steering MITSUBISHI ECLIPSE 1990 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 214 of 391

.-. --POWER STEERING

- Power Steering Gear Box Construction19-5

-POWER STEERING GEAR BOX CONSTRUCTIONRlsJLIIUB,

ne steering gear box is of the rack and pinion type

with a built-in hydraulic control unit which uses a

compact and highly reliable rotary valve.The steering gear box, in the same way as the

manual steering gear box, is installed to the body by

way of the mounting rubber in order to reduce the

transmission of vibrations.

Section A-A

Beari

1-$ysy input shaft

To oilreservoir

LFrom oil

I’Rotary valve

Yoke spring

13A0257

Section B-B

From oil pumpTo oil reservoir

To cylinder tubeleft chamber

To cylinder tube

13A0077right chamber

Page 215 of 391

19-6POWER STEERING- Pinion and Valve Assembly Construction

PINION AND VALVE ASSEMBLY

CONSTRUCTION

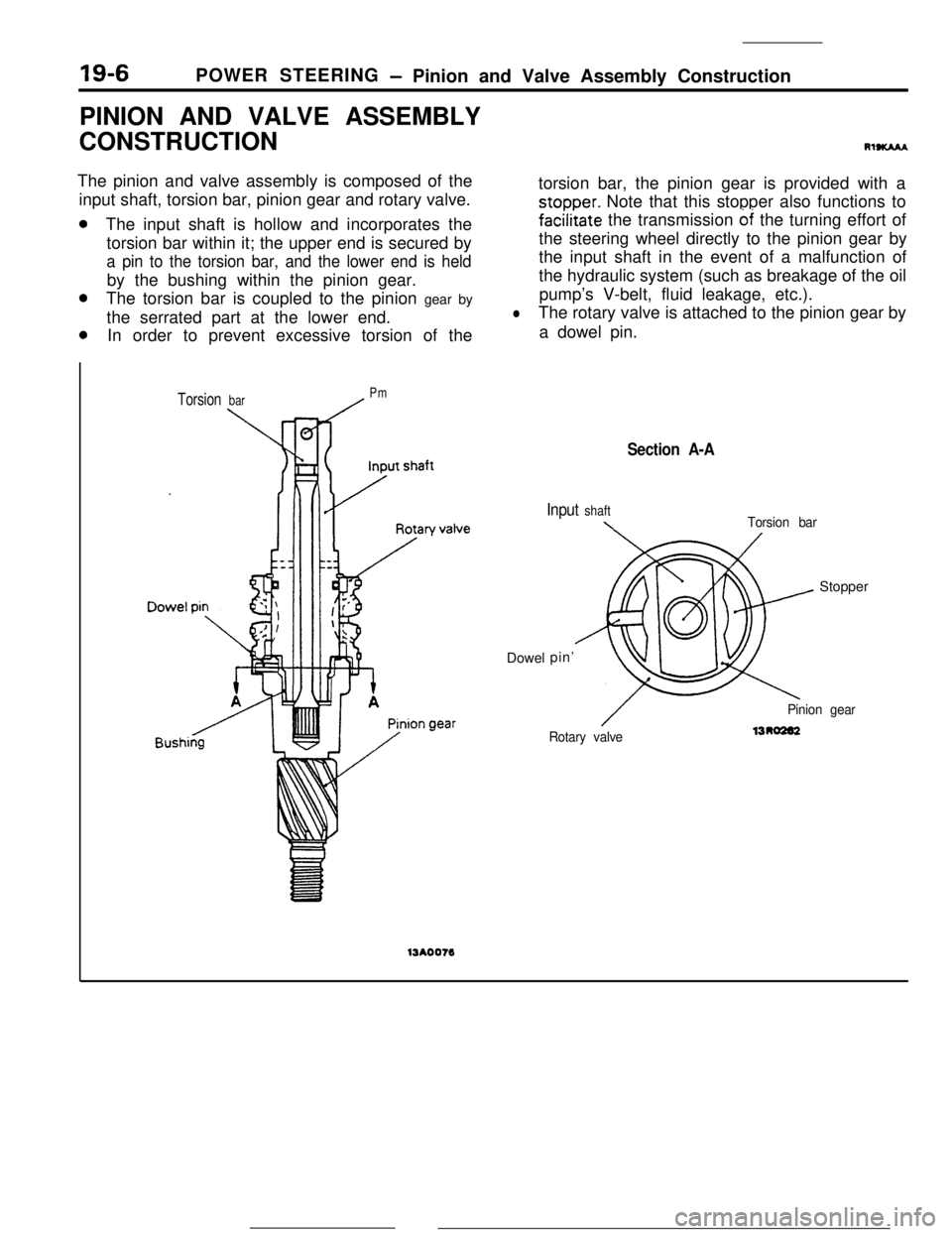

RISKAMThe pinion and valve assembly is composed of the

input shaft, torsion bar, pinion gear and rotary valve.torsion bar, the pinion gear is provided with a

stopper. Note that this stopper also functions to

The input shaft is hollow and incorporates the

fa&tate the transmission 6i the turning effort of

torsion bar within it; the upper end is secured bythe steering wheel directly to the pinion gear by

a pin to the torsion bar, and the lower end is heldthe input shaft in the event of a malfunction of

by the bushing within the pinion gear.the hydraulic system (such as breakage of the oil

The torsion bar is coupled to the pinion gear bypump’s V-belt, fluid leakage, etc.).

the serrated part at the lower end.

lThe rotary valve is attached to the pinion gear by

In order to prevent excessive torsion of thea dowel pin.

