clock MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 69 of 391

ELECTRICAL - Lighting8-17

Front turnsignal light

(Optical horn)

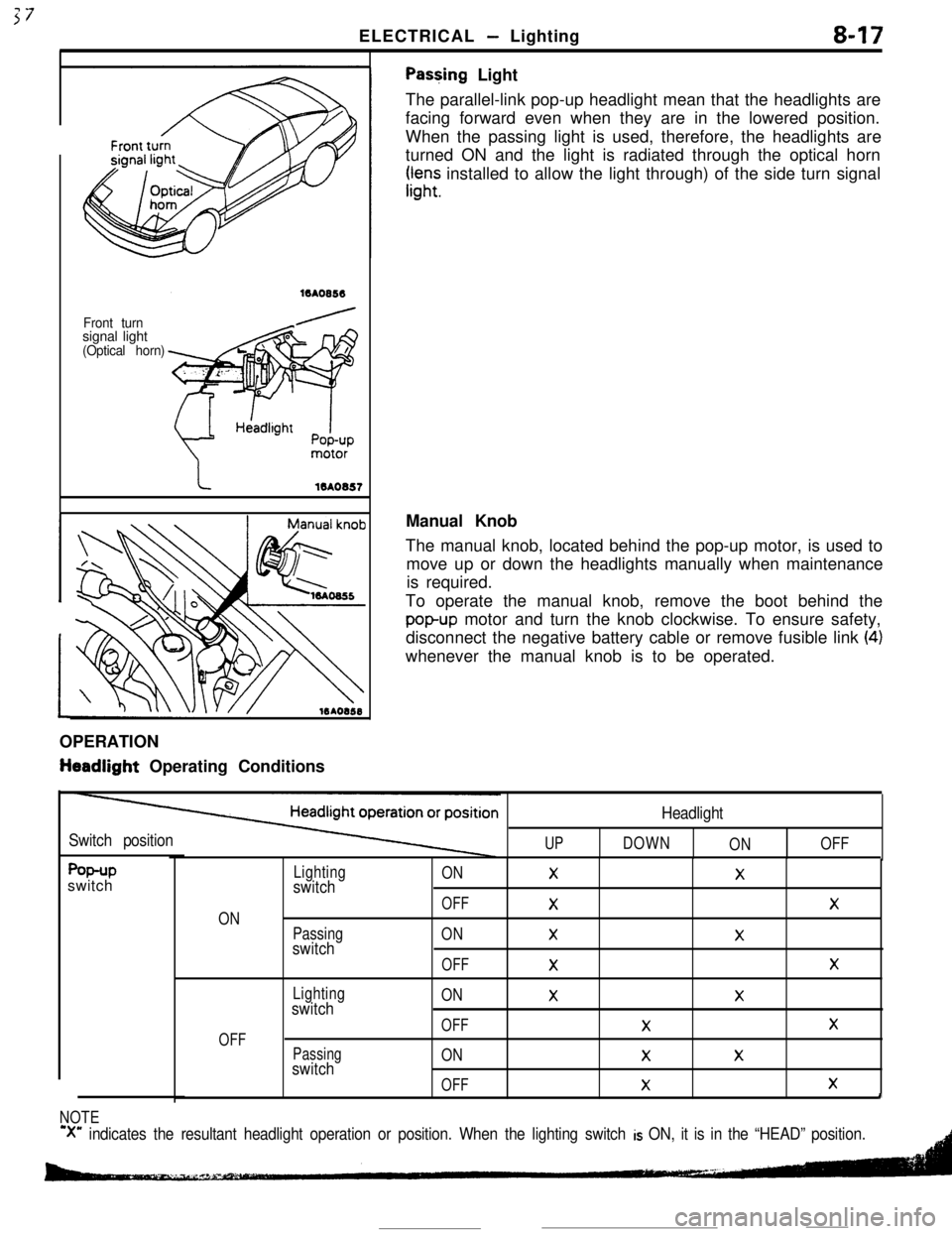

Pas+ing Light

The parallel-link pop-up headlight mean that the headlights are

facing forward even when they are in the lowered position.

When the passing light is used, therefore, the headlights are

turned ON and the light is radiated through the optical horn

rr,“;; installed to allow the light through) of the side turn signal

OPERATION

tieadlight Operating ConditionsManual Knob

The manual knob, located behind the pop-up motor, is used to

move up or down the headlights manually when maintenance

is required.

To operate the manual knob, remove the boot behind the

popup motor and turn the knob clockwise. To ensure safety,

disconnect the negative battery cable or remove fusible link

(4)whenever the manual knob is to be operated.

Switch positionUP

Headlight

DOWN

ONOFF

f%+Pswitch

ON

OFF

Lightingswitch

Passingswitch

Lightingswitch

Passingswitch

ONXX

OFF

XX

ONXX

OFF

XX

ONXX

OFFXX

ONXX

OFF

XXI

NOTE

‘X” indicates the resultant headlight operation or position. When the lighting switch is ON, it is in the “HEAD” position.

