rod MITSUBISHI ECLIPSE 1990 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 335 of 391

23-18BODY -Body Color Code / Body Color Code Interpretation / Solid

izsiii

Noofl -ENGINE -TNANS I

coLm %F

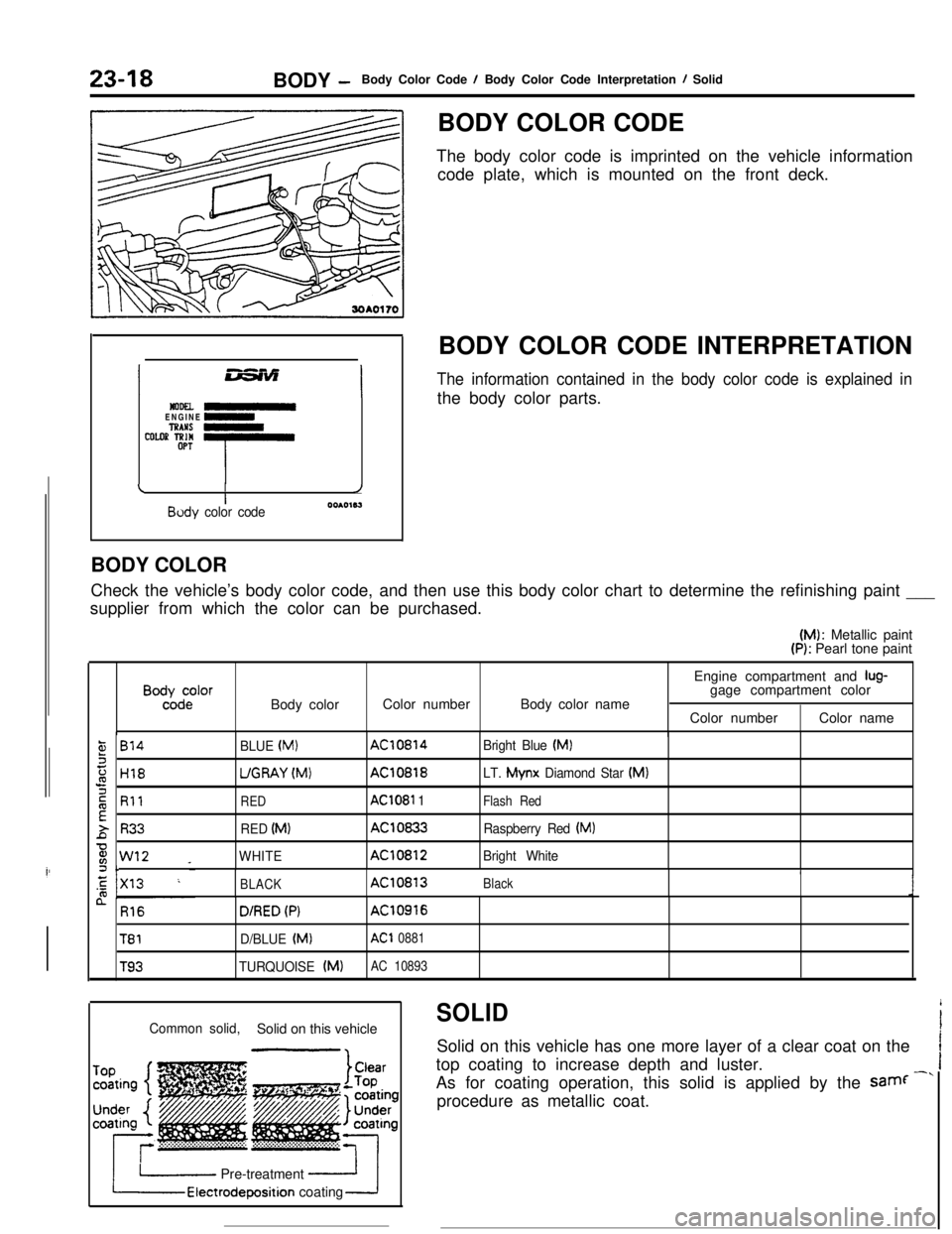

-T-iI/IBody color code0010163BODY COLOR CODE

The body color code is imprinted on the vehicle information

code plate, which is mounted on the front deck.

BODY COLOR CODE INTERPRETATION

The information contained in the body color code is explained inthe body color parts.

BODY COLOR

Check the vehicle’s body color code, and then use this body color chart to determine the refinishing paint ___

supplier from which the color can be purchased.(M): Metallic paint

(P): Pearl tone paint

B”%d:‘orBody colorColor numberBody color nameEngine compartment and

lug-gage compartment color

Color numberColor name

,814

H18

Rll

R33

w12 _c

BLUE (MI

UGRAY (Mvt)

RED

RED (MI

WHITE

AC10814

AC10818

AC1081 1

AC10833

AC10812Bright Blue

(MI

LT. Mynx

Diamond Star (MI

Flash Red

Raspberry Red (MI

Bright White

BLACKAC10813Black

n R16

T81

T93

D/RED (PIAC10916

D/BLUE (Ml

AC1 0881

TURQUOISE (MIAC 10893

SOLID

i

Common solid,Solid on this vehicleISolid on this vehicle has one more layer of a clear coat on the

Itop coating to increase depth and luster.

