crank MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 9 of 391

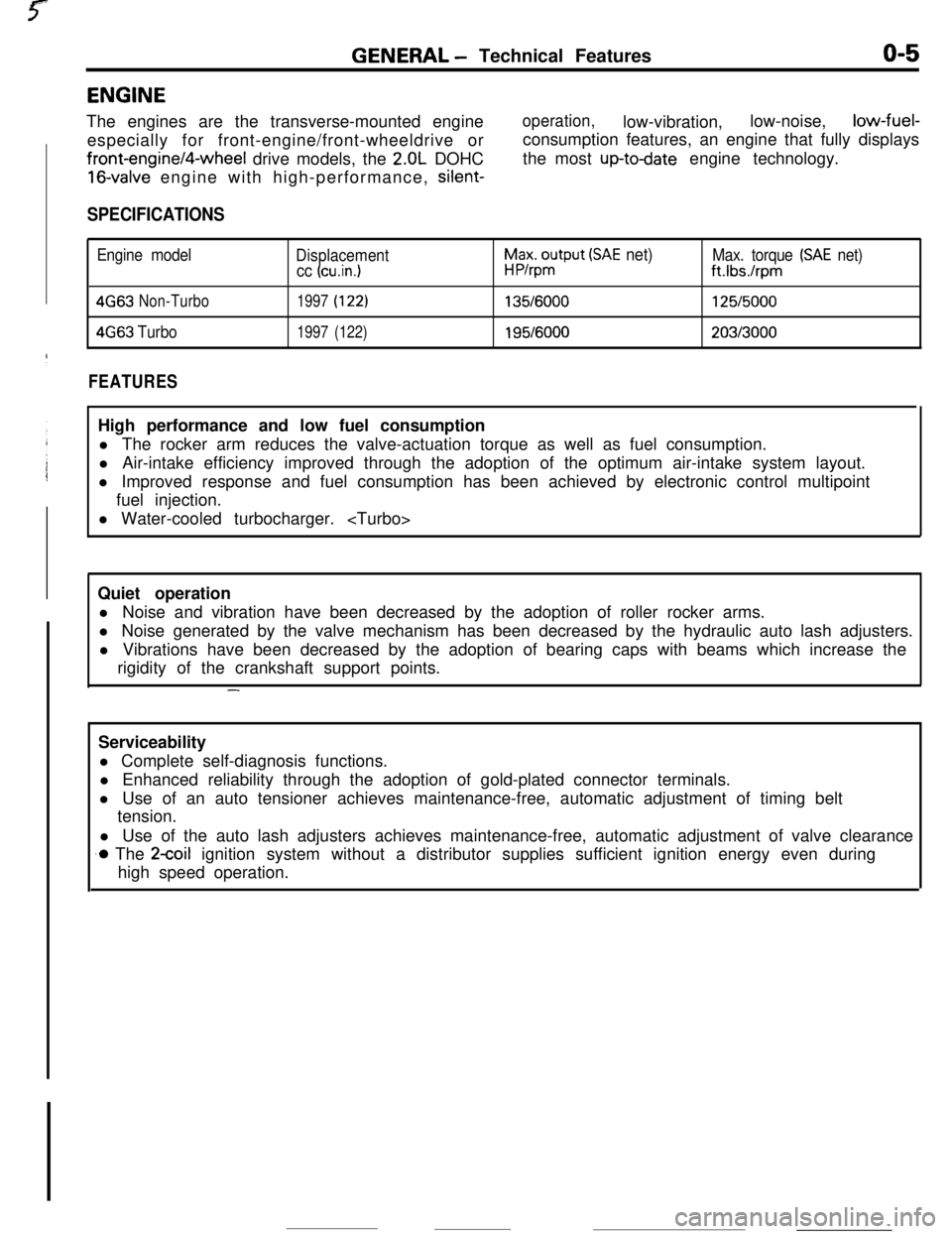

GENERAL - Technical Featureso-5ENGINE

The engines are the transverse-mounted engine

especially for front-engine/front-wheeldrive orfront-engine/4-wheel drive models, the

2.OL DOHC

16-valve engine with high-performance, silent-

operation,low-vibration,low-noise,low-fuel-

consumption features, an engine that fully displays

the most

up-todate engine technology.

SPECIFICATIONS

Engine model

Displacement

cc (cu.in.1

h$xo$put (SAE net)Max. torque (SAE net)

ft.Ibs./rpm

4G63Non-Turbo1997(122)135/6000125/5000

4663Turbo1997(122)195/6000203/3000

FEATURESHigh performance and low fuel consumption

l The rocker arm reduces the valve-actuation torque as well as fuel consumption.

l Air-intake efficiency improved through the adoption of the optimum air-intake system layout.

l Improved response and fuel consumption has been achieved by electronic control multipoint

fuel injection.

l Water-cooled turbocharger.

Quiet operation

l Noise and vibration have been decreased by the adoption of roller rocker arms.

l Noise generated by the valve mechanism has been decreased by the hydraulic auto lash adjusters.

l Vibrations have been decreased by the adoption of bearing caps with beams which increase the

rigidity of the crankshaft support points.

-Serviceability

l Complete self-diagnosis functions.

l Enhanced reliability through the adoption of gold-plated connector terminals.

l Use of an auto tensioner achieves maintenance-free, automatic adjustment of timing belt

tension.

l Use of the auto lash adjusters achieves maintenance-free, automatic adjustment of valve clearance

.o The 2coil ignition system without a distributor supplies sufficient ignition energy even during

high speed operation.