Torsion barPm13AOO76Dowel

Section A-A

Input shaft\Torsion barpin’Stopper

/Rotary valvePinion gear1310202

Page 216 of 391

:POWER STEERING

- Pinion and Valve Assembly Construction19-7 ’fOPERATION OF THE PINION AND VALVE

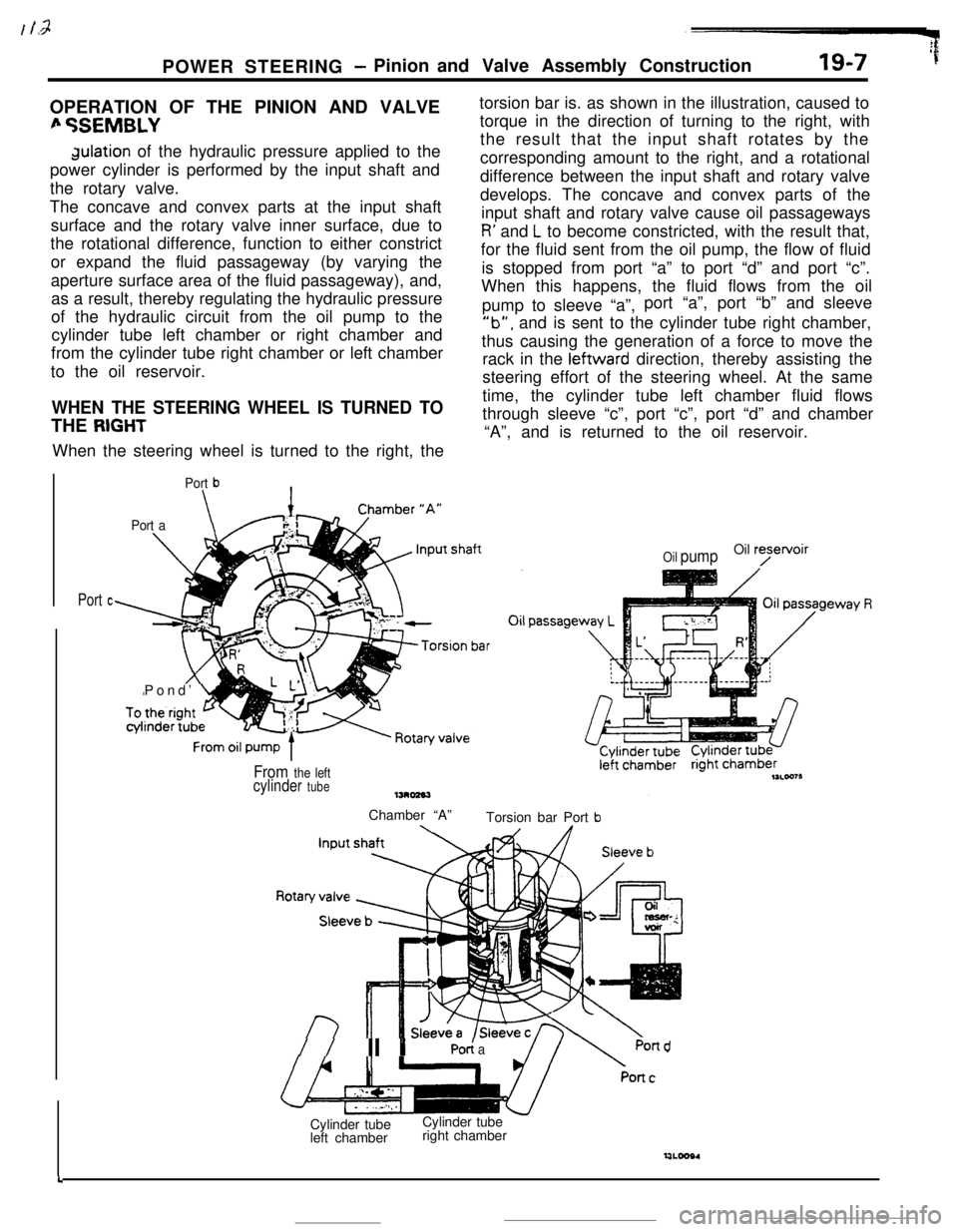

fi %EMBLYdulation of the hydraulic pressure applied to the

power cylinder is performed by the input shaft and

the rotary valve.

The concave and convex parts at the input shaft

surface and the rotary valve inner surface, due to

the rotational difference, function to either constrict

or expand the fluid passageway (by varying the

aperture surface area of the fluid passageway), and,

as a result, thereby regulating the hydraulic pressure

of the hydraulic circuit from the oil pump to the

cylinder tube left chamber or right chamber and

from the cylinder tube right chamber or left chamber

to the oil reservoir.

WHEN THE STEERING WHEEL IS TURNED TOTHE

RIGHTWhen the steering wheel is turned to the right, the

Port b\

Port a\Pond’

Ltorsion bar is. as shown in the illustration, caused to

torque in the direction of turning to the right, with

the result that the input shaft rotates by the

corresponding amount to the right, and a rotational

difference between the input shaft and rotary valve

develops. The concave and convex parts of the

input shaft and rotary valve cause oil passageways

R’ and L to become constricted, with the result that,

for the fluid sent from the oil pump, the flow of fluid

is stopped from port “a” to port “d” and port “c”.

When this happens, the fluid flows from the oil

pump to sleeve “a”,port “a”, port “b” and sleeve

‘lb”, and is sent to the cylinder tube right chamber,

thus causing the generation of a force to move the

rack in the leftward direction, thereby assisting the

steering effort of the steering wheel. At the same

time, the cylinder tube left chamber fluid flows

through sleeve “c”, port “c”, port “d” and chamber

“A”, and is returned to the oil reservoir.

