rod MITSUBISHI ECLIPSE 1990 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 240 of 391

_-

21-16AUTOMATIC TRANSAXLE - General InformationAUTOMATIC

TRANSAXLE

GENERAL INFQRMATIONRzlBBACF4A22 automatic transaxles with different shift pattern are introduced to match engine output characteristics.

These F4A22 automatic transaxles are transaxles of KM1 70 Type II series and each is a two-mode

electronically controlled automatic transaxle with shift patterns of two modes.

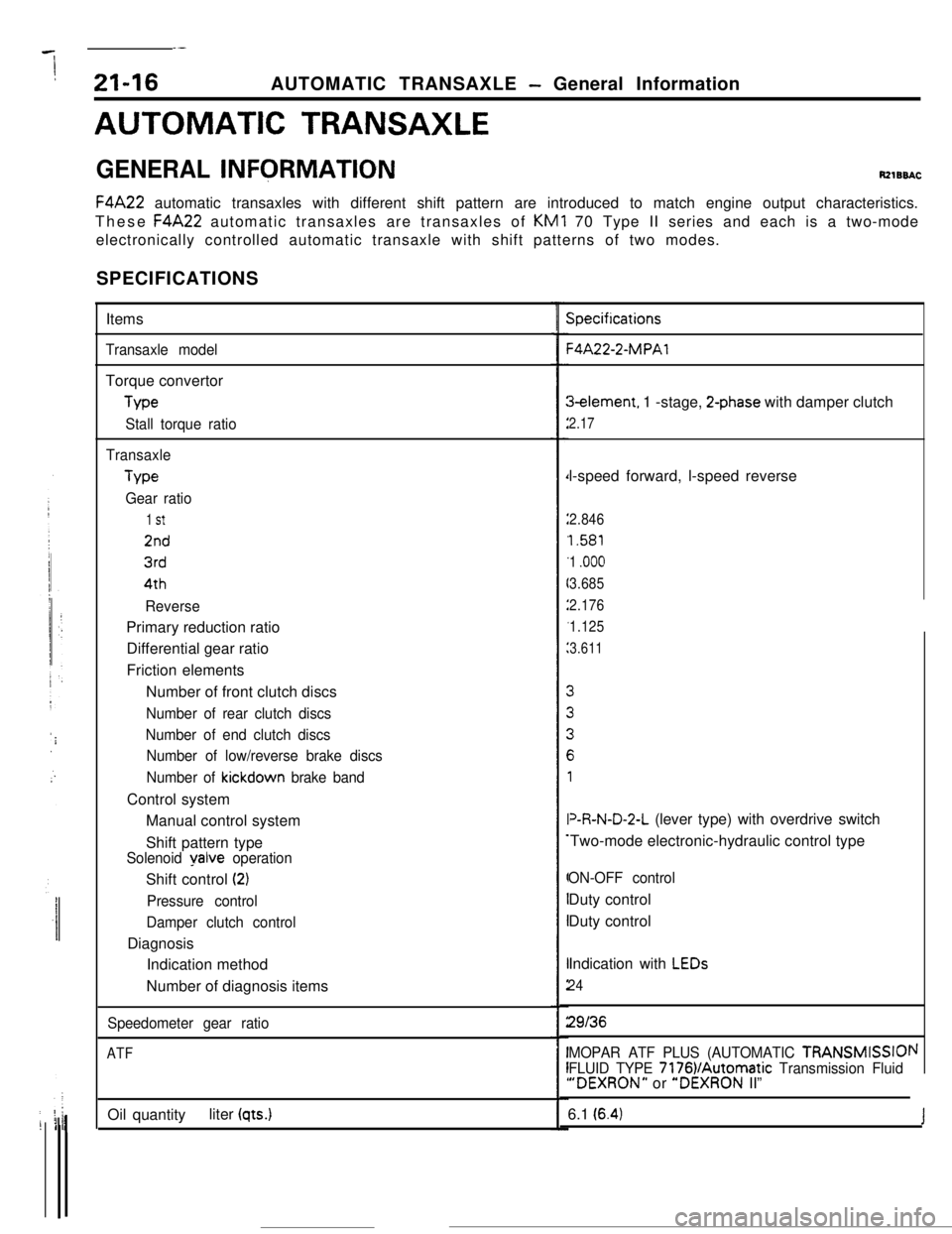

SPECIFICATIONS

Items

Transaxle modelTorque convertor

Me

Stall torque ratio

TransaxleType

Gear ratio

1 St

2nd

3rd4th

ReversePrimary reduction ratio

Differential gear ratio

Friction elements

Number of front clutch discs

Number of rear clutch discs

Number of end clutch discs

Number of low/reverse brake discs

Number of

kickdown brake bandControl system

Manual control system

Shift pattern type

Solenoid yalve operationShift control

(2)

Pressure control

Damper clutch controlDiagnosis

Indication method

Number of diagnosis items

Speedometer gear ratio

ATFOil quantityliter

(qts.)

Specifications-4A22-2-MPAl3element, 1 -stage,

2-phase with damper clutch

2.17l-speed forward, l-speed reverse

2.846

1.581

1

.ooo

3.685

2.176

1.125

3.611V&N-D-2-L (lever type) with overdrive switch

Two-mode electronic-hydraulic control type

ON-OFF controlDuty control

Duty control

Indication with

LEDs

24

29136

MOPAR ATF PLUS (AUTOMATIC TRANSMISSIOI

FLUID TYPE 7176VAutomatic Transmission Fluid“DEXRON” or “DEXRON II”