Page 10 of 391

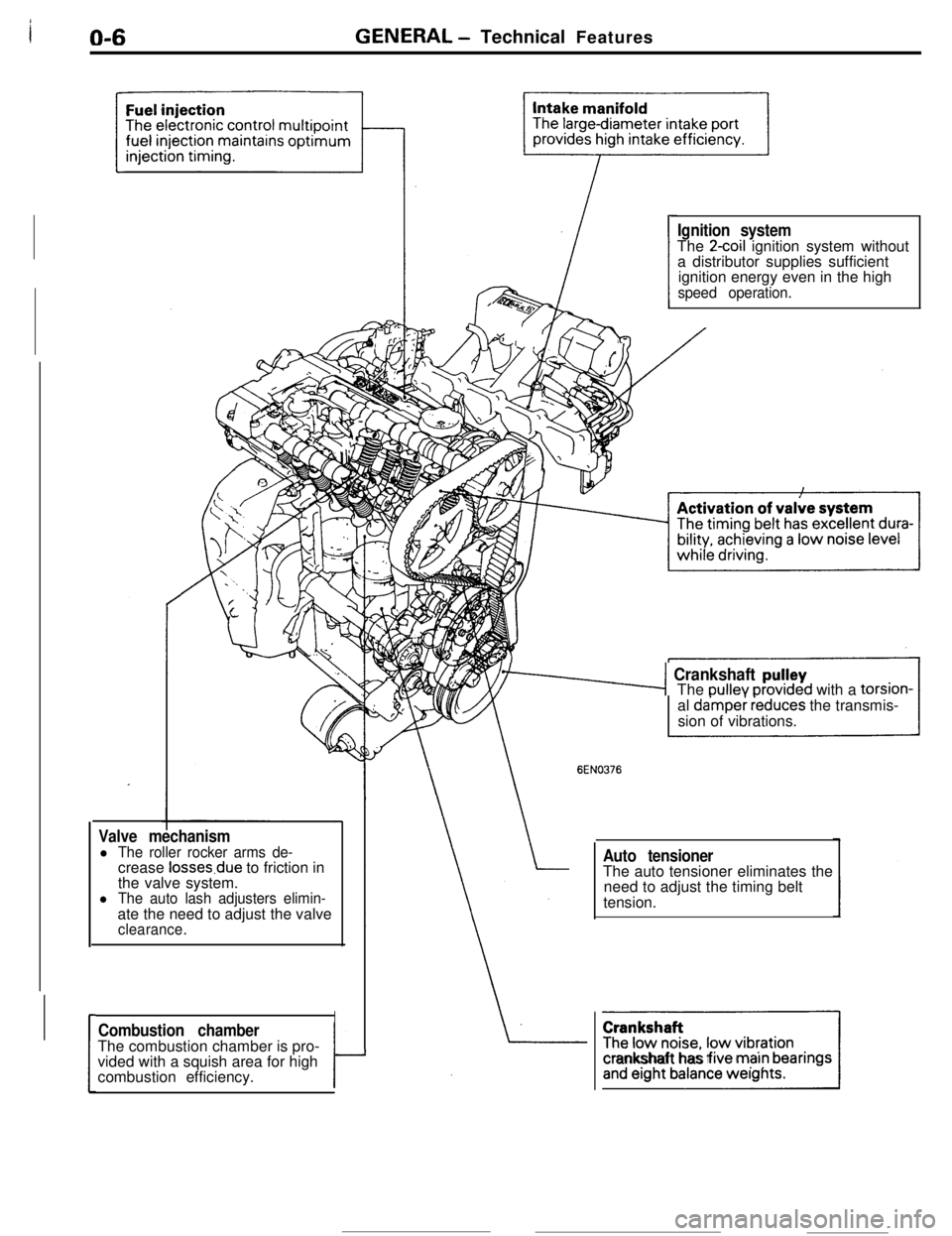

O-6GENERAL - Technical Features

Valve mechanisml The roller rocker arms de-crease losses.due to friction in

the valve system.

l The auto lash adjusters elimin-ate the need to adjust the valve

clearance.

ICombustion chamberThe combustion chamber is pro-

vided with a squish area for high

combustion efficiency.

tJ

Ignition systemThe 2coil ignition system without

a distributor supplies sufficient

ignition energy even in the high

speed operation.

76-4 Crankshaft pu!leyThe oullev orovrded with a torsion-

al

da’mper ieduces the transmis-

sion of vibrations.

EN0376

Auto tensionerThe auto tensioner eliminates the

need to adjust the timing belt

tension.

]Icrankshaft has five marn bearings

Page 59 of 391

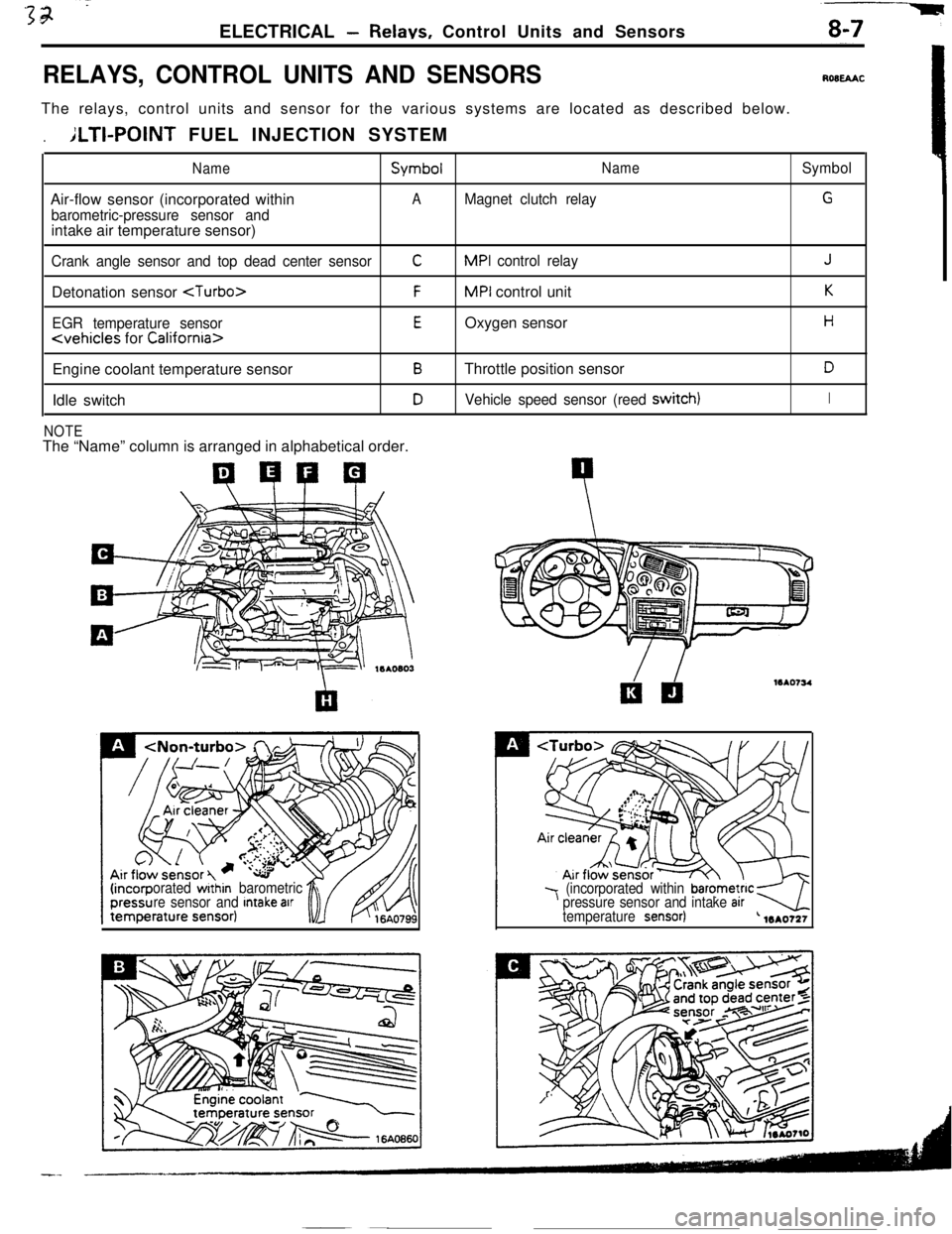

ELECTRICAL -Relavs, Control Units and Sensors

RELAYS, CONTROL UNITS AND SENSORSROBEAACThe relays, control units and sensor for the various systems are located as described below.