Port c

Oil pumpOil ryetvoir

From the leftcylinder tubeChamber “A”

Torsion bar Port

b

//II YPO< aPond

4Cylinder tube

left chamberCylinder tube

right chamber

Page 217 of 391

19-8POWER STEERING -Pinion and Valve Assembly Construction

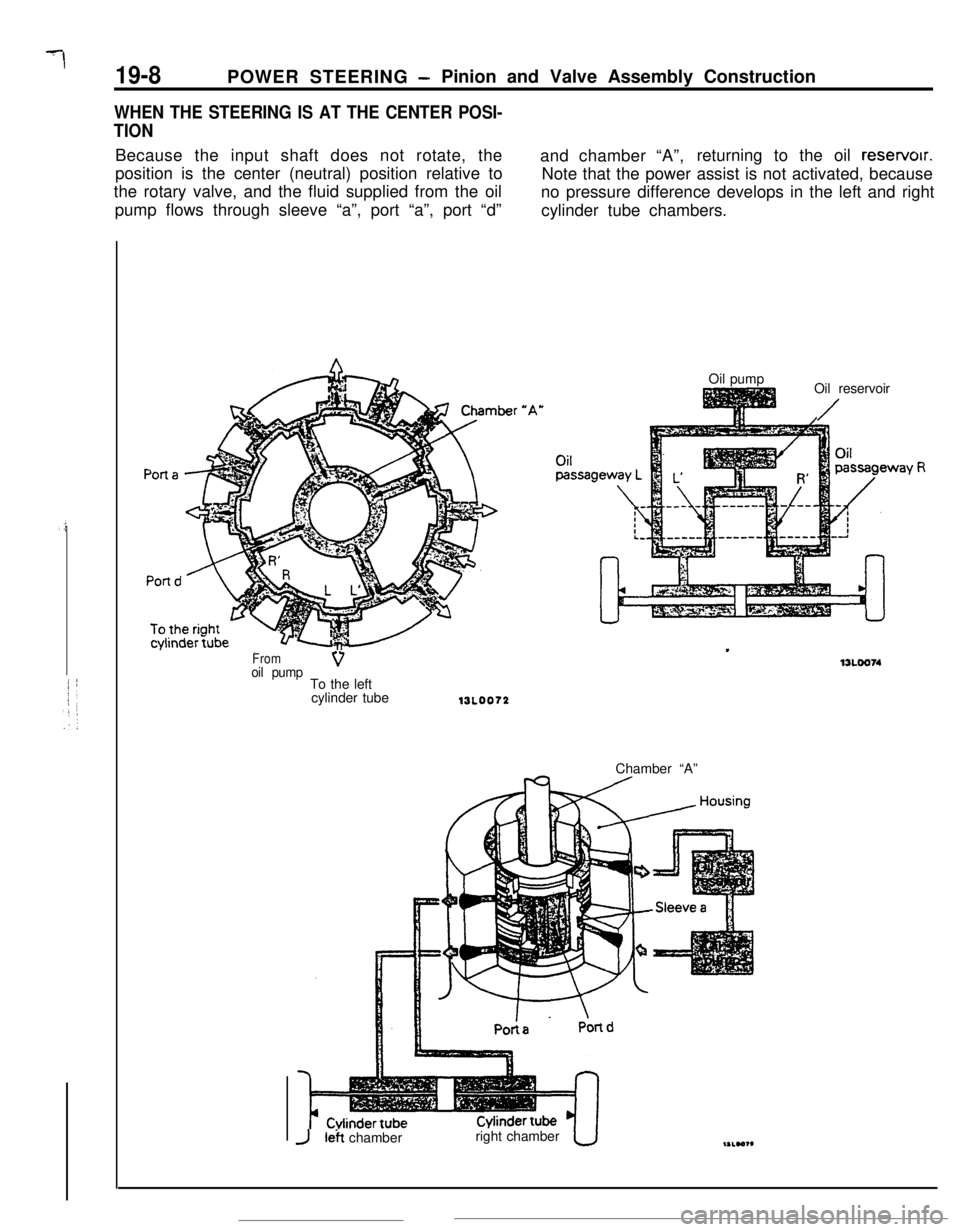

WHEN THE STEERING IS AT THE CENTER POSI-

TIONBecause the input shaft does not rotate, the

and chamber “A”,returning to the oil reservoir.

position is the center (neutral) position relative to

Note that the power assist is not activated, because

the rotary valve, and the fluid supplied from the oil

no pressure difference develops in the left and right

pump flows through sleeve “a”, port “a”, port “d”

cylinder tube chambers.

Fromoil pumpVTo the left

cylinder tubeOil pump

Oil reservoir

/

13L0072Chamber “A”