\I6.1

(6.4)J

Page 252 of 391

.-

I

21-28AUTOMATIC TRANSAXLE - Transaxle Mechanism

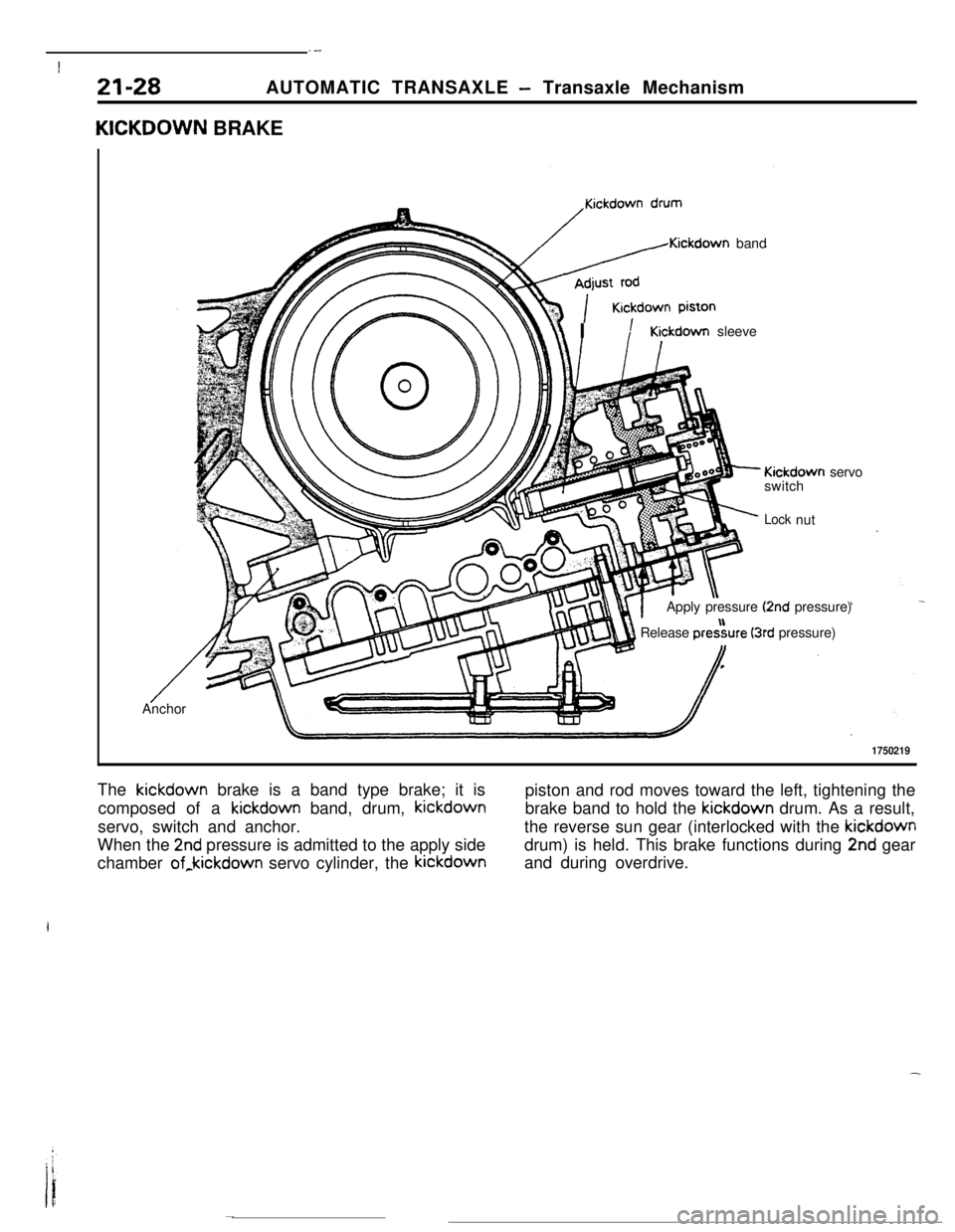

KICKDOWN BRAKE

/Kickdown band

r\\ IKickdown sleeve

- Kickdown servo

switch

;‘- Locknut

Apply pressure

(2nd pressure)

1 Release pre&re (3rd pressure)I,

/ --Anchor

1750219The kickdown brake is a band type brake; it is

piston and rod moves toward the left, tightening the

composed of a kickdown band, drum, kickdownbrake band to hold the kickdown drum. As a result,

servo, switch and anchor.the reverse sun gear (interlocked with the kickdown

When the

2nd pressure is admitted to the apply sidedrum) is held. This brake functions during 2nd gear

chamber of,kickdown servo cylinder, the kickdownand during overdrive.

Page 255 of 391

iAUTOMATIC TRANSAXLE

- Transaxle Mechanism

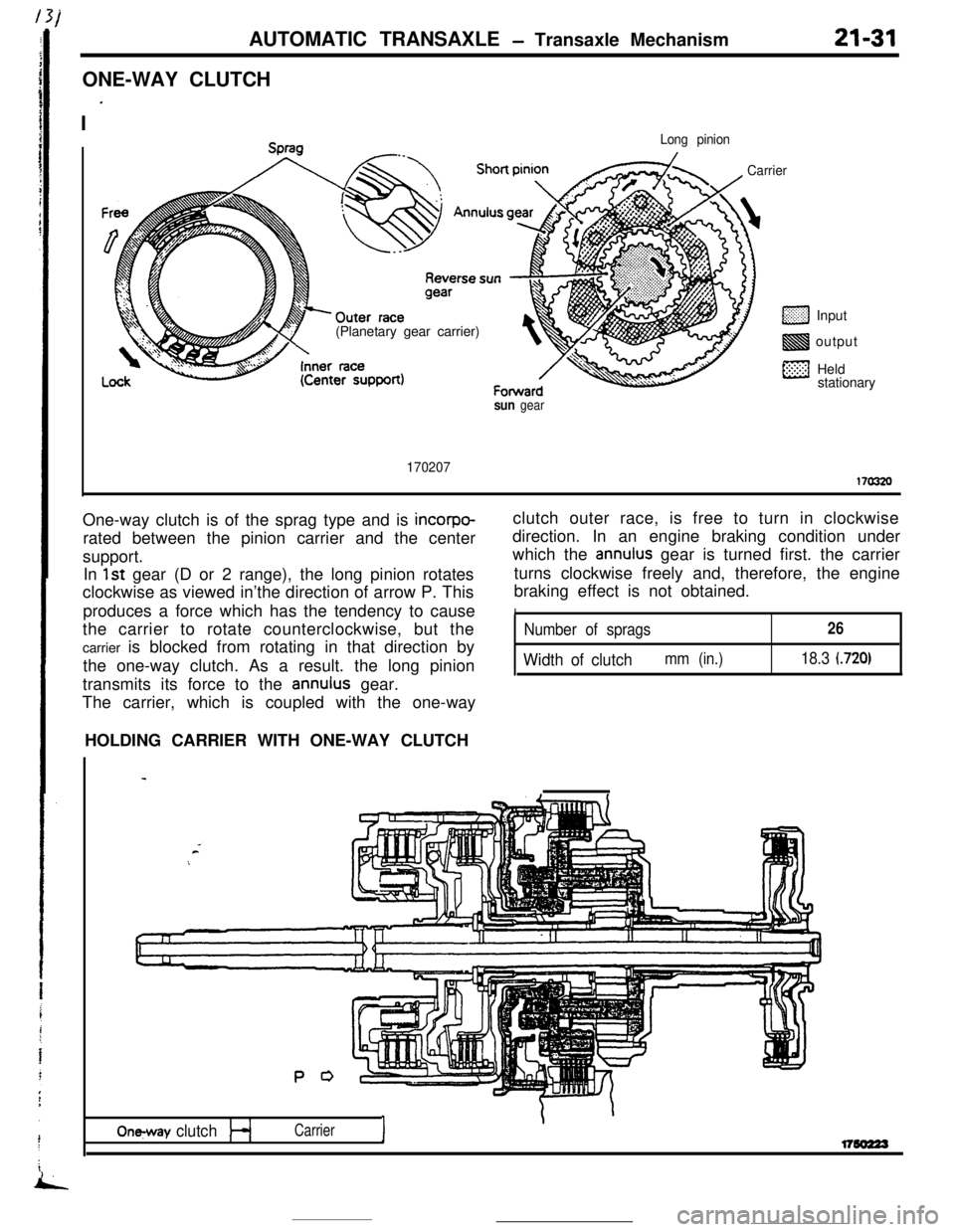

ONE-WAY CLUTCH

I

’

21-31

Long pinion(Planetary gear carrier)

CarrierInput

output

Held

stationary

sun gear

170207170320One-way clutch is of the sprag type and is

incorpo-rated between the pinion carrier and the center

support.

