compression ratio MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 18 of 391

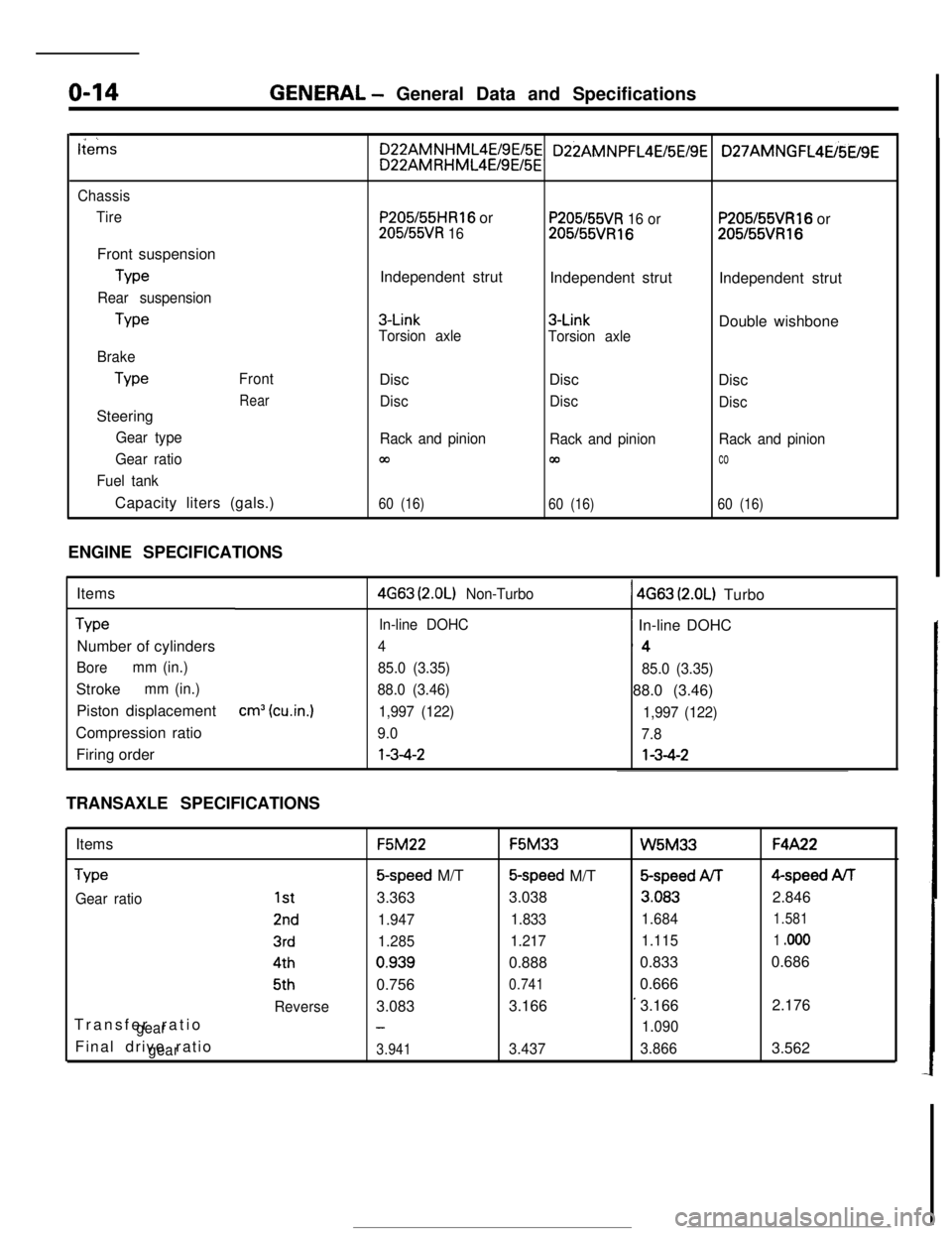

o-14GENERAL - General Data and Specifications

tiems

Chassis

TireFront suspension

Type

Rear suspensionType

Brake

TypeFront

RearSteering

Gear type

Gear ratio

Fuel tankCapacity liters (gals.)

P205/55HR16 or

205l55VR 16Independent strut

3-Link

Torsion axleDisc

Disc

Rack and pinion

m

60 (16)

P205/55VR 16 or205155VR16Independent strut

3-Link

Torsion axleDisc

Disc

Rack and pinion

00

60 (16)

P205155VR16 or205155VR16Independent strut

Double wishbone

Disc

Disc

Rack and pinion

co

60 (16)ENGINE SPECIFICATIONS

Items

TypeNumber of cylinders

Boremm (in.)Stroke

mm (in.)Piston displacement

Compression ratio

Firing order

cm3 (cu.in.)