.ILTI-POINT FUEL INJECTION SYSTEM

NameSymbolNameSymbolAir-flow sensor (incorporated within

AMagnet clutch relayG

barometric-pressure sensor andintake air temperature sensor)

Crank angle sensor and top dead center sensorCMPI control relayJDetonation sensor

EGR temperature sensorEOxygen sensorH

Engine coolant temperature sensor

BThrottle position sensorDIdle switch

DVehicle speed sensor (reed switch)I

NOTEThe “Name” column is arranged in alphabetical order.

orated within barometric

re sensor and Intake arr7 (incorporated within barometnc kpressure sensor and intake arrtemperature sensor)-4L 1mo721

Page 70 of 391

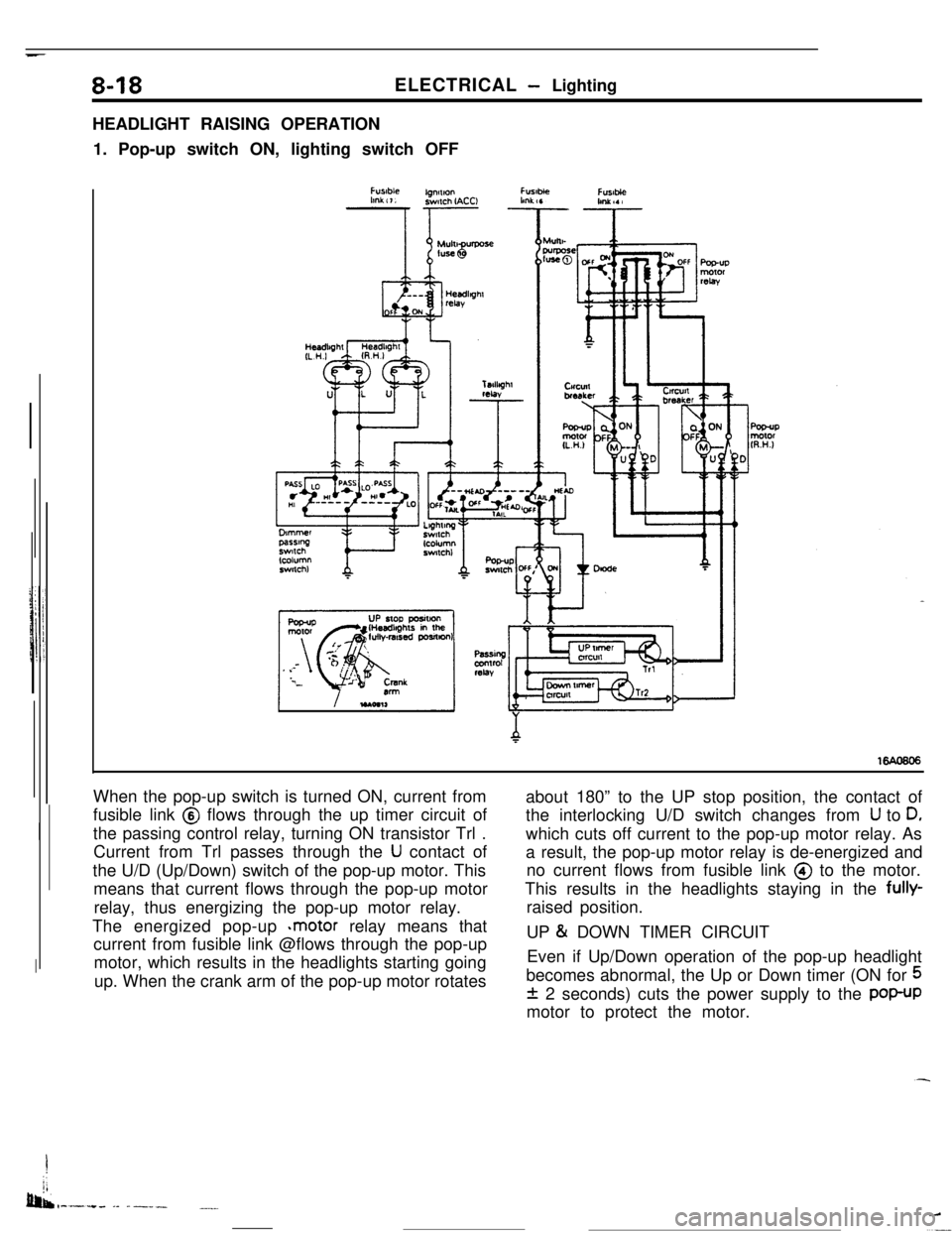

8-18ELECTRICAL - Lighting

HEADLIGHT RAISING OPERATION

1. Pop-up switch ON, lighting switch OFF

When the pop-up switch is turned ON, current from

fusible link @ flows through the up timer circuit of

the passing control relay, turning ON transistor Trl .

Current from Trl passes through the

U contact of

the U/D (Up/Down) switch of the pop-up motor. This

means that current flows through the pop-up motor

relay, thus energizing the pop-up motor relay.

The energized pop-up

*motor relay means that

current from fusible link @flows through the pop-up

motor, which results in the headlights starting going

up. When the crank arm of the pop-up motor rotatesabout 180” to the UP stop position, the contact of

the interlocking U/D switch changes from

U to D,which cuts off current to the pop-up motor relay. As

a result, the pop-up motor relay is de-energized and

no current flows from fusible link @ to the motor.

This results in the headlights staying in the fully-

raised position.

UP

& DOWN TIMER CIRCUIT

Even if Up/Down operation of the pop-up headlight

becomes abnormal, the Up or Down timer (ON for

5

f 2 seconds) cuts the power supply to the POP-UPmotor to protect the motor.