In

1st gear (D or 2 range), the long pinion rotates

clockwise as viewed in’the direction of arrow P. This

produces a force which has the tendency to cause

the carrier to rotate counterclockwise, but the

carrier is blocked from rotating in that direction by

the one-way clutch. As a result. the long pinion

transmits its force to the

annulus gear.

The carrier, which is coupled with the one-wayclutch outer race, is free to turn in clockwise

direction. In an engine braking condition under

which the

annulus gear is turned first. the carrier

turns clockwise freely and, therefore, the engine

braking effect is not obtained.

INumber of sprags26

Width of clutchmm (in.)18.3 (720)HOLDING CARRIER WITH ONE-WAY CLUTCH

P 0

On-y clutchI

\Carrierl7so223

Page 263 of 391

AUTOMATIC TRANSAXLE - Transaxle Mechanism

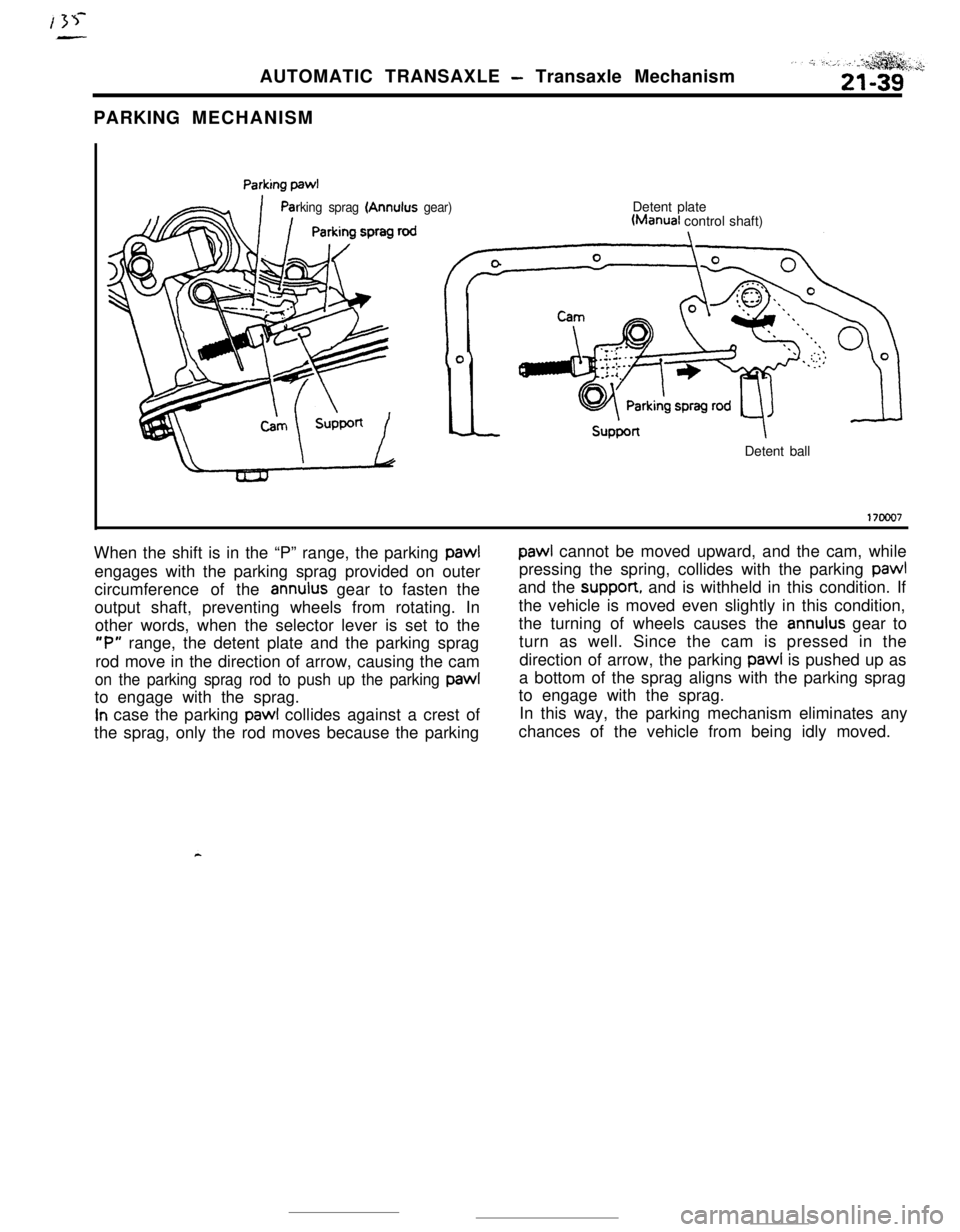

PARKING MECHANISM

rking sprag (Annulus gear)Detent plateWanual control shaft)

Detent ball

17ooo7When the shift is in the “P” range, the parking pawl

paw1 cannot be moved upward, and the cam, while

engages with the parking sprag provided on outerpressing the spring, collides with the parking

paw1circumference of the

annulus gear to fasten theand the suppon, and is withheld in this condition. If

output shaft, preventing wheels from rotating. Inthe vehicle is moved even slightly in this condition,

other words, when the selector lever is set to thethe turning of wheels causes the

annulus gear to

“P” range, the detent plate and the parking spragturn as well. Since the cam is pressed in the

rod move in the direction of arrow, causing the camdirection of arrow, the parking pawl is pushed up as

on the parking sprag rod to push up the parking paw1a bottom of the sprag aligns with the parking sprag

to engage with the sprag.to engage with the sprag.

In case the parking paw1 collides against a crest of

the sprag, only the rod moves because the parkingIn this way, the parking mechanism eliminates any

chances of the vehicle from being idly moved.

Page 269 of 391

‘4) Once the operation is step (2) is completed, the

hydraulic control device functions by hydraulic

pressure force to change the state of the

clutches and brakes to accomplish the gear

shifting. To minimize the shock that would

otherwise be produced during gear shifting,

hydraulic pressure is controlled during the gear

shifting period by the “duty control” of the

pressure control solenoid valve. The duty control

is explained later.

‘HYDRAULIC PRESSURE CONTROL DURING

SHFIING(1) The hydraulic pressure that functions during

gear shifting to engage the clutches and apply

the brakes is regulated by the pressure control

valve, The hydraulic pressure that works on the

pressure control valve is further regulated by the

pressure control solenoid valve which functions

under the control of the transaxle control unit.