4G63 (2.OL) Non-Turbo1 4663 (2.OL) Turbo

In-line DOHC~ In-line DOHC

4‘4

85.0 (3.35)

85.0 (3.35)

88.0 (3.46)88.0 (3.46)

1,997 (122)

1,997 (122)

9.0

7.8l-3-4-2l-3-4-2

TRANSAXLE SPECIFICATIONS

Items

Type

Gear ratioTransfer ratio

gearFinal drive ratio

gear

1st

2nd

3rd4th5th

ReverseF5M22F5M33

W5M33F4A22

5-speed M/T5-speed M/T&speed ArF4-speed AiT

3.3633.038

3.0832.846

1.9471.8331.6841.581

1.2851.2171.1151 .ooo0.9390.8880.8330.686

0.756

0.7410.666

3.0833.166

’3.1662.176

-1.090

3.9413.4373.8663.562

Page 87 of 391

=--Y

jl

1 /

i "

_. ---“._ _ _ ._ ..-..+_LI_y_--- -

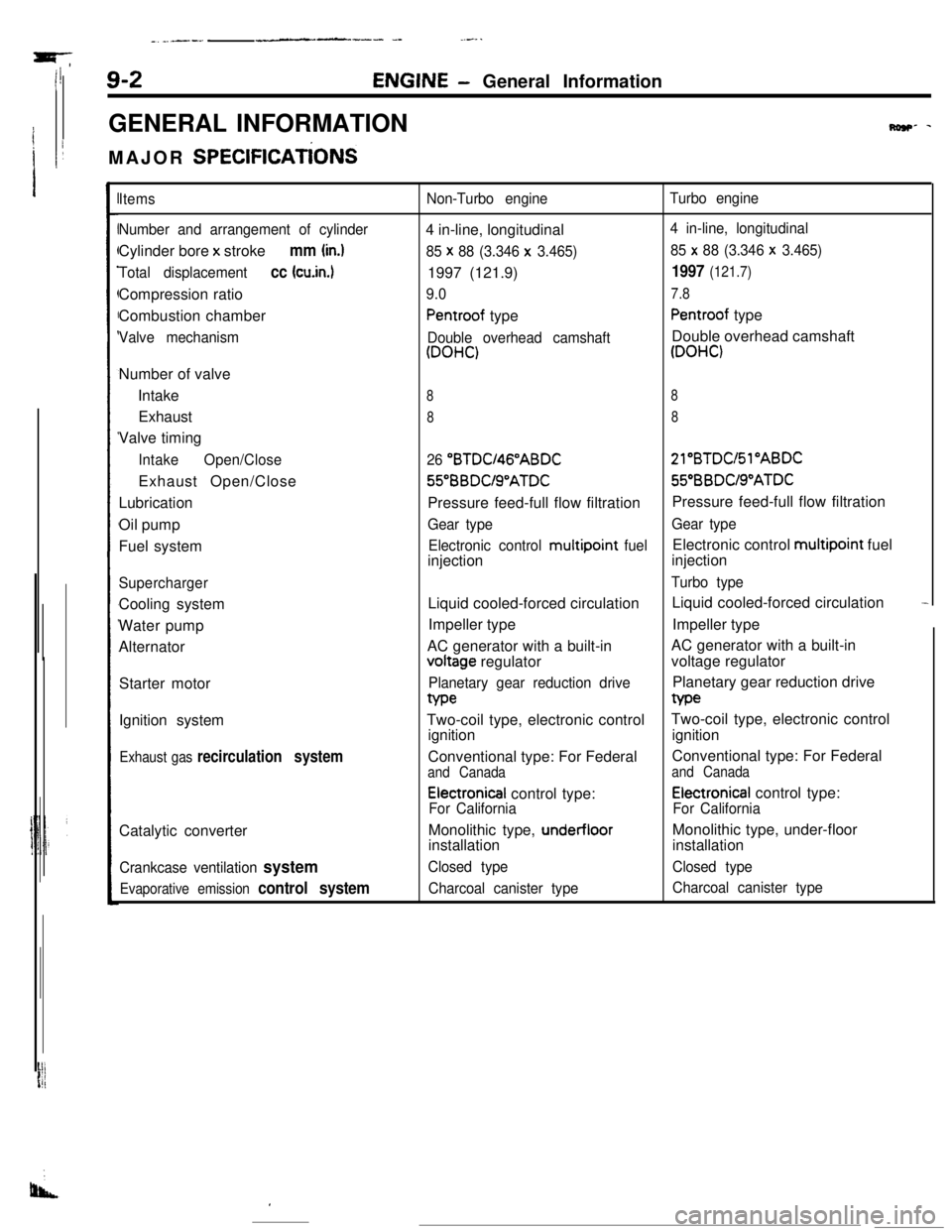

9-2ENGINE- General Information

GENERAL INFORMATION

MAJOR

SPEClFlCATiONS

Row- -

Items

Number and arrangement of cylinderCylinder bore x stroke

mm (in.)