I

jj

bib,-.-.+. -- ------.__

Page 72 of 391

_ -. _ -.__-ELECTRICAL

- Lighting

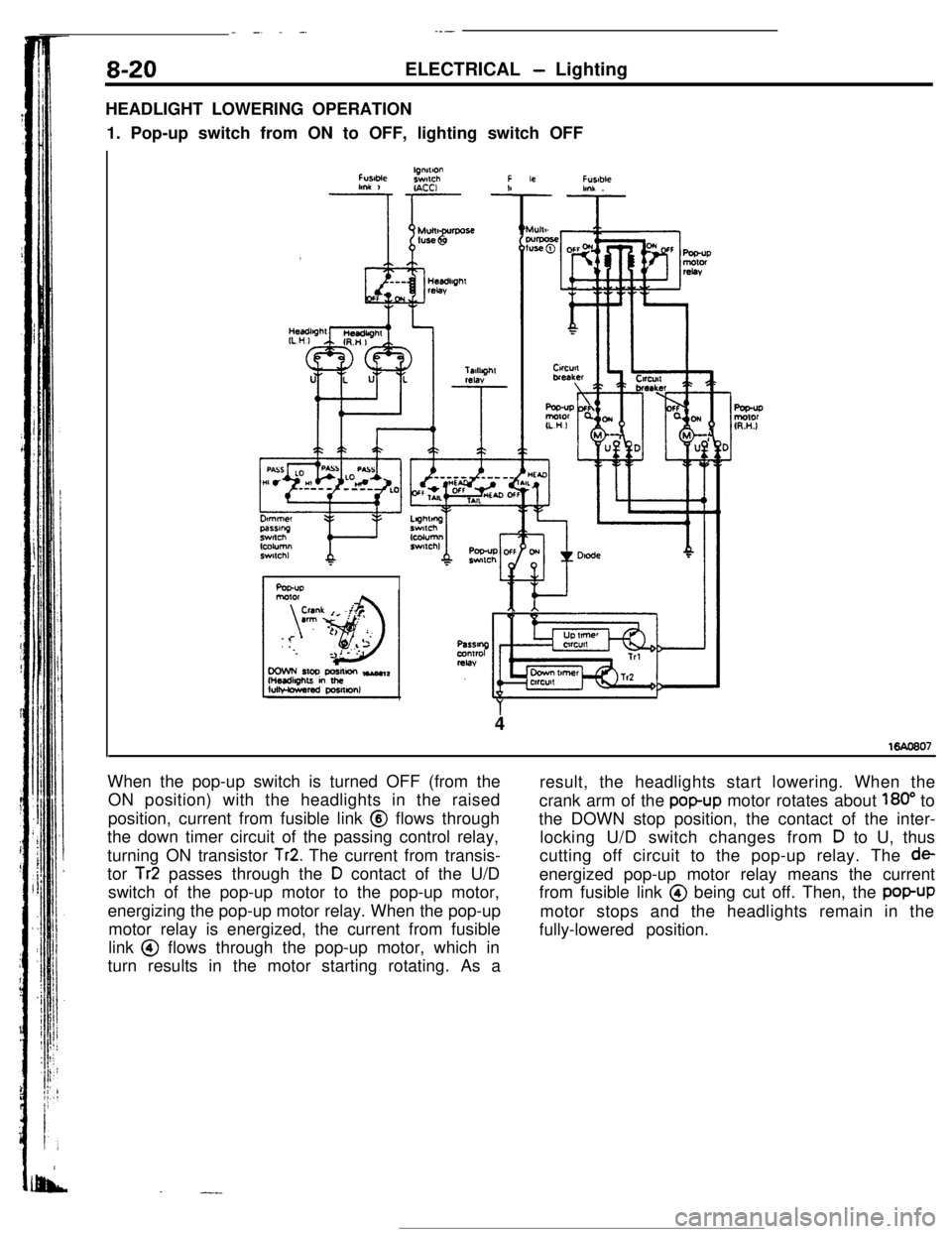

HEADLIGHT LOWERING OPERATION

1. Pop-up switch from ON to OFF, lighting switch OFF

FUslMelgnnlonswlchFlmk 1r- -!IACCI

Ar

Fusablehnk .

4

When the pop-up switch is turned OFF (from the

ON position) with the headlights in the raised

position, current from fusible link @ flows through

the down timer circuit of the passing control relay,

turning ON transistor

Tr2. The current from transis-

tor

Tr2 passes through the D contact of the U/D

switch of the pop-up motor to the pop-up motor,

energizing the pop-up motor relay. When the pop-up

motor relay is energized, the current from fusible

link @ flows through the pop-up motor, which in

turn results in the motor starting rotating. As a

.-.-result, the headlights start lowering. When the

crank arm of the

popup motor rotates about 180” to

the DOWN stop position, the contact of the inter-

locking U/D switch changes from

D to U, thus

cutting off circuit to the pop-up relay. The

deenergized pop-up motor relay means the current

from fusible link @ being cut off. Then, the

popUPmotor stops and the headlights remain in the

fully-lowered position.