The transaxle control unit controls the solenoid

valve through the duty control, thus providing

appropriate regulation of the hydraulic pressure.

(2)

(3)

(4)The transaxle control unit decides the timing of

the gear shifting period (during which ‘it per-

forms hydraulic pressure control for gear shift-

ing) according to the change in the kickdown

drum rotating speed that it detects. The unit

identifies the time just before the kickdown

brake is applied and uses that as the timing for

initiating control of the hydraulic pressure which

is to be applied to the kickdown brake.

When the transaxle is cold, the fluid viscosity is

high, causing slower oil pressure response. in

such conditions, the transaxle control unit pro-

vides a correction for the oil pressure by

changing the control duty of the pressure control

solenoid valve.

This control is performed when the fluid temper-

atures as indicated by the oil temperature

sensor is lower than

60°C (140°F).After the engine has been started and the

vehicle is inmotion, the transaxle

continues torefine its performance

est possiblegear shifting.control unit

for smooth-

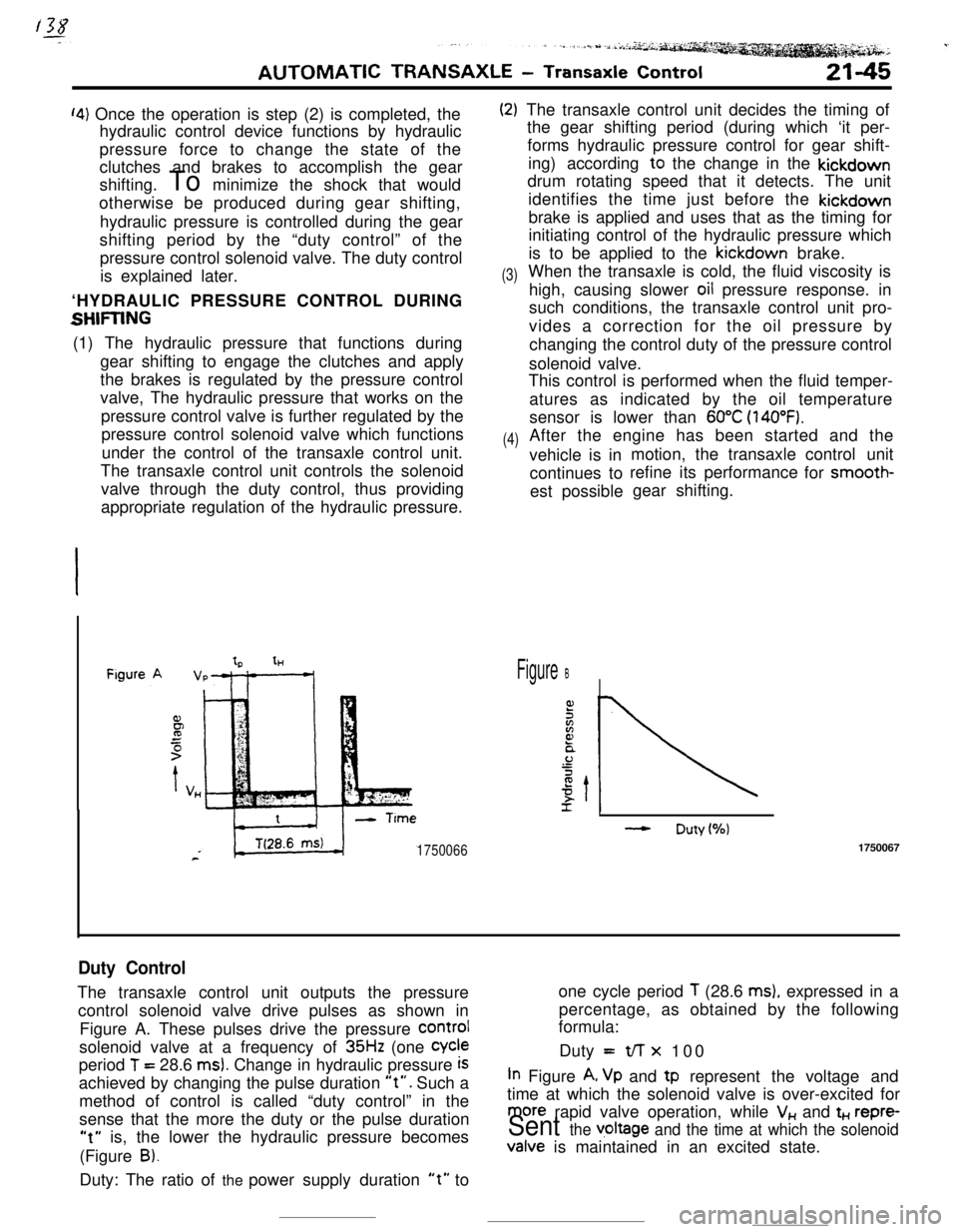

tHFigure B

- Duty(%)

17500661750067

Duty ControlThe transaxle control unit outputs the pressureone cycle period

T (28.6 ms), expressed in a

control solenoid valve drive pulses as shown inpercentage, as obtained by the following

formula:

Figure A. These pulses drive the pressure

COrmIsolenoid valve at a frequency of

35Hz (one Cycleperiod

T = 28.6 ms). Change in hydraulic pressure iSDuty =t/-r x 100

achieved by changing the pulse duration

“t”. Such aIn Figure A, Vp and tp represent the voltage and

method of control is called “duty control” in thetime at which the solenoid valve is over-excited for

sense that the more the duty or the pulse duration

more rapid valve operation, while V,, and t+., repre-

“t” is, the lower the hydraulic pressure becomesSent the v,oltage and the time at which the solenoid(Figure

B).Valve is maintained in an excited state.

