length MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 8 of 391

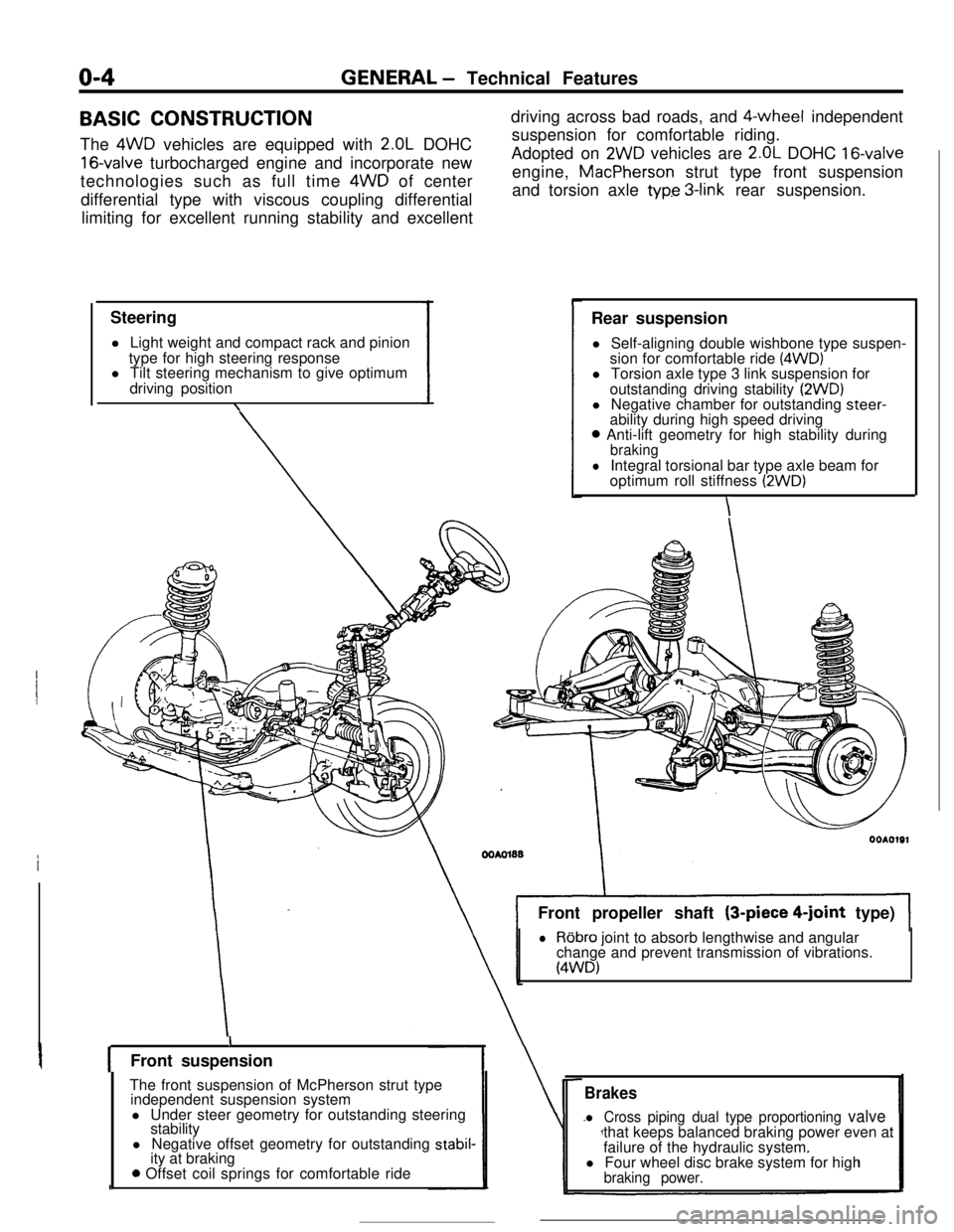

o-4GENERAL - Technical Features

BASIC CONSTRUCTION

The 4WD vehicles are equipped with

2.OL DOHC

16-valve turbocharged engine and incorporate new

technologies such as full time 4WD of center

differential type with viscous coupling differential

limiting for excellent running stability and excellent

Steering

l Light weight and compact rack and pinion

type for high steering response

l Tilt steering mechanism to give optimum

driving position

\driving across bad roads, and $-wheel independent

suspension for comfortable riding.

Adopted on

2WD vehicles are 2.OL DOHC 16-valveengine, MacPherson strut type front suspension

and torsion axle

typ.e 3-link rear suspension.

Rear suspension

l Self-aligning double wishbone type suspen-

sion for comfortable ride

(4WD)l Torsion axle type 3 link suspension for

outstanding driving stability

(2WD)l Negative chamber for outstanding steer-

ability during high speed driving

0 Anti-lift geometry for high stability duringbraking

lIntegral torsional bar type axle beam for

optimum roll stiffness (2WD)

\Front propeller shaft (3-piece

4-joint type)

lRobro joint to absorb lengthwise and angular

change and prevent transmission of vibrations.

(4WD)

IFront suspension

The front suspension of McPherson strut type

independent suspension system

l Under steer geometry for outstanding steering

stability

l Negative offset geometry for outstanding

stabil-ity at braking

0 Offset coil springs for comfortable ride

Brakes

l Cross piping dual type proportioning valvethat keeps balanced braking power even at

failure of the hydraulic system.

l Four wheel disc brake system for high

braking power.