Page 75 of 391

ELECTRICAL- Ermine Electrical8-23

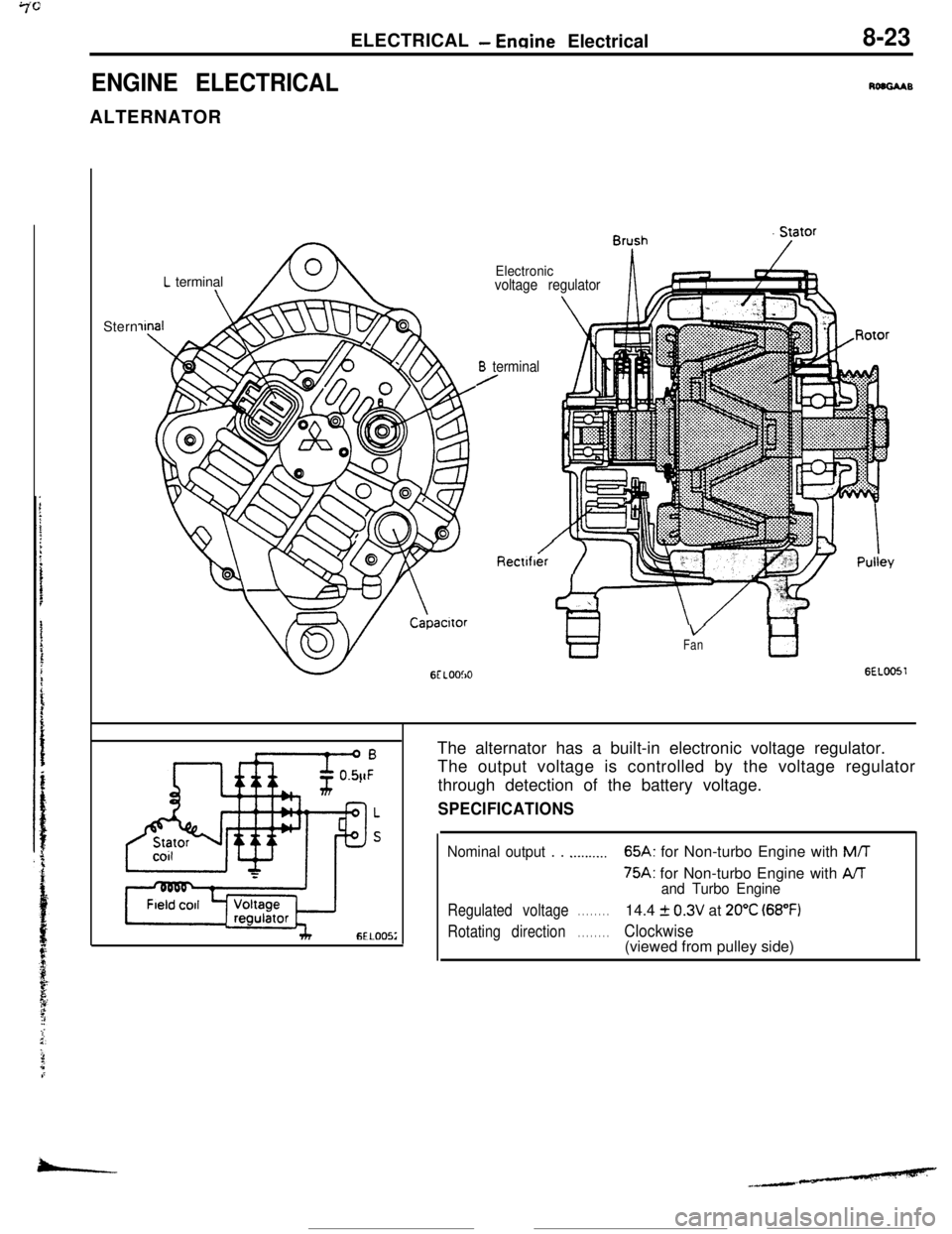

ENGINE ELECTRICALRoaGAABALTERNATOR

L terminal\Stern

Electronicvoltage regulator

B terminal/

Rectlfber‘i ‘IT

VFantl

GEL0051The alternator has a built-in electronic voltage regulator.

The output voltage is controlled by the voltage regulator

through detection of the battery voltage.

SPECIFICATIONS

Nominal output . . .._...._..65A: for Non-turbo Engine with M/T

75A: for Non-turbo Engine with AAand Turbo Engine

Regulated voltage. . . . . . . .14.4 f 0.3V at 20°C (68°F)

Rotating direction. . . . . . . .Clockwise(viewed from pulley side)