Duty: The ratio of the power supply duration

“t” to

Page 271 of 391

AUTOMATIC TRANSAXLE - Transaxle Control21-47

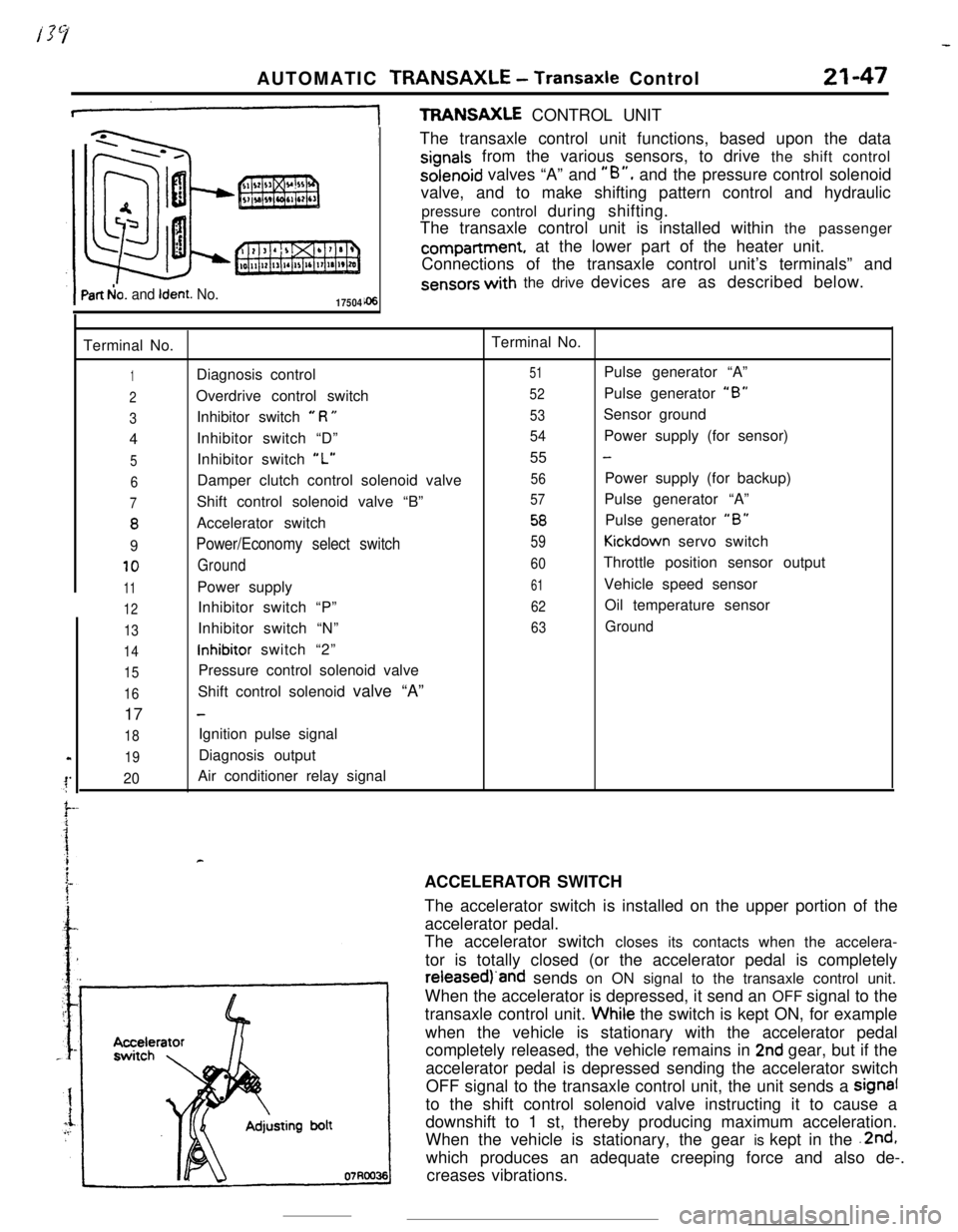

+TFWNSAXLE CONTROL UNIT

Part b!o. and Ident. No.17504The transaxle control unit functions, based upon the data

signals from the various sensors, to drive the shift controlsolenoid valves “A” and

“B”, and the pressure control solenoid

valve, and to make shifting pattern control and hydraulic

pressure control during shifting.

The transaxle control unit is installed within the passengercompartment, at the lower part of the heater unit.

Connections of the transaxle control unit’s terminals” and

sensors with the drive devices are as described below.

Terminal No.Terminal No.

1Diagnosis control51Pulse generator “A”

2Overdrive control switch52Pulse generator “B”

3Inhibitor switch e R U53Sensor ground

4Inhibitor switch “D”

54Power supply (for sensor)

5Inhibitor switch “L”55 -

6Damper clutch control solenoid valve56Power supply (for backup)

7Shift control solenoid valve “B”57Pulse generator “A”

8Accelerator switch58Pulse generator “B”

9Power/Economy select switch59Kickdown servo switch

10Ground60Throttle position sensor output

11Power supply61Vehicle speed sensor

12Inhibitor switch “P”62Oil temperature sensor

13Inhibitor switch “N”63Ground

14inhibitor switch “2”

15Pressure control solenoid valve

16Shift control solenoid valve “A”

17

-

18Ignition pulse signal

19Diagnosis output

20Air conditioner relay signal

rACCELERATOR SWITCH

The accelerator switch is installed on the upper portion of the

accelerator pedal.

The accelerator switch closes its contacts when the accelera-

tor is totally closed (or the accelerator pedal is completelyreieasedj‘and sends on ON signal to the transaxle control unit.

When the accelerator is depressed, it send an OFF signal to the

transaxle control unit. Whiie the switch is kept ON, for example

when the vehicle is stationary with the accelerator pedal

completely released, the vehicle remains in

2nd gear, but if the

accelerator pedal is depressed sending the accelerator switch

OFF signal to the transaxle control unit, the unit sends a signal

to the shift control solenoid valve instructing it to cause a

downshift to 1 st, thereby producing maximum acceleration.

When the vehicle is stationary, the gear is kept in the .2nd,

which produces an adequate creeping force and also de-.

creases vibrations.