Page 79 of 391

-----. _-- ___ELECTRICAL

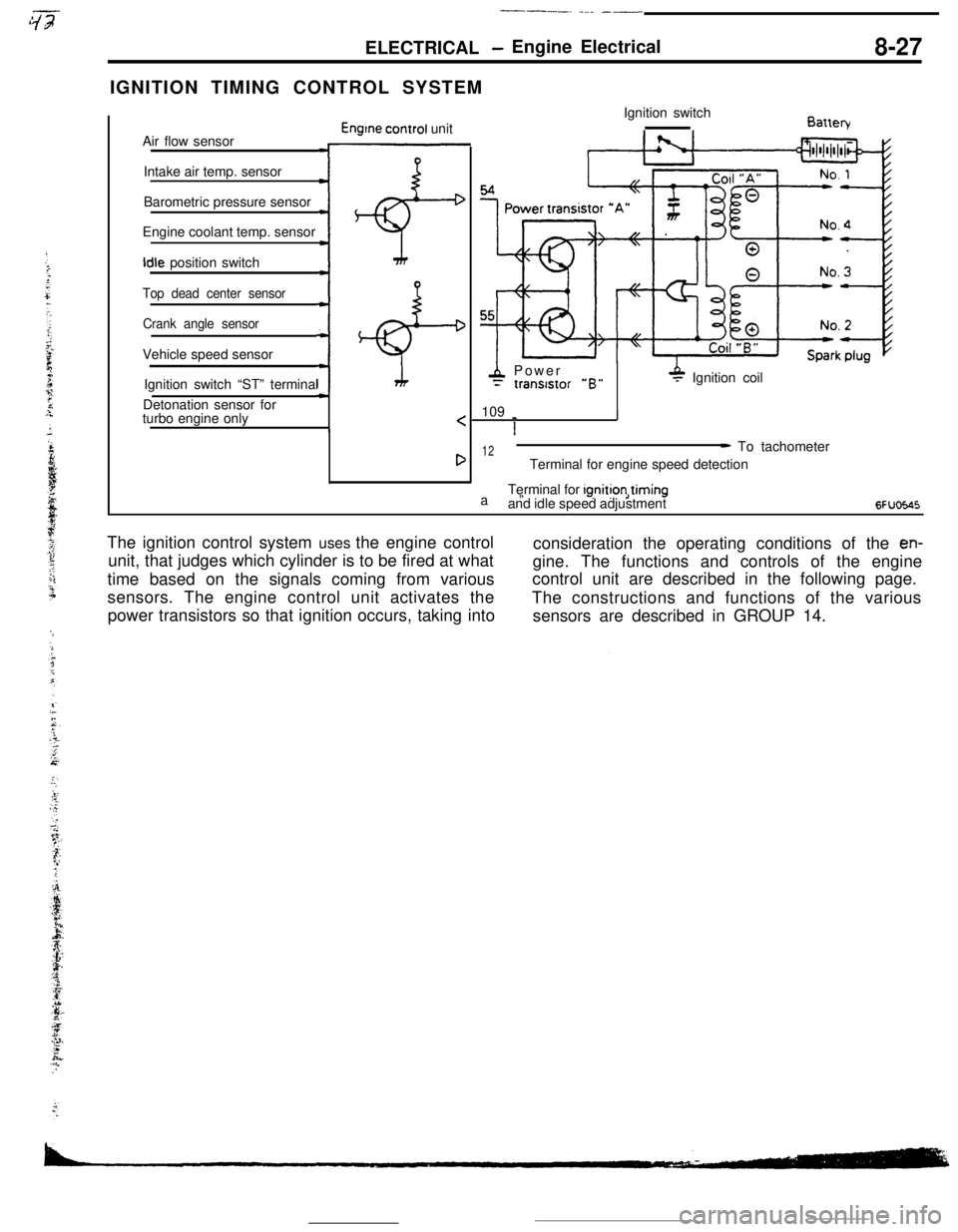

- Engine Electrical8-27IGNITION TIMING CONTROL SYSTEM

Air flow sensor

Engtne control unit

Intake air temp. sensor

Barometric pressure sensor

Engine coolant temp. sensorIdle position switch

:+

Top dead center sensor

Crank angle sensorVehicle speed sensor

;+Ignition switch “ST” terminal

Detonation sensor for

turbo engine only

4 Power= tranststor “B”P Ignition coil

109

_

I

1

12a”- To tachometer

Terminal for engine speed detection

Terminal for ignition,timing

and idle speed adjustment

6FUoE.45The ignition control system uses the engine control

consideration the operating conditions of the

en-unit, that judges which cylinder is to be fired at what

gine. The functions and controls of the engine

time based on the signals coming from variouscontrol unit are described in the following page.

sensors. The engine control unit activates the

The constructions and functions of the various

power transistors so that ignition occurs, taking into

sensors are described in GROUP 14.

Page 81 of 391

. ,-s- ,-T,“~:~y.“‘~...:tg==ELECTRICAL

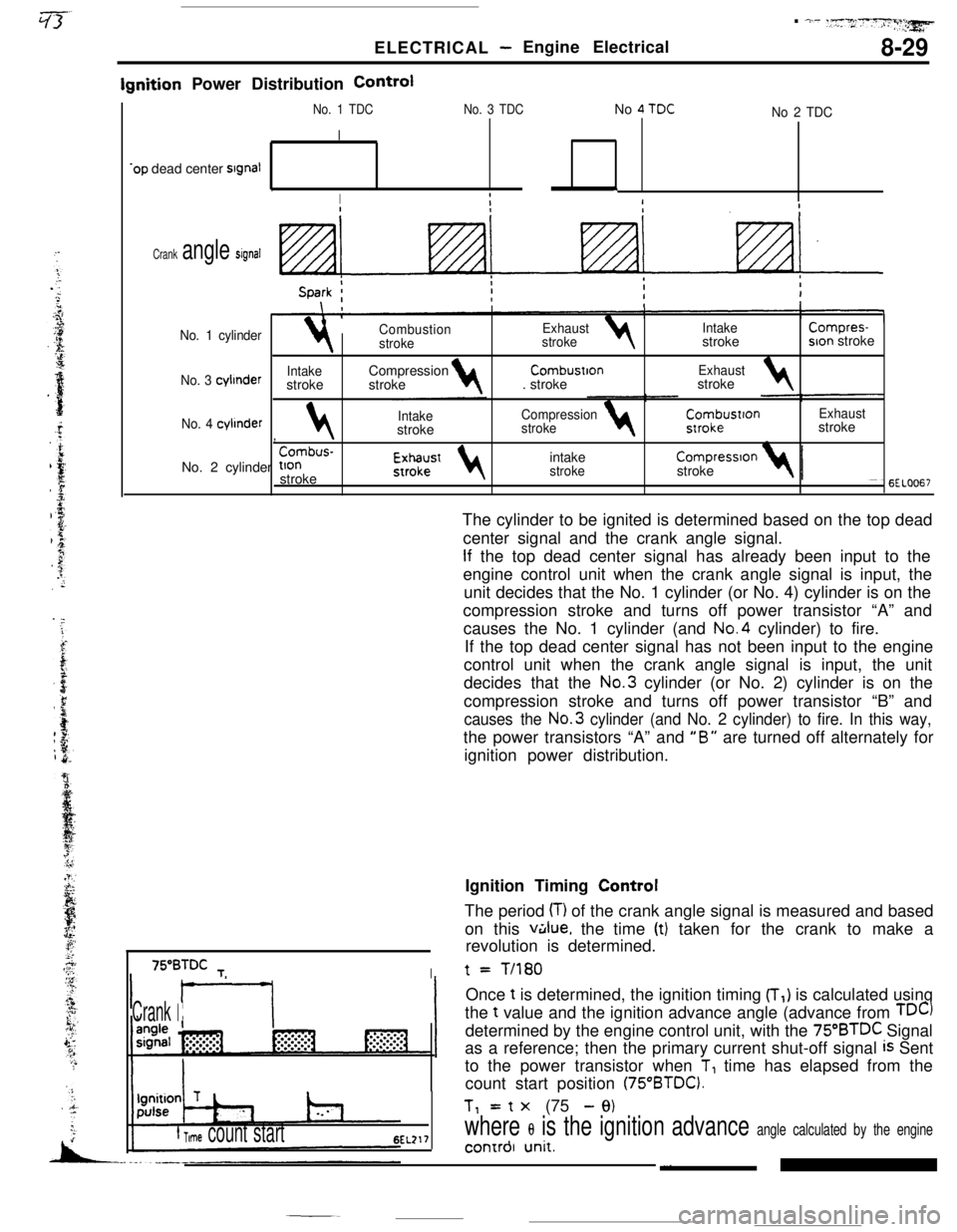

-Engine Electrical8-29Ignition Power Distribution Control

No. 1 TDC

I

No. 3 TDCNo 4TDCNo 2 TDC

‘op dead center signal,\

I1IIII

Crank angle signal

No. 1 cylinderCombustionExhaustIntakeCompres-

strokestrokestrokeslon stroke

IntakeCompression

t\

CombustionExhaust

No. 3 cyltnderstrokestroke. strokestroke

No. 4 cylinder, t\

IntakeCompressionstrokestroker$,mkbeustlonExhauststroke

Combus-No. 2 cylinder tlon

strokeintake

strokeCompresslon

stroke6EL0067

75”BTDC TI

Crank 1

f Time count start6EL217The cylinder to be ignited is determined based on the top dead

center signal and the crank angle signal.

