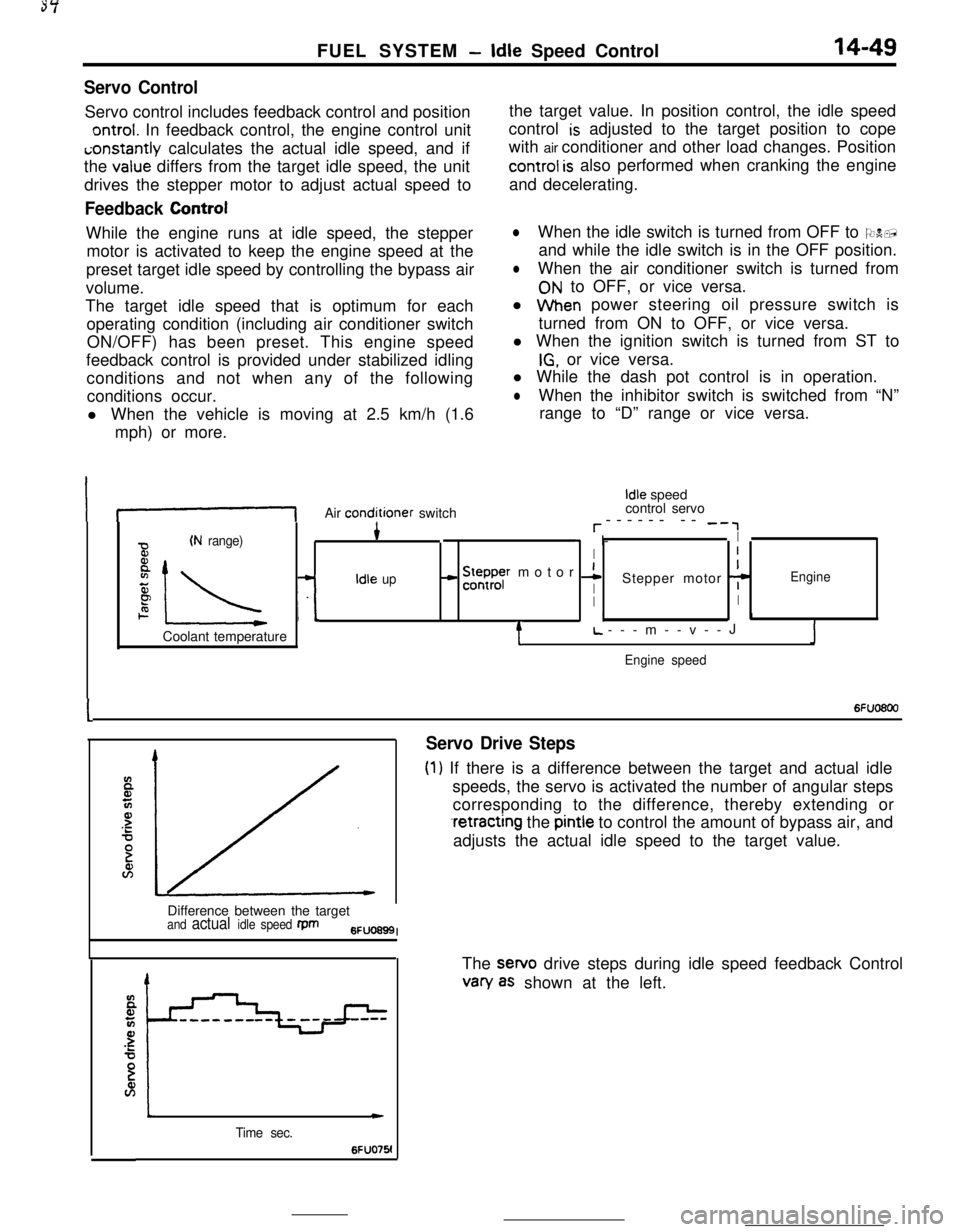

Servo ControlServo control includes feedback control and position

ontrol. In feedback control, the engine control uniti;onstantly calculates the actual idle speed, and if

the

value differs from the target idle speed, the unit

drives the stepper motor to adjust actual speed to

Feedback ControlWhile the engine runs at idle speed, the stepper

motor is activated to keep the engine speed at the

preset target idle speed by controlling the bypass air

volume.