Page 17 of 391

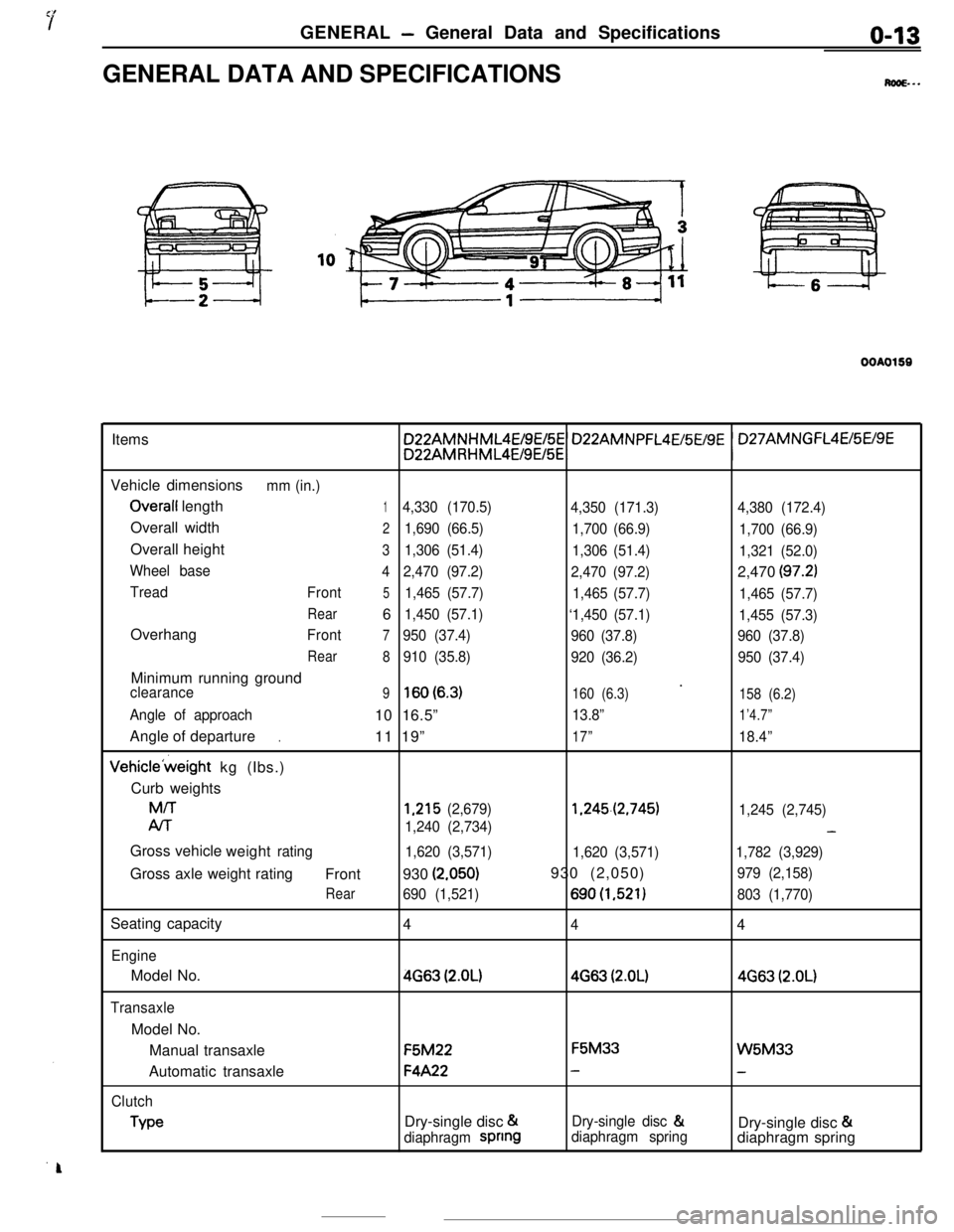

GENERAL - General Data and Specificationso-13GENERAL DATA AND SPECIFICATIONS

M...

OOAO159Items

Vehicle dimensions

mm (in.)

Overall length14,330 (170.5)

4,350 (171.3)4,380 (172.4)Overall width

21,690 (66.5)

1,700 (66.9)

1,700 (66.9)Overall height

31,306 (51.4)

1,306 (51.4)

1,321 (52.0)

Wheel base

42,470 (97.2)

2,470 (97.2)2,470

(97.2)

Tread

Front51,465 (57.7)

1,465 (57.7)

1,465 (57.7)

Rear61,450 (57.1)

‘1,450 (57.1)

1,455 (57.3)Overhang

Front7950 (37.4)

960 (37.8)960 (37.8)

Rear

8910 (35.8)

920 (36.2)950 (37.4)Minimum running ground

’clearance9lsO(6.3)160 (6.3)

158 (6.2)

Angle of approach10 16.5”13.8”1’4.7”Angle of departure

11 19”

17”18.4”.Vehicle’weight kg (Ibs.)

Curb weightsM/T

1,215 (2,679)1.245.(2,745)

1,245 (2,745)

Al-r

1,240 (2,734)-Gross vehicle

weight

rating

1,620 (3,571)

1,620 (3,571)1,782 (3,929)Gross axle weight rating

Front930

(2.050)930 (2,050)979 (2,158)

Rear690 (1,521)690(1,521)803 (1,770)Seating capacity

4

44

EngineModel No.

4663 (2.OL)4663 (2.OL)4663 (2.OL)

TransaxleModel No.