-

Page 76 of 391

.-

8-24ELECTRICAL- Engine Electrical

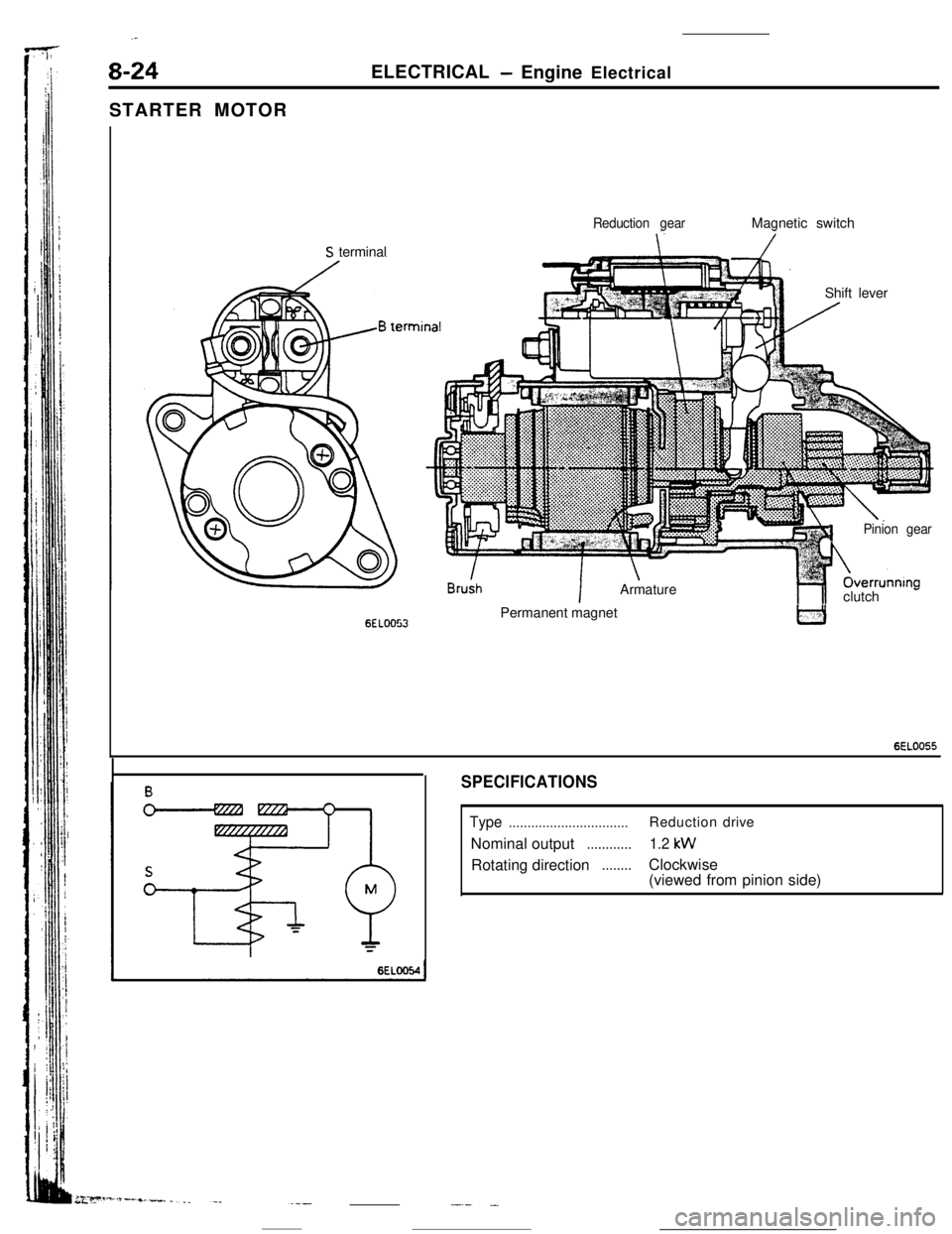

STARTER MOTOR

Reduction gearMagnetic switch

S terminal

Shift lever

6ELOO53

!n

IArmature

1Pinion gearOverrunnIng

hlclutch -Permanent magnet

6EL0055

SPECIFICATIONS

Type................................Reductiondrive

Nominal output

............1.2 kWRotating direction

........Clockwise

(viewed from pinion side)

-.- .-

Page 128 of 391

14-16FUEL SYSTEM - Sensors

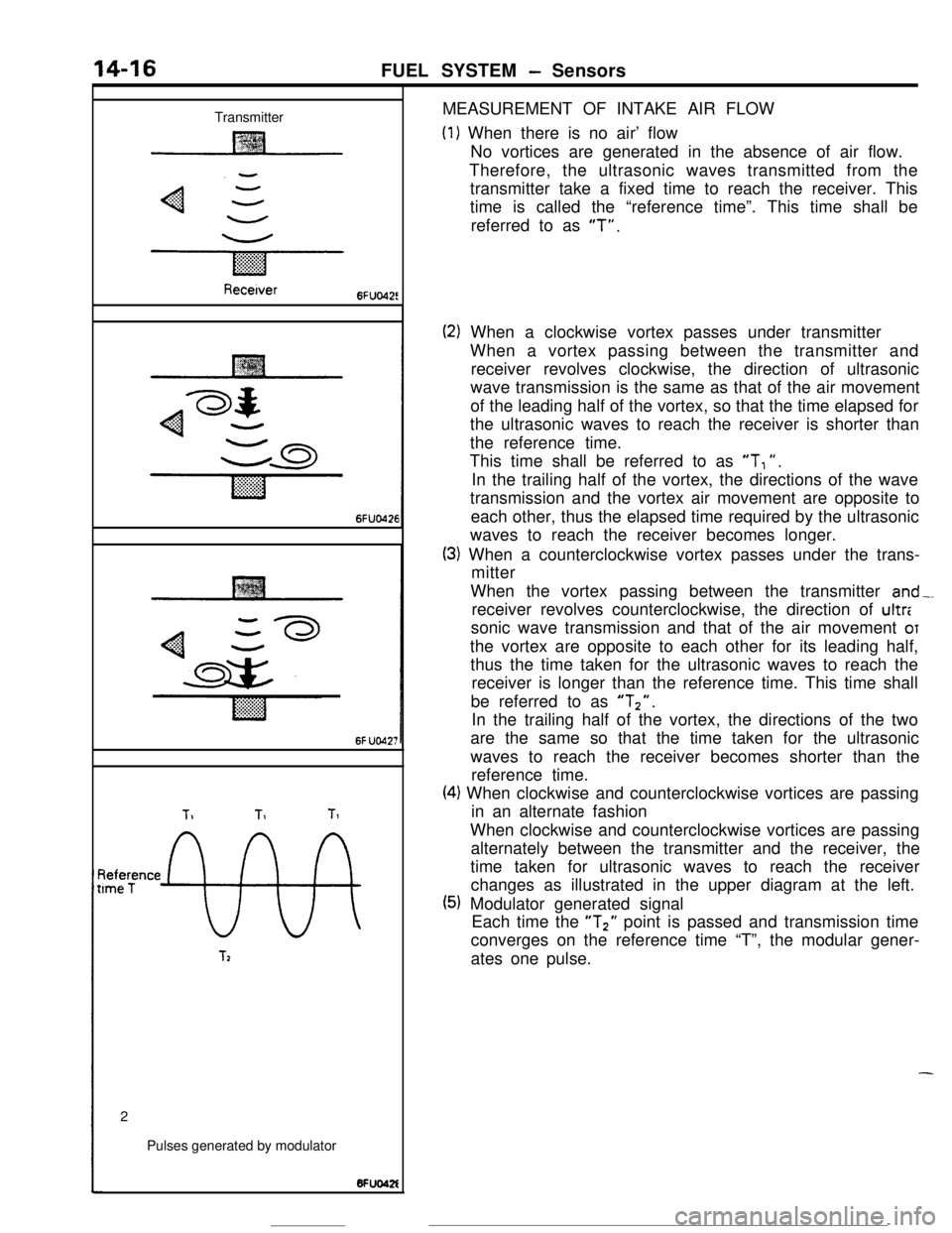

TransmitterMEASUREMENT OF INTAKE AIR FLOW

(1) When there is no air’ flow

No vortices are generated in the absence of air flow.

Therefore, the ultrasonic waves transmitted from the

transmitter take a fixed time to reach the receiver. This

time is called the “reference time”. This time shall be

referred to as

“T”.

Recetver6FUo42!

6FUO426

6f UO42;

TIT1Tl

~tee;ence

9%

T22

Pulses generated by modulator

(2) When a clockwise vortex passes under transmitter

When a vortex passing between the transmitter and

receiver revolves clockwise, the direction of ultrasonic

wave transmission is the same as that of the air movement

of the leading half of the vortex, so that the time elapsed for

the ultrasonic waves to reach the receiver is shorter than

the reference time.

This time shall be referred to as

“T, “.

In the trailing half of the vortex, the directions of the wave

transmission and the vortex air movement are opposite to

each other, thus the elapsed time required by the ultrasonic

waves to reach the receiver becomes longer.