IAs for coating operation, this solid is applied by the samf

-”procedure as metallic coat.

I Pre-treatmentElectrodeposition coating

Page 344 of 391

BODY- Door Mirrors .23-27

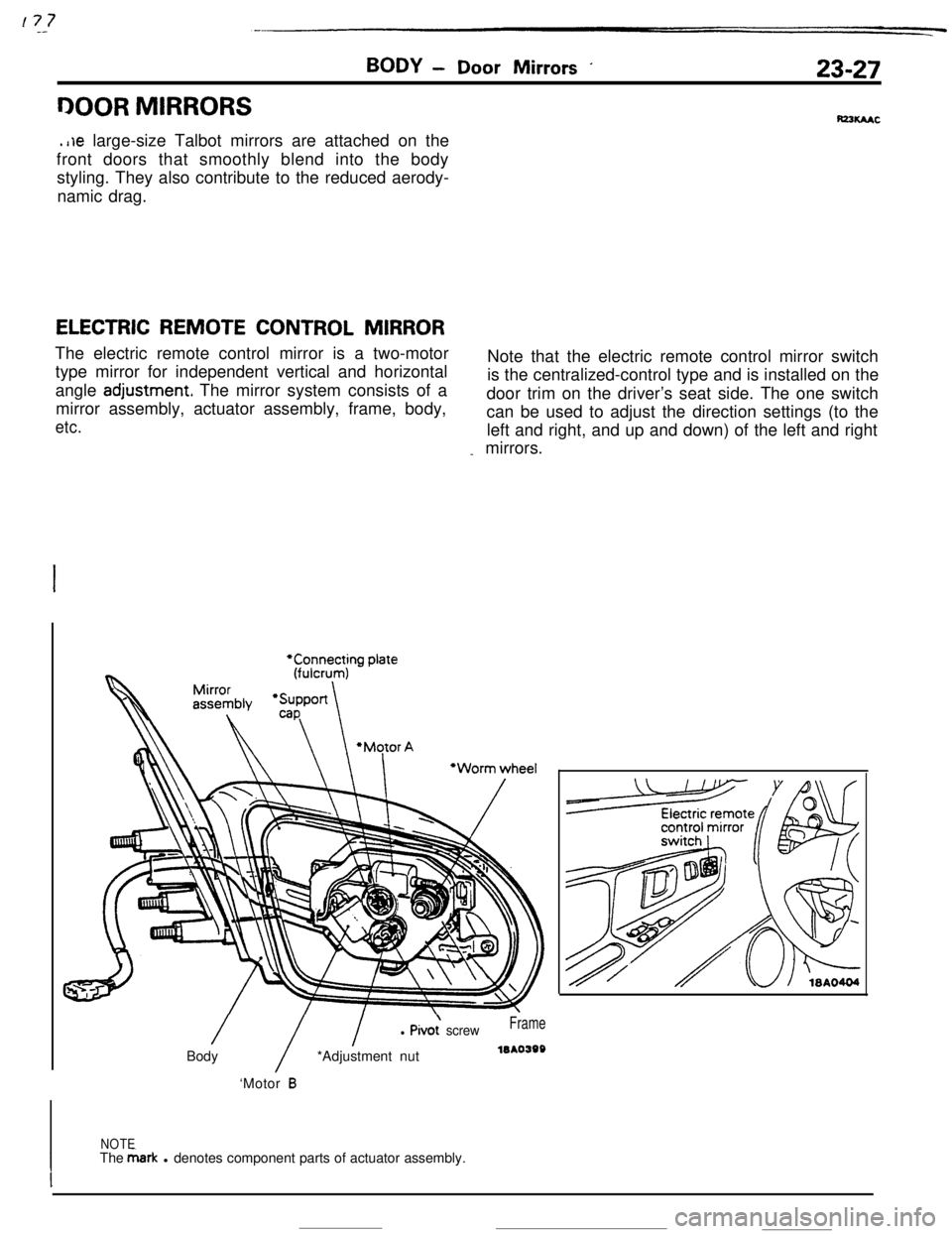

DOOR MIRRORSIPIKhAC

.i~e large-size Talbot mirrors are attached on the

front doors that smoothly blend into the body

styling. They also contribute to the reduced aerody-

namic drag.

ELECTRIC REMOTE CONTROL MIRRORThe electric remote control mirror is a two-motor

type mirror for independent vertical and horizontalNote that the electric remote control mirror switch

angle

adjustment The mirror system consists of ais the centralized-control type and is installed on the

mirror assembly, actuator assembly, frame, body,door trim on the driver’s seat side. The one switch

etc.can be used to adjust the direction settings (to the

left and right, and up and down) of the left and right

_ mirrors.

/

/

l Pivo; screwFrameBody*Adjustment nutleAo398

‘Motor

B

NOTE

IThe &ark l denotes component parts of actuator assembly.

I

Page 349 of 391

23-32BODY - Seat Belts

OPERATION OF AUTOMATIC SEAT BELTS

The operation of the Automatic Seat Belts is as follows.