The target idle speed that is optimum for each

operating condition (including air conditioner switch

ON/OFF) has been preset. This engine speed

feedback control is provided under stabilized idling

conditions and not when any of the following

conditions occur.

l When the vehicle is moving at 2.5 km/h (1.6

mph) or more.the target value. In position control, the idle speed

control

is adjusted to the target position to cope

with air conditioner and other load changes. Position

control is also performed when cranking the engine

and decelerating.

lWhen the idle switch is turned from OFF to ON,

and while the idle switch is in the OFF position.

lWhen the air conditioner switch is turned from

ON to OFF, or vice versa.

l When power steering oil pressure switch is

turned from ON to OFF, or vice versa.

l When the ignition switch is turned from ST to

IG, or vice versa.

l While the dash pot control is in operation.

lWhen the inhibitor switch is switched from “N”

range to “D” range or vice versa.

If-1Air conditioner switch

Idle speed

control servo

r------ -- -‘,

(N range)4* I-I

BI

8

IL -L

- !5ysr motor 1I

zIdle upIStepper motor 7Engine

PII2. I.1Coolant temperature

tL.---m--v--JJ

Engine speed

I6Fuo6oo

Servo Drive Steps

(1) If there is a difference between the target and actual idle

speeds, the servo is activated the number of angular steps

corresponding to the difference, thereby extending or

.retracting the pintle to control the amount of bypass air, and

adjusts the actual idle speed to the target value.

Difference between the target

and actual idle speed fpm6FUO699I

Time sec.

c

6FUO76!The sewo drive steps during idle speed feedback Control

van/ as shown at the left.