Total displacementcc (cu.in.1Compression ratio

Combustion chamber

Valve mechanismNumber of valve

Intake

Exhaust

Valve timing

IntakeOpen/CloseExhaust Open/Close

Lubrication

Oil pump

Fuel system

SuperchargerCooling system

Water pump

Alternator

Starter motor

Ignition system

Exhaust gas recirculation systemCatalytic converter

Crankcase ventilation system

Evaporative emission control system

Non-Turbo engineTurbo engine4 in-line, longitudinal

4 in-line, longitudinal

85 x

88 (3.346 x 3.465)85 x 88 (3.346 x 3.465)1997 (121.9)

1997 (121.7)

9.07.8

Pentroof typePentroof type

Double overhead camshaftDouble overhead camshaft

(DOHC)(DOHC)

88

88

26 “BTDU46”ABDC21”BTDC/Sl”ABDC56BBDUS”ATDC55”BBDUS”ATDC

Pressure feed-full flow filtrationPressure feed-full flow filtration

Gear typeGear type

Electronic control multipoint

fuelElectronic control multipoint fuel

injectioninjection

Turbo typeLiquid cooled-forced circulationLiquid cooled-forced circulation

-Impeller typeImpeller type

AC generator with a built-involtage regulatorAC generator with a built-in

voltage regulator

Planetary gear reduction drivePlanetary gear reduction drivetype

Two-coil type, electronic controlTwo-coil type, electronic control

ignitionignition

Conventional type: For FederalConventional type: For Federal

and Canadaand Canada

Electronical control type:Electronical control type:

For CaliforniaFor CaliforniaMonolithic type,

under-floorMonolithic type, under-floor

installationinstallation

Closed typeClosed type

Charcoal canister typeCharcoal canister type

I

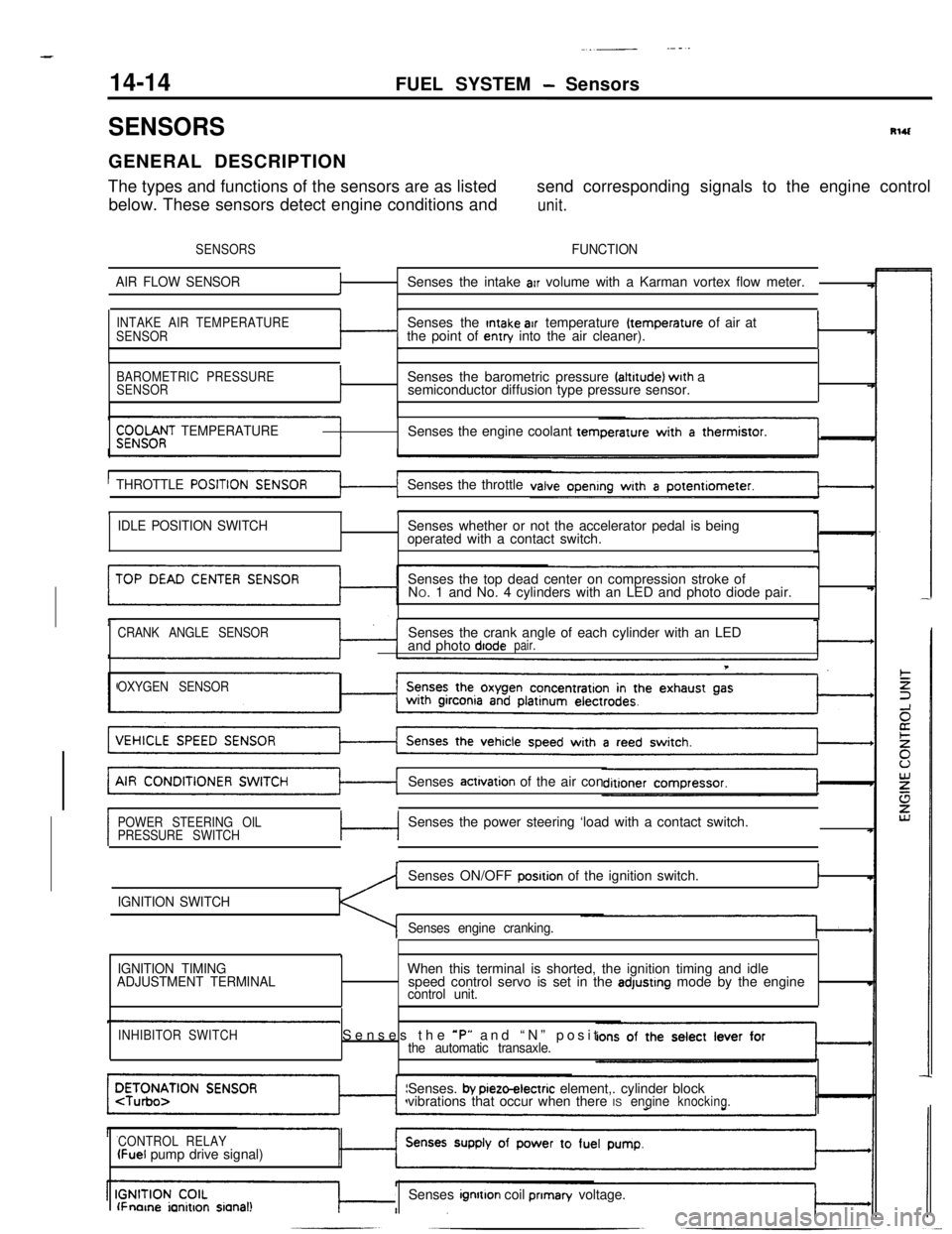

Page 126 of 391

14-14

.._~- ---.FUEL SYSTEM

- Sensors

SENSORSRlUGENERAL DESCRIPTION

The types and functions of the sensors are as listedsend corresponding signals to the engine control

below. These sensors detect engine conditions and

unit.

SENSORSFUNCTION

AIR FLOW SENSOR

fSenses the intake arr volume with a Karman vortex flow meter.

INTAKE AIR TEMPERATURE

SENSORSenses the Intake air temperature (temperature of air at

the point of entry into the air cleaner).I

BAROMETRIC PRESSURE

SENSORISenses the barometric pressure faltrtude) wrth a

semiconductor diffusion type pressure sensor.

$;;OOf;T TEMPERATURESenses the engine coolant tern

THROTTLE

POSITISenses the throttle

tI

IDLE POSITION SWITCHSenses whether or not the accelerator pedal is being

operated with a contact switch.

Senses the top dead center on compression stroke of

NO. 1 and No. 4 cylinders with an LED and photo diode pair.

CRANK ANGLE SENSORSenses the crank angle of each cylinder with an LED

and photo diodepair.

T

OXYGEN SENSORSenses

actrvation of the air con

POWER STEERING OIL

PRESSURE SWITCHc-lSenses the power steering ‘load with a contact switch.

IGNITION SWITCHSenses ON/OFF

posrtion of the ignition switch.I

Senses engine cranking.

,

IGNITION TIMING

ADJUSTMENT TERMINALWhen this terminal is shorted, the ignition timing and idle

speed control servo is set in the adjustrng mode by the enginecontrol unit.

INHIBITOR SWITCHSenses the *P” and “N” positthe automatic transaxle.Senses.

by pieto-electric element,. cylinder block

vibrations that occur when there ISengineknocking.

CONTROL RELAY

(Fuel pump drive signal)

lFnorne ianitron sianal!Senses ignrtton coil prIman/ voltage.