JI& chamberright chamber

Page 218 of 391

POWER STEERING -Pinion and Valve Assembly Construction

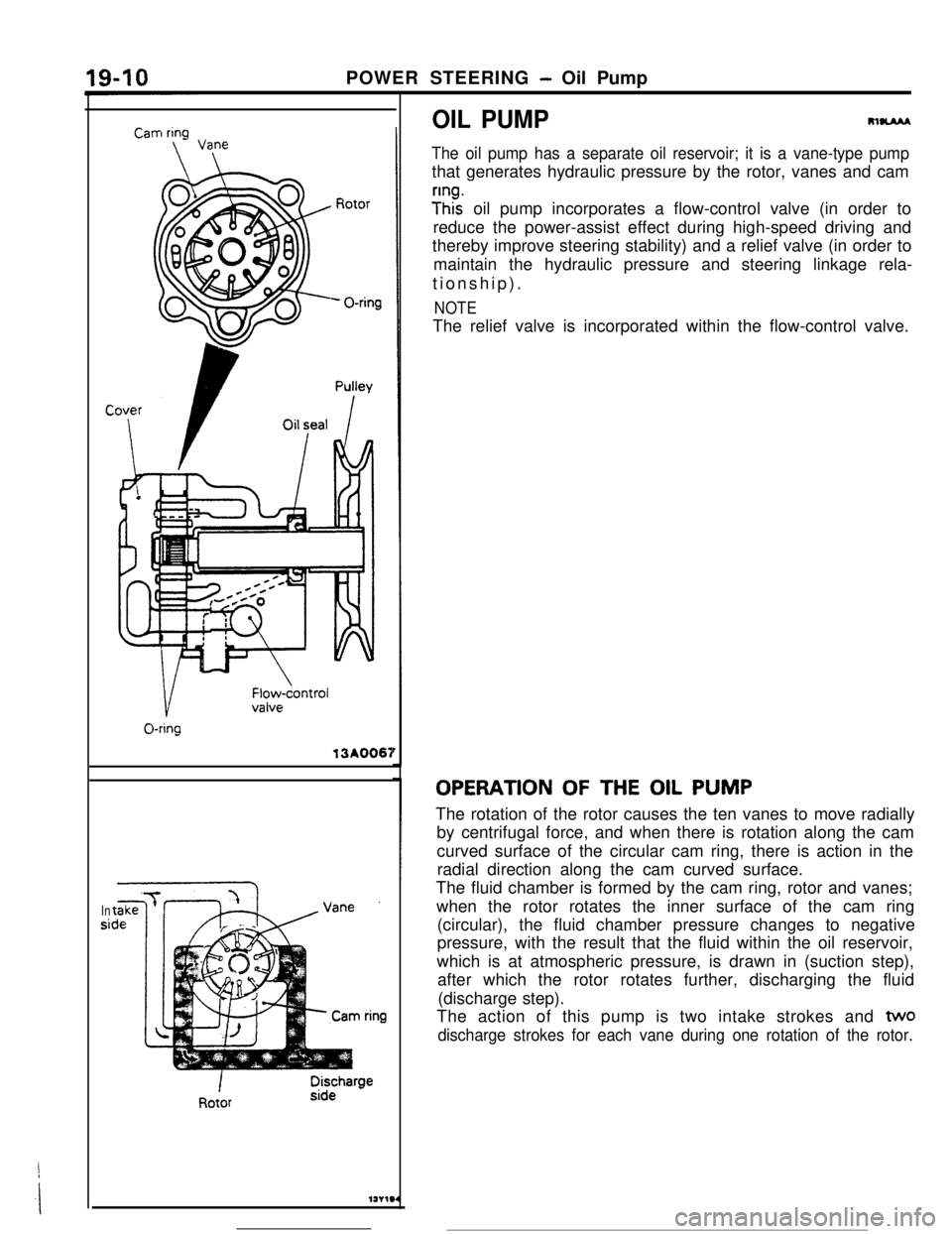

WHEN THE STEERING WHEEL IS TURNED TO

THE LEFT

IS-9

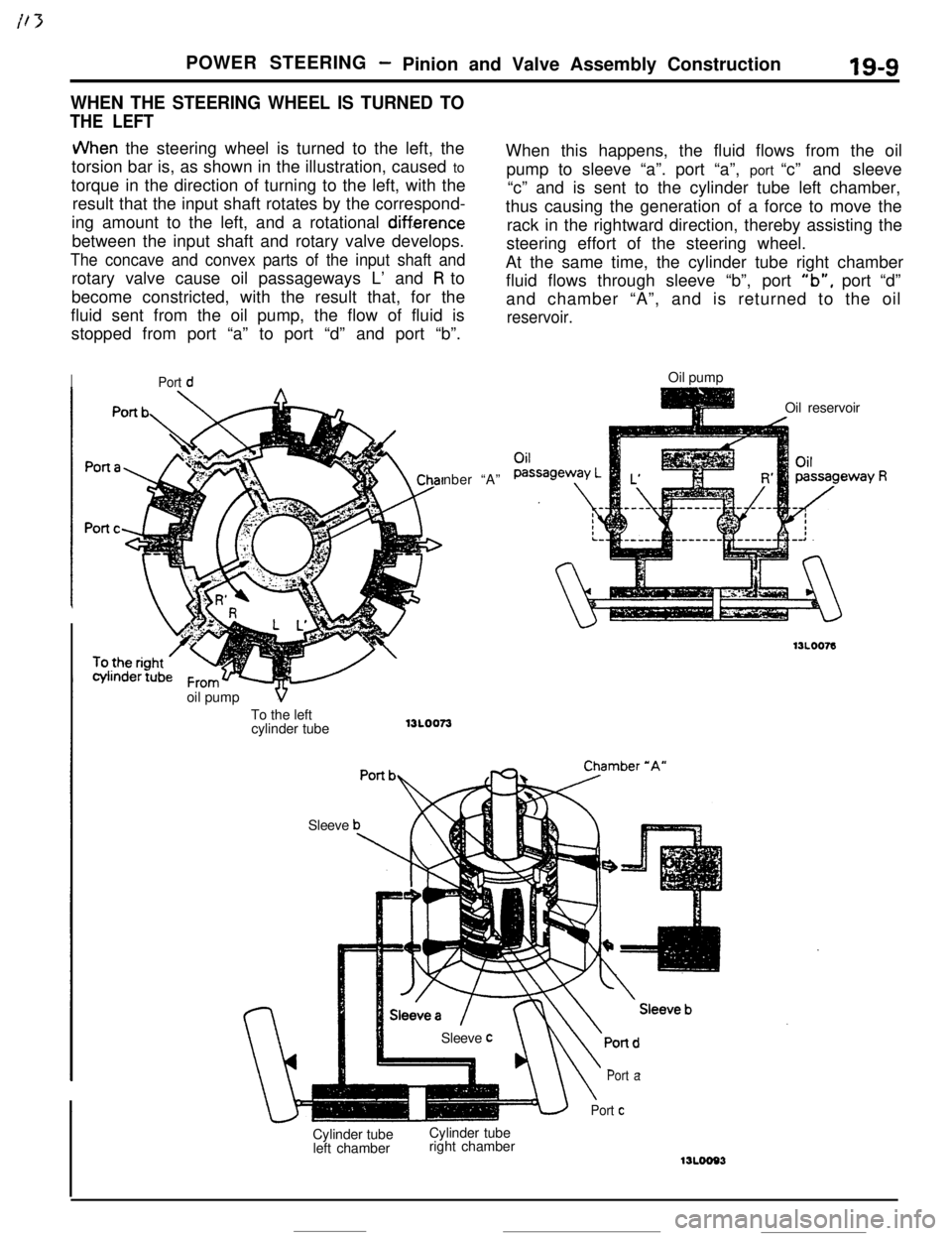

JVhen the steering wheel is turned to the left, the

torsion bar is, as shown in the illustration, caused to

torque in the direction of turning to the left, with the

result that the input shaft rotates by the correspond-

ing amount to the left, and a rotational

diff.erencebetween the input shaft and rotary valve develops.