(3) When a counterclockwise vortex passes under the trans-

mitter

When the vortex passing between the transmitter

and-.receiver revolves counterclockwise, the direction of ultr:

sonic wave transmission and that of the air movement

OTthe vortex are opposite to each other for its leading half,

thus the time taken for the ultrasonic waves to reach the

receiver is longer than the reference time. This time shall

be referred to as

“Tz”.In the trailing half of the vortex, the directions of the two

are the same so that the time taken for the ultrasonic

waves to reach the receiver becomes shorter than the

reference time.

(4) When clockwise and counterclockwise vortices are passing

in an alternate fashion

When clockwise and counterclockwise vortices are passing

alternately between the transmitter and the receiver, the

time taken for ultrasonic waves to reach the receiver

changes as illustrated in the upper diagram at the left.

(5) Modulator generated signal

Each time the “T2” point is passed and transmission time

converges on the reference time “T”, the modular gener-

ates one pulse.

-

Page 160 of 391

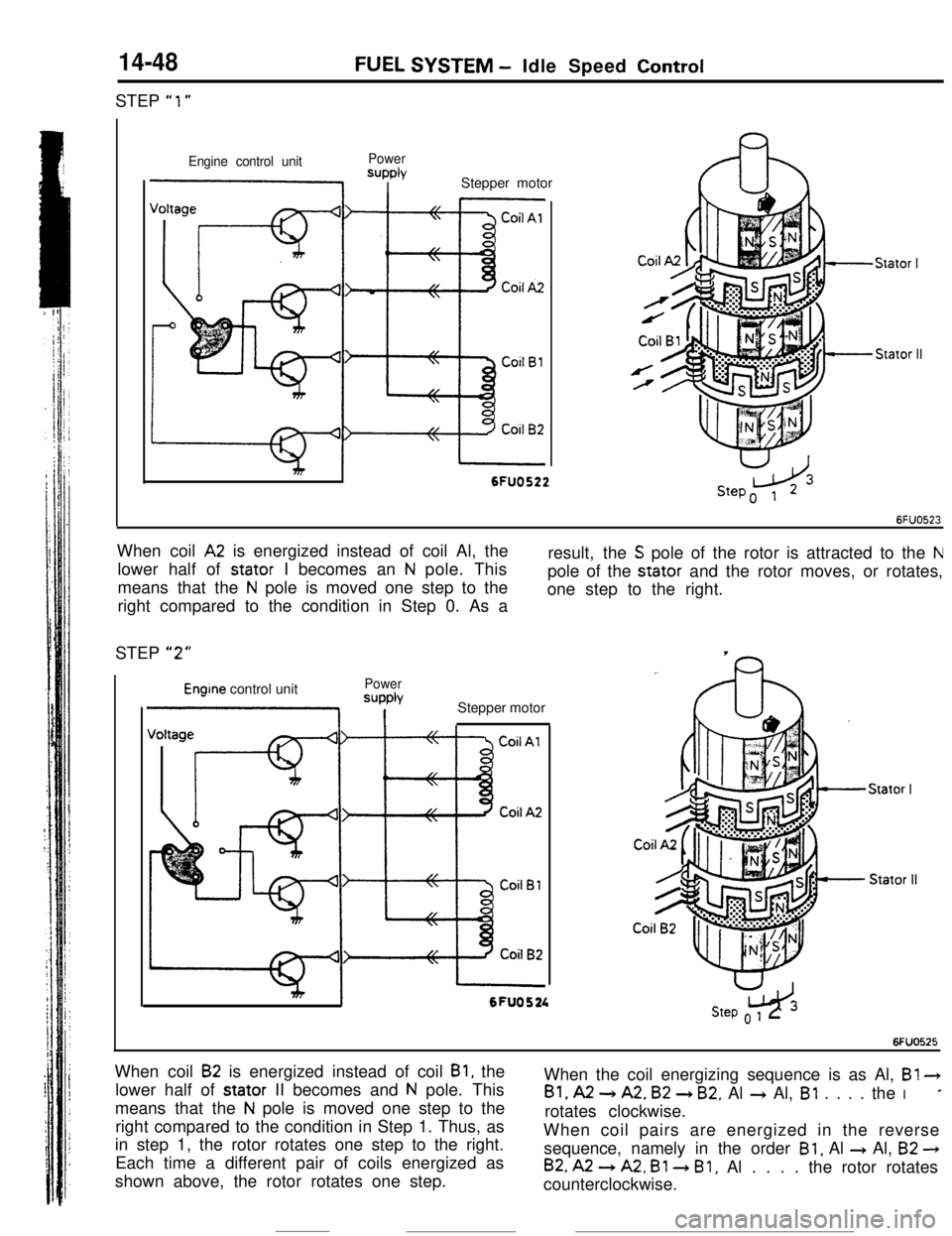

14-48STEP

“1”

FUEL SYSTEM - Idle Speed Control

Engine control unitPowerSUPPlYI IStepper motor

Stator I

Stator II

I6FUO522When coil

A2 is energized instead of coil Al, the

lower half of stator I becomes an

N pole. This

means that the

N pole is moved one step to the

right compared to the condition in Step 0. As aresult, the

S pole of the rotor is attracted to the Npole of the stator and the rotor moves, or rotates,

one step to the right.

STEP

“2”

Engine control unitPower

=JPPb

1 IStepper motor

Stator IStator II

mI6FU0524w3Step o 1 2

6FUO525When coil

B2 is energized instead of coil Bl, the

lower half of stator II becomes and

N pole. This

means that the

N pole is moved one step to the

right compared to the condition in Step 1. Thus, as

in step 1, the rotor rotates one step to the right.

Each time a different pair of coils energized as

shown above, the rotor rotates one step.When the coil energizing sequence is as Al, B!

3

Bl, A2 -) A2. B2 + B2. Al + Al, Bl . . . . the I*rotates clockwise.

When coil pairs are energized in the reverse

sequence, namely in the order

Bl, Al + Al, B2 -)

B2, A2 --) A2, Bl 3 Bl, Al . . . . the rotor rotates

counterclockwise.