Manual transaxleF5M22F5M33

W5M33Automatic transaxle

F4A22--

Clutch

TypeDry-single disc &Dry-single disc &

Dry-single disc &

diaphragm spnngdiaphragm springdiaphragm spring

Page 21 of 391

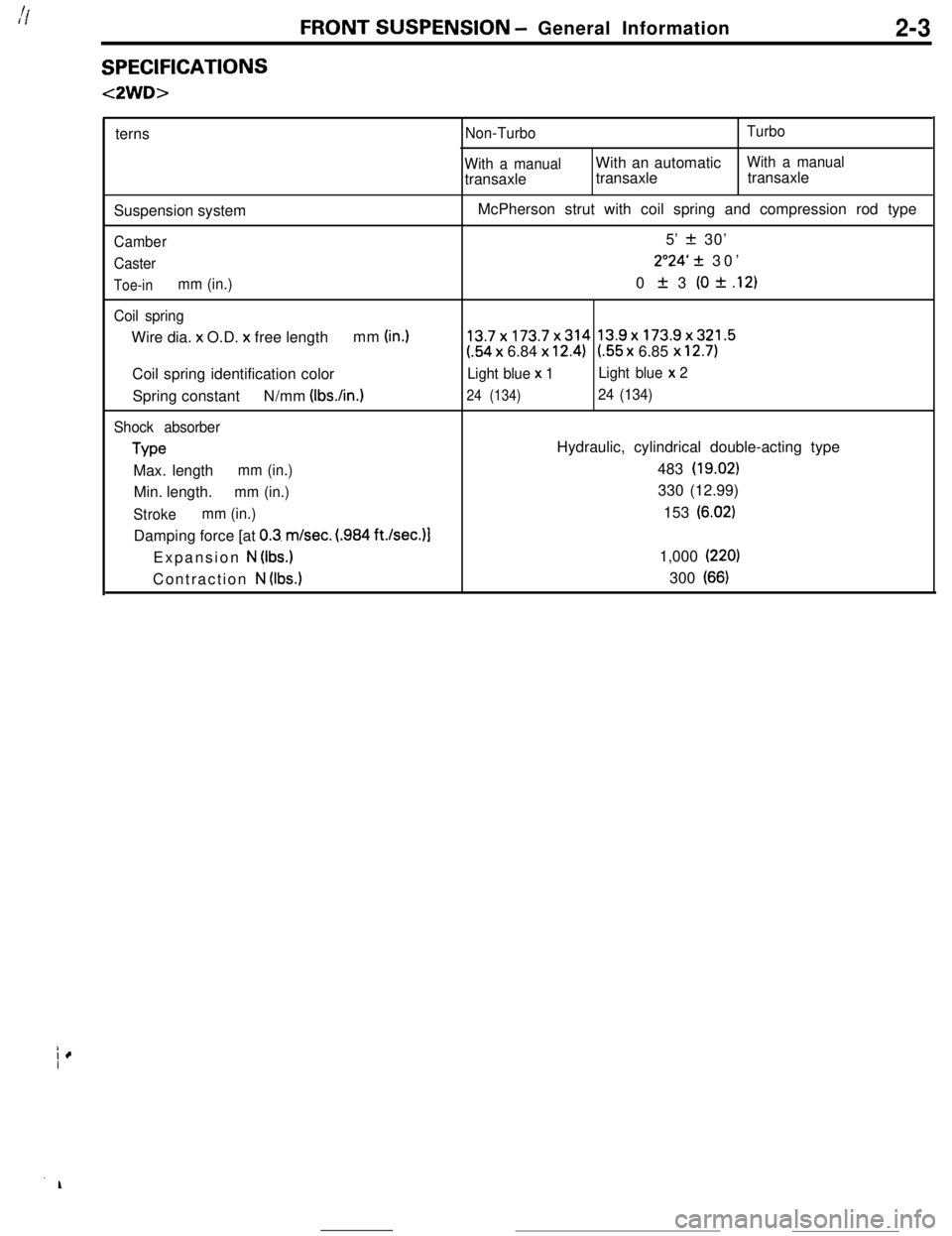

FRONT SUSPENSION - General Information2-3

SPECIFICATIONS

<2WD>terns

Suspension system

Camber

Caster

Toe-inmm (in.)

Coil springWire dia. x O.D.

x free lengthmm (in.)Coil spring identification color

Spring constantN/mm (IbsAn.)

Shock absorber

TypeMax. length

mm (in.)Min. length.

mm (in.)

Strokemm (in.)Damping force [at

0.3. m/set. (.984 ft./sec.)l

Expansion

N (Ibs.)Contraction

N (Ibs.)

Non-TurboTurbo

With a manualWith an automatic

With a manualtransaxletransaxletransaxle

McPherson strut with coil spring and compression rod type

5’

z!z 30’

2”24’ 31 30’

0

It 3 (0 * .12)

13.7x173.7x314 13.9x173.9x321.5

(.54 x 6.84 x 12.4)l.55 x 6.85 x 12.7)

Light blue x 1Light blue x 2

24 (134)24 (134)Hydraulic, cylindrical double-acting type

483

(19.02)330 (12.99)

153

(6.02)1,000

(220)300

(66)

Page 22 of 391

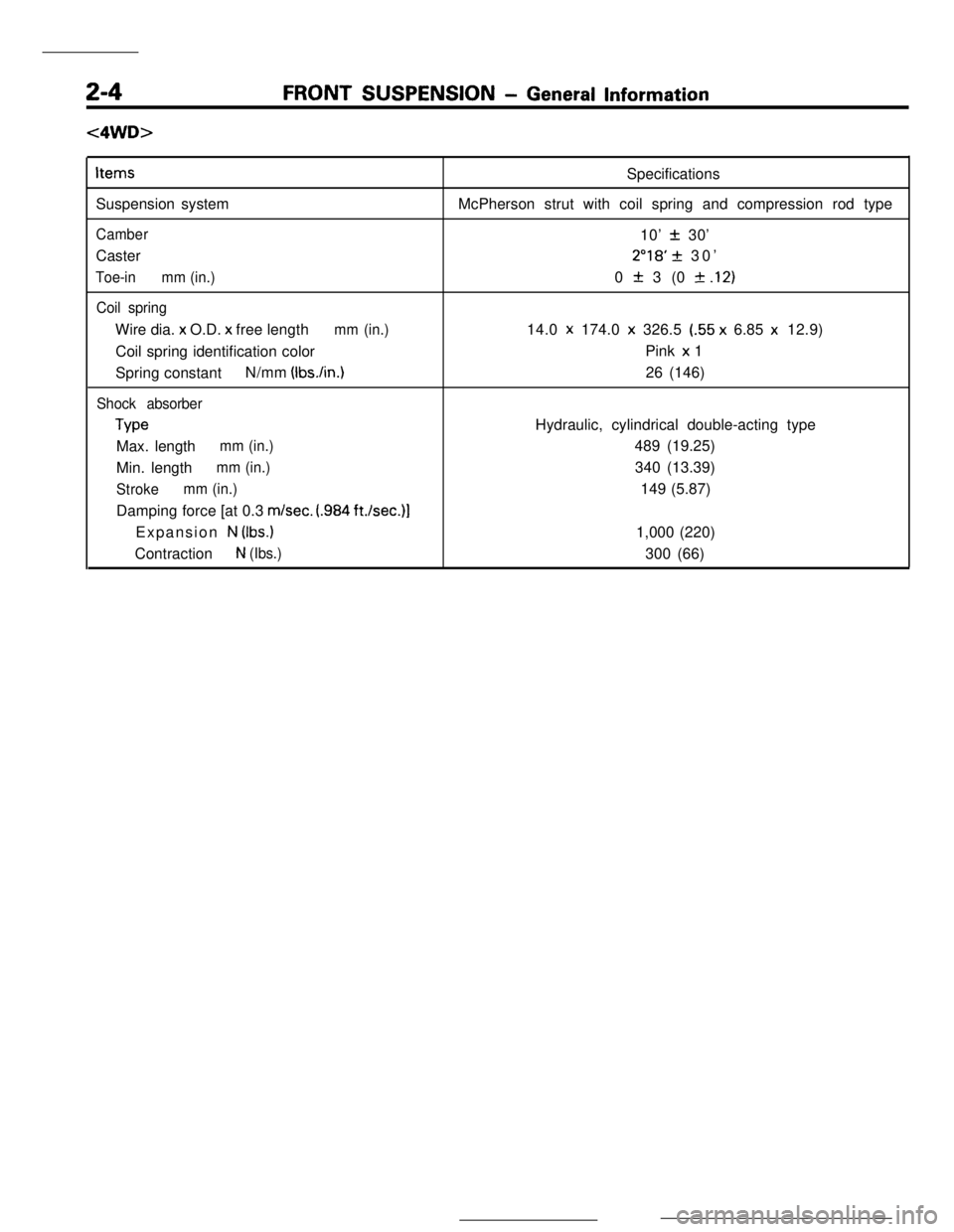

FRONT SUSPENSION - General Information

c4WD>Items

Suspension system

CamberCaster

Toe-inmm (in.)