If the top dead center signal has already been input to the

engine control unit when the crank angle signal is input, the

unit decides that the No. 1 cylinder (or No. 4) cylinder is on the

compression stroke and turns off power transistor “A” and

causes the No. 1 cylinder (and No.4 cylinder) to fire.

If the top dead center signal has not been input to the engine

control unit when the crank angle signal is input, the unit

decides that the No.3 cylinder (or No. 2) cylinder is on the

compression stroke and turns off power transistor “B” and

causes the No.3 cylinder (and No. 2 cylinder) to fire. In this way,the power transistors “A” and

“B” are turned off alternately for

ignition power distribution.t

= T/180Once

t is determined, the ignition timing (T,) is calculated using

the t value and the ignition advance angle (advance from

TDC)determined by the engine control unit, with the

75”BTDC Signal

as a reference; then the primary current shut-off signal

is Sent

to the power transistor when

T, time has elapsed from the

count start position

(75“BTDC).Tl= t

x (75 - 9)

where 8 is the ignition advance angle calculated by the engine_, ~4 -‘*Lonrrol unlr.Ignition Timing Control

The period

(T) of the crank angle signal is measured and based

on this

v&lue, the time (t) taken for the crank to make a

revolution is determined.

Page 82 of 391

8-30ELECTRICAL - Engine Electrical

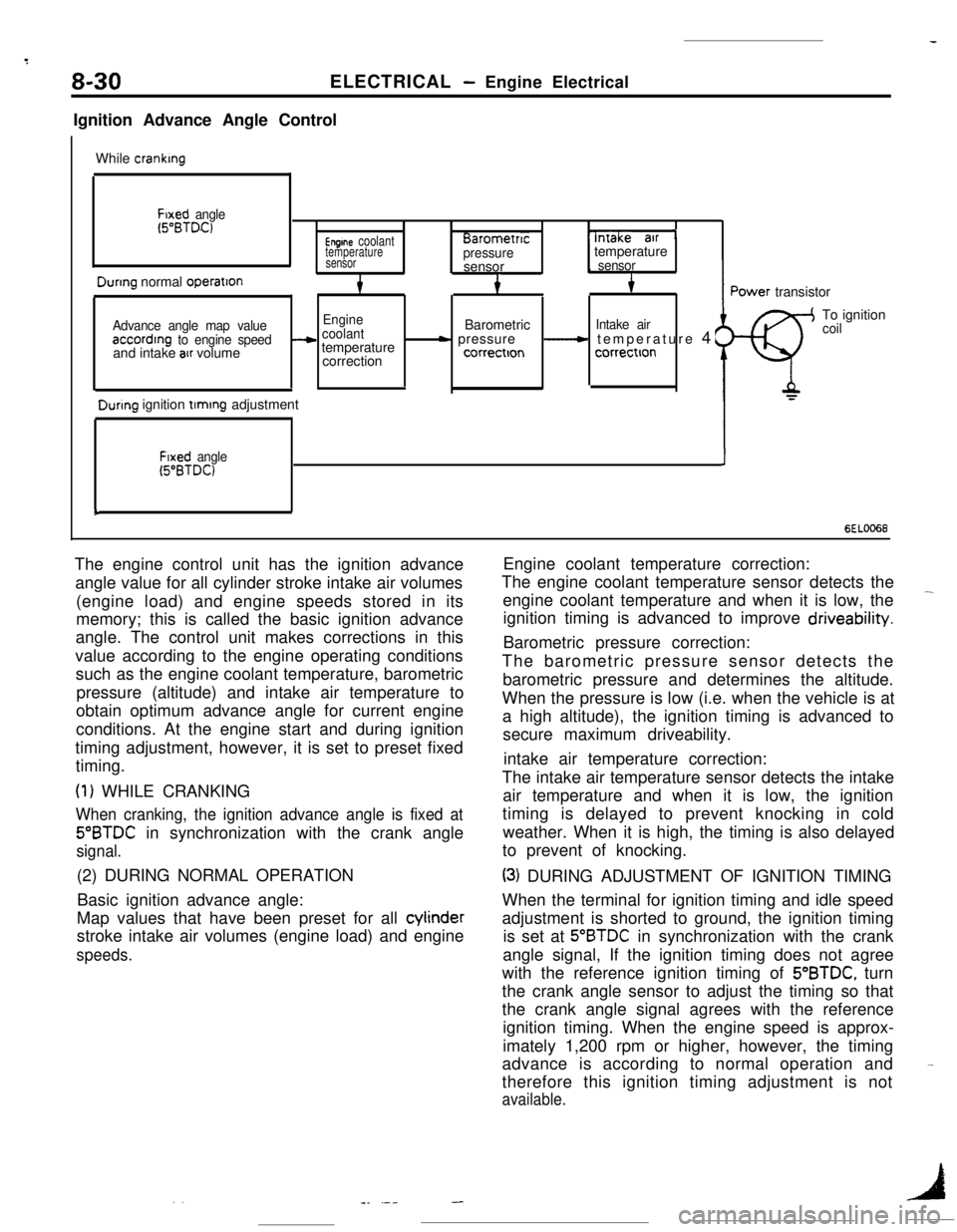

Ignition Advance Angle Control

While

cranking

Fixed angle(5”BTD.C)Engme coolantBarometnc‘-Intake air 1temperaturepressuretemperaturesensorsensor, sensor

Dunng normal operatlon4i+

Advance angle map valueEngine

coolantBarometricIntake airaccording to engine speed4and intake air volumetemperature- pressure__c temperature 4

correctioncorrectloncorrectton

Durtng ignition tlmmg adjustment

Fixed angle(5”BTDC)

c

=ower transistor

-$To ignition

coil

s

6EL0066The engine control unit has the ignition advance

angle value for all cylinder stroke intake air volumes

(engine load) and engine speeds stored in its

memory; this is called the basic ignition advance

angle. The control unit makes corrections in this

value according to the engine operating conditions

such as the engine coolant temperature, barometric

pressure (altitude) and intake air temperature to

obtain optimum advance angle for current engine

conditions. At the engine start and during ignition

timing adjustment, however, it is set to preset fixed

timing.