Page 245 of 391

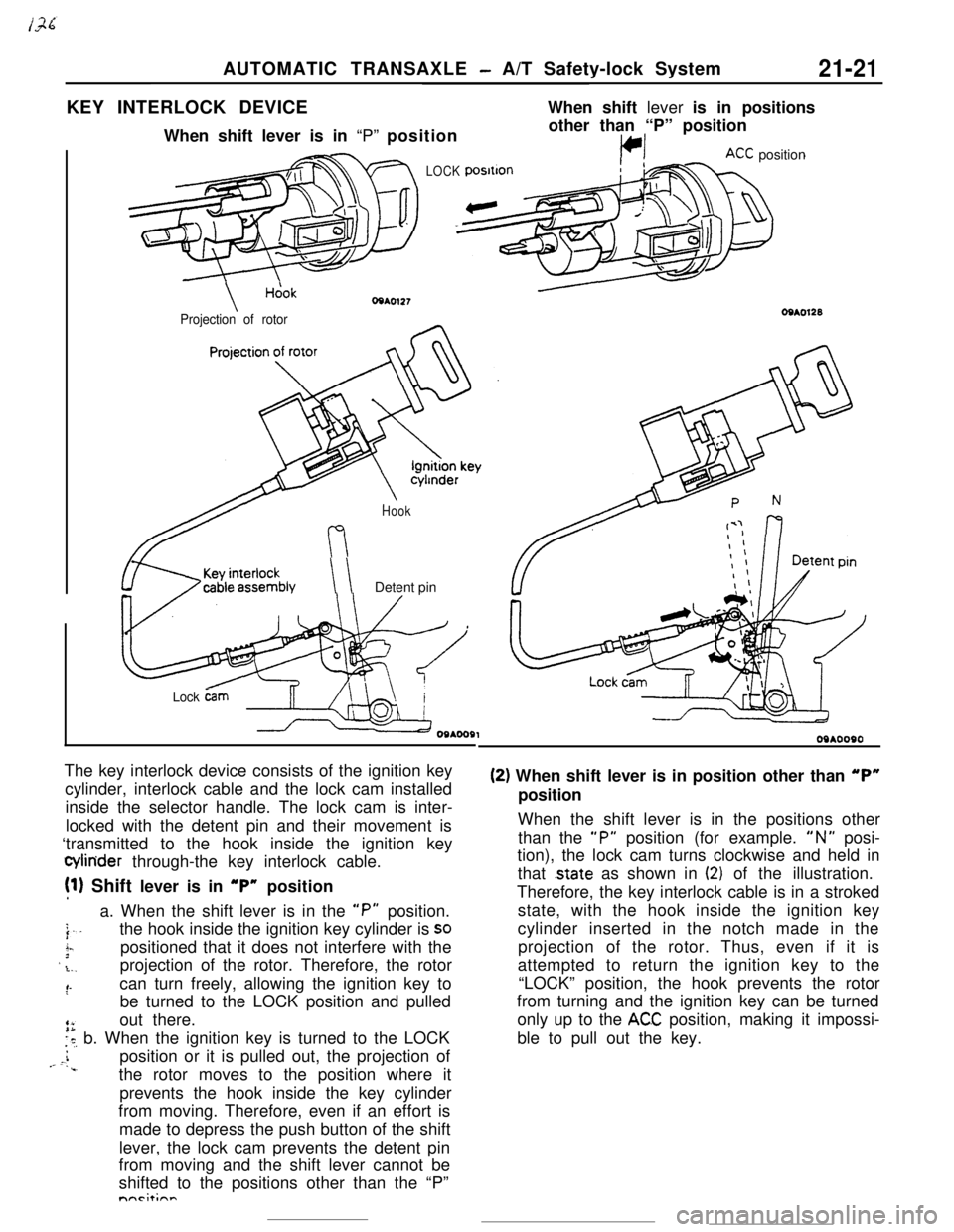

AUTOMATIC TRANSAXLE - A/T Safety-lock System21-21KEY INTERLOCK DEVICEWhen shift lever is in positions

When shift lever is in “P” position

LOCK

\Hcjok

Projection of rotorother than “P” position

KC position

Hook

\ \Detent pin

Lock &mThe key interlock device consists of the ignition key

cylinder, interlock cable and the lock cam installed

inside the selector handle. The lock cam is inter-

locked with the detent pin and their movement is

‘transmitted to the hook inside the ignition key

Q4inder through-the key interlock cable.

!l) Shift lever is in “P” position

a. When the shift lever is in the

“P” position.

j..the hook inside the ignition key cylinder is SO

i-.3positioned that it does not interfere with the’ .L.,projection of the rotor. Therefore, the rotor

:‘-can turn freely, allowing the ignition key to

be turned to the LOCK position and pulled

out there.

is, b. When the ignition key is turned to the LOCK

i,- c.position or it is pulled out, the projection of‘..the rotor moves to the position where it

prevents the hook inside the key cylinder

from moving. Therefore, even if an effort is

made to depress the push button of the shift

lever, the lock cam prevents the detent pin

from moving and the shift lever cannot be

shifted to the positions other than the “P”nnrit;nn

09*0090

(2) When shift lever is in position other than “P”position

When the shift lever is in the positions other

than the

“P” position (for example. “N” posi-

tion), the lock cam turns clockwise and held in

that

.state as shown in (2) of the illustration.

Therefore, the key interlock cable is in a stroked

state, with the hook inside the ignition key

cylinder inserted in the notch made in the

projection of the rotor. Thus, even if it is

attempted to return the ignition key to the

“LOCK” position, the hook prevents the rotor

from turning and the ignition key can be turned

only up to the

ACC position, making it impossi-

ble to pull out the key.