Coil springWire dia. x O.D. x free length

mm (in.)Coil spring identification color

Spring constantN/mm

(Ibs./in.)

Shock absorber

TypeMax. length

mm (in.)Min. length

mm (in.)

Strokemm (in.)Damping force [at 0.3

m/set. (.984 ft./set.)]Expansion

N (Ibs.)Contraction

N (Ibs.)Specifications

McPherson strut with coil spring and compression rod type

10’

+- 30’

2”18’ + 30’

0

zk 3 (0 f .l2)14.0 x 174.0

x 326.5 (.55 x 6.85 x 12.9)

Pink x 1

26 (146)

Hydraulic, cylindrical double-acting type

489 (19.25)

340 (13.39)

149 (5.87)

1,000 (220)

300 (66)

Page 30 of 391

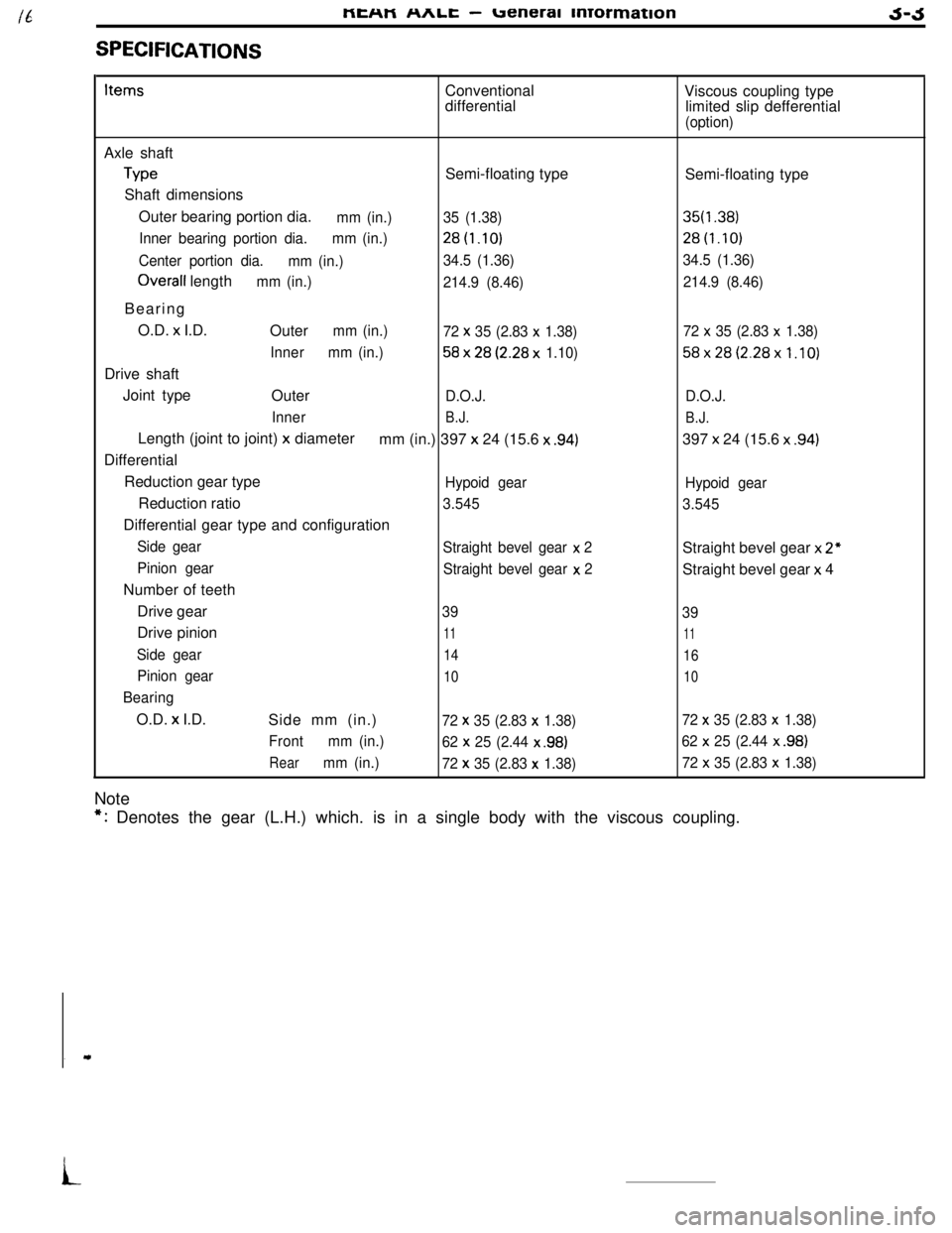

SPECIFICATIONSMEHM

nnlL -ueneral mrormationJ-JItemsConventional

differentialViscous coupling type

limited slip defferential

(option)Axle shaft

TypeSemi-floating type

Shaft dimensions

Outer bearing portion dia.

mm (in.)35 (1.38)

Inner bearing portion dia.mm (in.)28t1.10)

Center portion dia.

mm (in.)34.5 (1.36)

Overall lengthmm (in.)

214.9 (8.46)Bearing

O.D. x I.D.

Outer

mm (in.)

72 x 35 (2.83 x 1.38)

Innermm (in.)

58x28(2.28x 1.10)Drive shaft

Joint type

Outer

D.O.J.

Inner

B.J.Length (joint to joint)

x diameter

mm (in.) 397 x 24 (15.6 x .94)Differential

Reduction gear type

Hypoid gearReduction ratio

3.545Differential gear type and configuration

Side gear

Straight bevel gear x 2

Pinion gear

Straight bevel gear x

2Number of teeth

Drive gear

39Drive pinion

11

Side gear14

Pinion gear10

BearingO.D.

x I.D.

Side mm (in.)72 x 35 (2.83 x 1.38)

Frontmm (in.)

62 x

25 (2.44 x .98)

Rearmm (in.)

72 x 35 (2.83 x 1.38)NoteSemi-floating type

35f1.38)28t1.10)

34.5 (1.36)

214.9 (8.46)

72

x 35 (2.83 x 1.38)

58x28(2.28x1.10)

D.O.J.