Page 284 of 391

21-60AUTOMATIC TRANSAXLE - Transaxle Control

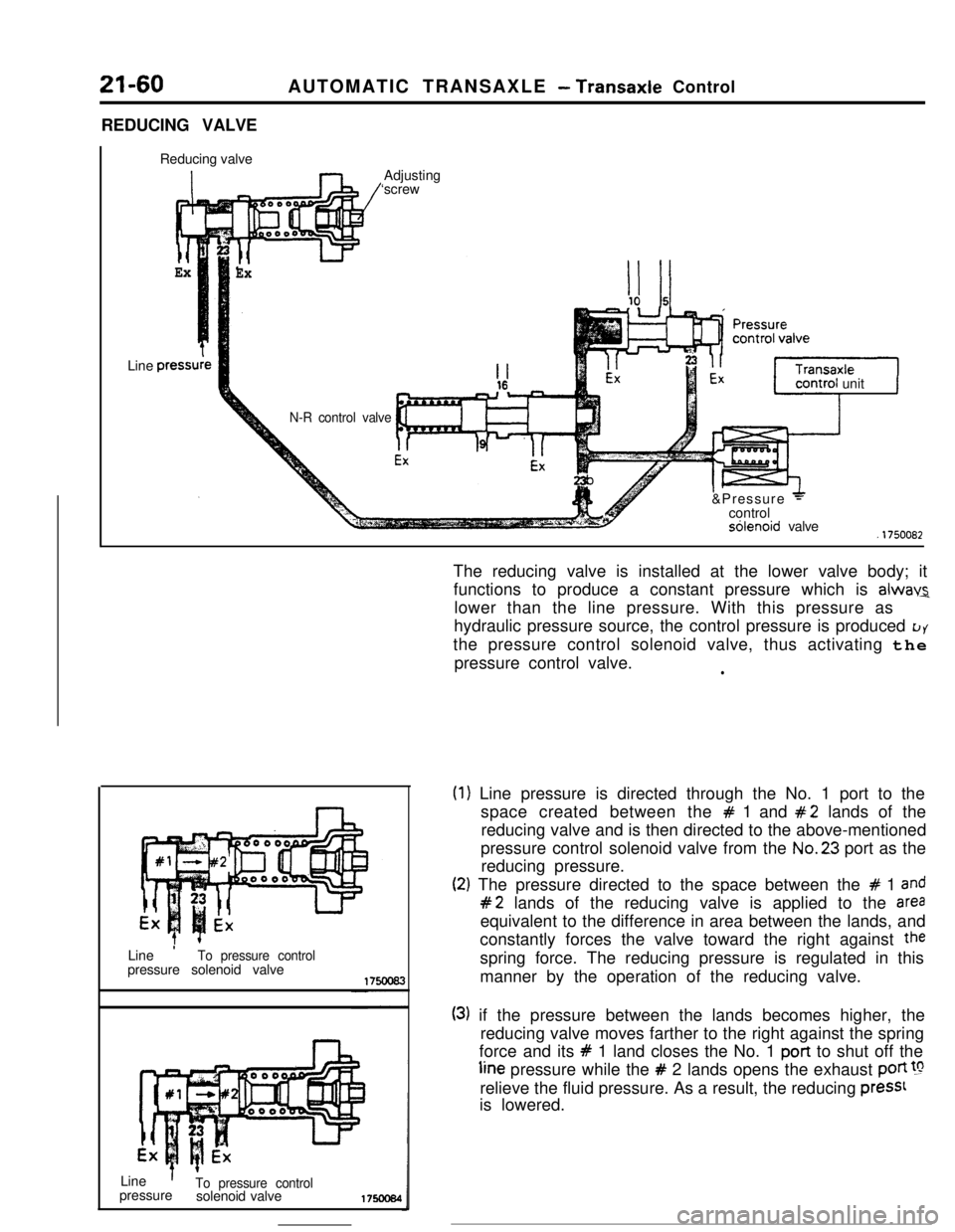

REDUCING VALVE

Reducing valve

ExLine

press1

ExAdjusting

‘screw

N-R control valveunit

J&Pressure

+controlsblenoid valve.1750082

Line

’To pressure controlpressure solenoid valve

Line

’To pressure controlpressure

solenoid valve175ocs4The reducing valve is installed at the lower valve body; it

functions to produce a constant pressure which is

alwav2lower than the line pressure. With this pressure as

hydraulic pressure source, the control pressure is produced

LJYthe pressure control solenoid valve, thus activating the

pressure control valve.

l

(1

(2

) Line pressure is directed through the No. 1 port to the

space created between the

# 1 and #2 lands of the

reducing valve and is then directed to the above-mentioned

pressure control solenoid valve from the No.23 port as the

reducing pressure.

:) The pressure directed to the space between the # 1 and

#2 lands of the reducing valve is applied to the areaequivalent to the difference in area between the lands, and

constantly forces the valve toward the right against

thespring force. The reducing pressure is regulated in this

manner by the operation of the reducing valve.

(3) if the pressure between the lands becomes higher, the

reducing valve moves farther to the right against the spring

force and its

# 1 land closes the No. 1 port to shut off theline pressure while the

# 2 lands opens the exhaust poti !grelieve the fluid pressure. As a result, the reducing

press1is lowered.

Page 294 of 391

21-72AUTOMATIC TRANSAXLE - Transaxle Control

_. --.

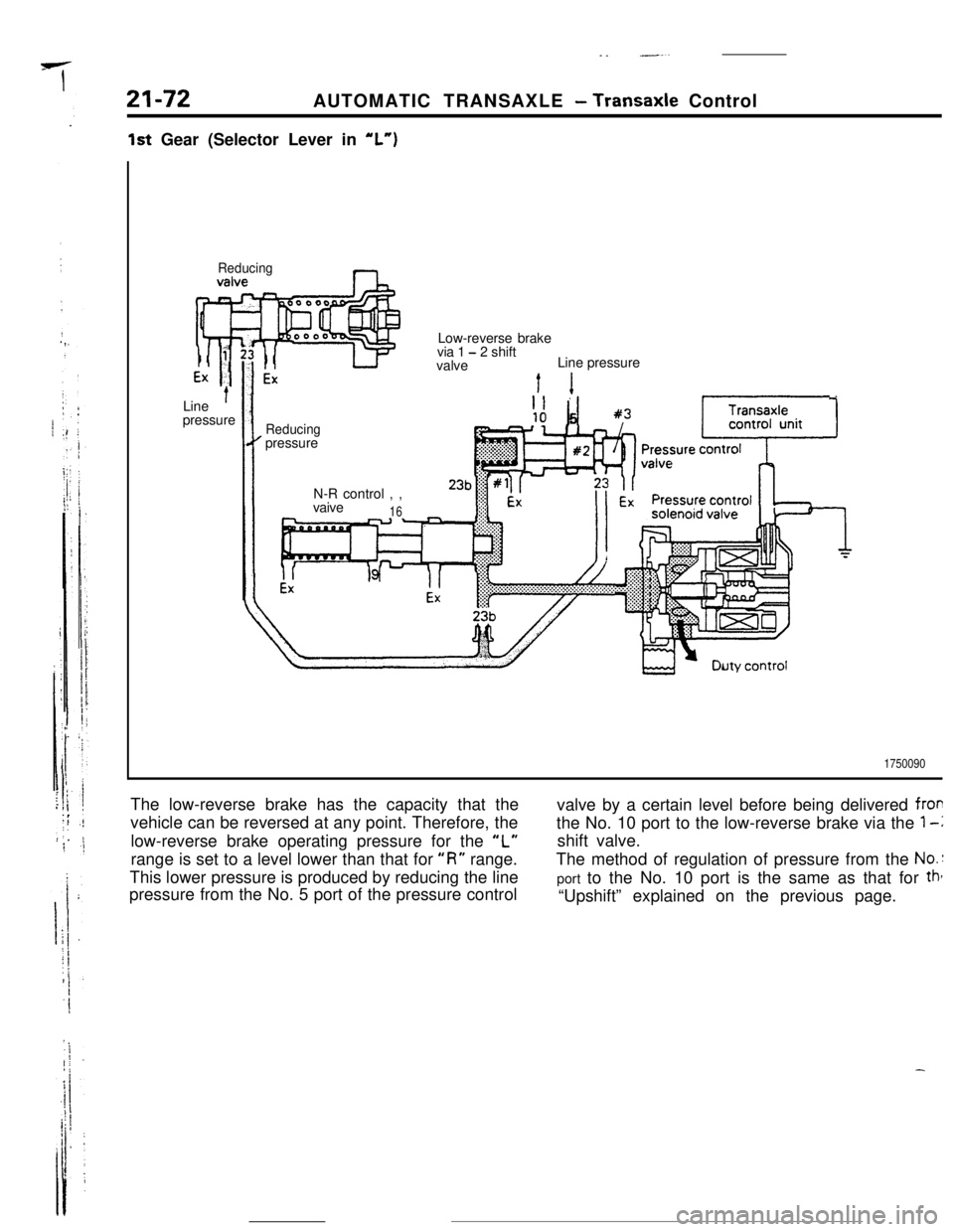

1st Gear (Selector Lever in “L”)

ReducingnLow-reverse brake

via 1

- 2 shift

valveLine pressure

Line

’pressureI1

Reducingpressure

N-R control , ,

vaive

16--.. -

1750090The low-reverse brake has the capacity that the

vehicle can be reversed at any point. Therefore, the

low-reverse brake operating pressure for the

“L”range is set to a level lower than that for

“I?” range.