Page 255 of 391

iAUTOMATIC TRANSAXLE

- Transaxle Mechanism

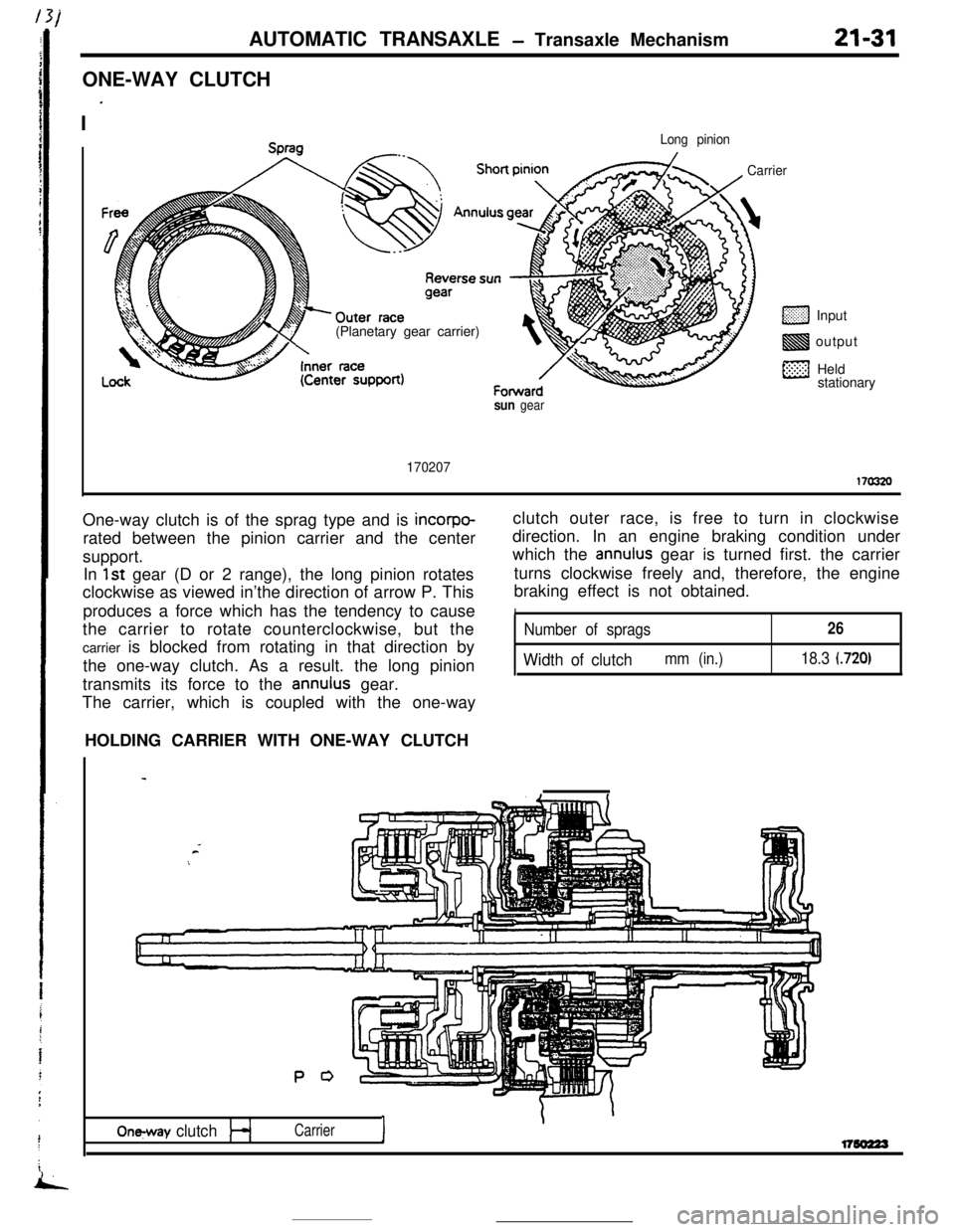

ONE-WAY CLUTCH

I

’

21-31

Long pinion(Planetary gear carrier)

CarrierInput

output

Held

stationary

sun gear

170207170320One-way clutch is of the sprag type and is

incorpo-rated between the pinion carrier and the center

support.

In

1st gear (D or 2 range), the long pinion rotates

clockwise as viewed in’the direction of arrow P. This

produces a force which has the tendency to cause

the carrier to rotate counterclockwise, but the

carrier is blocked from rotating in that direction by

the one-way clutch. As a result. the long pinion

transmits its force to the

annulus gear.

The carrier, which is coupled with the one-wayclutch outer race, is free to turn in clockwise

direction. In an engine braking condition under

which the

annulus gear is turned first. the carrier

turns clockwise freely and, therefore, the engine

braking effect is not obtained.