B.J.397 x 24 (15.6 x

.94)

Hypoid gear

3.545Straight bevel gear x

2”Straight bevel gear x 4

39

11

16

10

72 x 35 (2.83 x 1.38)

62

x 25 (2.44 x .98)

72 x 35 (2.83 x 1.38)

*: Denotes the gear (L.H.) which. is in a single body with the viscous coupling.

i

Page 31 of 391

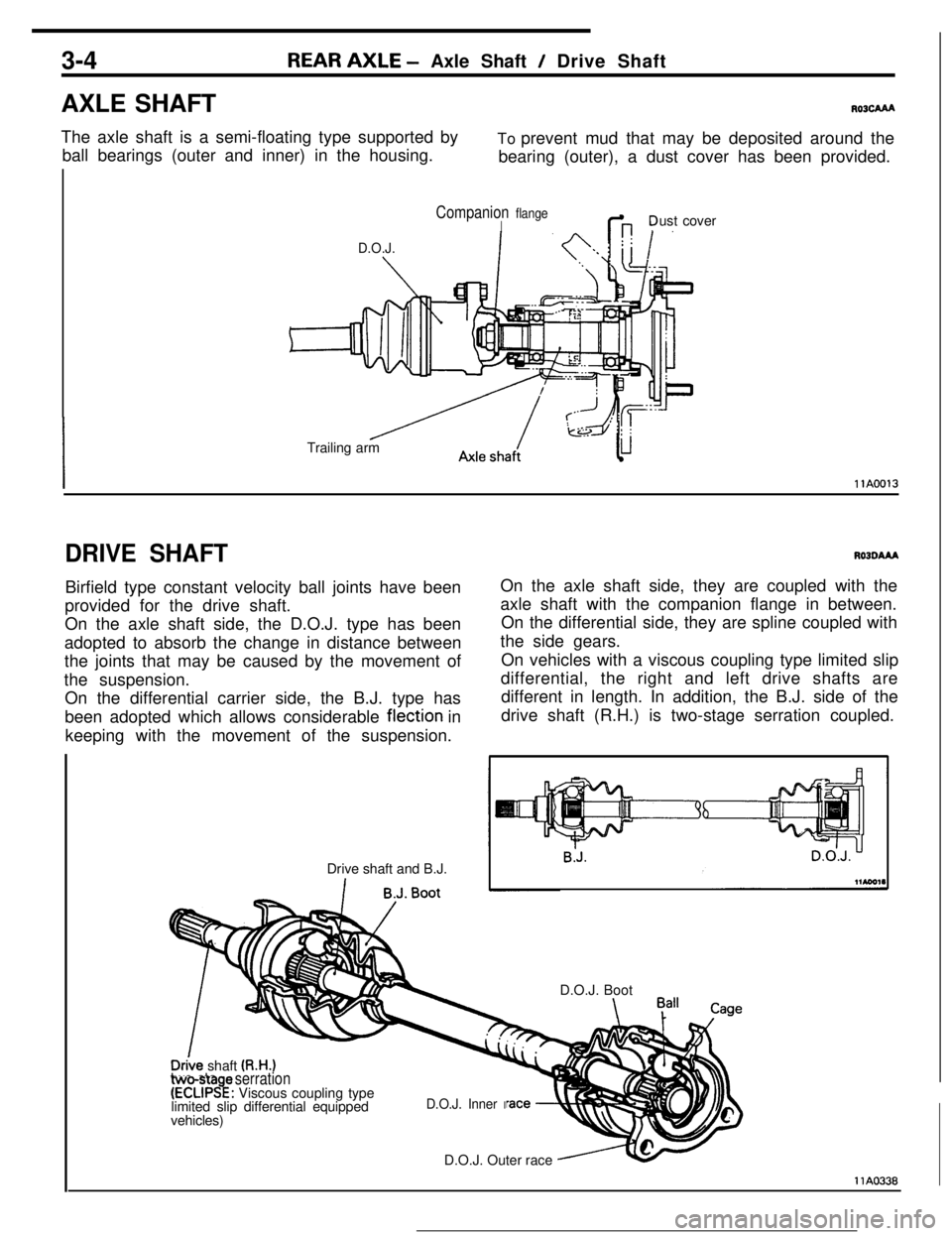

3-4REAR AXLE - Axle Shaft / Drive Shaft

AXLE SHAFT

R03cAAAThe axle shaft is a semi-floating type supported by

ball bearings (outer and inner) in the housing.To prevent mud that may be deposited around the

bearing (outer), a dust cover has been provided.

D.O.J.

Companion flangeIG ?ust cover

Trailing arm

IllA0013

DRIVE SHAFTBirfield type constant velocity ball joints have been

provided for the drive shaft.

On the axle shaft side, the D.O.J. type has been

adopted to absorb the change in distance between

the joints that may be caused by the movement of

the suspension.

On the differential carrier side, the B.J. type has

been adopted which allows considerable flection in

keeping with the movement of the suspension.

Drive shaft and B.J.RO3OAAAOn the axle shaft side, they are coupled with the

axle shaft with the companion flange in between.

On the differential side, they are spline coupled with

the side gears.

On vehicles with a viscous coupling type limited slip

differential, the right and left drive shafts are

different in length. In addition, the B.J. side of the

drive shaft (R.H.) is two-stage serration coupled.

D.O.J. Boot

_vehicles)