The concave and convex parts of the input shaft androtary valve cause oil passageways L’ and

R to

become constricted, with the result that, for the

fluid sent from the oil pump, the flow of fluid is

stopped from port “a” to port “d” and port “b”.

IPort dnber “A”

SleeveWhen this happens, the fluid flows from the oil

pump to sleeve “a”. port “a”, port “c” and sleeve

“c” and is sent to the cylinder tube left chamber,

thus causing the generation of a force to move the

rack in the rightward direction, thereby assisting the

steering effort of the steering wheel.

At the same time, the cylinder tube right chamber

fluid flows through sleeve “b”, port

“b”, port “d”

and chamber “A”, and is returned to the oil

reservoir.Oil pump

Oil reservoir

Cylinder tube

left chamberCylinder tube

right chamber

\

Port a

Port cSleeve

coil pump

VTo the left

cylinder tube

13L0073

Page 219 of 391

POWER STEERING - Oil Pump13A0067

Insi

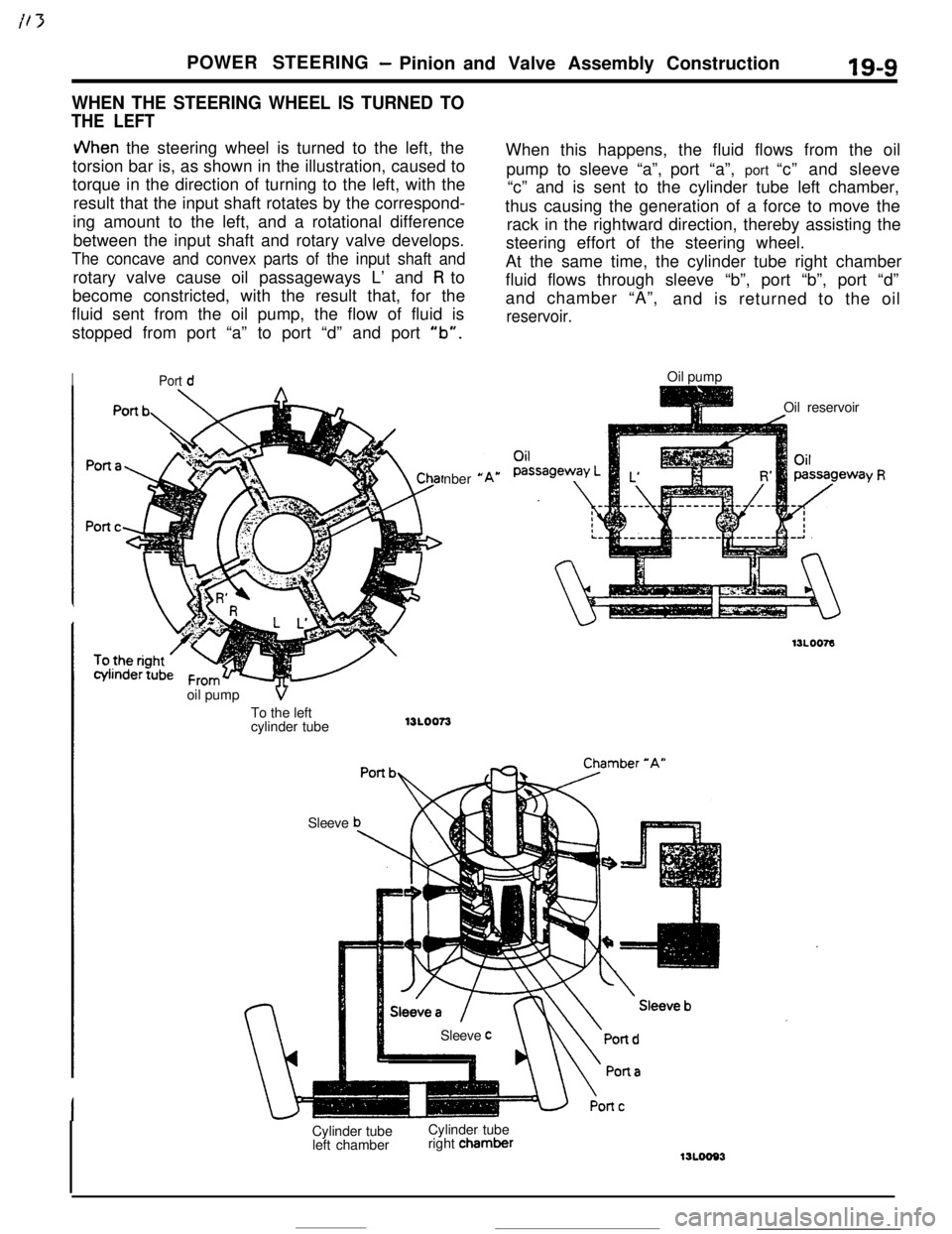

OIL PUMPRlUAM

The oil pump has a separate oil reservoir; it is a vane-type pumpthat generates hydraulic pressure by the rotor, vanes and cam

y”ht oil pump incorporates a flow-control valve (in order to

reduce the power-assist effect during high-speed driving and

thereby improve steering stability) and a relief valve (in order to

maintain the hydraulic pressure and steering linkage rela-

tionship).