(1) WHILE CRANKING

When cranking, the ignition advance angle is fixed at

5”BTDC in synchronization with the crank angle

signal.(2) DURING NORMAL OPERATION

Basic ignition advance angle:

Map values that have been preset for all cylinder

stroke intake air volumes (engine load) and engine

speeds.Engine coolant temperature correction:

The engine coolant temperature sensor detects the

engine coolant temperature and when it is low, the

-ignition timing is advanced to improve driveability.

Barometric pressure correction:

The barometric pressure sensor detects the

barometric pressure and determines the altitude.

When the pressure is low (i.e. when the vehicle is at

a high altitude), the ignition timing is advanced to

secure maximum driveability.

intake air temperature correction:

The intake air temperature sensor detects the intake

air temperature and when it is low, the ignition

timing is delayed to prevent knocking in cold

weather. When it is high, the timing is also delayed

to prevent of knocking.

(3) DURING ADJUSTMENT OF IGNITION TIMING

When the terminal for ignition timing and idle speed

adjustment is shorted to ground, the ignition timing

is set at

5”BTDC in synchronization with the crank

angle signal, If the ignition timing does not agree

with the reference ignition timing of 5’BTDC, turn

the crank angle sensor to adjust the timing so that

the crank angle signal agrees with the reference

ignition timing. When the engine speed is approx-

imately 1,200 rpm or higher, however, the timing

advance is according to normal operation and

therefore this ignition timing adjustment is not

available.

-

. .1-_ .---

Page 83 of 391

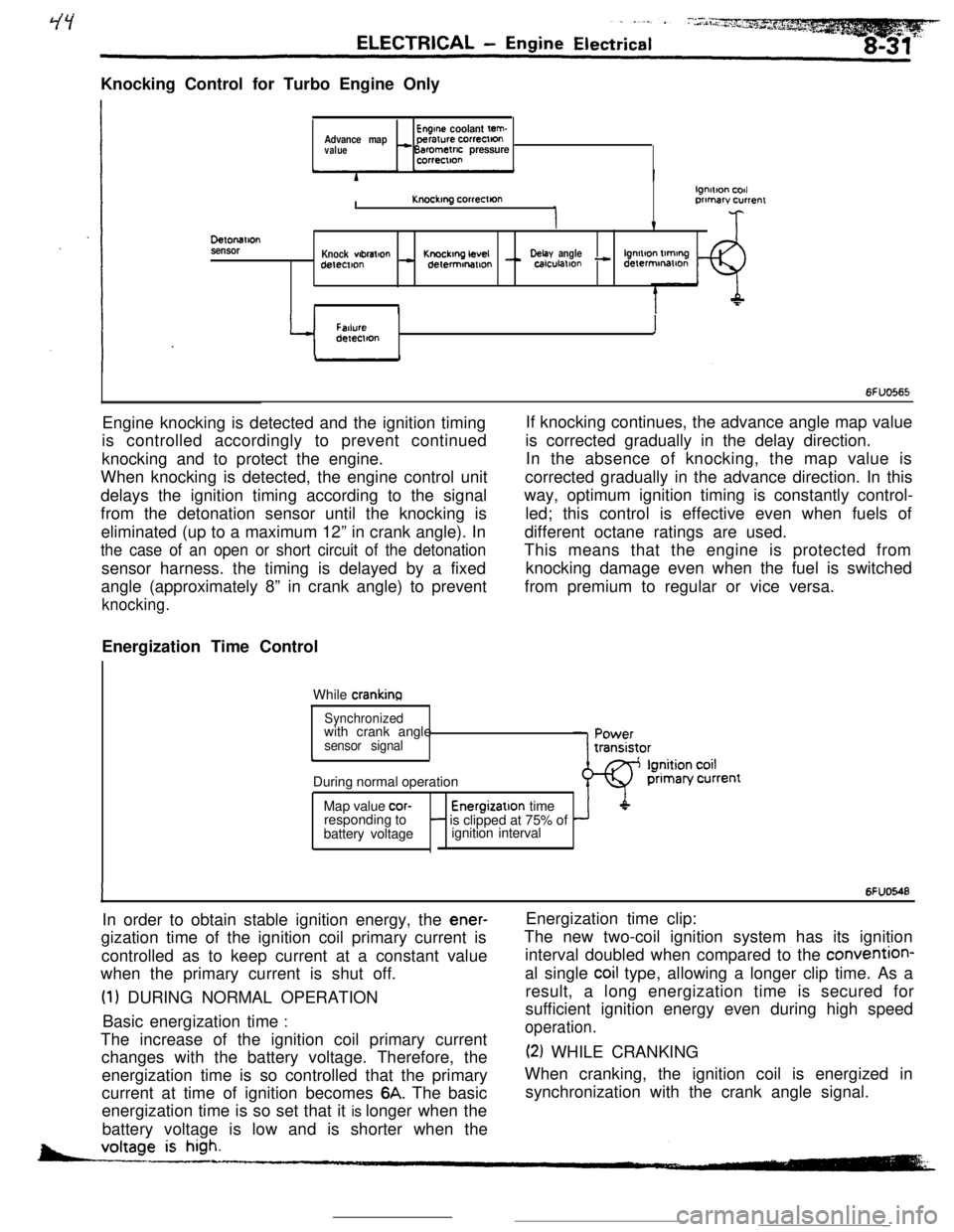

Knocking Control for Turbo Engine OnlyEngine coolant tern.Advance mapperarure correctton

value- Barometric pressurecorrectton

DelonaIlon

sensorI

lgnmon codKnockmg correcllonprimary currenr

v

Knock wbral+onKnockmg LevelDelay anglelgnmon tlmtngdetemon- delermonmon - calculallon - derermmatlon

II

Y

FatlureIdeIeclton

6FUO565Engine knocking is detected and the ignition timing

is controlled accordingly to prevent continued

knocking and to protect the engine.

When knocking is detected, the engine control unit

delays the ignition timing according to the signal

from the detonation sensor until the knocking is

eliminated (up to a maximum 12” in crank angle). In

the case of an open or short circuit of the detonationsensor harness. the timing is delayed by a fixed

angle (approximately 8” in crank angle) to prevent

knocking.Energization Time Control

While

crankinaIf knocking continues, the advance angle map value

is corrected gradually in the delay direction.

In the absence of knocking, the map value is

corrected gradually in the advance direction. In this

way, optimum ignition timing is constantly control-

led; this control is effective even when fuels of

different octane ratings are used.

This means that the engine is protected from

knocking damage even when the fuel is switched

from premium to regular or vice versa.