(1) The belts fasten itself around the occupant when the front

door is closed with the ignition switch in the “ON” position.

(2) The belts release itself from the occupant when the front

door is opened with the ignition switch in the

*“ON” or

“LOCK” or “ACC” position.

(3) The belts cease to fasten itself around the occupant if the

ignition switch is turned to “LOCK” or “ACC” or when the

front door is opened during the belt motion.

(4) The belts for the driver’s and front passenger’s seats

operate independently of each other.

Lever springStopper, Rod A

Sub paw1

Gear B

Rod B19po37:

Sub’pawlIWO374

IStopperGear AI

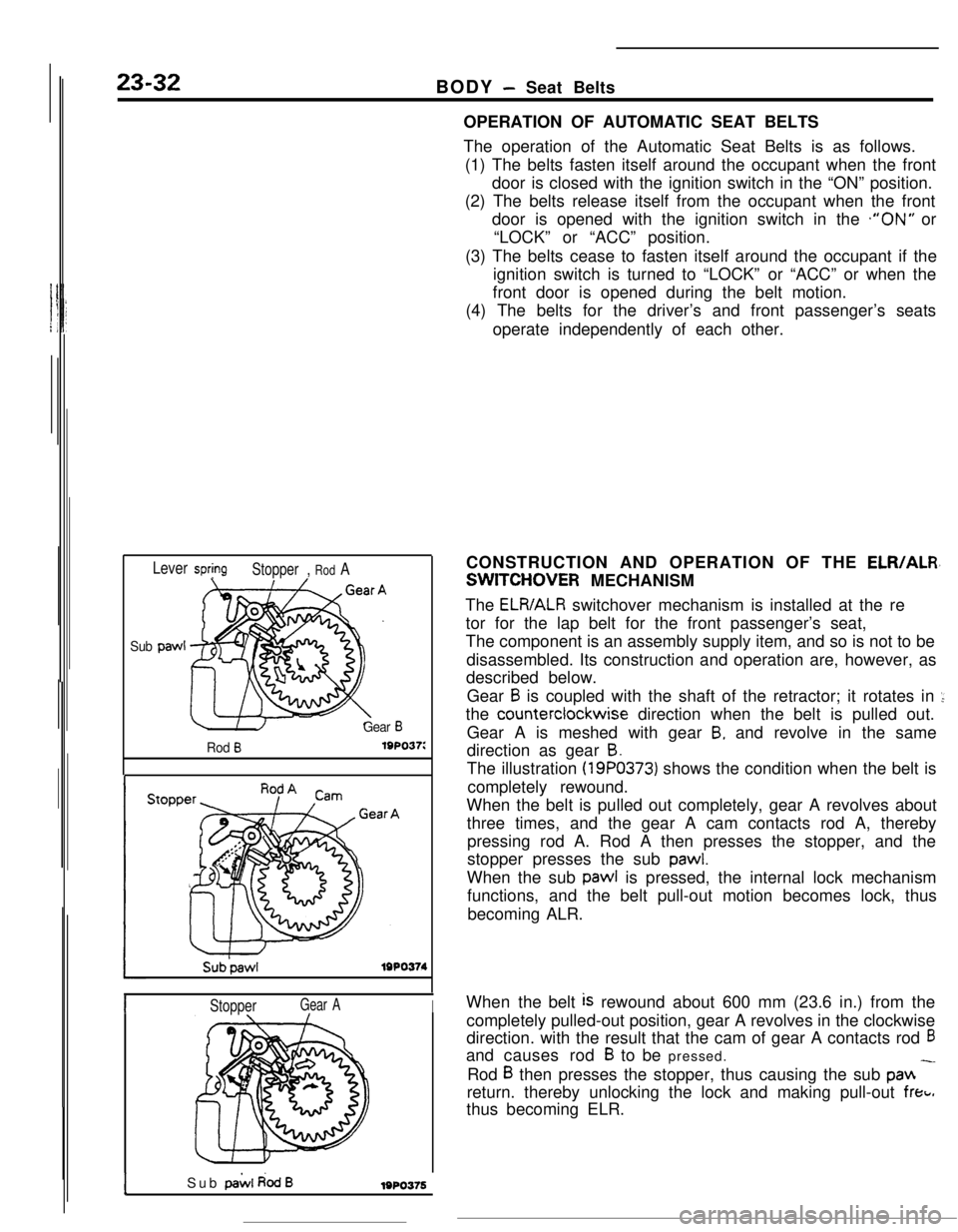

ISub pai.4 dodB1980376CONSTRUCTION AND OPERATION OF THE

ELR/ALR,

SWITCHOVER MECHANISM

The

ELR/ALR switchover mechanism is installed at the re

tor for the lap belt for the front passenger’s seat,

The component is an assembly supply item, and so is not to be

disassembled. Its construction and operation are, however, as

described below.

Gear

B is coupled with the shaft of the retractor; it rotates in ::the counterclockwise direction when the belt is pulled out.