INumber of sprags26

Width of clutchmm (in.)18.3 (720)HOLDING CARRIER WITH ONE-WAY CLUTCH

P 0

On-y clutchI

\Carrierl7so223

Page 257 of 391

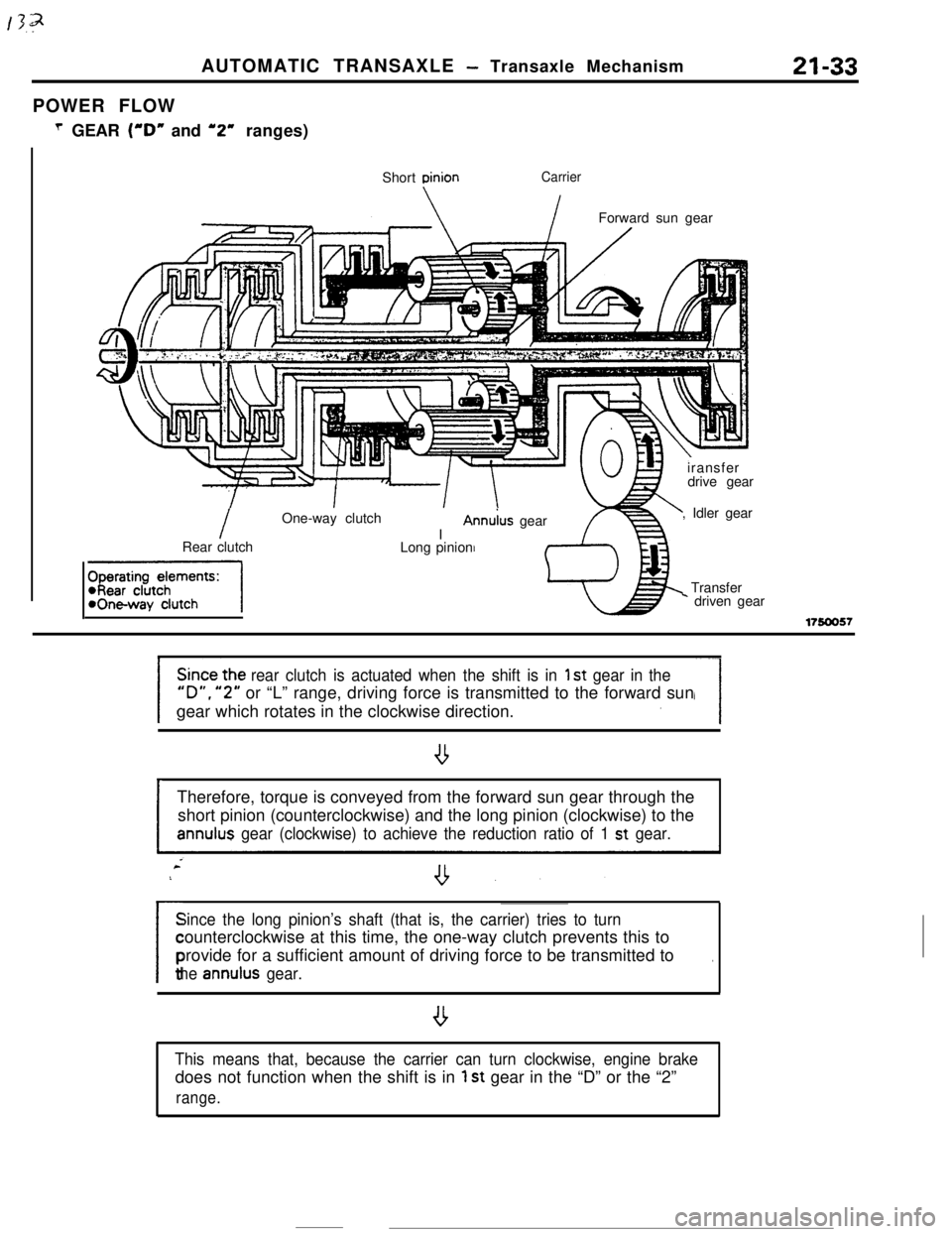

AUTOMATIC TRANSAXLE - Transaxle Mechanism21-33

POWER FLOW

T GEAR (“D” and ‘2” ranges)

Short

DinionCarrier

IForward sun gear

IOne-way clutch

IAnn&s gear

Rear clutch

-1Long pinioniransfer

drive gear

, Idler gear

Transfer* driven gear

17!50057

rear clutch is actuated when the shift is in 1 st gear in the

“D”. “2” or “L” range, driving force is transmitted to the forward sun

gear which rotates in the clockwise direction.

ITherefore, torque is conveyed from the forward sun gear through the

short pinion (counterclockwise) and the long pinion (clockwise) to theannulus gear (clockwise) to achieve the reduction ratio of 1 st gear.

Since the long pinion’s shaft (that is, the carrier) tries to turn

/counterclockwise at this time, the one-way clutch prevents this to

provide for a sufficient amount of driving force to be transmitted to

.

the annulus gear.

,

This means that, because the carrier can turn clockwise, engine brakedoes not function when the shift is in

1 st gear in the “D” or the “2”

range.

Page 259 of 391

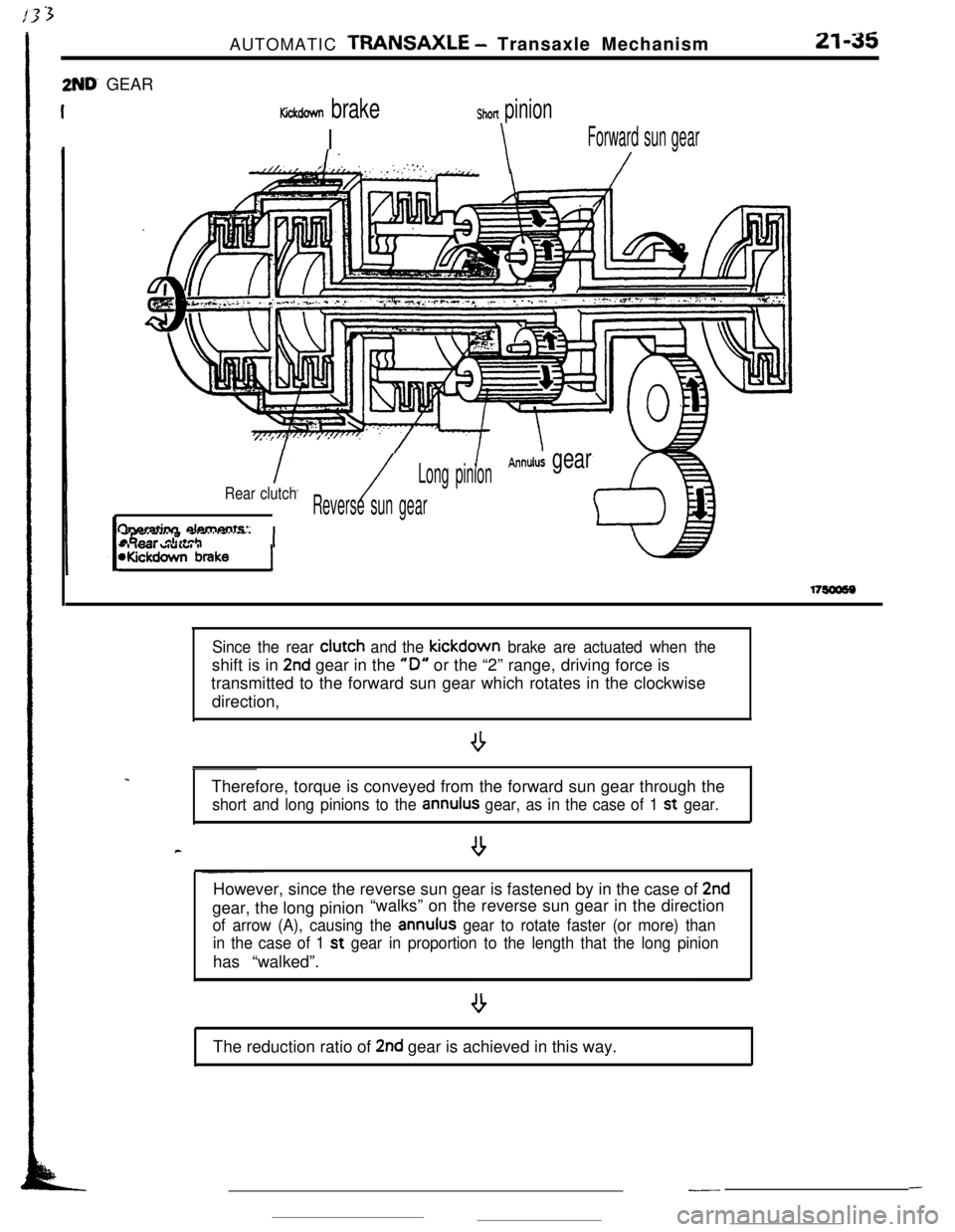

2ND’ GEARAUTOMATIC

TRANSAXLE - Transaxle Mechanism21-35

Kickdown brake

I

Shon pinion

\Forward sun gear

1.//LT.//. , ,’ .‘,,i.:,;:.:‘.,.‘,\/

/

Annulus gearLong pinion

Rear clutch/Reverse sun gear

fharatinn damants:

-, IWI WUIUI IWickdown brakeI

.

c

Since the rear clutch and the kickdown brake are actuated when theshift is in

2nd gear in the “0” or the “2” range, driving force is

transmitted to the forward sun gear which rotates in the clockwise

direction,

Therefore, torque is conveyed from the forward sun gear through the

short and long pinions to the annulus gear, as in the case of 1 st gear.

--However, since the reverse sun gear is fastened by in the case of

2ndgear, the long pinion“walks” on the reverse sun gear in the direction

of arrow (A), causing the annulus gear to rotate faster (or more) than

in the case of 1 st

gear in proportion to the length that the long pinionhas “walked”.

The reduction ratio of

2nd gear is achieved in this way.

---

Page 262 of 391

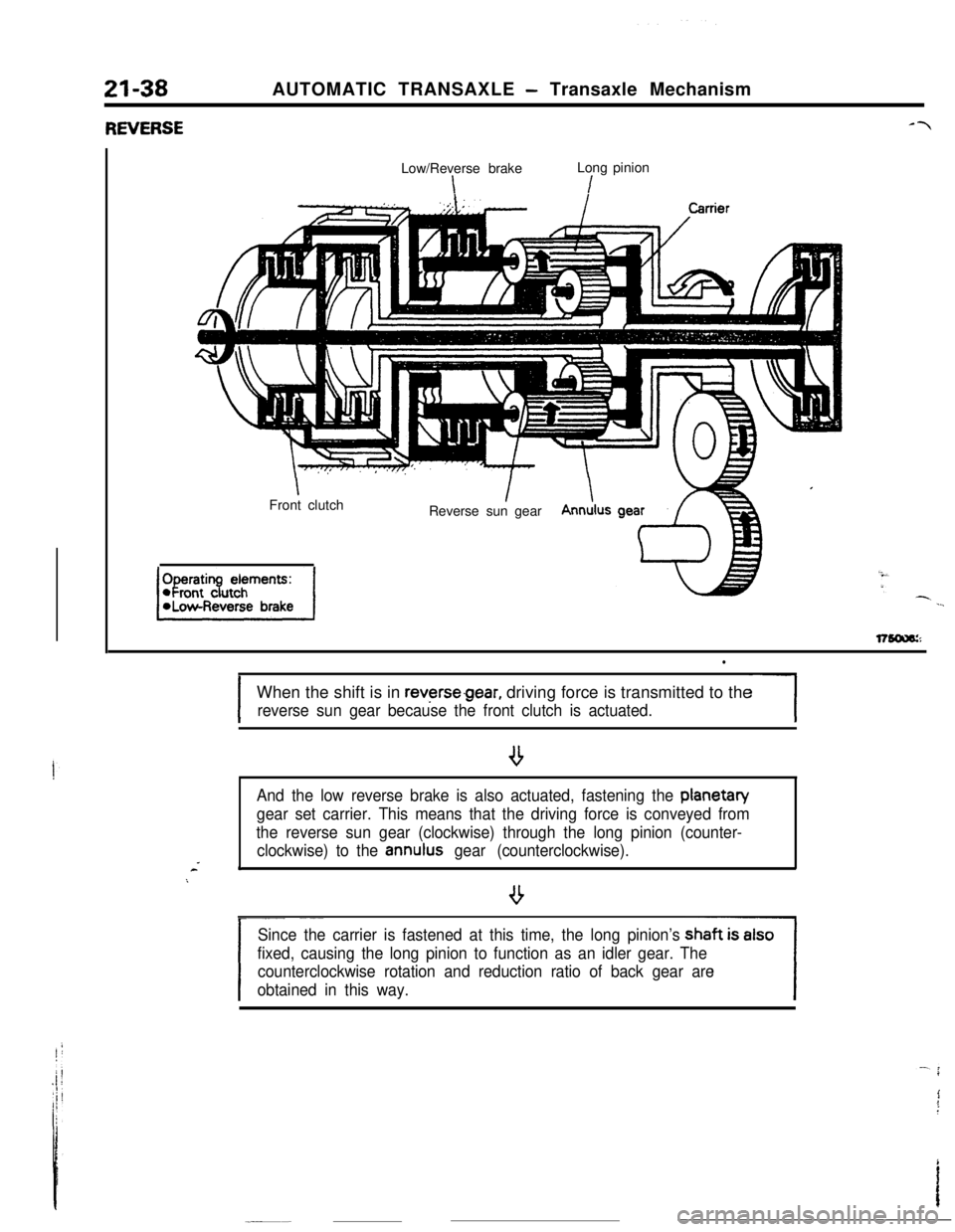

21-38RNERSEAUTOMATIC TRANSAXLE - Transaxle Mechanism

Low/Reverse brakeLong pinion

\I

IFront clutchIReverse sun gearIAnnulus

l

IWhen the shift is in

reverse.gear, driving force is transmitted to the

reverse sun gear because the front clutch is actuated.-1

And the low reverse brake is also actuated, fastening the planetan/

gear set carrier. This means that the driving force is conveyed from

the reverse sun gear (clockwise) through the long pinion (counter-

clockwise) to the

annulus gear (counterclockwise).*

/

- ~~_~

Since the carrier is fastened at this time, the long pinion’s

fixed, causing the long pinion to function as an idler gear. The

counterclockwise rotation and reduction ratio of back gear are

obtained in this way.