NOTEThe relief valve is incorporated within the flow-control valve.

OPERATION OF THE OIL PUMP

The rotation of the rotor causes the ten vanes to move radially

by centrifugal force, and when there is rotation along the cam

curved surface of the circular cam ring, there is action in the

radial direction along the cam curved surface.

The fluid chamber is formed by the cam ring, rotor and vanes;

when the rotor rotates the inner surface of the cam ring

(circular), the fluid chamber pressure changes to negative

pressure, with the result that the fluid within the oil reservoir,

which is at atmospheric pressure, is drawn in (suction step),

after which the rotor rotates further, discharging the fluid

(discharge step).

The action of this pump is two intake strokes and

two

discharge strokes for each vane during one rotation of the rotor.

Page 220 of 391

POWER STEERING- Pinion and Valve Assembly Construction19-9

WHEN THE STEERING WHEEL IS TURNED TO

THE LEFT

JVhen the steering wheel is turned to the left, the

torsion bar is, as shown in the illustration, caused to

torque in the direction of turning to the left, with the

result that the input shaft rotates by the correspond-

ing amount to the left, and a rotational difference

between the input shaft and rotary valve develops.

The concave and convex parts of the input shaft androtary valve cause oil passageways L’ and

R to

become constricted, with the result that, for the

fluid sent from the oil pump, the flow of fluid is

stopped from port “a” to port “d” and port

“b”.

IPort dnber

*oil pump

VTo the left

cylinder tube13LOO73

SleeveWhen this happens, the fluid flows from the oil

pump to sleeve “a”,port “a”, port “c” and sleeve

“c” and is sent to the cylinder tube left chamber,

thus causing the generation of a force to move the

rack in the rightward direction, thereby assisting the

steering effort of the steering wheel.

At the same time, the cylinder tube right chamber

fluid flows through sleeve “b”, port “b”, port “d”

and chamber “A”,

and is returned to the oil

reservoir.Oil pump

Oil reservoir

Sleeve

cCylinder tube

left chamberCylinder tube

right chamber

‘Y R

Page 221 of 391

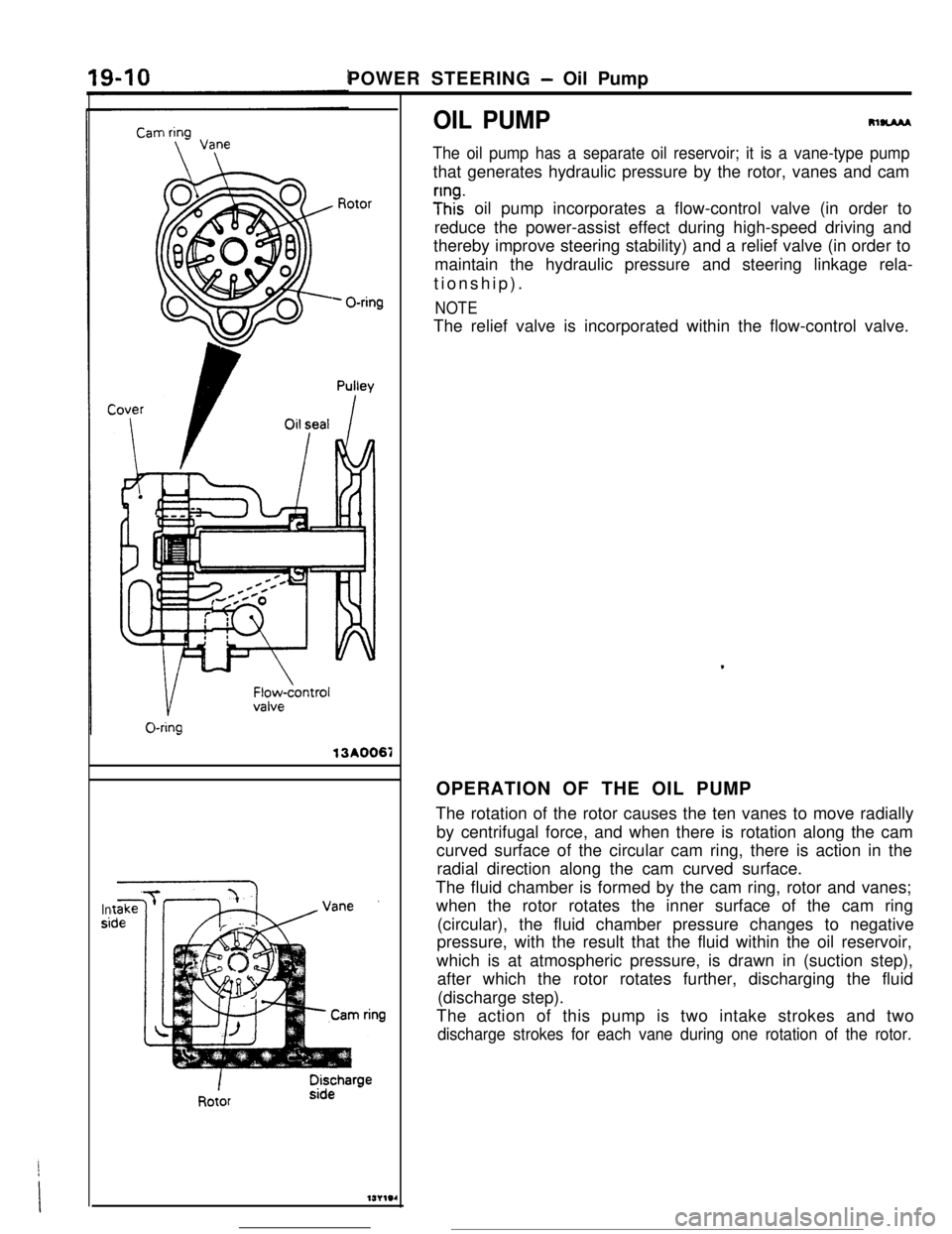

POWER STEERING - Oil Pump

OIL PUMP13A0067

Insi

m-

The oil pump has a separate oil reservoir; it is a vane-type pumpthat generates hydraulic pressure by the rotor, vanes and cam

;Inhz oil pump incorporates a flow-control valve (in order to

reduce the power-assist effect during high-speed driving and

thereby improve steering stability) and a relief valve (in order to

maintain the hydraulic pressure and steering linkage rela-

tionship).