Gear A is meshed with gear

B, and revolve in the same

direction as gear

B.The illustration

(19PO373) shows the condition when the belt is

completely rewound.

When the belt is pulled out completely, gear A revolves about

three times, and the gear A cam contacts rod A, thereby

pressing rod A. Rod A then presses the stopper, and the

stopper presses the sub

pawl.When the sub pawl is pressed, the internal lock mechanism

functions, and the belt pull-out motion becomes lock, thus

becoming ALR.

When the belt

is rewound about 600 mm (23.6 in.) from the

completely pulled-out position, gear A revolves in the clockwise

direction. with the result that the cam of gear A contacts rod

6and causes rod

B to be pressed.

Rod

B then presses the stopper, thus causing the sub pan -return. thereby unlocking the lock and making pull-out

freti.thus becoming ELR.

Page 370 of 391

HEATERS AND AIR CONDITIONING - Heater Construction24-7

IKnob posltionDamper position and air flow direction

Air outflow locations

Outside air

Recircu-lation air

2010246

Recircu-iation airDEF

2OAO247Temperature Control Knob

IKnob positionDamper position and air ‘flow directionOperation

When the temperature control knob or

the heater control is rotated fully

counterclockwise toward the cool air

position, the upper side of the heater

core will be blocked up by the blend

air damper A. whereas the lower side

of the heater core

will be blocked up by

the blend air damper 8. As a result.

all the air from the blower motor does

not pass through the heater core but

directly flows out as cool air.

Blend air damper CBlend air damper A

x!= cY?l-nY-/

-1 From

To air Voutflowopenings*blower

motor

Hester ‘OreOUO,,O

Blend air damper CBlend air damper A,//7When the temperature control knob of

the heater control is rotated fully

ctockwise toward the warm air position.the blend air dampers A and Bwill block the cool air paths.

The cool air from the blower motor

passes through the heater core for

maximum heating..

Tooutflow

openings

Blend al’r damper B

When the temperature control knob of

the heater control is rotated to the

mid position, the blend air dampers A

and B will split the air stream intotwo branches, one passing through the

heater core and one not passing through

the heater core. The blend damper air

Cintroduces cool air from the heater core

top into the heater unit chamber. Air

conditioning is provided by mixing this

cool air with hot air heated by the

heater cores.

Blend air damper CBlend/ air damper AL

2OAO391Blend air damoer B

--.-__.__ ,_ .