This lower pressure is produced by reducing the line

pressure from the No. 5 port of the pressure controlvalve by a certain level before being delivered

frorthe No. 10 port to the low-reverse brake via the

1-lshift valve.

The method of regulation of pressure from the

No.:port to the No. 10 port is the same as that for

tht“Upshift” explained on the previous page.

Page 321 of 391

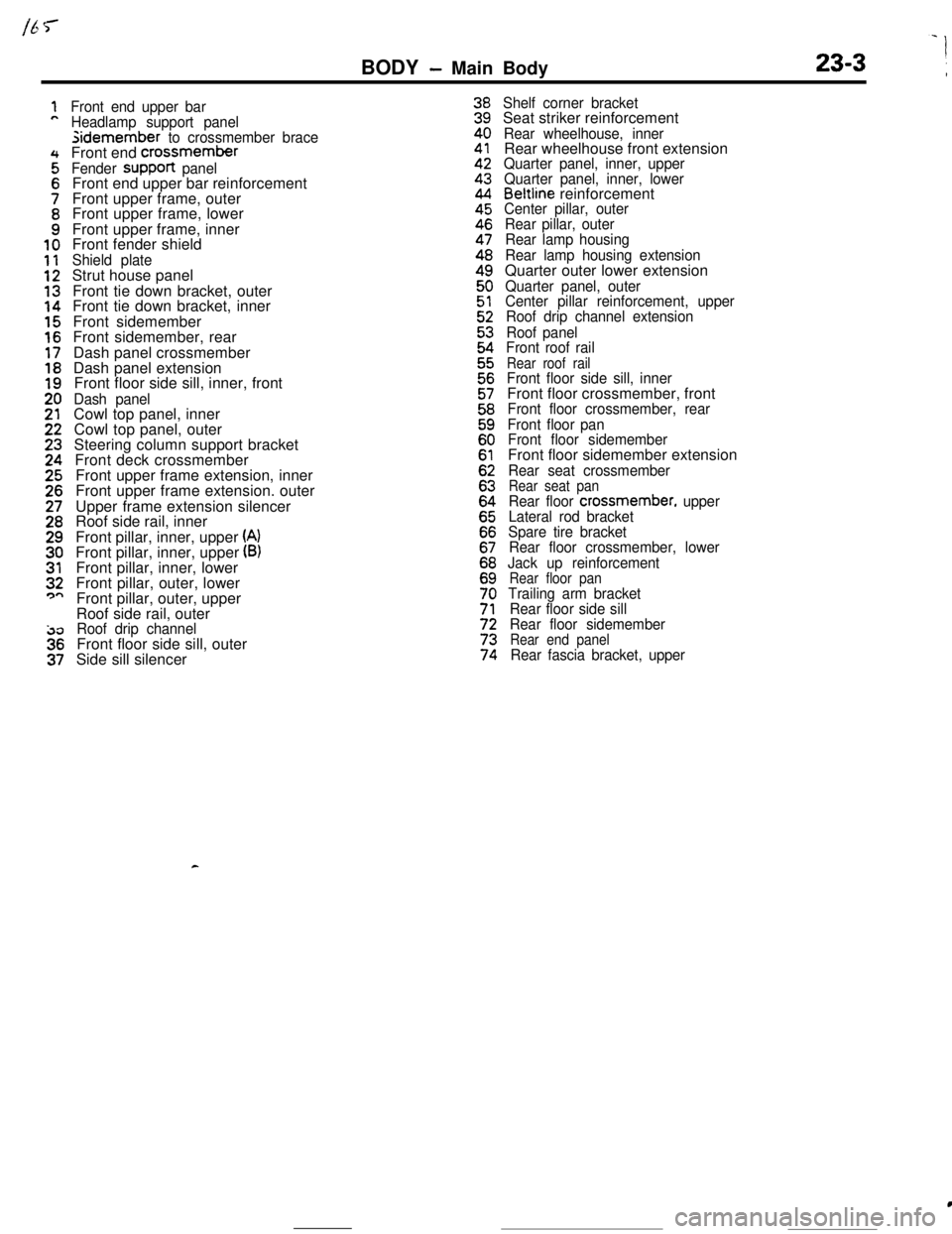

BODY - Main Body23-3 \

Front end upper bar

Headlamp support panelsidemember

to crossmember braceFront end crossmember

Fender suppoR panelFront end upper bar reinforcement

Front upper frame, outer

Front upper frame, lower

Front upper frame, inner

Front fender shield

Shield plateStrut house panel

Front tie down bracket, outer

Front tie down bracket, inner

Front sidemember

Front sidemember, rear

Dash panel crossmember

Dash panel extension

Front floor side sill, inner, front

Dash panelCowl top panel, inner

Cowl top panel, outer

Steering column support bracket

Front deck crossmember

Front upper frame extension, inner

Front upper frame extension. outer

Upper frame extension silencer

Roof side rail, inner

Front pillar, inner, upper

(A)Front pillar, inner, upper (B)Front pillar, inner, lower

Front pillar, outer, lower

Front pillar, outer, upper

Roof side rail, outer

Roof drip channelFront floor side sill, outer

Side sill silencer

Shelf corner bracketSeat striker reinforcement

Rear wheelhouse, innerRear wheelhouse front extension

Quarter panel, inner, upper

Quarter panel, inner, lower

Beltline reinforcementCenter pillar, outer

Rear pillar, outer

Rear lamp housing

Rear lamp housing extensionQuarter outer lower extension

Quarter panel, outer

Center pillar reinforcement, upper

Roof drip channel extension

Roof panel

Front roof rail

Rear roof railFront floor side sill, innerFront floor crossmember, front

Front floor crossmember, rear

Front floor pan

Front floor sidememberFront floor sidemember extension

Rear seat crossmemberRear seat panRear floor crossmember, upper

Lateral rod bracket

Spare tire bracket

Rear floor crossmember, lower

Jack up reinforcement

Rear floor panTrailing arm bracket

Rear floor side sill

Rear floor sidemember

Rear end panelRear fascia bracket, upper

c

c

Page 325 of 391

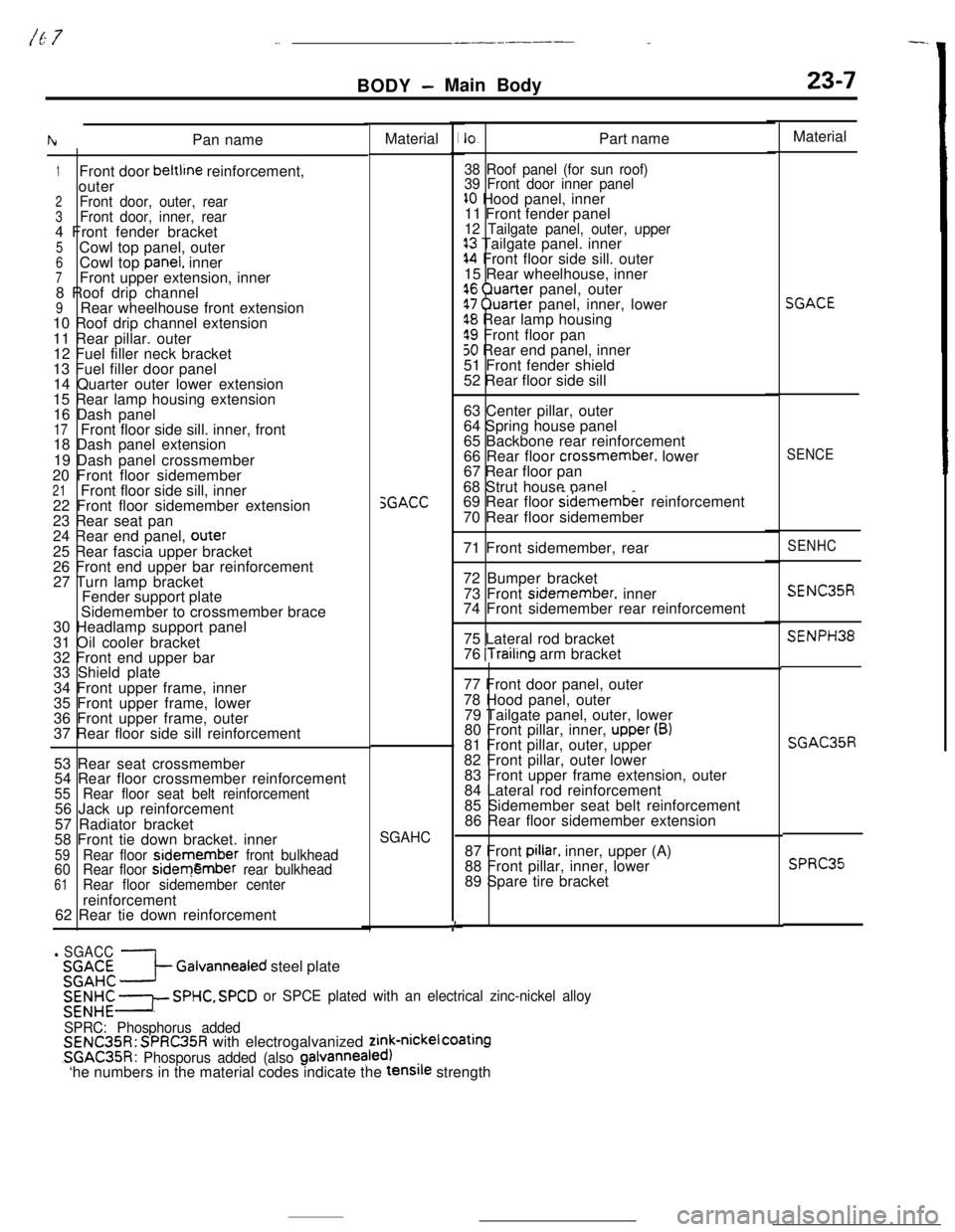

/E 7_.___-__----_BODY

- Main Body23-7Material

IhPan name

1Front door beltline reinforcement,

outer

2Front door, outer, rear3Front door, inner, rear4 Front fender bracket

5Cowl top panel, outer6Cowl top panel. inner7Front upper extension, inner

8 Roof drip channel

9Rear wheelhouse front extension

10 Roof drip channel extension