Page 162 of 391

14-50FUEL SYSTEM- Idle Speed Control

SDeed adiustina screwI -Throttle valve

Lw-3O(-22) 0132) 30(86! 601140) 9ofl94)Coolant temperature

“C (OF)6FUO641

E94

72--2--I

Q--.-.-z

3201.000 --4-\-\

5P9.o%IIIaI L-2O(-41 Of3214Of104)801176)Coolant temperature

“C VF)6FU028E

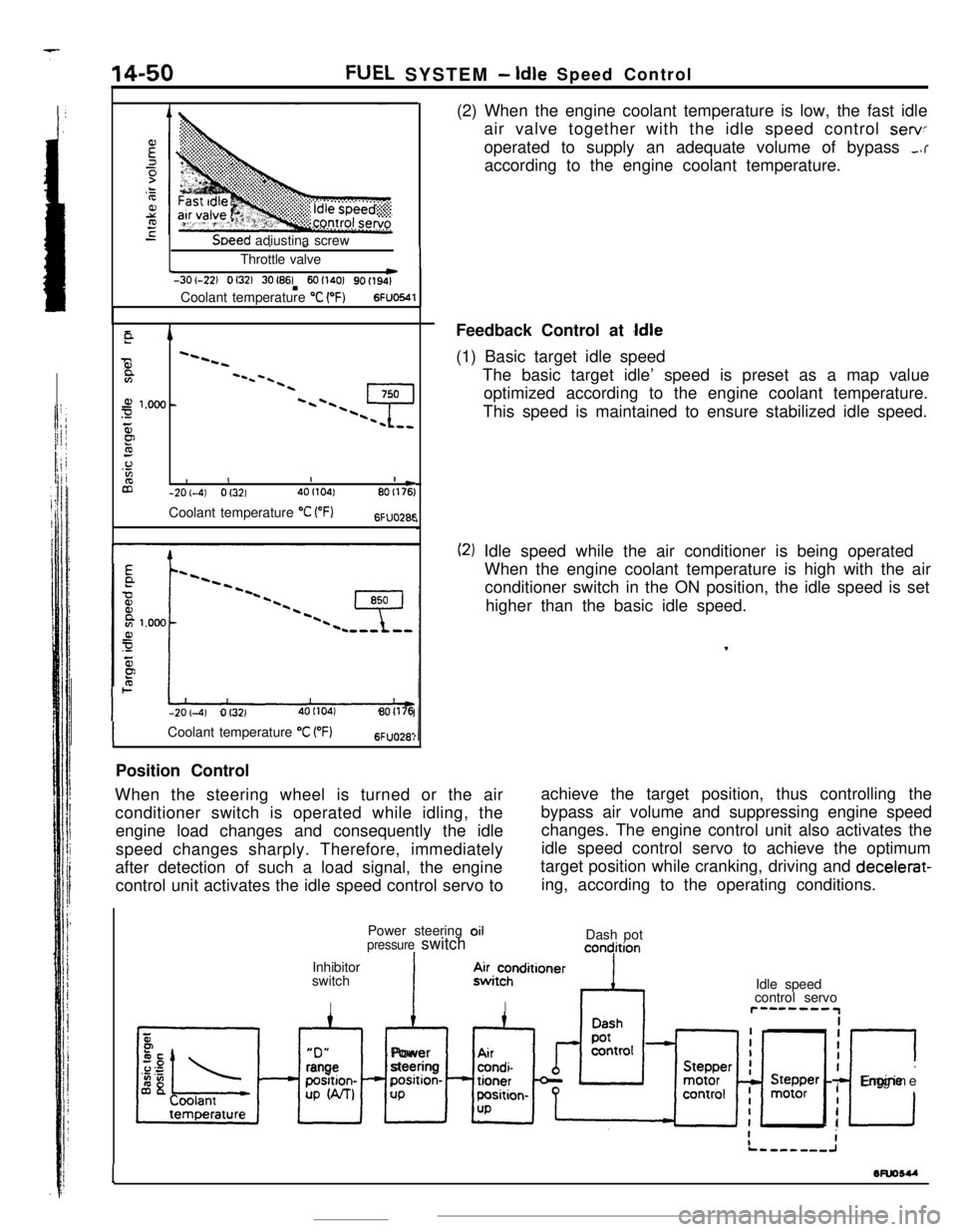

-201-4) Of3214OI104180(176(2) When the engine coolant temperature is low, the fast idle

air valve together with the idle speed control

servoperated to supply an adequate volume of bypass

,.raccording to the engine coolant temperature.

Feedback Control at

Idle(1) Basic target idle speed

The basic target idle’ speed is preset as a map value

optimized according to the engine coolant temperature.

This speed is maintained to ensure stabilized idle speed.

(2) Idle speed while the air conditioner is being operated

When the engine coolant temperature is high with the air

conditioner switch in the ON position, the idle speed is set

higher than the basic idle speed.

,

ICoolant temperature “C VF)6FUO28:Position Control

When the steering wheel is turned or the air

conditioner switch is operated while idling, theachieve the target position, thus controlling the

engine load changes and consequently the idlebypass air volume and suppressing engine speed

changes. The engine control unit also activates the

speed changes sharply. Therefore, immediately

after detection of such a load signal, the engine

control unit activates the idle speed control servo toidle speed control servo to achieve the optimum

target position while cranking, driving and decelerat-

ing, according to the operating conditions.

Power steering oil

pressure switchIInhibitor

switch

IDash pot

concjition“D”