Page 374 of 391

25-2EMISSION CONTROL SYSTEMS - General Information

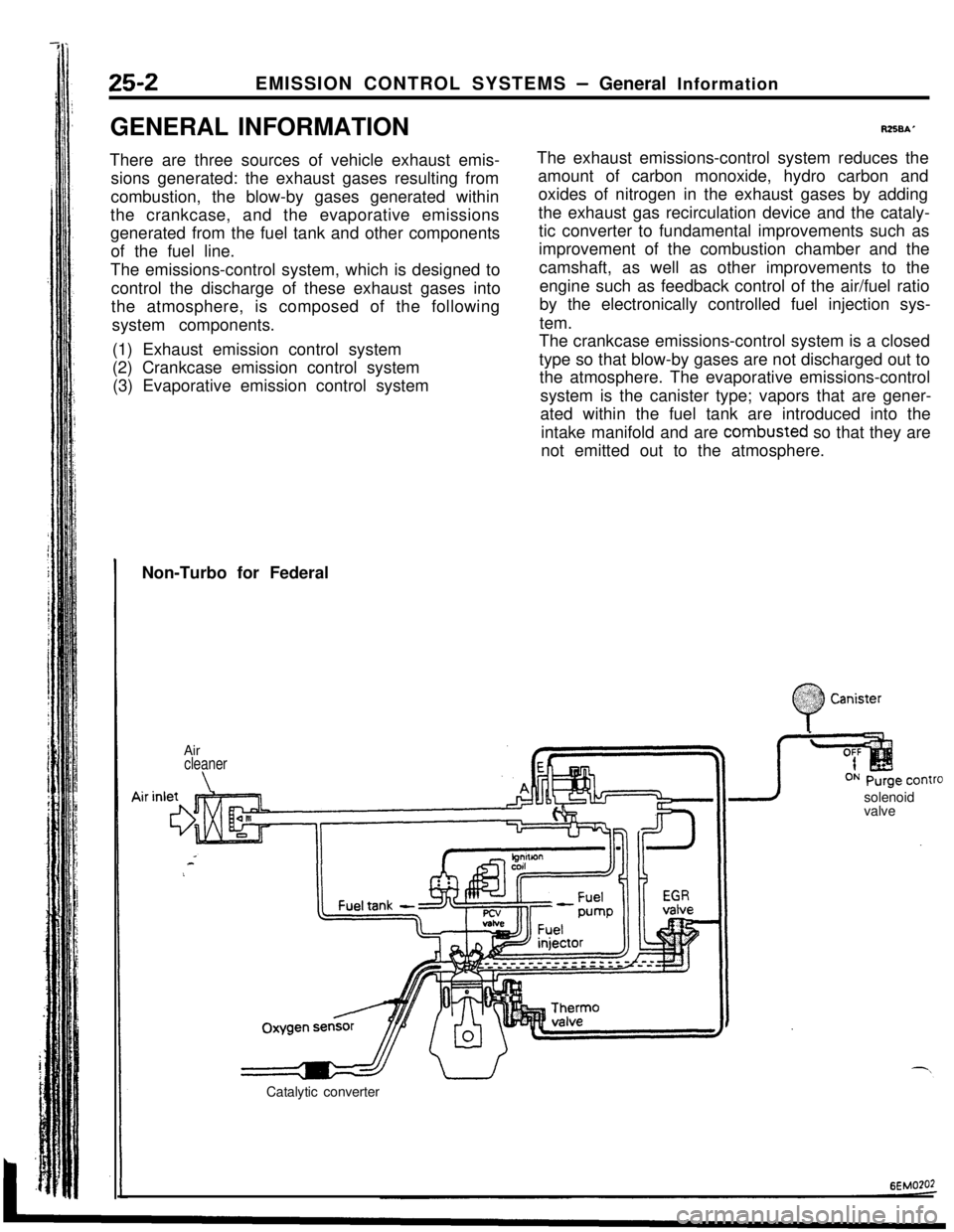

GENERAL INFORMATION

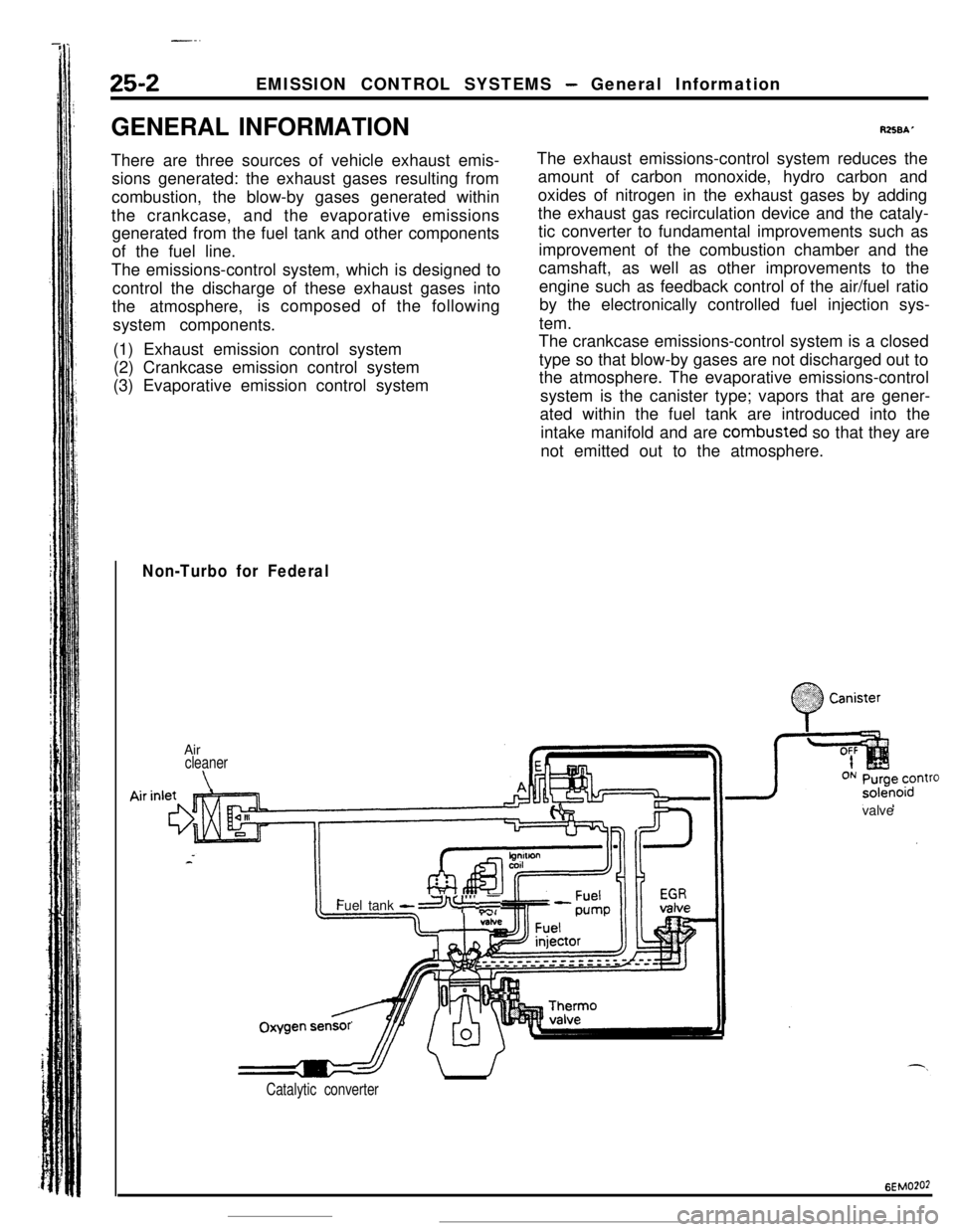

There are three sources of vehicle exhaust emis-

sions generated: the exhaust gases resulting from

combustion, the blow-by gases generated within

the crankcase, and the evaporative emissions

generated from the fuel tank and other components

of the fuel line.