D.O.J. Outer race

D&e shaft (R.H.)two-sta e serration(ECLIPS!: Viscous coupling type

limited slip differential equipped

D.O.J. Inner I

llA0338

Page 192 of 391

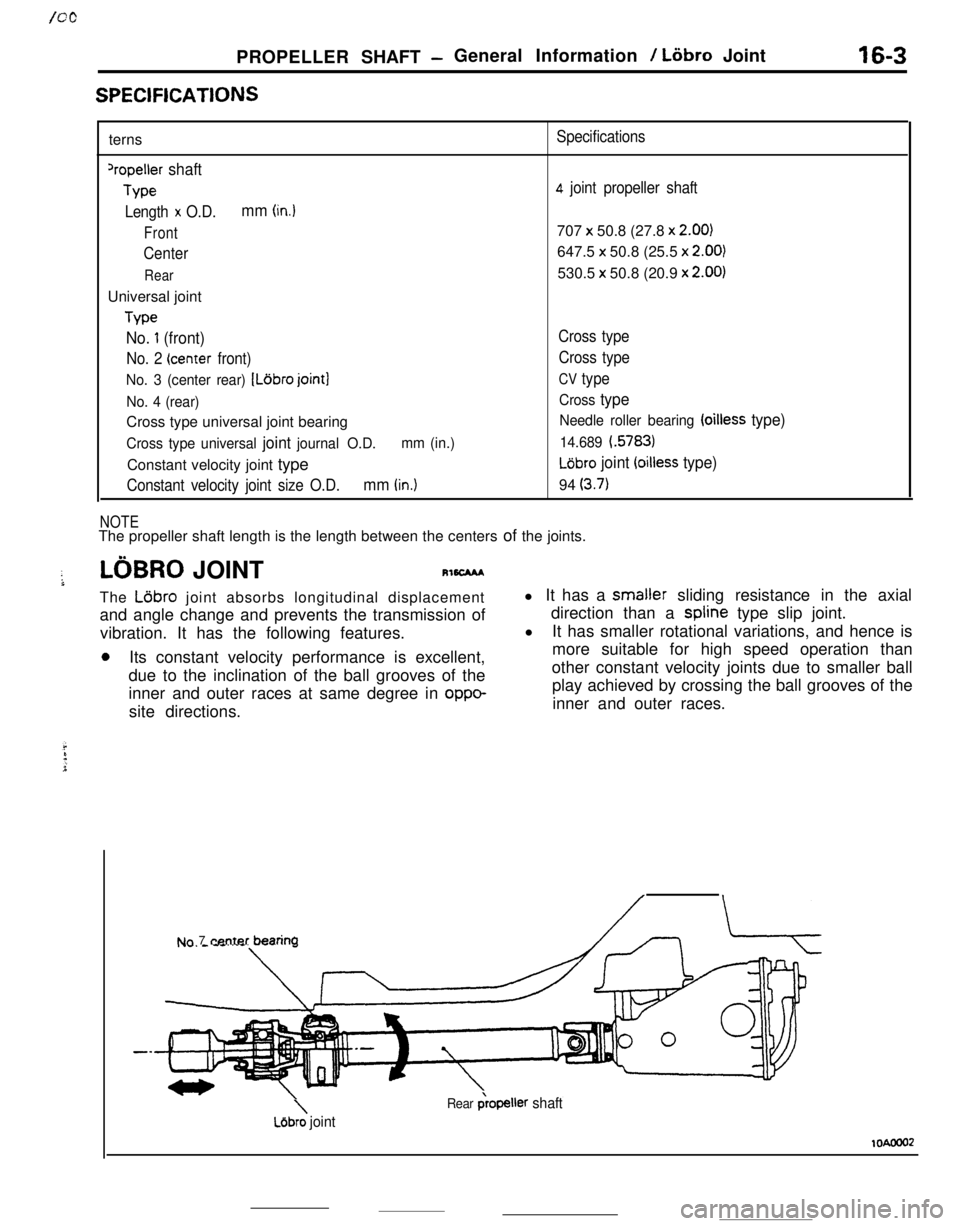

PROPELLER SHAFT -General Information / Liibro Joint16-3

SPEClFlCATlONSterns

‘repeller shaft

Type

Length

x O.D.mm (in.)

Front

Center

RearUniversal joint

Type

No. 1 (front)

No. 2 (center front)

No. 3 (center rear) [Ldbro joint]

No. 4 (rear)Cross type universal joint bearing

Cross type universal joint journal O.D.mm (in.)Constant velocity joint type

Constant velocity joint size O.D.mm (in.)

NOTE

Specifications

4 joint propeller shaft707

x 50.8 (27.8 x 2.00)647.5 x 50.8 (25.5 x

2.00)530.5 x 50.8 (20.9 x

2.00)

Cross type

Cross type

CV type

Cross type

Needle roller bearing (oilless type)

14.689 i.5783)

LGbro joint (oilless type)94

(3.7)The propeller shaft length is the length between the centers of the joints.

LOBRO JOINTRl6CMAThe

L6bro joint absorbs longitudinal displacement

and angle change and prevents the transmission of

vibration. It has the following features.

0Its constant velocity performance is excellent,

due to the inclination of the ball grooves of the

inner and outer races at same degree in

oppo-site directions.l It has a smaller sliding resistance in the axial

direction than a spline type slip joint.

l

It has smaller rotational variations, and hence is

more suitable for high speed operation than

other constant velocity joints due to smaller ball

play achieved by crossing the ball grooves of the

inner and outer races.