NOTEThe relief valve is incorporated within the flow-control valve.

.OPERATION OF THE OIL PUMP

The rotation of the rotor causes the ten vanes to move radially

by centrifugal force, and when there is rotation along the cam

curved surface of the circular cam ring, there is action in the

radial direction along the cam curved surface.

The fluid chamber is formed by the cam ring, rotor and vanes;

when the rotor rotates the inner surface of the cam ring

(circular), the fluid chamber pressure changes to negative

pressure, with the result that the fluid within the oil reservoir,

which is at atmospheric pressure, is drawn in (suction step),

after which the rotor rotates further, discharging the fluid

(discharge step).

The action of this pump is two intake strokes and two

discharge strokes for each vane during one rotation of the rotor.

Page 222 of 391

POWER STEERING - Oil Pump

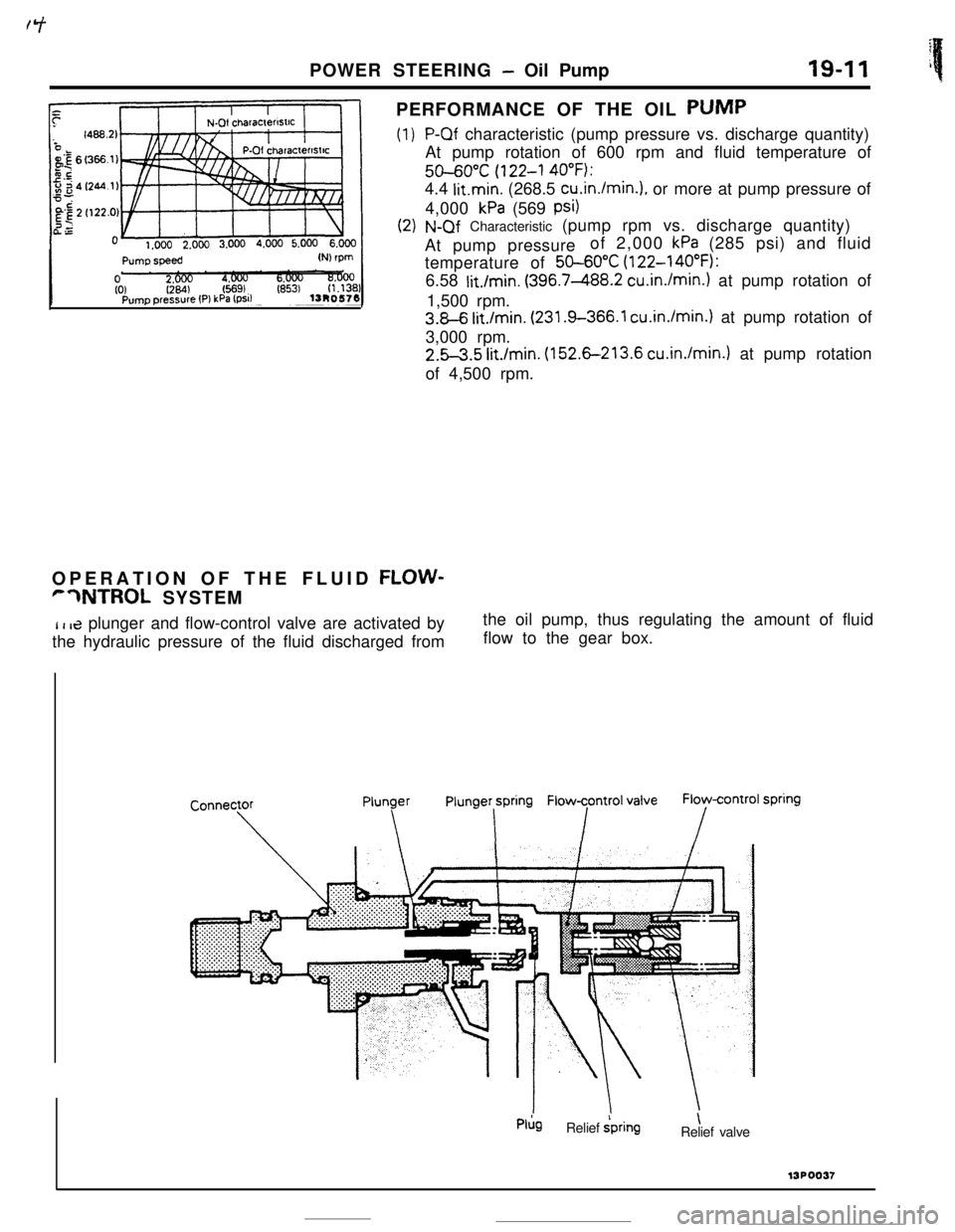

PERFORMANCE OF THE OIL PUMP

(1)

19-11 i

P-Qf characteristic (pump pressure vs. discharge quantity)

At pump rotation of 600 rpm and fluid temperature of

50-6O”C (122-l 40°F):4.4

litmin. (268.5 cu.in./min.), or more at pump pressure of

4,000

kPa (569 psi)

N-Qf Characteristic (pump rpm vs. discharge quantity)

At pump pressureof 2,000

kPa (285 psi) and fluid

temperature of

50-60X (122-140°F):

6.58

lit./min. (396.7-488.2 cu.in./min.) at pump rotation of

1,500 rpm.

3.8-6 lit./min. (231.9-366.1 cu.in./min.) at pump rotation of

3,000 rpm.