The emissions-control system, which is designed to

control the discharge of these exhaust gases into

the atmosphere, is composed of the following

system components.

(1) Exhaust emission control system

(2) Crankcase emission control system

(3) Evaporative emission control system

R258A’The exhaust emissions-control system reduces the

amount of carbon monoxide, hydro carbon and

oxides of nitrogen in the exhaust gases by adding

the exhaust gas recirculation device and the cataly-

tic converter to fundamental improvements such as

improvement of the combustion chamber and the

camshaft, as well as other improvements to the

engine such as feedback control of the air/fuel ratio

by the electronically controlled fuel injection sys-

tem.

The crankcase emissions-control system is a closed

type so that blow-by gases are not discharged out to

the atmosphere. The evaporative emissions-control

system is the canister type; vapors that are gener-

ated within the fuel tank are introduced into the

intake manifold and are combusted so that they are

not emitted out to the atmosphere.

Non-Turbo for Federal

Air

cleaner

\solenoid

valve

Catalytic converter

:

0

$2:) Canister:.:

Page 376 of 391

--.

25-2EMISSION CONTROL SYSTEMS - General Information

GENERAL INFORMATION

There are three sources of vehicle exhaust emis-

sions generated: the exhaust gases resulting from

combustion, the blow-by gases generated within

the crankcase, and the evaporative emissions

generated from the fuel tank and other components

of the fuel line.

The emissions-control system, which is designed to

control the discharge of these exhaust gases into

the atmosphere,is composed of the following

system components.

(1) Exhaust emission control system

(2) Crankcase emission control system

(3) Evaporative emission control system

RZSBAThe exhaust emissions-control system reduces the

amount of carbon monoxide, hydro carbon and

oxides of nitrogen in the exhaust gases by adding

the exhaust gas recirculation device and the cataly-

tic converter to fundamental improvements such as

improvement of the combustion chamber and the

camshaft, as well as other improvements to the

engine such as feedback control of the air/fuel ratio

by the electronically controlled fuel injection sys-

tem.

The crankcase emissions-control system is a closed

type so that blow-by gases are not discharged out to

the atmosphere. The evaporative emissions-control

system is the canister type; vapors that are gener-

ated within the fuel tank are introduced into the

intake manifold and are combusted so that they are

not emitted out to the atmosphere.

Non-Turbo for Federal

.;. :

0

.%??? CanisterAir

cleaner

\valveOxygenFuel tank

-a I”’ ,T

sensr’