Nn 7 center bearina

\Lejbro joint

Rear &opeller shaft

lOAooo2

Page 202 of 391

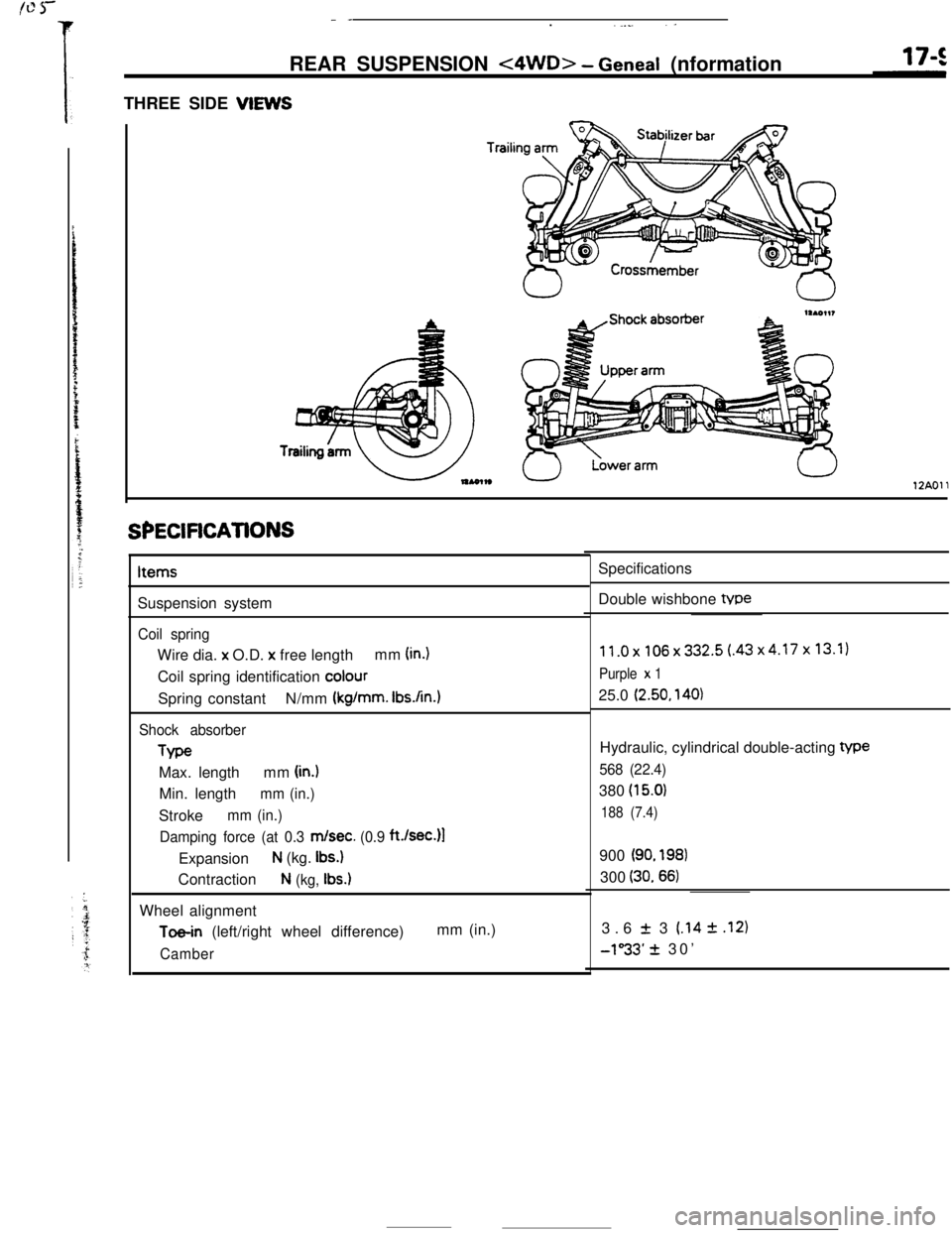

_ -. ..__ .-

REAR SUSPENSION

<4WD> - Geneal (nformation

THREE SIDE VIEWS

Trailil

12AOll

SPECiFiCATiONSItems

Suspension system

Coil springWire dia. x O.D.

x free lengthmm (in.)Coil spring identification

colourSpring constantN/mm

(kg/mm. Ibs.An.1

Shock absorberType

Max. lengthmm

(in.)Min. length

mm (in.)Stroke

mm (in.)

Damping force (at 0.3

m/set. (0.9 ft./sec.)l

Expansion

N (kg. Ibs.)Contraction

N (kg, Ibs.)Wheel alignment

Toe-in (left/right wheel difference)mm (in.)

CamberSpecifications

Double wishbone tvpe

11.0x106x332.5(.43x4.17x13.1)

Purple x 125.0

(2.50, 140)Hydraulic, cylindrical double-acting

We

568 (22.4)380

(15.0)

188 (7.4)900

(90. 198)300

(30.66)3.6

f 3 (.14 2 .I21

-1”33’ + 30’

Page 259 of 391

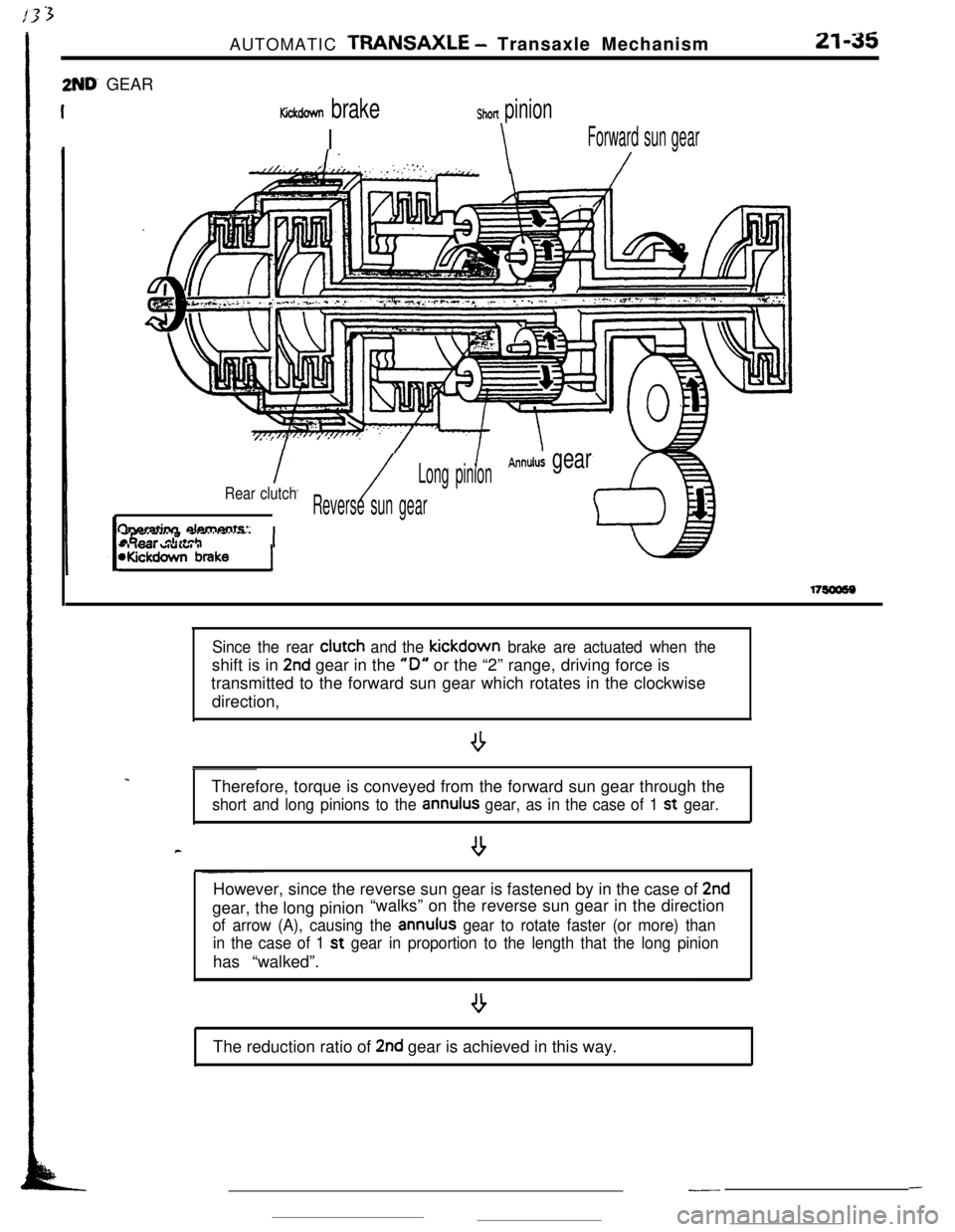

2ND’ GEARAUTOMATIC

TRANSAXLE - Transaxle Mechanism21-35

Kickdown brake

I

Shon pinion

\Forward sun gear

1.//LT.//. , ,’ .‘,,i.:,;:.:‘.,.‘,\/

/

Annulus gearLong pinion

Rear clutch/Reverse sun gear

fharatinn damants:

-, IWI WUIUI IWickdown brakeI

.

c

Since the rear clutch and the kickdown brake are actuated when theshift is in

2nd gear in the “0” or the “2” range, driving force is

transmitted to the forward sun gear which rotates in the clockwise

direction,

Therefore, torque is conveyed from the forward sun gear through the

short and long pinions to the annulus gear, as in the case of 1 st gear.