Page 148 of 391

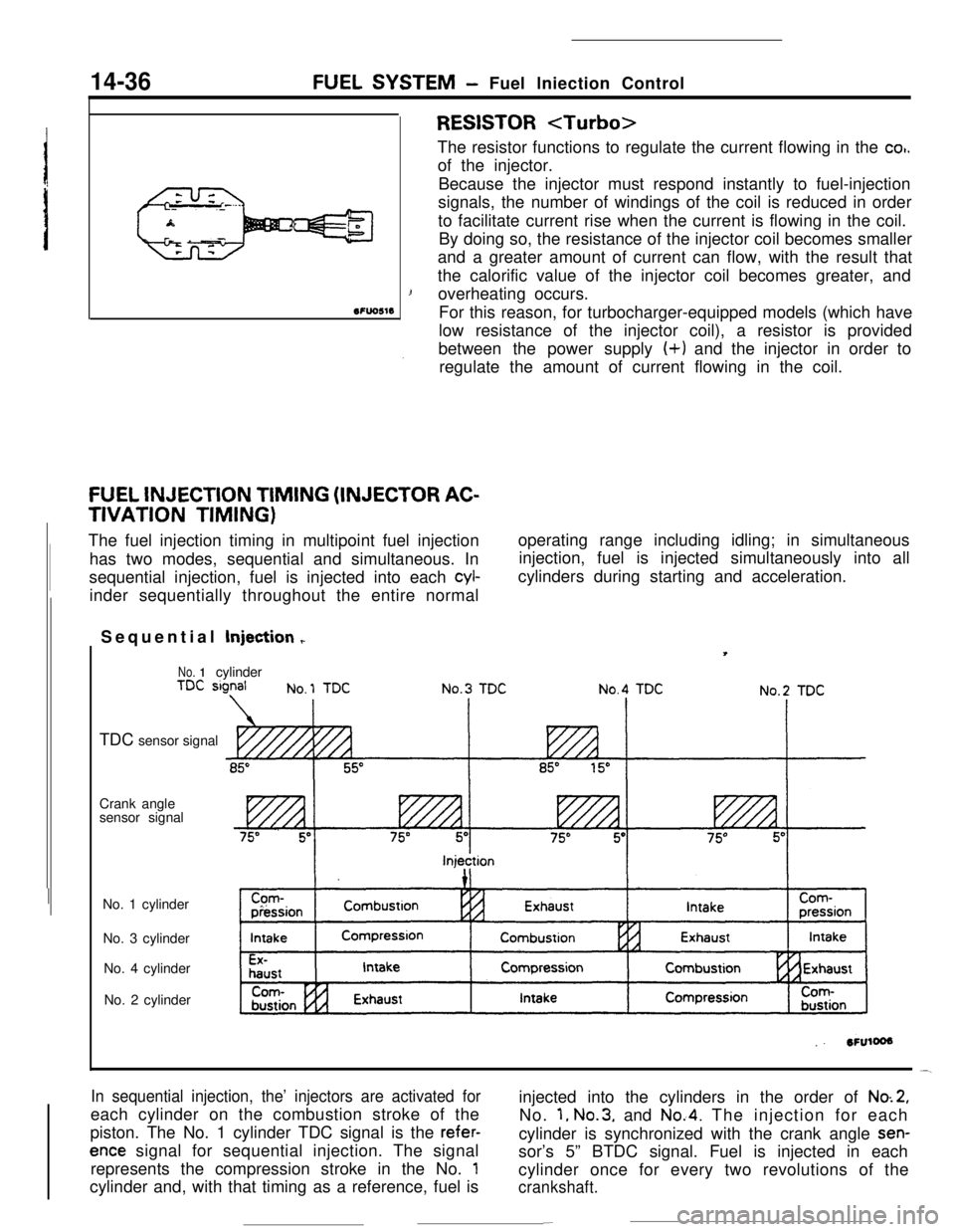

14-36FUEL SYSTEM- Fuel lniection Control

SFUOSlS

RESISTOR

co,.of the injector.

Because the injector must respond instantly to fuel-injection

signals, the number of windings of the coil is reduced in order

to facilitate current rise when the current is flowing in the coil.

By doing so, the resistance of the injector coil becomes smaller

and a greater amount of current can flow, with the result that

the calorific value of the injector coil becomes greater, and

1overheating occurs.

For this reason, for turbocharger-equipped models (which have

low resistance of the injector coil), a resistor is provided

between the power supply (+) and the injector in order to

regulate the amount of current flowing in the coil.

FUEL INJECTION TIMING (INJECTOR AC-

TIVATION TIMING)

The fuel injection timing in multipoint fuel injection

has two modes, sequential and simultaneous. In

sequential injection, fuel is injected into each

cyl-inder sequentially throughout the entire normaloperating range including idling; in simultaneous

injection, fuel is injected simultaneously into all

cylinders during starting and acceleration.

Sequential Injection

r

No. 1cylinder

TDC sensor signal

Crank angle

sensor signal

No. 1 cylinder

No. 3 cylinder

No. 4 cylinder

No. 2 cylinder

In sequential injection, the’ injectors are activated foreach cylinder on the combustion stroke of the

piston. The No. 1 cylinder TDC signal is the

refer-

ence signal for sequential injection. The signal

represents the compression stroke in the No.

1cylinder and, with that timing as a reference, fuel isinjected into the cylinders in the order of

No.2,No.

1, No.3, and No.4. The injection for each

cylinder is synchronized with the crank angle

sen-sor’s 5” BTDC signal. Fuel is injected in each

cylinder once for every two revolutions of the

crankshaft.

-