Catalytic converter

6EMO?O2

Page 383 of 391

---- .~ _ _EMISSION CONTROL SYSTEMS

- Catalytic Converter I Air-fuel Mixture Ratio Control System25-9

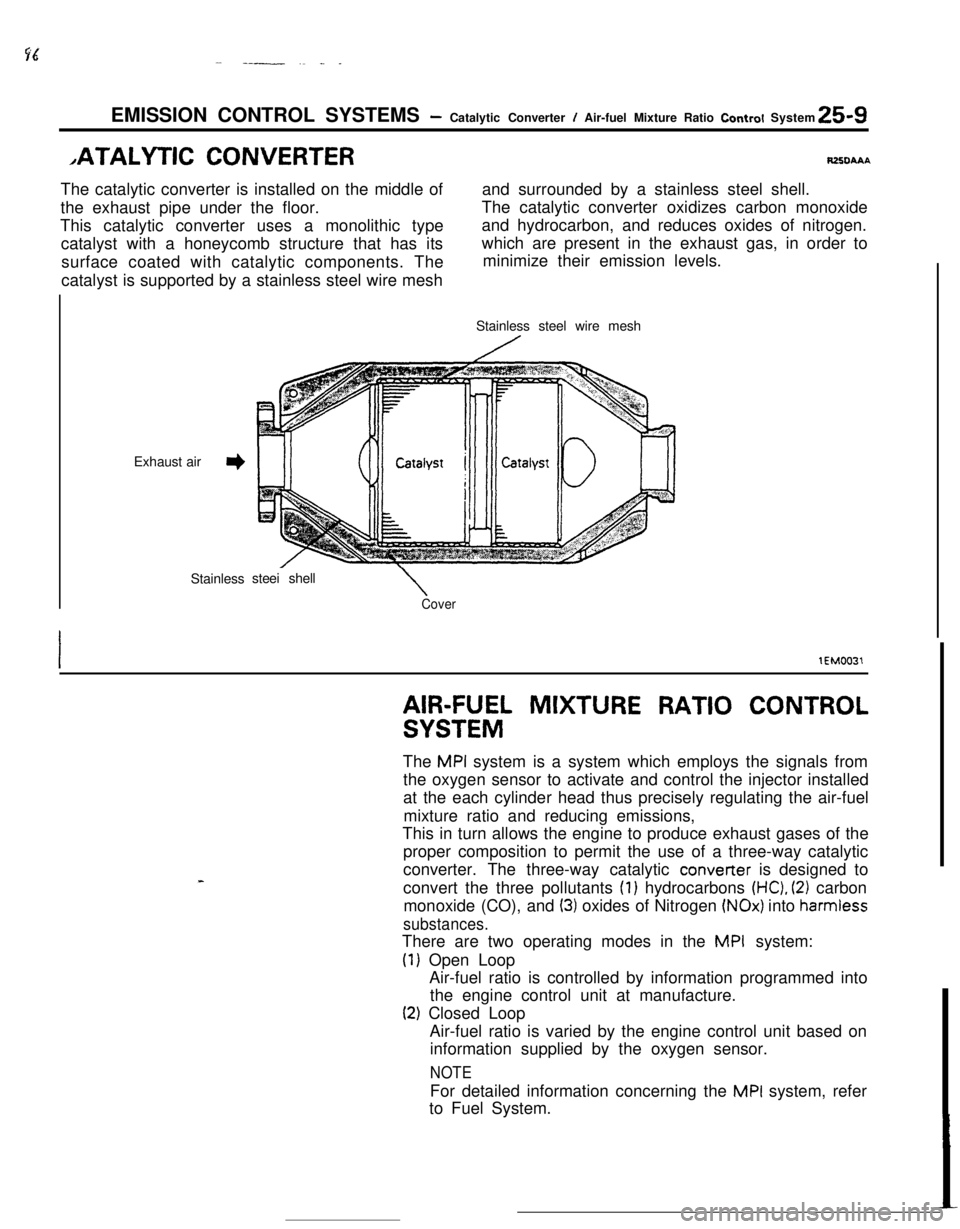

,ATALYTlC CONVERTERRZXIAAAThe catalytic converter is installed on the middle ofand surrounded by a stainless steel shell.

the exhaust pipe under the floor.The catalytic converter oxidizes carbon monoxide

This catalytic converter uses a monolithic type

catalyst with a honeycomb structure that has itsand hydrocarbon, and reduces oxides of nitrogen.

surface coated with catalytic components. Thewhich are present in the exhaust gas, in order to

minimize their emission levels.

catalyst is supported by a stainless steel wire mesh

Exhaust air

3Stainlesssteei shell

\CoverStainless steel wire mesh

lEM0031

AIR-FUEL MIXTURE RATIO CONTROL

SYSTEMThe

MPI system is a system which employs the signals from

the oxygen sensor to activate and control the injector installed

at the each cylinder head thus precisely regulating the air-fuel

mixture ratio and reducing emissions,

This in turn allows the engine to produce exhaust gases of the

proper composition to permit the use of a three-way catalytic

converter. The three-way catalytic converter is designed to

convert the three pollutants

(1) hydrocarbons (HC), (2) carbon

monoxide (CO), and

(3) oxides of Nitrogen (NOx) into harmiess

substances.There are two operating modes in the

MPI system:

(1) Open Loop

Air-fuel ratio is controlled by information programmed into

the engine control unit at manufacture.

(2) Closed Loop

Air-fuel ratio is varied by the engine control unit based on

information supplied by the oxygen sensor.

NOTEFor detailed information concerning the

MPI system, refer

to Fuel System.

Page 387 of 391

EMISSION CONTROL SYSTEMS- Evaporative Emission Control System25-13

IFrom canister1

,To intake air plenum or throttle body

7EMOlPControl

relavPurge control

solenoid valve

Battery

g

6

,zEngine control

unit

From throttle body

4To purge

control

valve

SEMo2laControl relay

3:

1.

Purge control

solenoid valve

zBattery g

Engtne controlunii

bfuo532JPURGE CONTROL SOLENOID VALVE

The purge-control solenoid valve is the ON/OFF control type of

solenoid valve; it functions to control the introduction of purge

air to the intake air plenum from the canister.

PURGE CONTROL SOLENOID VALVE

The purge-control solenoid valve is the ON/OFF control type of

solenoid valve; it functions to control the activation of the

purge-control valve.

ITo throttle body11PURGE CONTROL VALVE

The purge-control valve functions to control the introduction of

purge air to the air-intake hose from the canister.