--However, since the reverse sun gear is fastened by in the case of

2ndgear, the long pinion“walks” on the reverse sun gear in the direction

of arrow (A), causing the annulus gear to rotate faster (or more) than

in the case of 1 st

gear in proportion to the length that the long pinionhas “walked”.

The reduction ratio of

2nd gear is achieved in this way.

---

Page 354 of 391

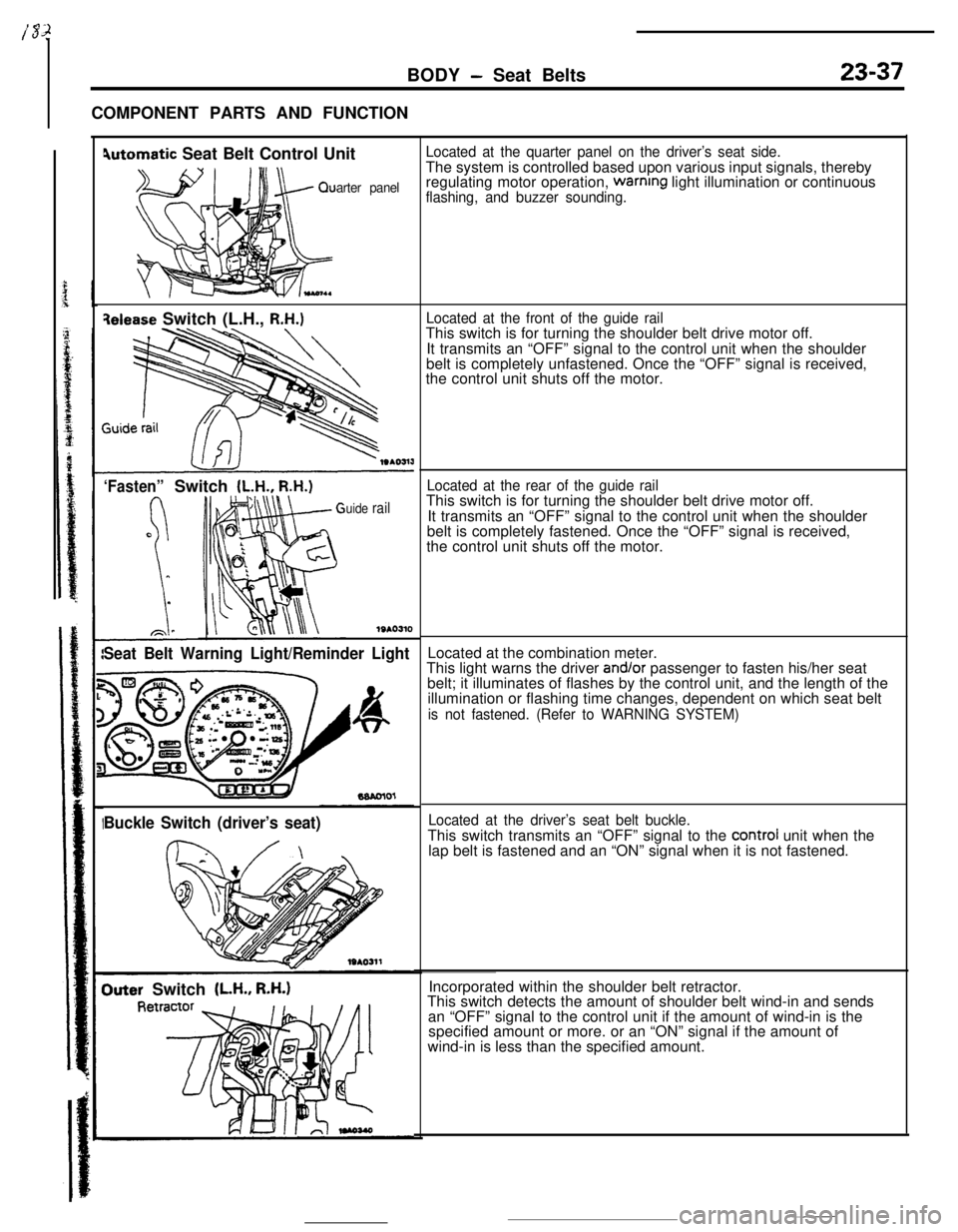

BODY - Seat Belts23-37COMPONENT PARTS AND FUNCTION

4utomatic Seat Belt Control Unit

arter panel

qelease Switch (L.H., R.H.)

‘Fasten”Switch (L.H., R.H.)

uide rail

1SAO310

Seat Belt Warning Light/Reminder Light

Buckle Switch (driver’s seat)

Outer Switch (LH., R.H.)

Located at the quarter panel on the driver’s seat side.The system is controlled based upon various input signals, thereby

regulating motor operation,

warnrng light illumination or continuousflashing, and buzzer sounding.

Located at the front of the guide railThis switch is for turning the shoulder belt drive motor off.

It transmits an “OFF” signal to the control unit when the shoulder

belt is completely unfastened. Once the “OFF” signal is received,

the control unit shuts off the motor.

Located at the rear of the guide railThis switch is for turning the shoulder belt drive motor off.

It transmits an “OFF” signal to the control unit when the shoulder

belt is completely fastened. Once the “OFF” signal is received,

the control unit shuts off the motor.

Located at the combination meter.

This light warns the driver

and/or passenger to fasten his/her seat

belt; it illuminates of flashes by the control unit, and the length of the

illumination or flashing time changes, dependent on which seat belt

is not fastened. (Refer to WARNING SYSTEM)

Located at the driver’s seat belt buckle.This switch transmits an “OFF” signal to the

control unit when the

lap belt is fastened and an “ON” signal when it is not fastened.

Incorporated within the shoulder belt retractor.

This switch detects the amount of shoulder belt wind-in and sends

an “OFF” signal to the control unit if the amount of wind-in is the

specified amount or more. or an “ON” signal if the amount of

wind-in is less than the specified amount.