2.5-3.5 Mnin. (152.6-213.6 cu.in./min.) at pump rotation

of 4,500 rpm.

OPERATION OF THE FLUID

FLOW-

r7NTROL SYSTEM

I t 13 plunger and flow-control valve are activated bythe oil pump, thus regulating the amount of fluid

the hydraulic pressure of the fluid discharged fromflow to the gear box.

Pl;lgRelief ipring\

Relief valve13POO37

Page 223 of 391

19-12POWER STEERING - Oil Pump

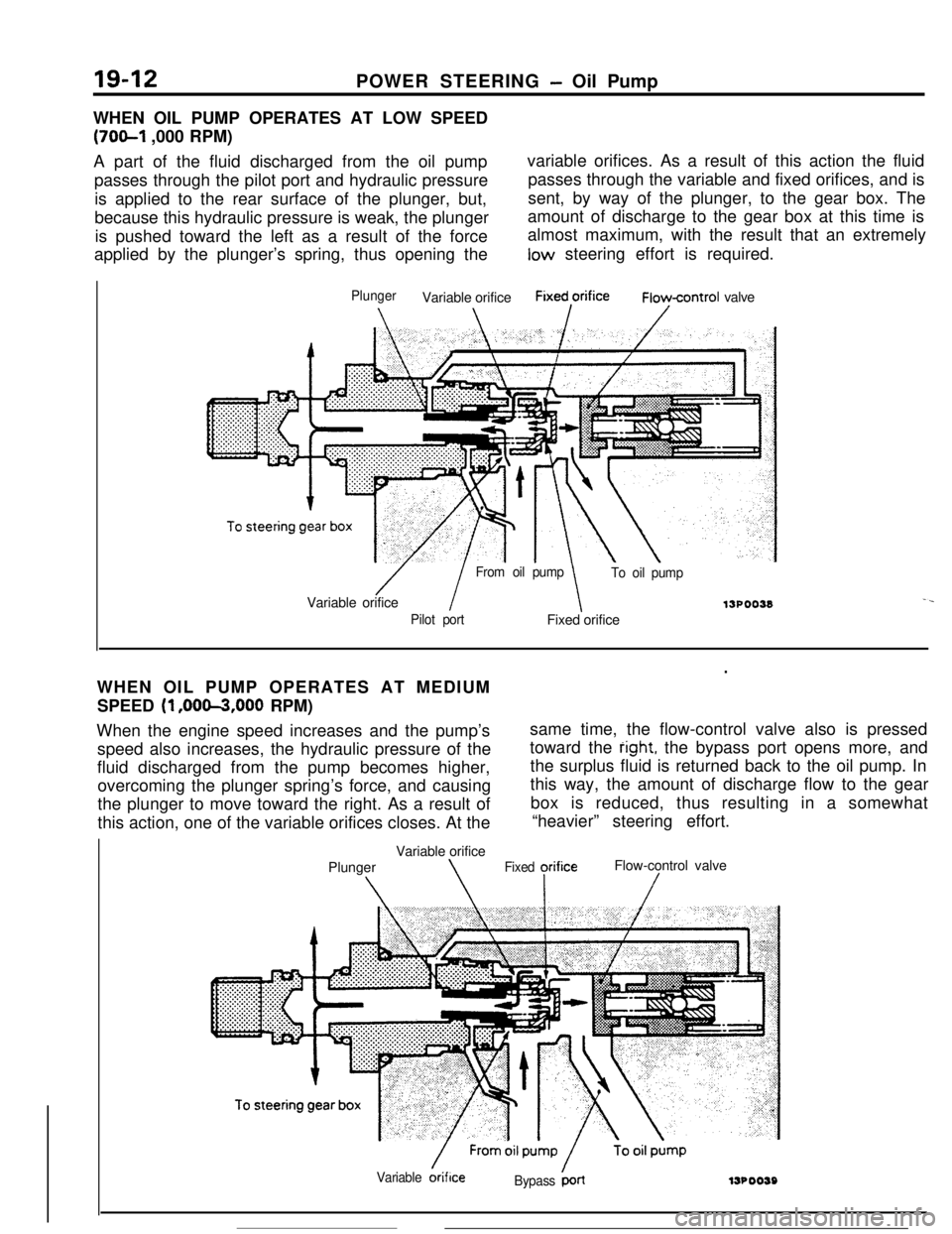

WHEN OIL PUMP OPERATES AT LOW SPEED

(70&l ,000 RPM)

A part of the fluid discharged from the oil pumpvariable orifices. As a result of this action the fluid

passes through the pilot port and hydraulic pressurepasses through the variable and fixed orifices, and is

is applied to the rear surface of the plunger, but,sent, by way of the plunger, to the gear box. The

because this hydraulic pressure is weak, the plungeramount of discharge to the gear box at this time is

is pushed toward the left as a result of the forcealmost maximum, with the result that an extremely

applied by the plunger’s spring, thus opening thelow steering effort is required.

PlungerVariable orificeFixed,orificeFioycontrol valve

/ I

From oil pump

To oil pumpVariable orifice

13POO38-.

Pilot portFixed orifice

.WHEN OIL PUMP OPERATES AT MEDIUM

SPEED

(1 ,OOm,OOO RPM)

When the engine speed increases and the pump’ssame time, the flow-control valve also is pressed

speed also increases, the hydraulic pressure of thetoward the

right, the bypass port opens more, and

fluid discharged from the pump becomes higher,the surplus fluid is returned back to the oil pump. In

overcoming the plunger spring’s force, and causingthis way, the amount of discharge flow to the gear

the plunger to move toward the right. As a result ofbox is reduced, thus resulting in a somewhat

this action, one of the variable orifices closes. At the“heavier” steering effort.

Variable orifice

PlungerFlow-control valve

\\Fixed yrifice/

Variable &iflceBypass ‘LrllJPOO59