11 Rear pillar. outer

12 Fuel filler neck bracket

13 Fuel filler door panel

14 Quarter outer lower extension

15 Rear lamp housing extension

16 Dash panel

17Front floor side sill. inner, front

18 Dash panel extension

19 Dash panel crossmember

20 Front floor sidemember

21Front floor side sill, inner

22 Front floor sidemember extension

23 Rear seat pan

24 Rear end panel,

outer25 Rear fascia upper bracket

26 Front end upper bar reinforcement

27 Turn lamp bracket

Fender support plate

Sidemember to crossmember brace

30 Headlamp support panel

31 Oil cooler bracket

32 Front end upper bar

33 Shield plate

34 Front upper frame, inner

35 Front upper frame, lower

36 Front upper frame, outer

37 Rear floor side sill reinforcement

SGACCIO.Part name

38 Roof panel (for sun roof)

39 Front door inner panel

10 Hood panel, inner

11 Front fender panel

12 Tailgate panel, outer, upper13 Tailgate panel. inner14 Front floor side sill. outer

15 Rear wheelhouse, inner

16 Quaner panel, outer17 Quarter panel, inner, lower18 Rear lamp housing

19 Front floor pan50 Rear end panel, inner

51 Front fender shield

52 Rear floor side sill

63 Center pillar, outer

64 Spring house panel

65 Backbone rear reinforcement

66 Rear floor

crossmember. lower

67 Rear floor pan

68 Strut house panel

69 Rear floor sidemember reinforcement

70 Rear floor sidemember

71 Front sidemember, rear

72 Bumper bracket

73 Front

sidemember. inner

74 Front sidemember rear reinforcement

75 Lateral rod bracket

76

ITrailing arm bracket

53 Rear seat crossmember

54 Rear floor crossmember reinforcement

55Rear floor seat belt reinforcement56 Jack up reinforcement

57 Radiator bracket

58 Front tie down bracket. inner

59Rear floor sidemember front bulkhead

60Rear floor sidemember rear bulkhead61Rear floor sidemember centerreinforcement77 Front door panel, outer

78 Hood panel, outer

79 Tailgate panel, outer, lower

80 Front pillar, inner, upper(B)

81 Front pillar, outer, upper

82 Front pillar, outer lower

83 Front upper frame extension, outer

84 Lateral rod reinforcement

85 Sidemember seat belt reinforcement

86 Rear floor sidemember extension

SGAHC87 Front pillar, inner, upper (A)

88 Front pillar, inner, lower

89 Spare tire bracket

62 Rear tie down reinforcement

i

l SGACC%;k; 3 Gaivannealed steel plate

;E;;E I SPHC, SPCD or SPCE plated with an electrical zinc-nickel alloy

SPRC: Phosphorus added

SENC35R: SPRC35R with electrogalvanized zink-nickel CoatingSGAC35R:

Phosporus added (also galvannealed)‘he numbers in the material codes indicate the tensile strengthMaterial

SGACE

SENCE

SENHC

SENC35R

SENPH38

SGAC35R

SPRC35