xl

rangeposition-

UP W-U

IAlPower

steeringposition-

UP.4~i~hnditioner

IIdle speed

control servor”--““IiiI

I

c

IEngine

I

I

1wuosu

-

Page 163 of 391

FUEL SYSTEM -Idle Speed Control14-51

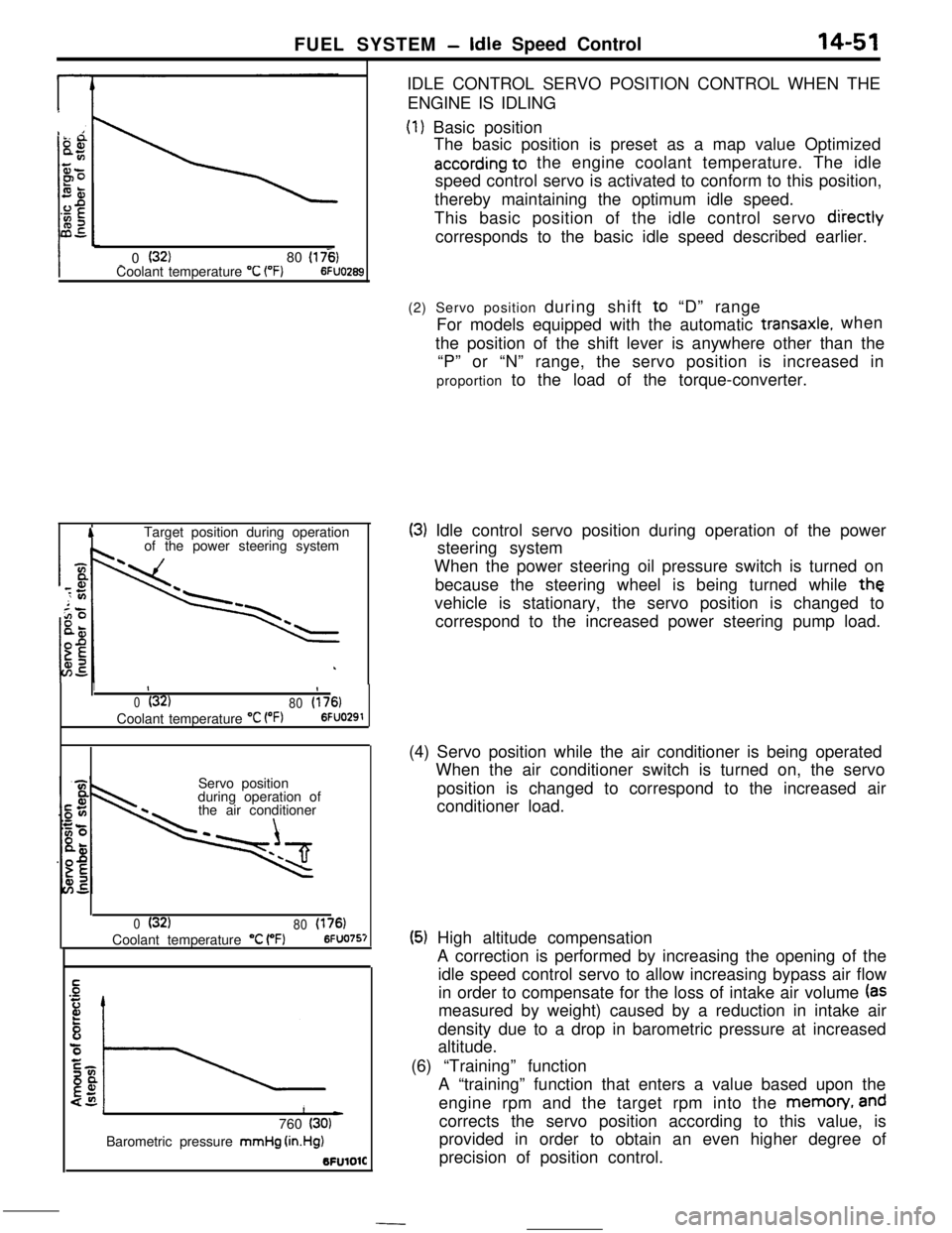

_ 0 (32)80 (175)Coolant temperature “C (“F)6FUO2653

ATarget position during operation

of the power steering systemIDLE CONTROL SERVO POSITION CONTROL WHEN THE

ENGINE IS IDLING

(1) Basic position

The basic position is preset as a map value Optimized

according to the engine coolant temperature. The idle

speed control servo is activated to conform to this position,

thereby maintaining the optimum idle speed.

This basic position of the idle control servo

diiectlycorresponds to the basic idle speed described earlier.

1II

0(32)

80(176)Coolant temperature

“C VW6FUO291Servo position

during operation of

the air conditioner

0(32)

80(176)Coolant temperature “C (“F)6FUO757

1L)760 (30)Barometric pressure mmHg

(in.Hg)BFUlOlC(2) Servo position during shift to “D” range

For models equipped with the automatic

transaxle.when

the position of the shift lever is anywhere other than the

“P” or “N” range, the servo position is increased in

proportion to the load of the torque-converter.

(3) Idle control servo position during operation of the power

steering system

When the power steering oil pressure switch is turned on

because the steering wheel is being turned while

thevehicle is stationary, the servo position is changed to

correspond to the increased power steering pump load.

(4) Servo position while the air conditioner is being operated

When the air conditioner switch is turned on, the servo

position is changed to correspond to the increased air

conditioner load.

(5) High altitude compensation

A correction is performed by increasing the opening of the

idle speed control servo to allow increasing bypass air flow

in order to compensate for the loss of intake air volume

(asmeasured by weight) caused by a reduction in intake air

density due to a drop in barometric pressure at increased

altitude.

(6) “Training” function

A “training” function that enters a value based upon the

engine rpm and the target rpm into the memon/,

andcorrects the servo position according to this value, is

provided in order to obtain an even higher degree of

precision of position control.