0 From canister

Page 388 of 391

--.25-14EMISSION CONTROL SYSTEMS

- Evaporative Emisson Control System

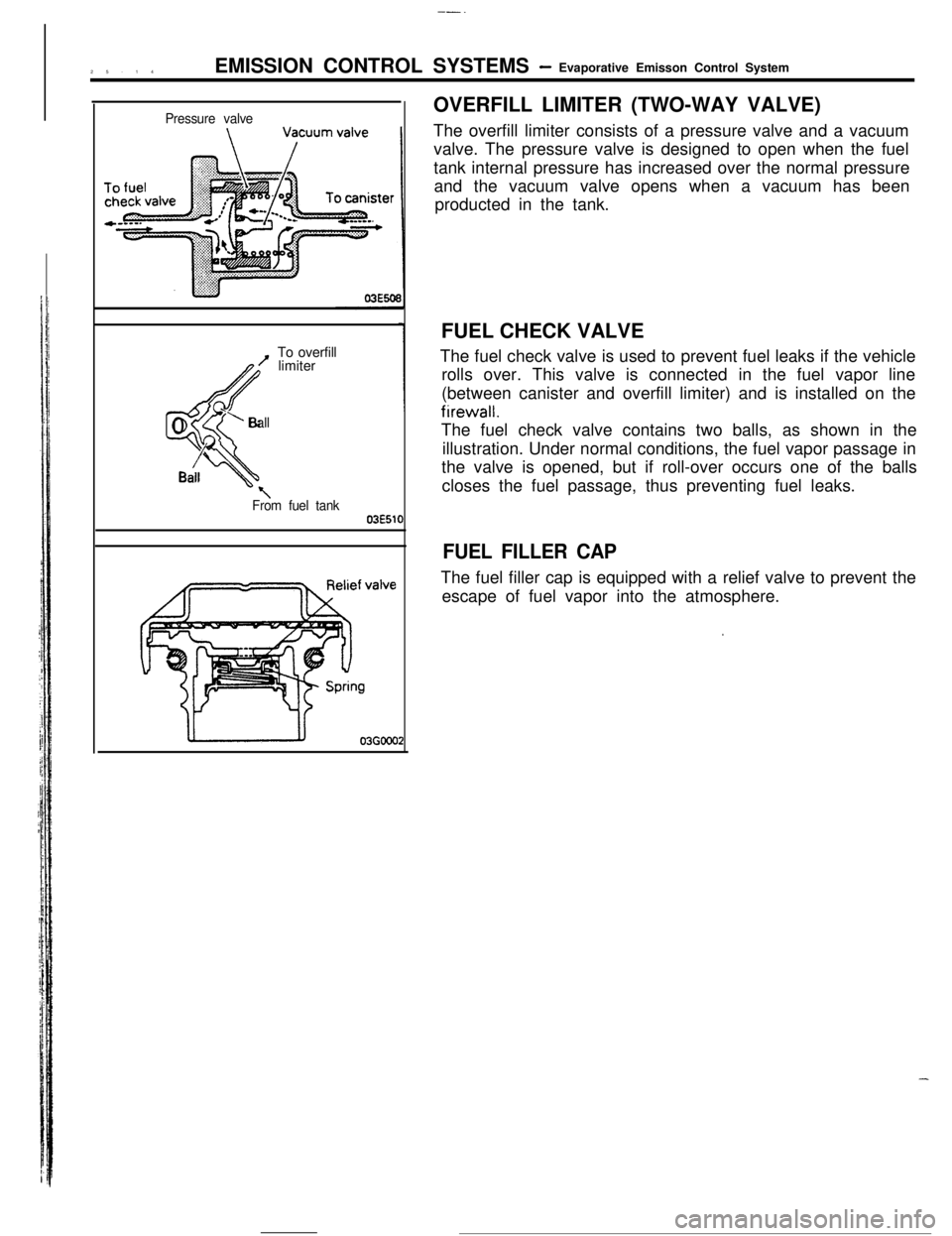

Pressure valveTo overfill

’ limiter

40

” Ball

Bail

\From fuel tank03E51fOVERFILL LIMITER (TWO-WAY VALVE)

The overfill limiter consists of a pressure valve and a vacuum

valve. The pressure valve is designed to open when the fuel

tank internal pressure has increased over the normal pressure

and the vacuum valve opens when a vacuum has been

producted in the tank.

FUEL CHECK VALVE

The fuel check valve is used to prevent fuel leaks if the vehicle

rolls over. This valve is connected in the fuel vapor line

(between canister and overfill limiter) and is installed on thefirewall.

The fuel check valve contains two balls, as shown in the

illustration. Under normal conditions, the fuel vapor passage in

the valve is opened, but if roll-over occurs one of the balls

closes the fuel passage, thus preventing fuel leaks.

FUEL FILLER CAPThe fuel filler cap is equipped with a relief valve to prevent the

escape of fuel vapor into the atmosphere.

.

-

Page 391 of 391

UNITED STATES

The special service tools referred to herein are required for certain service operations. These special service tools

or their equivalent, if not obtainable through a local source are available through the following outlet.32615 Park Lane, Garden City, Michigan 48135, U.S.A.

TRIANGLE SPECIAL PRODUCTS GROUP

(MILLER SPECIAL TOOLS)

DIVISION OF THE TRIANGLE CORPORATION

CANADA .

b’f CANADA

1, CHRYSLERThe special service tools referred to herein are required for certain service operations. These special

service tools

or their equivalent, if not obtainable through a local source are available through the following outlet.

C 8r D Riley Enterprises Ltd., P.O. Box 243, Amherstburg, Ontario N9V 224INTERNATIONAL

!!!hif INTERNA’IIONAL

1, CHRYSLERThe special service toOk referred to herein are required for certain service operations. These special

service tools

or their equivalent, if not obtainable through a local source are available through the following outlet.

32615 Park Lane, Garden City, Michigan 48135, U.S.A.

TRIANGLE SPECIAL PRODUCTS GROUP

(MILLER SPECIAL TOOLS)

DIVISION OF THE TRIANGLE CORPORATION