Synchronizedwith crank angle

sensor signalcDuring normal operation

Map value

cor-Energizatlon time

responding to- is clipped at 75% of

battery voltageignition interval

IIn order to obtain stable ignition energy, the

ener-gization time of the ignition coil primary current is

controlled as to keep current at a constant value

when the primary current is shut off.

(1) DURING NORMAL OPERATION

Basic energization time

:The increase of the ignition coil primary current

changes with the battery voltage. Therefore, the

energization time is so controlled that the primary

current at time of ignition becomes

6A. The basic

energization time is so set that it is longer when the

battery voltage is low and is shorter when the

6FUO548Energization time clip:

The new two-coil ignition system has its ignition

interval doubled when compared to the convention-

al single

coil type, allowing a longer clip time. As a

result, a long energization time is secured for

sufficient ignition energy even during high speed

operation.

(2) WHILE CRANKING

When cranking, the ignition coil is energized in

synchronization with the crank angle signal.

-

Page 87 of 391

=--Y

jl

1 /

i "

_. ---“._ _ _ ._ ..-..+_LI_y_--- -

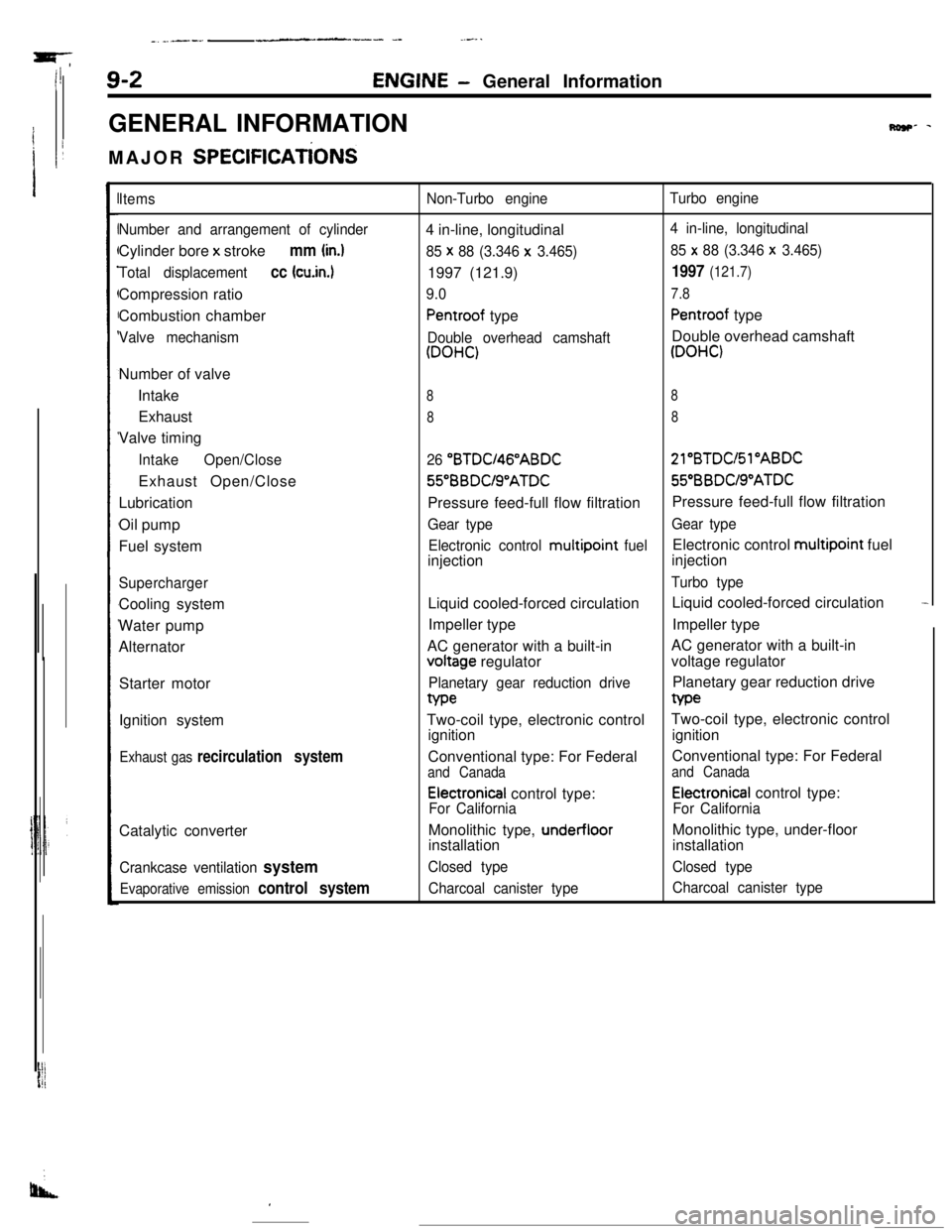

9-2ENGINE- General Information

GENERAL INFORMATION

MAJOR

SPEClFlCATiONS

Row- -

Items

Number and arrangement of cylinderCylinder bore x stroke

mm (in.)

Total displacementcc (cu.in.1Compression ratio

Combustion chamber

Valve mechanismNumber of valve

Intake

Exhaust

Valve timing

IntakeOpen/CloseExhaust Open/Close

Lubrication

Oil pump

Fuel system

SuperchargerCooling system

Water pump

Alternator

Starter motor

Ignition system

Exhaust gas recirculation systemCatalytic converter

Crankcase ventilation system

Evaporative emission control system

Non-Turbo engineTurbo engine4 in-line, longitudinal

4 in-line, longitudinal

85 x

88 (3.346 x 3.465)85 x 88 (3.346 x 3.465)1997 (121.9)

1997 (121.7)

9.07.8

Pentroof typePentroof type

Double overhead camshaftDouble overhead camshaft

(DOHC)(DOHC)

88

88

26 “BTDU46”ABDC21”BTDC/Sl”ABDC56BBDUS”ATDC55”BBDUS”ATDC

Pressure feed-full flow filtrationPressure feed-full flow filtration

Gear typeGear type

Electronic control multipoint

fuelElectronic control multipoint fuel

injectioninjection

Turbo typeLiquid cooled-forced circulationLiquid cooled-forced circulation

-Impeller typeImpeller type

AC generator with a built-involtage regulatorAC generator with a built-in

voltage regulator

Planetary gear reduction drivePlanetary gear reduction drivetype

Two-coil type, electronic controlTwo-coil type, electronic control

ignitionignition

Conventional type: For FederalConventional type: For Federal

and Canadaand Canada

Electronical control type:Electronical control type:

For CaliforniaFor CaliforniaMonolithic type,

under-floorMonolithic type, under-floor

installationinstallation

Closed typeClosed type

Charcoal canister typeCharcoal canister type

I